Predicting Mining Areas Deformations under the Condition of High Strength and Depth of Cover

Abstract

1. Introduction

- Based on models of continuous media [13];

- Intermediate solutions–using models of the continuous medium and empirical axioms [16];

- Numerical methods that are gaining popularity due to the development of digital technology [17,18,19,20]. FLAC3D software is the most frequently used. Based on the software-based calculations, Gang and Yang [3] determined a safe distance from a mining boundary to an urbanized area, which allowed extracting 1.5 million Mg of coal and avoiding damage to surface structures. It should be noted that mining was conducted at a shallow depth, which made the preparation of the data relatively easy. To a great extent, the course of the deformation process undoubtedly depends on natural and geological conditions [4]. The geological structure of the rock mass especially has an impact on the extent of deformations or the kinetics of the process. This makes it necessary to have a good understanding of the parameter values used for predictions. In these cases, using numerical methods is very helpful; however, this also has certain limitations, because the parameters of the rock strength change during extraction. Capturing these changes in a model is both difficult and time-consuming. For instance, in the work of Zhu et al. [21], the analyses were conducted to determine the impact of the depth of loose overburden on the course of deformations using FLAC3D software.

2. Materials and Methods

2.1. Rock Mass Structure

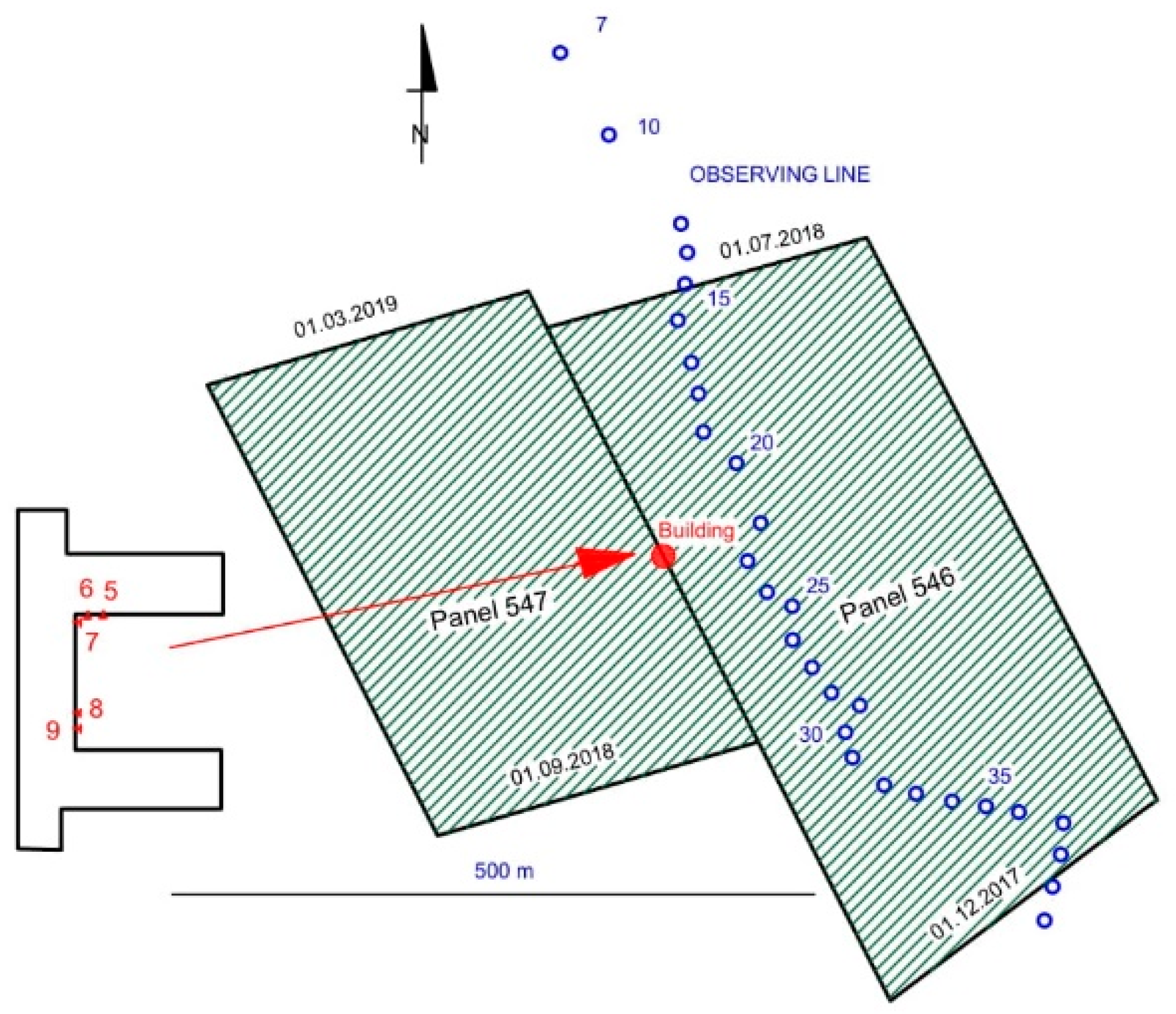

2.2. Coal Mining

2.3. Land Surveying and Results

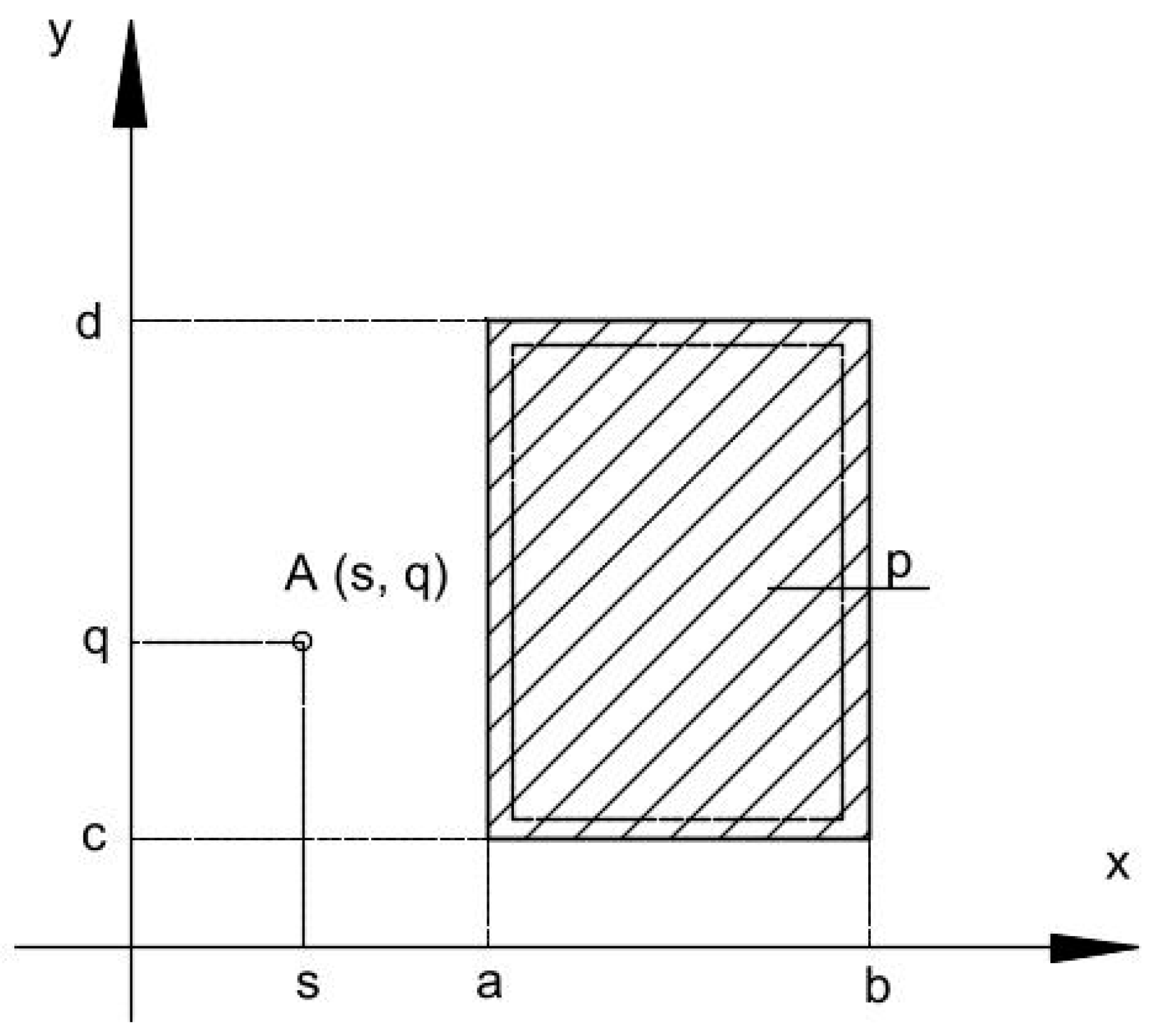

2.4. Analysis Method Used

- ξ = x − s,

- η = y − q.

- Exploitation coefficient (of roof control)—a, dimensionless quantity. Its value depends on the method of liquidation of the selected part of the deposit. In the Upper Silesian Coal Basin, for caving mining the values are a = 0.7–0.9;

- Main impact radius r, expressed in meters. This parameter is used interchangeably with the parameter tan β, where β is the angle of the reach of the main impact.

- Extraction periphery is an additional parameter in the theory-p.

- w(t)—temporary subsidence,

- wk—asymptotic (final) subsidence,

- c—subsidence rate coefficient (time), 1/year or 1/day. According to S. Knothe [28], for the Upper Silesian Coal Basin c = 0.5–7, 1/year

3. Results

- -

- identification of the parameter values: a, p, tan β on the basis of final subsidence registered on the measurement line section;

- -

- identification of parameter c value based on the lowering of the point over time.

