Abstract

Analysis of the change of overall energy efficiency performance of an energy system is a fundamental work for the energy-saving policymaking. However, previous studies seldom focus on energy stages from useful energy to final service, while most attention are paid on stages from energy source to useful energy. In this paper, we develop a high-resolution the Societal Exergy Analysis and Logarithmic Mean Divisia Index (SEA-LMDI) method to analysis changes and driving factors of the aggregate exergy efficiency, in which the boundary of the SEA is extended to passive systems and final services, and a LMDI decomposition method is developed to quantify contributions of efficiency factors and structure factors of all six stages on the aggregate exergy efficiency. A case study of China during 2005–2015 reveals that: (a) the aggregate exergy efficiency from energy source to final service is only from 3.7% to 4.8% during 2005–2015, showing a huge theoretical potential of efficiency improvement. (b) Large passive losses are identified in passive systems and nearly 2/3 of useful energy can be theoretically saved by improving passive systems. (c) Deep analysis of industrial coal-fired boilers indicates that the internal structural adjustments are also important for the aggregate improvement.

1. Introduction

Improving the energy efficiency at all stages of energy systems is considered as a critical action to mitigate climate change while also meeting people’s increasing demand for final energy service [1]. The IEA (International Energy Agency, Paris, France) claims that the energy efficiency improvement from 2016 to 2018 lowered the energy demand by 4% and avoided 3.5 billion tons of carbon dioxide emissions. It is expected that this energy efficiency improvement will continue to contribute to achieving the 2 °C goal of the Paris Agreement [2]. At the national level, policies related to energy efficiency have also been the main concern for policymakers, such as in China [3] and Germany [4].

As we know, the energy system is a complex system. To improve energy efficiency at different stages in energy systems, many technologies have emerged. For policymakers, given the limitation of time and resources, priority should be given to key technologies that have bigger potential and will deliver better gains [5]. To identify these key fields of energy efficiency improvements and guide future policymaking, the first step is to estimate the overall energy efficiency performance of the entire energy system.

In previous work, the assessment model of the overall energy efficiency performance of energy systems can be divided into two categories: the top-down energy intensity model and the bottom-up thermodynamic efficiency model [6]. The energy intensity is defined as the energy consumption per unit of GDP (Gross Domestic Product), providing a top-down approach to connect energy consumption with economic development; however, the energy intensity model cannot fully reflect technological progress in fields underlying energy systems, which will lead to the neglect of some key technologies [7]. In contrast, the thermodynamic efficiency model can provide a bottom-up approach to observe technological progress underlying energy systems.

Based on different thermodynamic laws, the thermodynamic efficiency model includes the first-law energy efficiency and the second-law energy efficiency (or exergy efficiency). In the first-law energy efficiency model, energy is conserved and cannot be created or destroyed, but the energy quality differences between the inputs and the useful outputs are not considered. This will lead to some unreasonable results. For example, the first-law energy efficiency of a heat pump will be greater than 100%. On the other hand, the exergy efficiency can distinguish the quality difference between 1 kJ electricity and 1 kJ heat by their ability to perform work, where exergy represents the maximum amount of useful work can be obtained when the system is brought to equilibrium with the surroundings [8]. As a result, exergy is considered as a more scientific metric and the exergy efficiency analysis has been widely used to evaluate the overall energy efficiency performance of energy systems, since exergy can consider both the energy quantity difference and the energy quality difference (see Section 2.2).

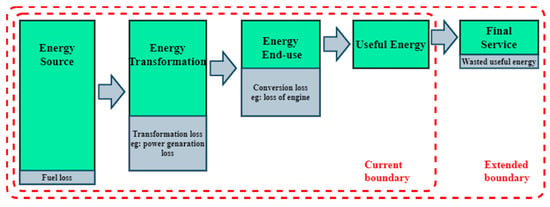

The exergy efficiency analysis of societal energy systems, also referred to as Societal Exergy Analysis (SEA), first divides a societal energy system into several stages, including energy source, energy transformation, and energy end-use, then further analyzes the exergy input and output of each stage, and finally aggregates these stages to evaluate the aggregate exergy efficiency [9]. Most previous studies of SEA only focus on the energy stages from the energy source to useful energy, as shown in Figure 1. However, what people need is not energy itself, but the “final services” it provides. For instance, what people really need is not heat energy itself, but the thermal comfort provided by heat energy. Loss not only occurs in the process from the energy source to useful energy but also in providing final services, such as heat losses due to poor insulation of a room [10]. Therefore, to systematically identify key fields of energy efficiency improvements, the analysis boundary of the exergy efficiency analysis is supposed to be extended to final service.

Figure 1.

The energy flow of a societal energy system in the Societal Exergy Analysis.

Moreover, limited attention was paid to the driving factors analysis in the SEA. The analysis of driving factors helps deeply understand the change mechanism of the aggregate exergy efficiency and provide further policymaking interventions. These limited papers mainly analyzed the end-use stage’s driving factors [11,12,13], without considering the final service. Obviously, excessive attention to the end-use stage may overlook other stages’ potential. Therefore, a method of driving factor analysis considering all stages of the whole energy system also needs to be further developed to comprehensively understand changes of the aggregate exergy efficiency.

In the author’s previous studies, a method named “the Logarithmic Mean Divisia Index (LMDI) decomposition method based on energy allocation analysis” was developed ahead to analyzed changes and driving factors of energy consumption (see Section 2.3), of which the idea can be learnt to fill the research gap mentioned above. In this paper, we develop a high-resolution Societal Exergy Analysis and Logarithmic Mean Divisia Index (SEA-LMDI) method to analyse the changes and driving factors of the aggregate exergy efficiency of energy systems, in which the boundary of the SEA is extended to passive systems and final services, and a LMDI decomposition method considering all stages of energy systems is developed to quantify contributions of efficiency factors and structure factors of all six stages on the aggregate exergy efficiency.

China is used as the case study in this investigation. In recent years, China’s economy has experienced rapid development, however with increasing energy demand and carbon emission. The data show that China’s energy consumption and carbon emission have increased at an average annual rate of 3.8% and 2.6% in the past 10 years, respectively [14]. To tackle this challenge, the improvement of energy efficiency has been given priority and incorporated into China’s national strategy text since the 11th National Five-Year Plan in 2006 [15,16,17]. Further, China is going through a fast transition period with one of the most complex energy systems, and a variety of new technologies are emerging. Therefore, it is essential to have a comprehensive overview of the overall energy efficiency performance of China to evaluate the current efficiency level and find key areas for future improvements.

The key energy-consuming fields in China need to be further analyzed. In recent years, thanks to the efficiency improvement policy in many technical fields, many higher-efficiency devices have been newly built, and most old and low-efficiency devices have been eliminated or reduced [18]. However, this technology replacement has resulted in the co-existence of a lot of new and old technologies, which resulted in what is known as China’s “Dual Structure” problem. This problem is not only a problem in China but commonly found in many developing countries. Despite the dual structure problem being quite widespread, very little literature has addressed it, and the potential for future improvement has not been clearly identified. Thus, in this investigation, we conducted further analysis of the “Dual structure” problem in China to better guide future efficiency improvement.

The contributions of this paper can be summarized as follows:

- The current boundary of SEA is extended to the final service to observe changes of the aggregate exergy efficiency from the energy source to the final service.

- A driving factor analysis method considering all stages of the whole energy system is developed to systemically decompose what factors drive aggregate exergy efficiency.

- A deep analysis of the “dual structure” problem in China was conducted to provide deep understandings of efficiency improvements in developing countries like China.

2. Literature Review

This section is organized as follows: Section 2.1 introduces the current energy efficiency models of the top-down energy intensity model and the bottom-up thermodynamic efficiency model. Section 2.2 provides literature review of the SEA and identifies current research gaps. Section 2.3 describes the “logarithmic mean divisia index decomposition (LMDI) method based on energy allocation analysis” developed ahead in the author’s previous analysis of energy consumption, which provides ideas for the method developed in this article.

2.1. Energy Efficiency Model of Energy Systems

Energy efficiency is a generic term and hard to defined in an unequivocal way. In general, energy efficiency is defined as the ratio of useful output to energy input in Equation (1) [6]. The issue then becomes how to precisely state the useful output and energy input, and a number of indicators can be used to monitor changes in energy efficiency:

Concerning the energy efficiency model of energy systems, it can be divided into two categories based on different definitions of the useful output: the top-down energy intensity model and the bottom-up thermodynamic efficiency model.

- (1)

- Top-down energy intensity model. The useful output is measured by the gross domestic product (GDP). Energy intensity is the reciprocal of energy efficiency and is defined as the energy consumption per unit of GDP. Energy intensity can provide a top-down approach to connect energy consumption with economic development. Since the data are easy to obtain and easy to calculate, the energy intensity is the most used indicator to evaluate the overall energy efficiency performance at the macrolevel, such as a country [19,20,21], an economic-sector like industry [22], or a region [23,24].

- (2)

- Bottom-up thermodynamic efficiency model. The useful output and the energy input are both measured by thermodynamic units, including the first-law energy efficiency and the second-law energy efficiency (also known as “exergy efficiency”). The thermodynamic efficiency model can provide a bottom-up view to observe the technology progress underlying energy systems. In the thermodynamic efficiency model, the energy system is divided into different stages, and then the technical energy efficiency of each stage is calculated one by one, and finally, the overall energy efficiency is obtained by aggregation [9]. For example, Nakicenovic [25] evaluated the global first-law energy efficiency and exergy efficiency in 1990. Liu et al. [26] analyzed the first-law and exergy efficiency of the Chinese urban residential sector.

