Experimental and Mathematical Investigation of the Thermophysical Properties of Coal–Water Slurries Based on Lignite

Abstract

:1. Introduction

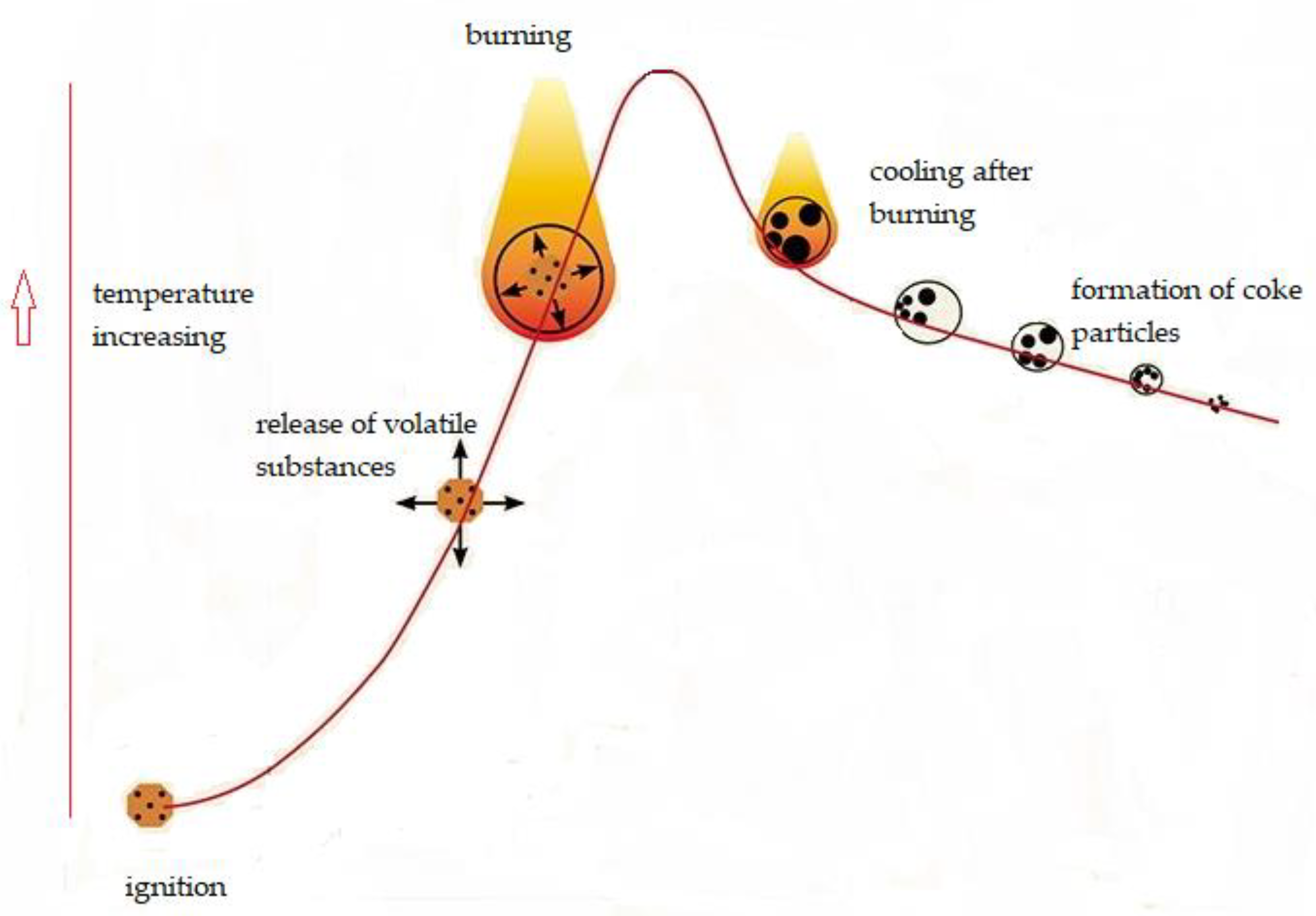

1.1. Information on Developments in the Scientific Field on the Preparation of Coal Dust and Its Further Combustion

1.2. Modern Hypotheses and Their Confirmation by Researchers