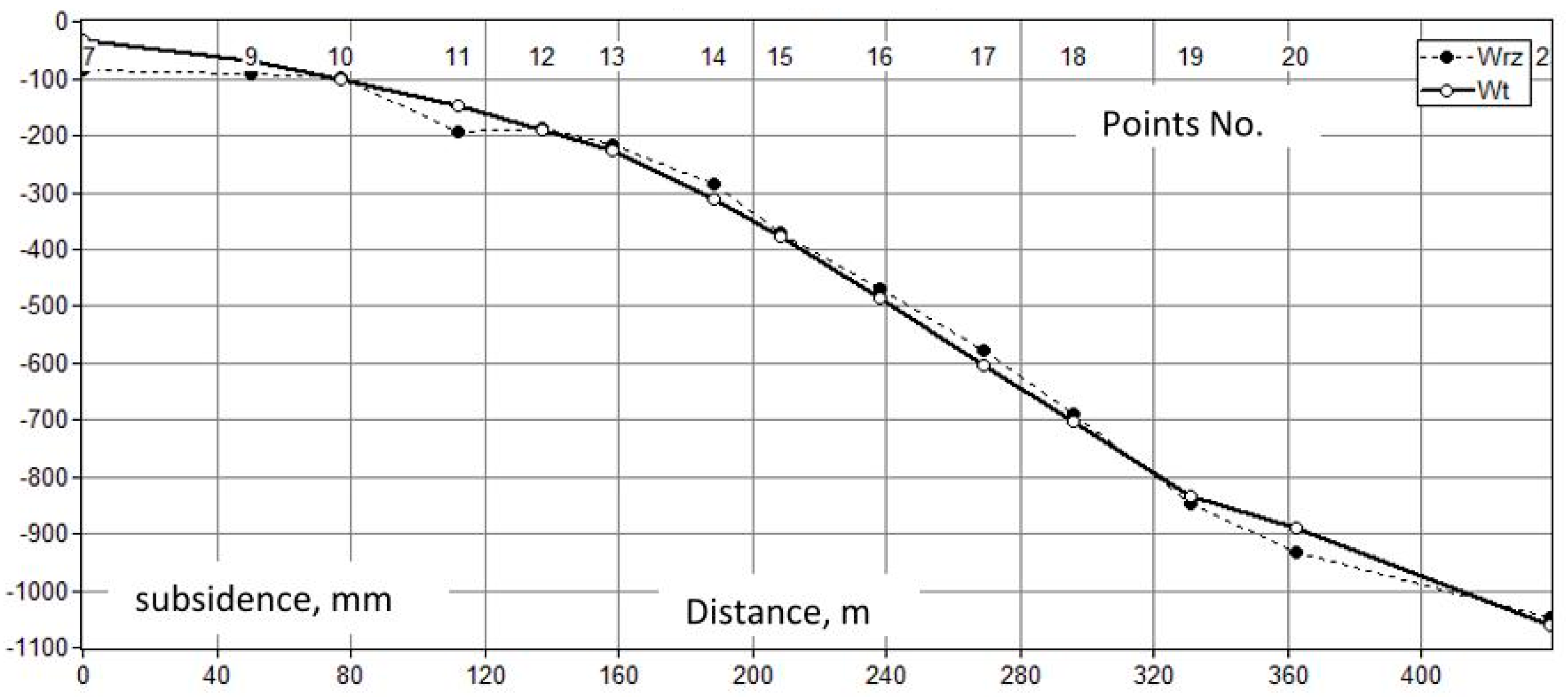

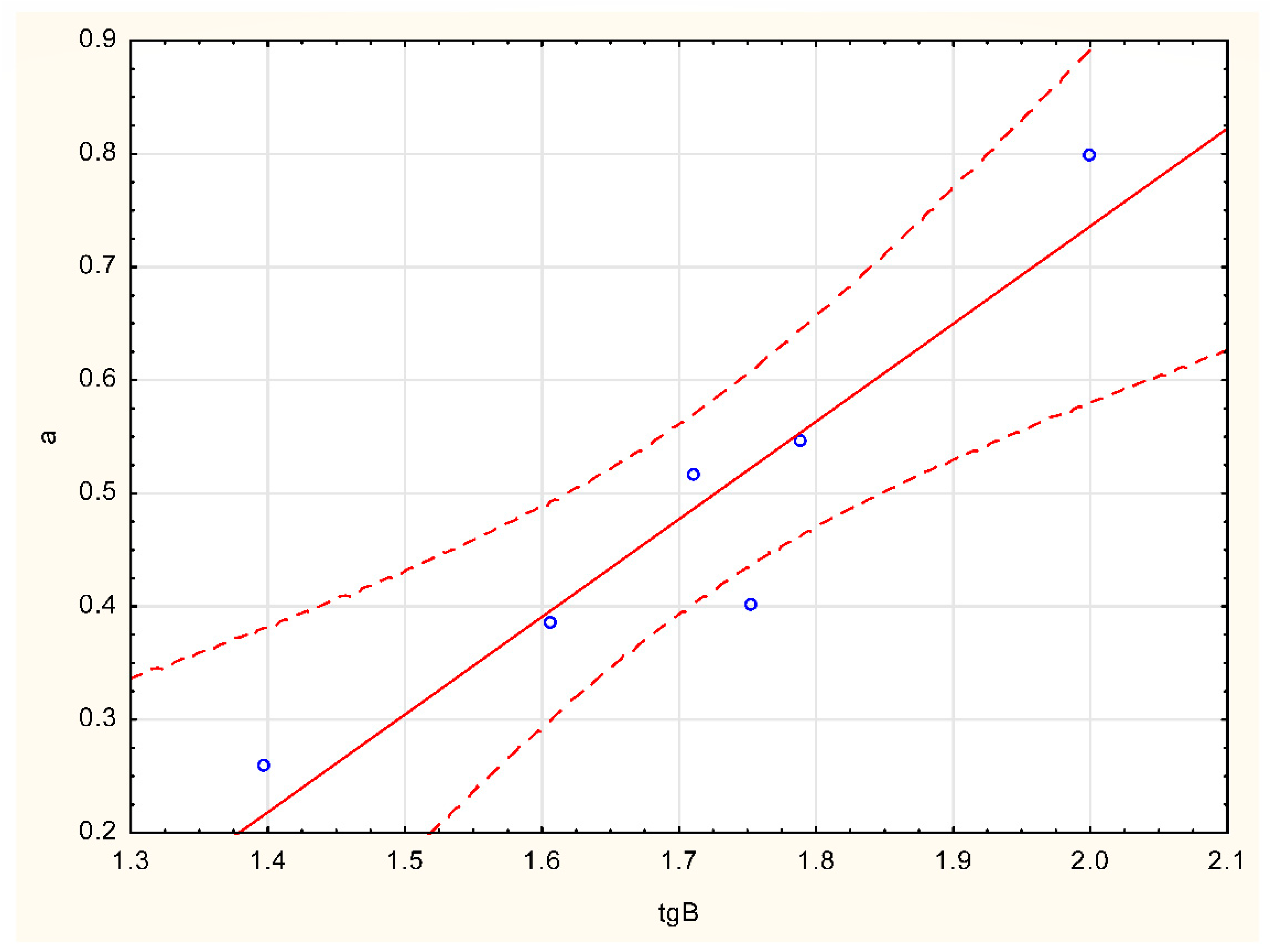

3.1. Identification of Parameter Values on the Basis of Determined Subsidence

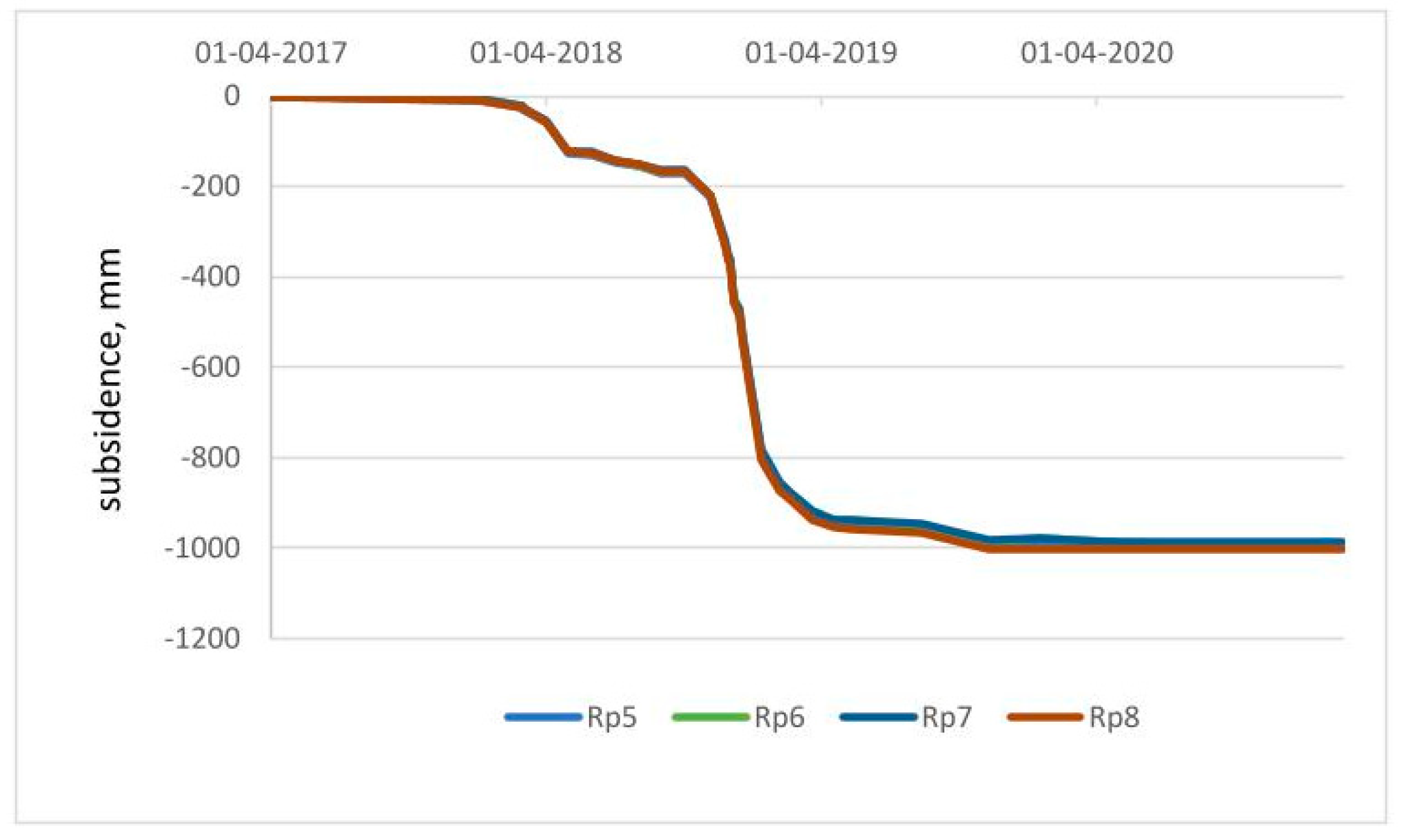

3.2. Identification of Subsidence Rate Coefficient

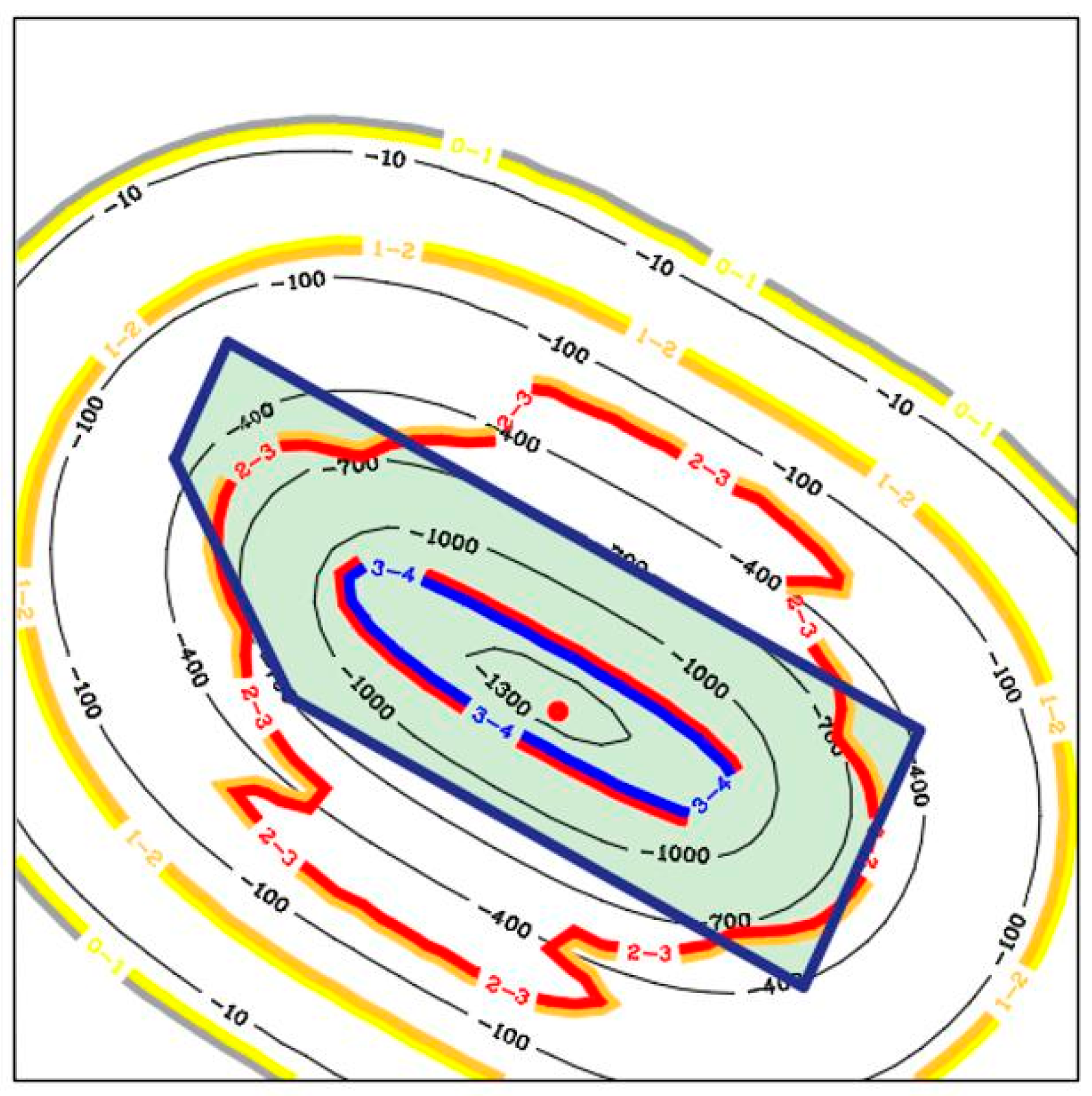

3.3. Prediction of Ground Deformation As a Result of Planned Extraction

- -

- exploitation coefficient a = 0.517;

- -

- tangent of the range of main impacts tan β = 1.71;

- -

- extraction periphery p = 40 m.

- -

- exploitation coefficient a = 0.800;

- -

- tangent of the range of main impacts tan β = 2.00;

- -

- extraction periphery p = 40 m.

