Model Predictive Control for PMSM Based on Discrete Space Vector Modulation with RLS Parameter Identification

Abstract

:1. Introduction

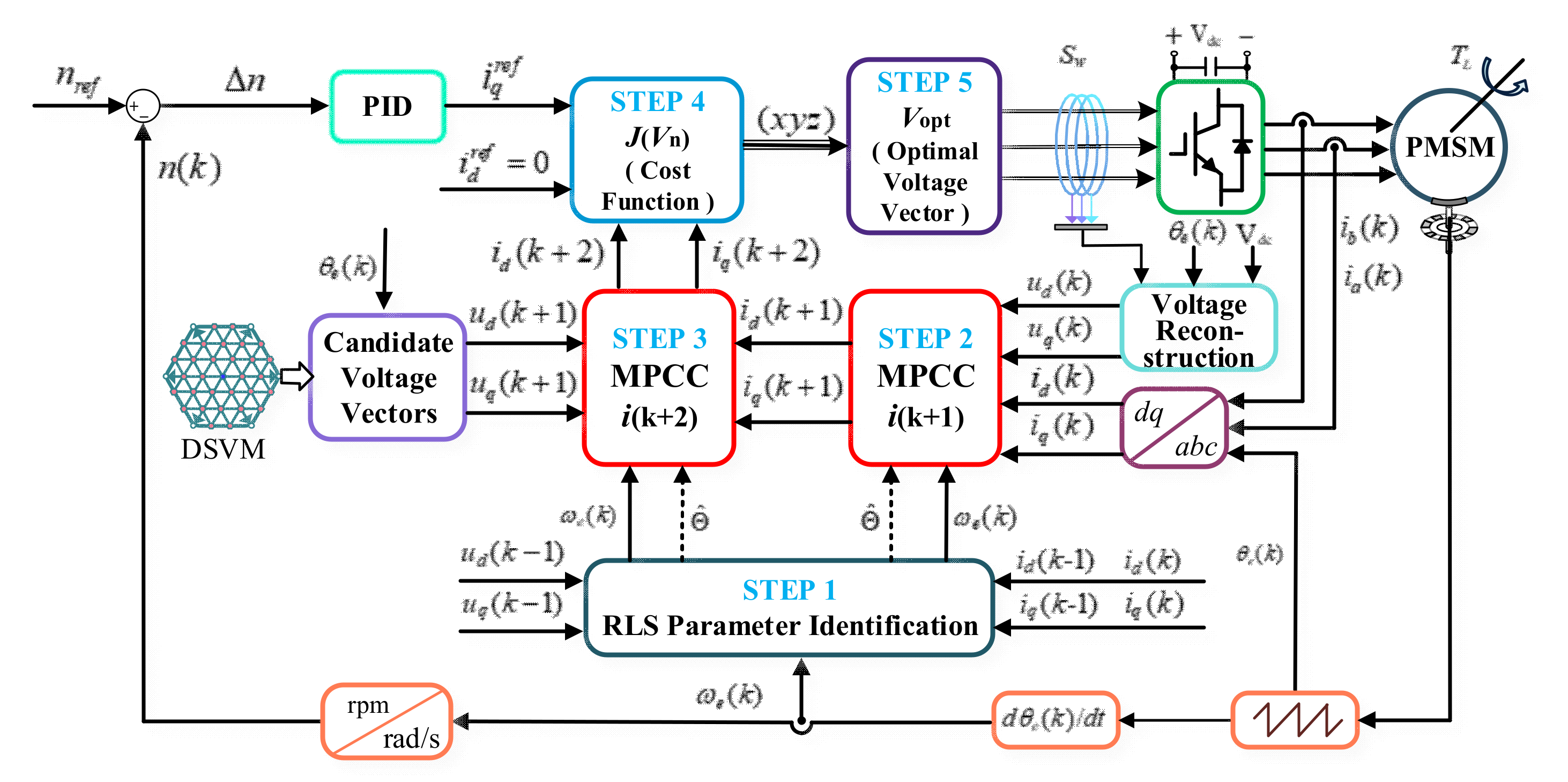

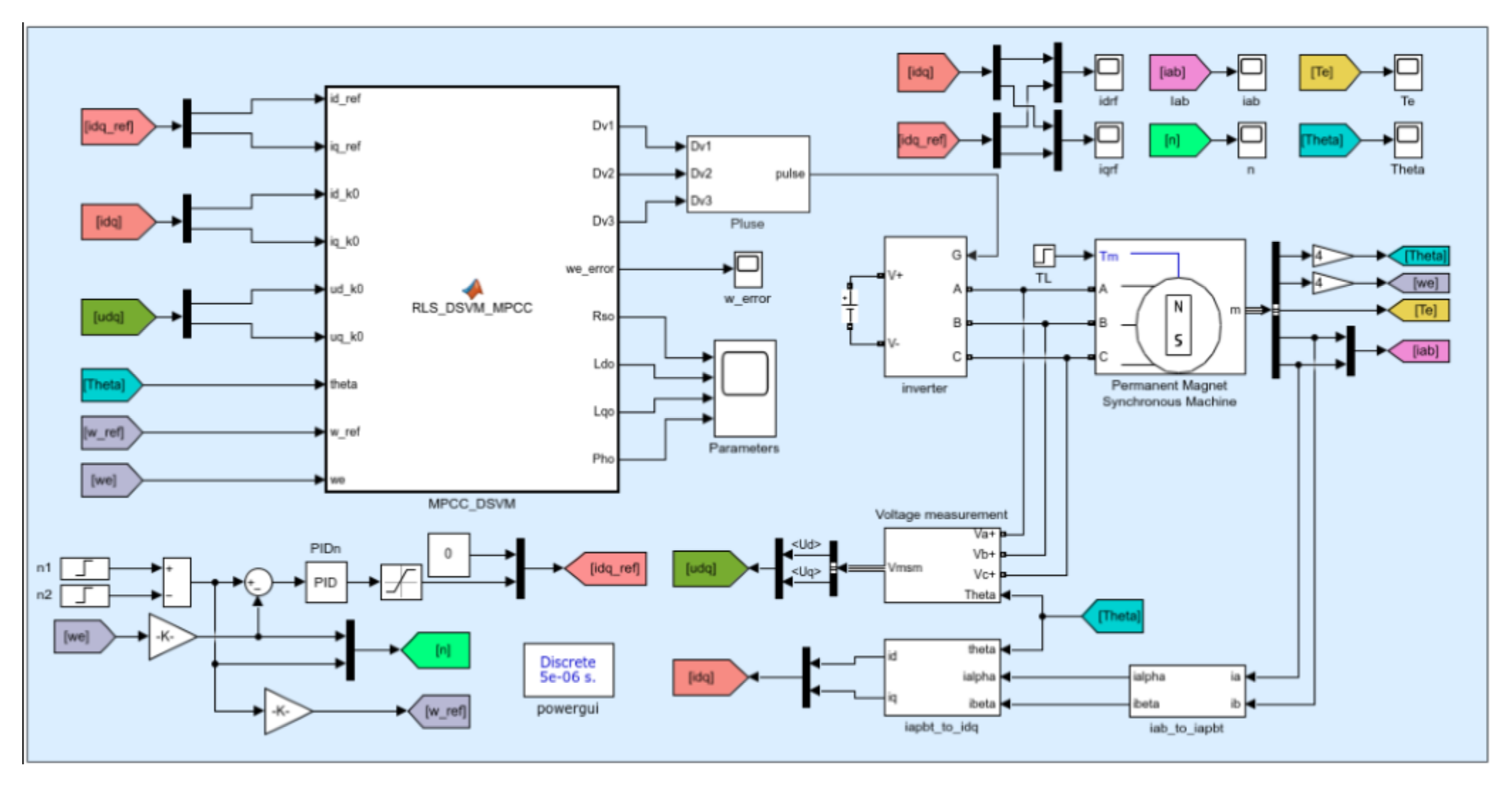

2. The Principles of RLS-DSVM-MPC

2.1. The Mathematical Model of PMSM

2.2. The Principles of MPCC

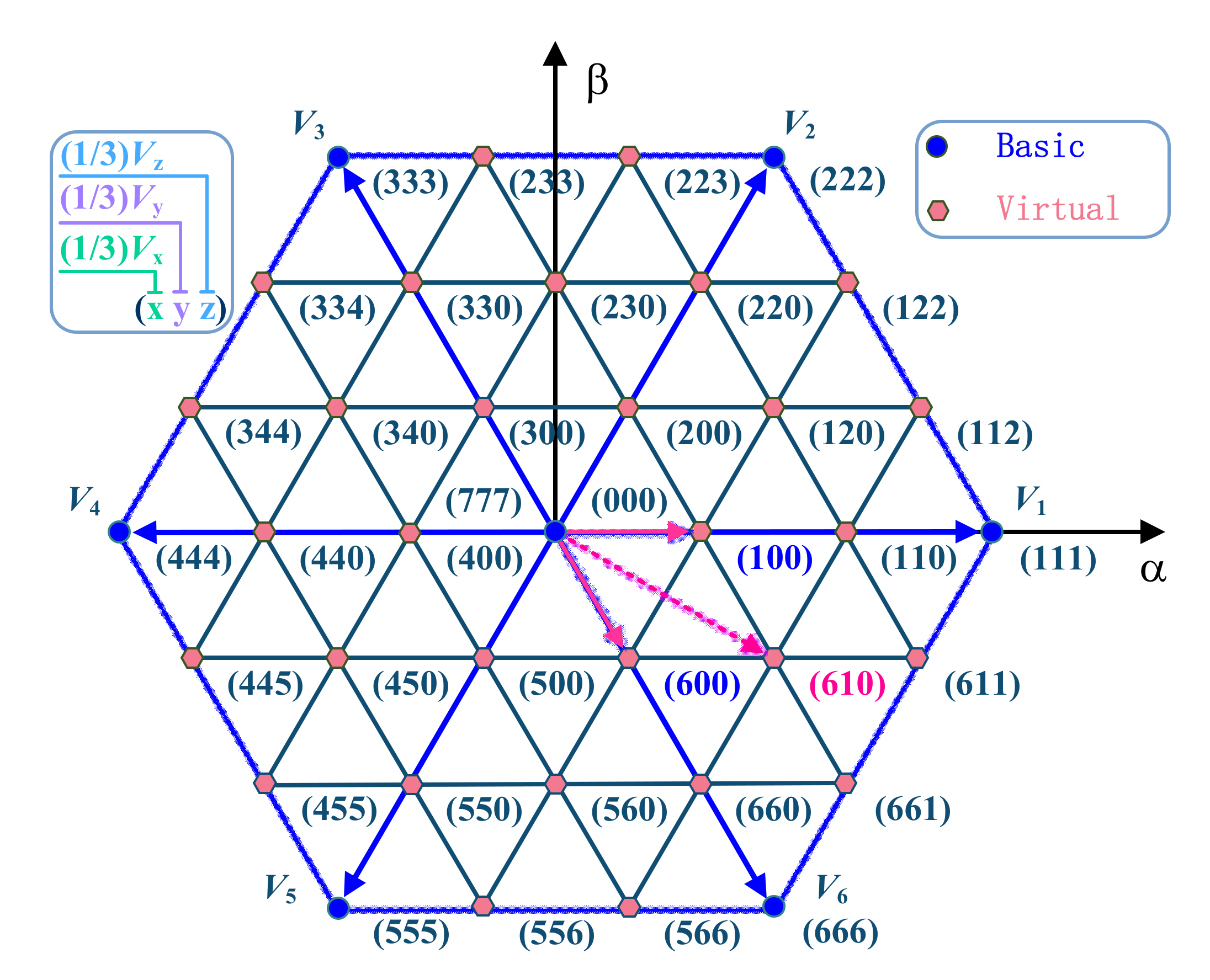

2.3. The Principles of DSVM

2.4. Parameter Identification Using RLS

3. The Implementation of RLS-DSVM-MPC

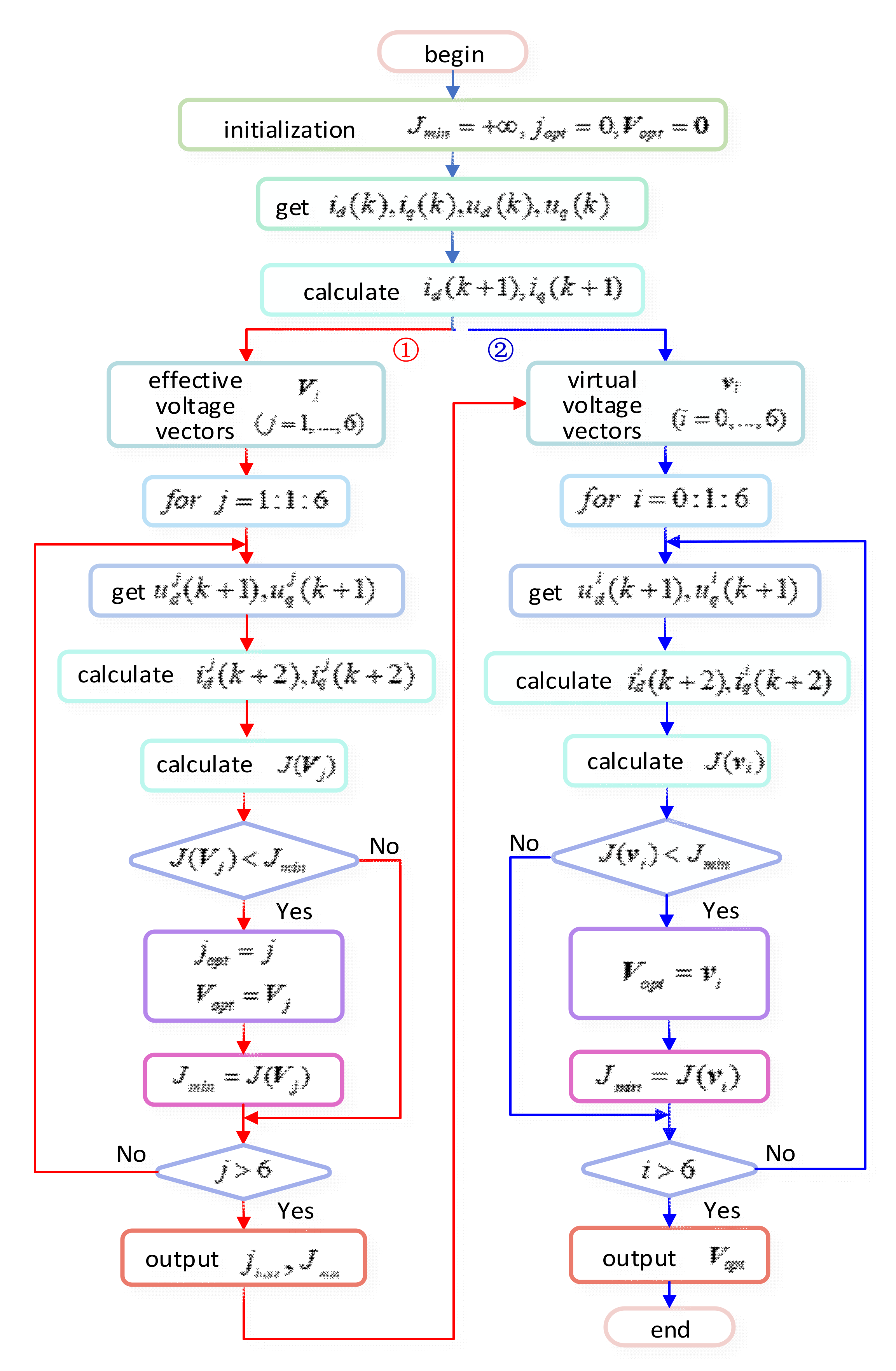

3.1. The Implementation of DSVM-MPCC Module

3.2. The Realization of RLS Parameter Identification

3.3. The Update Conditions of RLS Parameter Identification

