A Caprock Evaluation Methodology for Underground Gas Storage in a Deep Depleted Gas Reservoir: A Case Study for the X9 Lithologic Trap of Langgu Sag, Bohai Bay Basin, China

Abstract

:1. Introduction

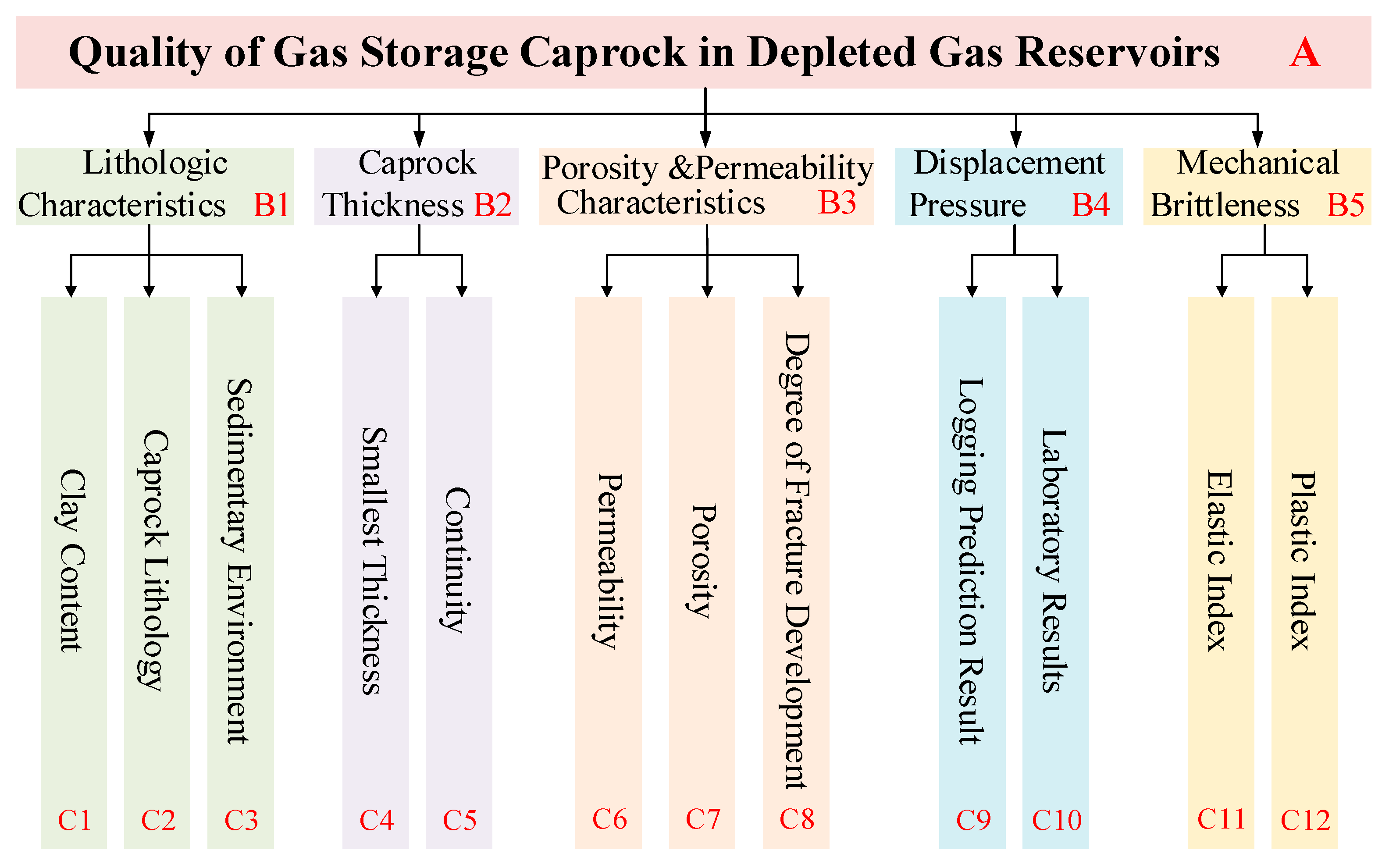

2. Evaluation Indexes of Sealing Capacity of Caprock