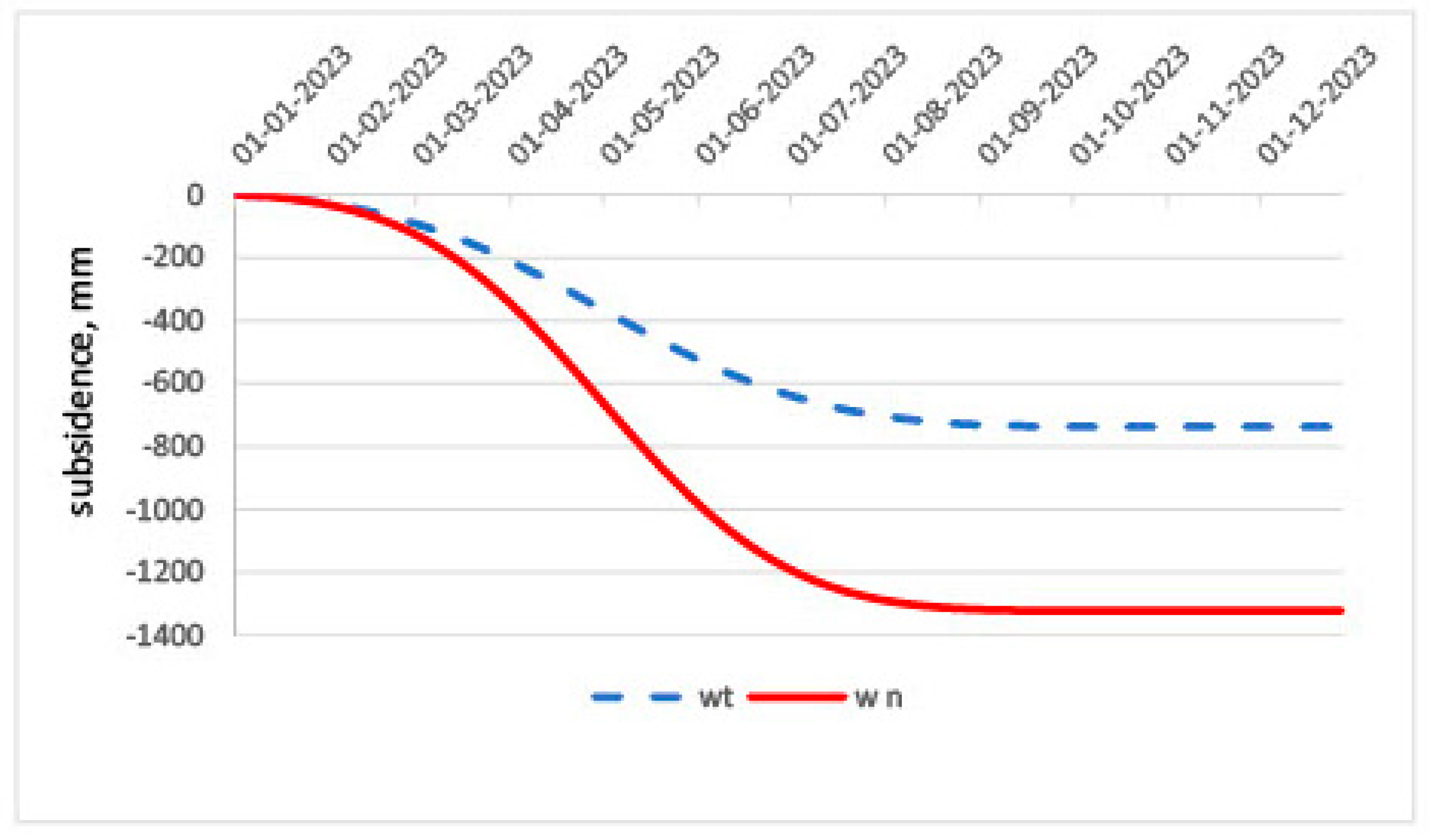

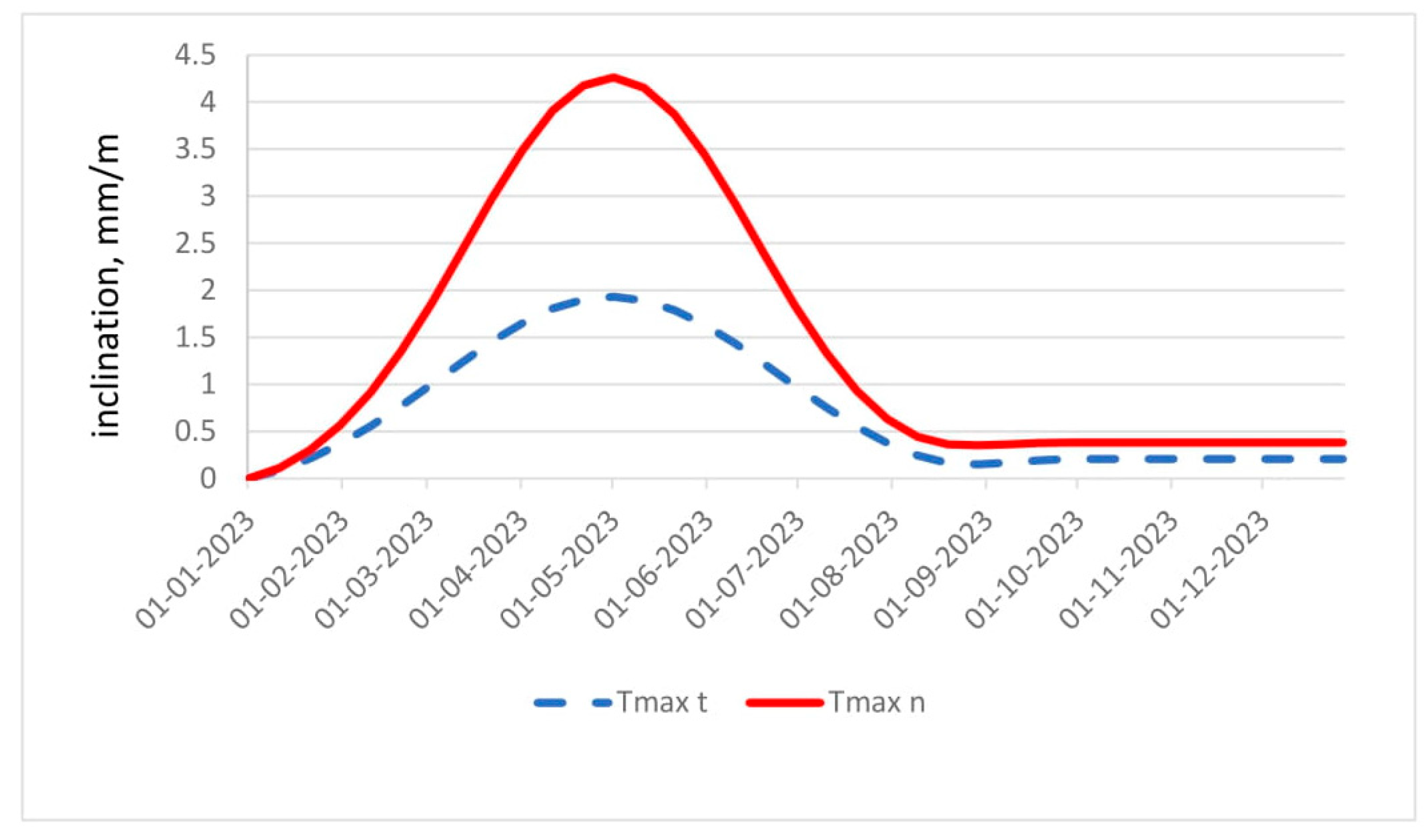

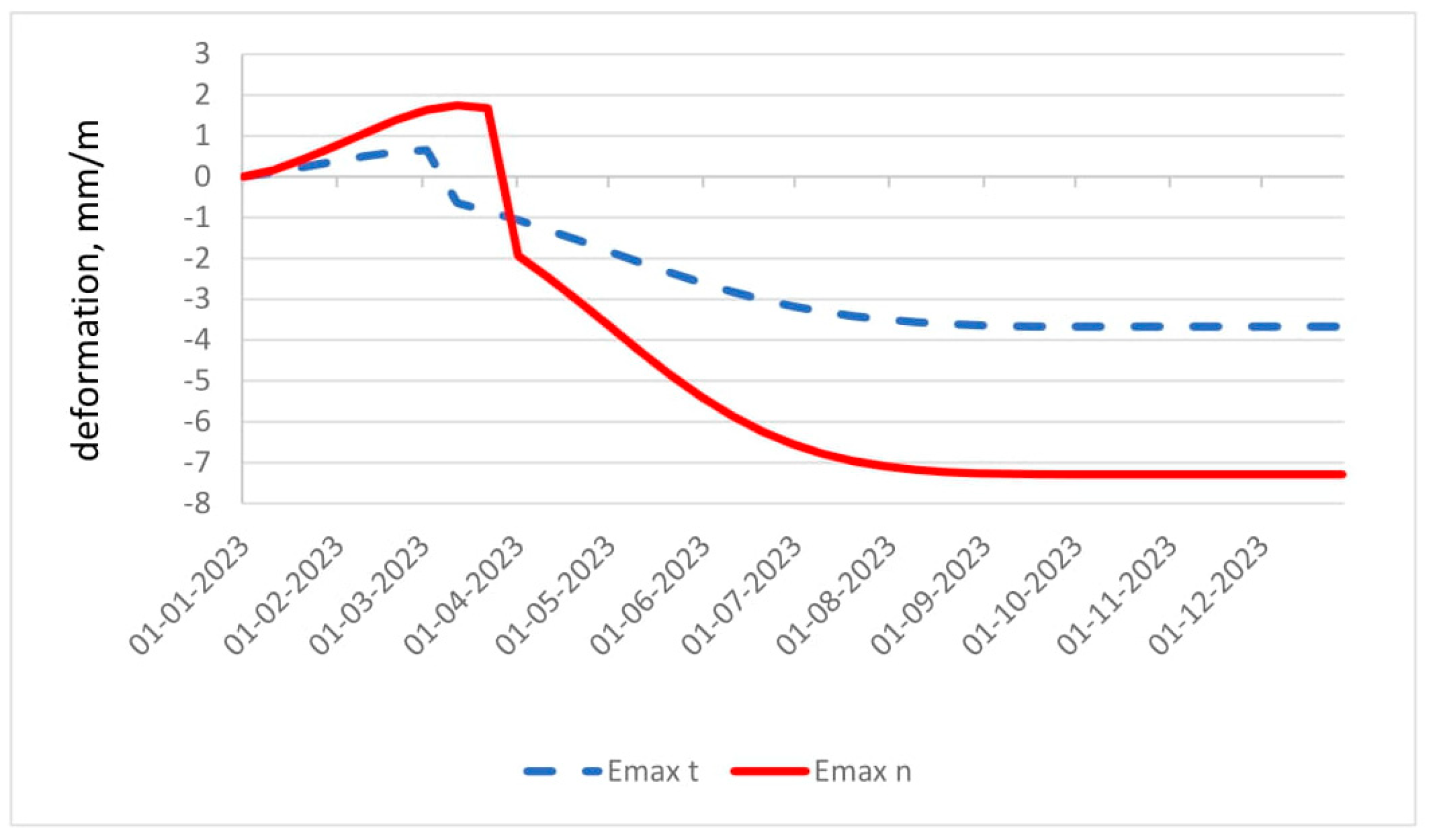

3.4. Detailed Forecast for the Selected Object

- -

- exploitation coefficient a = 0.517;

- -

- tangent of the range of main impacts tan β = 1.71;

- -

- extraction periphery p = 40 m;

- -

- subsidence rate coefficient c = 0.05 1/day.

- -

- exploitation coefficient a = 0.800;

- -

- tangent of the range of main impacts tan β = 2.00;

- -

- extraction periphery p = 40 m;

- -

- c -> ∞.

4. Discussion

5. Conclusions

- Geological and mining conditions, including the structure of the rock mass, have a significant impact on the parameter values necessary for the preparation of mining area deformation predictions. In cases where these conditions differ significantly from the average ones in a given area, it is particularly important to identify the parameter values based on the measurement results. Taking typical parameter values significantly influences the quality of the calculation results and leads to wrong conclusions about possible damage to buildings. Consequently, it leads to wrong decision-making regarding the possibility of conducting a planned mining extraction:

- In unusual geological conditions, when the overburden is made of strong limestone rocks, preliminary research indicated a gradual increase in the values of and tan β parameters up to the values commonly used for predictions. The previous experience has implied the influence of rock mass mechanical properties on the value of tan β parameter. Based on the research results presented in this paper it is clear that there is also a correlation between the values of the coefficient of roof control and the values of tan β, which are dependent