To find key technical fields that will deliver the largest gains, the bottom-up thermodynamic efficiency model is more suitable. Energy intensity focuses more on the relationship between macro-economic development and energy consumption, which has implications for decision-making on decoupling economic growth from energy consumption [27]; however, it cannot provide an estimate of the extent to which the technical energy efficiency can be improved for a given technology or device underlying the energy systems [7]. In contrast, thermodynamic efficiency describes energy systems’ energy efficiency on a physical and technological basis [28]. If one’s goal is the technical improvement of energy systems, the thermodynamic efficiency model is more suitable.

In the thermodynamic efficiency model, the exergy efficiency is considered as a more scientific indicator. The first-law energy efficiency measures efficiency via the first law of thermodynamics, which says that energy is conserved and cannot be created or destroyed. A significant problem with first-law energy efficiency is that it does not consider the energy quality difference of the energy inputs and outputs [6], where 1 kJ electricity and 1 kJ heat are considered as the same in the amount of energy. For certain devices, the calculated heat output is far more than the electricity inputs unreasonably, such as heat pumps. On the other hand, the exergy efficiency measures efficiency based on the first and second laws of thermodynamics. Exergy represents the maximum amount of useful work obtained when the system is brought to equilibrium with the surroundings [8]. The energy quality difference between 1 kJ electricity and 1 kJ heat can be distinguished through their ability to perform work. As a result, since it can consider both the energy quantity and energy quality, exergy efficiency analysis has been an efficient tool to evaluate the overall energy efficiency performance of energy systems.

2.2. Societal Exergy Analysis

As an objective metrics, exergy has been widely used for the system analysis of energy [29,30,31], environment [32], ecology [33], and sustainability [34,35]. For example, Dincer [29] addressed the important role of exergy in the policymaking of energy and solving related environmental problems. Gong and Wall [30] conducted the exergy analysis of the energy and material flow in Sweden. Jorgensen and Nielsen introduced a modified form of exergy named eco-exergy as an ecological indicator [33] and applied this to the sustainability analysis of a society [34].

The bottom-up exergy analysis of energy systems is also called Societal Exergy Analysis (SEA), which has been widely used to assess the supply, demand, and technology characteristics of energy systems on a global, national, or sectoral level [36]. As defined in Equation (2), SEA first divides energy systems into several stages, including energy source, energy transformation, and energy end-use, then further analyzes the exergy input and output of each stage, and finally aggregates these stages to evaluate the aggregate exergy efficiency [9]:

The SEA allows us to follow the historical evolution of energy efficiency improvement and understand approaches to improving future energy efficiency performance [28]. Reistad [37] was the first scholar to use the SEA for the exergy efficiency analysis of the US in 1970. Subsequently, Rosen [38] evaluated the exergy flow through the four main sectors in Canada in 1986. Dincer et al. [39] analyzed the sectoral exergy utilization in Saudi Arabia between 1990 to 2001. Utlu and Hepbalsi [40] applied this model to assess Turkey’s sectoral exergy efficiency in 1999 and 2000. Ayres et al. [41] conducted a time-series analysis of the exergy efficiency of the US from 1900 to 1998. Furthermore, Warr et al. [42] provided a cross-country comparison of the exergy efficiency in Austria, Japan, the UK, and the US throughout the 20th century.

Most SEA studies focus on the energy chain from the energy source to useful energy—see Figure 1. The earlier studies applied the concept of exergy to evaluate the overall efficiency performance of energy systems. The energy system was divided into energy sources (e.g., coal, natural gas, and solar), electricity generation, and end-use sectors (e.g., industry, transportation, and household). Each end-use sector was split into several components to assess their technical performance individually. For example, Reistad was the first scholar to determine that the aggregate exergy efficiency of the US was 21% when considering the energy source to useful energy in 1970. Nakicenovic [25] and Cullen and Allwood [43] applied the SEA at a global level of 10% in 1990 and 11% in 2005. On the other hand, recent papers focus more on the role of useful work in end energy use and economic activity [36], such as the evolution of useful energy or useful work intensity (useful work/gross domestic product). For example, Brockway et al. explored the trend of useful energy in the US and the UK from 1960 to 2010 [11] and China from 1971 to 2010 [13]. Serrenho et al. [12] calculated the useful work intensity for each EU-15 country in 1960–2009 from the IEA energy balances.

However, what people need is not energy itself, but the “final services” it provides. For instance, what people need is not heat energy itself, but the thermal comfort provided by heat energy [10]. Some scholars have stepped forward in this field. Nakicenovic [25] pointed out that the inclusion of the useful to service efficiency would help observe the larger potential for efficiency improvements. Cullen and Allwood [5] introduced a “passive system” between the end-use stage and the final service stage to trace the global energy system’s energy flow from the energy source to the final service. Then, Sun et al. [44] allocated the useful energy output to the passive system and final service in China.

Meanwhile, limited attention was paid to the analysis of driving factors, while most SEA-based studies concentrated on the evolution analysis of exergy efficiency. The analysis of driving factors helps us understand the energy efficiency evolution mechanism and provide further policy interventions; however, these papers often only analyzed the driving factors of the end-use stage [11,12,13]. For example, Serrenho et al. [12] analyzed the driving factors of thermodynamic efficiency improvement and the structural change of the end-use stage in fifteen EU countries from 1960 to 2009. Obviously, the energy system includes other stages besides the end-use stage, and excessive attention to the end-use stage may overlook the potential of other stages; therefore, a driving factor analysis method considering all stages of the whole energy system needs to be developed.

In short, to systematically observe more key fields for energy efficiency improvement, the analysis boundary of the exergy efficiency analysis should be extended to the final service, and a driving factor analysis method considering the driving factors of all stages of the whole energy system should be developed, allowing us to understand the changes and driving factors of the aggregate exergy efficiency from the energy source to the final service.

2.3. LMDI Decomposition Method Based on Energy Allocation Analysis

In the author’s previous studies, a method named “the logarithmic mean divisia index (LMDI) decomposition method based on energy allocation analysis” was developed prior to this study to analyze the evolution and driving factors of energy consumption [45,46,47,48]. In this method, the energy system was divided into stages of energy source, transformation, end-use conversion devices, passive systems, and final service, to trace energy flow from the energy source to the final service, and then, a LMDI decomposition technique was applied to quantify contributions of different driving factors on energy consumption. This method was used for the analysis of energy consumption, but the idea of this method can be adapted to fill the research gap mentioned in Section 2.2.

The energy allocation analysis provides an accounting method based on the systematic analysis of energy input, flow, and conversion of a complex energy system, where the data are normally sourced from national or regional energy balance sheets [48]. The so-called allocation only shows the energy allocation in the total energy balance and does not reflect the loss at each stage [49]. Cullen and Allwood [5] are the earlier scholars who performed the energy allocation analysis to systematically analyze the global energy flow of five stages of energy systems, including energy source, transformation, conversion device, passive system, and final service. To more visually present the whole scenario of energy systems, Sankey diagrams are used to map the energy flow of a complex energy system. The Sankey diagram is a specific type of flow diagram in which the width of the arrows is proportional to the flow quantity and the color of the flow distinguishes the flow type. On this basis, Ma et al. [45] applied the energy allocation analysis to China and mapped China’s energy flow in 2005. Chong et al. [49] traced the energy flow from primary energy to end-use in Malaysia. Yang et al. [50] systematically analyzed the carbon flow in various stages of China’s energy systems. Zhao et al. [51] provided a deep overview of energy consumption disparities in 29 provinces in China.

The LMDI decomposition method is a kind of index decomposition analysis (IDA), and was first proposed by Ang and Choi [52] in 1997 to solve the unexplained residual term problem that existed in previous IDA methods. In the LMDI decomposition method, the first and most important step is to establish a rigorous LMDI decomposition identity, where the aggregate variable is decomposed into the product of several predefined driving factors and each factor has a clear physical meaning. For example, energy intensity is decomposed into the product of sector economic structure and sector energy intensity, as shown in Equation (3). Then, a general LMDI decomposition forum is used to quantify the relative contribution of each driving factor from period 0 to T, as described in Equations (4) and (5):

where, the subscript i stands for different end-use sectors, such as the industry sector or the transportation sector, is the aggregate energy intensity, is the total energy consumption, is the total economic output, is the sector economic structure, is the sector energy intensity, is the relative contribution of factor , and is the relative contribution of factor .

After a series of developments of methodology [53,54,55,56], the LMDI decomposition method has become a mainstream method to understand the change mechanism of energy systems under development [57]. The LMDI method is widely used for the analysis of to analyze the driving factors of energy consumption [58], energy intensity [59], and carbon emission [60]. Chong et al. combined the LMDI decomposition method and the energy allocation analysis to analysis analyze the driving factors of energy consumption [38] and energy-related CO2 emission [48]. They pointed that the LMDI method can better describe the process of energy supply, energy conversion, and energy consumption physically, and can better analyze some technical driving factors, such as the end-use energy structure, energy mix in electricity generation, and electricity generation efficiency.

Therefore, as the analysis boundary of the exergy efficiency analysis is extended to the final service, the LMDI decomposition method can be applied to develop a driving factor analysis method that consider the driving factors of the whole energy system.

3. Method and Data

3.1. The Societal Exergy Analysis of the Energy System

The general steps of the SEA have been well-established in previous studies [9,26,61]—see Figure 2 for a summary of these steps. In this section, some key features and improvements of each step are introduced.

Figure 2.

General steps of the Societal Exergy Analysis.