2.1. Lithologic Characteristics

2.2. Caprock Thickness

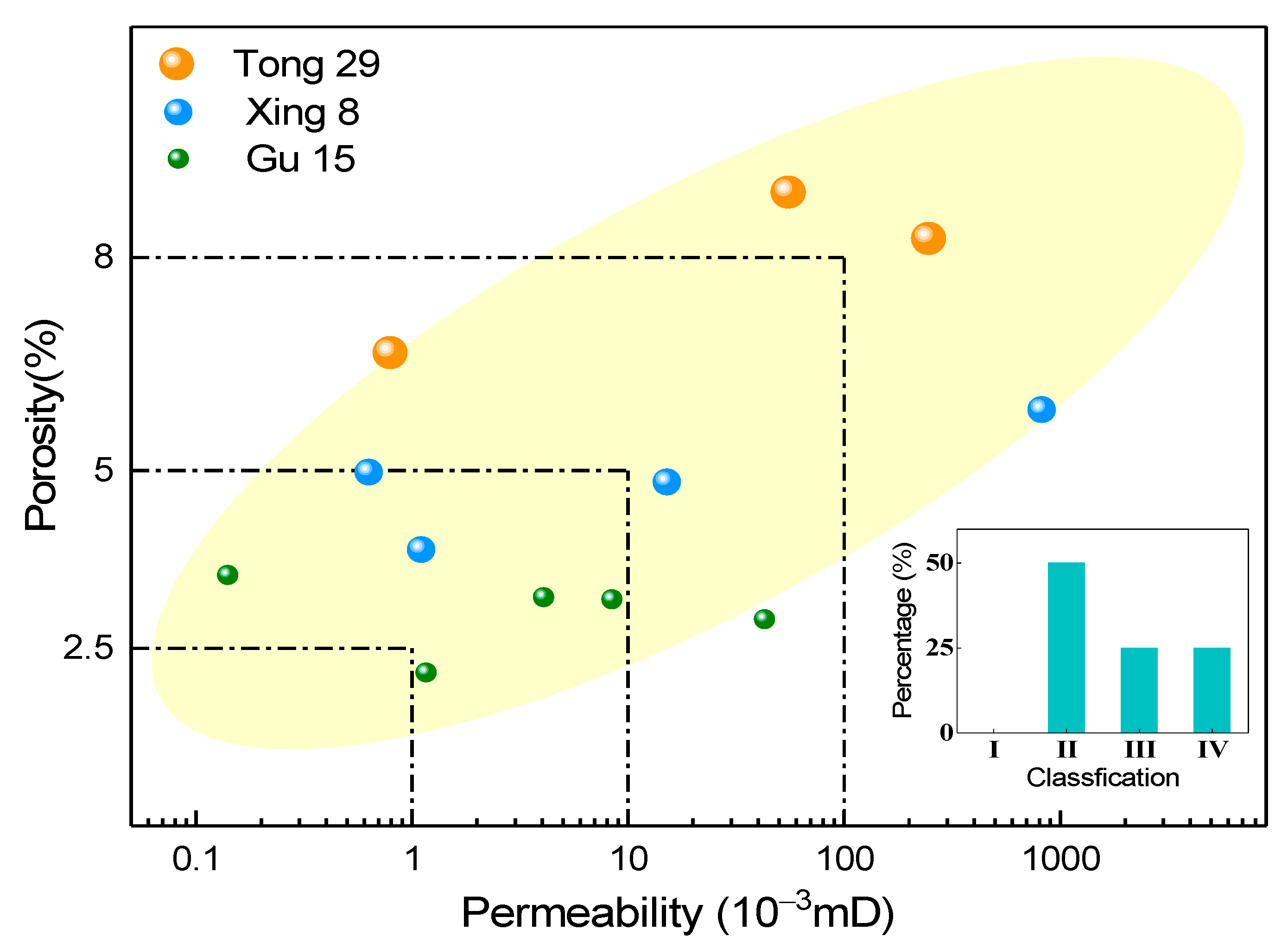

2.3. Porosity and Permeability Characteristics of Caprock

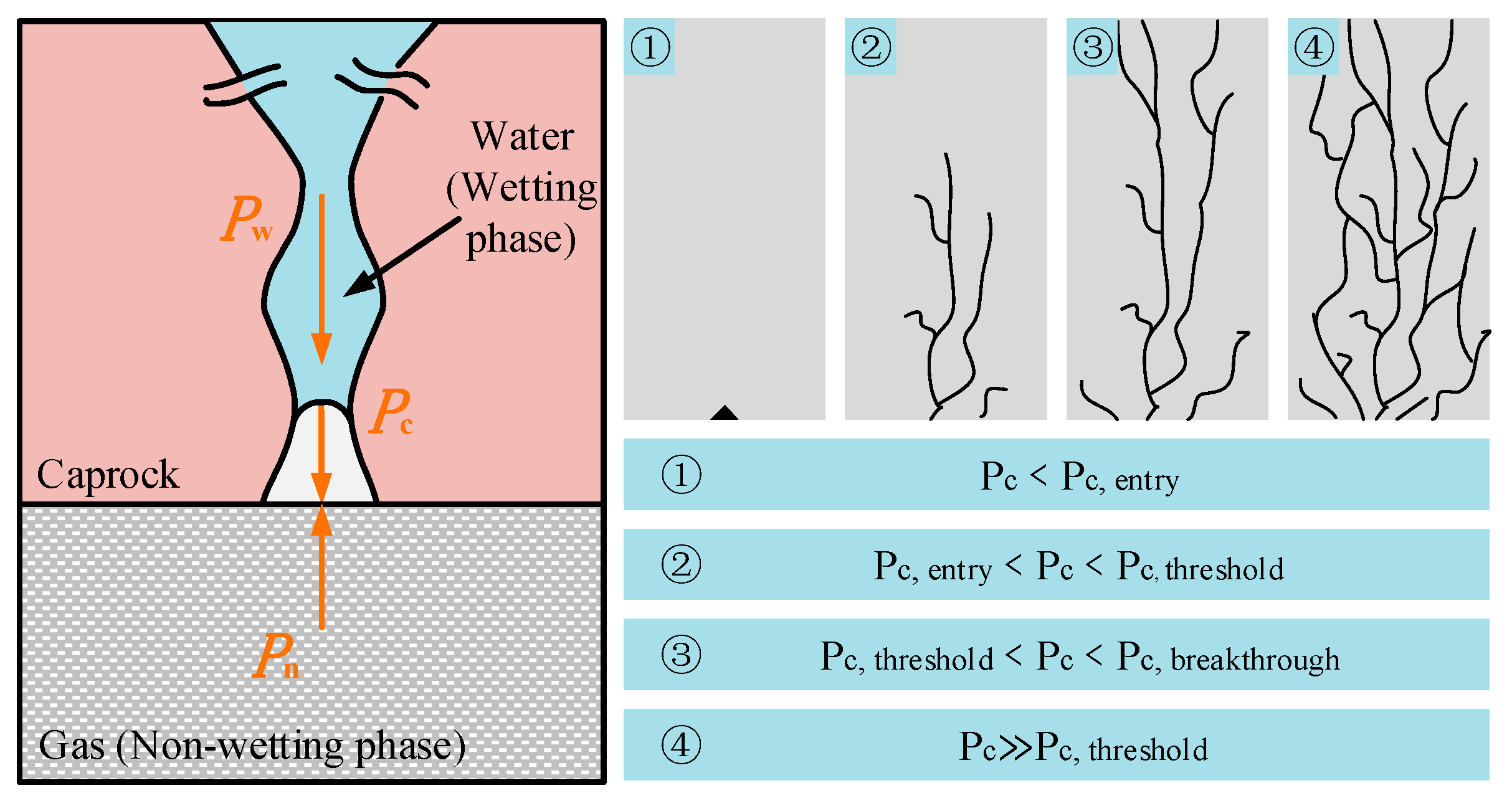

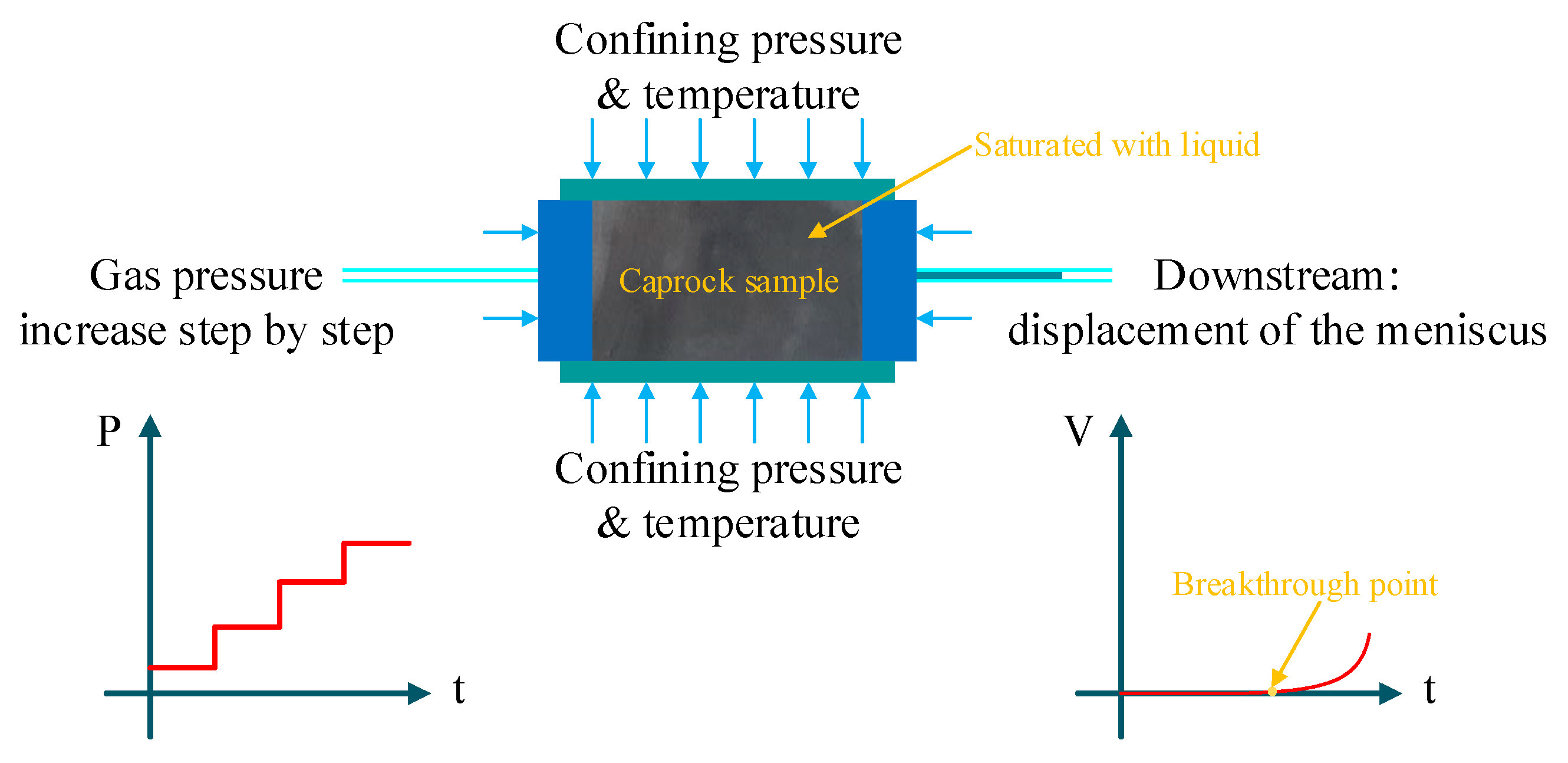

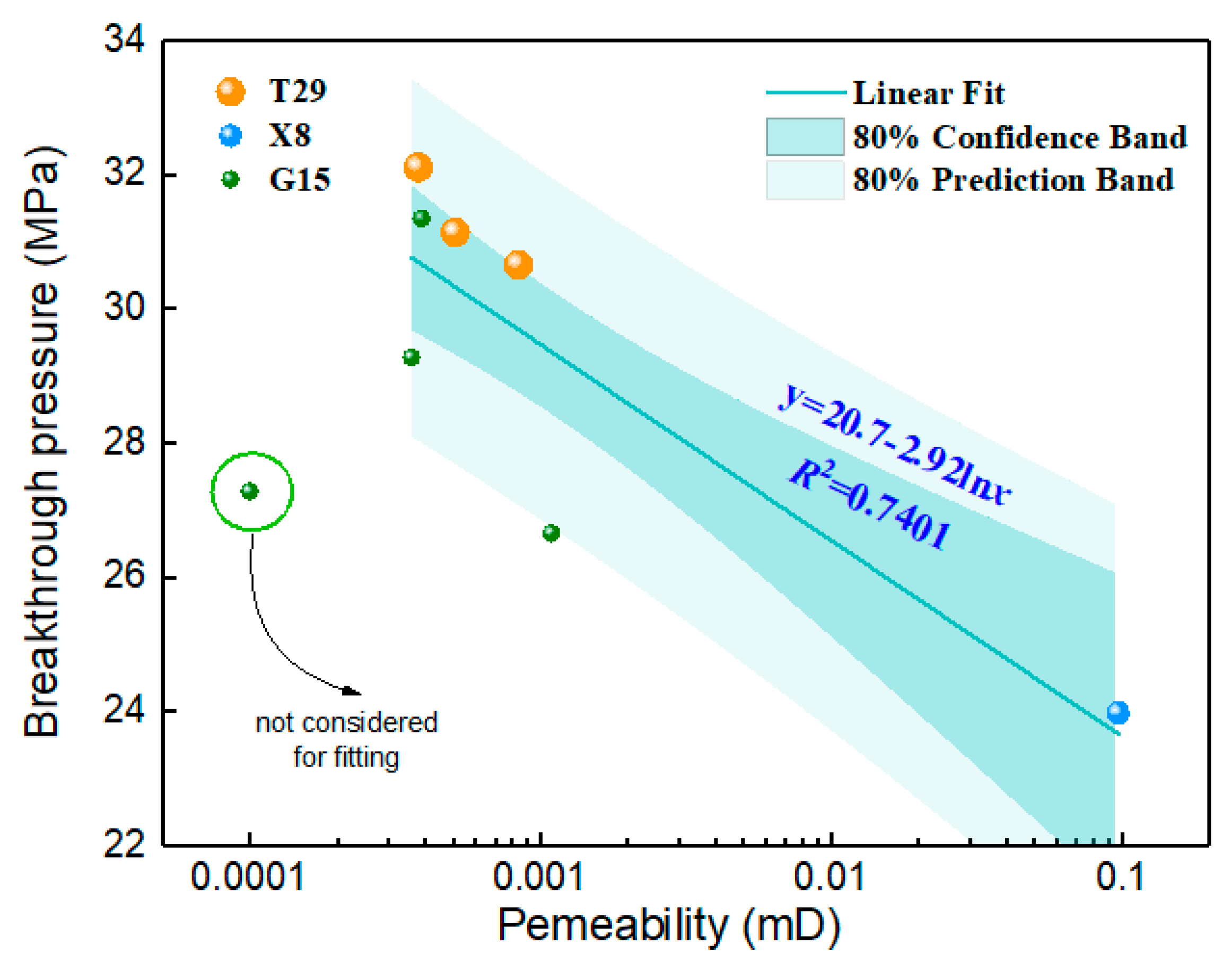

