Miniaturization of an Offshore Platform with Medium-Frequency Offshore Wind Farm and MMC-HVDC Technology

Abstract

:1. Introduction

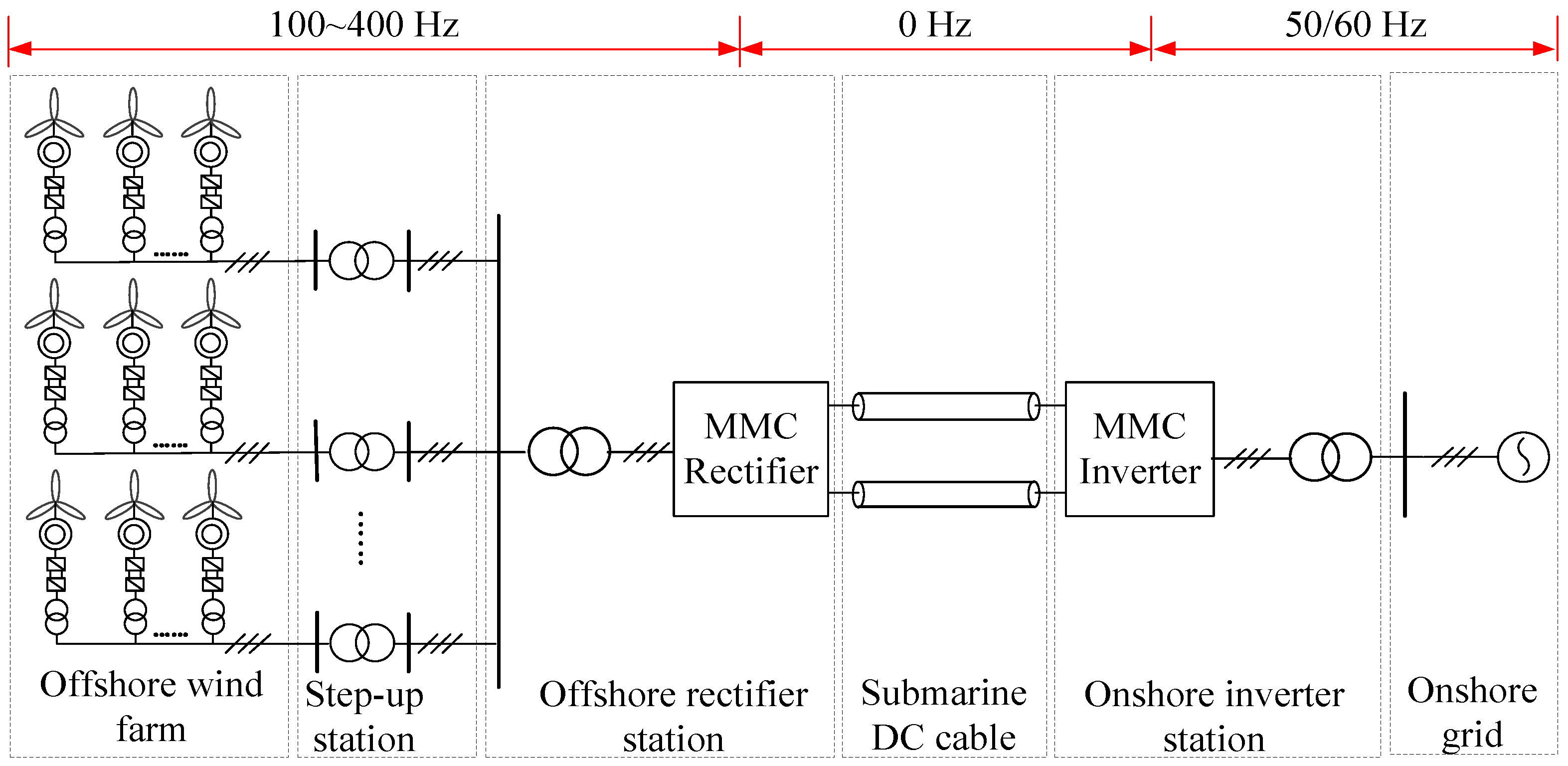

2. Basic Principles

2.1. System Topology

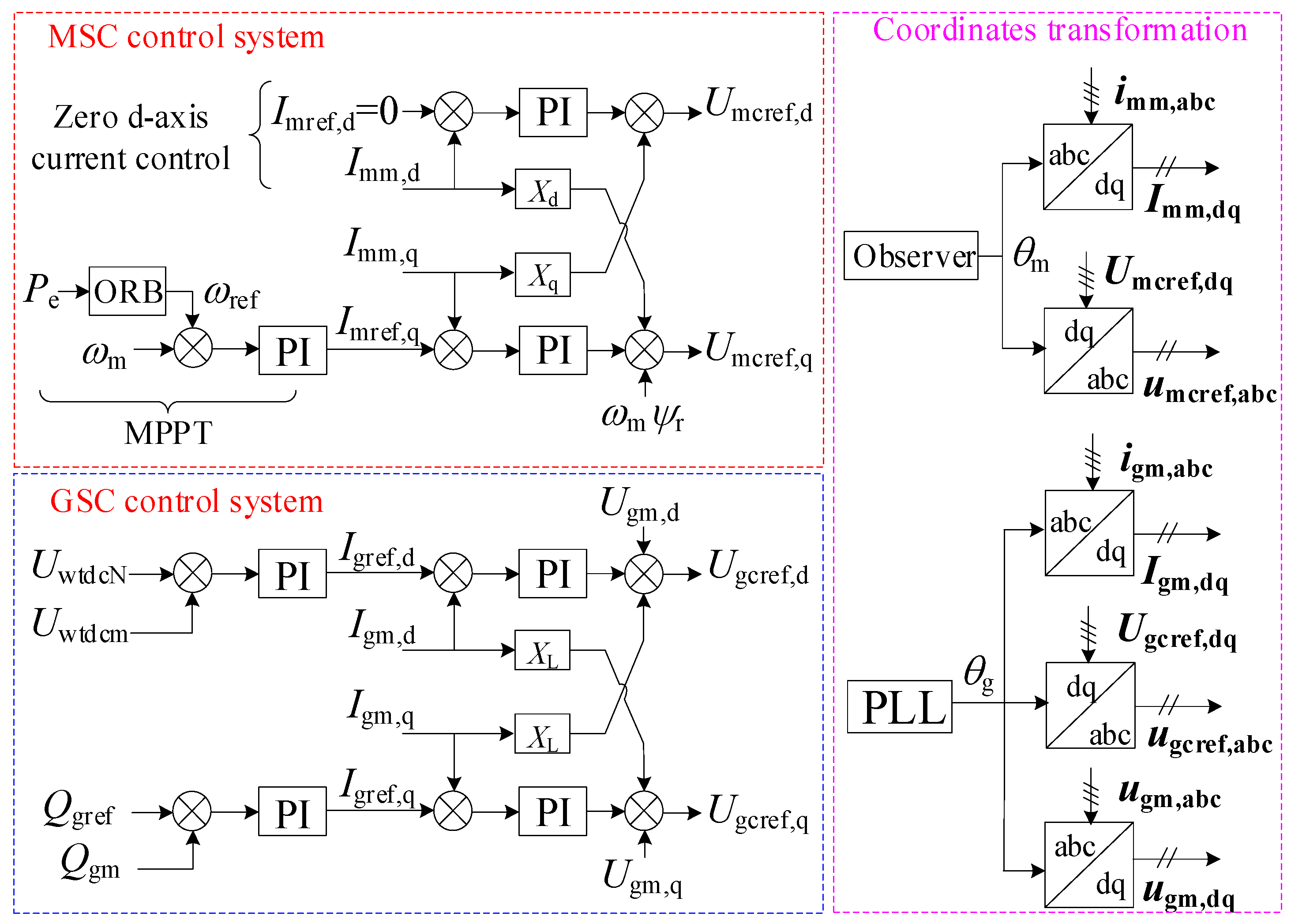

2.2. Control Strategies