3.1.1. Stage Division of the Energy System

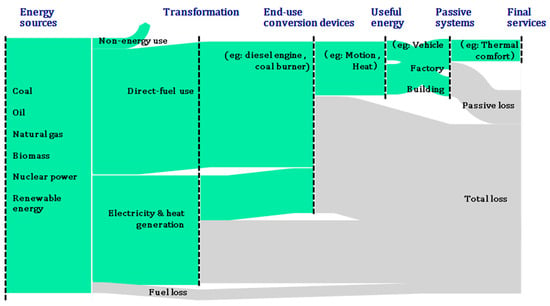

As shown in Figure 3, the energy system is first divided into common stages; then, each stage is further divided into different sectors, including energy source (e.g., coal, oil, renewable energy), transformation (e.g., electricity and heat generation), end-use conversion device (e.g., diesel engine, burner, electric motor), and useful energy (e.g., motion, heat).

Figure 3.

The stage division of the energy system.

To extend the analysis to the final service, the concept of the passive system is used here to trace energy flow from the useful energy to the final service. The term passive system was first introduced by Cullen and Allwood [5]. The passive system is the last technical stage of the energy chain. In contrast to conversion devices, passive systems do not actively or intentionally convert energy to another form. Instead, useful energy is held or trapped in passive systems for a time to provide a level of final service and is finally lost to the environment as waste energy. For example, a car body holds kinetic energy to provide a transport service, and the room traps light to provide illumination.

The energy system of China from 2005 to 2015 was taken as a case study for our investigation, since China’s economy has experienced rapid development and energy systems have been going through a fast transition in these past few years. Meanwhile, given that the China’s government published the national development plan every five years, and a large number of statistical data would be updated at that time, the year of 2005, 2011, 2016 were chosen in the case study. The data are mainly sourced from the “China Energy Statistical Yearbook” (2006, 2011, 2016) [62,63,64], “Wang Qingyi-Energy Data” (2006, 2011, 2016) [65,66,67], and partly from “The 13th Five-Year Plan for Energy Development” [68] and “The 13th Five-Year Plan for Renewable Energy Development” [69]. The processing of exergy flow data refers to the study of Ma et al. [45]. Detailed data are summarized in Table A1, Table A2 and Table A3.

3.1.2. Exergy Input of the Energy System

The exergy input of fossil fuel is calculated by chemical exergy. The chemical exergy of a substance is the maximum work that can be obtained when it is brought to chemical equilibrium in each reference environment at a constant temperature and pressure [70]. It has been widely used to characterize the exergy input of fossil fuel [26,71]. Chemical exergy can be obtained by multiplying the fuel’s low heating value (LHV) and exergy factor , as shown in Equation (6), and values of the exergy factor are listed in Table 1.

Table 1.

Values of the exergy factor .

The exergy of non-fossil energy is derived by its electricity production and average fossil efficiency conversion factor, which is often used by the US Energy Information Administration (EIA, Washington, DC, USA) and BP [29]. In this study, the pressure P0 = 101,325 Pa and temperature T0 = 298.15 K is adopted as the reference environment [72].

3.1.3. Exergy Efficiency of the Process

For an energy chain ranging from the energy source to the end-use conversion device, exergy efficiency is derived by multiplying the first-law energy efficiency and the quality factor , since, in most practical situations, exergy efficiency data are not easy to find, whereas the first-law energy efficiency is easier to obtain. Table A4 lists the exergy efficiency data of the power and heat generation sector and end-use conversion device stage:

The passive energy loss of a passive system is estimated by the “best practice” method. Given that the exergy efficiency is often defined as the ratio of the exergy output to the exergy input as Equation (1), it can also be defined by Equation (8) as the “actual” energy consumed relative to the “ideal” minimum energy required in a process [6]. This definition can be used to measure how close a real conversion process is to the ideal limits. On this basis, the “best practice” method is developed to evaluate how efficient a passive system is relative to the ideal limits. [73,74]. First, passive systems are divided into three groups: vehicles (car, truck, plane, ship, and train), factories (furnace, driven system, and steam system), and buildings (hot water, heated/cooled space, appliance, illuminated space). Then, for each, a physical model is established based on basic physical laws, such as Fourier’s law of thermal conduction. Finally, for parameters in each model, current values and ideal value are estimated to derive passive losses by Equation (8). Physical models of passive systems have been introduced and described in Cullen et al.’s research [73]. The results of calculations are summarized in Table A5:

where represents the “actual” energy consumption in a process, represents the “ideal” minimum energy required in a process.

3.1.4. Aggregate Exergy Efficiency

In this study, the aggregate exergy efficiency from the energy source to the final service of the whole energy system is defined as Equation (9):

where the numerator is the sum of the exergy delivered to final service n, including passenger transport, communication, and thermal comfort, as listed in Table A1, Table A2 and Table A3, The denominator is the sum of the chemical exergy input excluding the exergy flowing to non-energy use from different energy source i, including coal, oil, and renewable energy, as listed in Table A1, Table A2 and Table A3.

3.2. LMDI Decomposition Method of Driving Factor Analysis

In this section, the LMDI decomposition method was used to quantify the relative contributions of factors. Nine factors of efficiency and structure factors of each stage were identified and incorporated into a novel LMDI identity. Following the exergy flow of energy systems, these nine factors are energy source utilization coefficient, energy source structure, transformation structure, power and heat generation efficiency, end-use structure, end-use conversion efficiency, passive structure, passive efficiency, and service structure.

We followed the LMDI decomposition guide proposed by Ang [54,55] and the decomposition steps are as follows:

- (1)

- First, a novel LMDI decomposition identity including all nine driving factors is established.

- = the aggregate exergy efficiency from the energy source to the final service.

- = the exergy delivered to final service n, when energy flow of energy source i passes through transformation sector j, end-use device k, and passive system m.

- = the total exergy input. It is the sum of the chemical exergy input from different energy source i excluding the exergy flowing to non-energy use.

- = the sum of exergy used for direct-fuel use and power & heat generation.

- = the exergy input of energy source i.

- = the exergy flowing into sector i (or j, k, m, n) in stage X. X represents different stages shown in Figure 3, which are the energy source, transformation, end-use conversion device, passive system, and final service.

- = the exergy flowing out of stage X.

- = energy source utilization coefficient.

- = energy source structure.

- = transformation structure.

- = power and heat generation efficiency.

- = end-use structure.

- = end-use conversion efficiency.

- = passive structure.

- = passive efficiency

- = service structure.

- (2)

- Then, assuming that the aggregate exergy efficiency changes from time 0 to time T. The change rate of these nine driving factors is characterized in the following expression:

- = change rate of the aggregate final service efficiency from time 0 to time T.

- = relative contribution of driving factor Y from time 0 to time T. Y represents different driving factors described in step (1).

- (3)

- Finally, relative contributions of nine driving factors are quantitatively decomposed by the following formula:

3.3. Further Analysis of “Dual Structure” Problem in China

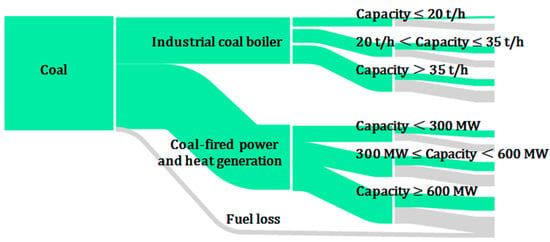

In this section, we provide further evaluation of the “Dual Structure” problem. The use of coal in China was taken as the case study due to its significant use in China.

According to different outputs of coal use, the coal use in China is divided into the industrial coal boiler (generating steam for heating) and the coal-fired power and heat generation (mainly generating electricity with some steam directly used for heating), as shown in Figure 4. Each is further divided into different levels of technical devices according to their capacities. For an industrial coal boiler, it is divided into capacity ≤20, 20~35, and >35 t/h, and for coal-fired power plants, it is divided into capacity <300, 300~600, and ≥600 MW. Then, the LMDI decomposition method is used to quantify driving effects of factors, including the coal utilization coefficient, capacity structure, and conversion efficiency listed in Equation (13). Table A6, Table A7 and Table A8 lists the coal use proportion, exergy efficiency, and capacity structure data [75,76,77,78,79]:

Figure 4.

Schematic diagram of the “Dual Structure” of coal in China.

In the above equation, subscript k represents a technical device with different capacities.

4. Results

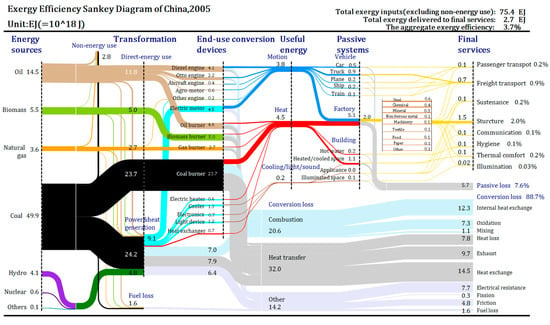

4.1. The Aggregate Exergy Efficiency of China from 2005 to 2015

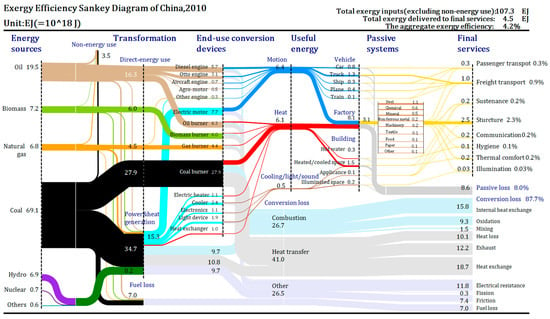

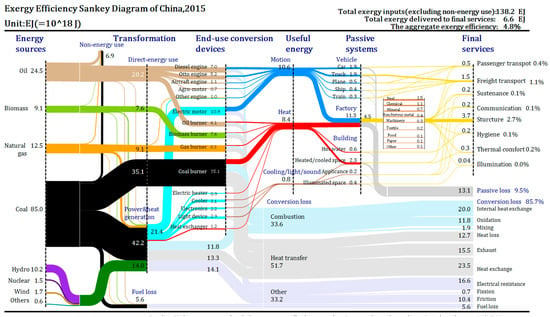

The exergy flow and exergy conversion from the energy source to the final service of China in 2005, 2010, and 2015 are summarized in Table A1, Table A2 and Table A3 and mapped using Sankey diagrams in Figure 5, Figure 6 and Figure 7. As presented in Figure 5, Figure 6 and Figure 7, the primary energy enters the energy system, undergoes different stages and causes losses, and finally outputs useful energy to provide final services, where the arrow represents the direction of exergy flow, the color represents different exergy flows, and the width represents the amount of exergy flow.