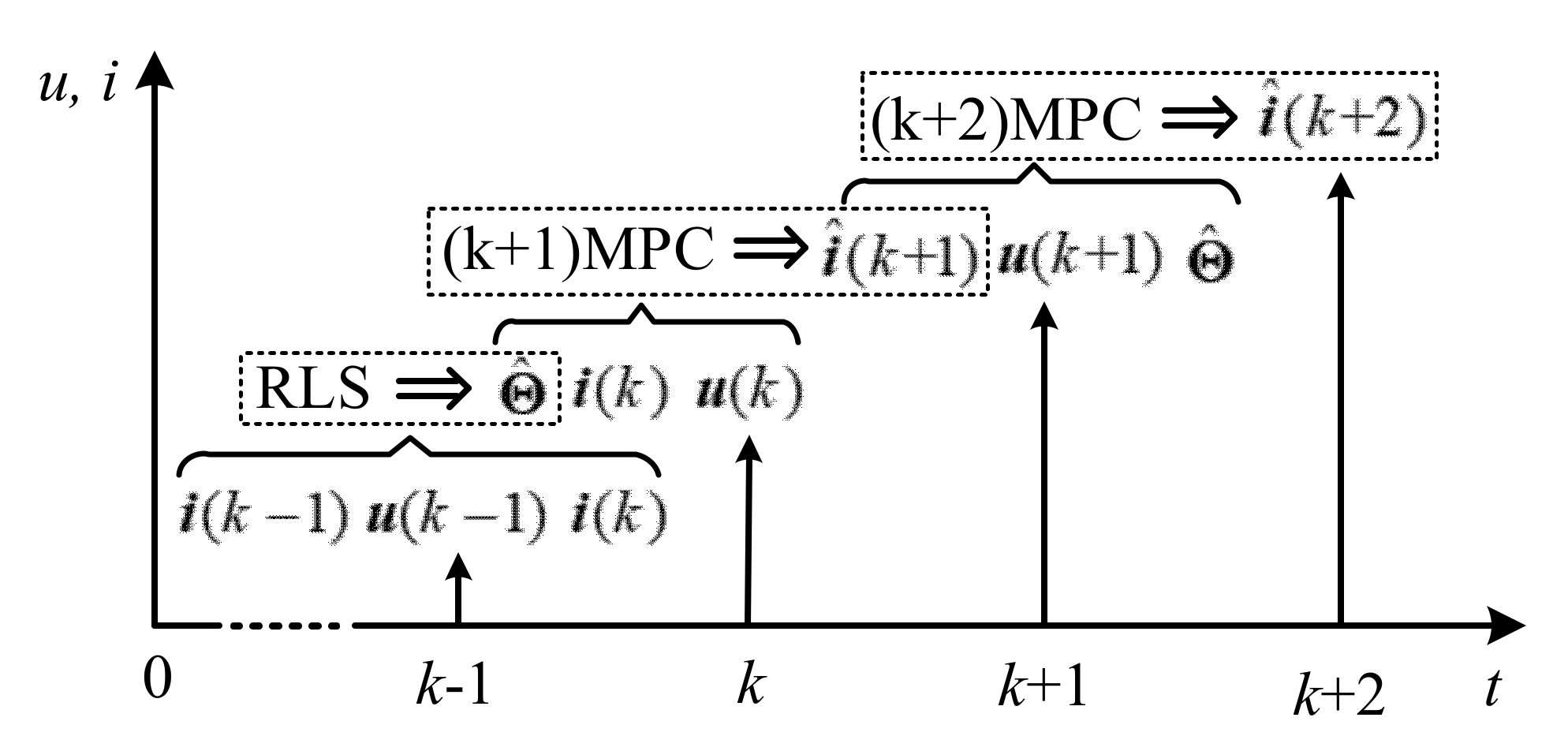

3.4. The Time Sequence of RLS Parameter Identification and MPC

4. Results and Analysis of Simulation

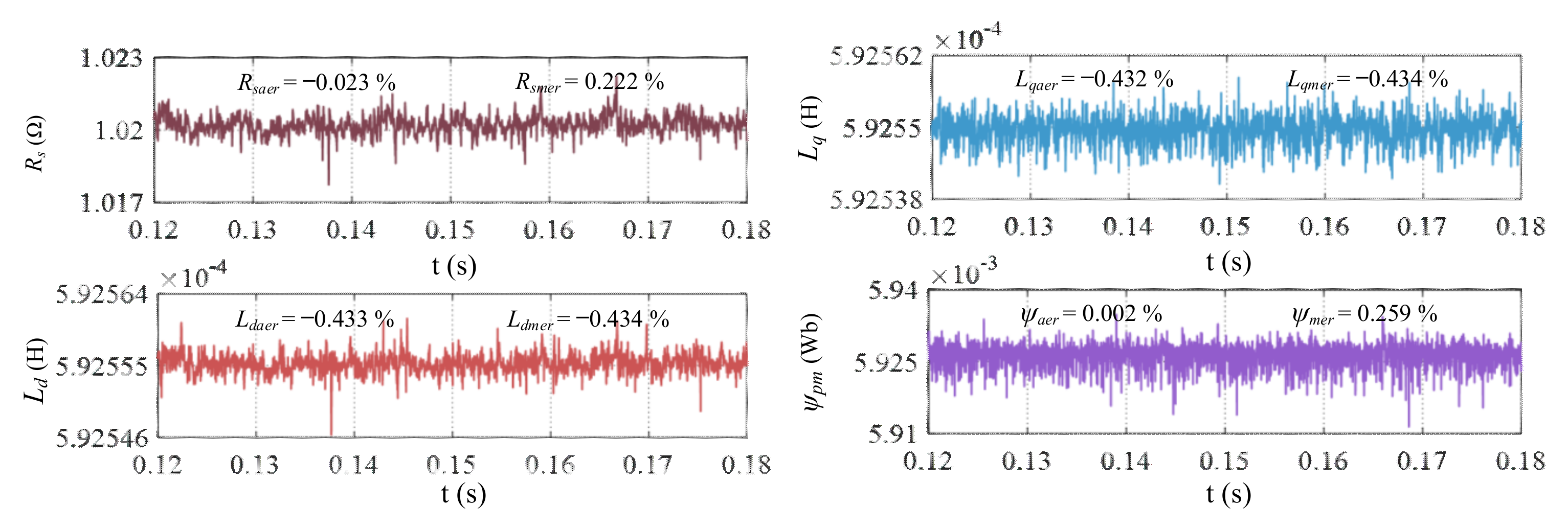

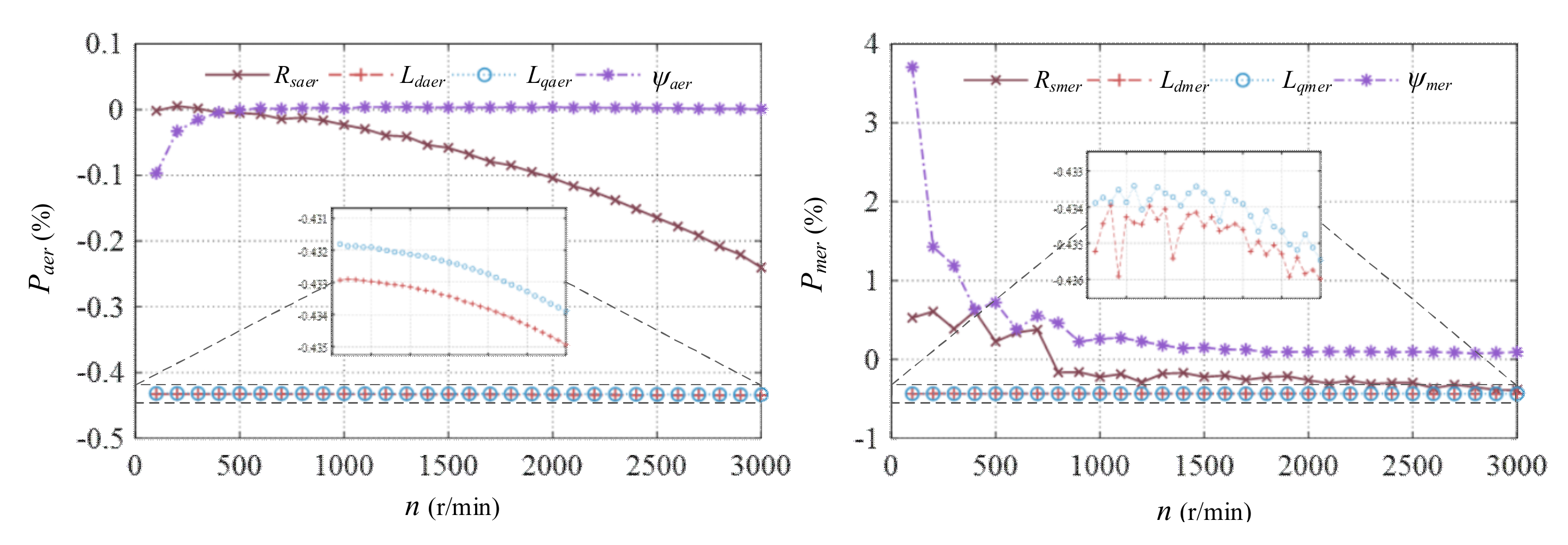

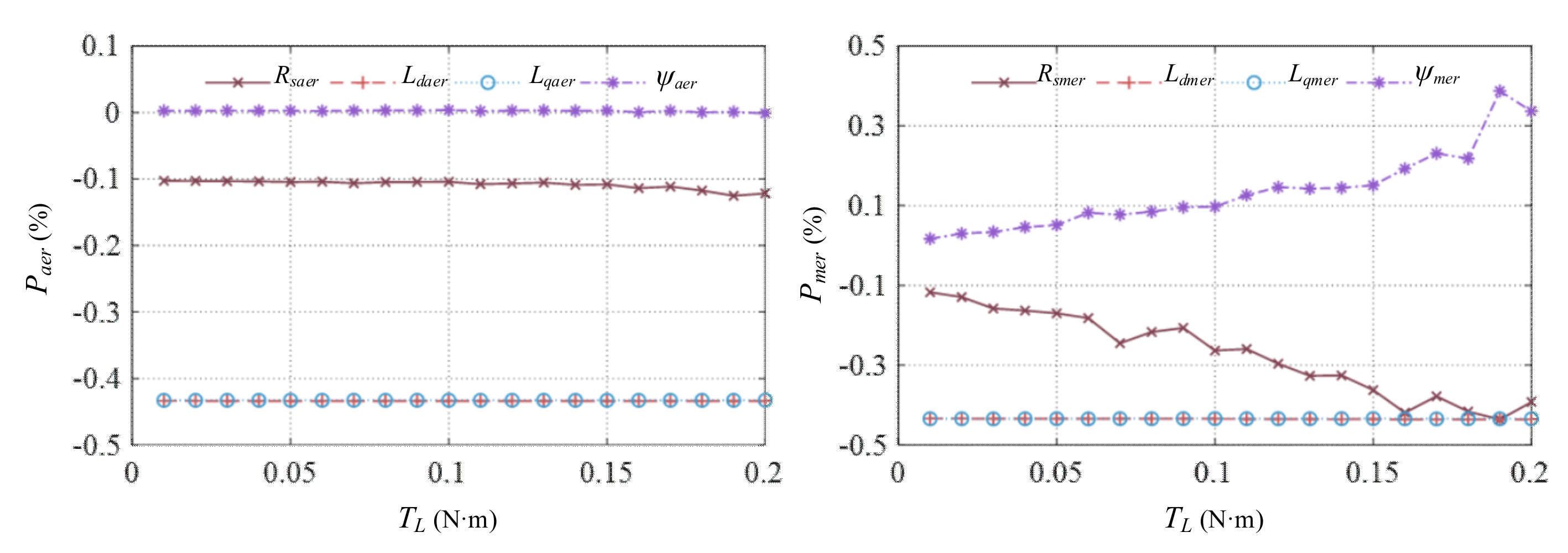

4.1. Static Accuracy of RLS-DSVM-MPC

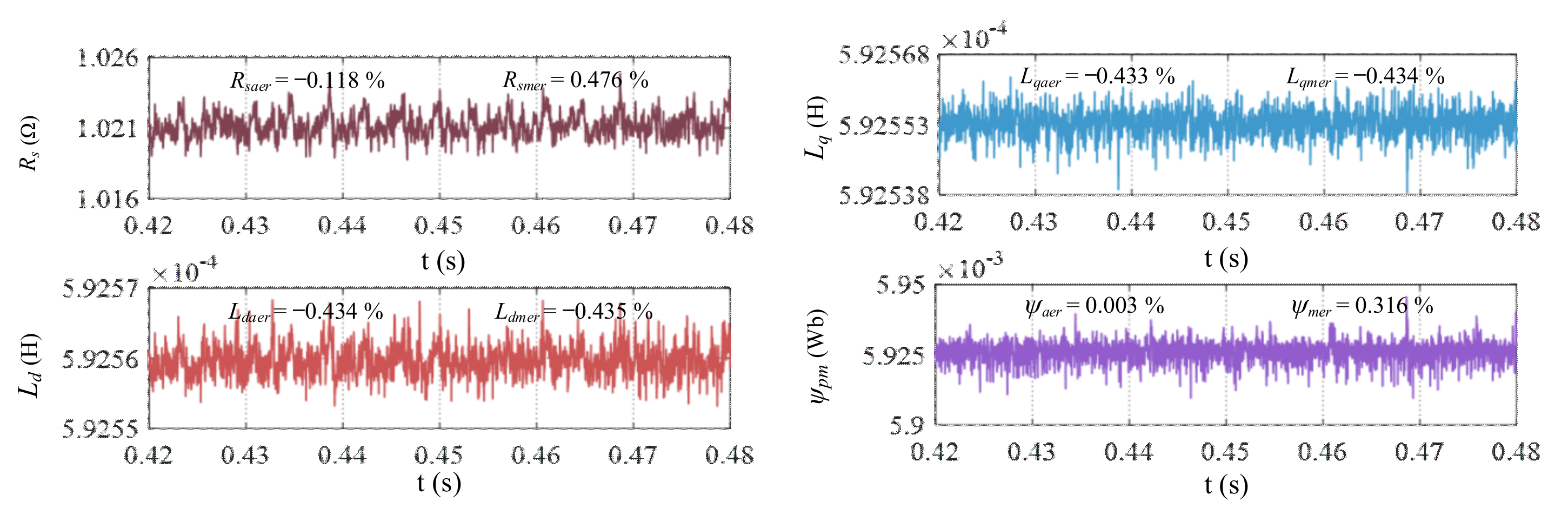

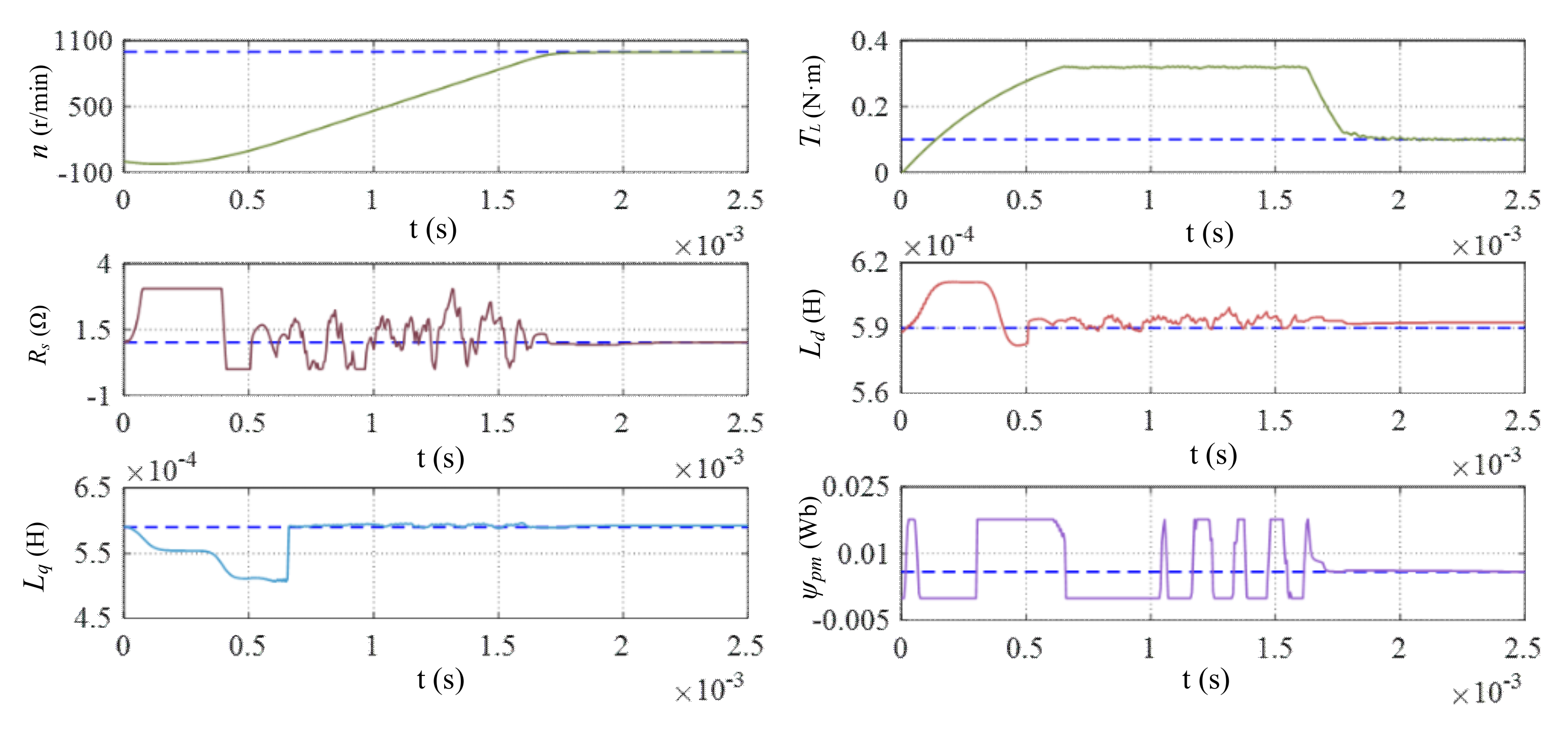

4.2. Dynamic Accuracy of RLS-DSVM-MPC

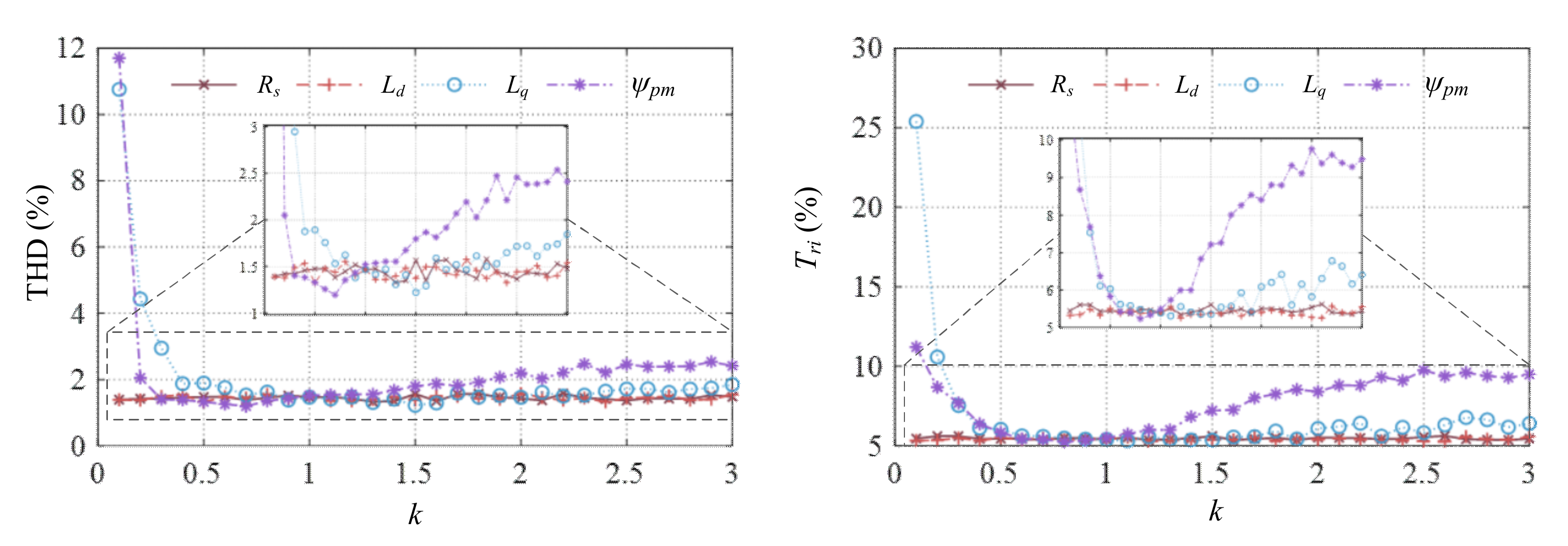

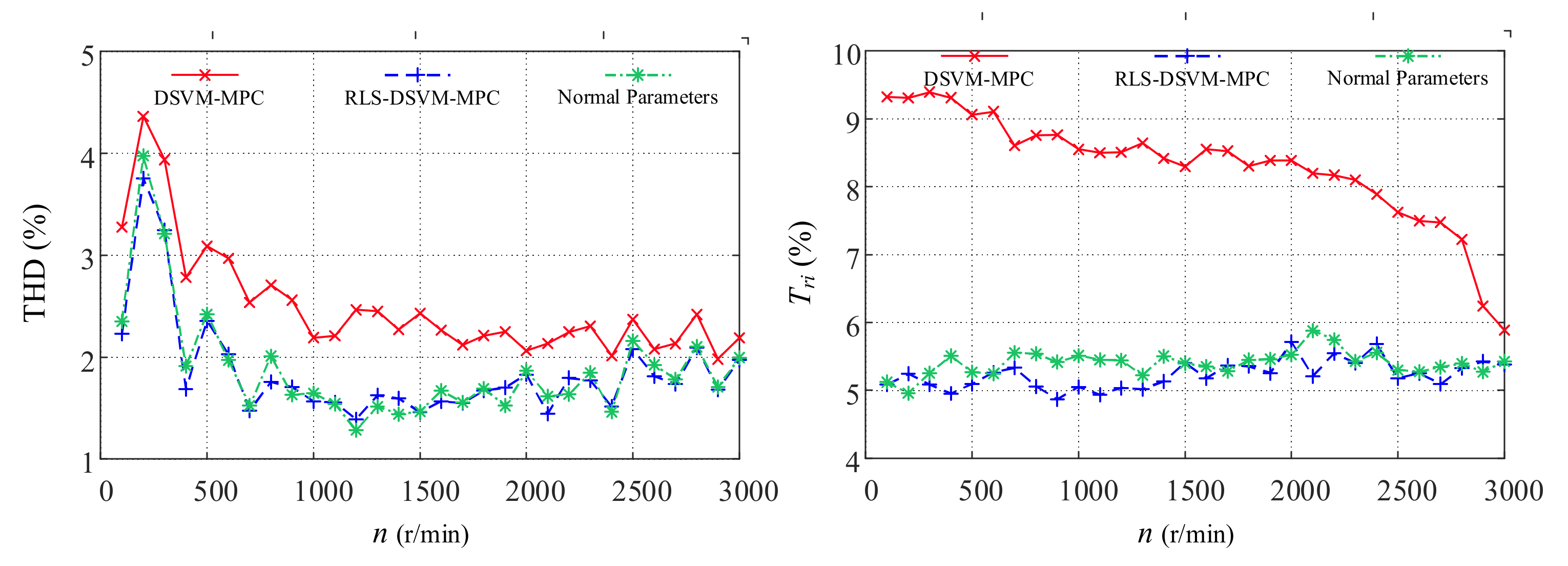

4.3. Performance Analysis of DSVM-MPC and RLS-DSVM-MPC

- —the harmonic component,

- —the fundamental component,

