Abstract

This paper analyzes the potential of solar thermal systems for being employed for process heating in cotton-based textile industries. The technological capability of a flat plate collector (FPC) to meet the solar industrial process heating (SIPH) requirement in yarn production is assessed. Moreover, the usability of a parabolic trough collector (PTC) in meeting the technological mandates of SIPH in fabric processing units is critically examined. Further, this paper reports the findings of a study on the potential cost advantage of solar process heating over the conventional process heating practices in cotton-based textile industries. The approach involves the selection of the locations of sample textile industries and the employable solar collector technologies, as well as assessment of financial reward, if any. Eight different cotton-based textile industries located in different geographical domains (in India) are selected. The selected textile industries are situated within the textile hubs existing in different states across India. Analysis of technoeconomic benefit derivable in selected textile industries using FPC for hot water generation and PTC for steam generation is presented. In the case of FPC-based SIPH systems, the maximum value of solar fraction is estimated to be 0.30 and the corresponding estimation for the levelized cost of useful thermal energy (LCUTE) delivered comes out as INR 790/GJ to INR 1020/GJ. On the other hand, in case of parabolic-trough-solar-concentrator-based SIPH systems, LCUTE is estimated in the range of INR 1030/GJ to INR 1610/GJ. From a critical analysis of financial viability in consideration of related factors such as payback time and return on investment in SIPH, it appears that the SIPH systems for hot water generation may be a good choice, whereas SIPH systems for steam generation are seen to have longer payback periods and lower returns on investment, and, therefore, it seems that adequate financial support from central and state governments with additional supports from bilateral or multilateral organizations may enable them to become a sustainable technology option.

1. Introduction

Many industries need to make use thermal energy for industrial process heating. In many cases, the temperature requirement for SIPH lies within 50–300 °C. It has been common to make use of fossil fuel to generate the above temperature; in the process, a lot of greenhouse emission has been taking place. Reduction of CO2 is a matter of global concern, and hence SIPH within a low temperature regime demands the use of alternative energy sources to meet the thermal energy requirement for industrial process heating. Incidentally, industries such as dairy, textile, etc., require a huge amount of water at elevated temperature or in the form of steam. Whether solar thermal systems can be gainfully employed for process heating in such industries is a question to address. Incidentally, the textile industry is water-intensive and requires a huge volume of water for SIPH. Moreover, the studies so far conducted on the use of SIPH in textile industries have not examined the influence of climate and locations on the performance of the useable solar thermal technologies. However, the climatic conditions and annually available global horizontal irradiance/direct normal incidence (GHI/DNI) greatly influences the performance of a solar thermal system. To date, there is no report or comprehensive study that compares the performances of solar thermal systems used for SIPH at various locations and ambient conditions. In a textile industry, both electrical and thermal energy is required. Thermal energy shares a major portion of the energy requirement in a textile industry as there are the requirements of considerable process heating for the purposes of dyeing, bleaching, and various finishing operations in textile production. The overall economic viability of an energy-intensive industrial process depends upon the overall cost of energy needed to be incurred to run the process [1]. In the textile industry, the process heating for various activities is run at low and intermediate temperatures which range within 50–200 °C [2,3,4]. The idea of replacing conventional energy by renewable energy sources is not new; it has emanated since the global oil crisis became dominant in the 1970s [5,6,7,8]. The use of solar energy for various commercial needs and the evolution of potential technology for effectively harnessing the capability of clean solar energy to meet the electrical and thermal energy without furtherance of environmental threat are discussed by earlier workers [9,10,11,12,13,14,15,16]. Mathematical modeling has established that integrating solar energy for process heating in the dairy industry is technically feasible and becomes an attractive proposition if a high-performance vacuum tube collector is used and diffuse radiation is effectively collected [11]. The use of parabolic disc and parabolic trough collectors (PDC and PTC) is reported to be quite effective in meeting the thermal energy demand (0.250 GJ/ton of milk production) and temperature requirement (~180 °C) of Indian dairy industries. While a general analysis is made to assess the potential use of renewable energy in industry process heating [12,13], effectiveness of the parabolic trough collector in meeting the thermal energy requirement of Indian paper industries has also been elaborately studied [14]. Likewise, studies on the assessment of feasibility of utilizing solar energy for process heating purposes in textile industries are also documented in the literature [17,18,19,20,21,22]. Efficacy of the use of solar process heating systems in textile industries have been critically analyzed elsewhere [23,24,25,26,27]. It is shown that the use of solar energy in the cotton-based textile industry can reduce ~2457–7648 thousand tons of greenhouse gas emissions [23] and that the economic advantage of using solar energy by employing parabolic trough collector of area ~550 m2 for process heating in textile industries or vacuum tube or PDC for attaining the temperature of 50–200 °C is also demonstrated elsewhere [24,25,26]. It is reported that employment of a parabolic-trough-concentrator-based solar process heating system (without storage) in a textile industry in Prato (Italy) can annually save 40 to 50% of the natural gas consumption by the industry [25,26]. In these studies, reduction of CO2 emissions with the use of solar process heating has also been estimated. It is estimated that a solar collector area of 97,144 m2 is required to meet the hot water demand of the Indian textile industry [19]. By these, 386 kilotons of oil equivalent of fossil fuels can be replaced annually in the case of Indian textile industries [22,28]. It is proposed that solar collector technologies can be a good option for supply of thermal energy in the textile industry [29,30,31]. The employment of the Scheffler solar concentrator at high altitude regions, viz., Ladakh region of India, has shown that it is possible to melt ice and produce a maximum of 5 L water/day at an affordable cost of ~INR 0.9/liter of water produced [32]. It therefore appears that adoption of solar process heating in Indian textile industries is a lucrative option. Moreover, there is a lot of encouragement from the government in terms of incentivizing such ventures of using solar energy for commercial activities. It is known that continuous consumption of fossil fuel not only degrades its quality but also makes it dear. Accordingly, apart from environmental degradation, the use of fossil fuel for industrial activity is gradually facing a challenge against nonavailability. Taking these into consideration, it is obvious that moderate heating of water in textile processing units with the aid of solar energy can be the alternate strategy.