Figure 5.

Exergy efficiency Sankey diagram from the energy source to final service of China in 2005.

Figure 6.

Exergy efficiency Sankey diagram from the energy source to final service of China in 2010.

Figure 7.

Exergy efficiency Sankey diagram from the energy source to final service of China in 2015.

According to the diagrams in Figure 5, Figure 6 and Figure 7, the main features of changes of the aggregate exergy efficiency of China’ energy system are identified and discussed:

- (1)

- The aggregate exergy efficiency of China from the energy source to final service was just 3.7% in 2005, 4.2% in 2010, and 4.8% in 2015. This shows an increasing trend; however, it is still at a very low level. This means that just less than 5% of exergy input ultimately provided final services, and significant potential for future improvement was identified.

- (2)

- Losses mainly occurred in the end-use conversion stage and the power and heat generation sector. The average exergy efficiency was 16% (2005), 19% (2010), and 21% (2015) for the end-use conversion stage and 30% (2005), 34% (2010), and 35% (2015) for the power and heat generation sector. Among these two technical sectors, fuel was upgraded into higher quality energy, such as electricity and mechanical work. Due to the thermodynamic limit, an irreversible loss would inevitably occur, mainly as a result of combustion and heat transfer losses. On the other hand, limited by inappropriate operation and unpredicted conditions in practice, the actual operating efficiency of these conversion devices never reaches the theoretical design value, resulting in more losses. Thankfully, with the continuous promotion of efficiency improvement in these fields in China, the technical design and operation level of conversion devices have constantly been improving to reduce the loss.

- (3)

- There is considerable potential for the improvement of passive systems. We found that just 32% (2005), 34% (2010), and 34% (2015) of the exergy input of passive systems were delivered to final services. In contrast to conversion devices, passive systems do not actively convert energy to another form, instead, they hold useful energy in order to provide a level of final service. The efficiency of a conversion device is related to how they convert fuel into useful energy; however, the efficiency of a passive system is based on avoiding unintended losses of useful energy in order to provide final services, e.g., reducing the friction or drag of a car, and or increasing the seal or insulation of a house. For example, in China, over 80% of useful energy of building passive systems were lost without providing needed services. Several factors inhibit the deployment of more efficient technical solutions in buildings: the variety of building designs, the existence of a large number of old buildings with poor seal and insulation, improper setting of cooling or heating temperature, and so on.

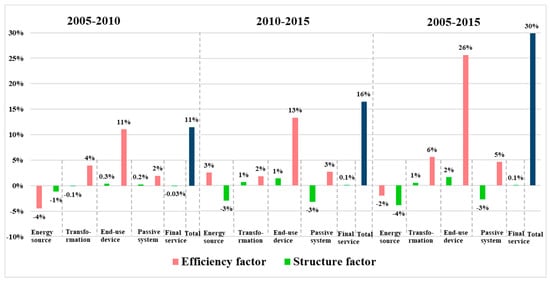

4.2. LMDI Decomposition Results of Driving Factors

Relative contributions of efficiency and structure factors on the aggregate exergy efficiency are quantitatively decomposed by the LMDI decomposition method, as illustrated in Table 2 and Figure 8. The efficiency improvement of the end-use conversion stage and power and heat generation sector has always been the most important driving factors, and contributions of passive systems were considerable. In this section, we discuss and explain the driving factors of each stage.

Table 2.

Logarithmic Mean Divisia Index (LMDI) decomposition results of driving factors in China.

Figure 8.

Relative contributions of the efficiency and structure factors of each stage in China from 2005 to 2015. (Note: Horizontal axis-different energy stages of energy system; Vertical axis-Relative contributions of different efficiency and structure factors on the aggregate exergy efficiency).

4.2.1. Energy Source

The energy source utilization coefficient is defined as the ratio of exergy used by direct fuel use and power and heat generation to the total exergy input, which was 0.98 (2005), 0.93 (2010), and 0.96 (2015), with contributions of −4% (2005–2010) and 3% (2010–2015) to the aggregate exergy efficiency. In short, reducing fuel loss is helpful, such as coal preparation losses, and oil and gas transportation pipeline losses.

As for the energy source structure, there was a negative decrease of −1% (2005–2010) and −4% (2010–2015). Due to China’s continuous efforts of promoting renewable energy and reducing fossil energy in recent years, the share of renewable energy has increased rapidly as the share of coal and oil fell sharply; however, the exergy efficiency of the whole energy chain of fossil energy was higher than renewable energy. That is why the adjustment of energy sources has negative effects on the aggregate exergy efficiency.

4.2.2. Power and Heat Generation Sector

The transformation structure represents how much energy was delivered to the power and heat generation sector, which was 0.41 (2005), 0.45 (2010), and 0.46 (2015), with contributions of −0.1% (2005–2010) and 1% (2010–2015). Since there is one more exergy conversion process in the power and heat generation sector, more energy being delivered to this sector, more losses are caused. However, this negative effect can be diluted by the efficiency improvement of power and heat generation.

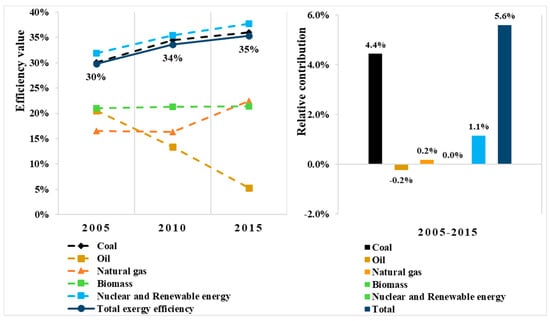

The efficiency improvement of the power and heat generation sector has significant contributions of 4% (2005–2010) and 2% (2010–2015). As shown in Figure 9 (Left), the exergy efficiency of the whole sector increased from 30% to 35% from 2005 to 2015, contributing 5.4%. This is closely related to the recent efforts to improve the efficiency of the power and heat generation sector. For the power and heat generation sub-sectors, the exergy efficiency of all sub-sectors except oil increased year by year; coal-fired power and heat generation has the largest contribution, reaching 4.3% as shown in Figure 9 (Right). This is because that coal has always been the most important source of power and heat generation in China, accounting for more than 70% of the total power and heat generation. The efficiency improvement of the coal-fired power and heat generation is crucial to aggregate efficiency improvement.

Figure 9.

The efficiency of different power and heat generation sub-sectors in China from 2005 to 2015 (Left); Relative contributions of efficiency improvements in the power and heat generation sector in China from 2005 to 2015 (Right).

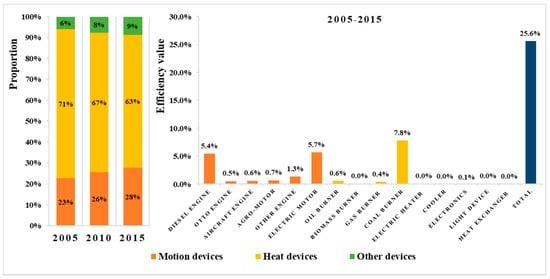

4.2.3. End-Use Conversion Device

The contribution of the end-use conversion device is important to the improvement of aggregate exergy efficiency. Concerning end-use structure, its contribution increased from 0.3% (2005–2010) to 1% (2010–2015). As Figure 10 (Left) shows, more energy was converted into motion energy in devices (e.g., energy converted by Otto engines, aircraft engines, and electric motors), which increased from 23% (2005) to 26% (2010), and 28% (2015). As these motion devices have a higher efficiency than other devices, this adjustment contributed most to aggregate improvement.

Figure 10.

The proportion of the end-use structure in China from 2005 to 2015 (Left); Relative contributions of efficiency improvements of conversion devices in China from 2005 to 2015 (Right).

The improvement of end-use conversion efficiency has always been the most important driving factor. Thanks to the continuous attention to the efficiency improvement of end-use conversion devices, its contribution was far more than other driving factors, with 11% (2005–2010) and 13% (2010–2015). As shown in Figure 10 (Right), the more energy the end-use conversion device consumed, the more significant its contribution to the aggregate improvement was. For example, coal burners always occupied the largest proportion of energy-use and contributed the most, at 7.9%. Diesel and gasoline engines consumed the most fuel oil and contributed 3.6% and 1.8%. In short, improving the efficiency of end-use conversion devices is still the most important task to improve the aggregate efficiency of the whole energy system.