3. Main Circuit Parameters

3.1. Transformers

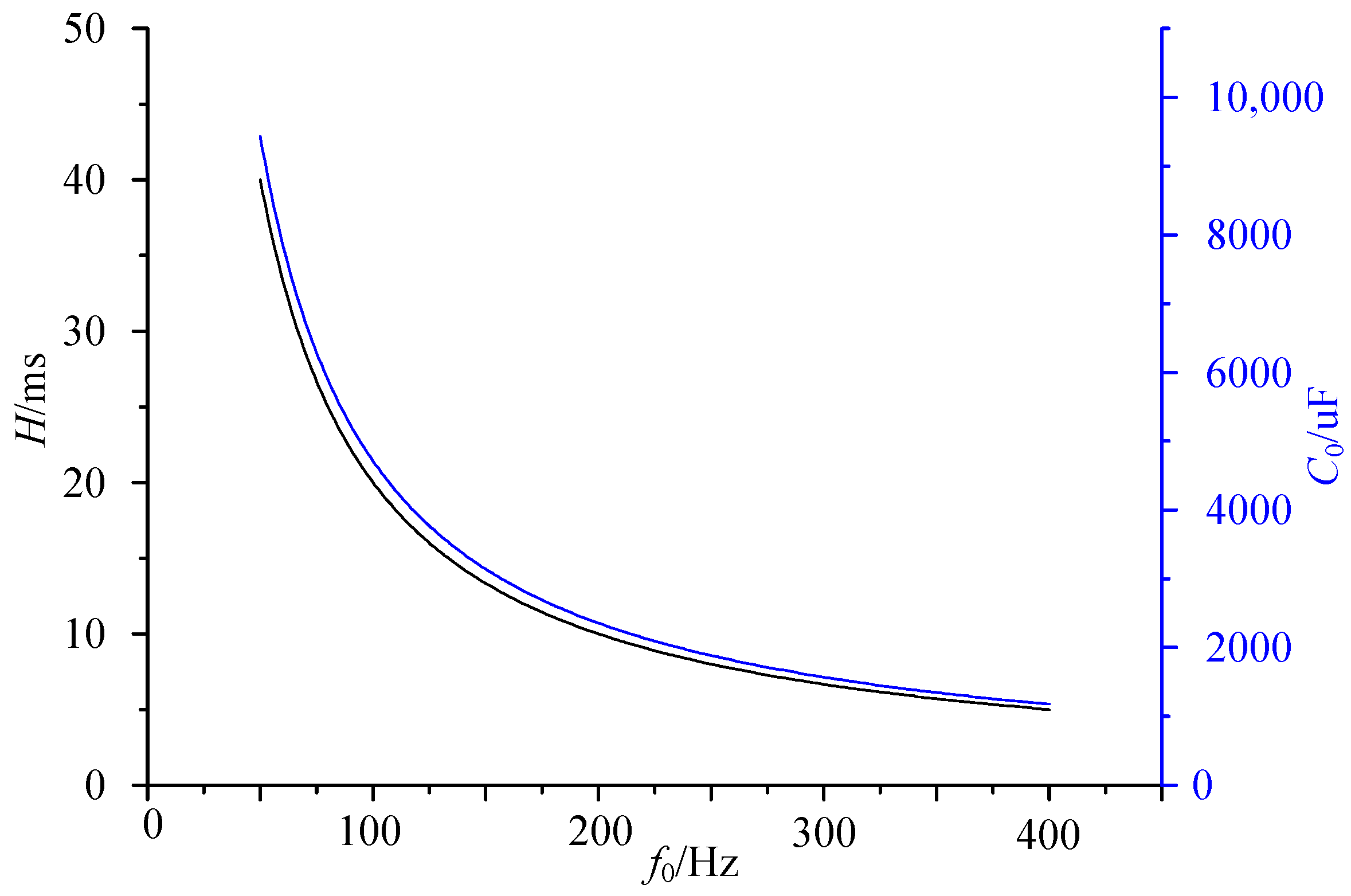

3.2. SM Capacitors

3.3. Arm Inductors

