Effect of Combined Particle Size Reduction and Fe3O4 Additives on Biogas and Methane Yields of Arachis hypogea Shells at Mesophilic Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Analysis

2.3. Experimental Set Up

3. Results and Discussions

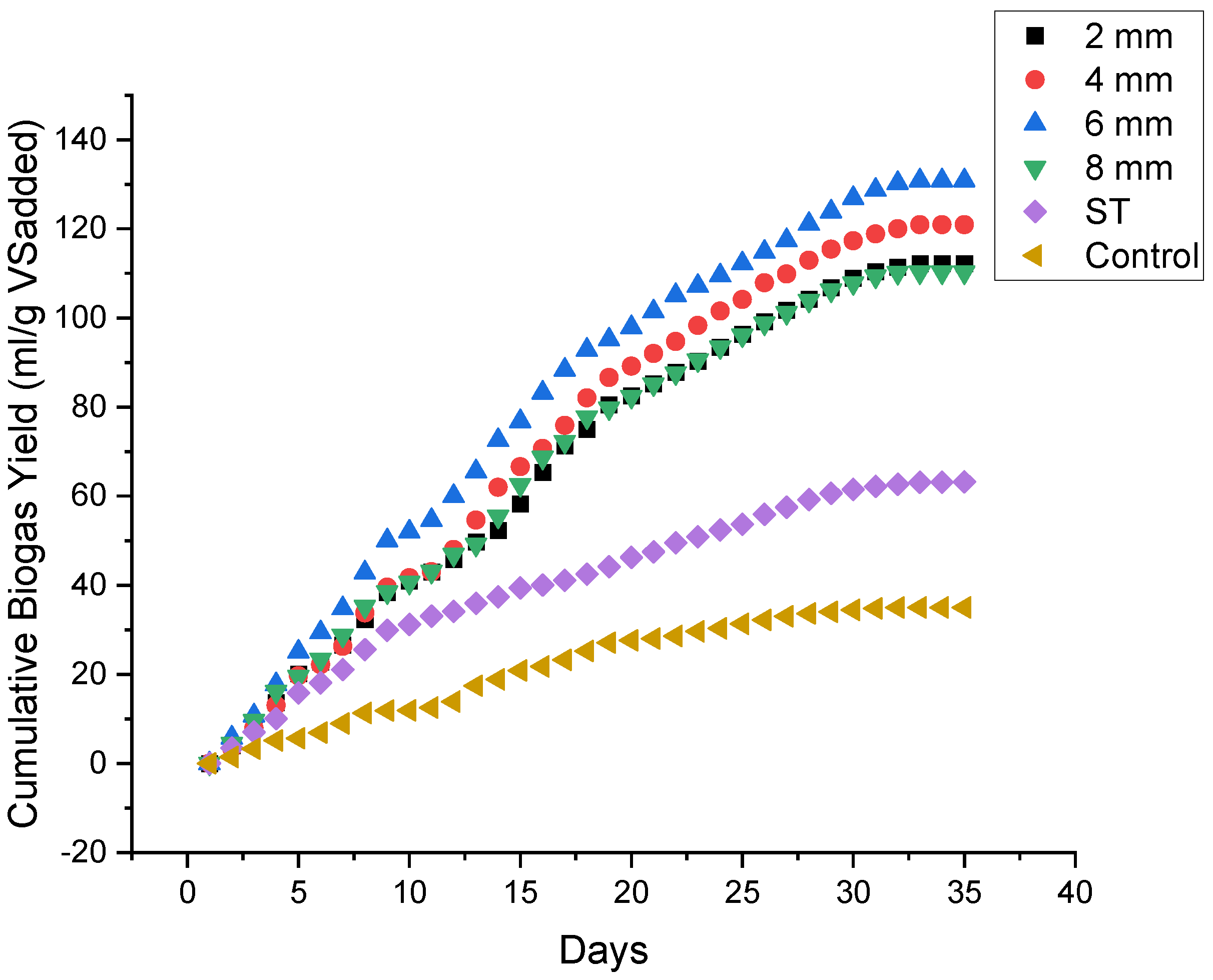

3.1. Effects of Pretreatment on Cumulative Biogas Yield

3.2. Effects of Pretreatment on Cumulative Methane Yield

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muralikrishna, I.V.; Manickam, V. Natural Resource Management and Biodiversity Conservation. In Environmental Management; BSP Books, Pvt Ltd.: Hyderabad, India, 2017; pp. 23–35. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Yang, H.; Xia, M.; Li, K.; Chen, X.; Chen, H. Co-pyrolysis of lignocellulosic biomass and microalgae: Products characteristics and interaction effect. Bioresour. Technol. 2017, 245, 860–868. [Google Scholar] [CrossRef] [PubMed]