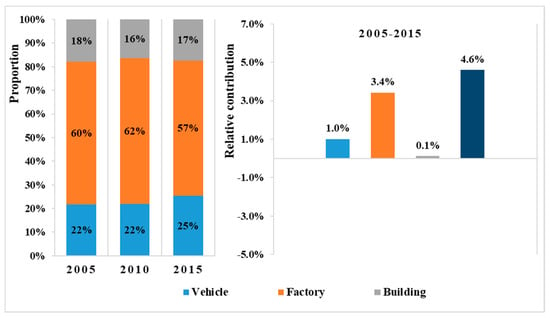

4.2.4. Passive System

The contribution of passive systems is considerable and cannot be ignored moving forward. Regarding the passive system structure, it contributed 0.2% (2005–2010) and –3% (2010–2015). As Figure 11 (Left) shows, the share of factory passive systems increased first and then fell from 60% to 62% and 57%, respectively; however, the vehicle passive systems increased from 22% to 25%. Since the factory passive system accounts for a bigger share, it has a greater impact on aggregate efficiency improvement.

Figure 11.

The share of passive structure in China from 2005 to 2015 (Left); Relative contributions of efficiency improvement for passive systems in China from 2005 to 2015 (Right).

The contribution of passive efficiency improvement is rising with contributions of 2% (2005–2010) and 3% (2010–2015). As Figure 11 (Right) and Table A5 show, small efficiency changes in passive systems can make significant contributions as the passive efficiency was still relatively low; therefore, the efficiency improvements of passive systems cannot be ignored and holds incredible potential for future improvements in aggregate efficiency.

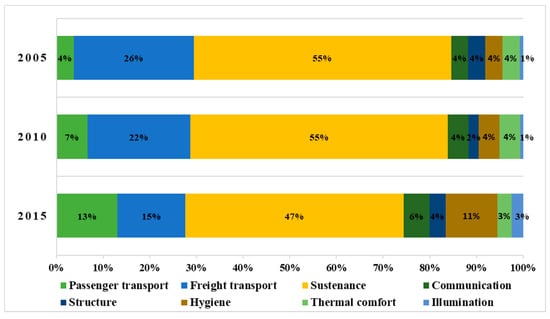

4.2.5. Final Service

The contribution of the final service structure is not clear; this is mainly due to the offsetting among different final services. As Figure 12 shows, the proportion of structure and freight transport services dropped significantly, while passenger transport, communication, and hygiene grew. Obviously, rapid development in the early stage in China led to significant increases in energy consumption, mainly due to infrastructure construction. Then, as China entered the high-quality development stage, the demand for such final services increased, e.g., passenger transport, communication, and thermal comfort. For example, high-speed railways were rapidly constructed, and car sales began to increase. However, because these energy flows delivering to final services were mostly with relatively low efficiency, effects of these structure adjustment among these final services were offset each other.

Figure 12.

The share of exergy delivered to final services in China from 2005 to 2015.

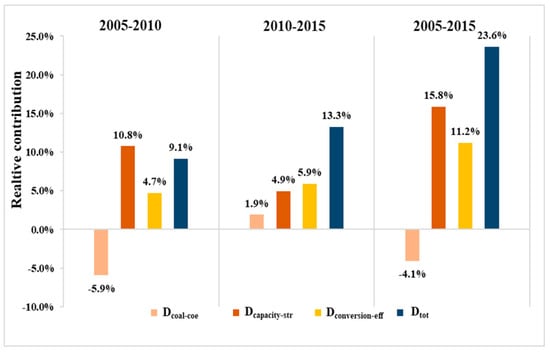

4.3. Further Decomposition Results of “Dual Structure” Problem in China

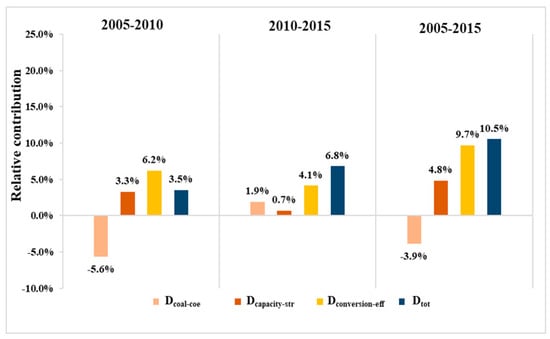

The “Dual structure” problem in China, the co-existence of new and old technologies, is further analyzed using the method in Section 3.3. The results are listed in Table 3 and illustrated in Figure 13 and Figure 14.

Table 3.

LMDI decomposition results of the “Dual Structure” problem in China.

Figure 13.

Relative contributions of driving factors of industrial coal boiler in China from 2005 to 2015.

Figure 14.

Relative contributions of driving factors of coal-fired power and heat generation in China from 2005 to 2015.

For the industrial coal boiler, the aggregate exergy efficiency increased by 23.6%, and the adjustment of the capacity structure was the main driving factor, contributing 15.8% (2005–2015). Interestingly, from 2005 to 2010, the adjustment of the capacity structure was the main driving factor contributing 10.8%, while the improvement of conversion efficiency contributed only 4.7%; however, from 2010 to 2015, the contribution of efficiency improvement rose to 5.9%, catching up with the capacity structure adjustment of 4.9% to become the main driving factor. It is obvious that the drastic capacity structure adjustment in the early stage played a significant role in the aggregate efficiency improvements; however, with the reduction of the structure adjustment potential, its contributions decreased and fell behind the efficiency improvement in the later stage.

For the coal-fired power and heat generation, the aggregate exergy efficiency increased by 10.5%. The improvement of conversion efficiency has always been the main driving factor, contributing 9.7% (2005–2015). Since coal-fired power and heat generation units are operating at a higher efficiency level in the early stage, the capacity structure adjustment played a role, but its contribution was limited, even less than that of efficiency improvement. Later, contributions of both decreased, and the contribution of capacity structure adjustment was negligible.

In short, for the energy-intensive sectors that have low efficiency, e.g., industrial coal boilers, the adjustment of capacity structure has a significant effect and will continue to contribute for a while. At the same time, there is still much room to improve the conversion efficiency, as most industrial coal-fired boilers are operating at a low level of efficiency. In contrast, the efficiency of coal-fired power units is generally at a relatively high level, and the contribution of internal capacity structure adjustment is limited.

5. Discussion

5.1. International Comparison

The results found in this study can be compared with previous works. In this study, we extended the boundary of the SEA to the final service, as most studies have only concentrated on the energy chain from the energy source to useful energy. In order to make a meaningful comparison, the aggregate exergy efficiency from the energy source to the useful energy is listed separately—see Table 4; our results are similar to previous studies. The main discrepancy lies in the aggregate exergy efficiency from the energy source to the final service, likely due to the introduction of passive systems where huge energy losses were identified.

Table 4.

Comparison of results with previous studies.

Comparing the driving factor analysis with previous studies is not easy—the analysis of driving factors in the SEA is limited, and most do not cover all stages of the whole energy system and instead just the end-use conversion stage. Looking into these limited studies, Brockway et al. [13] conducted a similar study in China, but they concluded that the structure change was the main contributor to the aggregate improvement. This is because they defined the structural change as a combined effect of the structure of two different stages. If we look at these stages separately, the improvement of end-use efficiency is still the main driving factor, which is in line with results obtained in this study.

5.2. Improvement of Model Resolution

The improvement of model resolution can be helpful to better understand the efficiency improvement potential of energy systems.

In this paper, the analysis boundary of the exergy efficiency model was extended to the final service to trace energy flow and conversion from the energy source to the final service. In contrast to previous studies that mostly focused on the end-use conversion stage, the energy chain of useful energy output passing through passive systems to provide final services was further analyzed. The results show that just less than 5% of exergy input ultimately provided desirable final services. The results also indicate huge improvement potential in passive systems besides end-use conversion devices.

A driving factor analysis method that considers all stages of the whole energy system was developed to understand relative contributions of each stage of an energy system. In previous studies, excessive attention was paid to the end-use conversion stage. The decomposition results in this study indicated that efficiency improvements in the end-use conversion stage and power and heat generation sector were important, but improvements in passive systems were also considerable. The results of the decomposition analysis show that we should pay attention to both how to convert fuel into useful energy more efficiently, and also how to avoid unintended losses of useful energy when providing final services.

Further, a deep analysis of key technical fields may yield different insights, such as a deep analysis of the “Dual Structure” problem in China. If we observe decomposition results from the view of the end-use conversion stage, the efficiency improvement contributed most, and contributions of structure adjustment were limited; however, a deep analysis of the “dual structure” problem of coal-fired power and heat generation sector and industrial coal boilers implied that internal structural adjustments are equally important for aggregate improvements. Especially for energy-intensive devices with low efficiency, like industrial coal-fired boilers, internal structure adjustment using high-efficiency boilers to replace low-efficiency boilers played a greater role than efficiency improvement in general.

5.3. Uncertainty and Limitation

The main uncertainty of this study lies in the data accuracy. Data used in this paper were mainly sourced from Chinese government authorized sources, literature reviews, and expert interviews. However, rigorous data are not always directly available, and the best available data are adopted based on reasonable estimation. Despite this data uncertainty, this study provides a comprehensive framework to observe changes and driving factors of aggregate exergy efficiency to direct priorities now. If in the future, more accurate data sources are available, future studies should take them into account.

The main limitation of this paper is that the final service loss has not been taken into consideration. This loss is not the physical loss but is more related to human behavior, e.g., improper use of space heating and cooling, waste of food, and ineffective of private cars. In the future, the waste of final services should be further explored.