1.3. The Purpose and Objectives of the Study

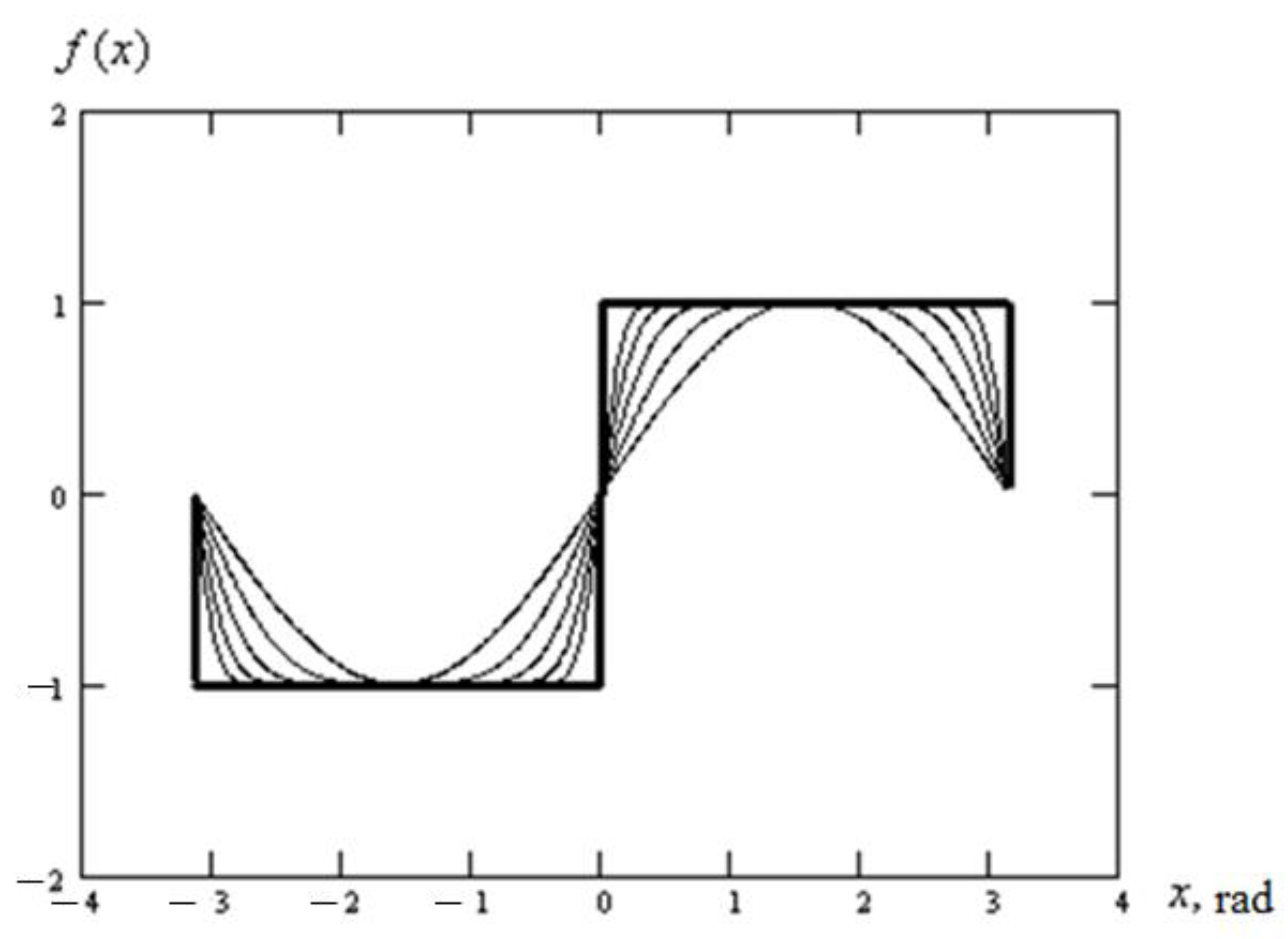

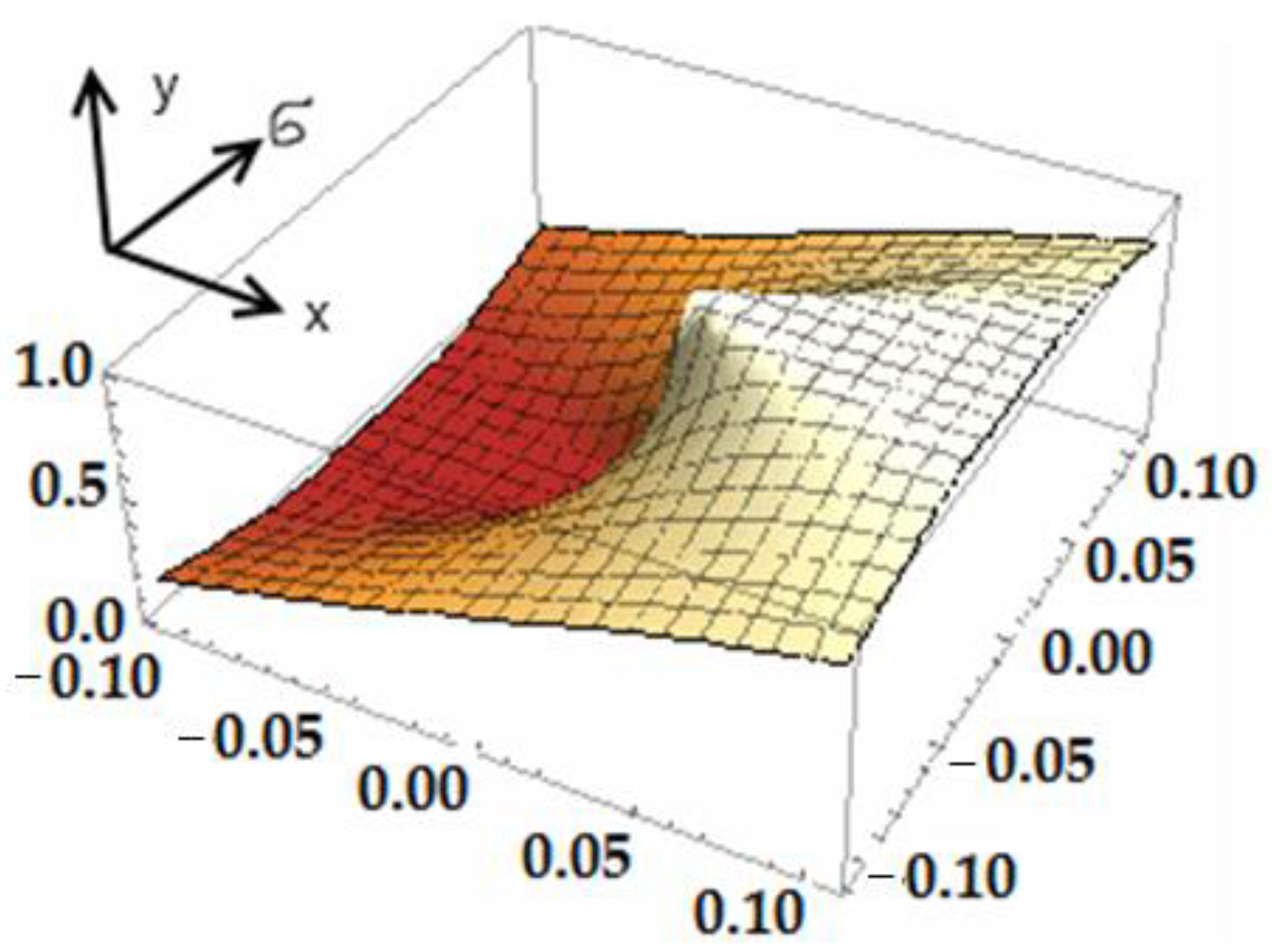

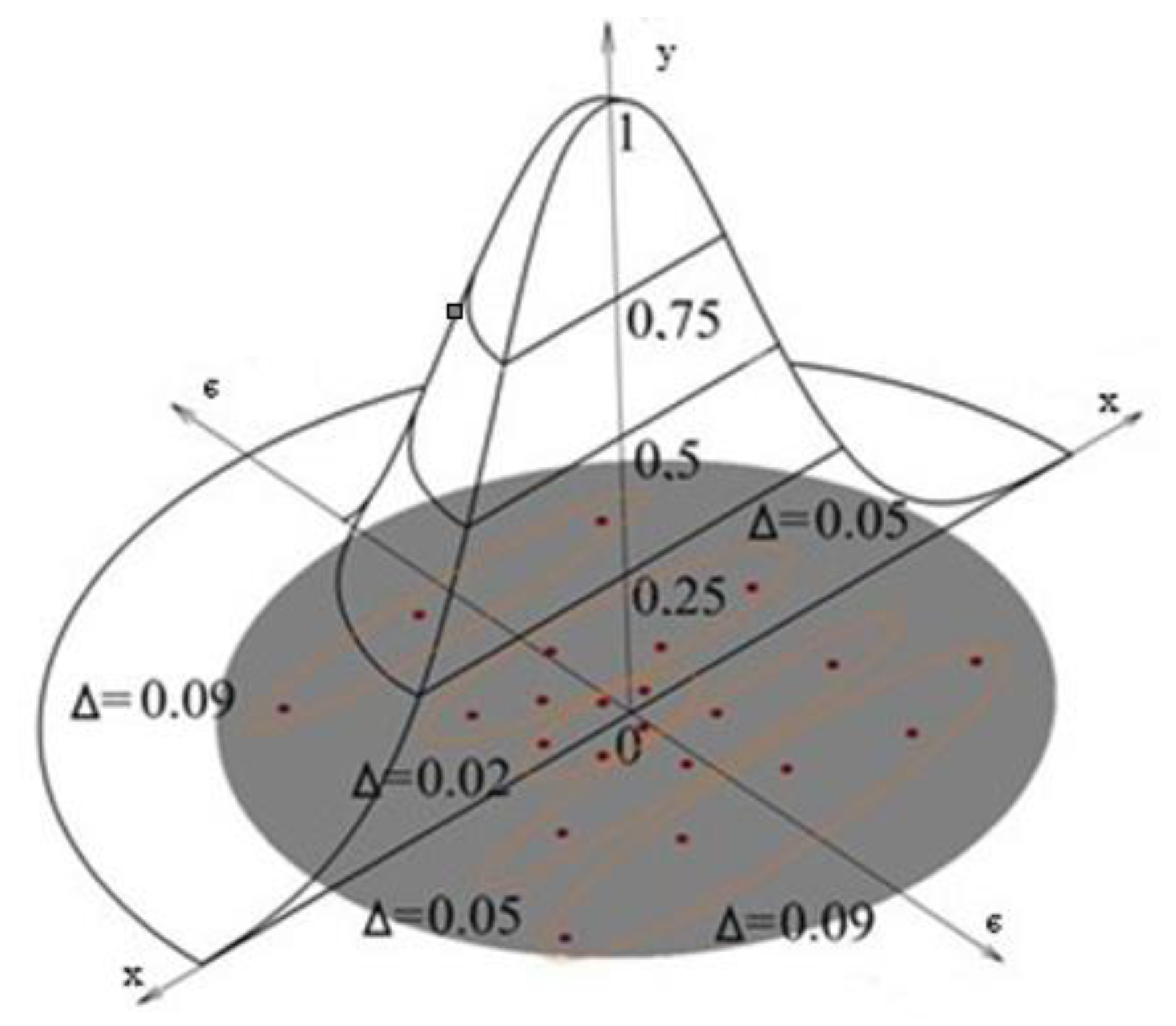

- Transform the standard function of coal dust analysis and combustion into a continuous integrated function for further application in the mathematical modeling of coal dust burning in an ensemble.