- Dahunsi, S.O.; Adesulu-Dahunsi, A.T.; Osueke, C.O.; Lawal, A.I.; Olayanju, T.M.A.; Ojediran, J.O.; Izebere, J.O. Biogas generation from Sorghum bicolor stalk: Effect of pretreatment methods and economic feasibility. Energy Rep. 2019, 5, 584–593. [Google Scholar] [CrossRef]

- Mirmohamadsadeghi, S.; Karimi, K.; Zamani, A.; Amiri, H.; Horváth, I.S. Enhanced solid-state biogas production from lignocellulosic biomass by organosolv pretreatment. BioMed Res. Int. 2014, 2014, 350414. [Google Scholar] [CrossRef] [PubMed]

- Mo, T.; Lau, K.T.; Li, Y.; Poon, C.K.; Wu, Y.; Chu, P.K.; Luo, Y. Commercialization of Electric Vehicles in Hong Kong. Energies 2022, 15, 942. [Google Scholar] [CrossRef]

- Dahunsi, S.O. Mechanical pretreatment of lignocelluloses for enhanced biogas production: Methane yield prediction from biomass structural components. Bioresour. Technol. 2019, 280, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Lizasoain, J.; Rincón, M.; Theuretzbacher, F.; Enguídanos, R.; Nielsen, P.J.; Potthast, A.; Zweckmair, T.; Gronauer, A.; Bauer, A. Biogas production from reed biomass: Effect of pretreatment using different steam explosion conditions. Biomass Bioenergy 2016, 95, 84–91. [Google Scholar] [CrossRef]

- Alfa, I.M.; Dahunsi, S.O.; Iorhemen, O.T.; Okafor, C.C.; Ajayi, S.A. Comparative evaluation of biogas production from Poultry droppings, Cow dung and Lemon grass. Bioresour. Technol. 2014, 157, 270–277. [Google Scholar] [CrossRef] [Green Version]

- Piechota, G. Removal of siloxanes from biogas upgraded to biomethane by Cryogenic Temperature Condensation System. J. Clean. Prod. 2021, 308, 127404. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Olatunji, K.O.; Jo, A. Comparative Analysis of Co-Digestion of Cow Dung and Jatropha Cake at Ambient Temperature. J. Fundam. Renew. Energy Appl. 2018, 8, 1000271. [Google Scholar] [CrossRef]

- Xue, Y.; Chen, H.; Zhao, W.; Yang, C.; Ma, P.; Han, S. A review on the operating conditions of producing bio-oil from hydrothermal liquefaction of biomass. Int. J. Energy Res. 2016, 40, 865–877. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A.; Olatunji, K.O. Biogas Yields Variance from Anaerobic Co-Digestion of Cow Dung with Jatropha Cake under Mesophilic Temperatures. J. Phys. Conf. Ser. 2019, 1378, 032060. [Google Scholar] [CrossRef]

- Baghel, R.S.; Trivedi, N.; Gupta, V.; Neori, A.; Reddy, C.R.K.; Lali, A.; Jha, B. Biorefining of marine macroalgal biomass for production of biofuel and commodity chemicals. Green Chem. 2015, 17, 2436–2443. [Google Scholar] [CrossRef]

- Hanjie, Z. Sludge Treatment to Increase Biogas Production; Trita-LWR Degree Project 10-20; Skolan för Arkitektur och Samhällsbyggnad, Kungliga Tekniska Högskolan: Stockholm, Sweden, 2010. [Google Scholar]

- Wyman, V.; Henríquez, J.; Palma, C.; Carvajal, A. Lignocellulosic waste valorisation strategy through enzyme and biogas production. Bioresour. Technol. 2018, 247, 402–411. [Google Scholar] [CrossRef] [PubMed]

- Luo, T.; Huang, H.; Mei, Z.; Shen, F.; Ge, Y.; Hu, G.; Meng, X. Hydrothermal pretreatment of rice straw at relatively lower temperature to improve biogas production via anaerobic digestion. Chin. Chem. Lett. 2019, 30, 1219–1223. [Google Scholar] [CrossRef]