6. Conclusions

In this paper, a high-resolution SEA-LMDI method was developed to systemically and comprehensively analysis changes and driving factors of the aggregate exergy efficiency of energy systems. First, we extended the current boundary of the SEA to include passive systems and final services, and the results are visualized by the Exergy Efficiency Sankey diagram, which details the energy flow from the energy source to the final service. Then, we applied the LMDI decomposition method to quantify the relative contributions of the structure factor and the efficiency factor of each stage of the whole energy system. Moreover, we conducted a deep analysis of key fields, taking the “Dual Structure” problem of coal use in China as an example.

With China as the case study, the results allow several key insights. (1) Only less than 5% of exergy input ultimately provided the final services people need. Although the aggregate exergy efficiency from the energy source to the final service showed an increasing trend, it is still at a low level. (2) Decomposition results reveal that the efficiency improvement of the end-use conversion stage and the power and heat generation stage have significant contributions to the aggregate improvement, but the contribution of the passive system is noteworthy. As just around 30% of useful energy passed through passive systems and finally provided final services, small improvements in passive efficiency can make a considerable contribution to the aggregate efficiency improvement. (3) Deep analysis of the “Dual Structure” problem of coal use in China indicated that, for energy-intensive and low-efficiency devices like industrial coal boilers, the internal structure adjustment, using high-efficiency devices to replace low-efficiency devices, also played an important role in improving aggregate exergy efficiency.

Based on this study, the following implications can be drawn:

- The overall energy efficiency performance of China’s energy system is still at a low level. Significant potential for future efficiency improvement exists and deserves to be explored, especially in the context of carbon neutrality and sustainable development.

- Energy efficiency improvements in technology devices, including end-use conversion devices and power and heat generation, will continue to make a considerable contribution to the aggregate improvements. Attention should be paid to the improvement of the conversion of fuel into more useful energy, such as optimizing thermodynamic designs, reducing heat transfer and combustion losses, and improving the equipment operation levels.

- Sufficient attention should be paid to the role of passive systems. The efficiency of a passive system depends on how well unintended losses of useful energy providing final services can be addressed, such as reducing the friction or drag of a car and promoting the seal and insulation of a house.

- For key energy-consuming fields, it is also a good idea to replace low-efficiency equipment directly with high-efficiency equipment.

This study provides a high-resolution view to identify key technological fields for future energy efficiency improvements of energy systems. This can play a positive role in the policymaking of energy-saving and carbon emission reduction. In the next step, work can be performed to estimate the waste of the final service. This loss relates more to human behavior than technical systems, e.g., food wastage. Given the emphasis on reducing unnecessary waste, future work on this front would reveal more avenues moving forward.

Author Contributions

Conceptualization, Y.L. and L.M.; methodology, Y.L. and C.C.; data curation, Y.L.; writing—original draft preparation, Y.L.; writing—review and editing, L.M. and C.C.; supervision, L.M.; funding acquisition, Z.L. and W.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China [grant number 71690245]. The authors gratefully acknowledge the support of BP in the form of Phase II and Phase III Collaboration between BP and Tsinghua University, and the support of the Tsinghua-Rio Tinto Joint Research Centre for Resources, Energy, and Sustainable Development.

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable

Data Availability Statement

All data are available in the public domain.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| SEA | Societal Exergy Analysis |

| exergy efficiency | |

| LMDI | Logarithmic Mean Divisia Index |

| the first-law energy efficiency | |

| LHV | Low Heating Value |

| exergy factor | |

| exergy | |

| quality factor | |

| useful output | |

| S | structure factor |

| D | the change rate of driving factor |

Appendix A

Table A1.

Vertical slices of exergy flow of China in 2005.

Table A1.

Vertical slices of exergy flow of China in 2005.

| Energy Source | EJ | Transformation | EJ | Conversion Device | EJ | Useful Energy | EJ | Passive System | EJ | Final Service | EJ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil | 14.5 | Direct-energy use | 43.3 | Diesel engine | 4.1 | Motion | 3.8 | Car | 0.5 | Passenger transport | 0.1 |

| Biomass | 5.5 | Power & heat generation | 30.5 | Otto engine | 2.2 | Heat | 4.5 | Truck | 0.9 | Freight transport | 0.7 |

| Natural gas | 3.6 | Non-energy use | 2.8 | Aircraft engine | 0.4 | Cooling/light/sound and others | 0.2 | Plane | 0.2 | Sustenance | 0.1 |

| Coal | 49.9 | Fuel loss | 1.6 | Agro-motor | 0.6 | Combustion loss | 13.6 | Ship | 0.2 | Communication | 0.1 |

| Hydro | 4.1 | Other engine | 0.2 | Heat transfer loss | 24.1 | Train | 0.1 | Structure | 1.5 | ||

| Nuclear | 0.6 | Electric motor | 4.5 | Other loss | 6.3 | Factory | 5.1 | Hygiene | 0.1 | ||

| Others | 0.1 | Oil burner | 4.6 | Hot water | 0.2 | Thermal comfort | 0.1 | ||||

| Biomass burner | 5.0 | Heated/cooled space | 1.1 | Illumination | 0.02 | ||||||

| Gas burner | 2.7 | Appliance | 0.04 | ||||||||

| Coal burner | 23.7 | Illuminated space | 0.1 | Passive loss | 5.7 | ||||||

| Electric heater | 0.6 | ||||||||||

| Heat exchanger | 0.7 | ||||||||||

| Cooler | 1.3 | ||||||||||

| Electronics | 0.7 | ||||||||||

| Light device | 1.2 |

Table A2.

Vertical slices of exergy flow of China in 2010.

Table A2.

Vertical slices of exergy flow of China in 2010.

| Energy Source | EJ | Transformation | EJ | Conversion Device | EJ | Useful Energy | EJ | Passive System | EJ | Final Service | EJ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil | 19.5 | Direct-energy use | 54.8 | Diesel engine | 5.7 | Motion | 6.4 | Car | 0.8 | Passenger transport | 0.3 |

| Biomass | 7.2 | Power & heat generation | 45.5 | Otto engine | 3.1 | Heat | 6.1 | Truck | 1.3 | Freight transport | 1.0 |

| Natural gas | 6.8 | Non-energy use | 3.5 | Aircraft engine | 0.7 | Cooling/light/sound and others | 0.5 | Plane | 0.3 | Sustenance | 0.2 |

| Coal | 69.1 | Fuel loss | 7.0 | Agro-motor | 0.5 | Combustion loss | 17.0 | Ship | 0.4 | Communication | 2.5 |

| Hydro | 6.9 | Other engine | 1.0 | Heat transfer loss | 30.2 | Train | 0.1 | Structure | 0.2 | ||

| Nuclear | 0.7 | Electric motor | 7.7 | Other loss | 9.8 | Factory | 8.1 | Hygiene | 0.1 | ||

| Others | 0.6 | Oil burner | 6.3 | Hot water | 0.3 | Thermal comfort | 0.2 | ||||

| Biomass burner | 6.0 | Heated/cooled space | 1.5 | Illumination | 0.03 | ||||||

| Gas burner | 4.4 | Appliance | 0.1 | ||||||||

| Coal burner | 27.9 | Illuminated space | 0.2 | Passive loss | 8.6 | ||||||

| Electric heater | 1.1 | ||||||||||

| Heat exchanger | 1.0 | ||||||||||

| Cooler | 2.4 | ||||||||||

| Electronics | 1.1 | ||||||||||

| Light device | 1.9 |

Table A3.

Vertical slices of exergy flow of China in 2015.

Table A3.

Vertical slices of exergy flow of China in 2015.

| Energy Source | EJ | Transformation | EJ | Conversion Device | EJ | Useful Energy | EJ | Passive System | EJ | Final Service | EJ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil | 24.5 | Direct-energy use | 72.0 | Diesel engine | 7.0 | Motion | 10.6 | Car | 1.9 | Passenger transport | 0.5 |

| Biomass | 9.1 | Power & heat generation | 60.6 | Otto engine | 5.2 | Heat | 8.4 | Truck | 1.9 | Freight transport | 1.5 |

| Natural gas | 12.5 | Non-energy use | 6.9 | Aircraft engine | 1.1 | Cooling/light/sound and others | 0.8 | Plane | 0.5 | Sustenance | 0.2 |

| Coal | 85.0 | Fuel loss | 5.6 | Agro-motor | 0.7 | Combustion loss | 21.8 | Ship | 0.4 | Communication | 0.2 |

| Hydro | 10.2 | Other engine | 1.0 | Heat transfer loss | 38.4 | Train | 0.3 | Structure | 3.7 | ||

| Nuclear | 1.5 | Electric motor | 10.9 | Other loss | 13.5 | Factory | 11.3 | Hygiene | 0.2 | ||

| Wind | 1.7 | Oil burner | 6.1 | Hot water | 0.6 | Thermal comfort | 0.3 | ||||

| Others | 0.6 | Biomass burner | 7.6 | Heated/cooled space | 2.3 | Illumination | 0.04 | ||||

| Gas burner | 8.3 | Appliance | 0.2 | ||||||||

| Coal burner | 35.1 | Illuminated space | 0.4 | Passive loss | 13.1 | ||||||

| Electric heater | 0.9 | ||||||||||

| Heat exchanger | 1.2 | ||||||||||

| Cooler | 3.1 | ||||||||||

| Electronics | 2.2 | ||||||||||

| Light device | 2.9 |

Table A4.

Exergy efficiency of the end-use conversion device stage and the power and heat generation sector.

Table A4.