Taking stock of the available solar thermal systems employable for industrial process heating, one would notice that the simplest solar heating system available for the said purpose is the flat plate collector (FPC), which makes use of a flat plate for collecting the solar radiation incident on its surface. The collected solar energy is converted to heat by default. A fluid is made to pass inside the collector, so that heat transfer can take place between the working fluid (water) and the hot collector. This raises the temperature of the fluid. FPC does not have an optical concentrator and so the heat loss is quite high when compared with the other available concentrating system. The poorer collection efficiency cannot the raise the temperature of the fluid to any high value and, in general, the operating temperature of FPC lies within 70 °C and 95 °C. For industrial process heating applications, thus, the employment of FPCs for solar industrial process heating (SIPH) is recommendable until the temperature requirement exceeds ~80–95 °C. The choice of this technology for low-temperature applications is merited by the ease of its manufacturing, low cost, least maintenance, and being permanently fixed without any need for tracking. On the other hand, the parabolic trough collector (PTC) is known to be an established technology for SIPH. The PTC is able to concentrate solar radiation with the aid of a set of mirrors. A receiver tube through which passes the working fluid is placed at the focus. The focused radiation produces a good amount of heat that raises the temperature of working fluid to a considerably high value. The aperture width of PTCs, for employment in industrial process heating applications, is normally kept within the range of 1–2 mm. With the help of this, the temperature of water is generally raised to within 80 °C and 180 °C; however, if the PTC is chosen for power plant application, one needs to make use of a much larger collector area such that the desirably high-temperature steam can be produced. Due to concentrating ability, the PTC can generate much higher temperature than what FPC can do with identical solar-energy-collecting surface area. This implies a better thermodynamic efficiency of PTC over FPC. Due to not being able to concentrate the solar radiation, FPC bears a higher area for heat loss and, hence, it suffers from lower thermal efficiency. In contrast, the concentrator, such as PTC, can only focus the direct solar radiation, and so its performance degrades on cloudy days; moreover, PTC must have a sun tracking system by movement of the collector, such that solar radiation may be kept focused throughout the day. This leads to higher maintenance and construction cost [33]. It is therefore envisaged that FPC can be comfortably used for SIPH in textile industries if the temperature requirement is low. Thus, FPC is a suitable technology for yarn production where hot water within the temperature range from 80 °C to 95 °C is required. For fabric processing, the temperature requirement is rather high and it is required to use steam at a temperature lying within the range of 120 °C to 180 °C. Therefore, the use of concentrating technologies (PTC) needs to be invoked for the purpose.

For real-life scenarios, the sustainable use of solar process heating in Indian textile industries does not appear plausible unless the practice is proven to be financially rewarding to the concerned industries. It is for this reason that a cost–benefit analysis for use of solar industrial process heating in Indian textile industries appears to be pragmatically important. While the technological feasibility is accepted, its prudence in application in actual industrial scenarios needs be established in an Indian context. Hence, an attempt is made to assess technoeconomic attractiveness of solar industry process heating (SIPH) in the cotton-based textile industry of India.

2. Methodology

With the aim to examine the economics of using solar thermal systems for SIPH in textile industries, the study is conducted with an well-visualized theoretical framework which envisages to provide the answer to the research questions of the current study, viz., (i) Is solar thermal system a feasible technology for SIPH in textile industries? (ii) ipso facto, What must be the technology configuration? (iii) What is the quantum of thermal energy needed for various processes and what is the cost of production of useful thermal energy to be provided by solar systems? Finally, one needs to answer if the option is a lucrative business alternative.

Initiation of the study necessitates the selection of experimental industries. In this act, the scientific mandate is that there should be ample annual availability of solar radiation at the selected industrial locations and that there must be a good scope for comparative performance analysis so as to ensure appreciable variation in the availability of solar energy.

Since the SIPH need for different produces is well identified, the use of FPC is recommended for yarn production, whereas PTC is considered for fabric processing. The very grounds of such proposition is that yarn production needs hot water within a temperature regime of ~80–95 °C, whereas fabric processing needs steam at higher temperatures of 120–180 °C, and that FPC is not able to meet the needs of fabric processing and PTC is cost-prohibitive in yarn production [34]. Based on the productivity, it is possible to calculate the thermal energy requirement for an individual process by principles of calorimetry. The calculated thermal energy need can be used to find out the solar collector area of FPC/PTC with the aid of gathered information about the direct normal irradiance (DNI) and the global horizontal irradiance (GHI). The well-known formula [17,35] is available for calculation of collector areas. The efficiencies of FPC and PTC are taken as 60% and 66%, respectively [36]. However, the design of FPC and PTC is conditioned by the certainty in availability of solar energy as per need and under all unforeseen odds (if any), and a factor of safety is invoked by judiciously fixing the design values of GHI and DNI. These finally ensure the performance analysis of the chosen technology configuration which aims to authenticate that the use of SIPH in textile industries is a technologically feasible option.

Now that the information about thermal energy need is known and the cost of energy producing materials/accessories are available, it is possible to use a standard protocol for financial analysis [15,16,32]. The use of a standard model [27] enables us to calculate the levelized cost of useful thermal energy for yarn production/fabric processing for all the chosen locations of varying abundance in available solar radiation. Taking the least advantageous situation into consideration, a cost comparison with the existing practices can establish the technoeconomic feasibility of SIPH with complete knowledge in its economic advantage. The following sections furnish the details of methodology used in the present investigation.

The methodology followed in the present study is enumerated below:

- (a)

- Selection of location-based sample industries which are supposedly cotton-based textile industries; this is proposed for simulating the behavior of the proposed systems under various conditions available for operation. As stated before, these include availability of solar radiation, different daytime duration that is the available operating hours, and other climatic conditions.

- (b)

- Estimation of required thermal energy for various processing in cotton-based textiles production.

- (c)

- Determination of required solar collector area for process heating demand.

- (d)

- Fixation of appropriate solar thermal technologies.

- (e)

- Performance evaluation of the selected technology.

- (f)

- Assessment of technoeconomic feasibility of the proposed process.

2.1. Study Locations

The total solar radiation incident on a horizontal surface is known as global horizontal irradiance (GHI); the normal component of solar radiation falling on a collector surface is called direct normal incidence (DNI). GHI is obtained from the summation of direct normal incidence, diffuse horizontal incidence, and the ground reflected radiation. The entire component is useable for generation of heat by the flat plate collector, and GHI fixes the design parameter of the flat plate collector.

This study aims to examine the efficacy of a solar thermal system as an economic SIPH in textile industries as function of changing GHI and DNI. To gather a general idea if the use of solar thermal systems is technologically beneficial and is a lucrative option for environment protection by doing away with the exploitation of dwindling fossil fuel resources, it is required to conduct the real-life studies under different conditions of solar radiation availability, ambient temperature, and other climatic conditions, viz., average number of cloudy days, duration of daytime at various seasons (depends upon the latitude and longitude of a place). Even if it is admitted that replacement of fossil fuel by solar energy is technologically feasible for SIPH and sociologically mandatory [37,38] to reduce CO2 emission, vis à vis curtailment in health expenditure of a country [37], what remains to be known is the direct economic denomination accruable by the use of solar technology for process heating in Indian textile industries. Therefore, the selection of locations should be made in such a way that there is enough scope for comparison of cases with widely varying annual availability of solar radiation. Incidentally, in a country such as India, the textile industry hubs are located at different regions across the country. The location of textile industry clusters in India spans from northern to southern India as well as from western to eastern India. The locations appreciably vary in latitude and longitude with different climatic conditions [17]. Moreover, the annually available GHI and DNI vary widely among these locations. This is evident from the data provided in Table 1. We have primarily selected eight such locations which show appreciable variation in the above parameters that significantly affect the performance of solar thermal systems. This constitutes the basis of selection of experimental industries.

Table 1.

Locations selected for the present study with corresponding annual average values of GHI, DNI, and ambient temperature (source: Meteonorm 8 database).

