1. Introduction

The operation of thermoelectric generators (TGs) requires continuous planning so that costs are minimized. For this reason, experts address the thermal unit commitment (TUC) problem from several perspectives and apply different solving techniques. Obtaining solutions that balance generation costs and computational burden is usually the goal of electrical system researchers in many countries [

1,

2,

3]. The major challenge regarding TUC comes from the specific characteristics of power generation planning problems in general [

4], which consist of two stages [

5]: (i) the operation decisions (ON/OFF) of the power plants, known as unit commitment (UC), and (ii) the economic dispatch of the plants in operation.

TUC optimization aims to reduce operational costs over the planning horizon. The problem has a combinatorial nature and is thus hard to solve [

4]. In addition, the existence of limitations regarding the generating units, e.g., minimum down- and up-times, adds complexity to the problem.

Many different approaches can be utilized to tackle the TUC problem, which can be written as a mixed-integer nonlinear programming (MINLP) formulation or by its linear approximation [

6]. The operation decisions are given by binary variables, whereas continuous variables represent the power dispatch.

Over the decades that the TUC problem has been studied, several techniques have been applied to it. From 1982 to recent years, “Branch and Bound” and “Branch and Cut” algorithms have been enhanced to handle UC [

7,

8]. However, the need for faster simulations has led to the development of heuristic-based methods. These approaches were enhanced by applying information that was inherent to the problem, as in [

9,

10]. In a more recent context, so-called metaheuristics have provided good results whilst keeping a low computational effort, as shown in [

10,

11,

12].

It is known that the only way to guarantee global optimality for a combinatorial problem is to perform an exhaustive search. However, such an approach compromises viability when the problem has a significant number of variables due to the simulation time required by the intended application. Heuristic methods aim to greatly reduce the computational burden, although securing the global solution is not guaranteed.

In [

13], a novel hybrid genetic-imperialist competitive algorithm was utilized to refine solutions obtained from a model that applies priority lists to make operation decisions. In [

14], considerations of minimum up- and down-times were added to the priority list approach to remove TGs that cause power generation to exceed the required demand. The authors proposed heterogeneous comprehensive-learning particle-swarm optimization to perform the economic dispatch. Both these papers require a number of parameters to be tuned and adjusted.

In general, it is desired that thermoelectric operation planning is solved within the shortest amount of time possible while granting the best possible solution [

15]. To aid in such a task, heuristic information can be utilized to decrease the number of variables and therefore reduce the search space of a TUC problem. The techniques presented in [

16,

17,

18,

19] propose tools to decrease simulation duration through search space reduction.

Based on the aforementioned affirmations and taking into consideration the importance of reducing both the generation cost and the computational effort when addressing TUC, this paper brings the following contributions:

A method to obtain the so-called “relevance matrix” (RM), which indicates the hourly relevance of each TG over the planning horizon. This matrix can be used to reduce the number of operation alternatives while preserving the quality of solutions and meeting all operational constraints. In addition, it requires no tuning of parameters.

A guide on how to pair the proposed method with a nonlinear programming solver, thus enabling comparisons with approaches found in the literature.

The remainder of this paper is organized as follows.

Section 2 presents the characteristics and formulation of the TUC problem.

Section 3 provides the steps to obtain the trigger matrix.

Section 4 explores case studies.

Section 5 concludes the work and discusses potential future studies.

3. Proposed Method

In general, the number of possible operation combinations in the TUC problem is equal to

[

25], which reflects the ON/OFF decisions of each TG for each period of the planning horizon. As more TGs are considered and more discretizations are in place regarding the planning horizon, the combinatorial complexity increases. In other words, the search space becomes larger. This paper utilizes heuristic information written as hybrid priority lists (HPLs), which are described ahead.

3.1. Hybrid Priority Lists

An HPL is established from a set of predefined priority lists, which are constructed with sensitivity indexes related to the TGs. These indexes can be based on technical and/or economic characteristics. In this paper, the priority lists that were used to originate the HPLs were created according to the indexes that follow.

3.1.1. Full-Load Average Production Cost (FLAC)

Although the FLAC [

27] does not consider the hourly power demand, it is vastly utilized to generate initial solutions for complex problems. Its calculation is given by Equation (

11). The lower the FLAC of a TG, the higher the priority it has to operate. Therefore, from fuel cost coefficients and maximum power values, a single priority list is established regardless of the load.