- Olatunji, K.O.; Madyira, D.M.; Ahmed, N.A.; Jekayinfa, S.O.; Ogunkunle, O. Modelling the effects of particle size pretreatment method on biogas yield of groundnut shells. Waste Manag. Res. 2022, 0734242X2110738. [Google Scholar] [CrossRef]

- Moshi, A.P.; Temu, S.G.; Nges, I.A.; Malmo, G.; Hosea, K.M.M.; Elisante, E.; Mattiasson, B. Combined production of bioethanol and biogas from peels of wild cassava Manihot glaziovii. Chem. Eng. J. 2015, 279, 297–306. [Google Scholar] [CrossRef]

- Matsakas, L.; Nitsos, C.; Vörös, D.; Rova, U.; Christakopoulos, P. High-titer methane from organosolv-pretreated spruce and birch. Energies 2017, 10, 263. [Google Scholar] [CrossRef] [Green Version]

- Nges, I.A.; Li, C.; Wang, B.; Xiao, L.; Yi, Z.; Liu, J. Physio-chemical pretreatments for improved methane potential of Miscanthus lutarioriparius. Fuel 2016, 166, 29–35. [Google Scholar] [CrossRef]

- Olatunji, K.O.; Ahmed, N.A.; Ogunkunle, O. Optimization of biogas yield from lignocellulosic materials with different pretreatment methods: A review. Biotechnol. Biofuels 2021, 14, 159. [Google Scholar] [CrossRef]

- Wu, Y.; Qu, J.; Daoud, W.A.; Wang, L.; Qi, T. Flexible composite-nanofiber based piezo-triboelectric nanogenerators for wearable electronics. J. Mater. Chem. A 2019, 7, 13347–13355. [Google Scholar] [CrossRef]

- Faisal, S.; Hafeez, F.Y.; Zafar, Y.; Majeed, S.; Leng, X.; Zhao, S.; Saif, I.; Malik, K.; Li, X. A Review on Nanoparticles as Boon for Biogas Producers—Nano Fuels and Biosensing Monitoring. Appl. Sci. 2018, 9, 59. [Google Scholar] [CrossRef] [Green Version]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Romero-Güiza, M.S.; Vila, J.; Mata-Alvarez, J.; Chimenos, J.M.; Astals, S. The role of additives on anaerobic digestion: A review. Renew. Sustain. Energy Rev. 2016, 58, 1486–1499. [Google Scholar] [CrossRef]

- Xu, R.; Xu, S.; Zhang, L.; Florentino, A.P.; Yang, Z.; Liu, Y. Impact of zero valent iron on blackwater anaerobic digestion. Bioresour. Technol. 2019, 285, 121351. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Shi, X.; Guo, G.; Zhao, A.; Zhao, Y. Stabilization of sewage sludge in the presence of nanoscale zero-valent iron (nZVI): Abatement of odor and improvement of biogas production. J. Mater. Cycles Waste Manag. 2013, 15, 461–468. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Comparison of nanoparticles effects on biogas and methane production from anaerobic digestion of cattle dung slurry. Renew. Energy 2016, 87, 592–598. [Google Scholar] [CrossRef]

- El Nemr, A.; Hassaan, M.A.; Elkatory, M.R.; Ragab, S.; Pantaleo, A. Efficiency of Fe3O4 Nanoparticles with Different Pretreatments for Enhancing Biogas Yield of Macroalgae Ulva intestinalis Linnaeus. Molecules 2021, 26, 5105. [Google Scholar] [CrossRef]

- Hu, Y.; Hao, X.; Zhao, D.; Fu, K. Enhancing the CH4 yield of anaerobic digestion via endogenous CO2 fixation by exogenous H2. Chemosphere 2015, 140, 34–39. [Google Scholar] [CrossRef]

- Casals, E.; Barrena, R.; García, A.; González, E.; Delgado, L.; Busquets-Fité, M.; Font, X.; Arbiol, J.; Glatzel, P.; Kvashnina, K.; et al. Programmed iron oxide nanoparticles disintegration in anaerobic digesters boosts biogas production. Small 2014, 10, 2801–2808. [Google Scholar] [CrossRef] [Green Version]

- Ajeigbe, H.A.; Waliyar, F.; Echekwu, C.A.; Ayuba, K.; Motagi, B.N.; Eniayeju, D.; Inuwa, A. A Farmer’s Guide to Groundnut Production in Nigeria; International Crops Research Institute for the Semi-Arid Tropics: Patancheruvu, India, 2015. [Google Scholar]

- Madhusudhana, B. A Survey on Area, Production and Productivity of Groundnut Crop in India. IOSR J. Econ. Financ. 2013, 1, 1–7. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 20 July 2021).

