Multi-Objective Optimization Design and Analysis of V-Shape Permanent Magnet Synchronous Motor

Abstract

:1. Introduction

2. PSMS Specification

3. Multi-Objective Optimization Design and Analysis

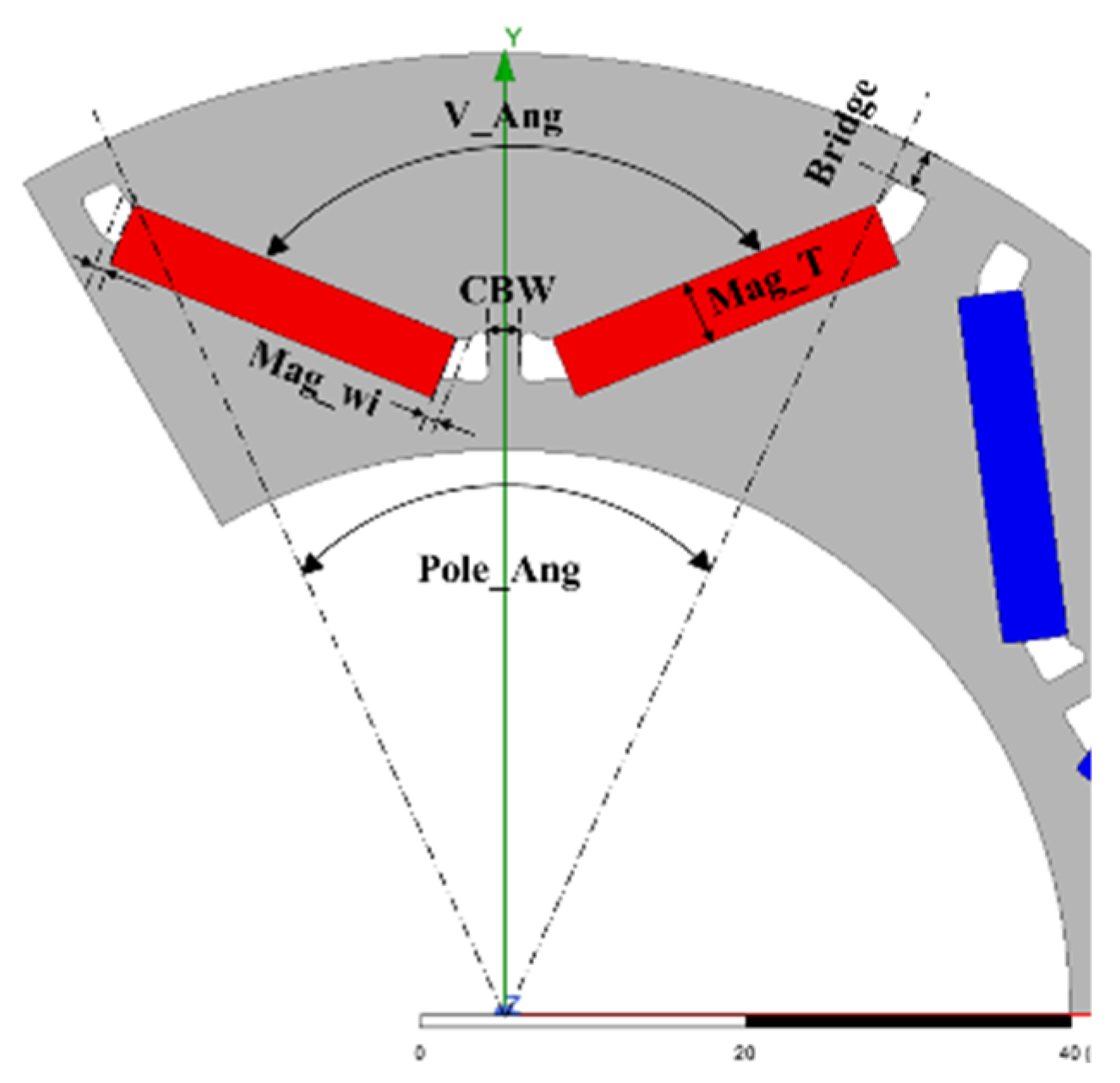

3.1. Design and Experiments Technqiue

3.2. Sensitivity Analysis

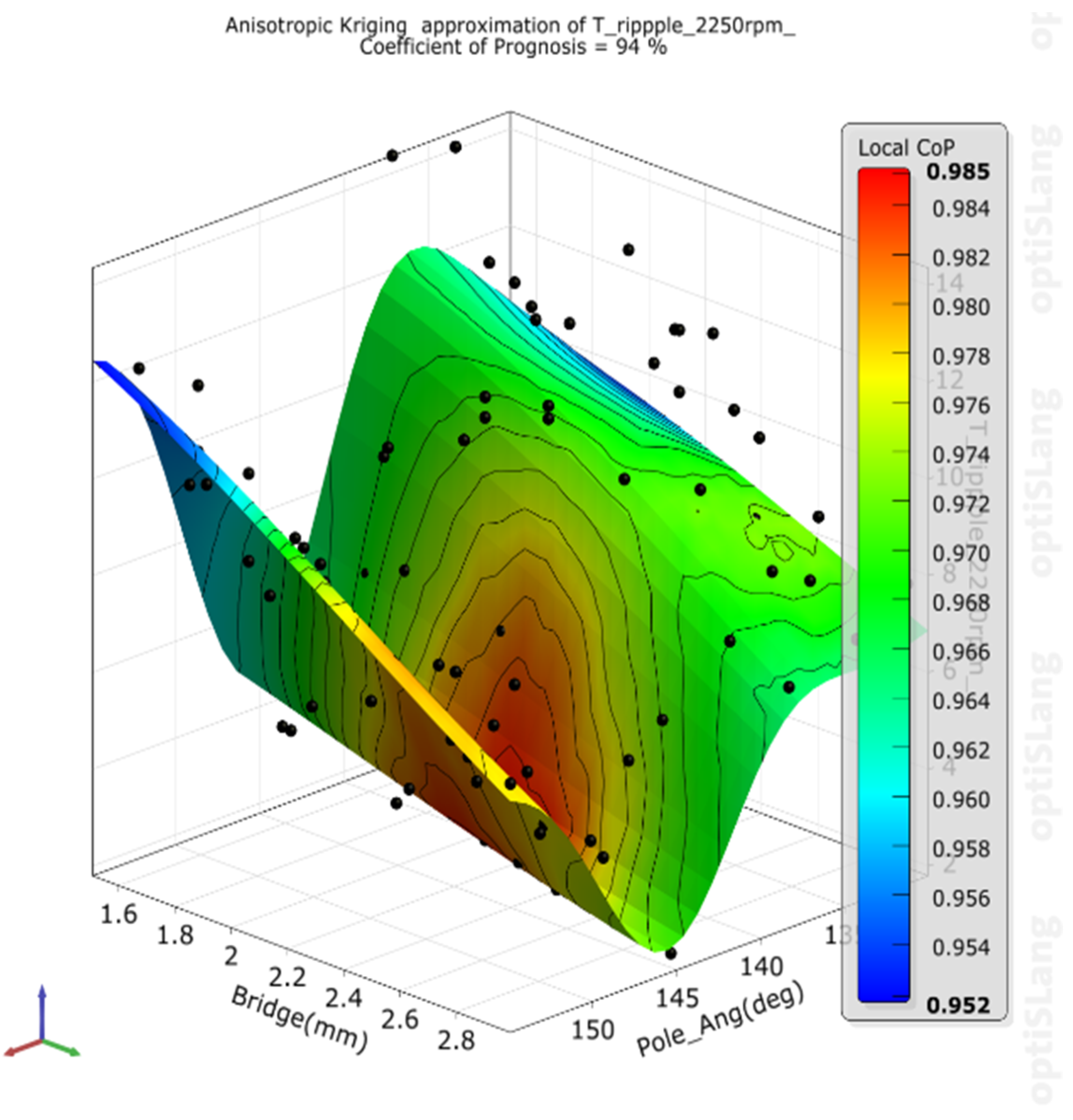

3.3. Response Surface Results

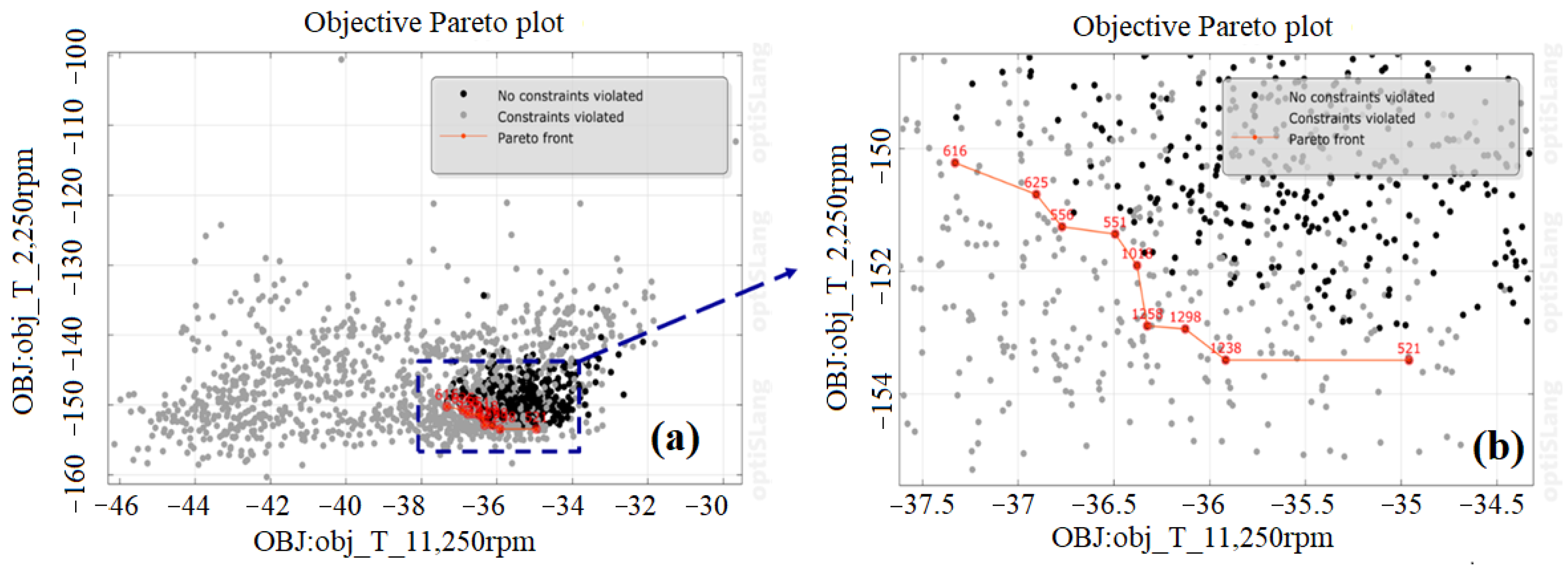

3.4. Optimization Analysis

3.5. Optimization Results and Discussion