3.1.2. Production Marginal Cost (PMC)

The PMC index is obtained by taking the derivative of the operational cost [

28]. In this case, the index is given by a linear function, as shown by Equation (

12). Analogously to the previous index, the lower the PMC of a unit, the higher its priority to be activated; hence, a single priority list is determined.

3.1.3. Lagrange Sensitivity (LS)

In [

29], the authors defined an operational decision function (

), which assumes continuous values in [0, 1]. These values represent the ON/OFF status of the TGs. To impose this behavior, a sigmoid function was utilized, as in Equation (

13).

Given a known power demand in a specific period of the planning horizon, all TGs are initially offline. Then, a high-cost dummy TG is inserted so that the power requirement is met. As a next step, each TG, one by one, is activated, and its impact on the cost is evaluated. This impact represents a Lagrange multiplier since it determines how much the objective function is affected by the TG activation.

The procedure described above is executed for each period of the planning horizon, thus originating a sensitivity matrix (SM). This matrix indicates how intensively each TG is capable of reducing the objective function at each moment of the simulation, hence defining a distinct priority list for each period of the planning horizon. The SM indexes take into consideration the operational cost of each TG and the power demand, which is not true for the previously presented indexes, meaning that the list can change at each discretization of the horizon. Consequently, T priority lists are set in place.

3.2. Permutation of Priority Lists

Each of the aforementioned indexes defines a different priority of TGs to meet the demand schedule. To create new lists, this work performs permutations of the lists granted by the three indexes presented. In other words, for each period of the planning horizon, a priority for the TGs is randomly chosen (equiprobable procedure) among the three index possibilities described. Therefore, according to this randomization process regarding the priority of TGs, a new priority list for the TGs is obtained, which is an HPL.