on the rock mass structure. When analyzing the impact of planned extraction on more important objects, predictions should take into account the parameter values obtained during land surveying for specific geological and mining conditions. Such predictions should take into account a delay in the impacts, e.g., according to Equation (11).

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Strzałkowski, P.; Litwa, P. Environmental protection problems in the areas of former mines with emphasis on sinkholes: Selected examples. Int. J. Environ. Sci. Technol. 2021, 18, 771–780. [Google Scholar] [CrossRef]

- Guo, W.; Guo, M.; Tan, Y.; Bai, E.; Zhao, G. Sustainable development of resources and the environment: Mining—Induced eco-geological environmental damage and mitigation measures—A case study in the Henan coal mining area, China. Sustainability 2019, 11, 4366. [Google Scholar] [CrossRef]

- Li, G.; Yang, Q. Prediction of Mining Subsidence in Shallow Coal Seam. Math. Probl. Eng. 2020, 2020, 7956947. [Google Scholar] [CrossRef]

- Strzałkowski, P. Zarys Ochrony Terenów Górniczych; Wyd. Pol. Śl.: Gliwice, Poland, 2015. [Google Scholar]

- Kratzsh, H. Mining Subsidence Engineering; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1983. [Google Scholar]

- Lee, F.T.; Abel, J.F., Jr. Subsidence from Underground Mining: Environmental Analysis and Planning Considerations; Geological Survey Circular, 876; United States Department: Washington, DC, USA, 1983. [Google Scholar]

- Kwiatek, J. (Ed.) Ochrona Obiektów Budowlanych na Terenach Górniczych; Wydawnictwo Głównego Instytutu Górnictwa: Katowice, Poland, 1997. [Google Scholar]

- Knothe, S. Prognozowanie Wpływów Eksploatacji Górniczej; Wydawnictwo Śląsk: Katowice, Poland, 1984. [Google Scholar]