To calculate the collector area, one needs to have the knowledge of available solar radiation at the particular location. It is imperative that the use of a solar thermal system for industrial process heating is not feasible unless there is ample availability of solar energy. Moreover, the industrial process heating in many industries requires a low to moderate temperature of 50–250 °C. As stated earlier, the FPC can cater to low temperature needs, and for relative higher temperature needs we need to use PTC. These two systems require different data about the available solar radiation. While DNI is required for PTC (as it cannot use diffuse radiation), the design of FPC requires GHI, as diffuse radiation is useable by FPC. Hence, to study the requirement of a textile industry at a location, one should have the idea of annual, seasonal, and day-wise figures of both DNI and GHI. Based on the suitability in respect of available solar energy, we selected the study locations spanning across the country and with appreciable variation in available radiation so as to gather a better understanding of the useability of solar thermal systems in process heating for the textile industries. This would also affirm the economic viability of the proposed technology in Indian textile industries. However, the concept is generic and is applicable for any region across the globe.

In accordance with the available information from the Meteonorm 8 database, the following locations with existing knowledge of their annual average ambient temperature (Ta) global horizontal irradiance (GHI) and direct normal irradiance (DNI) are selected for the study (Table 1).

2.2. Estimation of the Useful Thermal Energy Requirement

In a cotton-based textile industry, spinning, weaving, and processing consume the major portion of thermal energy. In spinning mills, thermal energy in the form of hot water is required for sizing and dyeing of yarn, whereas in fabric processing units, steam at intermediate temperatures is often required for operations such as de-sizing, scouring, dyeing, bleaching, drying, etc. The temperature of yarn production lies within 85–95 °C; following the preceding discussion, it is recommended that FPC should be used for yarn production.

The average thermal energy requirement may be calculated by the simple calorimetric formula: Heat energy required = mass × specific heat × (final temperature − initial temperature). Based on this, the thermal energy requirement for a specific case is shown in Table 2; following the same procedure, heat requirement in the case of steam production for use in fabric processing can be calculated. It is apparent from Table 2 that for an annual yarn production of amount 4560 tons, the thermal energy requirement comes out to be 2.64 GJ/hour or 5.05 GJ/kg when the water temperature is required to be enhanced from 15.1–95 °C. Similarly, calculation of thermal energy requirement for PTC of working temperature range, 80–180 °C, can show that the thermal energy requirement is 5.08 GJ per hour or 52.625 GJ/kg. Derived from previous reports [23], indicative values of thermal energy needed for various operations in a cotton-based textile industry are furnished in Table 3.

Table 2.

Thermal energy requirement for 4560 tons yarn in one year.

Table 3.

Consumption requirement of thermal energy in textile production [23].

2.3. Selection of Solar Thermal Technologies

It is apparent from the foregoing discussion that the selection of solar technology should be made in accordance with the thermal energy demand of a particular process in textile industries. Moreover, elegant comparative study due to Jamadi et al. has demonstrated that under identical conditions, PTC provides a higher efficiency and better thermal energy quality than FPC [34]. Moreover, a number of studies have credited PTC over all other available concentrating technologies [36,39,40,41,42]. Comparative study on the efficacy of different solar concentrating collectors for application in a trigeneration system has revealed that the performance of parabolic trough collectors is superior to linear Fresnel reflectors and parabolic disc collectors. A throughout-year study in Athens, Greece, indicated that PTC offers a system energy efficiency of around 65% with a simple payback of ~6 years, whereas the disc collector exhibits an efficiency of 62% at a payback of ~11 years [36].

The temperature for cotton yarn production is different from fabric processing units, and hence solar thermal technology to be applied in each case may differ; in view of lower temperature requirement in spinning mills (requiring only hot water at lower temperatures, ~85–95 °C), a flat plate collector appears to be sufficient for yarn production. In contrast, the need for steam/hot water at higher temperature for fabric processing leads to the employment of a parabolic-trough-solar-concentrator-based SIPH system. Thus, the fields of employment of FPC (in yarn production) and PTC (in fabric processing) are made fixed for further study on technoeconomic viability. In this context, it is recalled that a number of concentrating technologies are available for heating of water or production of steam [36,43]. Based on this information, the present study focuses on the use of PTC for SIPH in textile industries. In the case of fabric processing, the inlet temperature is kept at 60 °C, whereas the steam temperature requirement is 180 °C.

In the present investigation, the PTC is made of a glass mirror with solar grade silver film of 0.15 mm thickness; the reflectivity is higher than 93%. The receiver tube placed at the focal region is made of AISI 304 stainless steel of diameter 30 mm with wall thickness 1.5 mm. The solar-grade absorber coating used to absorb the radiation possesses absorptivity of 0.90–0.95. There is a borosilicate glass cover. The cover is a 2 mm thick linear round tube of diameter 50 mm with a transmittivity of 95%.

It is important to estimate the requirement of the solar collector area that enables to achieve the useful thermal energy delivery for running the industry throughout the year. It is known that the area of the solar collector field (Ac) for producing hot water with the aid of a flat plate collector is obtained by the following equation [35].

where Ac is the area of solar collector field (ASC), Ph represents the process heat requirement per hour (GJ/h), GHId denotes the design value of GHI, and is the overall thermal efficiency of solar energy SIPH system at the selected design value of the GHI (written as GHId) or DNI (written as DNId). While GHId needs to be used to determine the collector area for the case of FPC that produces hot water of temperature of 85–95 °C, GHId needs to be replaced by DNId in Equation (1) for the case of solar-concentrator-based steam generation systems, say, PTC. Hence, the required collector area for a PTC can be obtained from the same Equation (1) by writing

The overall efficiency of FPC, , as the selected SIPH is taken as 60%, whereas that for a PTC for steam production in fabric processing (working temperature in the present case is 140–180 °C) shall be 66%.

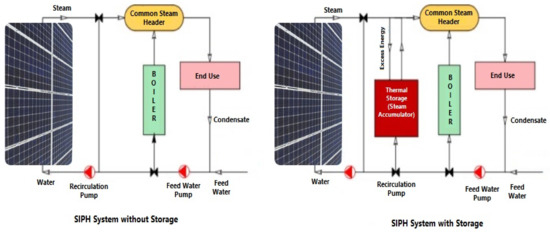

For the design value, SIPH gives rise to its nominal thermal output which should be sufficient to continue production with or without backup support; if the solar radiation incident on the collector is less than the design value, SIPH output will be less than the nominal value, whereas it will be more when the solar radiation incident on the solar collector exceeds the design value. The excess energy so produced at a time may be stored via a well-designed thermal storage system; this enhances the overall enhancement thermal efficiency and hence ensures economic advantage. The thermal energy storage system is essentially a steam accumulator and is integrated in the PTC setup. The stored energy can be used whenever there is a shortfall in required energy. The integration of a storage system in PTC setup is schematically shown in Figure 1. On the basis of a design DNI value (DNId) of 600 W/m2, the collector area of PTC is calculated for all the eight experimental sites. The thermal energy requirement for a PTC is calculated on the basis of temperature range which is taken as 60–180 °C; it is found to be 5.08 GJ/kg. The annual energy delivered and the amount to store (the amount generated in excess of requirement) are calculated and the results with the use of a thermal storage system are furnished in Table 4.