2.4. Displacement Pressure

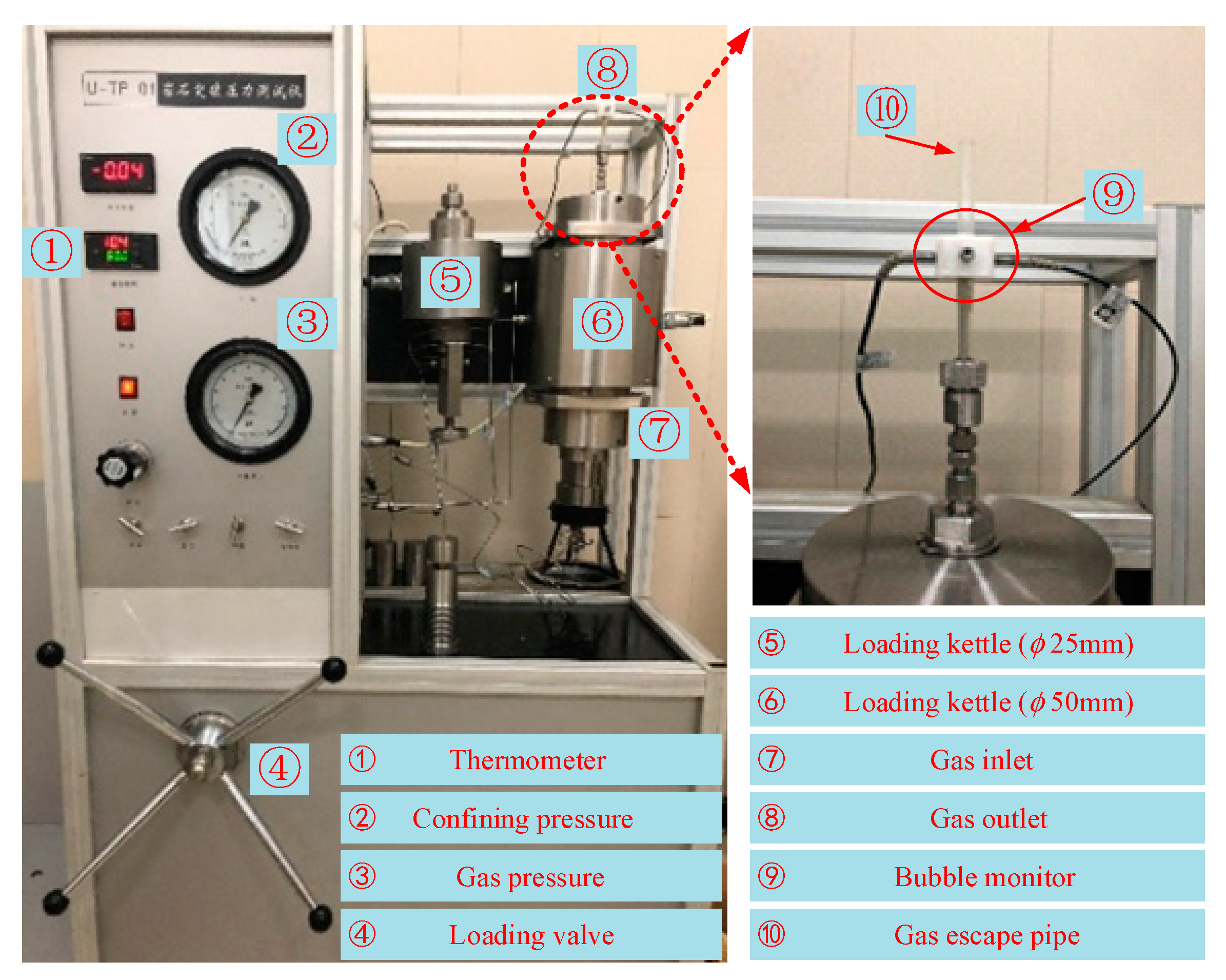

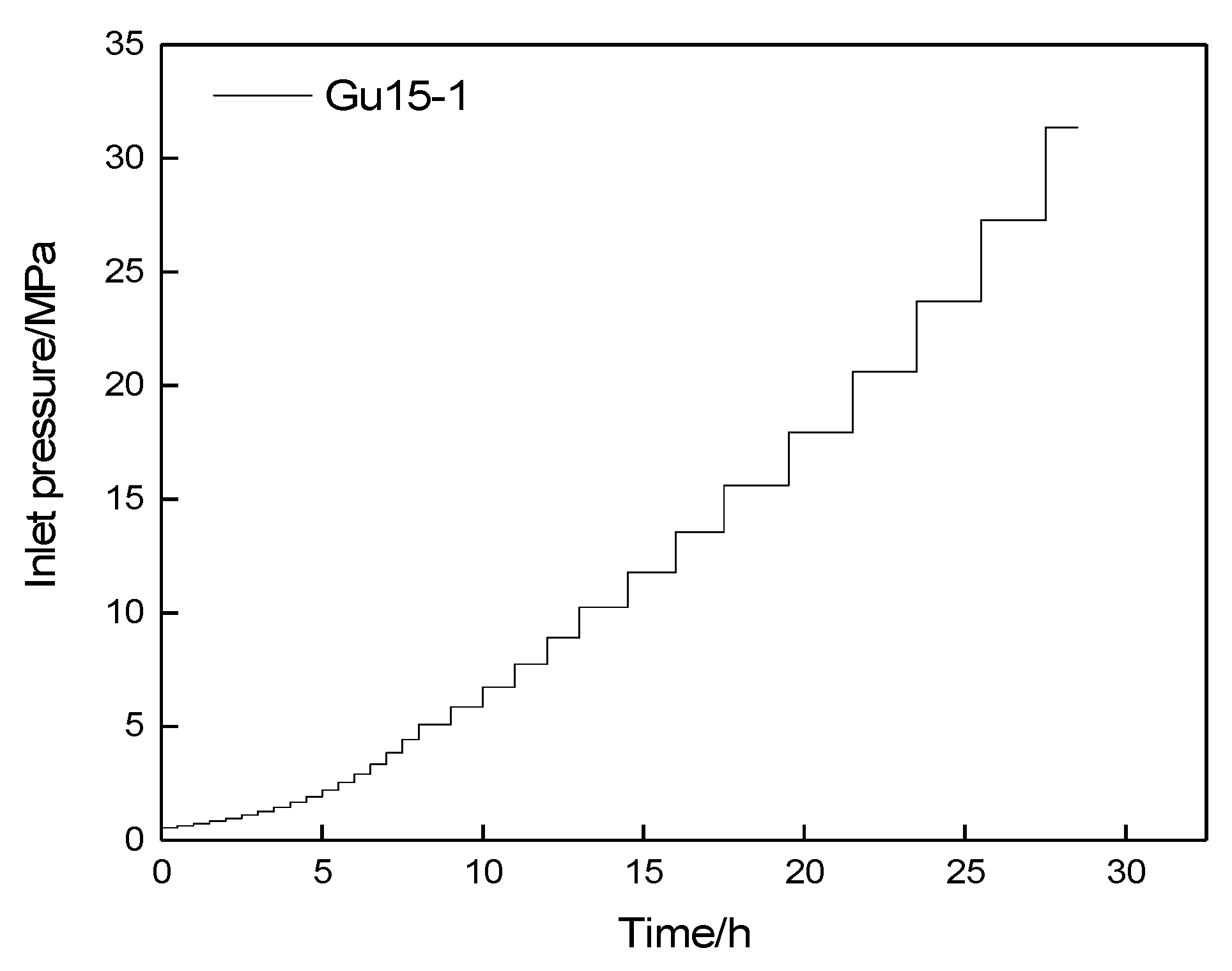

2.4.1. Direct Displacement Method

2.4.2. Acoustic Time Method

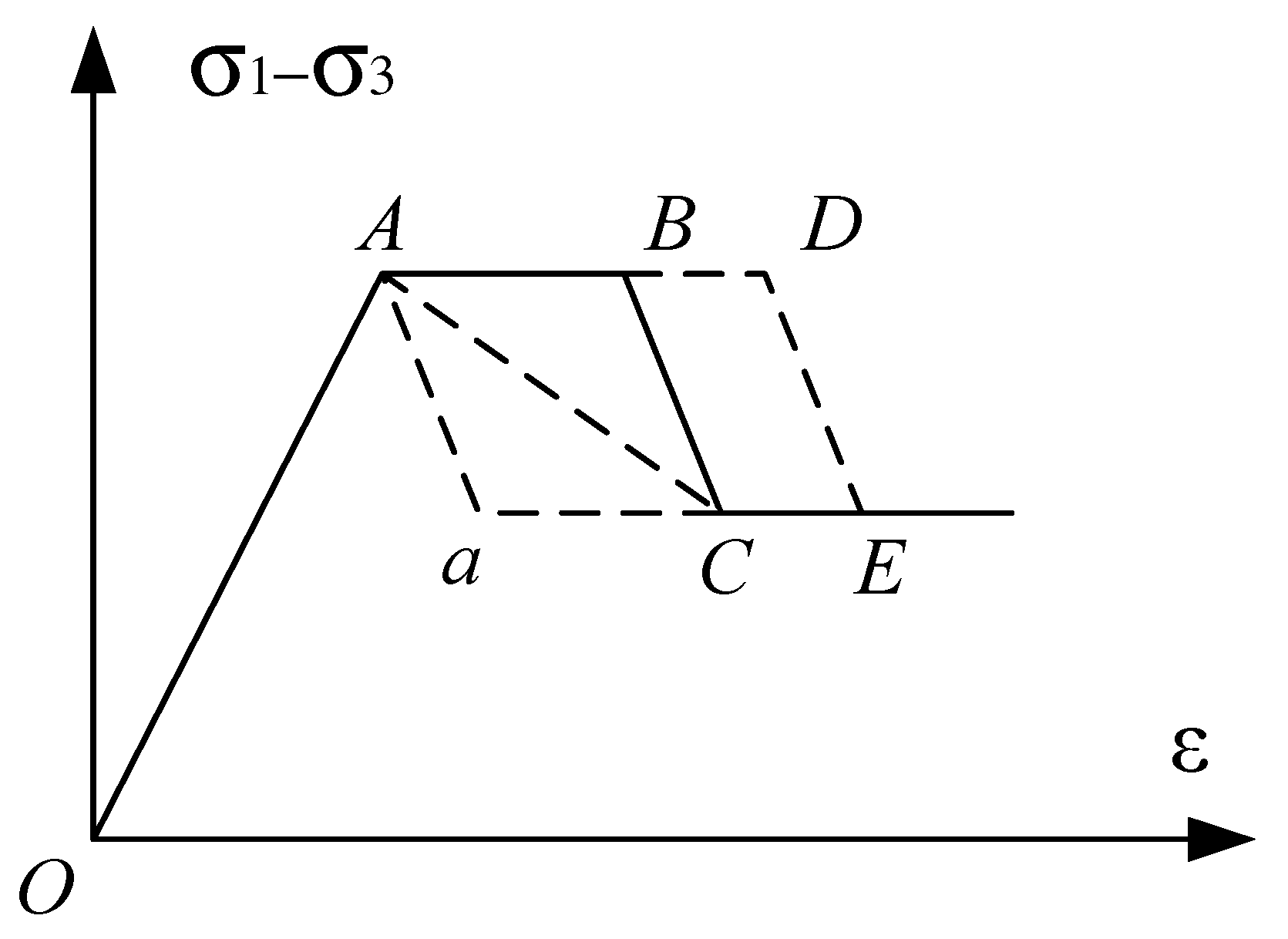

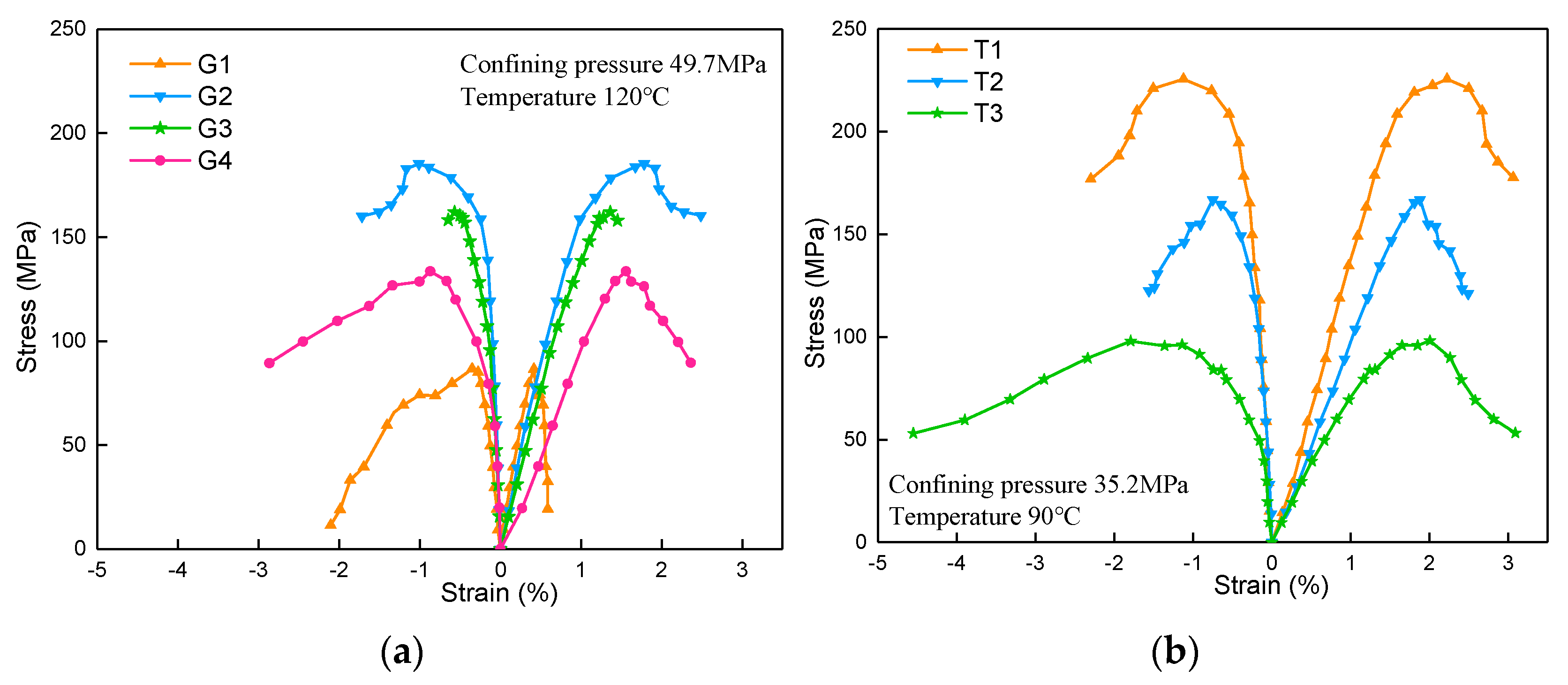

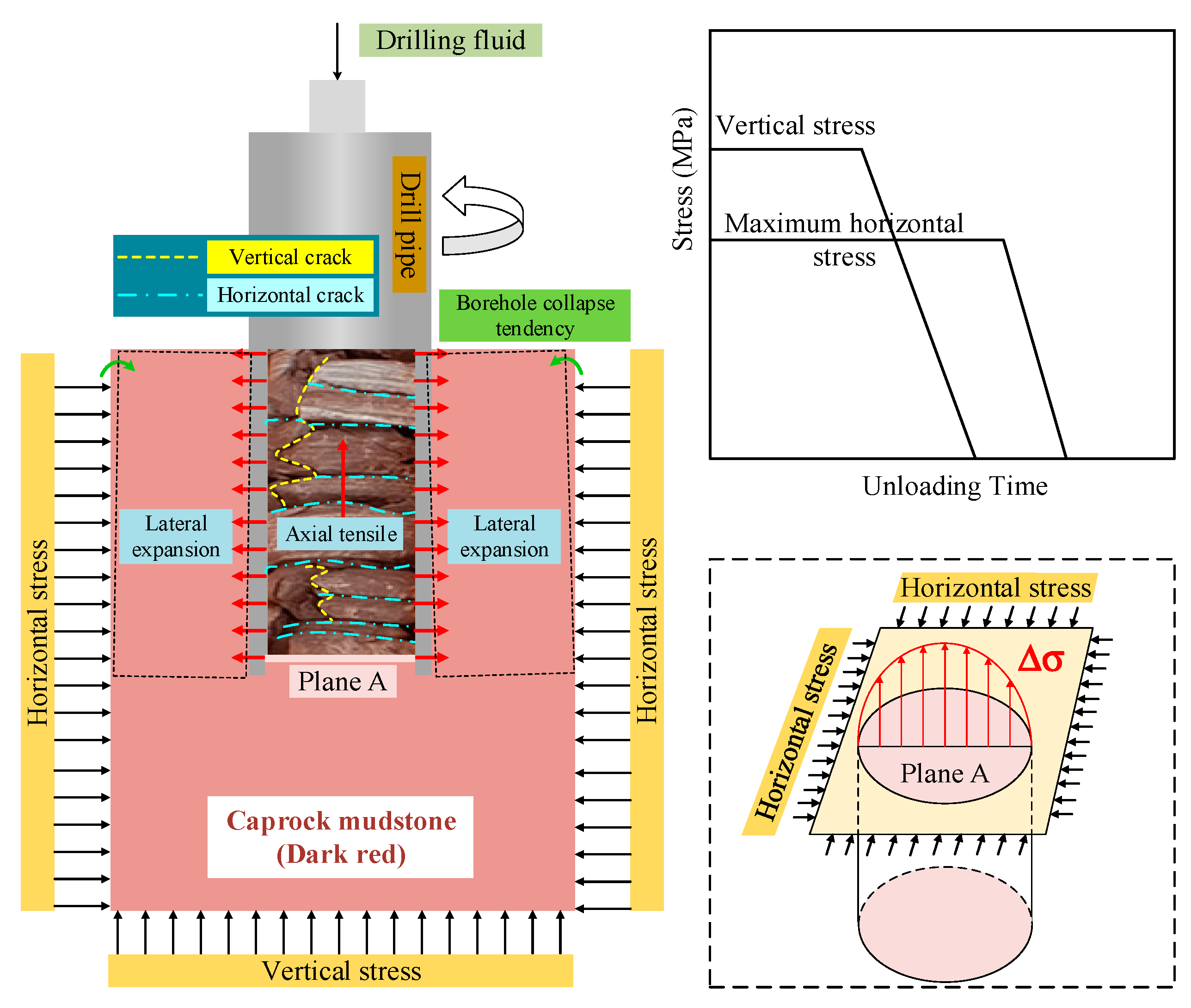

2.5. Caprock Brittleness Based on Triaxial Compression Tests

- (1)

- Define the relative magnitude of post-peak stress drop:

- (2)

- Define the absolute rate of post-peak stress drop:

- (3)

- Define the yield influence coefficient:

- (4)

- Finally, define the plasticity index Bp:

