Review of the Requirements for Load Following of Small Modular Reactors

Abstract

:1. Introduction

2. Overview of Small Modular Reactors

2.1. Classified by Moderator

2.2. Classified by Reaction Type

2.3. Advanced Generation IV Reactors

3. Needs and Definitions of Load-Following Operation

3.1. Increase in Variable Generation in Power Grids

3.2. Definitions and Types of Load Following

- (1)

- Load Following

- (2)

- Frequency Control

- (3)

- Voltage stability

- (4)

- European Utilities Requirements (EUR) for Load Following

4. Requirements for the Load-Following Operation of SMRs

4.1. Power Change Dependent on Grid Plans

- (1)

- Planned Operation

- (2)

- Unplanned Operation

4.2. Power Change Dependent on Frequency

- (1)

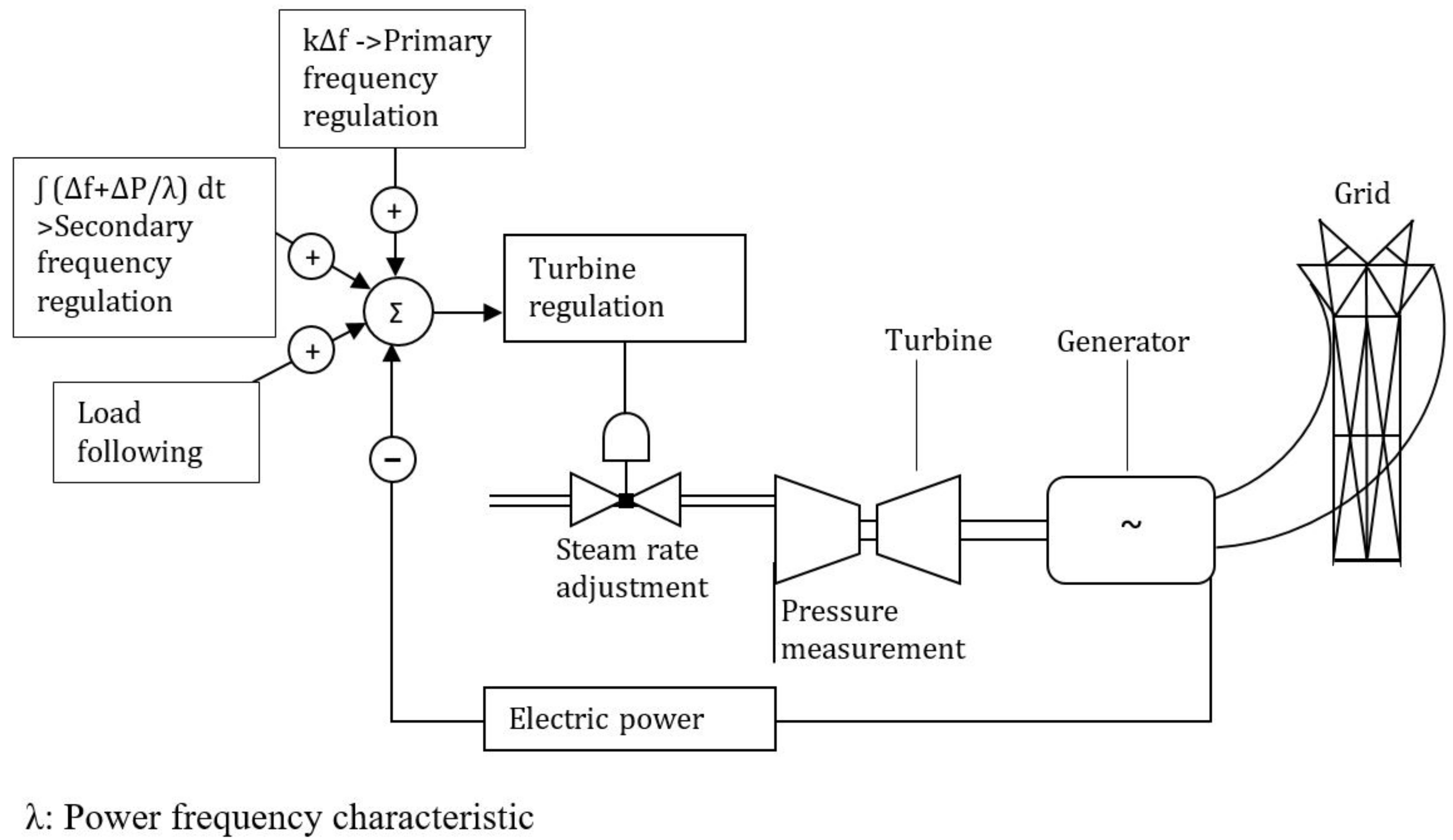

- Automatic Generation Control (AGC)