- Ojiewo, C.O.; Janila, P.; Bhatnagar-Mathur, P.; Pandey, M.K.; Desmae, H.; Okori, P.; Mwololo, J.; Ajeigbe, H.; Njuguna-Mungai, E.; Muricho, G.; et al. Advances in Crop Improvement and Delivery Research for Nutritional Quality and Health Benefits of Groundnut (Arachis hypogaea L.). Front. Plant Sci. 2020, 11, 29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nigam, S.N. Groundnut at a Glance; International Crops Research for the Semi-Arid Tropics: Patancheruvu, India, 2014. [Google Scholar]

- Robert, U.W.; Etuk, S.E.; Agbasi, O.E.; Ekong, S.A.; Nathaniel, E.U.; Anonaba, A.; Nnana, L.A. Valorisation of Waste Carton Paper, Melon Seed Husks, and Groundnut Shells to Thermal Insulation Panels for Structural Applications. Polytechnica 2021, 4, 97–106. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Adebayo, A.O.; Oniya, O.O.; Olatunji, K.O. Comparative Analysis of Biogas and Methane Yields from Different Sizes of Groundnut Shell in a Batch Reactor at Mesophilic Temperature. J. Energy Res. Rev. 2020, 5, 34–44. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, R.; He, Y.; Li, Y.; Feng, L.; Chen, C.; Liu, G. Influence of particle size and alkaline pretreatment on the anaerobic digestion of corn stover. BioResources 2013, 8, 5850–5860. [Google Scholar] [CrossRef] [Green Version]

- AOAC International. Official Methods of Analysis, 21st ed.; AOAC International: Rockville, MD, USA, 2019; Available online: https://www.aoac.org/official-methods-of-analysis-21st-edition-2019/ (accessed on 15 October 2021).

- Verein Deutscher Ingenieure. Organischer Stoffe Substrat Charakterisierung, V. Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests VDI 4630 VDI-RICHTLINIEN; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2016. [Google Scholar]

- Linke, B.; Schelle, H. Solid State Anaerobic Digestion of Organic Wastes. In Proceedings of the Agricultural Engineering into Third Millenium AgEng Warwick, Warwick, UK, 2–7 July; pp. 2–7.

- Luo, Y.; Wu, Y. Comment on “Effects of particle size and coating on decomposition of alumina-extracted residue from high-alumina fly ash”: Proposition of the shrinking cylinder model. J. Hazard. Mater. 2021, 401, 123818. [Google Scholar] [CrossRef]

- Rabii, A.; Aldin, S.; Dahman, Y.; Elbeshbishy, E. A Review on Anaerobic Co-Digestion with a Focus on the Microbial Populations and the Effect of Multi-Stage Digester Configuration. Energies 2019, 12, 1106. [Google Scholar] [CrossRef] [Green Version]

- Grewal, J.; Ahmad, R.; Khare, S.K. Development of cellulase-nanoconjugates with enhanced ionic liquid and thermal stability for in situ lignocellulose saccharification. Bioresour. Technol. 2017, 242, 236–243. [Google Scholar] [CrossRef]

- Perwez, M.; Ahmad, R.; Sardar, M. A reusable multipurpose magnetic nanobiocatalyst for industrial applications. Int. J. Biol. Macromol. 2017, 103, 16–24. [Google Scholar] [CrossRef]

- Ossinga, C.G. Application of Iron Oxide Nanoparticles for Biogas Yield Optimization from Winery Solid Waste and Sorghum Stover. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2020. [Google Scholar]

- Zaidi, A.A.; Feng, R.; Malik, A.; Khan, S.Z.; Shi, Y.; Bhutta, A.J.; Shah, A.H. Combining Microwave Pretreatment with Iron Oxide Nanoparticles Enhanced Biogas and Hydrogen Yield from Green Algae. Processes 2019, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Suanon, F.; Sun, Q.; Li, M.; Cai, X.; Zhang, Y.; Yan, Y.; Yu, C.P. Application of nanoscale zero valent iron and iron powder during sludge anaerobic digestion: Impact on methane yield and pharmaceutical and personal care products degradation. J. Hazard. Mater. 2017, 321, 47–53. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, Y.; Li, Y.; Quan, X.; Zhao, Z. Comparing the mechanisms of ZVI and Fe3O4 for promoting waste-activated sludge digestion. Water Res. 2018, 144, 126–133. [Google Scholar] [CrossRef]