3.3. Obtaining RM

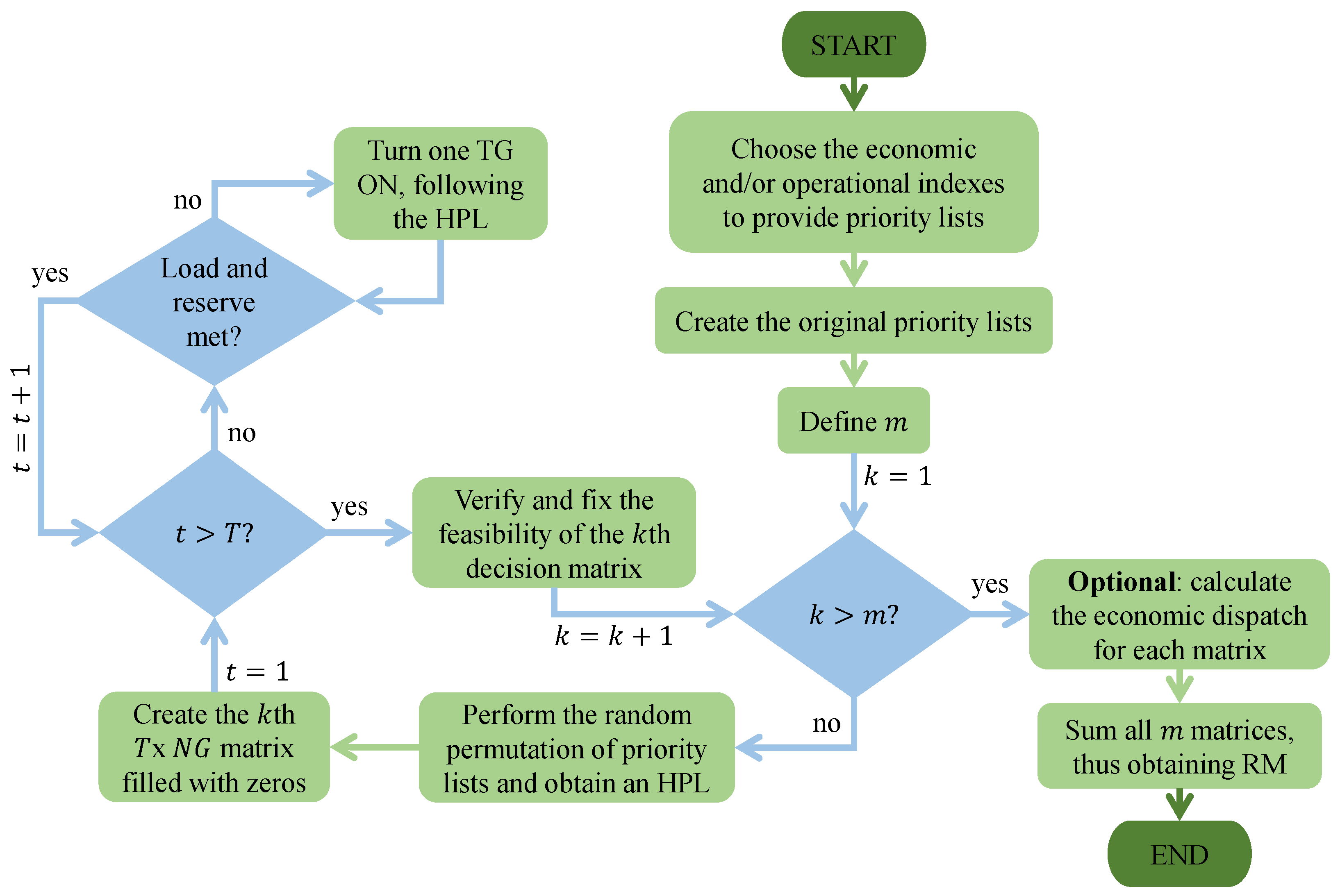

The following step-by-step procedure explains how to obtain the relevance matrix.

Define m: this parameter represents the number of decision matrices that will form the RM.

Retrieve the HPLs: for each decision matrix to be created, an HPL is needed. Hence, the random permutation procedure (previous subsection) is carried out m times, thus providing m HPLs.

Create decision matrices: m binary matrices of dimensions TxNG are created. Initially, they are filled with zeros, which represents a TG being OFF. For each matrix at each period of the planning horizon and following the HPLs from the previous step, the TGs are assigned as ON (filled with one) up to the point where the power and reserve requirements are met.