- (2)

- Governor-Free (GF) Control

4.3. Coordinated Rapid Load Following

4.4. Multi-Module Unit Operation

4.5. Cogeneration with Non-Electric Applications

5. Other Considerations for Load Following

5.1. Regulatory Requirements

- (1)

- Safety Regulations

5.2. Technical Considerations

- (1)

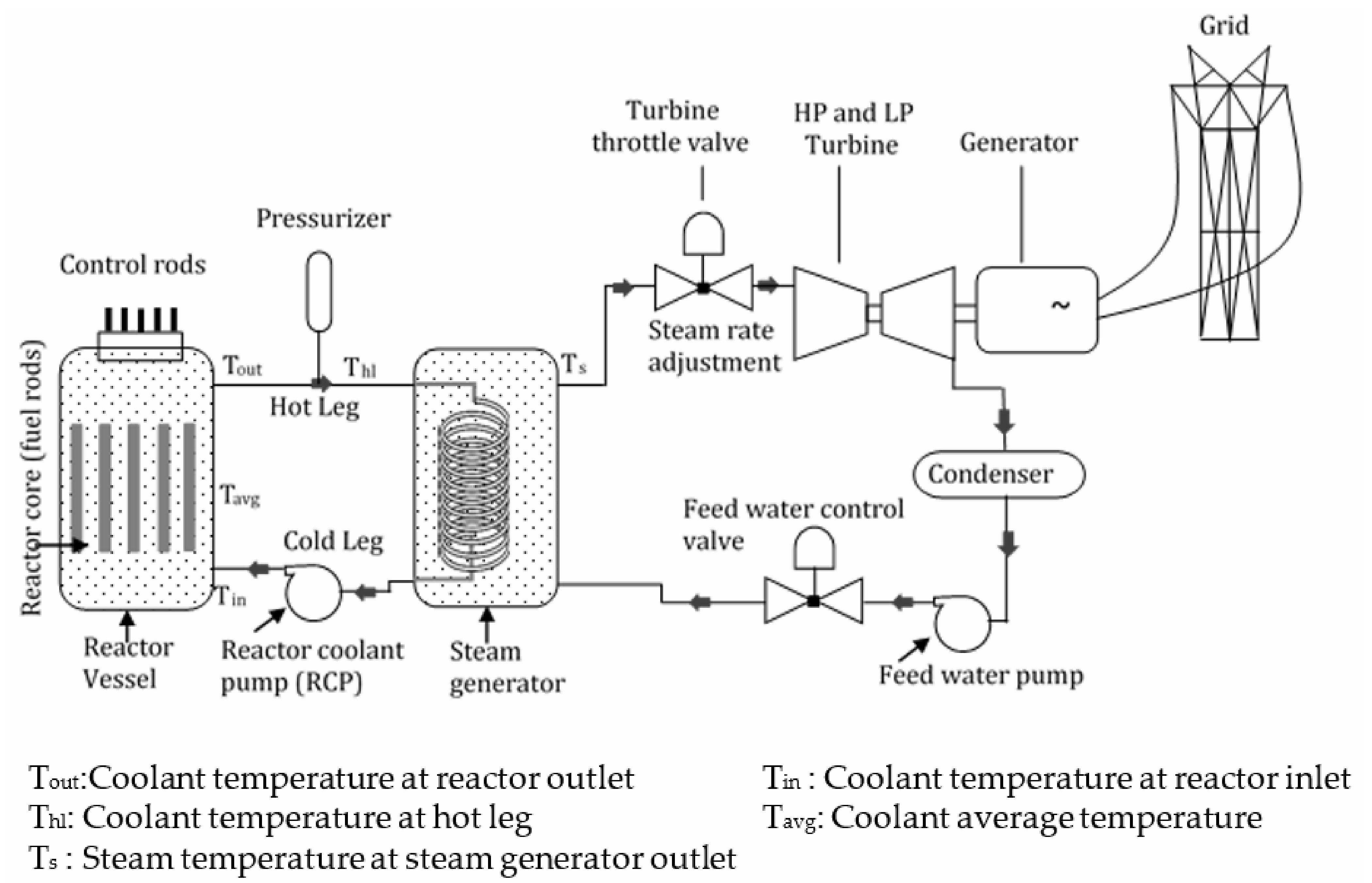

- Physical aspects of power regulation

- (2)