- Zych, J. Metoda prognozowania wpływów eksploatacji górniczej na powierzchnię terenu uwzględniająca asymetryczny przebieg procesu deformacji. Zesz. Nauk. Politech. Śląskiej 1987, 164, 17–19. [Google Scholar]

- Li, J.; Wang, L. Mining subsidence monitoring model based on BPM-EKTF and TLS and its application in building mining damage assessment. Environ. Earth Sci. 2021, 80, 396. [Google Scholar] [CrossRef]

- Zhu, X.; Guo, G.; Zha, J.; Chen, T.; Fang, O.; Yang, X. Surface dynamic subsidence prediction model of solid backfill mining. Environ. Earth Sci. 2016, 75, 1007. [Google Scholar] [CrossRef]

- Zhao, B.; Guo, Y.; Mao, X.; Zhai, D.; Zhu, D.; Huo, Y.; Sun, Z.; Wang, J. Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga Based on the Probability Integration Model. Energies 2022, 15, 2282. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Zhang, D. Characteristics of Roof Ground Subsidence While Applying a Continuous Excavation Continuous Backfill Method in Longwall Mining. Energies 2020, 13, 95. [Google Scholar] [CrossRef]

- Vušović, N.; Vlahović, M.; Kržanović, D. Stochastic method for prediction of subsidence due to the underground coal mining integrated with GIS, a case study. Environ. Earth Sci. 2021, 80, 67. [Google Scholar] [CrossRef]

- Chen, Q.; Li, J.; Enke, H. Dynamic simulation for the process of mining subsidence based on cellular automata model. Open Geosci. 2020, 12, 832–839. [Google Scholar] [CrossRef]

- Chudek, M. Geomechanika z Podstawami Ochrony Środowiska Górniczego I Powierzchni Terenu; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2002. [Google Scholar]

- Wesołowski, M. Numerical modeling of exploitation relics and faults influence on rock mass deformations. Arch. Min. Sci. 2016, 61, 893–906. [Google Scholar] [CrossRef][Green Version]

- Guzy, A.; Witkowski, W.T. Land Subsidence Estimation for Aquifer Drainage Induced by Underground Mining. Energies 2021, 14, 4658. [Google Scholar] [CrossRef]

- Feng, Z.; Guo, W.; Xu, F.; Yang, D.; Yang, W. Control Technology of Surface Movement Scope with Directional Hydraulic Fracturing Technology in Longwall Mining: A Case Study. Energies 2019, 12, 3480. [Google Scholar] [CrossRef]

- Zhang, B.; Ye, J.; Zhang, Z.; Xu, L.; Xu, N. A Comprehensive Method for Subsidence Prediction on Two-Seam Longwall Mining. Energies 2019, 12, 3139. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, W.; Wang, Z.; Wang, C.; Li, W.; Wang, C. Simulation Analysis of Influencing Factors of Subsidence Based on Mining under Huge Loose Strata: A Case Study of Heze Mining Area, China. Geofluids 2020, 2020, 6357683. [Google Scholar] [CrossRef]

- Peng, S.S. Coal Mine Ground Control, 3rd ed.; West Virginia University: Morgantown, WV, USA, 2008; p. 750. [Google Scholar]

- Li, J.; Zhang, J.X.; Huang, Y.; Zhang, Q.; Xu, J.M. An investigation of surface deformation after fully mechanized, solid back fill mining. Int. J. Min. Sci. Technol. 2012, 22, 453–457. [Google Scholar] [CrossRef]

- Orwat, J. Causes analysis of occurrence of the terrain surface discontinuous deformations of a linear type. International Conference on Applied Sciences. J. Phys. Conf. Ser. 2020, 1426, 012016. [Google Scholar] [CrossRef]

- Orwat, J. Mining exploitation forecasted effects caused by a hard coal extraction from a thick seam. In Proceedings of the International Conference on Applied Sciences, Hunedoara, Romania, 9–11 May 2019. [Google Scholar] [CrossRef]

- Whittaker, B.W.; Redish, D.J. Subsidence—Occurrence, Prediction and Control; Elsevier: Amsterdam, The Netherlands; Elsevier: Oxford, UK; Elsevier: New York, NY, USA; Elsevier: Tokyo, Japan, 1989. [Google Scholar]

- Han, J.; Zou, J.; Hu, C.; Yang, W. Study on Size Design of Shaft Protection Rock/Coal Pillars in Thick Soil and Thin Rock Strata. Energies 2019, 12, 2553. [Google Scholar] [CrossRef]

- Knothe, S. Wpływ czasu na kształtowanie się niecki osiadania. Arch. Min. Metall. 1953, 1, 51–62. [Google Scholar]

- Ścigała, R. Komputerowe Wspomaganie Prognozowania Deformacji Górotworu i Powierzchni Wywołanych Podziemną Eksploatacją Górniczą; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2008. [Google Scholar]

- Ścigała, R. The identification of parameters of theories used for prognoses of post mining deformations by means of present software. Arch. Min. Sci. 2013, 58, 1347–1357. [Google Scholar] [CrossRef]

- Kryzia, K.; Majcherczyk, T.; Niedbalski, Z. Variability of exploitation coefficient of Knothe theory in relation to rock mass strata type. Arch. Min. Sci. 2018, 63, 767–782. [Google Scholar] [CrossRef]