- Apply the density of normal distribution of probable deviations from the mean for mathematical description of analysis and combustion; use the Gauss curve according to the selected type of function.

- Normalize the function describing the ensemble of particles gradually undergoing exothermic oxidation while burning in a torch.

- Use differential curves in piece-linear functions or their approximation of recursive functions for reducing errors in mathematical modeling.

- Verify the adequacy of mathematical modeling methods; compare the calculation errors of the standard method with the method developed by the authors.

1.4. Scientific Novelty of the Methods and Methodology of the Research

2. Research Methodology

3. Experimental Procedures

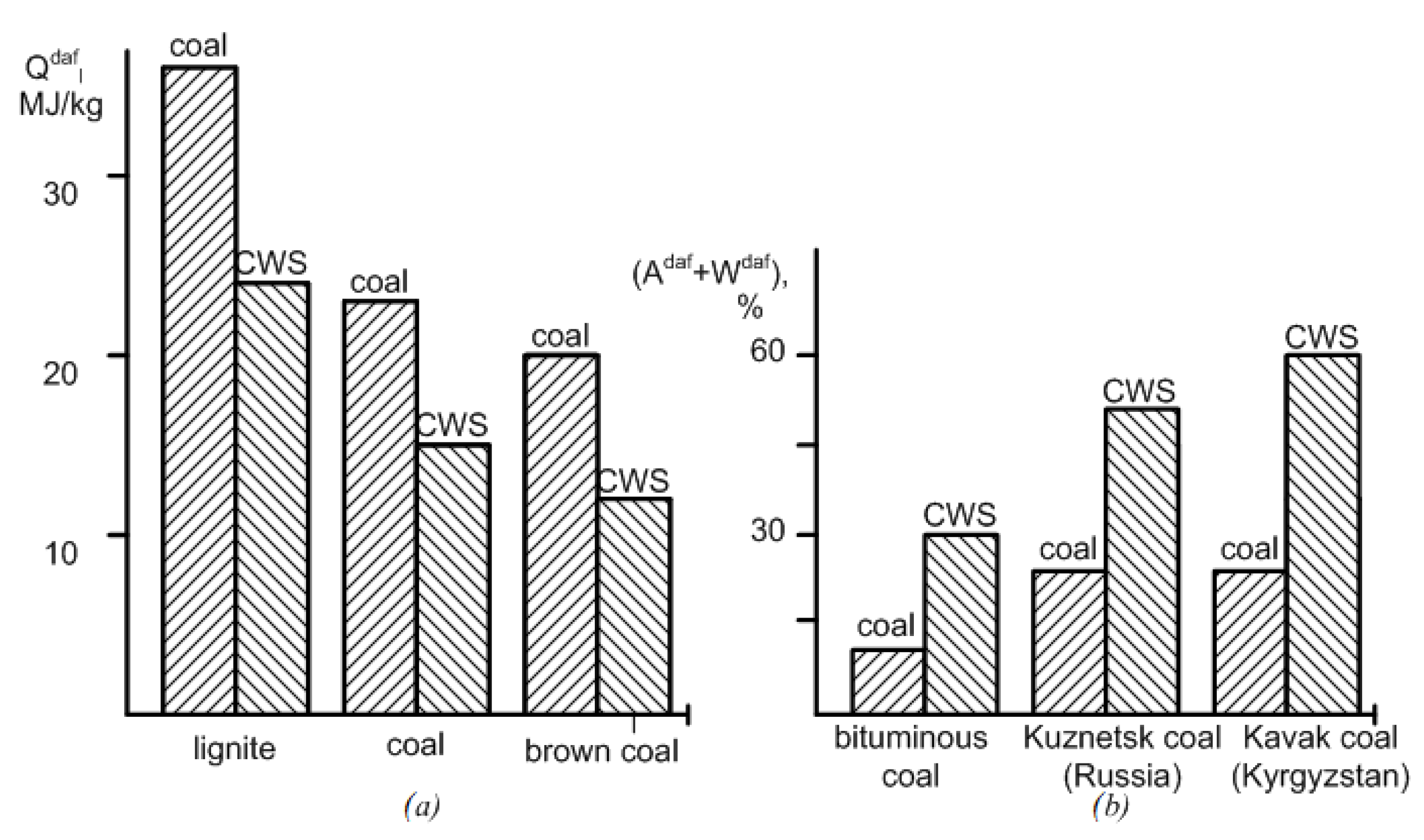

3.1. Investigation of the Properties of Coal–Water Suspensions

3.2. Experimental Study of the Properties of Coal–Water Suspension

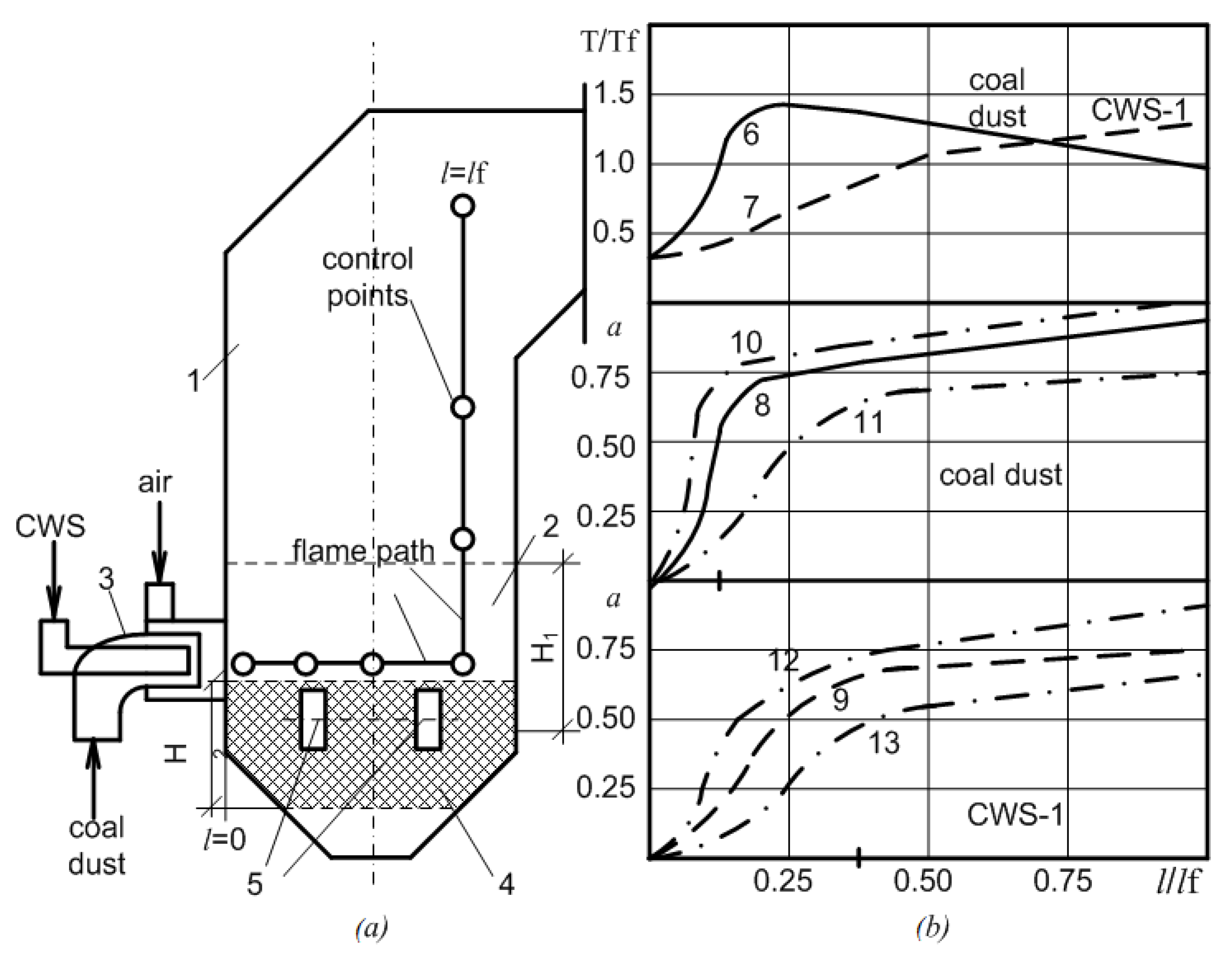

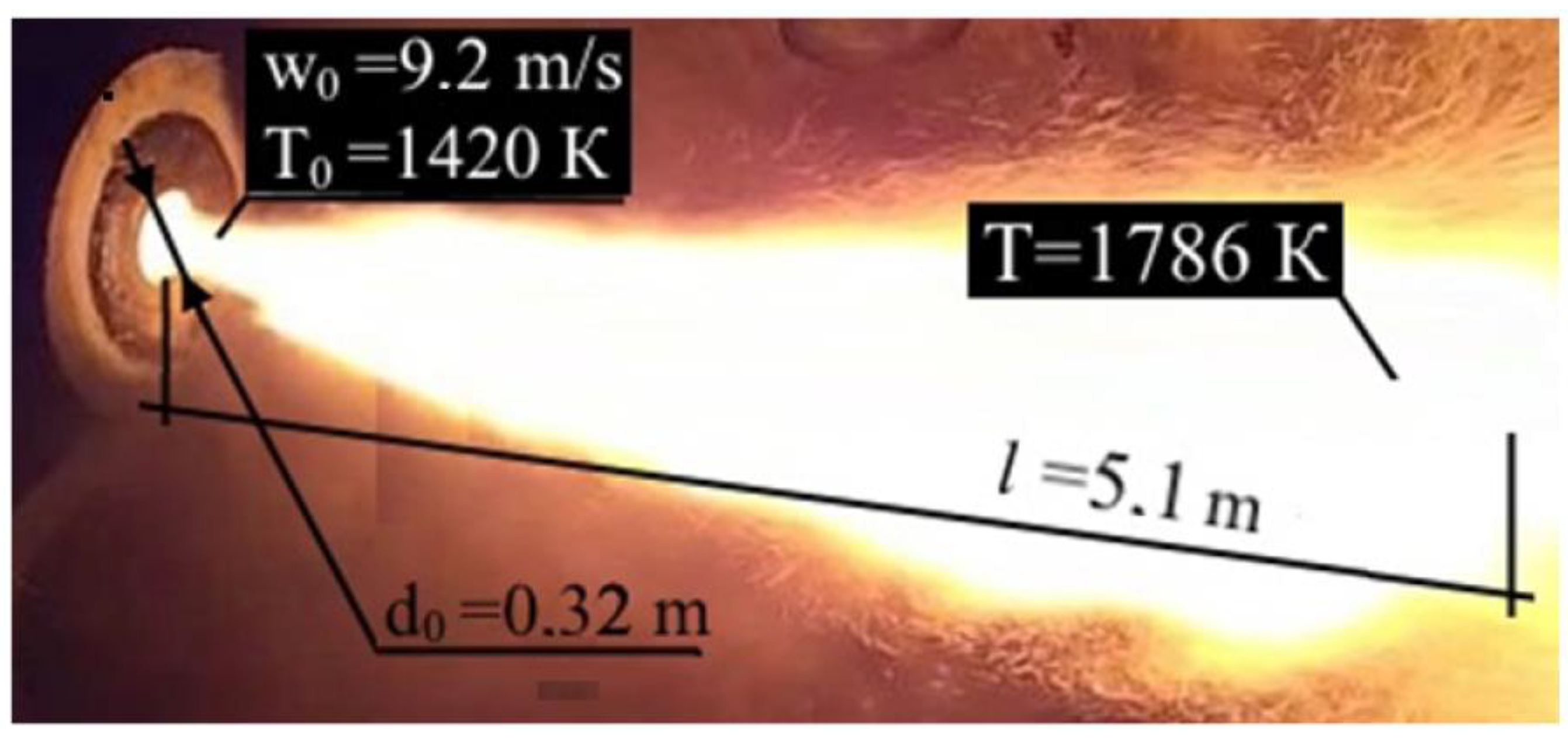

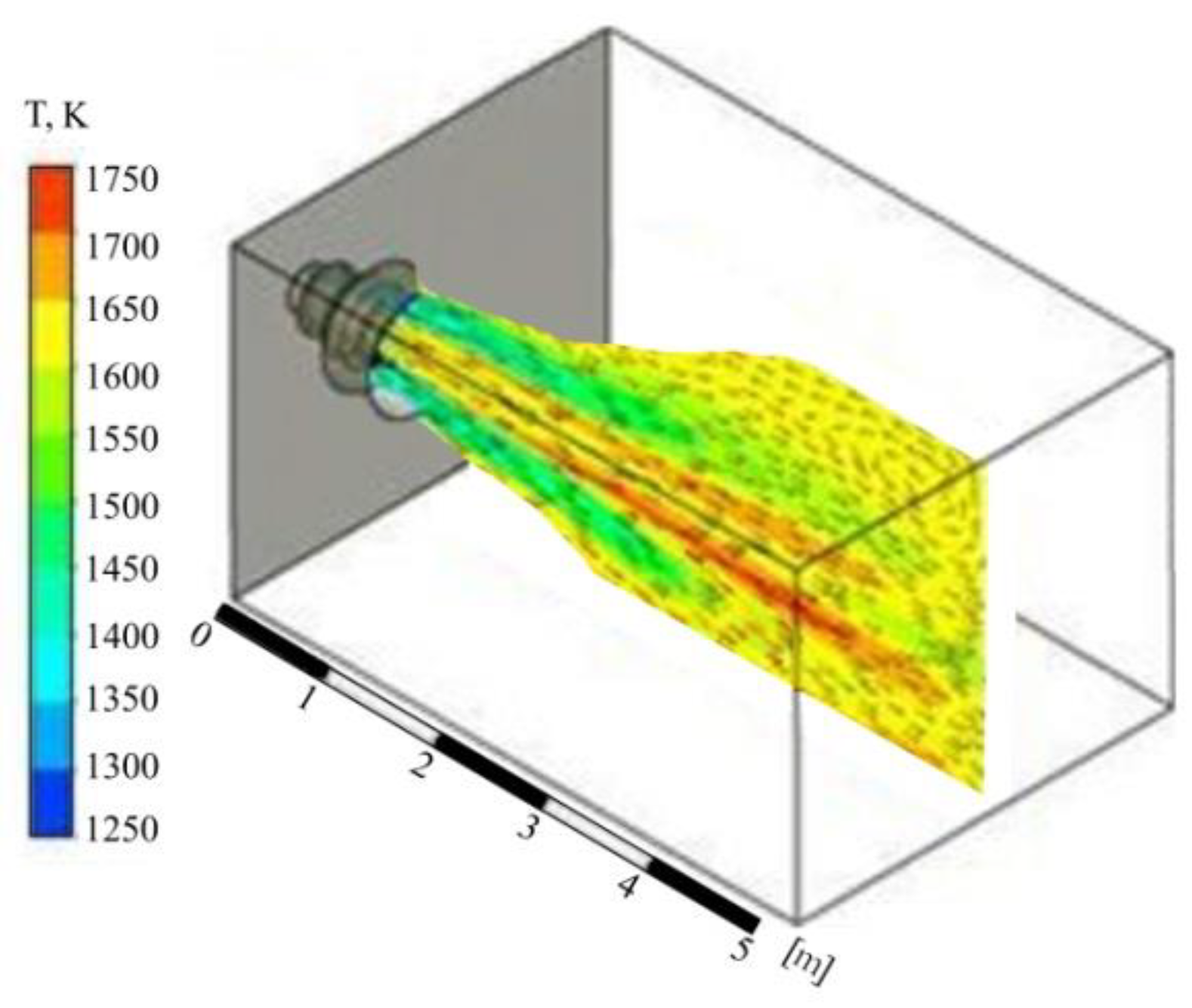

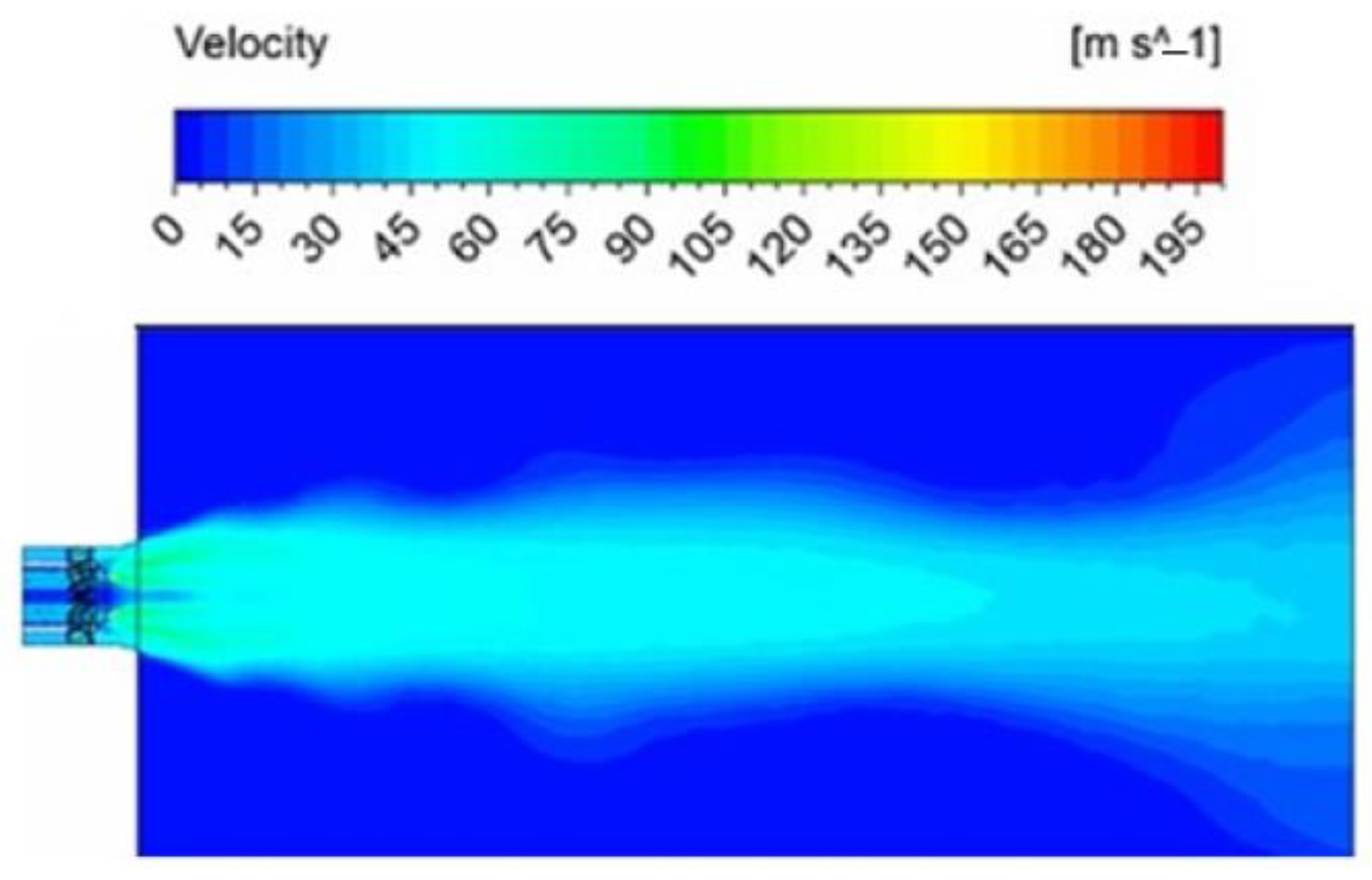

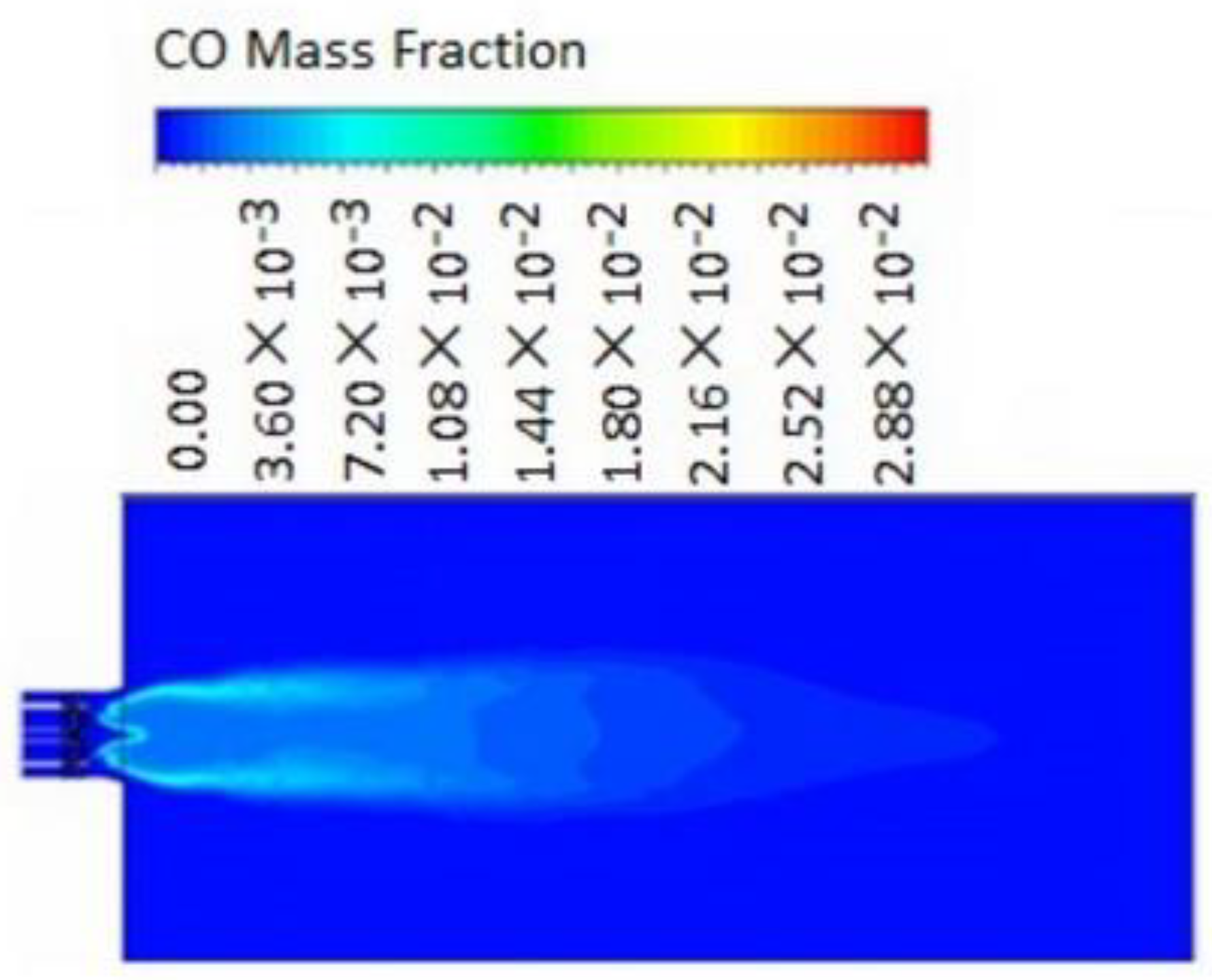

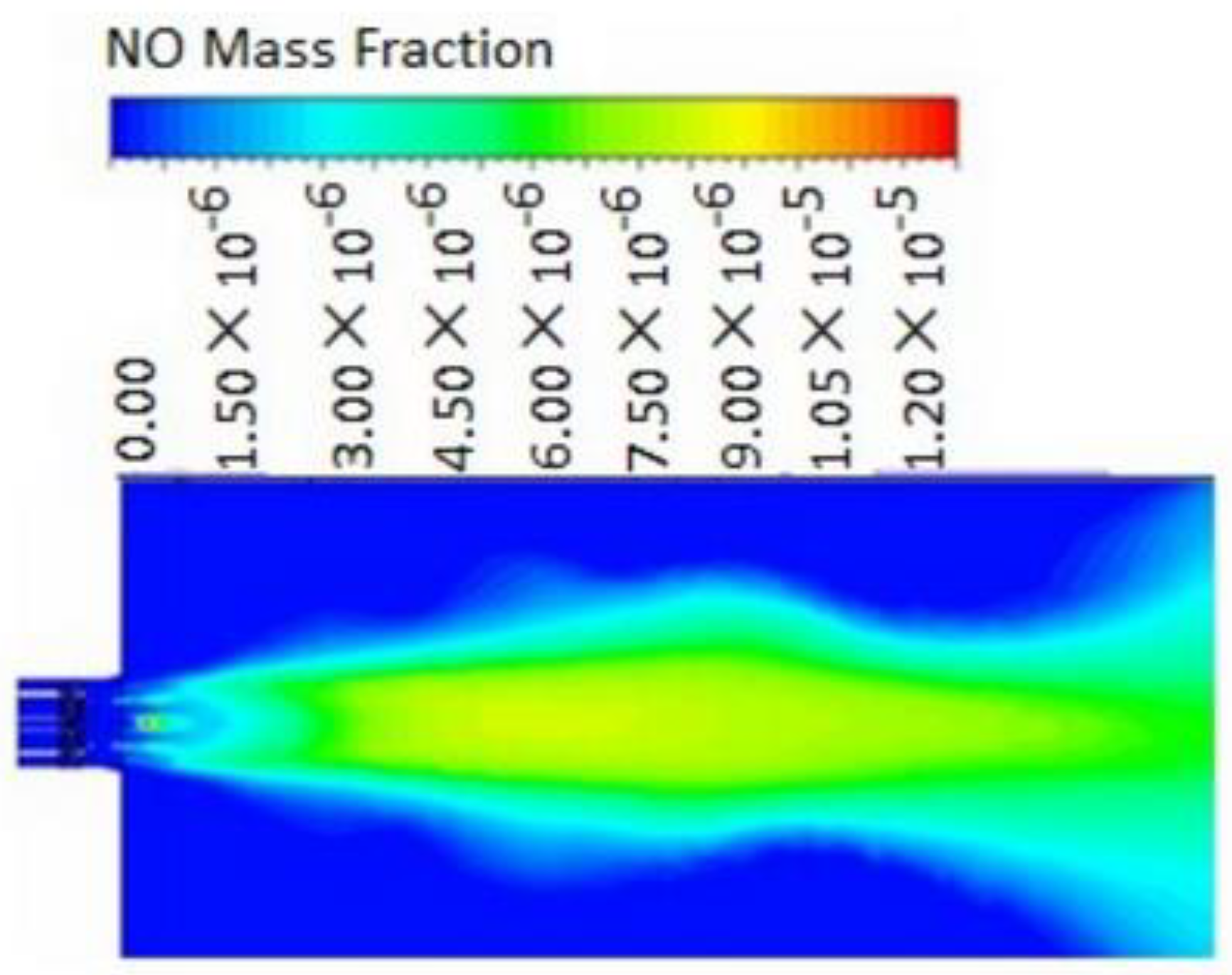

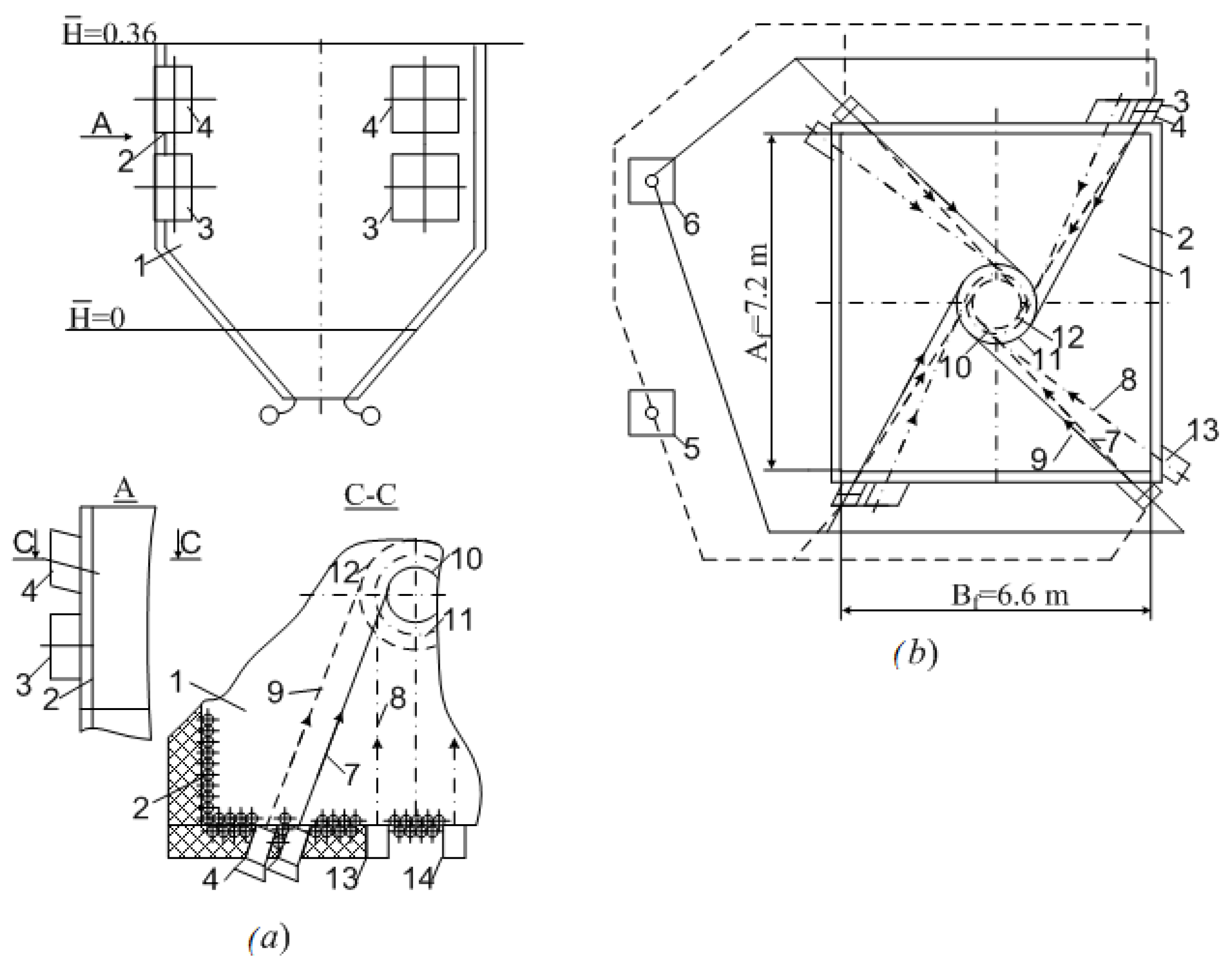