- Influence of the load following on the lifetime of components

5.3. Interaction of Grid Characteristics with Nuclear Power Plants

- (1)

- Effects of Grid Frequency Change on NPP

- (2)

- Effect of Grid Voltage Change on NPP

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAC | Alternative AC |

| AGC | Automatic Generation Control |

| AGR | Advanced Gas-cooled Reactor |

| AVR | Automatic Voltage Regulator |

| EUR | European Utilities Requirements |

| FOAK | First of A Kind |

| FP | Full Power |

| GCR | Gas-Cooled Reactor |

| GDC | General Design Criteria |

| GF | Governor-Free |

| GFL | Grid-Following |

| GFM | Grid-Forming |

| HTGR | High-Temperature Gas-Cooled Reactor |

| HWR | Heavy Water Reactor |

| LCFR | Lead-Cooled Fast Reactor |

| LNG | Liquefied Natural Gas |

| LWR | Light Water Reactor |

| MSR | Molten Salt Reactor |

| NRC | Nuclear Regulatory Commission |

| NPP | Nuclear Power Plant |

| PPS | Preferred Power Supply |

| RES | Renewable Energy System |

| RTP | Rated Thermal Power |

| SCFR | Sodium-Cooled Fast Reactor |

| SMR | Small Modular Reactor |

| TSO | Transmission System Operator |

| VRE | Variable Renewable Energy |

References

- IAEA. Advances in Small Modular Reactor Technology Developments; A Booklet Supplement to the IAEA Advanced Reactors Information System (ARIS); IAEA: Vienna, Austria, 2020; p. 354. [Google Scholar]

- Kuznetsov, A.L.V. Current Status, Technical Feasibility and Economics of Small Modular Reactors; OECD: Paris, France, 2011. [Google Scholar]

- International Atomic Energy Agency. Technology Roadmap for Small Modular Reactor Deployment; NR-T-1.18; International Atomic Energy Agency: Vienna, Austria, 2021. [Google Scholar]

- Zohuri, B. Small Modular Reactors as Renewable Energy Sources; Springer: Cham, Switzerland, 2019. [Google Scholar]

- IAEA. IAEA-TECDOC-1972 Benefits and Challenges of Small Modular Fast Reactors; IAEA: Vienna, Austria, 2021. [Google Scholar]

- IRENA. Renewable Capacity Statistiques De Capacité Estadísticas De Capacidad; IRENA: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- U.S. Energy Information Administration. Administration. International Electricity Data. Available online: https://www.eia.gov/international/data/world (accessed on 12 July 2022).

- Kroposki, B.; Johnson, B.; Zhang, Y.; Gevorgian, V.; Denholm, P.; Hodge, B.M.; Hannegan, B. Achieving a 100% Renewable Grid: Operating Electric Power Systems with Extremely High Levels of Variable Renewable Energy. IEEE Power Energy Mag. 2017, 15, 61–73. [Google Scholar] [CrossRef]

- Pierre, I.; Lorubio, G. Flexible Generation: Backing Up Renewables; Union of the Electricity Industry-EURELECTRIC Depot legal: D/2011/12.105/47; RESAP: Paris, France, 2011. [Google Scholar]

- Bose, D.; Hazra, A.; Mukhopadhyay, S.; Gupta, A. A Co-ordinated Control Methodology for Rapid Load-Following Operation of a Pressurized Water Reactor Based Small Modular Reactor. Nucl. Eng. Des. 2020, 367, 110748. [Google Scholar] [CrossRef]

- Nuclear Energy Agency. Technical and Economic Aspects of Load Following with Nuclear Power Plants; NEA, OECD: Paris, France, 2011; pp. 1–51. [Google Scholar]

- IAEA (International Atomic Energy Agency). Non-Baseload Operation in Nuclear Power Plants: Load Following and Frequency Control Modes of Flexible Operation; IAEA Nuclear Energy Series; IAEA: Vienna, Austria, 2018; pp. 1–190. [Google Scholar]