3. Materials and Methods for Study Area

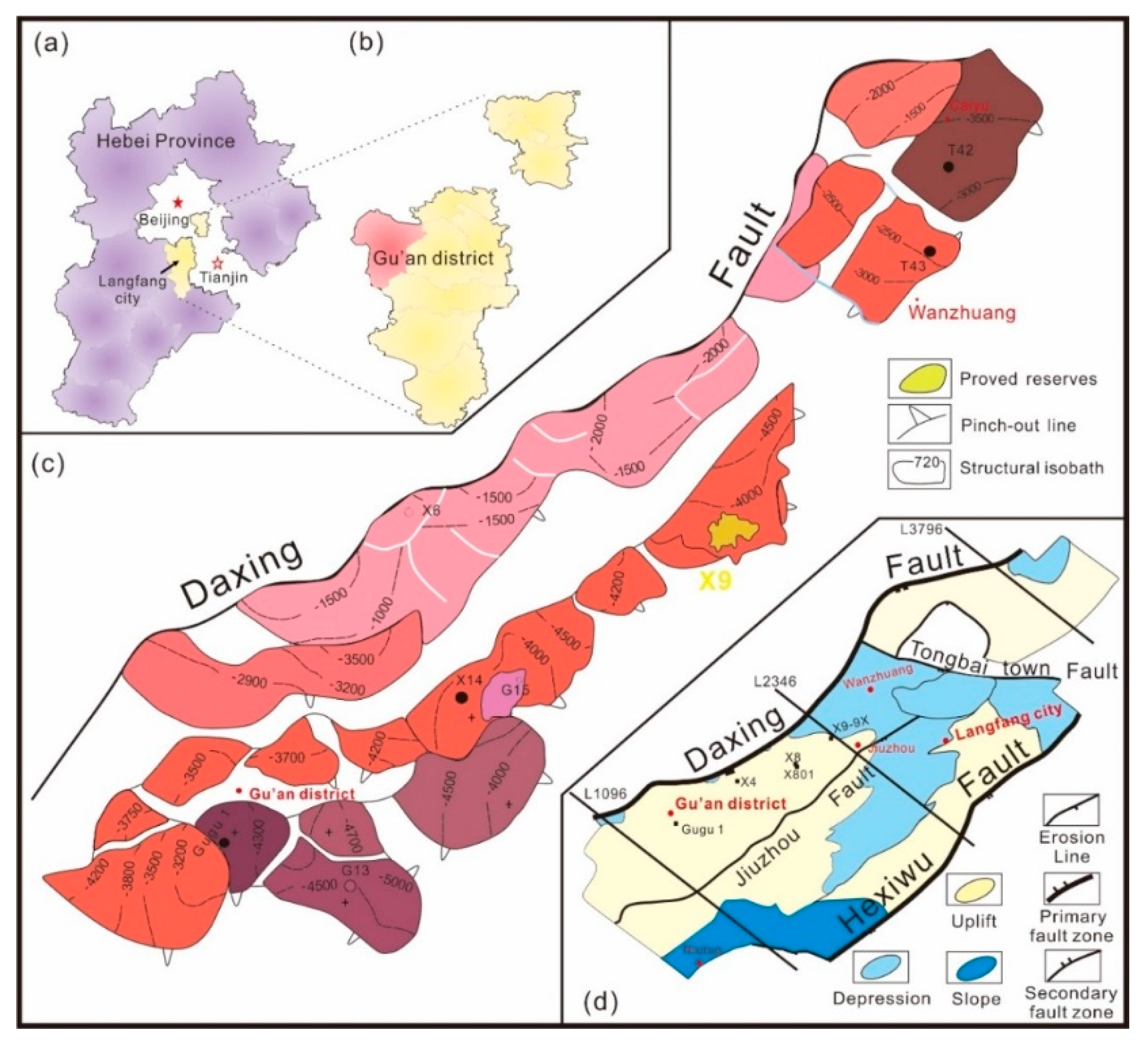

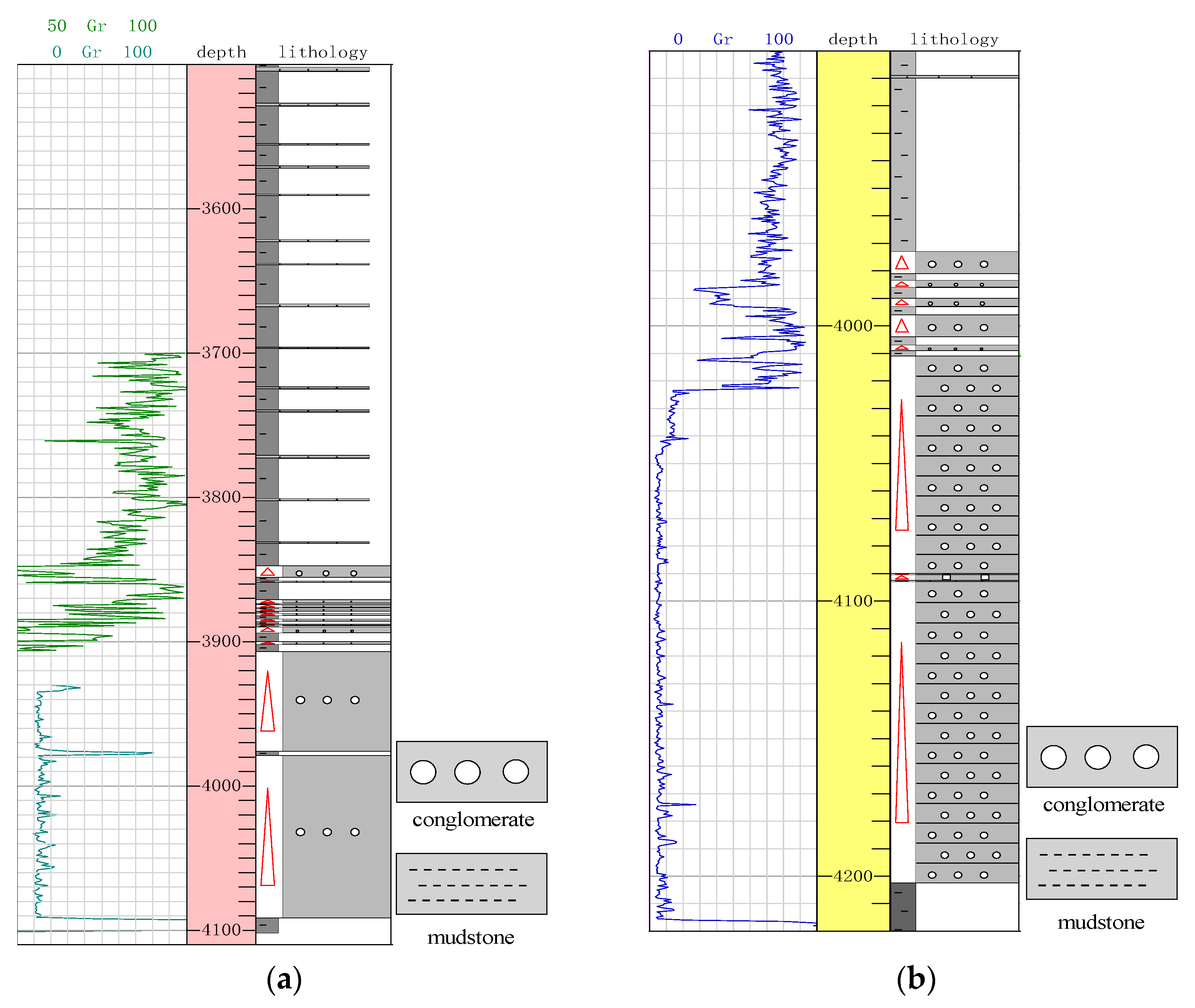

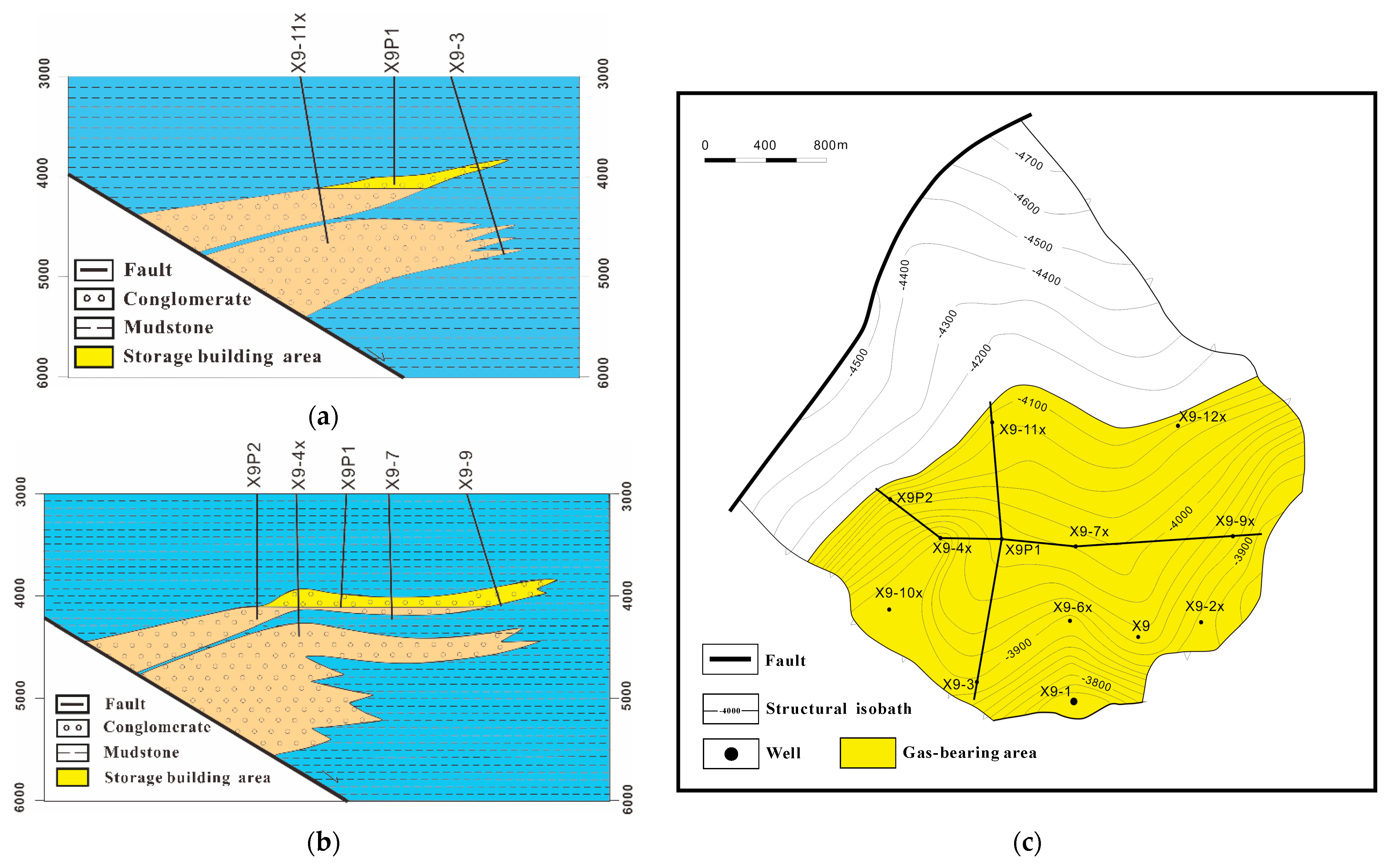

3.1. Study Area of X9 Lithologic Trap

3.2. Evaluation Model Based on AHP Method

3.2.1. Target Hierarchy of Comprehensive Evaluation

3.2.2. Weight Coefficient

3.2.3. Comprehensive Evaluation Model

4. Results and Discussions

4.1. Results of Experiments and Comprehensive Evaluation

4.2. Discussion

5. Conclusions

- (1)

- In this paper, the factors influencing the caprock quality are analyzed in detail from five aspects: caprock lithology, thickness, porosity and permeability characteristics, displacement pressure, and mechanical properties of caprock, and 12 basic evaluation indexes are selected. Based on the relevant research results, the classification criteria for each basic indicator are initially proposed, and the comprehensive evaluation model based on the Analytic Hierarchy Process method is established.

- (2)

- Based on the failure mechanism of mudstone caprock, an analytical method for evaluating the sealing capacity of mudstone caprock using the brittleness index is proposed. The method considers the full stress-strain curve characteristics of mudstone, based on the mechanical analysis of the whole process of rock failure, and comprehensively utilizes the peak strain and the post-peak curve shape to form an evaluation index.

- (3)

- Taking the X9 depleted gas reservoir as an example, the quality of the target caprock is evaluated by the above method. The caprock suitability value was M = 8.77, the caprock quality was suitable for underground gas storage, and the conditions for rebuilding into gas storage were available. The evaluation results are consistent with the expert demonstration results, which verified the effectiveness of the method.