3.3. Experimental and Numerical Simulation of the Combustion Process of Coal and Coal–Water Suspension

3.4. Processing of Experimental Results

3.5. Comparison of Experimental Data Taking into Account New Approximation Methods

4. Results and Discussion

4.1. Results

4.2. Discussion

4.2.1. Application of Mathematical Combustion Models for the Design of Thermal Power Equipment

4.2.2. Use of Coal–Water Slurry for Combustion

5. Conclusions

- The authors presented the results of experimental studies of the thermophysical properties of coal and a coal–water mixture. With respect to the coal–water mixture, its movement through pipelines and combustion were considered. The results obtained were compared with the results of calculations using a mathematical model and the results of numerical modeling in Ansys.

- New methods of approximation of step functions were used for the mathematical model of error estimation. These methods make it possible to reduce errors in the approximation of the functions of the thermal properties of coal, in particular, in determining the coefficient of kinematic viscosity, ash content, and humidity by approximating the obtained data, and the use of new mathematical methods reduces the error in calculations.

- Data on numerical modeling of hydraulic transport and combustion processes are presented, and a data validation procedure is carried out. The data convergence shown and their location in the selected band of uncertainties satisfy the requirements for verification of experimental data adopted in the European Union and in the Eurasian Union.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ρmix | density of coal–water mixture, kg/m3; |

| υ | kinematic viscosity coefficient, m2/s; |

| cp | heat capacity of the water–coal mixture, J/(kg K); |

| D | pipeline diameter, m; |

| V | the speed of the water–coal mixture, m/s; |

| imix | specific pressure losses during the movement of the hydraulic mixture (experimental data); |

| iwat | specific pressure losses during water movement (experimental data); |

| imid | middle specific pressure losses during water movement (calculated data); |

| λs | hydraulic friction coefficient for hydraulically smooth pipelines; |

| Qdafltheor | heat of combustion of freshly extracted coal, MJ/kg; |

| Qdaflreal | heat of combustion of coal delivered to the Bishkek CHP warehouse, MJ/kg; |

| lf | torch length, m; |

| Tf | torch temperature, K; |

| Adaf | ash content of fuel, %; |