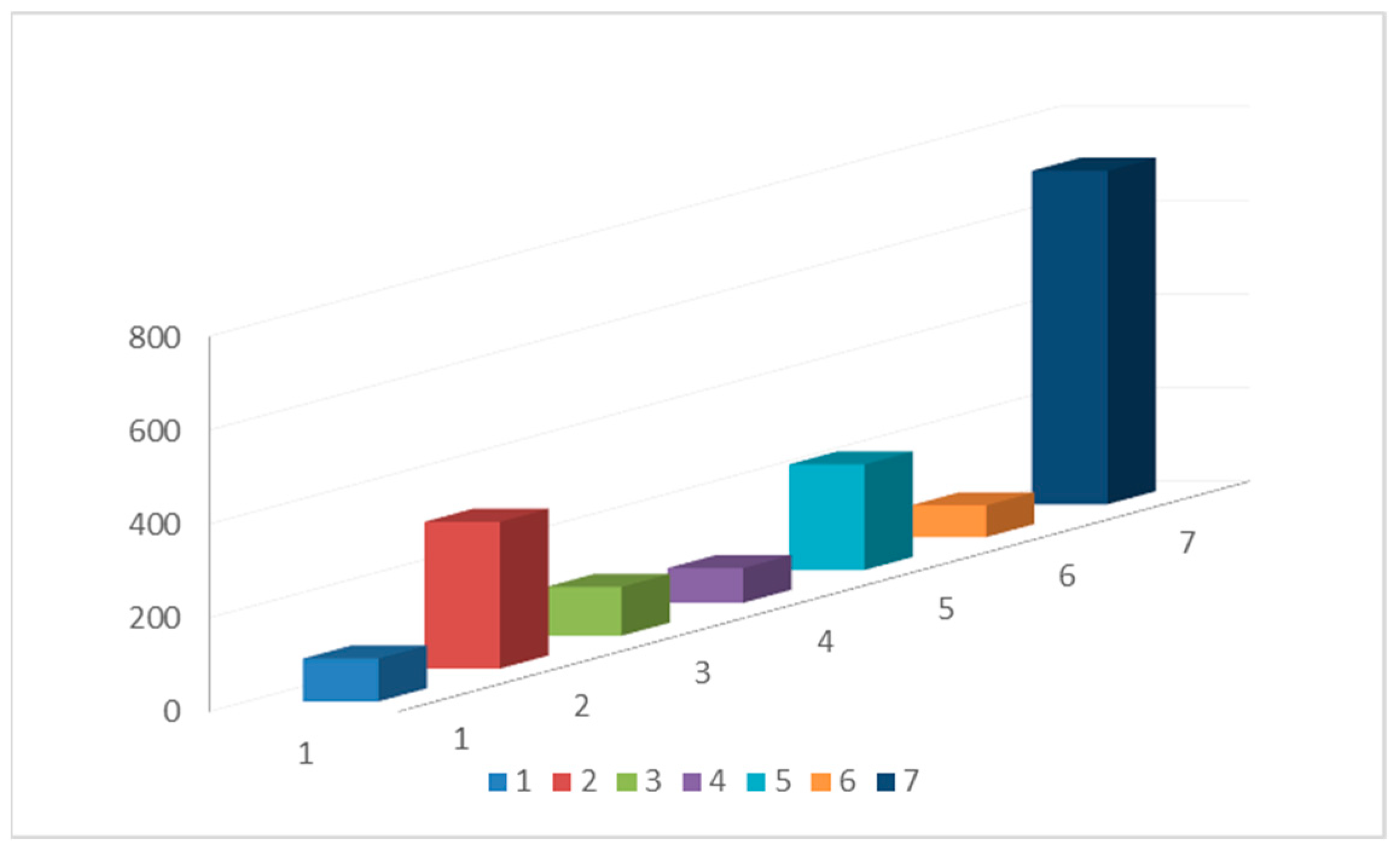

| Seam/Panel | Start | End | H, m |

|---|---|---|---|

| 546/1 | 1 December 2017 | 31 December 2017 | 597 |

| 546/2 | 1 January 2018 | 31 March 2018 | 580 |

| 546/3 | 1 April 2018 | 1 July 2018 | 565 |

| 547/4 | 1 September 2018 | 30 September 2018 | 575 |

| 547/5 | 1 October 2018 | 31 December 2018 | 565 |

| 547/6 | 1 January 2019 | 1 March 2019 | 557 |

| Category | T, mm/m | R, 1/km | ε, mm/m |

|---|---|---|---|

| 0 | T ≤ 0.5 | 40 ≤ │R│ | │ε│ ≤ 0.3 |

| I | 0.5 < T ≤ 2.5 | 20 ≤ │R│ < 40 | 0.3 < │ε│ ≤ 1.5 |

| II | 2.5 < T ≤ 5 | 12 ≤ │R│ < 20 | 1.5 < │ε│ ≤ 3.0 |

| III | 5 < T ≤ 10 | 6 ≤ │R│ < 12 | 3.0 < │ε│ ≤ 6.0 |

| IV | 10 < T ≤ 15 | 4 ≤ │R│ < 6 | 6.0 < │ε│ ≤ 9.0 |

| V | T > 15 | │R│ < 4 | |ε| > 9 |

| Pkt | X | Y | wrz | wt | V | VV | sumV | sumVV |

|---|---|---|---|---|---|---|---|---|

| 7 | 340.0 | 895.0 | −86.0 | −32.4 | −53.6 | 2875.2 | 53.6 | 2875.2 |

| 9 | 370.0 | 855.0 | −91.0 | −67.7 | −23.3 | 542.6 | 76.9 | 3417.8 |

| 10 | 380.0 | 830.0 | −98.0 | −100.2 | 2.2 | 4.8 | 79.1 | 3422.6 |

| 11 | 405.0 | 805.0 | −194.0 | −145.6 | −48.4 | 2344.1 | 127.5 | 5766.7 |

| 12 | 420.0 | 785.0 | −187.0 | −189.1 | 2.1 | 4.6 | 129.7 | 5771.3 |

| 13 | 435.0 | 770.0 | −216.0 | −226.4 | 10.4 | 109.0 | 140.1 | 5880.3 |

| 14 | 435.0 | 740.0 | −286.0 | −311.6 | 25.6 | 657.1 | 165.7 | 6537.4 |

| 15 | 435.0 | 720.0 | −371.0 | −377.3 | 6.3 | 39.4 | 172.0 | 6576.8 |

| 16 | 435.0 | 690.0 | −469.0 | −486.3 | 17.3 | 298.1 | 189.3 | 6875.0 |

| 17 | 440.0 | 660.0 | −579.0 | −603.3 | 24.3 | 592.8 | 213.6 | 7467.8 |

| 18 | 450.0 | 635.0 | −688.0 | −700.8 | 12.8 | 164.7 | 226.5 | 7632.5 |

| 19 | 450.0 | 600.0 | −848.0 | −834.8 | −13.2 | 175.0 | 239.7 | 7807.5 |

| 20 | 475.0 | 580.0 | −931.0 | −888.9 | −42.1 | 1773.1 | 281.8 | 9580.6 |

| 23 | 485.0 | 505.0 | −1047.0 | −1060.5 | 13.5 | 181.5 | 295.3 | 9762.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strzałkowski, P. Predicting Mining Areas Deformations under the Condition of High Strength and Depth of Cover. Energies 2022, 15, 4627. https://doi.org/10.3390/en15134627

Strzałkowski P. Predicting Mining Areas Deformations under the Condition of High Strength and Depth of Cover. Energies. 2022; 15(13):4627. https://doi.org/10.3390/en15134627

Chicago/Turabian StyleStrzałkowski, Piotr. 2022. "Predicting Mining Areas Deformations under the Condition of High Strength and Depth of Cover" Energies 15, no. 13: 4627. https://doi.org/10.3390/en15134627

APA StyleStrzałkowski, P. (2022). Predicting Mining Areas Deformations under the Condition of High Strength and Depth of Cover. Energies, 15(13), 4627. https://doi.org/10.3390/en15134627