- (4)

- Due to the difficulty of core drilling and preservation of mudstone caprock, the mechanics and deformation characteristics of the mudstone caprock are less understood at present, and the mechanical response which plays a key role in the sealing capacity of gas storage caprock still needs further study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, C.; Zhao, Q.; Chen, J.; Jian, J.; Yang, Z.; Sun, Q.; Lu, J.; Zhang, G. Natural gas in China: Development trend and strategic forecast. Nat. Gas Ind. 2018, 5, 380–390. [Google Scholar] [CrossRef]

- Ding, G.; Li, C.; Wang, J.; Xu, H.; Zheng, Y.; Wanyan, Q.; Zhao, Y. The status quo technical development direction of under-ground gas storages in China. Nat. Gas Ind. 2015, 35, 107–112. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, P. Practical Design Technology for Underground Gas Storage; Petroleum Industry Press: Beijing, China, 2011; pp. 22–44. [Google Scholar]

- Zheng, D.; Xu, H.; Wang, J.; Sun, J.; Zhao, K.; Li, C.; Shi, L.; Tang, L. Key evaluation techniques in the process of gas reservoir being converted into underground gas storage. Pet. Explor. Dev. 2017, 44, 840–849. [Google Scholar] [CrossRef]

- Zhou, Y.; Jin, Z.; Zhu, D.; Yuan, Y.; Li, S. Current status and progress in research of hydrocarbon cap rocks. Pet. Geol. Exp. 2012, 34, 234–245. [Google Scholar] [CrossRef]

- Shu, P.; Gao, T.; Wang, H.; Liang, S. Cap rock sealing-property classifying standard and evaluation of Shengping gas storage in Daqing Oilfield. Pet. Geol. Oilfield Dev. Daqing 2019, 38, 272–276. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, A.; Shu, A. Study on sealing evaluation of gas storage cap and fault in Jilin oil area. In Proceedings of the National Natural Gas Academic Annual Conference Proceedings, Wuhan, China, 27–28 June 2015. [Google Scholar]

- Zhang, C.; Yu, Q. Breakthrough pressure and permeability in partially water-saturated shales using methane–carbon diox-ide gas mixtures: An experimental study of Carboniferous shales from the eastern Qaidam Basin, China. AAPG Bull. 2019, 103, 273–301. [Google Scholar] [CrossRef]

- Ma, C.; Lin, C.; Dong, C.; Luan, G.; Zhang, Y.; Sun, X.; Liu, X. Quantitative Relationship Between Argillaceous Caprock Thickness and Maximum Sealed Hydrocarbon Column Height. Nat. Resour. Res. 2019, 29, 2033–2049. [Google Scholar] [CrossRef]

- Grunau, R. A worldwide look at the cap-rock problem. J. Pet. Geol. 1987, 10, 245–266. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Bertier, P.; Busch, A.; Krooss, B. Experimental investigation of the sealing capacity of generic clay-rich caprocks. Int. J. Greenh. Gas Control 2013, 19, 620–641. [Google Scholar] [CrossRef]

- Schlomer, S.; Krooss, B. Experimental characterisation of the hydrocarbon sealing efficiency of cap rocks. Mar. Pet. Geol. 1997, 14, 565–580. [Google Scholar] [CrossRef]

- Li, J.; Yan, Q.; Zhang, Y.; Liu, G.; Wang, X. The special sealing mechanism of caprock for Quaternary biogenetic gas in Sanhu area, Qaidam Basin, China. Sci. China Ser. D Earth Sci. 2008, 51, 45–52. [Google Scholar] [CrossRef]

- Bai, B.; Hu, Q.; Li, Z.; Lü, G.; Li, X. Evaluating the Sealing Effectiveness of a Caprock-Fault System for CO2-EOR Storage: A Case Study of the Shengli Oilfield. Geofluids 2017, 2017, 8536724. [Google Scholar] [CrossRef] [Green Version]

- Kivi, I.; Makhnenko, R.; Vilarrasa, V. Two-Phase Flow Mechanisms Controlling CO2 Intrusion into Shaly Caprock. Transp. Porous Media 2022, 141, 771–798. [Google Scholar] [CrossRef]

- Fu, X.; Jia, R.; Wang, H.; Wu, T.; Meng, L.; Sun, Y. Quantitative evaluation of fault-caprock sealing capacity: A case from Dabei-Kelasu structural belt in Kuqa Depression, Tarim Basin, NW China. Pet. Explor. Dev. 2015, 42, 329–338. [Google Scholar] [CrossRef]

- Diao, H. Rock mechanical properties and brittleness evaluation of shale reservoir. Acta Petrol. Sin. 2016, 29, 3300–3306. [Google Scholar]

- Lü, X.; Wang, Y.; Yu, H.; Bai, Z. Major factors affecting the closure of marine carbonate caprock and their quantitative evalu-ation: A case study of Ordovician rocks on the northern slope of the Tazhong uplift in the Tarim Basin, western China. Mar. Pet. Geol. 2017, 83, 231–245. [Google Scholar] [CrossRef]

- Gao, S.; Wei, N.; Li, C. Review of CO2 breakthrough pressure measurement methods on caprocks. Rock Soil Mech. 2015, 36, 2716–2727. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Schlomer, S.; Krooss, B. Gas breakthrough experiments on fine-grained sedimentary rocks. Geofluids 2002, 2, 3–23. [Google Scholar] [CrossRef]

- Espinoza, D.; Santamarina, J. CO2 breakthrough-Caprock sealing efficiency and integrity for carbon geological storage. Int. J. Greenh. Gas Control 2017, 66, 218–229. [Google Scholar] [CrossRef] [Green Version]

- Liu, S. Research on Preserving Conditions of Gas in Deep Interval of Jiyang Basin. Ph.D. Thesis, China University Petro-Leum, Beijing, China, 2008. [Google Scholar]

- Heath, E.; Dewers, A.; McPherson, L.; Nemer, B.; Kotula, G. Pore-lining phases and capillary breakthrough pressure of mudstone caprocks: Sealing efficiency of geologic CO2 storage sites. Int. J. Greenh. Gas Control 2012, 11, 204–220. [Google Scholar] [CrossRef]

- You, X. Study on assessment method of caprocks in natural gas pools. Int. Oil Gas Geol. 1991, 12, 261–275. [Google Scholar] [CrossRef]

- Fu, G.; Chen, Z.; Jiang, Z. Evaluation of the sealing ability of caprock and its application. Pet. Explor. Dev. 1995, 22, 30–46. [Google Scholar]

- Fan, M.; Chen, H.; Yu, L.; Zhang, W.; Liu, W.; Bao, Y. Evaluation standard of mudstone caprock combining specific surface area and breakthrough pressure. Pet. Geol. Exp. 2011, 33, 87–90. [Google Scholar] [CrossRef]

- Sun, M.; Liu, G.; Li, J. Features of cap rocks of gas pools and criteria of identification. Nat. Gas Ind. 2008, 28, 36–38. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, G. Improvement and application of the methods of gas reservoir cap sealing ability. Acta Sedmentologica Sin. 2010, 28, 388–394. [Google Scholar]

- Fan, X. Researches and Application of Caprock Logging Evaluation Method. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2003. [Google Scholar]

- Downey, M. Evaluating Seals for Hydrocarbon Accumulations. Am. Assoc. Pet. Geol. 1984, 68, 1752–1763. [Google Scholar] [CrossRef]

- Kivi, I.; Ameri, M.; Molladavoodi, H. Shale brittleness evaluation based on energy balance analysis of stress-strain curves. J. Pet. Sci. Eng. 2018, 167, 1–19. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.; Petre, E.; Grieser, B.; Kundert, D. A practical use of shale petrophysics for stimulation design opti-mization: All shale plays are not clones of the barnett shale. In Proceedings of the SPE Annual Technical Conference & Exhibition, Denver, CO, USA, 21–24 September 2008. SPE 115258. [Google Scholar]

- Shu, K.; Jia, S.; Gao, Y.; Geng, Y.; Ba, J.; Lei, M.; Liu, T.; Xi, Z. An improved method to evaluate brittleness of cap rock based on complete stress-strain curve. J. Guangxi Univ. (Nat. Sci. Ed.) 2018, 43, 248–260. [Google Scholar] [CrossRef]

- Guo, B.; Gong, S.; Tao, Y. Project Risk Management; Publishing House of Electronics Industry: Beijing, China, 2008; pp. 62–150. [Google Scholar]

- Saaty, T. There is no mathematical validity for using fuzzy number crunching in the analytic hierarchy process. J. Syst. Sci. Syst. Eng. 2006, 15, 457–464. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Pan, Z. Report: The Reasonable Development Mode and Feasibility Study on Gas Storage Construction of X9 Gas Reservoir; Exploration and Development Research Institute of Huabei Oilfield: Renqiu, China, 2010. [Google Scholar]

- Zheng, Y.; Sun, J.; Qiu, X.; Lai, X.; Liu, J.; Guo, Z.; Wei, H.; Min, Z. Connotation and evaluation technique of geological integrity of UGSs in oil/gas fields. Nat. Gas Ind. B 2020, 7, 594–603. [Google Scholar] [CrossRef]

- Słota-Valim, M.; Golabek, A.; Szott, W.; Sowizdlzal, K. Analysis of Caprock Tightness for CO2 Enhanced Oil Recovery and Sequestration: Case Study of a Depleted Oil and Gas Reservoir in Dolomite, Poland. Energies 2021, 14, 3065. [Google Scholar] [CrossRef]