- Andriamanohiarisoamanana, F.J.; Shirai, T.; Yamashiro, T.; Yasui, S.; Iwasaki, M.; Ihara, I.; Nishida, T.; Tangtaweewipat, S.; Umetsu, K. Valorizing waste iron powder in biogas production: Hydrogen sulfide control and process performances. J. Environ. Manag. 2018, 208, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Mu, H.; Zheng, X.; Chen, Y.; Chen, H.; Liu, K. Response of anaerobic granular sludge to a shock load of zinc oxide nanoparticles during biological wastewater treatment. Environ. Sci. Technol. 2012, 46, 5997–6003. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhang, D.; Dai, L.; Chen, Y.; Dai, X. Effects of metal nanoparticles on methane production from waste-activated sludge and microorganism community shift in anaerobic granular sludge. Sci. Rep. 2016, 6, 25857. [Google Scholar] [CrossRef] [PubMed]

- Pu, Y.; Hu, F.; Huang, F.; Davison, B.H.; Ragauskas, A.J. Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol. Biofuels 2013, 6, 15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maroušek, J. Pretreatment of sunflower stalks for biogas production. Clean Technol. Environ. Policy 2013, 15, 735–740. [Google Scholar] [CrossRef]

- Olatunji, K.O.; Ahmed, N.A.; Madyira, D.M.; Adebayo, A.O.; Ogunkunle, O.; Adeleke, O. Performance evaluation of ANFIS and RSM modeling in predicting biogas and methane yields from Arachis hypogea shells pretreated with size reduction. Renew. Energy 2022, 189, 288–303. [Google Scholar] [CrossRef]

- Menardo, S.; Airoldi, G.; Balsari, P. The effect of particle size and thermal pre-treatment on the methane yield of four agricultural by-products. Bioresour. Technol. 2012, 104, 708–714. [Google Scholar] [CrossRef]

- Herrmann, C.; Heiermann, M.; Idler, C.; Prochnow, A. Particle Size Reduction during Harvesting of Crop Feedstock for Biogas Production I: Effects on Ensiling Process and Methane Yields. Bioenergy Res. 2012, 5, 926–936. [Google Scholar] [CrossRef]

- Motte, J.C.; Escudié, R.; Hamelin, J.; Steyer, J.P.; Bernet, N.; Delgenes, J.P.; Dumas, C. Substrate milling pretreatment as a key parameter for Solid-State Anaerobic Digestion optimization. Bioresour. Technol. 2015, 173, 185–192. [Google Scholar] [CrossRef]

- Siddhu, M.A.H.; Li, J.; Zhang, J.; Huang, Y.; Wang, W.; Chen, C.; Liu, G. Improve the Anaerobic Biodegradability by Copretreatment of Thermal Alkali and Steam Explosion of Lignocellulosic Waste. BioMed Res. Int. 2016, 2016, 2786598. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naegele, H.J.; Mönch-Tegeder, M.; Haag, N.L.; Oechsner, H. Effect of substrate pretreatment on particle size distribution in a full-scale research biogas plant. Bioresour. Technol. 2014, 172, 396–402. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, L.F.R.; Bochmann, G. Pretreatment of Feedstock for Enhanced Biogas Production Pretreatment of Feedstock for Enhanced Biogas Production (Electronic Version); IEA: Bioenergy, Austria, 2014; ISBN 978-1-910154-05-2. [Google Scholar]

- Ilhan, Z.E.; Marcus, A.K.; Kang, D.-W.; Rittmann, B.E.; Krajmalnik-Brown, R. pH-Mediated Microbial and Metabolic Interactions in Fecal Enrichment Cultures. mSphere 2017, 2, e00047-17. [Google Scholar] [CrossRef] [Green Version]

- Muvhiiwa, R.F.; Matambo, T.S.; Chafa, P.M.; Chikowore, N.; Chitsiga, T.; Low, M. Effect of Temperature and PH on Biogas Production from Cow Dung and Dog Faeces. Afr. Insight 2016, 45, 167–181. [Google Scholar]