- —the th harmonic.

- —the maximum value of the torque,

- —the minimum value of the torque,

- —the value of the normal torque.

5. Conclusions

- (1)

- RLS parameter identification was proposed to predict the PMSM parameters. Through the proposed method, the PMSM parameters can be identified accurately. and compared with the traditional DSVM-MPC, the proposed RLS-DSVM-MPC has a much better control performance.

- (2)

- A preselection method for candidate voltage vectors in DSVM were introduced, it can reduce the number of candidate voltage vectors from 38 to 13, and greatly release the computational burden of DSVM-MPC.

- (3)

- Through the results of simulation, we found that the accuracy of identified parameters are mainly affected by velocity while rarely affected by load, and the accuracy in high velocity is better than that in low velocity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Leng, J. Summary on development of permanent magnet synchronous motor. In Proceedings of the Chinese Control and Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 689–693. [Google Scholar]

- Ichikawa, S.; Tomita, M.; Doki, S.; Okuma, S. Sensorless control of permanent-magnet synchronous motors using online parameter identification based on system identification theory. IEEE Trans. Ind. Electron. 2006, 53, 363–372. [Google Scholar] [CrossRef]

- Casadei, D.; Profumo, F.; Serra, G.; Tani, A. FOC and DTC: Two viable schemes for induction motors torque control. IEEE Trans. Power Electron. 2002, 17, 779–787. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.K.; Nam, K.; Lim, S.K. A simple indirect field-oriented control scheme for multiphase induction machine. IEEE Trans. Ind. Electron. 2005, 52, 1177–1184. [Google Scholar] [CrossRef]

- Bao, G.; Qi, W.; He, T. Direct Torque Control of PMSM with Modified Finite Set Model Predictive Control. Energies 2020, 13, 234. [Google Scholar] [CrossRef] [Green Version]