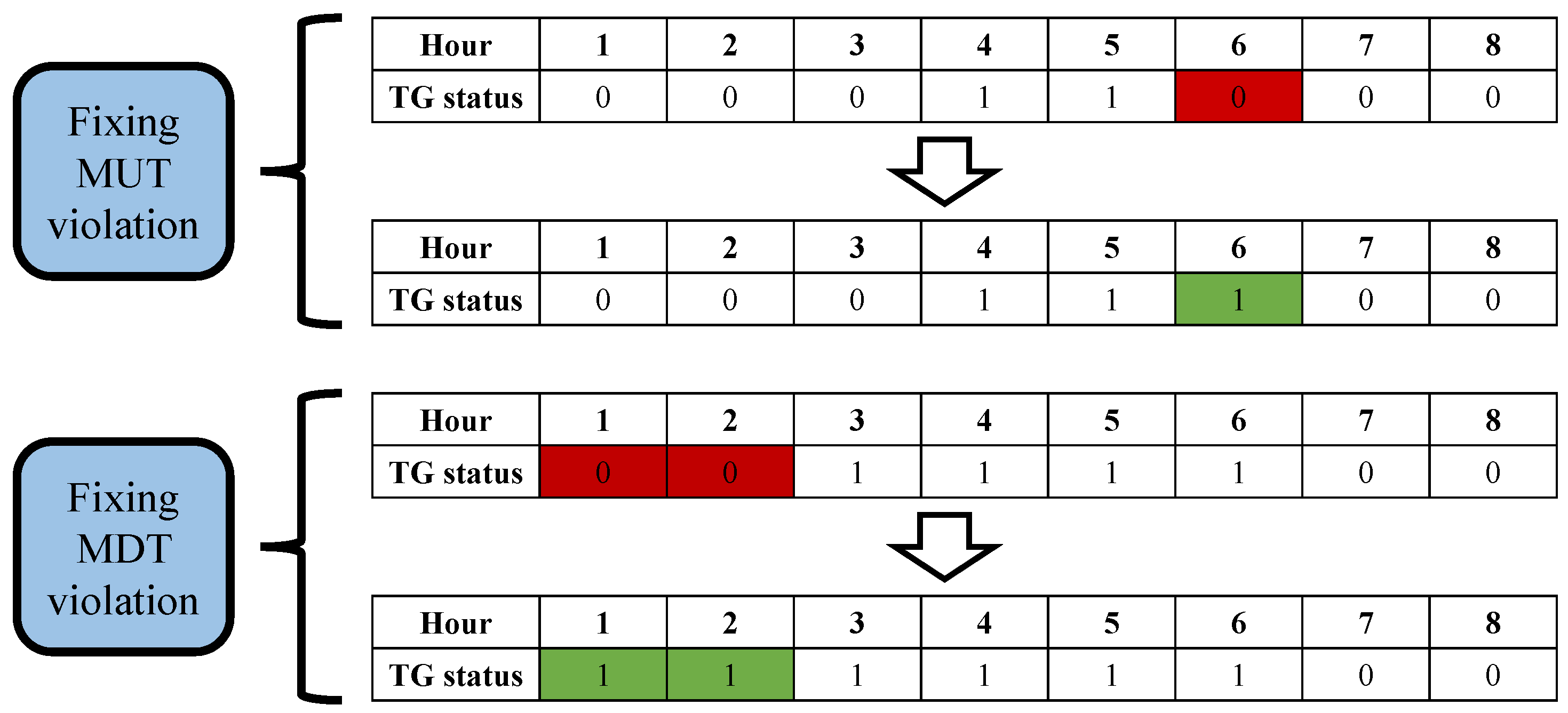

Verify and fix feasibility: every generated decision matrix is checked. Matrices that do not meet the MDT and/or MUT requirements are adjusted and made feasible. To perform this task, two different actions are applicable according to the violation case:

If a TG is set as OFF in a way that MUT is violated, the offline operational status that compromises feasibility is switched. In other words, at these periods, the TG is changed from OFF to ON, thus guaranteeing that MUT, load and reserve are satisfied.

If a TG is set as ON in a way that MDT is violated, once again the offline decisions causing non-feasibility are modified. One might consider switching the ON decisions to OFF, which would indeed fix the MDT violation. However, this could make it impossible to meet the load and reserve requirements, hence leading to a computationally heavy cycle of turning TGs OFF and ON until all constraints are respected. Therefore, the former approach is more suitable since it efficiently enables MDT, load and reserve attendance.

Calculate dispatch (optional): at this point, with part of the operation decisions established according to the relevance levels, the economic dispatch can be calculated by optimizing the problem with respect to the remaining variables. By experimentation, the cost values retrieved from this calculation have been shown to be competitive compared to those in the literature. Although this is merely an optional part of the whole process, it demonstrates the effectiveness of the HPL. It is highlighted that the most important part of the method relates to the binary decision matrices obtained from Step 4, and that calculating the dispatch at the current stage is not mandatory.

Obtain RM: the RM is given by the sum of all m binary matrices. This final matrix provides the relevance of each TG at each period of the planning horizon.

To make the feasibility-fixing process (Step 4) more intelligible, simple examples (for one generic TG) with MUT and MDT equal to 3 h over 8 h of operation are demonstrated in

Figure 1. For the MUT case, it is observed that the TG being OFF at hour 6 violates the minimum time of 3 h for it to remain online. Therefore, it is changed to ON at the mentioned hour. Regarding the MDT case, the TG being ON at hour 3 means that it remained offline for only 2 h, which is a violation of the 3 h MDT. For this reason, it is switched to ON at hours 1 and 2. It is noted that such modifications make the operation feasible.

To summarize the process proposed in this paper,

Figure 2 depicts an iterative flowchart. In other words, all the explanations previously described are presented visually so that the method can be more easily understood.

3.4. Relevance levels

To exemplify the proposed method and its effectiveness, an example using a four-TG system operating for 8 h is provided in the following. For readers who wish to replicate the presented results, the necessary system data can be retrieved from [

30].

The procedure presented in

Figure 2 was carried out. The FLAC, PMC and LS indexes were used to define the initial priority lists, which are shown in

Table 1. As discussed in

Section 3.1.1,

Section 3.1.2 and

Section 3.1.3, the priority lists from FLAC and PMC are independent of the power demand and are thus static over the planning horizon. On the other hand, the list granted by LS is affected by the load and is thus dynamic and liable to variation over the planned periods.