Figure 1.

SIPH systems (PTC) used for the present study.

Table 4.

Calculated values of thermal energy storage (TES) with corresponding solar fraction (SF) of PTC at DNId = 600 W/m2.

Solar fraction denotes the ratio of energy provided by the SIPH (FPC or PTC) and the total thermal energy required for the entire process. Thus, it depends upon the factors such as overall thermal load, storage sizes, the available solar radiation, that is, GHI or DNI (which vary with difference in climatic conditions at various geographical locations), and operational conditions. Therefore, solar fraction can be expressed as ((energy delivered by solar thermal system – energy stored)/(actual thermal energy required for the entire process)). Hence, a higher value of solar fraction is indicative of the fact that the share of solar energy in meeting the thermal load of the industrial process heating is higher. Table 4 furnishes the solar fraction of all the experimental locations for a specific DNId of 600 W/m2.

It may be mentioned that thermal storage system integration offers the advantage of supplying energy at the time when the availability of solar radiation is lean, such as on cloudy days or when it is not available, e.g., night. The steam accumulator can hold the steam energy under stringent conditions and it is maintained in the TES. The available steam can be gainfully used in the evening for some period of time.

After deriving the solar collector area (Equation (1)), the deliverable thermal energy in the SIPH is calculated on an hourly basis for the entire year; the difference in the observed values of deliverable thermal energy is ascribed to the variation of GHI/DNI in timescale as well as from one place to other. The values of GHI or DNI for each hour of the whole year are obtainable from the use of Meteonorm 8 software. For each of the selected locations, the data are collected. A spreadsheet-based program that internalizes the performance characteristics of the solar collector as well as the hourly values of solar radiation and ambient temperature has been developed and is used for study. This exercise has been repeated for all the selected locations of clusters of cotton-based textile mills in the country.

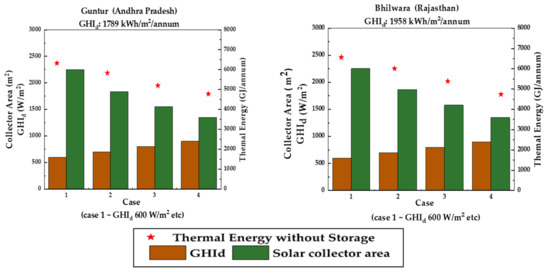

Figure 2 demonstrates the impact of changing the design value on the performance of SIPH. With increase in GHId value, the solar collector area will decrease in accordance with Equation (1). Based on prefixed thermal energy requirement, the needed solar collector area is found to decrease. However, the actual available solar radiation varies with time, and hence the value of thermal energy delivered is also changed. Quite obviously, the decrease in collector area will lead to diminution in delivered thermal energy. The red points in Figure 1 denote the variation in the delivered thermal energy as a function of collector area. It is known that a lower collector area delivers a lower amount of solar thermal energy. Since the available GHI is location-dependent (Table 1) and collector area is decided by the GHId value and the collector efficiency (~60% for FPC), one may find that there is an appreciable variation in delivered energy with collector area for the solar thermal system without the thermal energy storage (TES) system. It is imperative that such variation is generic, and it is for this reason the curves are of the same qualitative form for all the selected locations.

Figure 2.

Variation of thermal energy with changing GHId values for each of the selected locations.

From the foregoing discussion, it is apparent that depending upon the actual availability of solar radiation on a specific day, the thermal energy deliverable by a designed solar heating system may be higher than the actual requirement. In that case, some extra energy will be created, and a well-designed thermal storage system may be incorporated in the SIPH system. On the contrary, if by chance the actual available radiation falls short of the design value, the deliverable energy may run into deficit; in that case, some kind of backup support will be required. Quite often, an efficient thermal storage system, when inbuilt into the system, provides a solution to the problem. Thermal storage systems in SIPH is a subject of research interest. In the present study, the SIPH envisages the use of a thermal storage system whose effectiveness in performance of solar thermal systems is enumerated elsewhere [44]. However, the design value of the collector area should be so fixed as to have some factor of safety so that the available solar thermal energy is able to run the production even under odd situations. The realization of the importance of a thermal storage system entices to make up a design scheme of PTC, as shown in Figure 1. The present study has taken into consideration such a scheme while contemplating the proposed financial analysis. In contrast, for a low-temperature operation, as in yarn production, we propose the use of FPC for which thermal energy storage is not economically feasible. This is because the latitude in working temperature can be 75–95 °C and, hence, overdesign in GHId is not planned, as otherwise both the size of FPC and that of hot water storage would have to be made rather large and, hence, heat loss area will be significantly enhanced. In our study, we have not considered such provision and have paid our attention to the use of TES in PTC only for fabric processing. However, the feasibility of employment of TES in the case of FPC is not precluded by the above fact that we have not considered its usage. For the case of higher availability of GHI, it is also possible to design FPC of relatively less collector area with sufficient improvement in design. In such case, it may be possible for the thermal energy delivered by the system to exceed the energy requirement for process heating, and hence a TES can be the solution for avoidance of thermal energy loss.

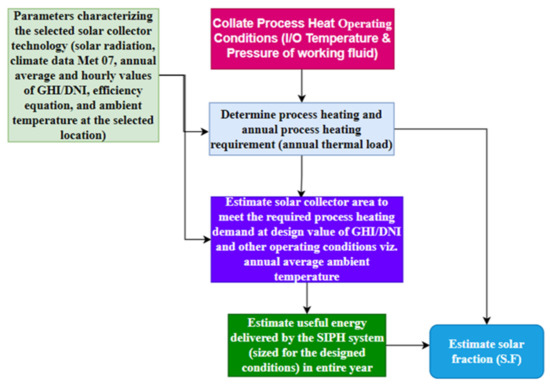

A light diesel oil fired boiler (design code: IBR-1950) was used in the present study. The capacity of the boiler is 5000 kg/hour at a working pressure of 10.54 kg/cm2, the feed water temperature is 85 °C, and the output temperature of the boiler is 180 °C. The thermal efficiency of the LDO boiler is 85%. The activity flow chart for performance analysis of the SIPH system with FPC as well as PTC is furnished in Figure 3, which gives information of the steps followed in the present work, and implication of individual actions was already narrated in the preceding discussion.

Figure 3.

A schematic of the methodology adopted for performance estimation of SIPH systems.

2.4. Model for Financial Analysis

As stated earlier, technological feasibility is a necessary but not a sufficient driving force to invoke solar thermal heating system for SIPH in Indian textile industries. Unless the prescribed solar thermal technology is proven to be financially rewarding to the textile industries, advocacy in favor of employment of solar technology to replace the existing ones will turn out to be a futile exercise. This has enticed a number of workers to conduct technoeconomic assessment of solar thermal systems for various kinds of process heating [15,16,32]. However, modeling the technoeconomics of implementing SIPH for yarn production/fabric processing by textile industries is yet to be integrated with decision support systems in the act of technology diversification in Indian textile industries. Following the different strategies adopted so far in technoeconomic analysis of solar thermal systems, a newer approach in financial analysis of SIPH replacing conventional process heating methods is adopted in the current investigation.