| Wdaf | fuel humidity, %; |

| Vdaf | the output of volatile combustible substances of fuel, %. |

References

- Zhang, Y.; Xu, Z.; Liu, D.; Chen, Y.; Zhao, W.; Ren, G. The influence of water occurrences in CWSs made of lignite and bituminous coal on slurrying performances. Powder Technol. 2022, 398, 117150. [Google Scholar] [CrossRef]

- Ahamed, M.; Perera, M.; Matthai, S.; Ranjith, P.; Dong-Yin, L. Coal composition and structural variation with rank and its influence on the coal-moisture interactions under coal seam temperature conditions—A review article. J. Pet. Sci. Eng. 2019, 180, 901–917. [Google Scholar] [CrossRef]

- Chai, Z.; Ren, Y.; Zhang, R.; Feng, L.; Liu, S.; Wang, Z.; Zeng, M. Stability and settling performance of coal water slurries under vibration conditions. Powder Technol. 2020, 376, 351–362. [Google Scholar] [CrossRef]

- Chai, Z.; Zeng, M.; Ren, Y.; Zhang, R.; Feng, L.; Zhao, Z. Prediction method on the static stability of a coal water mixture. Energy Fuels 2019, 33, 3998–4008. [Google Scholar] [CrossRef]

- Kuznetsov, G.; Vershinina, K.; Valiullin, T.; Strizhak, P. Differences in ignition and combustion characteristics of waste-derived oil-water emulsions and coal-water slurries containing petrochemicals. Fuel Process. Technol. 2018, 179, 407–421. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, D.; Lun, Z.; Zhao, C.; Wang, H. Occurrence of water within different rank coals: A review. Energy Sources Part A Recover. Util. Environ. Eff. 2020, A, 1–19. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Liu, J.; Liu, H.; Wang, M.; Cheng, J. Synergistic effects of mixing waste activated carbon and coal in co-slurrying and CO2 co-gasification. Powder Technol. 2021, 395, 883–892. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Wang, S.; Cheng, J. Slurrying Property and Mechanism of Coal–Coal Gasification Wastewater–Slurry. Energy Fuels 2018, 32, 4833–4840. [Google Scholar] [CrossRef]

- Keboletse, K.P.; Ntuli, F.; Oladijo, O.P. Influence of coal properties on coal conversion processes-coal carbonization, carbon fiber production, gasification and liquefaction technologies: A review. Int. J. Coal Sci. Technol. 2021, 8, 817–843. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, H.; Fan, T.; Zhou, J.; Liu, X.; Li, Y.; Zhao, G.; Wang, Y.; Zeng, M. Investigation on chemical structure and hydrocarbon generation potential of lignite in the different pretreatment process. Fuel 2021, 291, 120205. [Google Scholar] [CrossRef]