The parameter

m was set equal to 100. Following

Figure 2, random permutations of the lists were performed so that the HPLs could be obtained. Then, the 100 decision matrices were summed to create the RM, which is revealed in

Table 2. As an observation, the utilization of colors in this table will soon be clarified. This final matrix allows us to verify how often a TG is set as ON at each period of the planning horizon. For instance,

Table 2 shows that for the 100 decision matrices generated, TG 2 at hour 6 was activated on 38 occasions.

An interesting observation from

Table 2 is that TG 1 was always ON, given that it has the highest priority in all three initial lists (

Table 1). For all other TGs, different activation combinations occur. Furthermore, regarding TG 4, the null values for hours 6, 7 and 8 demonstrate that this unit was never required for the load and reserve demands.

This paper considers three different levels of relevance for operation planning:

(

![Energies 15 07153 i001 Energies 15 07153 i001]()

) units that were triggered in all of the

m planning alternatives;

(

![Energies 15 07153 i002 Energies 15 07153 i002]()

) units that were triggered in fewer than 10% of the

m matrices, thus being classified as low relevance TGs;

(

![Energies 15 07153 i003 Energies 15 07153 i003]()

) units that were never triggered and, for this reason, are not relevant.

Regarding the 10% criterion to classify a TG as a low relevance unit, this value was determined empirically. More specifically, experimentation revealed that values lower than 10% tend to increase the computational burden since more variables are in place, although improvements in the quality of results were not observed. In opposition, values greater than 10% tend to excessively tighten the search space, thus sacrificing quality of solutions and occasionally leading to non-feasibility.

3.5. Search Space Reduction

From the previous subsection, part of the decision variables responsible for the ON/OFF status of the TGs are fixed according to the described relevance levels. More specifically, the process occurs as stated by Equation (

14).

In the example provided in

Table 2, one can notice that 9 out of the 32 decision variables remain unfixed, hence reducing the possible combinations from

to

. In other words, the procedure decreases the number of variables by 71.88%, whereas the number of combinations is decreased by 99.99%. It is clear that the proposed procedure greatly reduces the search region, thus enabling faster convergence of the optimization process.

4. Results and Discussions

To validate the proposed method and verify its applicability to the TUC problem, RM matrices were generated for the systems provided in [

25]. The system originally had 10 TGs, although variations with 20 and 40 TGs are also considered here. In all studies, the planning horizon corresponds to 24 h discretized over hourly periods. Data regarding the operational characteristics of the TGs are presented in

Table 3. Power demand information can be consulted in [

25]. The spinning reserve is considered to be 10% of the load, as in [

31]. The systems with 20 or 40 TGs replicate the data of the TGs and multiply the load by two and four, respectively.

Table 4 reveals the number of operation combinations for each system under study. This table alone demonstrates the complexity of UC problems. One can notice that the combinatorial explosion significantly enlarges the region of candidate solutions, hence making the problem more challenging.

Once the RM is obtained by the procedure disclosed in

Section 3.3 and the search region is reduced according to the criteria presented in

Section 3.5, the next step is given by the MINLP problem-solving process.

Given the many techniques applicable to solve UC problems, seeking better approaches is still relevant. The utilization of commercial software to solve MINLP complex problems makes the process faster and more effective [

6]. Thus, an academic license of the commercial solver Mosek [

32], version 10, was utilized in this paper. The simulations were carried out on a 2.4 Ghz Intel(R) Core(TM) i5-9300H processor.

Table 5 describes the search space reduction alternatives applied in this paper. In all of them,

m was set to 1000.

4.1. System with 10 TGs

The application of Step 6 (

Section 3.3) to the 10-unit system granted a cost of

$564,834.5, which is relatively close to the global solution. The related RM (obtained from step 6) is presented in

Table 6, in which the

,

and

relevance levels are highlighted according to the scheme shown in

Section 3.4.

Once again, the reduction to the search region is noticeable. As seen in

Table 6, most of the decision variables are fixed according to

,

and

. One can observe that TGs U1 and U2 are online during the whole planning horizon. In addition, all TGs are required during period 12. By combining all reduction criteria, 18 out of the 24 periods are addressed, since 6 periods (1, 2, 11, 12, 13 and 24) were completely decided by the RM. Even in period 22, which had the lowest number of variables fixed, 50% of the variables were decided by the RM.