4. Multi-Physical Analysis Results and Discussion

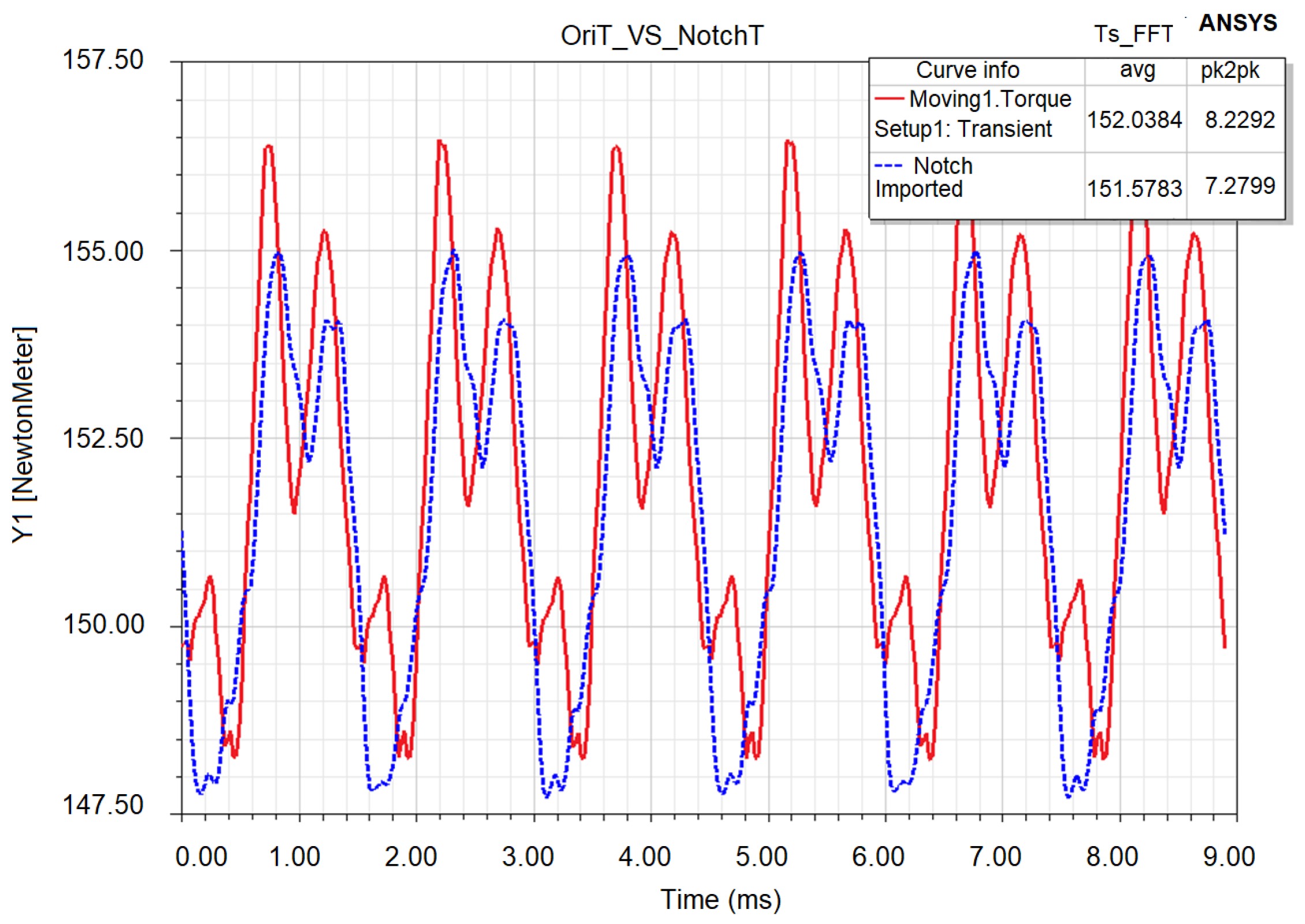

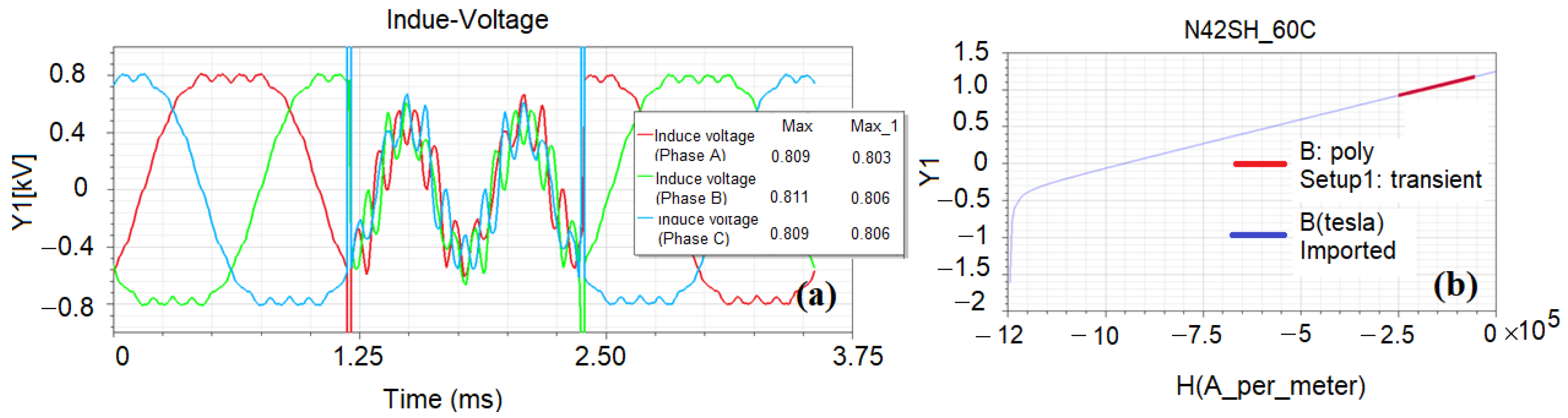

4.1. Optimal Design and Analysis of Electromagnetic Field

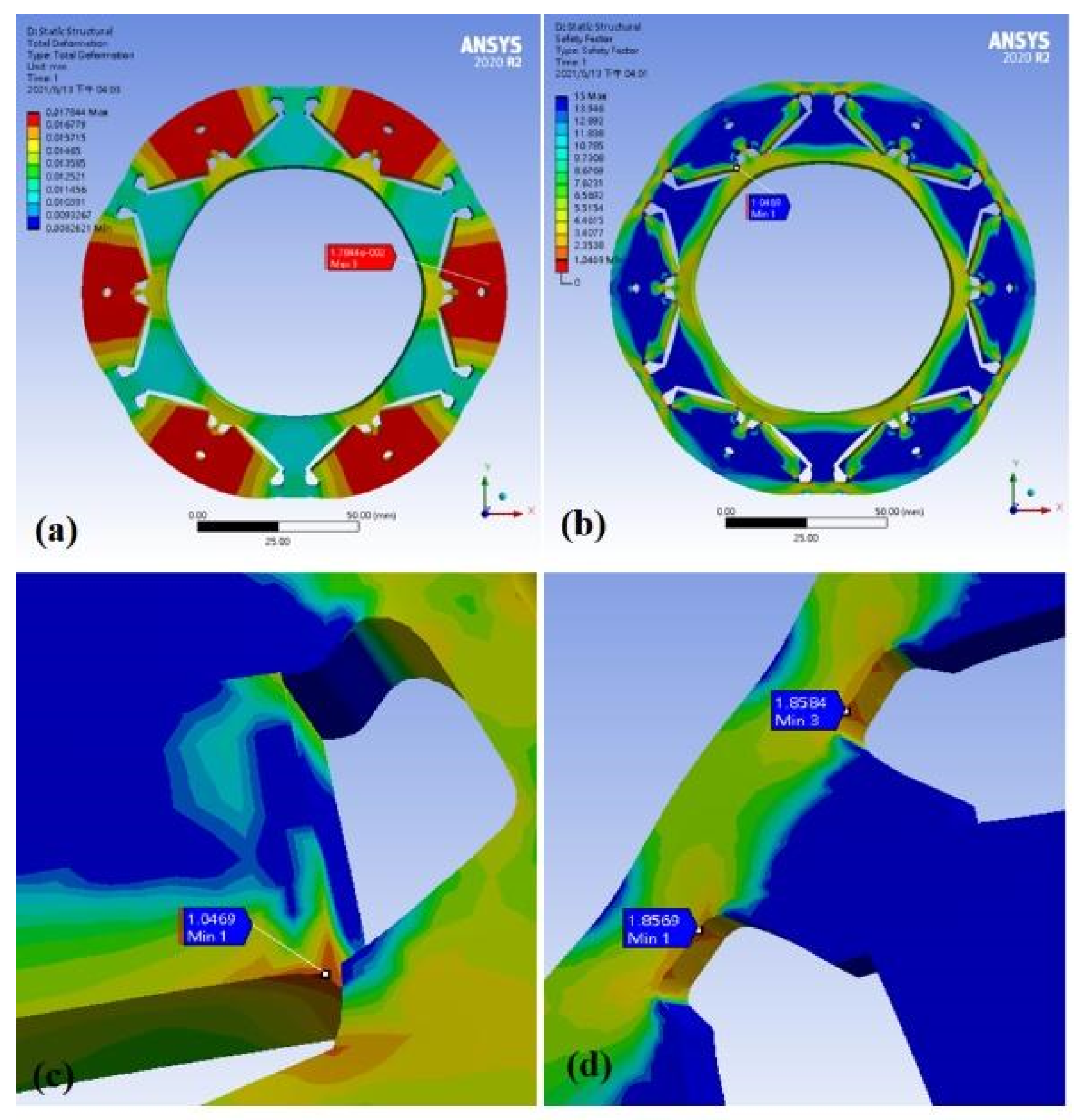

4.2. Structural Field Analysis

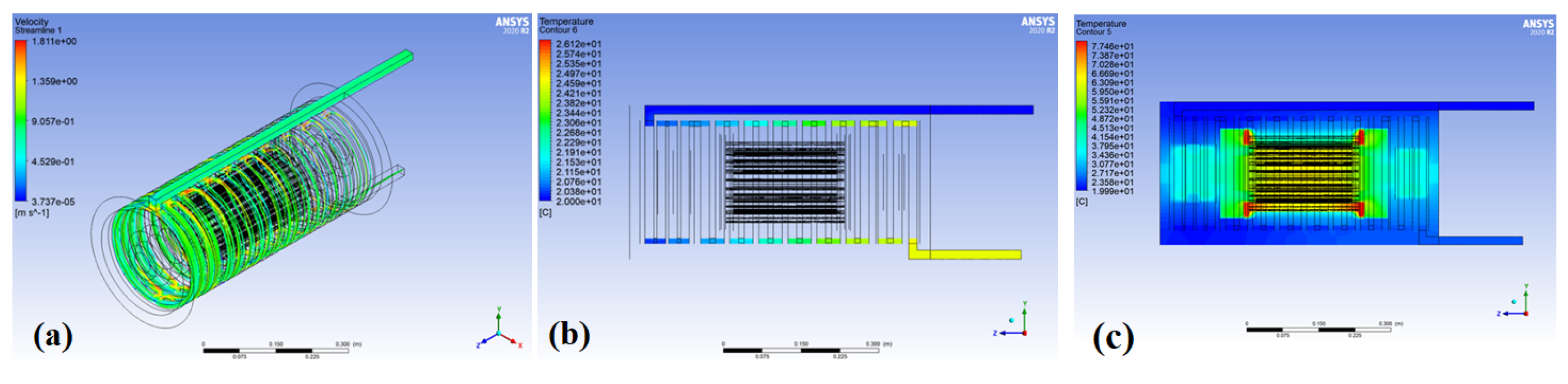

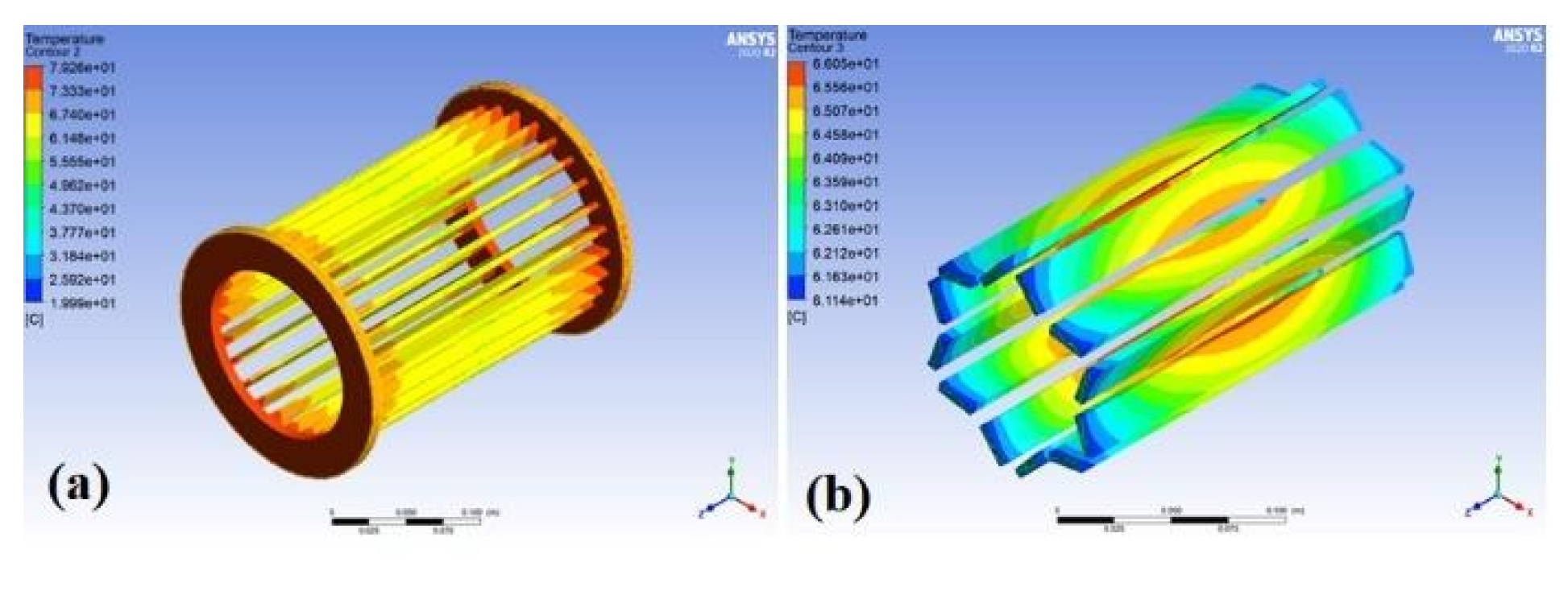

4.3. Temperature and Flow Field Analysis

4.4. Demagnetization of Permanent Magnets Analysis

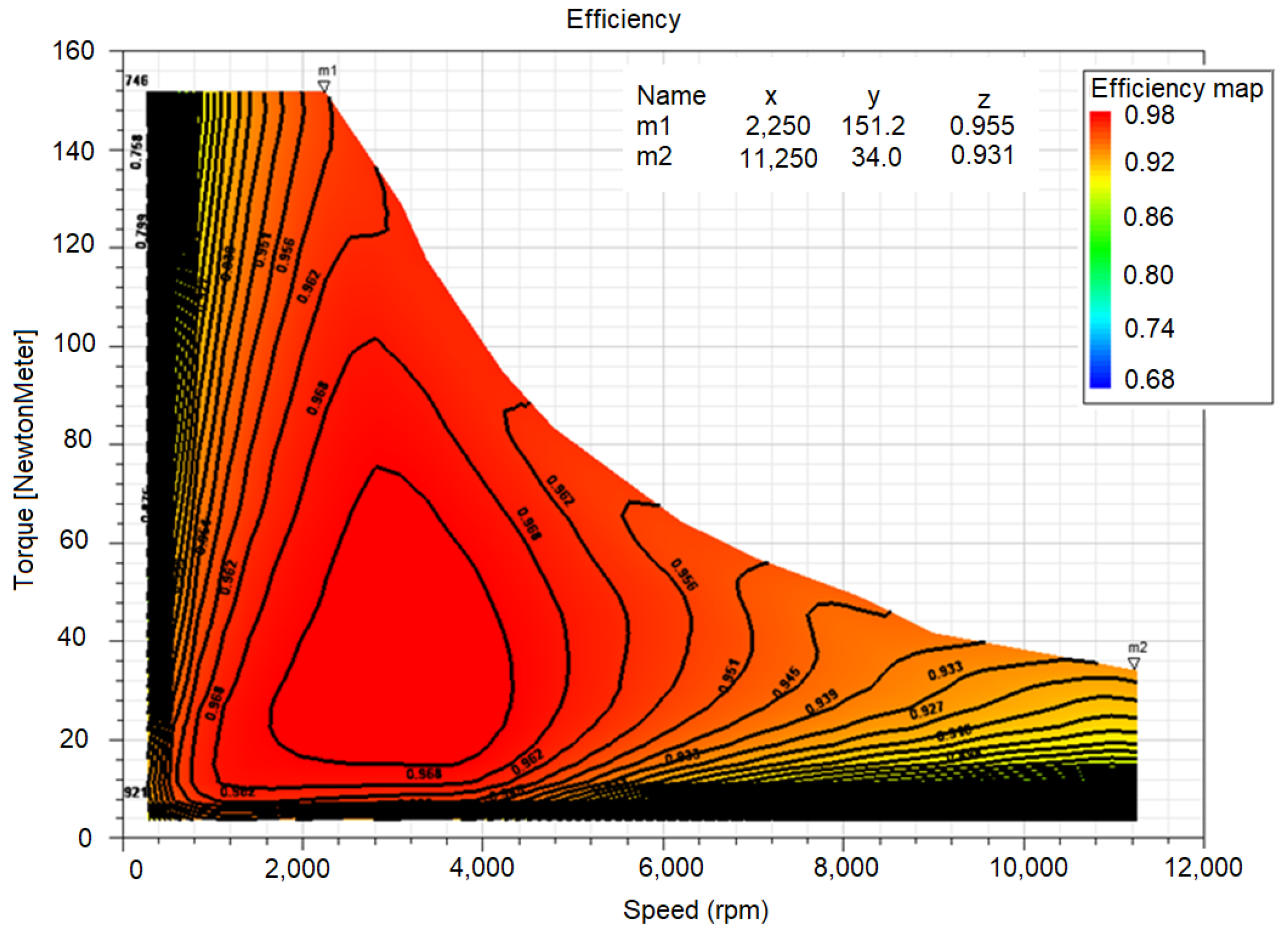