The analysis of process economy considers levelized cost of useful thermal energy (LCUTE) (Cl) delivered, and other financial parameters which determine the viability/attractiveness of the technology. LCUTE is estimated by the following formula [45].

where Cl represents LCUTE, denotes the unit cost of useful thermal energy delivered by the SIPH system (UCUTE) in jth year of its operation, d is the discount rate applicable for the investment, and n is the useful life of the system.

where denotes the annual amount of useful thermal energy delivered by the SIPH system (AUTED in jth year), stands for capital cost of the system for one year, and stands for operation and maintenance (this includes the fuel cost in jth year). Enhancement of operation and maintenance is taken into consideration by introducing a cost escalation constant term. Capital cost of the system for one year () can be derived from the following equation:

where C0 is the capital cost of the SIPH system, other notations having usual meaning. In case the energy is supplied by fossil fuel, the levelized cost can be calculated by use of similar equation. n is replaced by ncon and by , which will give the levelized cost due to use of fossil-fuel-based process heating. can be obtained by the following equation

d is the discount rate as applied to investment and ncon is the useful life of the conventional process heating system. Similarly, the unit cost of useful thermal energy from conventional sources may be written as

where the subscript “con” denotes the conventional source counterpart of the terms used in solar thermal energy equations, CVf represents the calorific value of fuel, is the efficiency of fuel utilization in the conventional process heating system, UPf,1 is the unit price of fuel in the jth year, and is the rate of annual escalation in the unit price of fuel. Discounted payback period (DPP) of the incremental investment made on the SIPH system was determined from the time of commencement of the project till the cumulative cash flow just becomes zero (i.e., the present value costs are equal to the present value benefits).

Bj is the benefit accrued per annum due to fuel savings insured by SIPH in the jth year; has its usual meaning. Equivalent financial benefit against the amount of fuel replaced can be expressed as

Net present value (NPV) of an investment in the SIPH system can be expressed as

The annual discount rate that leads net present value of investment zero is known as internal rate of return (IRR). IRR is obtained from the following relationship:

In the present study, it is assumed that the salvage value of the plant, including its disposal cost after expiry, is negligibly small.

3. Results and Discussion

Using the afore-described model for financial analysis, we attempt to make an initial estimate of useful energy delivered by the SIPH systems in the cotton-based textile industry in India vis à vis its financial attractiveness, if any. The realistic input parameters are decided on the basis of available information [46,47,48,49,50,51,52,53,54] and experience of some of the authors. The selected input parameter values are shown in Table 5. It may be noted that capital costs of FPC do not include any cost of the thermal storage system because we did not use TES in FPC. However, the capital cost of PTC includes the cost of the thermal storage system (TES). We attempted to find out the process heating requirement cost; for simplicity of calculation and, hence, to demonstrate the achievable benefit in using a solar thermal system, we present an indicative financial analysis. Collecting data on the usage of stored energy for process heating, suitable variation in DNId, and the elaborate cost benefit analysis shall constitute a separate paper.

Table 5.

Inputs for financial analysis of using a solar thermal system for SIPH in textile industries.

3.1. Cost Analysis for Cotton Yarn Production via FPC

Values of the solar collection area required for flat-plate-collector-based SIPH systems, useful thermal energy delivered, and values of solar fraction of the SIPH systems for hot water generation for the selected locations are estimated. The real-life estimation as presented in the paper is based on the input costs shown in Table 5; the data therein are based on the energy prices and other costs as applicable for 2016, being taken as the reference. The escalated input cost is also taken into consideration. However, suitable modification can be made in cost analysis with the aid of applicable multiplying factor, depending upon the rate of inflation.

The solar fraction decreases with an increase in the design value of insolation. In the present study, solar fraction is seen to attain a value of 0.30 for a GHId value of 600 W/m2 whereas it comes down 0.22 for a GHId of 900 W/m2. This observation is generic and is evident from Equation (1); it is clear that higher magnitude of GHId implies a lower collector area. A lower collector area is apt to deliver a lower amount of thermal energy. By definition of solar fraction, a lower value of delivered energy ought to lower the solar fraction irrespective of the use of TES or not. However, for the same collector area, the actual GHI or DNI will matter a lot. For a specific collector area, the region providing higher insolation on a yearly basis is apt to deliver higher thermal energy. Thus, solar fraction will depend both on GHId/DNId and climatic condition vis à vis the actually available GHI/DNI; while the former influences the collector area, the latter determines the generation capability of thermal energy by the collectors of the same area. It may also be noted that if the design value of GHId is kept on the lower side, the deliverable thermal energy by DPC will exceed the demand value and hence the extra energy can be stored for betterment of process economy. Hence, the provision of storage system ensures higher value of solar fraction for all values of GHId. It is observed that in SIPH systems which are designed to meet the thermal energy demand for process heating application, annual solar fraction is around 0.35; this implies that SIPH systems in the field necessitate the provision of auxiliary backup or an excessively large storage component.

3.2. Parabolic-Trough-Based SIPH System for Steam Generation (for Fabric Processing)

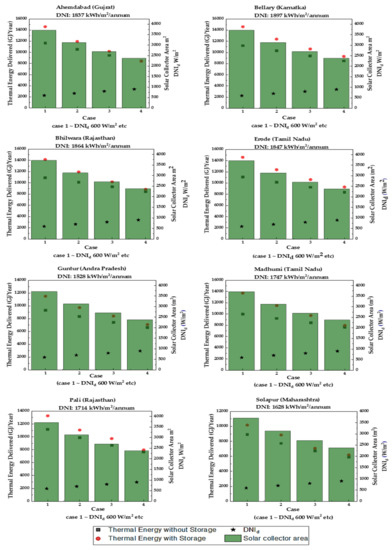

Figure 4 shows deliverable thermal energy by a parabolic concentrator (PTC) for collector areas based on the varying design values of DNI.

Figure 4.

Performance of parabolic-trough-based SIPH for the selected locations.

From the results of the present experiments with different DNId values (600 kWh/m2–900 kWh/m2), it is found that the estimated values of solar fractions for SIPH systems range from 0.13–0.29 with or without storage system. This is, however, less than what could be achieved for hot water production by FPC. This is due to the higher collection efficiency of flat-plate-collector-based SIPH systems as the required operating temperatures are lower. It may also be noted that the benefit of including a storage component in terms of an increase in the solar fraction is marginal at high values of DNId as the system operates at its nominal capacity for shorter durations and, consequently, the amount of energy likely to be dumped is very small.