- Ackermann, T.; Prevost, T.; Vittal, V.; Roscoe, A.J.; Matevosyan, J.; Miller, N. Paving the Way A Future without Inertial Is Closer Than You Think. IEEE Power Energy Mag. 2017, 15, 65–67. [Google Scholar] [CrossRef]

- Pattabiraman, D.; Lasseter, R.H.; Jahns, T.M. Comparison of Grid Following and Grid Forming Control for a High Inverter Penetration Power System. In Proceedings of the 2018 IEEE Power & Energy Society General Meeting (PESGM), Portland, OR, USA, 5–10 August 2018; pp. 1–5. [Google Scholar]

- Bruynooghe, C.; Eriksson, A.; Fulli, G. Load-Following Operating Mode at Nuclear Power Plants (NPPs) and Incidence on Operation and Maintenance (O&M) Costs. Compatibility with Wind Power Variability; European Commission: Luxembourg, 2010. [Google Scholar]

- Peakman, A.; Merk, B.; Hesketh, K. The potential of pressurised water reactors to provide flexible response in future electricity grids. Energies 2020, 13, 941. [Google Scholar] [CrossRef]

- Ingersoll, D.T.; Colbert, C.; Houghton, Z.; Snuggerud, R.; Gaston, J.W.; Empey, M. Can Nuclear Power and Renewables be Friends? In Proceedings of the ICAPP 2015, Nice, France, 3–6 May 2015; p. 9. [Google Scholar]

- Ludwig, H.; Salnikova, T.; Waas, U. Load-following Capability of German Nuclear Power Plants (NPPs). ATW Int. J. Nucl. Power 2010, 55, 4–5. [Google Scholar]

- World Nuclear Association. Small Nuclear Power Reactors. Available online: https://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/small-nuclear-power-reactors.aspx (accessed on 5 May 2022).

- Locatelli, G.; Boarin, S.; Fiordaliso, A.; Ricotti, M.E. Load following of Small Modular Reactors (SMR) by cogeneration of hydrogen: A techno-economic analysis. Energy 2018, 148, 494–505. [Google Scholar] [CrossRef]

- IAEA Advanced Reactors Information System. Characteristics of Advanced Reactors. Available online: https://aris.iaea.org/sites/operating.html (accessed on 7 July 2022).

- Locatelli, G.; Mancini, M.; Todeschini, N. Generation IV nuclear reactors: Current status and future prospects. Energy Policy 2013, 61, 1503–1520. [Google Scholar] [CrossRef]

- Kunitomi, K.; Yan, X.; Nishihara, T.; Sakaba, N.; Mouri, T. JAEA’S VHTR for Hydrogen and Electricity Cogeneration: GTHTR300C. Nucl. Eng. Technol. 2007, 39, 9–20. [Google Scholar] [CrossRef]

- Bickel, J.H. Grid Stability and Safety Issues Associated with Nuclear Power Plants. Evergr. Saf. Reliab. Technol. 2001, 14, 1–9. [Google Scholar]

- USNRC. Appendix A to Part 50—General Design Criteria for Nuclear Power Plants. US Nuclear Regulatory Commission. Med. Dosim. 2020, 13, 87–93. [Google Scholar]

- IEEE Std 765-1983; IEEE Standard for Preferred Power Supply (PPS) for NUclear Power Generating Stations. IEEE: New York, NY, USA, 1995. [CrossRef]

- IAEA. Design of Electrical Power Systems for Nuclear Power Plants; Specific Safety Guide, No. SSG-34; IAEA: Vienna, Austria, 2012; pp. 1–144. [Google Scholar]

- NuScale Power. Nuscale SMR Technology: An Ideal Solution for Repurposing U.S. Coal Plant Infrastructure and Revitalizing Communities; NuScale Power: Corvallis, OR, USA, 2021. [Google Scholar]

- Wenisch, A.; Becker, O. NPP Output Flexibility Expectations in the Light of Reality; Österreichisches Ökologie-Institut: Vienna, Austria, 2010. [Google Scholar]

- IAEA. Interaction of Grid Characteristics with Design and Performance of Nuclear Power Plants. A Guidebook; Technical Reports Series No. 224; International Atomic Energy Agency: Vienna, Austria, 1983. [Google Scholar]

- Chowdhury, A.H.; Rabby, M.K.M. A study on low grid voltage problem near Rooppur nuclear power plant. In Proceedings of the 8th International Conference on Electrical and Computer Engineering, ICECE, Dhaka, Bangladesh, 20–22 December 2014; pp. 289–292. [Google Scholar]