Exergy efficiency of the end-use conversion device stage and the power and heat generation sector.

| Conversion Sector | |||||

|---|---|---|---|---|---|

| 2005 | 2010 | 2015 | |||

| Power and heat generation | Coal | 94% | 32% | 36% | 38% |

| Oil | 94% | 22% | 14% | 6% | |

| Natural gas | 96% | 18% | 17% | 24% | |

| Biomass | 90% | 23% | 23% | 23% | |

| Nuclear and renewable energy | 100% | 34% | 38% | 40% | |

| End-use conversion device | Motion | ||||

| Diesel engine | 95% | 25% | 28% | 34% | |

| Otto engine | 99% | 23% | 25% | 30% | |

| Aircraft engine | 99% | 37% | 41% | 44% | |

| Agro-motor | 95% | 25% | 28% | 34% | |

| Other engine | 53% | 14% | 16% | 18% | |

| Electric motor | 93% | 42% | 46% | 51% | |

| Heat | |||||

| Oil burner | 25% | 11% | 13% | 15% | |

| Biomass burner | 20% | 4% | 4% | 4% | |

| Gas burner | 21% | 6% | 7% | 7% | |

| Coal burner | 31% | 14% | 16% | 18% | |

| Electric heater | 30% | 24% | 25% | 25% | |

| Heat exchanger | 15% | 13% | 13% | 13% | |

| Other | |||||

| Cooler | 6% | 5% | 6% | 7% | |

| Electronics | 30% | 6% | 7% | 8% | |

| Light device | 90% | 12% | 13% | 14% | |

Table A5.

Passive efficiency of passive systems.

Table A5.

Passive efficiency of passive systems.

| Passive System | Passive Efficiency | ||

|---|---|---|---|

| 2005 | 2010 | 2015 | |

| Vehicle | |||

| Car | 9.8% | 10.0% | 10.3% |

| Truck | 54.5% | 55.6% | 57.2% |

| Plane | 50.2% | 50.2% | 50.2% |

| Ship | 36.8% | 36.8% | 36.8% |

| Train | 46.7% | 47.6% | 49.0% |

| Factory | |||

| Driven System | 41.8% | 42.6% | 43.9% |

| Steam System | 34.0% | 34.7% | 35.7% |

| Furnace | 39.0% | 39.8% | 41.0% |

| Building | |||

| Hot Water System | 20.4% | 20.6% | 21.0% |

| Heated/Cooled Space | 3.8% | 3.9% | 3.9% |

| Appliance | 32.7% | 33.4% | 34.4% |

| Illuminated Space | 5.4% | 5.5% | 5.6% |

Table A6.

The proportion of coal used for industrial coal boilers and coal-fired power and heat generation.

Table A6.

The proportion of coal used for industrial coal boilers and coal-fired power and heat generation.

| 2005 | 2010 | 2015 | |

|---|---|---|---|

| Industrial coal boiler | 24% | 21% | 21% |

| Coal-fired power & heat generation | 50% | 51% | 51% |

Table A7.

Data for the “Dual Structure” of industrial coal boilers.

Table A7.

Data for the “Dual Structure” of industrial coal boilers.

| Capacity of Industrial Coal Boiler (t/h) | 2005 | 2010 | 2015 | |||

|---|---|---|---|---|---|---|

| Structure | Exergy Efficiency | Structure | Exergy Efficiency | Structure | Exergy Efficiency | |

| Capacity ≤ 20 | 81% | 15% | 62% | 16% | 50% | 17% |

| 20 < Capacity ≤ 35 | 7% | 20% | 8% | 21% | 10% | 21% |

| Capacity > 35 | 12% | 24% | 30% | 25% | 40% | 25% |

Table A8.

Data for the “Dual Structure” of coal-fired power and heat generation.

Table A8.

Data for the “Dual Structure” of coal-fired power and heat generation.

| Capacity of Coal-Fired Plants (MW) | 2005 | 2010 | 2015 | |||

|---|---|---|---|---|---|---|

| Structure | Exergy Efficiency | Structure | Exergy Efficiency | Structure | Exergy Efficiency | |

| Capacity < 300 | 54% | 33% | 27% | 35% | 21% | 36% |

| 300 ≤ Capacity < 600 | 41% | 34% | 36% | 37% | 36% | 39% |

| Capacity ≥ 600 | 5% | 38% | 37% | 39% | 43% | 40% |

References

- IPCC. Climate Change 2014: Synthesis Report; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Energy Efficiency 2019; International Energy Agency: Paris, France, 2019.

- National Development and Reform Commission. Energy Conservation, Energy Efficiency and High-Quality Development. Available online: https://www.ndrc.gov.cn/fzggw/wld/zy/lddt/202006/t20200630_1232504.html (accessed on 21 January 2021).

- Federal Ministry for Economic Affairs and Energy of Gemany. Energy Efficiency. Available online: https://www.bmwi.de/Redaktion/EN/Dossier/energy-efficiency.html (accessed on 21 January 2021).

- Cullen, J.M.; Allwood, J.M. The efficient use of energy: Tracing the global flow of energy from fuel to service. Energy Policy 2010, 38, 75–81. [Google Scholar] [CrossRef]

- Patterson, M.G. What is energy efficiency? Concepts, indicators and methodological issues. Energy Policy 1996, 24, 377–390. [Google Scholar] [CrossRef]

- Li, M.-J.; Tao, W.-Q. Review of methodologies and polices for evaluation of energy efficiency in high energy-consuming industry. Appl. Energy 2017, 187, 203–215. [Google Scholar] [CrossRef]

- Dewulf, J.; Van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its potential and limitations in environ-mental science and technology. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- Utlu, Z.; Hepbasli, A. A review on analyzing and evaluating the energy utilization efficiency of countries. Renew. Sustain. Energy Rev. 2007, 11, 1–29. [Google Scholar] [CrossRef]

- Haas, R.; Nakicenovic, N.; Ajanovic, A.; Faber, T.; Kranzl, L.; Müller, A.; Resch, G. Towards sustainability of energy systems: A primer on how to apply the concept of energy services to identify necessary trends and policies. Energy Policy 2008, 36, 4012–4021. [Google Scholar] [CrossRef]

- Brockway, P.E.; Barrett, J.R.; Foxon, T.J.; Steinberger, J.K. Divergence of Trends in US and UK Aggregate Exergy Efficiencies 1960–2010. Environ. Sci. Technol. 2014, 48, 9874–9881. [Google Scholar] [CrossRef]

- Serrenho, A.C.; Sousa, T.; Warr, B.; Ayres, R.U.; Domingos, T. Decomposition of useful work intensity: The EU (European Un-ion)-15 countries from 1960 to 2009. Energy 2014, 76, 704–715. [Google Scholar] [CrossRef]

- Brockway, P.E.; Steinberger, J.K.; Barrett, J.R.; Foxon, T.J. Understanding China’s past and future energy demand: An exergy effi-ciency and decomposition analysis. Appl. Energy 2015, 155, 892–903. [Google Scholar] [CrossRef]

- BP Statistical Review of World Energy; BP: London, UK, 2020.

- The 11th Five Year Plan of China; People’s Government of China: Beijing, China, 2006.

- The 12th Five Year Plan of China; People’s Government of China: Beijing, China, 2011.

- The 13th Five Year Plan of China; People’s Government of China: Beijing, China, 2016.

- Wang, W.; Li, Z.; Lyu, J.; Ni, W. Eliminating Outdated Capacity to Promote Energy Conservation in China’s Coal-Fired Power Industry. Engineering 2019, 5, 194–196. [Google Scholar] [CrossRef]

- Ma, C.; Stern, D.I. China’s changing energy intensity trend: A decomposition analysis. Energy Econ. 2008, 30, 1037–1053. [Google Scholar] [CrossRef]

- Liao, H.; Fan, Y.; Wei, Y. What induced China’s energy intensity to fluctuate: 1997–2006? Energy Policy 2007, 35, 4640–4649. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, C.; Hong, D. Why did China’s energy intensity increase during 1998–2006: Decomposition and policy analysis. Energy Policy 2010, 38, 1379–1388. [Google Scholar] [CrossRef]

- Wang, J.; Hu, M.; Rodrigues, J.F.D. The evolution and driving forces of industrial aggregate energy intensity in China: An ex-tended decomposition analysis. Appl. Energy 2018, 228, 2195–2206. [Google Scholar] [CrossRef]

- Zhang, P.; Shi, X.; Sun, Y.; Cui, J.; Shao, S. Have China’s provinces achieved their targets of energy intensity reduction? Reassess-ment based on nighttime lighting data. Energy Policy 2019, 128, 276–283. [Google Scholar] [CrossRef]

- Li, Y.; Sun, L.; Feng, T.; Zhu, C. How to reduce energy intensity in China: A regional comparison perspective. Energy Policy 2013, 61, 513–522. [Google Scholar] [CrossRef]

- Nakićenović, N.; Gilli, P.V.; Kurz, R. Regional and global exergy and energy efficiencies. Energy 1996, 21, 223–237. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Wang, D.; Liu, J. Energy and exergy utilizations of the Chinese urban residential sector. Energy Convers. Manag. 2014, 86, 634–643. [Google Scholar] [CrossRef]

- Proskuryakova, L.; Kovalev, A. Measuring energy efficiency: Is energy intensity a good evidence base? Appl. Energy 2015, 138, 450–459. [Google Scholar] [CrossRef]

- Paoli, L.; Cullen, J. Technical limits for energy conversion efficiency. Energy 2020, 192, 116228. [Google Scholar] [CrossRef]

- Dincer, I. The role of exergy in energy policy making. Energy Policy 2002, 30, 137–149. [Google Scholar] [CrossRef]