- Trujillo, N.; Rose-Coss, D.; Heath, J.E.; Dewers, T.A.; Ampomah, W.; Mozley, P.S.; Cather, M. Multiscale Assessment of Caprock Integrity for Geologic Carbon Storage in the Pennsylvanian Farnsworth Unit, Texas, USA. Energies 2021, 14, 5824. [Google Scholar] [CrossRef]

| Classification | Sedimentary Environment | Lithology | Argillaceous Content/% |

|---|---|---|---|

| I | Semi deep-deep lake facies Basin facies Wide sea continental basin facies | Salt gypsum rock Gypsum mudstone | >75 |

| II | Platform facies shore-shallow lake facies Delta front facies | Calcareous mudstone Mudstone | 50~75 |

| III | Platform margin Shoreline facies Delta diversion plain facies | Sandy mudstone Argillaceous siltstone | 25~50 |

| IV | River facies Alluvial fan facies | Argillaceous sandstone Dense limestone | <25 |

| Classification | Continuity | Thickness/m |

|---|---|---|

| I | Continuous, stable | >100 |

| II | Generally continuous, generally stable | 50~100 |

| III | Have a certain continuity, generally stable | 30~50 |

| IV | Poor continuity, instability | <30 |

| Classification | Crack Development | Porosity/% | Permeability/(10−3 mD) |

|---|---|---|---|

| I | Crack not developed | <2.5 | <1 |

| II | Small amount of crack developed | 2.5~5 | 1~10 |

| III | Certain degree of developed crack, and no thorough crack is formed | 5~8 | 10~100 |

| IV | Crack developed with penetrating cracks | >8 | >100 |

| Classification | Displacement Pressure/MPa |

|---|---|

| I | >20 |

| II | 5~20 |

| III | 1~5 |

| IV | <1 |

| Classification | Elasticity Index/% | Plasticity Index/% |

|---|---|---|

| I | <30 | >60 |

| II | 30~50 | 50~60 |

| III | 50~60 | 30~50 |

| IV | >60 | <30 |

| Value | Relative Importance |

|---|---|

| 1 | Equally important |

| 3 | Slightly important |

| 5 | Important |

| 7 | More important |

| 9 | Extremely important |

| Criteria Layer | Criteria Layer Weight Value Assignment ωiB | Indicator Layer | Indicator Layer Weight Value Assignment ωiC | Weight Value Relative to the Target Layer ωi |

|---|---|---|---|---|

| B1 | 0.044 | C1 | 0.110 | 0.005 |

| C2 | 0.309 | 0.014 | ||

| C3 | 0.581 | 0.025 | ||

| B2 | 0.096 | C4 | 0.333 | 0.032 |

| C5 | 0.667 | 0.064 | ||

| B3 | 0.196 | C6 | 0.412 | 0.081 |

| C7 | 0.260 | 0.051 | ||

| C8 | 0.328 | 0.064 | ||

| B4 | 0.560 | C9 | 0.500 | 0.280 |

| C10 | 0.500 | 0.280 | ||

| B5 | 0.104 | C11 | 0.333 | 0.035 |

| C12 | 0.667 | 0.069 |

| Caprock Quality Suitability | Comprehensive Indicator Value |

|---|---|

| Optimal | 9 < M ≤ 10 |

| Suitable | 7 < M ≤ 9 |

| Basically suitable | 6 < M ≤ 7 |

| Not suitable | M ≤ 6 |

| Well Number | Member | Lithology | Mineral Content/% | ||||

|---|---|---|---|---|---|---|---|

| Kaolinite | Chlorite | Illite | Illite-Montmorillonite Mixed Layer | Interlayer Ratio | |||

| RS 2X | Es2 + 3 | Gray mudstone | 6.9 | 6.7 | 33.3 | 53.1 | 45.8 |

| XG 1 | Es3 | Gray mudstone | 6.7 | 5.1 | 20.6 | 67.6 | 37.1 |

| Number | Well Number | Porosity/% | Permeability/(10−3 mD) | Density/(g·cm−3) |

|---|---|---|---|---|

| 1 | G15 | 2.16 | 1.16 | 2.61 |

| 2 | 2.91 | 42.80 | 2.66 | |

| 3 | 3.19 | 8.40 | 2.63 | |

| 4 | 3.22 | 4.06 | 2.65 | |

| 5 | 8.92 | 55.10 | 2.61 | |

| 6 | X8 | 6.66 | 0.79 | 2.53 |

| 7 | 4.98 | 0.63 | 2.54 | |

| 8 | 5.86 | 821.00 | 2.45 | |

| 9 | 4.84 | 15.10 | 2.51 | |

| 10 | T29 | 3.53 | 0.14 | 2.58 |

| 11 | 8.27 | 246.0 | 2.57 | |

| 12 | 3.89 | 1.10 | 2.57 |

| Number | Well Number | Sampling Depth/m | Permeability/(10−3 mD) | Breakthrough Pressure/MPa |

|---|---|---|---|---|

| 1 | G15 | 3904.54 | 0.39 | 31.35 |

| 2 | 3900.81 | 0.10 | 27.28 | |

| 3 | 3901.21 | 1.09 | 26.66 | |

| 4 | 3904.34 | 0.36 | 29.28 | |

| 5 | X8 | 2870.80 | 97.10 | 23.98 |

| 6 | T29 | 2834.00 | 0.84 | 30.66 |

| 7 | 2836.00 | 0.51 | 31.14 | |

| 8 | 2835.70 | 0.38 | 32.11 |

| Well No. | Δt μs/m | Displacement Pressure/MPa | Well No. | Δt μs/m | Displacement Pressure/MPa |

|---|---|---|---|---|---|

| X9 | 226 | 7.11 | X9-4 | 216 | 9.38 |

| X9-1 | 232 | 6.03 | X9-6 | 228 | 6.73 |

| X9-2 | 229 | 6.55 | X9-7 | 221 | 8.17 |

| X9-3 | 221 | 8.17 | X9-9 | 230 | 6.37 |

| No. | Well No. | Elastic Modulus/MPa | Poisson’s Ratio | Peak Strain/% | Peak Strength/MPa | Residual Strain/% | Residual Strength/MPa | Elasticity Index/% | Plasticity Index/% |

|---|---|---|---|---|---|---|---|---|---|

| G1 | G15 | 24,661.2 | 0.155 | 0.392 | 87.0 | 0.651 | 10.80 | 64.68 | 1.57 |

| G2 | 18,369.1 | 0.140 | 1.756 | 185.80 | 2.490 | 159.90 | 58.19 | 19.98 | |

| G3 | 15,398.3 | 0.163 | 1.364 | 161.28 | 1.482 | 157.85 | 41.45 | – | |

| G4 | 9443.5 | 0.104 | 1.517 | 132.91 | 2.323 | 90.67 | 55.68 | 67.32 | |

| T1 | T29 | 13,383.9 | 0.149 | 2.310 | 222.70 | 3.085 | 177.55 | 43.56 | 27.12 |

| T2 | 9738.5 | 0.111 | 1.894 | 165.24 | 2.471 | 120.95 | 53.12 | 55.62 | |

| T3 | 7281.1 | 0.143 | 2.084 | 97.67 | 3.173 | 53.75 | 33.38 | 67.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, S.; Wen, C.; Fu, X.; Liu, T.; Xi, Z. A Caprock Evaluation Methodology for Underground Gas Storage in a Deep Depleted Gas Reservoir: A Case Study for the X9 Lithologic Trap of Langgu Sag, Bohai Bay Basin, China. Energies 2022, 15, 4351. https://doi.org/10.3390/en15124351

Jia S, Wen C, Fu X, Liu T, Xi Z. A Caprock Evaluation Methodology for Underground Gas Storage in a Deep Depleted Gas Reservoir: A Case Study for the X9 Lithologic Trap of Langgu Sag, Bohai Bay Basin, China. Energies. 2022; 15(12):4351. https://doi.org/10.3390/en15124351

Chicago/Turabian StyleJia, Shanpo, Caoxuan Wen, Xiaofei Fu, Tuanhui Liu, and Zengqiang Xi. 2022. "A Caprock Evaluation Methodology for Underground Gas Storage in a Deep Depleted Gas Reservoir: A Case Study for the X9 Lithologic Trap of Langgu Sag, Bohai Bay Basin, China" Energies 15, no. 12: 4351. https://doi.org/10.3390/en15124351

APA StyleJia, S., Wen, C., Fu, X., Liu, T., & Xi, Z. (2022). A Caprock Evaluation Methodology for Underground Gas Storage in a Deep Depleted Gas Reservoir: A Case Study for the X9 Lithologic Trap of Langgu Sag, Bohai Bay Basin, China. Energies, 15(12), 4351. https://doi.org/10.3390/en15124351