The space reduction based on relevance levels decreased the number of variables as shown in

Table 7. Comparisons are made according to the total number of ON/OFF decision variables, which is 240 for this system. As noted, the total number of combinations regarding the ON/OFF decisions decreased from

to

.

From the RM presented in

Table 6 and considering the reduction alternatives provided in

Table 5, the optimization was executed for different optimality gap values regarding the branch and bound process. The results are compiled in

Table 8.

Table 8 reveals significant reduction in simulation duration when the proposed method is applied. When an optimality gap of 0% is in place, the global solution is achieved with a computational gain of more than 99% for alternative 5. It is also observed that the search region reduction method decreased the number of branches explored during the optimization process.

Based on the literature,

Table 9 shows the global solution for the 10-TG system. The relevance levels from

Table 6 were repeated to demonstrate that the RM together with the reduction criteria of Equation (

12) were able to fix variables adequately. More specifically, all decision variables that would be fixed as online are in fact active in the optimal solution. Furthermore, the ones that would be fixed as offline are indeed inactive in the optimized schedule.

4.2. Systems with 20 and 40 TGs

Analogously to the previous subsection, RM matrices were generated for systems with 20 and 40 TGs. The reduction results are presented in

Table 10, which demonstrates that the proposed method is also effective for larger systems.

Following the same criteria applied to the 10-TG system, the 20- and 40-TG systems were optimized to verify the impact of utilizing the relevance matrices.

Table 11 exhibits information about the simulations, in which NC indicates “no convergence” (simulations that reached 1 h without converging were interrupted).

Although the optimizer could not solve some of the simulations due to excessive usage of processing memory, the proposed method enabled faster achievement of solutions for medium-sized systems. For larger systems, the method significantly reduced the simulation duration and the number of explored branches, assuming a gap of 0.5%.

Table 12 provides results from the literature and from the proposed approach. The solutions from the proposed method were chosen from

Table 11 considering the cost versus simulation time trade-off. One can realize that the proposed search space reduction granted competitive cost values compared to the specialized literature. In addition, the simulation duration was low given the quality of the achieved solutions.

Table 12 shows that distinct approaches have been proposed over the last decades to solve the TUC problem. Classical, decomposition, heuristic and hybrid techniques have been utilized, each one with its own advantages and disadvantages.

Studies that address search space reduction usually require many parameters to be tuned when implementing the related methods. The approach presented here has simple implementation, does not require tuning of parameters, and can provide competitive results in terms of the trade-off between cost and simulation time.

5. Conclusions

This paper presented a new approach to reduce the search region for the thermal unit commitment problem. Performing such a reduction has shown to be important as it allows reduction of: (i) the complexity of the problem (significant decrease in the number of integer variables); (ii) the combinatorial explosion (fewer possible combinations of operation decisions); and (iii) processing time, i.e., the computational burden. Although a commercial solver was utilized here, it is highlighted that metaheuristics can also be used after the search space reduction occurs.

By simulating systems broadly studied in the literature, the proposed method was shown to effectively reduce the search region, thus decreasing the number of branches explored during the branch and bound phase of the optimization while preserving good solution quality.

For systems with 10 and 20 units, the relevance levels , and fixed more than 80% of the decision variables. For the system with 40 units, approximately 78% of the decision variables were fixed. It is noteworthy that the resulting operation cost values were competitive regarding the literature despite the considerable reduction in the number of variables.

The implementation simplicity and the utilization of the constructive heuristic through the sensitivity indexes demonstrate the potential for hybridization with other optimization techniques. In general, the proposed method can be an important contribution to help solve complex problems since it provides good-quality results in much shorter time.

For future studies, it is intended to analyze the impact of adding network constraints to the formulation, i.e., to verify to what extent the computational effort is affected. In addition, the authors intend to explore if other values for the relevance levels can improve the method by enabling even higher-quality results whilst keeping or even decreasing the computational burden. Finally, researching alternative priority indexes to create the relevance matrix is within the planned scope.

) units that were triggered in all of the m planning alternatives; (

) units that were triggered in all of the m planning alternatives; ( ) units that were triggered in fewer than 10% of the m matrices, thus being classified as low relevance TGs; (

) units that were triggered in fewer than 10% of the m matrices, thus being classified as low relevance TGs; ( ) units that were never triggered and, for this reason, are not relevant.

) units that were never triggered and, for this reason, are not relevant.