To understand the location specificity of the performance of an SIPH system meant to cater to process heating demand in a cotton-based textile cluster, one needs to follow, from Figure 4, that there results a significant variation in the amounts of annual useful energy delivered at different locations within the country. For example, in the case of a PTC-based SIPH with no storage system, the solar fraction for DINd ~600 kWh/m2 can be estimated at 0.26 at Ahmedabad (annual DNI of 1837 kWh/m2), while the corresponding value for Solapur (annual DNI of 1628 kWh/m2) comes out to be 0.20. The corresponding values for SIPH systems with storage are estimated at 0.29 and 0.21 for Ahmedabad and Solapur, respectively. Thus, while designing an SIPH system, optimal value of design DNI and the size of thermal energy storage are needed to be estimated separately for each location.

In general, it can be noted from Figure 4 that the textile industry at Bellary delivers a maximum thermal energy for PTC and also for FPC (Table 4), whereas a minimum amount is delivered by the textile industry at Solapur. If we compare the annual achievable GHI/DNI (Table 1), it will appear that Bellary gives rise to maximum GHI/DNI, where Solapur gives the lowest value of GHI/DNI; the geographical descriptions of Bellary and Solapur are, respectively, 15.13° N 76.92° E and 17.65° N 75.90° E. Thus, the difference in latitude and longitude of a place experiences different solar radiation; this is manifested in the difference in capacities to provide annual solar radiation in terms of GHI/DNI.

3.3. Assessment of Financial Performance

To assess the cost advantage of SIPH over the existing conventional industrial process heating systems, the cost of deliverable thermal energy is also calculated for the conventional process heating systems for use of different types of fuels normally employed in the cotton-based textile industries in India. Equation (5) is used for cost calculation using price data for different fuels, as provided in Table 6. The results obtained are presented in Table 6 for two scenarios: one for the case of uniform fuel price for the entire life period of the system, and the other with an annual price escalation by 5% in each year till the end-of-life period.

Table 6.

Expenditure to be incurred for conventional process heating systems.

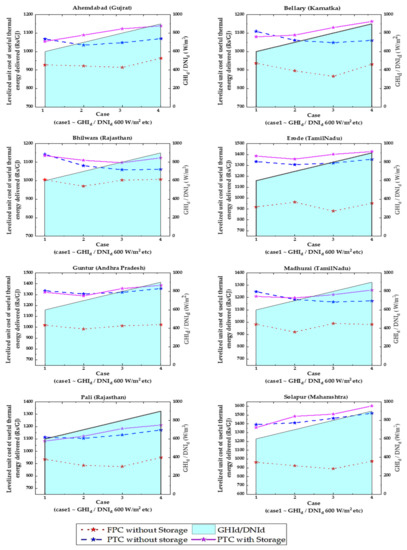

Estimates of levelized unit cost of energy delivered by the SIPH systems (both FPC- and PTC-based) at all the selected locations are presented in Figure 5.

Figure 5.

Calculated cost of deliverable thermal energy under various conditions.

It is evident from the results that the performance of solar thermal systems varies with locations. This is quite natural. For fixed values of GHId/DNId, the collector area becomes fixed. However, available values of GHI/DNI in real-life situations must vary with latitude and longitude of locations. On the basis of a fixed collector area, any variation in availability of solar radiation (solar thermal energy) signifies that the amount of deliverable thermal energy will be different. This leads to alteration in levelized cost of useful thermal energy delivered. Therefore, the results advocate that the annual performance of a solar thermal system (FPC/PTC) is globally dependent upon the climatic condition, which varies from place to place in terms of maximum achievable GHI/DNI, number of cloudy/rainy days, seasonal daytime available, etc. It can be observed from Table 1 that the lower the latitude and higher the longitude of a place, the higher the magnitude of receivable solar radiation. This follows from the positional relationship between the sun and Earth together with the motion of the Earth (both rotation about its own axis and revolution around the sun); also, the annual achievable value of solar radiation at a place is decided by the above.

It can be noted that the estimates are made for four different values of GHId and DNId. A comparison of the estimates presented in Figure 5 with the estimated levelized cost for conventional fossil-fuel-based systems in Table 6 makes it clear that for the case of uniform fuel prices, the conventional systems appear to be financially more attractive. However, in the more realistic assumption of a uniform annual escalation of 5% in the price of the fuel, the financial attractiveness of the SIPH systems seems to lag.

It may be further noted that, as is usually expected, the SIPH systems with storage to accumulate the excess energy are financially more attractive as compared to the systems without storage. This is true for all the conditions and locations. On the other hand, for parabolic-trough-based SIPH systems, the provision of storage system does not make much difference, as at most of the locations, minimum values of levelized cost are obtainable for the SIPH systems without the provision of thermal energy storage.

The values of other measures of financial performance at the selected locations are calculated as per the analysis explained in the preceding section (Table 7). From the foregoing discussion, it becomes clear that the change in latitude and longitude of location of textile industries experiences different situations to work under. Hence, for a specific design value of GHId or DNId, the performance of similarly designed solar thermal systems varies in respect of the amount of thermal energy that can be delivered by the solar systems. Accordingly, levelized cost of useful thermal energy obtainable from a solar thermal system in a location varies (Table 6 and Table 7).

Table 7.

Measures of financial viability of SIPH systems in the textile industry in India (for cotton-based yarn and fabric processing).

The results are applicable for both the case of FPC- and PTC-based heating, which are meant to be used for saving dear furnace oil being used in a conventional boiler. From the results, it may be observed that the SIPH for hot water generation to be used in cotton yarn production is an economically viable option at all locations considered in this study. On the other hand, the parabolic-trough-based SIPH system becomes somewhat competitive only under certain specific conditions (viz., no escalation of fuel price). It may be noted that payback period for the parabolic-tough-based SIPH system is very long. Moreover, parabolic-trough-based SIPH systems may be financially attractive only at such locations, where annual DNI values are more than 1650 kWh/m2/annum. The present exercise is suggestive of the fact that use of solar energy for process heating in the cotton-based textile industry bears a high potential for being cost-effective. In this context, it is very pertinent to mention that apart from direct financial benefit obtainable from the replacement of conventional process heating by solar thermal systems, there is great intangible benefit whose cost equivalence is not worked out in the present investigation. Noting that burning of one liter of light diesel oil (as is being used in the majority of textile industries for process heating) gives rise to the emission of 2.68 kg of CO2, and that expenditure of 41.868 GJ of thermal energy equals one ton oil equivalent, the amount of reduction in CO2 emission was calculated for both yarn production and fabric processing for textile industries under study. It is found that the use of SIPH for yarn production leads to a diminution in emission of CO2 by 382.5 tons for each ton of yarn production. For one ton of fabric processing, the calculated value in the reduction of CO2 is as high as 4264 tons.

4. Conclusions

From the study conducted in textile industries situated at various locations, it has transpired that the performance of a solar thermal system, both FPC and PTC, is highly sensitive to available annual GHI/DNI, ambient temperature, and other climatic conditions. The difference in deliverable thermal energy has a cost implication and the present study also looked into the technoeconomic feasibility. In the studied region, the technoeconomic feasibility is established with different performance level at various locations. This observation is generic and is applicable to all locations across the globe.