4. Operating Characteristics

4.1. Submarine Cable Transmission Capability

4.2. System Operation Losses

4.2.1. The Line Losses

4.2.2. The Transformer Losses

4.2.3. The Converter Losses

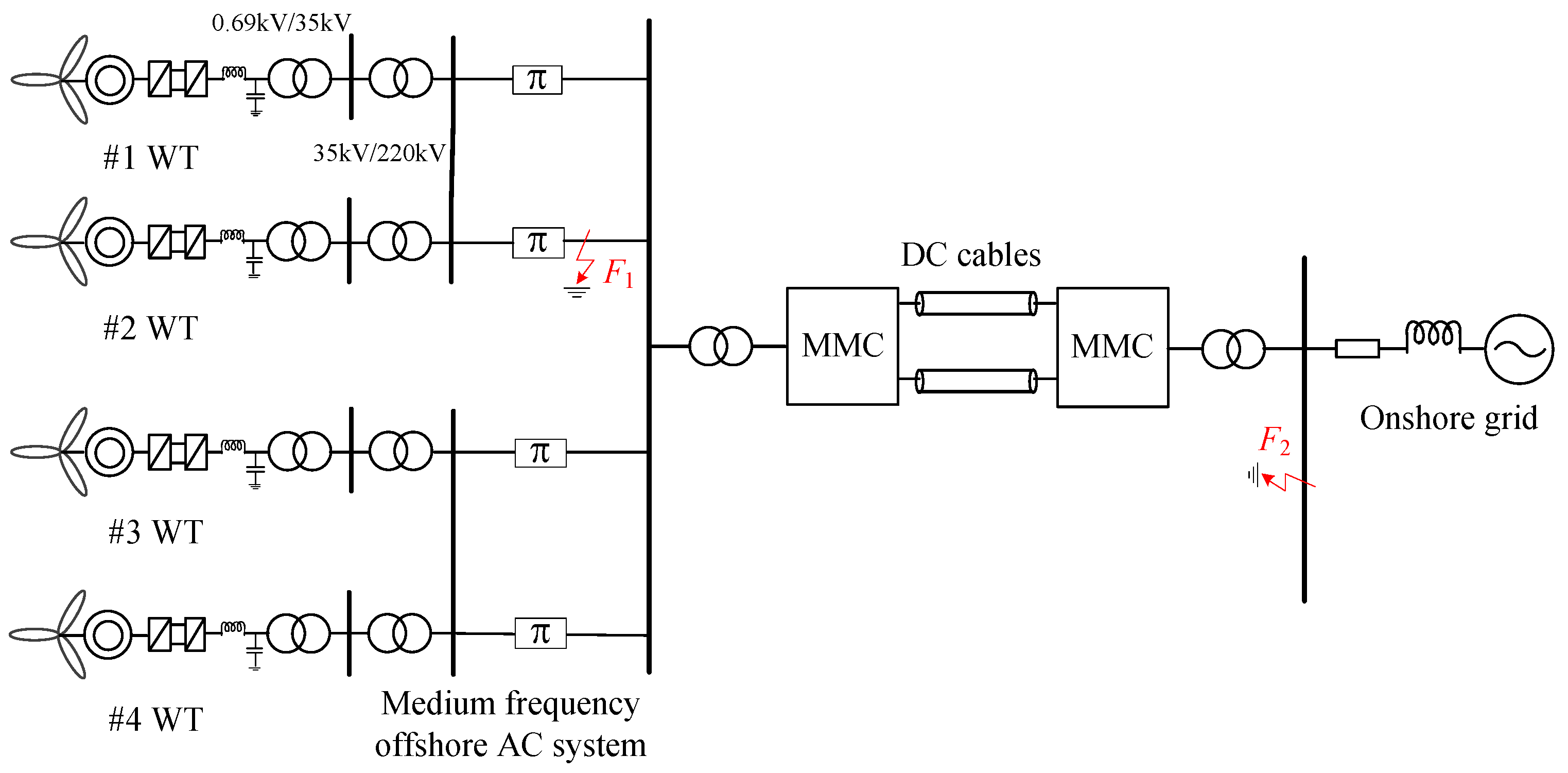

5. Case Study

5.1. System Parameters

5.2. Economic Analysis