- Gong, M.; Wall, G. Exergy Analysis of the Supply of Energy and Material Resources in the Swedish Society. Energies 2016, 9, 707. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; Calvo, G.; Ortego, A.; Ascaso, S.; Palacios, J.-L. Global material requirements for the energy transition. An exergy flow analysis of decarbonisation pathways. Energy 2018, 159, 1175–1184. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I.; Kanoglu, M. Role of exergy in increasing efficiency and sustainability and reducing environmental im-pact. Energy Policy 2008, 36, 128–137. [Google Scholar] [CrossRef]

- Jorgensen, S.; Nielsen, S.N. Application of exergy as thermodynamic indicator in ecology. Energy 2007, 32, 673–685. [Google Scholar] [CrossRef]

- Nielsen, S.N.; Jørgensen, S.E. Sustainability analysis of a society based on exergy studies—A case study of the island of Samsø (Denmark). J. Clean. Prod. 2015, 96, 12–29. [Google Scholar] [CrossRef]

- Skytt, T.; Nielsen, S.N.; Fröling, M. Energy flows and efficiencies as indicators of regional sustainability—A case study of Jämtland, Sweden. Ecol. Indic. 2019, 100, 74–98. [Google Scholar] [CrossRef]

- Sousa, T.; Brockway, P.E.; Cullen, J.M.; Henriques, S.T.; Miller, J.; Serrenho, A.C.; Domingos, T. The Need for Robust, Consistent Methods in Societal Exergy Accounting. Ecol. Econ. 2017, 141, 11–21. [Google Scholar] [CrossRef]

- Reistad, G.M. Available Energy Conversion and Utilization in the United States. J. Eng. Power 1975, 97, 429–434. [Google Scholar] [CrossRef]

- Rosen, M. Evaluation of energy utilization efficiency in Canada using energy and exergy analyses. Energy 1992, 17, 339–350. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M.M.; Al-Zaharnah, I. Analysis of sectoral energy and exergy use of Saudi Arabia. Int. J. Energy Res. 2004, 28, 205–243. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Turkey’s sectoral energy and exergy analysis between 1999 and 2000. Int. J. Energy Res. 2004, 28, 1177–1196. [Google Scholar] [CrossRef]

- Ayres, R.U.; Ayres, L.W.; Warr, B. Exergy, power and work in the US economy, 1900–1998. Energy 2003, 28, 219–273. [Google Scholar] [CrossRef]

- Warr, B.; Ayres, R.U.; Eisenmenger, N.; Krausmann, F.; Schandl, H. Energy use and economic development: A comparative analysis of useful work supply in Austria, Japan, the United Kingdom and the US during 100years of economic growth. Ecol. Econ. 2010, 69, 1904–1917. [Google Scholar] [CrossRef]

- Cullen, J.M.; Allwood, J.M. Theoretical efficiency limits for energy conversion devices. Energy 2010, 35, 2059–2069. [Google Scholar] [CrossRef]

- Sun, J.X.; Ma, L.W.; Ni, W.D.; Zheng, L. Reducing China’s Energy Consumption and CO2 Emissions by More Efficient Use of Energy; IEEE: New York, NY, USA, 2013; pp. 802–808. [Google Scholar]

- Ma, L.; Allwood, J.M.; Cullen, J.M.; Li, Z. The use of energy in China: Tracing the flow of energy from primary source to demand drivers. Energy 2012, 40, 174–188. [Google Scholar] [CrossRef]

- Chong, C.; Ma, L.; Li, Z.; Ni, W.; Song, S. Logarithmic mean Divisia index (LMDI) decomposition of coal consumption in China based on the energy allocation diagram of coal flows. Energy 2015, 85, 366–378. [Google Scholar] [CrossRef]

- Chong, C.; Liu, P.; Ma, L.; Li, Z.; Ni, W.; Li, X.; Song, S. LMDI decomposition of energy consumption in Guangdong Province, China, based on an energy allocation diagram. Energy 2017, 133, 525–544. [Google Scholar] [CrossRef]

- Chong, C.H.; Tan, W.X.; Ting, Z.J.; Liu, P.; Ma, L.; Li, Z.; Ni, W. The driving factors of energy-related CO2 emission growth in Malaysia: The LMDI decomposition method based on energy allocation analysis. Renew. Sustain. Energy Rev. 2019, 115, 109356. [Google Scholar] [CrossRef]

- Chong, C.; Ni, W.; Ma, L.; Liu, P.; Li, Z. The Use of Energy in Malaysia: Tracing Energy Flows from Primary Source to End Use. Energies 2015, 8, 2828–2866. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L.; Li, Z. A Method for Analyzing Energy-Related Carbon Emissions and the Structural Changes: A Case Study of China from 2005 to 2015. Energies 2020, 13, 2076. [Google Scholar] [CrossRef]

- Zhao, Y.; Kong, G.; Chong, C.; Ma, L.; Li, Z.; Ni, W. How to Effectively Control Energy Consumption Growth in China’s 29 Provinces: A Paradigm of Multi-Regional Analysis Based on EAALMDI Method. Sustainability 2021, 13, 1093. [Google Scholar] [CrossRef]

- Ang, B.W.; Choi, K.-H. Decomposition of Aggregate Energy and Gas Emission Intensities for Industry: A Refined Divisia Index Method. Energy J. 1997, 18, 59–73. [Google Scholar] [CrossRef]

- Ang, B.; Liu, F. A new energy decomposition method: Perfect in decomposition and consistent in aggregation. Energy 2001, 26, 537–548. [Google Scholar] [CrossRef]

- Ang, B. Decomposition analysis for policymaking in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Ang, B. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Ang, B.; Liu, N. Handling zero values in the logarithmic mean Divisia index decomposition approach. Energy Policy 2007, 35, 238–246. [Google Scholar] [CrossRef]

- Ang, B. LMDI decomposition approach: A guide for implementation. Energy Policy 2015, 86, 233–238. [Google Scholar] [CrossRef]

- Hardt, L.; Owen, A.; Brockway, P.; Heun, M.K.; Barrett, J.; Taylor, P.G.; Foxon, T.J. Untangling the drivers of energy reduction in the UK productive sectors: Efficiency or offshoring? Appl. Energy 2018, 223, 124–133. [Google Scholar] [CrossRef]

- Zhang, X.; Su, B.; Yang, J.; Cong, J. Index decomposition and attribution analysis of aggregate energy intensity in Shanxi Province (2000–2015). J. Clean. Prod. 2019, 238. [Google Scholar] [CrossRef]

- Wang, C.; Chen, J.; Zou, J. Decomposition of energy-related CO2 emission in China: 1957–2000. Energy 2005, 30, 73–83. [Google Scholar] [CrossRef]

- Motasemi, F.; Afzal, M.T.; Salema, A.A.; Moghavvemi, M.; Shekarchian, M.; Zarifi, F.; Mohsin, R. Energy and exergy utilization efficiencies and emission performance of Canadian transportation sector, 1990–2035. Energy 2014, 64, 355–366. [Google Scholar] [CrossRef]

- China Energy Statistical Yearbook 2006; China’s National Bureau of Statistics: Beijing, China, 2006.

- China Energy Statistical Yearbook 2011; China’s National Bureau of Statistics: Beijing, China, 2011.

- China Energy Statistical Yearbook 2016; China’s National Bureau of Statistics: Beijing, China, 2016.

- Wang, Q. Energy Data of 2006; Innovative Green Development Program: Beijing, China, 2006. [Google Scholar]

- Wang, Q. Energy Data of 2011; Innovative Green Development Program: Beijing, China, 2011. [Google Scholar]

- Wang, Q. Energy Data of 2016; Innovative Green Development Program: Beijing, China, 2016. [Google Scholar]

- The 13th Five-Year Plan for Energy Development; National Development and Reform Commission: Beijing, China, 2016.

- The 13th Five-Year Plan for Renewable Energy Development; National Development and Reform Commission: Beijing, China, 2016.

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes; Hemisphere Publishing Corporation: New York, NY, USA, 1987. [Google Scholar]

- Saidur, R.; Masjuki, H.; Jamaluddin, M. An application of energy and exergy analysis in residential sector of Malaysia. Energy Policy 2007, 35, 1050–1063. [Google Scholar] [CrossRef]

- Manso, R.; Sousa, T.; Domingos, T. Do the Different Exergy Accounting Methodologies Provide Consistent or Contradictory Results? A Case Study with the Portuguese Agricultural, Forestry and Fisheries Sector. Energies 2017, 10, 1219. [Google Scholar] [CrossRef]

- Cullen, J.M.; Allwood, J.M.; Borgstein, E.H. Reducing Energy Demand: What Are the Practical Limits? Environ. Sci. Technol. 2011, 45, 1711–1718. [Google Scholar] [CrossRef] [PubMed]

- Worrell, E.; Price, L.; Neelis, M.; Galitsky, C.; Zhou, N. World Best Practice Energy Intensity Values for Selected Industrial Sectors; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2007. [Google Scholar]

- Yu, J. Status and transformation measures of industrial coal-fired boiler in China. Clean Coal Technol. 2012, 18, 88–89. (In Chinese) [Google Scholar]

- Yang, Y.; Yang, Z.; Xu, G.; Wang, N. Situation and Prospect of Energy Consumption for China’s Thermal Power Generation. Proc. CSEE 2013, 33, 1–11. [Google Scholar]

- China Power Industry Annual Development Report 2006; China Electricity Council: Beijing, China, 2006.

- China Power Industry Annual Development Report 2011; China Electricity Council: Beijing, China, 2011.

- China Power Industry Annual Development Report 2016; China Electricity Council: Beijing, China, 2016.