The authors conclude that the financial attractiveness of SIPH for the cotton-based textile industry depends on several factors such as (a) solar collector technology to be used and its performance characteristics, (b) temperature and pressure requirements for process heating, (c) design value of insolation, (d) availability of solar radiation at locations of installation, and (e) the extent of thermal energy storage included in the system. The availability of radiance is different at different locations, so the cost of energy generation and the system’s performance are at variance with one another.

It is observed that solar heating systems of the cotton-based textile industry can achieve a solar fraction of 0.35 with storage system integrated to a flat plate collector, whereas the value appears to be around 0.30 in the case of a parabolic-trough-based system with a storage system. In consideration of uniform price of fossil fuels over the entire useful life of the system, the cost of thermal energy varies from INR 869/GJ for LSHS to INR 1285/GJ for natural-gas-based process heating. In case an annual escalation of 5% is considered for the price of fossil fuels, the cost would vary from INR 1023/GJ for LSHS to INR 1643/GJ for natural gas. It is finally inferred that SIPH in the textile industry can be attractive for locations of abundance in availability of solar radiation. It is also concluded that, for hot water generation, the values of discounted payback period are much smaller than the expected useful life of the SIPH system (11–14 years), whereas the payback period for PTC-based steam generation systems is rather large (19–23 years).

Author Contributions

Conceptualization, P.K. and K.K.S.; methodology, M.K.G.; software, M.K.B.; validation, S.K.S., S.K. and N.K.; formal analysis, P.K.; investigation, N.S.; resources, K.K.S.; data curation, M.K.B.; writing—original draft preparation, P.K.; writing—review and editing, S.K.S., S.K. and N.K.; visualization, M.K.G. and N.S.; supervision, B.Đ.; project administration, S.K.S. and S.K.; funding acquisition, N.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available based on reasonable request towards corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Orzuk, H.K. Energy usage and cost in textile industry: A case study for Turkey. Energy 2005, 6, 21–23. [Google Scholar]

- Kalogirou, S.A. The potential of solar industrial process heat applications. Appl. Energy 2003, 76, 337–361. [Google Scholar] [CrossRef]

- Adel, M.; Dayem, A.; Mohmad, M.A. Potential of solar energy utilization in the textile industry—A case study. Renew. Energy 2001, 23, 685–694. [Google Scholar]

- Claudia, V.; Battisti, R.; Drigo, S. Potential of Solar Heat for Industrial Processes. Solar Heat and Cooling Program Task 33 (IV) of International Energy Agency Vienna. 2008. Available online: http://www.aee-intec.at/0uploads/dateien561.pdf (accessed on 20 May 2008).

- Procter, D.; Mors, R.N. Solar Energy for the Australian food processing industry. Sol. Energy 1977, 19, 63–72. [Google Scholar] [CrossRef]

- Anand, D.K. Use of solar energy for industrial process heat. In Proceedings of the International Solar Energy Society Congress, New Delhi, India, 16–21 January 1978; pp. 2001–2008. [Google Scholar]

- Gordon, J.M.; Rabl, A. Design, Analysis and Optimization of Solar Industrial Process Heat Plants without Storage. Sol. Energy 1982, 28, 519–530. [Google Scholar] [CrossRef]

- Baer, D.; Gordon, J.M.; Zarmi, Y. Design and Optimization of Solar Steam Systems for Constant Load Applications. Sol. Energy 1985, 35, 137–151. [Google Scholar] [CrossRef]

- Quijera, J.A.; Alriols, M.G.; Labidi, J. Integration of a solar thermal system in a dairy process. Renew. Energy 2011, 36, 1843–1853. [Google Scholar] [CrossRef]

- Taibi, E.; Gielen, D.; Bazilian, M. The potential for renewable energy in industrial applications. Renew. Sustain. Energy Rev. 2012, 16, 735–744. [Google Scholar] [CrossRef]

- Beath, C.A. Industrial Energy Usage in Australia and the Potential for implementation of Solar Thermal Heat and Power. Energy 2012, 43, 261–272. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Carbon mitigation potential of solar industrial process heating: Paper industry in India. J. Clean. Prod. 2016, 112, 1683–1691. [Google Scholar] [CrossRef]

- Fuller, R.J. Solar industrial process heating in Australia—Past and current status. Renew. Energy 2021, 36, 216–221. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Potential of solar industrial process heating in dairy industry in India and consequent carbon mitigation. J. Clean. Prod. 2017, 140, 714–724. [Google Scholar] [CrossRef]

- Paraschiv, S.; Barbuta, N.; Misu Lizica Paraschiv, S. Technical and economic analysis of a solar air heating system integration in a residential building wall to increase energy efficiency by solar heat gain and thermal insulation. Energy Rep. 2020, 6, 459–474. [Google Scholar] [CrossRef]

- Dehghan, M.; Pfeiffer, C.F.; Rakhshani, E.; Bakhshi-Jafarabadi, R. A Review on Techno-Economic Assessment of Solar Water Heating Systems in the Middle East. Energies 2021, 14, 4944. [Google Scholar] [CrossRef]

- Lauterbach, B.; Schmitt, U.; Jordon, K. The potential of solar heat for industrial processes in Germany Renew. Sustain. Energy Rev. 2012, 16, 5121–5130. [Google Scholar] [CrossRef]

- Ramos, C.; Ramirez, R.; Beltran, J. Potential Assessment in Mexico for Solar Process Heat Applications in Food and Textile Industries. Energy Procedia 2014, 49, 1879–1884. [Google Scholar] [CrossRef]

- ABPS. Final Report on Market Assessment of Solar Water Heating Systems in Industrial Sectors; ABPS Advisory Infrastructure Private Ltd.: Maharashtra, India, 2010. Available online: http://mnre.gov.in/filemanager/UserFiles/Report_Market_Assessment_of_SWH_in_Idustrial_Sector.pdf (accessed on 9 May 2011).

- Cundapía, R.; Moyaa, S.L.; Valenzuela, L. Approaches to modelling a solar field for direct generation of industrial steam. Renew. Energy 2017, 103, 666–681. [Google Scholar] [CrossRef]

- Joubert, E.C.; Hess, S.; Van Niekerk, J.L. Large-scale solar water heating in South Africa: Status, barriers and recommendations. Renew. Energy 2016, 97, 809–822. [Google Scholar] [CrossRef]

- GIZ Identification of Industrial Sectors Promising for Commercialization of Solar Energy in India. 2011. Available online: http://mnre.gov.in/file-ComSolar.pdf (accessed on 1 November 2011).

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. GHG Mitigation Potential of Solar Industrial Process Heating in Producing Cotton based Textiles in India. J. Clean. Prod. 2017, 145, 74–84. [Google Scholar] [CrossRef]

- Gupta, S. Scope of solar energy utilization in the Indian textile factory. Sol. Energy 1989, 42, 311–388. [Google Scholar] [CrossRef]

- Ennio, A.; Carnevale, L.F.; Simone, P. Investigation on the feasibility of integration of high temperature solar energy in a textile factory. Renew. Energy 2011, 36, 3517–3529. [Google Scholar]

- Suresh, N.S.; Rao, B.S. Solar energy for process heating: A case study of selected Indian industries. J. Clean. Prod. 2017, 151, 439–451. [Google Scholar] [CrossRef]

- CII Annual Textile Statistics. Confederation of Indian Textile Industry 2015. Available online: http://www.citiindia.com/statistics/textile-statistics.html (accessed on 18 March 2016).