- Prade, T.; Svensson, S.E.; Hörndahl, T.; Kreuger, E. Impact of Harvest Date and Cutting Length of Grass Ley and Whole-Crop Cereals on Methane Yield and Economic Viability as Feedstock for Biogas Vehicle Fuel Production. Bioenergy Res. 2019, 12, 137–149. [Google Scholar] [CrossRef] [Green Version]

- Kulichkova, G.I.; Ivanova, T.S.; Köttner, M.; Volodko, O.I.; Spivak, S.I.; Tsygankov, S.P.; Blume, Y.B. Plant Feedstocks and their Biogas Production Potentials. Open Agric. J. 2020, 14, 219–234. [Google Scholar] [CrossRef]

- Kirby, M.E.; Mirza, M.W.; Hoskyns-Abrahall, H.; Fenwick, J.; Theodorou, M.K. Increasing the Methane Potential of Oat Husks Using a Novel Extrusion Pre-Treatment Technology Prior to Anaerobic Digestion. Front. Energy Res. 2020, 8, 253. [Google Scholar]

- Ajayi-Banji, A.A.; Rahman, S.; Sunoj, S.; Igathinathane, C. Impact of corn stover particle size and C/N ratio on reactor performance in solid-state anaerobic co-digestion with dairy manure. J. Air Waste Manag. Assoc. 2020, 70, 436–454. [Google Scholar] [CrossRef]

- Sreekanth, K.M.; Sahu, D. Effect of iron oxide nanoparticle in bio digestion of a portable food-waste digester. J. Chem. Pharm. Res. 2015, 7, 353–359. [Google Scholar]

- Hassaan, M.A.; Pantaleo, A.; Tedone, L.; Elkatory, M.R.; Ali, R.M.; El Nemr, A.; De Mastro, G. Enhancement of biogas production via green ZnO nanoparticles: Experimental results of selected herbaceous crops. Chem. Eng. Commun. 2021, 208, 242–255. [Google Scholar] [CrossRef]

- Ni, S.Q.; Ni, J.; Yang, N.; Wang, J. Effect of magnetic nanoparticles on the performance of activated sludge treatment system. Bioresour. Technol. 2013, 143, 555–561. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Zhang, Y.; Quan, X.; Chen, S. Enhanced anaerobic digestion of waste activated sludge digestion by the addition of zero valent iron. Water Res. 2014, 52, 242–250. [Google Scholar] [CrossRef] [PubMed]

- Men, Y.; Zheng, L.; Zhang, L.; Li, Z.; Wang, X.; Zhou, X.; Cheng, S.; Bao, W. Effects of Adding Zero Valent Iron on the Anaerobic Digestion of Cow Manure and Lignocellulose. Front. Bioeng. Biotechnol. 2020, 8, 1216. [Google Scholar] [CrossRef] [PubMed]

- Duc, N.M. Effects of CeO2 and ZnO Nanoparticles on Anaerobic Digestion and Toxicity of Digested Sludge. Master’s Thesis, Asian Institute of Technology, Khlong Nueng, Thailand, 2013. [Google Scholar]

- Otero-González, L.; Field, J.A.; Sierra-Alvarez, R. Inhibition of anaerobic wastewater treatment after long-term exposure to low levels of CuO nanoparticles. Water Res. 2014, 58, 160–168. [Google Scholar] [CrossRef] [PubMed]

- Nalinga, Y.; Legonda, I. The Effect of Particles Size on Biogas Production. Int. J. Innov. Res. Technol. Sci. 2016, 4, 9–13. [Google Scholar]

| Parameters | Substrate | Inoculum |

|---|---|---|

| Cellulose (%) | 38.21 | NA |

| Hemicellulose (%) | 18.22 | NA |

| Lignin (%) | 27.68 | NA |

| Total Solid (TS) (%) | 95.51 | 4.01 |

| Volatile Solid (VS) (%) | 91.27 | 84.83 |

| Ash content (%) | 5.96 | 13.07 |

| Moisture content (%) | 4.49 | 95.99 |

| Nitrogen (%) | 1.50 | 1.48 |

| Carbon (%) | 36.39 | 42.57 |

| Hydrogen (%) | 4.79 | 5.50 |

| Sulphur (%) | 0.53 | 0.60 |

| Digester | Treatment |

|---|---|

| A | 2 mm particle size |

| B | 4 mm particle size |

| C | 6 mm particle size |

| D | 8 mm particle size |

| E | Non-mechanical |

| F | Untreated substrate |

| Days | 2 mm | 4 mm | 6 mm | 8 mm | Single Treatment | Control |

|---|---|---|---|---|---|---|

| 1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 2 | 4.07 | 3.37 | 5.80 | 4.46 | 3.50 | 1.47 |