- Buja, G.S.; Kazmierkowski, M.P. Direct torque control of PWM inverter-fed AC motors-a survey. IEEE Trans. Ind. Electron. 2004, 51, 744–757. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Liang, D.; Liu, K. Online parameter estimation for permanent magnet synchronous machines: An overview. IEEE Access 2021, 9, 59059–59084. [Google Scholar] [CrossRef]

- Vazquez, S.; Rodriguez, J.; Rivera, M.; Franquelo, L.G.; Norambuena, M. Model predictive control for power converters and drives: Advances and trends. IEEE Trans. Ind. Electron. 2016, 64, 935–947. [Google Scholar] [CrossRef] [Green Version]

- Leon, J.I.; Kouro, S.; Franquelo, L.G.; Rodriguez, J.; Wu, B. The essential role and the continuous evolution of modulation techniques for voltage-source inverters in the past, present, and future power electronics. IEEE Trans. Ind. Electron. 2016, 63, 2688–2701. [Google Scholar] [CrossRef]

- Judewicz, M.G.; González, S.A.; Echeverría, N.I.; Fischer, J.R.; Carrica, D.O. Generalized predictive current control (GPCC) for grid-tie three-phase inverters. IEEE Trans. Ind. Electron. 2015, 63, 4475–4484. [Google Scholar] [CrossRef]

- Almér, S.; Mariethoz, S.; Morari, M. Sampled data model predictive control of a voltage source inverter for reduced harmonic distortion. IEEE T. Contr. Syst. T. 2012, 21, 1907–1915. [Google Scholar] [CrossRef]