4.5. Map Analysis of Global Characteristics of Optimized PMSM

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, A.; Jia, Y.; Soong, W.L. Comparison of five topologies for an interior permanent-magnet machine for a hybrid electric vehicle. IEEE Trans. Magn. 2011, 47, 3606–3609. [Google Scholar] [CrossRef]

- Dajaku, G.; Hofmann, H.; Hetemi, F.; Dajaku, X.; Xie, W.; Gerling, D. Comparison of two different ipm traction machines with concentrated winding. IEEE Trans. Ind. Electron. 2016, 63, 4137–4149. [Google Scholar] [CrossRef]

- Bozhko, S.; Rashed, M.; Hill, C.I.; Yeoh, S.S.; Yang, T. Flux-weakening control of electric starter–generator based on permanent-magnet machine. IEEE Trans. Transp. Electr. 2017, 3, 864–877. [Google Scholar] [CrossRef]

- Sun, X.; Jin, Z.; Wang, S.; Yang, Z.; Li, K.; Fan, Y.; Chen, L. Performance improvement of torque and suspension force for a novel five-phase BFSPM machine for flywheel energy storage systems. IEEE Trans. Appl. Supercond. 2019, 29, 0601505. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Zhao, J.; Belahcen, A. Research on the performances and parameters of interior PMSM used for electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 3533–3545. [Google Scholar] [CrossRef]

- Feng, S.; Jiang, W.; Zhang, Z.; Zhang, J.; Zhang, Z. Study of efficiency characteristics of Interior Permanent Magnet Synchronous Motors. IEEE Trans. Magn. 2018, 54, 8108005. [Google Scholar]

- Tiegna, H.; Amara, Y.; Barakat, G. Study of cogging torque in axial flux permanent magnet machines using an analytical model. IEEE Trans. Magn. 2014, 50, 845–848. [Google Scholar] [CrossRef]

- Shanshal, A.; Hoang, K.; Atallah, K. High-performance ferrite permanent magnet brushless machines. IEEE Trans. Magn. 2017, 55, 8104504. [Google Scholar] [CrossRef] [Green Version]

- Dutta, R.; Pouramin, A.; Rahman, M.F. A novel rotor topology for high performance fractional slot concentrated winding interior permanent magnet machine. IEEE Trans. Energy Convers. 2021, 36, 658–670. [Google Scholar] [CrossRef]