- Saxena, N.; Ganguli, S. Solar and Wind Power Estimation and Economic Load Dispatch Using Firefly Algorithm. Procedia Comput. Sci. 2015, 70, 688–700. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Garcia, A.F.; Rojas, E.; Perez, M.; Silva, R.; Escobedo, Q.H.; Agugliaro, F.M. A parabolic trough collector for cleaner industrial process heat. J. Clean. Prod. 2015, 89, 272–285. [Google Scholar] [CrossRef]

- Serban, A.; Nicoleta, B.; Misu, A.; Ciucescu, N.; Paraschiv, S. Economic and Environmental Analysis of Investing in Solar Water Heating Systems. Sustainability 2016, 8, 1286. [Google Scholar] [CrossRef]

- Agrawal, H.; Yadav, A. Economic analysis of solar thermal system for melting of ice at high altitude regions using Scheffler solar concentrator. Int. J. Sustain. Eng. 2021, 14, 497–506. [Google Scholar] [CrossRef]

- Häberle Dirk Krüger, A. Concentrating Solar Power Technology, 2nd ed.; Lovegrove, K., Stein, W., Eds.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Jamadi, F.; Arabpour, M.; Abdolzadeh, M. Solar Collectors Utilizing in the Heating System of a Room-An Experimental Investigation. Int. J. Renew. Energy Res. 2017, 7, 1836–1849. [Google Scholar]

- Solar Collectors: Engineering Reference—Energy Plus 8.0. Available online: https://bigladdersoftware.com/ (accessed on 1 April 2013).

- Bellos, E.; Tzivanidis, C. Concentrating Solar Collectors for a Trigeneration System—A Comparative Study. Appl. Sci. 2020, 10, 4492. [Google Scholar] [CrossRef]

- Mehmood, U.; Agyekum, E.B.; Kamel, S.; Shahinzadeh, H.; Moshayedi, A.J. Exploring the Roles of Renewable Energy, Education Spending, and CO2 Emissions towards Health Spending in South Asian Countries. Sustainability 2022, 14, 3549. [Google Scholar] [CrossRef]

- Mirhedayati, A.S.; Hadadi, Z.; Zanjani, S.M.; Shahinzadeh, H.; Bayindir, R.; Shaneh, M.; Moradi, J. Optimal operation of combined heat and power in competitive electricity markets: A case study in IAUN. Int. J. Renew. Energy Res. 2021, 11, 1013–1022. [Google Scholar]

- Hussein, N.; Jabba, A. Review on Parabolic Solar Concentrator Trough and Parabolic Solar Concentrator Dish. J. Mech. Eng. Res. Dev. 2021, 44, 381–386. [Google Scholar]

- Pakhare, A.N.; Pandey, H.; Selvam, M.; Jawahar, C.P. Experimental Performance Evaluation of a Parabolic Solar Dish Collector with Nanofluid, Concentrated Solar Thermal Energy Technologies; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Sagade, A.; Shinde, N. Performance evaluation of parabolic dish type solar collector for industrial heating application. Int. J. Energy Technol. Policy 2012, 8, 80–93. [Google Scholar] [CrossRef]

- Masood, F.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Saidur, R.; Alam, M.A.; Akhter, J.; Yusuf, M.; Mehmood, M.; Ali, M. A Review of Recent Developments and Applications of Compound Parabolic Concentrator-Based Hybrid Solar Photovoltaic/Thermal Collectors. Sustainability 2022, 14, 5529. [Google Scholar] [CrossRef]

- Praveen, R.P.; Kotturu, V.V. Chandra Mouli, Performance enhancement of parabolic trough collector solar thermal power plants with thermal energy storage capability. Ain Shams Eng. J. 2022, 13, 101716. [Google Scholar] [CrossRef]

- Pujar, H.; Sajjan, S.C. Design and Fabrication of Solar Paraboloid Concentrator. In Proceedings of the 2nd International Conference on Non-Conventional Energy: Nanotechnology & Nanomaterials for Energy & Environment (ICNNEE), West Bengal, India, 17–19 October 2019. [Google Scholar]

- Kandpal, T.C.; Garg, H. Financial Evaluation of Renewable Energy Technologies; Macmillan India Ltd.: Basingstoke, UK, 2003. [Google Scholar]

- Ernest Orlando Lawrence Berkeley National Laboratory. Assessment of Energy Use and Energy Savings Potential in Selected Industrial Sectors in India. 2005. Available online: https://eta-publications.lbl.gov/sites/default/files/lbnl-57293.pdf (accessed on 31 August 2005).

- SRCC Parabolic trough Collector. Solar Rating and Certification Corporation. Certification Number, 10001961. 2014. Available online: https://secure.solar-rating.org/Certification/Ratings/RatingsSummaryPage.aspx?type=1 (accessed on 30 March 2015).

- BEE. Manual of Pali textile cluster. A Study of Bureau of Energy Efficiency India. 2014. Available online: http://sameeeksha.org/pdf/dpr/PAL_TXT10.pdf (accessed on 1 December 2014).

- BEE. Detail Report on Energy Efficient Boiler in Surat Textile Cluster; Bureau of Energy Efficiency: New Delhi, India, 2013. Available online: http://sameeeksha.org/pdf/dpr/surat_3TPH.pdf (accessed on 1 December 2013).

- MP&NG. Indian Petroleum and Natural Gas Statistics; Ministry of Petroleum & Natural Gas. Government of India: New Delhi, India, 2017. Available online: http://www.petroleum.nic.in/docs/pngstat.pdf (accessed on 30 September 2017).

- CEA. Data on Data on Petroleum Fuels used in Various Gas Turbines & Diesel Engine Power Plants in the Country During 2003–2004; Central Electricity Authority: New Delhi, India, 2005. Available online: http://www.cea.nic.in/reports/articles/thermal/data_petroleum_fuels.pdf (accessed on 31 December 2005).

- MNRE. Reference Manual and Checklist for Hospitality Sector. UNDP/GEF Project on Global Solar Water Heating; Ministry of New and Renewable Energy Government of India: New Delhi, India, 2012. Available online: http://www.teriin.org/ResUpdate/Manuals_and_Checklists.pdf (accessed on 31 January 2012).

- Sun Focus. India’s Quest for Solar Steam and Process Heat; A Quarterly Magazine on Concentrated Solar Heat; SVS Press: New Delhi, India, 2016; Volume 3, Available online: http://www.in.undp.org/content/dam/india/docs/Sun%20Focus_Jan_March%202016_LD.pdf?download (accessed on 14 April 2016).

- CSH. Concentrated Solar Heat. Case Studies. 2016. Available online: http://www.cshindia.in/images/pdf/SKF.pdf (accessed on 31 December 2016).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).