| 3 | 8.51 | 7.94 | 10.75 | 9.59 | 7.05 | 3.29 |

| 4 | 13.67 | 13.06 | 17.75 | 16.12 | 10.08 | 5.16 |

| 5 | 20.13 | 19.68 | 25.11 | 19.52 | 15.87 | 5.65 |

| 6 | 22.76 | 22.19 | 29.41 | 23.37 | 18.13 | 6.88 |

| 7 | 26.59 | 26.28 | 34.81 | 28.75 | 21.11 | 8.97 |

| 8 | 32.30 | 33.78 | 42.84 | 35.22 | 25.55 | 11.31 |

| 9 | 38.42 | 39.59 | 50.04 | 38.48 | 29.92 | 11.85 |

| 10 | 40.91 | 41.69 | 52.04 | 40.62 | 31.18 | 11.90 |

| 11 | 42.94 | 43.03 | 54.65 | 43.06 | 33.05 | 12.53 |

| 12 | 45.77 | 48.05 | 60.04 | 46.88 | 34.12 | 13.89 |

| 13 | 49.77 | 54.62 | 65.55 | 49.14 | 35.98 | 17.45 |

| 14 | 52.34 | 62.00 | 72.56 | 55.43 | 37.39 | 18.90 |

| 15 | 58.24 | 66.60 | 76.80 | 62.57 | 39.42 | 20.88 |

| 16 | 65.36 | 70.72 | 83.20 | 68.67 | 40.06 | 21.78 |

| 17 | 71.26 | 75.88 | 88.36 | 72.26 | 41.13 | 23.26 |

| 18 | 75.01 | 82.04 | 92.84 | 77.71 | 42.49 | 25.25 |

| 19 | 80.48 | 86.63 | 95.14 | 79.73 | 44.17 | 27.11 |

| 20 | 82.54 | 89.16 | 97.87 | 82.33 | 46.28 | 27.63 |

| 21 | 82.17 | 92.03 | 101.47 | 85.13 | 47.51 | 28.03 |

| 22 | 87.81 | 94.71 | 105.10 | 87.66 | 49.54 | 28.59 |

| 23 | 90.34 | 98.32 | 107.16 | 90.53 | 50.86 | 29.65 |

| 24 | 93.40 | 101.55 | 109.55 | 93.45 | 52.40 | 30.31 |

| 25 | 96.35 | 104.12 | 112.21 | 96.11 | 53.72 | 31.35 |

| 26 | 99.19 | 107.89 | 114.82 | 98.81 | 55.95 | 32.22 |

| 27 | 101.78 | 109.87 | 117.42 | 101.14 | 57.51 | 33.01 |

| 28 | 104.21 | 112.96 | 121.07 | 103.91 | 59.25 | 33.67 |

| 29 | 106.78 | 115.43 | 123.88 | 106.19 | 60.64 | 34.02 |

| 30 | 108.93 | 117.32 | 126.88 | 107.84 | 61.53 | 34.49 |

| 31 | 110.37 | 118.86 | 128.72 | 109.35 | 62.17 | 34.82 |

| 32 | 111.44 | 120.02 | 130.25 | 110.17 | 62.66 | 34.99 |

| 33 | 112.16 | 120.92 | 130.85 | 110.25 | 63.08 | 34.99 |

| 34 | 112.16 | 120.92 | 130.85 | 110.25 | 63.17 | 34.99 |

| 35 | 112.16 | 120.92 | 130.85 | 110.25 | 63.19 | 34.99 |

| Days | 2 mm | 4 mm | 6 mm | 8 mm | Single Treatment | Control |

|---|---|---|---|---|---|---|

| 1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 2 | 3.21 | 2.41 | 4.47 | 2.63 | 2.71 | 1.05 |