- Geyer, T.; Quevedo, D.E. Multistep finite control set model predictive control for power electronics. IEEE Trans. Power Electron. 2014, 29, 6836–6846. [Google Scholar] [CrossRef]

- Vazquez, S.; Marquez, A.; Aguilera, R.; Quevedo, D.; Leon, J.I.; Franquelo, L.G. Predictive optimal switching sequence direct power control for grid-connected power converters. IEEE Trans. Ind. Electron. 2014, 62, 2010–2020. [Google Scholar] [CrossRef] [Green Version]

- Kouro, S.; Cortés, P.; Vargas, R.; Ammann, U.; Rodríguez, J. Model predictive control—A simple and powerful method to control power converters. IEEE Trans. Ind. Electron. 2008, 56, 1826–1838. [Google Scholar] [CrossRef]

- Geyer, T.; Beccuti, G.A.; Papafotiou, G.; Morari, M. Model predictive direct torque control of permanent magnet synchronous motors. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 199–206. [Google Scholar]

- Rodríguez, J.; Kennel, R.M.; Espinoza, J.R.; Trincado, M.; Silva, C.A.; Rojas, C.A. High-performance control strategies for electrical drives: An experimental assessment. IEEE Trans. Ind. Electron. 2011, 59, 812–820. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H. Model predictive torque control of induction motor drives with optimal duty cycle control. IEEE Trans. Power Electron. 2014, 29, 6593–6603. [Google Scholar] [CrossRef]

- Casadei, D.; Serra, G.; Tani, K. Implementation of a direct control algorithm for induction motors based on discrete space vector modulation. IEEE Trans. Power Electron. 2000, 15, 769–777. [Google Scholar] [CrossRef]

- Wei, X.; Chen, D.; Zhao, C. Minimization of torque ripple of direct-torque controlled induction machines by improved discrete space vector modulation. Electr. Pow. Syst. Res. 2004, 72, 103–112. [Google Scholar] [CrossRef]

- Vazquez, S.; Aguilera, R.P.; Acuna, P.; Pou, J.; Leon, J.I.; Franquelo, L.G.; Agelidis, V.G. Model predictive control for single-phase NPC converters based on optimal switching sequences. IEEE Trans. Ind. Electron. 2016, 63, 7533–7541. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Xia, C.; Yan, Y.; Wang, Z.; Shi, T. Torque ripple minimization of predictive torque control for PMSM with extended control set. IEEE Trans. Ind. Electron. 2017, 64, 6930–6939. [Google Scholar] [CrossRef]

- Hassine, I.M.B.; Naouar, M.W.; Mrabet-Bellaaj, N. Model predictive-sliding mode control for three-phase grid-connected converters. IEEE Trans. Ind. Electron. 2016, 64, 1341–1349. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Xie, W.; Wang, F.; Dou, M.; Kennel, R.M.; Gerling, D. Deadbeat model-predictive torque control with discrete space-vector modulation for PMSM drives. IEEE Trans. Ind. Electron. 2017, 64, 3537–3547. [Google Scholar] [CrossRef]

- Moon, H.C.; Lee, J.S.; Lee, K.B. A robust deadbeat finite set model predictive current control based on discrete space vector modulation for a grid-connected voltage source inverter. IEEE T. Energy Conver. 2018, 33, 1719–1728. [Google Scholar]

- Wang, T.; Liu, C.; Lei, G.; Guo, Y.; Zhu, J. Model predictive direct torque control of permanent magnet synchronous motors with extended set of voltage space vectors. IET Electr. Power App. 2017, 11, 1376–1382. [Google Scholar] [CrossRef]

- Amiri, M.; Milimonfared, J.; Khaburi, D.A. Predictive torque control implementation for induction motors based on discrete space vector modulation. IEEE Trans. Ind. Electron. 2018, 65, 6881–6889. [Google Scholar] [CrossRef]

- Lin, F.J.; Chen, S.Y.; Lin, W.T.; Liu, C.W. An online parameter estimation using current injection with intelligent current-loop control for ipmsm drives. Energies 2021, 14, 8138. [Google Scholar] [CrossRef]

- Rahman, K.M.; Hiti, S. Identification of machine parameters of a synchronous motor. IEEE Trans. Ind. Appl. 2005, 41, 557–565. [Google Scholar] [CrossRef]

- Brosch, A.; Hanke, S.; Wallscheid, O.; Böcker, J. Data-driven recursive least squares estimation for model predictive current control of permanent magnet synchronous motors. IEEE Trans. Power Electron. 2020, 36, 2179–2190. [Google Scholar] [CrossRef]

| Effective Voltage Vector | Group Number | Group Member |

|---|---|---|

| V1 | I | |

| V2 | II | |

| V3 | III | |

| V4 | IV | |

| V5 | V | |

| V6 | VI |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Number of pole pairs | 4 | Rated load | 0.2 N·m |

| Voltage of the bus | 24 V | Stator resistance | 1.02 Ω |

| Rated current | 4 A | Stator inductance | 0.59 mH |

| Rated power | 62 W | Moment of inertia | 28 g·cm2 |

| Rated speed | 3000 rpm | Back EMF Coefficient | 4.3 V/krpm |

| Parameters | P | I | D |

|---|---|---|---|

| Value | 0.2 | 1.5 | 0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Wang, J.; Xin, Z. Model Predictive Control for PMSM Based on Discrete Space Vector Modulation with RLS Parameter Identification. Energies 2022, 15, 4041. https://doi.org/10.3390/en15114041

Yu H, Wang J, Xin Z. Model Predictive Control for PMSM Based on Discrete Space Vector Modulation with RLS Parameter Identification. Energies. 2022; 15(11):4041. https://doi.org/10.3390/en15114041

Chicago/Turabian StyleYu, Hao, Jiajun Wang, and Zhuangzhuang Xin. 2022. "Model Predictive Control for PMSM Based on Discrete Space Vector Modulation with RLS Parameter Identification" Energies 15, no. 11: 4041. https://doi.org/10.3390/en15114041

APA StyleYu, H., Wang, J., & Xin, Z. (2022). Model Predictive Control for PMSM Based on Discrete Space Vector Modulation with RLS Parameter Identification. Energies, 15(11), 4041. https://doi.org/10.3390/en15114041