- World Bank. Tracking SDG7: The Energy Progress Report 2018; World Bank: Washington, DC, USA, 2018; p. 193. [Google Scholar]

- OECD/IEA. World Energy Model Documentation; OECD: Paris, France, 2021. [Google Scholar]

| Capacity (GW) | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|---|---|---|---|

| World | 1444 | 1566 | 1698 | 1852 | 2014 | 2185 | 2357 | 2542 | 2807 | 3064 |

| China | 302.1 | 359.5 | 414.7 | 479.1 | 541.0 | 620.9 | 695.5 | 758.8 | 899.6 | 1020 |

| India | 60.5 | 63.6 | 71.9 | 78.6 | 90.4 | 105.2 | 118.2 | 128.4 | 134.4 | 147.1 |

| Japan | 39.0 | 46.1 | 56.1 | 67.4 | 76.2 | 84.2 | 91.3 | 99.3 | 106.9 | 111.9 |

| Korea | 3.7 | 4.3 | 5.7 | 7.2 | 9.4 | 11.4 | 14.0 | 18.0 | 20.4 | 24.3 |

| Description | NPP | HC | Lign | CCG | PS |

|---|---|---|---|---|---|

| Start-up Time “Cold” | ~40H | ~6H | ~10H | <2H | ~0.1H |

| Start-up Time “warm” | ~40H | ~3H | ~6H | <1.5H | ~0.1H |

| Load Gradient (up) ”nominal output” | ~5%/M | ~2%/M | ~2%/M | ~4%/M | >40%/M |

| Load Gradient (down) ”nominal output” | ~5%/M | ~2%/M | ~2%/M | ~4%/M | >40%/M |

| Minimal Shutdown Time | No | No | No | No | ~10H |

| Minimal Possible Load | 50% | 40% | 40% | <50% | ~15% |

| Response Base | Response Mode | Parameter and Properties |

|---|---|---|

| Predicted daily demand variations | Load following | Low-power period (power level and duration) Power change rate (slow, fast) Time in cycle (beginning, end) |

| Spontaneous limited demand variations | Frequency control | Local frequency control: frequency deviation (ΔF) converted into power change (ΔP) (ΔP amplitude, slope of change) Remote frequency control: signal from the dispatcher (ΔP amplitude, slope of change) Superimposition of local and remote frequency control |

| Grid disturbances | Spinning reserve | Ramp (amplitude, slope, from minimum power level) Steps (amplitude, from minimum power level) House load capability (loss of off-site power without reactor trip) Fast (e.g., 5% rated thermal power/minute) return to full power without advance notice |

| Longer-term forecasted demand | Extended low-power operation | Reduced power level during extended period (number of occurrences, duration) |

| Common Requirements Applicable to NEW LWRs | Parameter |

|---|---|

| Continuous operation range (mandatory) | 50%~100% Pn |

| Down to minimum (option) | 20% |

| Primary control (mandatory); 2~30 s after deviation observed | ±2% Pn/min |

| Higher values by agreement between system operator and plant operator | ± 5% Pn/min |

| Activating total primary range of control requested | Within 30 s |

| Secondary control (option); several seconds to several minutes | ±10% |

| Load-Following Capabilities (option) | |

| Load-following capability until ( ) % of whole fuel cycle | 90% |

| Load-following range | 100% Pn~minimum |

| From full power to minimum load and back to full power operation | 2 per day, 5 per week Cumulatively 200 per year |

| Emergency load variation (by agreement between grid operator and unit operator); amplitude down to minimum load of the unit. | 20% of Pn/min. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-k.; Oyando, H.C. Review of the Requirements for Load Following of Small Modular Reactors. Energies 2022, 15, 6327. https://doi.org/10.3390/en15176327

Chang C-k, Oyando HC. Review of the Requirements for Load Following of Small Modular Reactors. Energies. 2022; 15(17):6327. https://doi.org/10.3390/en15176327

Chicago/Turabian StyleChang, Choong-koo, and Harold Chisano Oyando. 2022. "Review of the Requirements for Load Following of Small Modular Reactors" Energies 15, no. 17: 6327. https://doi.org/10.3390/en15176327

APA StyleChang, C.-k., & Oyando, H. C. (2022). Review of the Requirements for Load Following of Small Modular Reactors. Energies, 15(17), 6327. https://doi.org/10.3390/en15176327