| 3 | 7.04 | 5.50 | 8.27 | 5.42 | 5.49 | 2.33 |

| 4 | 11.79 | 9.10 | 13.64 | 8.74 | 7.81 | 3.64 |

| 5 | 14.30 | 13.75 | 19.34 | 12.93 | 12.35 | 3.96 |

| 6 | 17.02 | 15.57 | 22.65 | 14.52 | 14.15 | 4.81 |

| 7 | 20.91 | 18.46 | 26.80 | 15.10 | 16.54 | 6.24 |

| 8 | 25.54 | 23.86 | 32.98 | 18.87 | 20.06 | 7.90 |

| 9 | 27.96 | 27.92 | 38.56 | 22.94 | 23.51 | 8.27 |

| 10 | 29.62 | 29.25 | 40.11 | 24.36 | 24.50 | 8.29 |

| 11 | 31.40 | 30.15 | 42.11 | 25.48 | 26.01 | 8.65 |

| 12 | 33.93 | 33.95 | 46.29 | 27.17 | 26.87 | 9.54 |

| 13 | 35.41 | 38.74 | 50.59 | 29.70 | 28.34 | 12.06 |

| 14 | 39.48 | 44.45 | 55.44 | 31.19 | 29.46 | 13.08 |

| 15 | 45.19 | 47.16 | 59.23 | 35.11 | 31.07 | 14.52 |

| 16 | 50.08 | 49.63 | 64.15 | 39.91 | 31.53 | 15.11 |

| 17 | 52.97 | 52.98 | 68.12 | 43.83 | 32.30 | 16.09 |

| 18 | 56.95 | 57.30 | 71.54 | 46.19 | 33.36 | 17.51 |

| 19 | 58.94 | 59.99 | 73.32 | 49.79 | 34.63 | 18.86 |

| 20 | 60.79 | 61.78 | 75.81 | 50.93 | 36.29 | 19.20 |

| 21 | 62.76 | 63.82 | 78.53 | 52.48 | 37.27 | 19.27 |

| 22 | 64.54 | 65.74 | 81.87 | 54.05 | 38.93 | 19.62 |

| 23 | 66.72 | 68.15 | 83.01 | 55.52 | 40.00 | 20.37 |

| 24 | 69.00 | 70.22 | 84.87 | 57.38 | 41.23 | 20.81 |

| 25 | 71.06 | 71.90 | 86.90 | 59.19 | 42.27 | 21.52 |

| 26 | 73.10 | 74.45 | 88.92 | 62.21 | 44.08 | 22.15 |

| 27 | 74.87 | 75.72 | 90.90 | 63.74 | 45.31 | 22.68 |

| 28 | 76.78 | 77.98 | 93.71 | 65.13 | 46.60 | 23.13 |

| 29 | 78.48 | 79.64 | 95.82 | 66.65 | 47.69 | 23.37 |

| 30 | 79.61 | 80.98 | 98.01 | 67.83 | 48.34 | 23.69 |

| 31 | 80.41 | 82.06 | 99.38 | 68.50 | 48.82 | 23.93 |

| 32 | 80.92 | 82.90 | 100.50 | 68.90 | 49.22 | 24.03 |

| 33 | 80.93 | 83.49 | 100.86 | 69.04 | 49.56 | 24.03 |

| 34 | 80.93 | 83.49 | 100.86 | 69.04 | 49.66 | 24.03 |

| 35 | 80.93 | 83.49 | 100.86 | 69.04 | 49.66 | 24.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olatunji, K.O.; Madyira, D.M.; Ahmed, N.A.; Ogunkunle, O. Effect of Combined Particle Size Reduction and Fe3O4 Additives on Biogas and Methane Yields of Arachis hypogea Shells at Mesophilic Temperature. Energies 2022, 15, 3983. https://doi.org/10.3390/en15113983

Olatunji KO, Madyira DM, Ahmed NA, Ogunkunle O. Effect of Combined Particle Size Reduction and Fe3O4 Additives on Biogas and Methane Yields of Arachis hypogea Shells at Mesophilic Temperature. Energies. 2022; 15(11):3983. https://doi.org/10.3390/en15113983

Chicago/Turabian StyleOlatunji, Kehinde O., Daniel M. Madyira, Noor A. Ahmed, and Oyetola Ogunkunle. 2022. "Effect of Combined Particle Size Reduction and Fe3O4 Additives on Biogas and Methane Yields of Arachis hypogea Shells at Mesophilic Temperature" Energies 15, no. 11: 3983. https://doi.org/10.3390/en15113983

APA StyleOlatunji, K. O., Madyira, D. M., Ahmed, N. A., & Ogunkunle, O. (2022). Effect of Combined Particle Size Reduction and Fe3O4 Additives on Biogas and Methane Yields of Arachis hypogea Shells at Mesophilic Temperature. Energies, 15(11), 3983. https://doi.org/10.3390/en15113983