- Li, L.; Tong, S.; Duan, L.; Zhao, C.; Shi, Z. Effect of CO2 and H2O on lignite char structure and reactivity in a fluidized bed reactor. Fuel Process. Technol. 2020, 211, 106564. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, T.; Li, X.; Zhang, L.; Zhang, Z.; Chen, Y.; Wu, F.; Luo, C.; Zheng, C. NO formation mechanism of CH4/NH3 jet flames in hot co-flow under MILD-oxy condition: Effects of co-flow CO2 and H2O. Fuel 2021, 313, 123030. [Google Scholar] [CrossRef]

- Noble, A.; Luttrell, G.H. A review of state-of-the-art processing operations in coal preparation. Int. J. Min. Sci. Tech. 2015, 25, 511–521. [Google Scholar] [CrossRef]

- Peng, L.; Wang, Z.; Ma, W.; Chen, X.; Zhao, Y.; Liu, C. Dynamic influence of screening coals on a vibrating screen. Fuel 2018, 216, 484–493. [Google Scholar] [CrossRef]

- Osintsev, K.; Aliukov, S.; Kuskarbekova, S. Investigation of Operation of Coil-Flow Steam Generator of Serpentine Type in Conditions of Low Ambient Temperatures. Int. J. Heat Technol. 2021, 39, 1164–1172. [Google Scholar] [CrossRef]

- Osintsev, K.; Aliukov, S.; Prikhodko, Y. Management of the Torch Structure with the New Methodological Approaches to Regulation Based on Neural Network Algorithms. Energies 2021, 14, 1909. [Google Scholar] [CrossRef]

- Osintsev, K.V. Studying flame combustion of coal-water slurries in the furnaces of power-generating boilers. Therm. Eng. 2012, 59, 439–445. [Google Scholar] [CrossRef]

- Melzer, D. On the expressibility of piecewise-linear continuous functions as the difference of two piecewise-linear convex functions. In Quasidifferential Calculus; Demyanov, V.F., Dixon, L.C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1986; pp. 118–134. [Google Scholar] [CrossRef]

- Alyukov, S.V. Approximation of step functions in problems of mathematical modeling. Math. Model. Comput. Simulations 2011, 3, 661–669. [Google Scholar] [CrossRef]

- Zhiltsov Yu, V.; Elshin, V.V. Modeling of the Process of Burning Pulverized Coal Fuel in the bkz-500 Power Boiler Using the Ansys Fluent Software Package, Modern Technologies. System Analysis. Modeling no. 4; Irkutsk State University of Railway Transport: Irkutsk, Russia, 2016; pp. 150–154. [Google Scholar]

- Williams, F.A. Combustion Theory; Westview Press: Boulder, CO, USA, 1985. [Google Scholar]

- Spalding, D.B. Some Fundamentals of Combustion; Butterworth’s Academic Press: London, UK, 1955. [Google Scholar]

- Ponomarev, V.B. Calculation and Design of Equipment for Air Separation of Bulk Materials; Publishing House Ural University: Yekaterinburg, Russia, 2017. [Google Scholar]

- Pomerantsev, V.V.; Arefyev, K.M.; Akhmedov, D.B. Fundamentals of the Practical Theory of Combustion; Energoatomizdat: Leningrad, Russia, 1986. [Google Scholar]

- Barsky, M.D. Fractionation of Powders; Nedra: Moscow, Russia, 1980. [Google Scholar]

- Chernetsky, M.Y.; Gavrilov, A.A.; Dekterev, A.A.; Surzhikova, N.S. A modified mathematical model for calculating the flare burning of micro-mill coals. Therm. Fund. Energy Tech. 2009, 1, 159–166. [Google Scholar]

- Burdukov, P.A.; Popov, V.I.; Chernetskiy, M.Y.; Dekterev, A.; Hanjalić, K. Autothermal combustion of mechanically-activated micronized coal in a 5 MW pilot-scale combustor. Fuel 2014, 122, 103–111. [Google Scholar] [CrossRef]

- Mandø, M.; Rosendahl, L.; Yin, C.; Sørensen, H. Pulverized straw combustion in a low-NOx multifuel burner: Modeling the transition from coal to straw. Fuel 2010, 89, 3051–3062. [Google Scholar] [CrossRef]

- Asotani, T.; Yamashita, T.; Tominaga, H.; Uesugi, Y.; Itaya, Y.; Mori, S. Prediction of ignition behavior in a tangentially fired pulverized coal boiler using CFD. Fuel 2008, 87, 482–490. [Google Scholar] [CrossRef]

| Diameter D, m | 0.10 | 0.15 | 0.20 | 0.25 | 0.30 | 0.50 |

| Speed V, m/s | 0.70 | 0.85 | 1.0 | 1.2 | 1.4 | 1.5 |

| Diameter D, m | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

| Speed V, m/s | 1.15 1.35 | 1.25 1.45 | 1.35 1.55 | 1.40 1.65 | 1.50 1.80 | 1.60 1.95 | 1.65 2.00 |

| Velocity, V, m/s | Coefficient of Kinematic Viscosity of the Water–Coal Mixture, υ, m2/s | Maximum Deviation, Δ, m/s | Deviation Standard, σ | |

|---|---|---|---|---|

| Computation1 | 1.0 | 350 × 10−6 | 0.002 | 1 |

| Computation2 | 1.1 | 354 × 10−6 | 0.004 | 0.9 |

| Computation3 | 1.12 | 357 × 10−6 | 0.003 | 0.5 |

| Computation4 | 1.14 | 360 × 10−6 | 0.003 | 0.4 |

| Analysis | 1.1 | 348 × 10−6 | 0.002 | 0.9 |

| The Proportion of Water in the Coal–Water Mixture, W | Heat of Combustion of Coal–Water Mixture, Qdafl, MJ/kg | |||

| Computation5 | 30 | 16.2 | ||

| Computation6 | 35 | 15.3 | ||

| Computation7 | 40 | 14.1 | ||

| Computation8 | 45 | 13.2 | ||

| Analysis | 36.7 | 15.12 | ||

| Ash Content of Fuel, Adaf | Moisture Content, Wdaf | Maximum Deviation According to the Measurement Results, Δ, % | |

|---|---|---|---|

| Computation1 | 14.0 | 34 | 0.08 |

| Computation2 | 14.6 | 34 | 0.08 |

| Computation3 | 14.9 | 33 | 0.06 |

| Computation4 | 15.3 | 33 | 0.07 |

| Analysis1 | 15.7 | 32 | 0.06 |

| Analysis2 | 16.2 | 32 | 0.07 |

| Analysis3 | 16.6 | 31 | 0.06 |

| Analysis4 | 17.0 | 31 | 0.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osintsev, K.; Aliukov, S. Experimental and Mathematical Investigation of the Thermophysical Properties of Coal–Water Slurries Based on Lignite. Energies 2022, 15, 3814. https://doi.org/10.3390/en15103814

Osintsev K, Aliukov S. Experimental and Mathematical Investigation of the Thermophysical Properties of Coal–Water Slurries Based on Lignite. Energies. 2022; 15(10):3814. https://doi.org/10.3390/en15103814

Chicago/Turabian StyleOsintsev, Konstantin, and Sergei Aliukov. 2022. "Experimental and Mathematical Investigation of the Thermophysical Properties of Coal–Water Slurries Based on Lignite" Energies 15, no. 10: 3814. https://doi.org/10.3390/en15103814

APA StyleOsintsev, K., & Aliukov, S. (2022). Experimental and Mathematical Investigation of the Thermophysical Properties of Coal–Water Slurries Based on Lignite. Energies, 15(10), 3814. https://doi.org/10.3390/en15103814