- Carraro, E.; Bianchi, N.; Zhang, S.; Koch, M. Design and performance comparison of fractional slot concentrated winding spoke type synchronous motor with different slot pole combinations. IEEE. Trans. Ind. Appl. 2018, 54, 2276–2284. [Google Scholar] [CrossRef]

- Han, J.H.; Lee, J.; Kim, W.H. A study on optical design of the triangle type permanent magnet in IPMSM rotor by using the bo-behnken design. IEEE. Trans. Magn. 2015, 51, 8200704. [Google Scholar]

- Han, Z.; Liu, J.; Yang, W.; Pinhal, D.B.; Reiland, N.; Gerling, D. Improved online maximum-torque-per-ampere algorithm for speed controlled interior permanent magnet synchronous machine. IEEE Trans. Ind. Electron. 2019, 67, 3398–3408. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, W.; Hua, W.; Cao, R.; Qiu, H.; Guo, A. The design and optimization of an interior, permanent magnet synchronous machine applied in an electric traction vehicle requiring a low torque ripple. Appl. Sci. 2019, 9, 3634. [Google Scholar] [CrossRef] [Green Version]

- You, Y.M. Multi-objective optimization of a permanent magnet synchronous motor based on an automated design and analysis procedure. Microsyst. Technol. 2020, 26, 3477–3488. [Google Scholar] [CrossRef]

- Jin, L.; Wang, F.; Yang, Q. Performance analysis and optimization of permanent magnet synchronous motor based on deep learning. In Proceedings of the 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017; pp. 1–5. [Google Scholar]

- Sun, X.; Jin, Z.; Cai, Y.; Yang, Z.; Chen, L. Grey wolf optimization algorithm based state feedback control for a bearingless permanent magnet synchronous machine. IEEE Trans. Power Electron. 2020, 35, 13631–13640. [Google Scholar] [CrossRef]

- Vidanalage, B.D.S.G.; Toulabi, M.S.; Filizadeh, S. Multimodal design optimization of V-shaped magnet IPM synchronous machines. IEEE Trans. Ener. Conver. 2018, 33, 1547–1556. [Google Scholar] [CrossRef]

- Du, J.; Wang, X.; Lv, H. Optimization of magnet shape based on efficiency map of IPMSM for EVs. IEEE Trans. Appl. Supercond. 2016, 26, 1–7. [Google Scholar] [CrossRef]

- Han, S.H.; Jahns, T.M.; Soong, W.L.; Güven, M.K.; Illindala, M.S. Torque ripple reduction in interior permanent magnet synchronous machines using stators with odd number of slots per pole pair. IEEE Trans. Energy Convers. 2010, 25, 118–127. [Google Scholar] [CrossRef]

- Pouramin, A.; Dutta, R.; Rahman, M.F. Preliminary study on differences in the performance characteristics of concentrated and distributed winding ipm machines with different rotor topologies. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar]

- Hanselman, D.C. Minimum torque ripple, maximum efficiency excitation of brushless permanent magnet motors. IEEE Trans. Ind. Electron. 1994, 41, 292–300. [Google Scholar] [CrossRef]

- Huntington, D.E.; Lyrintzis, C.S. Improvements to and limitations of Latin hypercube sampling. Probabilistic Eng. Mech. 1998, 13, 245–253. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y. Maximum torque per ampere (MTPA) control for IPMSM drives based on a variable-equivalent-parameter MTPA control law. IEEE Trans. Power Electron. 2018, 34, 7092–7102. [Google Scholar] [CrossRef]

- Yun, B.C.; Han, K.K.; Lee, D.Y.; Kang, G.H.; Jang, K.B.; Shin, H.K.; Kim, G.T. A study on the improvement of dynamic characteristics in Interior Permanent Magnet motor by rotor shape design. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; pp. 3126–3130. [Google Scholar]

| Present Study | Siemens 1FE1113-6WU11 | Siemens 1FE1084-6WR11 | Ate AC-180-220-8 | |

|---|---|---|---|---|

| Pole number (pole) | 6 | 6 | 6 | 8 |

| Rated power (kW) | 34 | 33 | 31 | 25 |

| Rated speed (rpm) | 2250 | 2100 | 2300 | 3000 |

| Rated torque (N·m) | 144.34 | 150 | 130 | 127.7 |

| Rated current (Arms) | <75 | 60 | 60 | 102/48 |

| Maximum speed (rpm) | 11,250 | 6500 | 9000 | 11,910 |

| Speed expansion ratio | 5 | 3.1 | 3.9 | 4 |

| Power density (kw/m3) | 5995.86 | 5787.45 | 6828.79 | 4465.63 |

| Parameter | Values |

|---|---|

| Bridge (mm) | 2.5 |

| CBW (mm) | 2.0 |

| Mag_T (mm) | 4.0 |

| Mag_Wi (mm) | 0.5 |

| Pole_Ang (°E) | 150 |

| V_Ang (°M) | 135 |

| Parameter | Values |

|---|---|

| Current (Arms) | 66 |

| Winding method | Double-layer |

| Number of turns | 10 |

| Coil pitch | 4 |

| Effective cross-sectional area (mm2) | 109.5 |

| Slot occupancy rate (%) | 54 |

| Strand diameter (mm) | 0.56 |

| Number of parallel strands | 24 |

| Current density (A/mm2) | 14 |

| Phase resistance (20 °C) Ω | 0.121 |

| Copper loss (20 °C) W | 1584 |

| Parameter | Code | Initial Values | Variable Range |

|---|---|---|---|

| Bridge (mm) | Bridge (mm) | 2.5 | 1.5~3 |

| CBW (mm) | CBW (mm) | 2.0 | 1~3 |

| Mag_T (mm) | Mag_T (mm) | 4.0 | 3~5 |

| Mag_Wi (mm) | Mag_Wi (mm) | 0.5 | 0.5~3 |

| Pole_Ang (°E) | Pole_Ang (°E) | 150 | 130~155 |

| V_Ang (°M) | V_Ang (°M) | 135 | 130~180 |

| psi1 (e_deg) | psi1 (e_deg) | 40 | 20~50 |

| psi2 (e_deg) | psi2 (e_deg) | 84 | 82~84 |

| Boundary Condition | Parameters | Initial Values | Target Values |

|---|---|---|---|

| N = 2250 rpm, Irms = 0 A | Cogging_Torque (N·m) | 1.75 | <1% × Tavg |

| T_2250 rpm (N·m) | 149.25 | >151.52 | |

| N = 2250 rpm, Irms = 66 A | T_ripple_2250 rpm (%) | 7.3 | <10 |

| V_max_112.5 Hz (V) | 302 | <315 | |

| T_11,250 rpm (N·m) | 33.09 | >31.75 | |

| N = 11,250 rpm, Irms = 66 A | T_ripple_11,250 rpm (%) | 43 | <30 |

| V_max_562.5 Hz (V) | 280 | <315 |

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Bridge (mm) | 2.5 | 2.95 |

| CBW (mm) | 2.0 | 1.54 |

| Mag_T (mm) | 4.0 | 4.76 |

| Mag_Wi (mm) | 0.5 | 0.56 |

| Pole_Ang (°E) | 150 | 143.53 |

| V_Ang (°M) | 135 | 140.55 |

| psi1 (e_deg) | 40 | 40 |

| psi2 (e_deg) | 84 | 84 |

| Boundary Condition | Parameters | Initial Values | Optimized Values |

|---|---|---|---|

| N = 2250 rpm, Irms = 0 A | Cogging_Torque (N·m) | 1.75 | 0.39 (−0.36 N·m) |

| T_2250 rpm (N·m) | 149.25 | 152.24 (+2.99 N·m) | |

| N = 2250 rpm, Irms = 66 A | T_ripple_2250 rpm (%) | 7.3 | 5.5 |

| V_max_112.5 Hz (V) | 302 | 301 | |

| T_11,250 rpm (N·m) | 33.09 | 34.07 (+0.98 N·m) | |

| N = 11,250 rpm, Irms = 66 A | T_ripple_11,250 rpm (%) | 43 | 25.2 |

| V_max_562.5 Hz (V) | 280 | 294 |

| Boundary Condition | Parameters | Initial Values | D = 3 mm | D = 4 mm | D = 5 mm |

|---|---|---|---|---|---|

| N = 2250 rpm Irms = 66 A | T_2250 rpm (N·m) | 152.24 | 152.03 (−0.1%) | 151.69 (−0.4%) | 151.01 (−0.8%) |

| T_ripple rpm (%) | 5.5 | 5.4 | 5.2 | 5.0 |

| Boundary Condition | Parameters | Initial Values | O (0.50) | O (0.52) | O (0.54) |

|---|---|---|---|---|---|

| N = 2250 rpm Irms = 66 A | T_2250 rpm (N·m) | 152.24 | 152.03 | 152.03 | 151.93 |

| T_ripple rpm (%) | 5.5 | 5.4 | 5.4 | 5.3 |

| Boundary Condition | Parameters | Optimized Values | After |

|---|---|---|---|

| N = 2250 rpm, Irms = 0 A | Cogging_torque (N-m) | 0.39 | 1.40 (+1.01 N-m) |

| T_2250 rpm (N·m) | 152.24 | 151.38 (−0.56%) | |

| N = 2250 rpm, Irms =66 A | T_ripple_2250 rpm (%) | 5.5 | 4.8 |

| V_max_112.5 Hz (V) | 301 | 298 | |

| T_11,250 rpm (N·m) | 34.07 | 34.81 (+2.17%) | |

| N = 11,250 rpm, Irms = 66 A | T_ripple_11,250 rpm (%) | 25.2 | 38.5 |

| V_max_562.5 Hz (V) | 294 | 301 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.-C.; Nien, Y.-C.; Huang, S.-M. Multi-Objective Optimization Design and Analysis of V-Shape Permanent Magnet Synchronous Motor. Energies 2022, 15, 3496. https://doi.org/10.3390/en15103496

Wang S-C, Nien Y-C, Huang S-M. Multi-Objective Optimization Design and Analysis of V-Shape Permanent Magnet Synchronous Motor. Energies. 2022; 15(10):3496. https://doi.org/10.3390/en15103496

Chicago/Turabian StyleWang, Sheng-Ching, Yu-Cheng Nien, and San-Ming Huang. 2022. "Multi-Objective Optimization Design and Analysis of V-Shape Permanent Magnet Synchronous Motor" Energies 15, no. 10: 3496. https://doi.org/10.3390/en15103496

APA StyleWang, S.-C., Nien, Y.-C., & Huang, S.-M. (2022). Multi-Objective Optimization Design and Analysis of V-Shape Permanent Magnet Synchronous Motor. Energies, 15(10), 3496. https://doi.org/10.3390/en15103496