5.3. Simulation Results

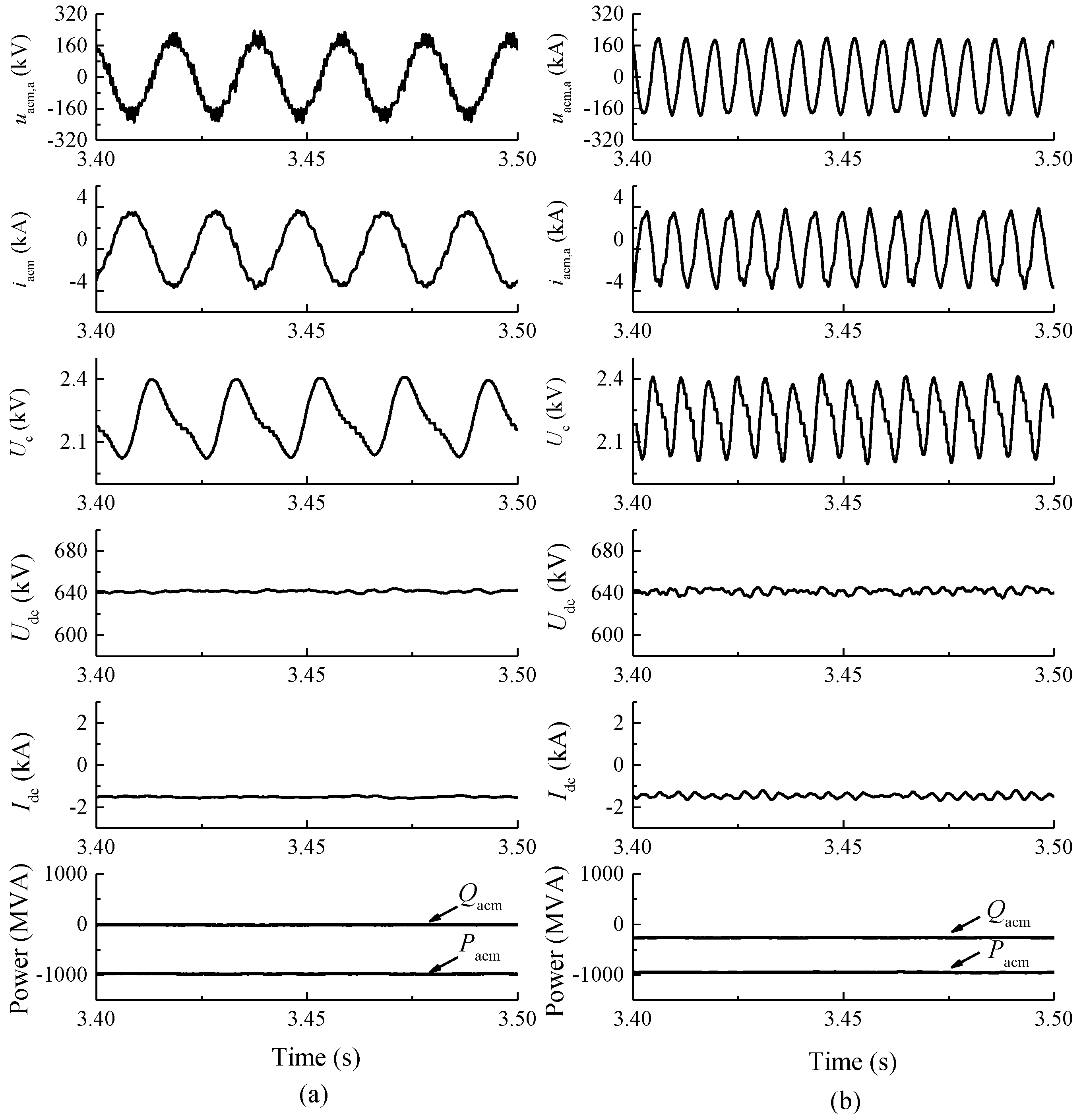

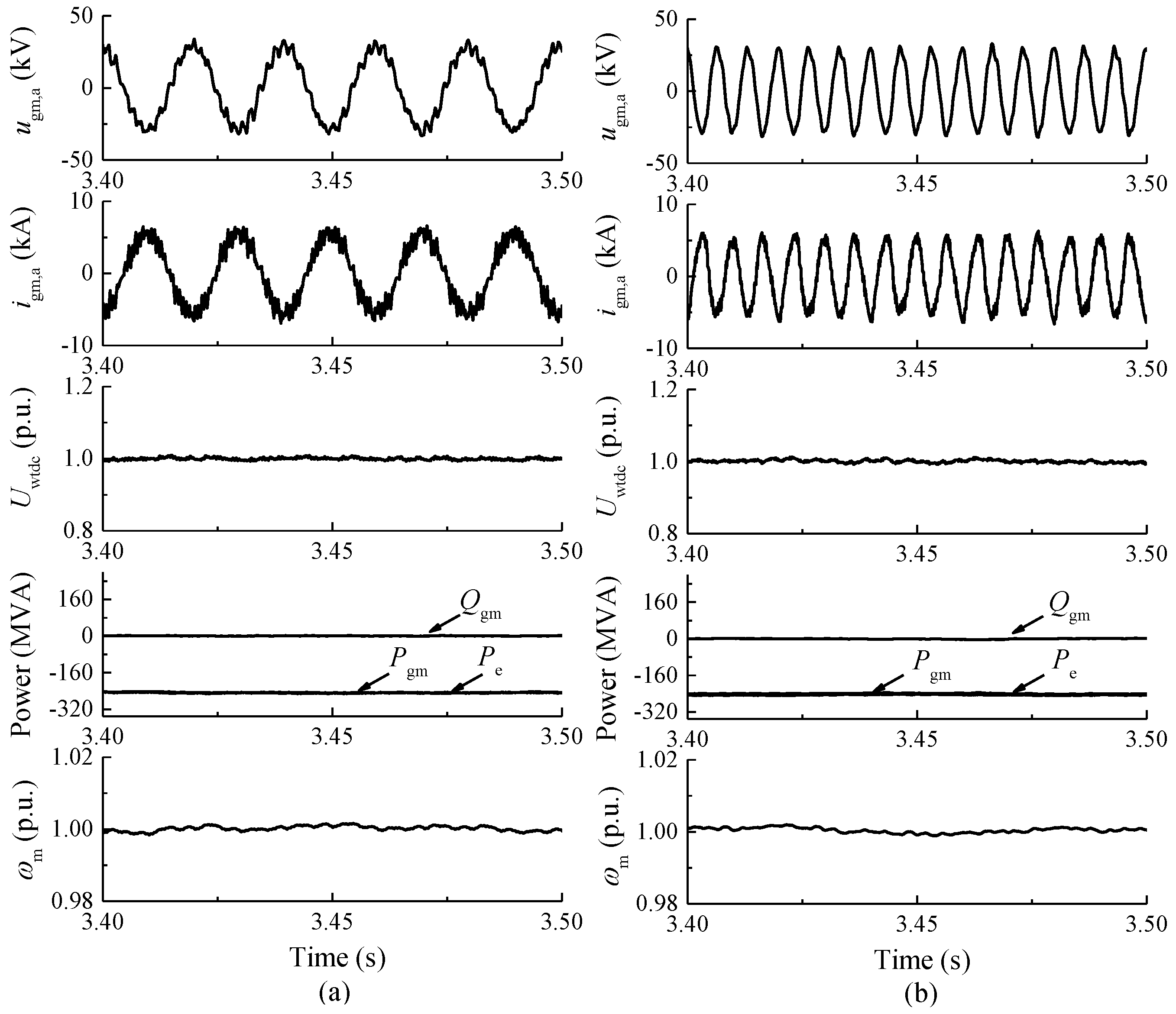

5.3.1. Steady-State Operating Point

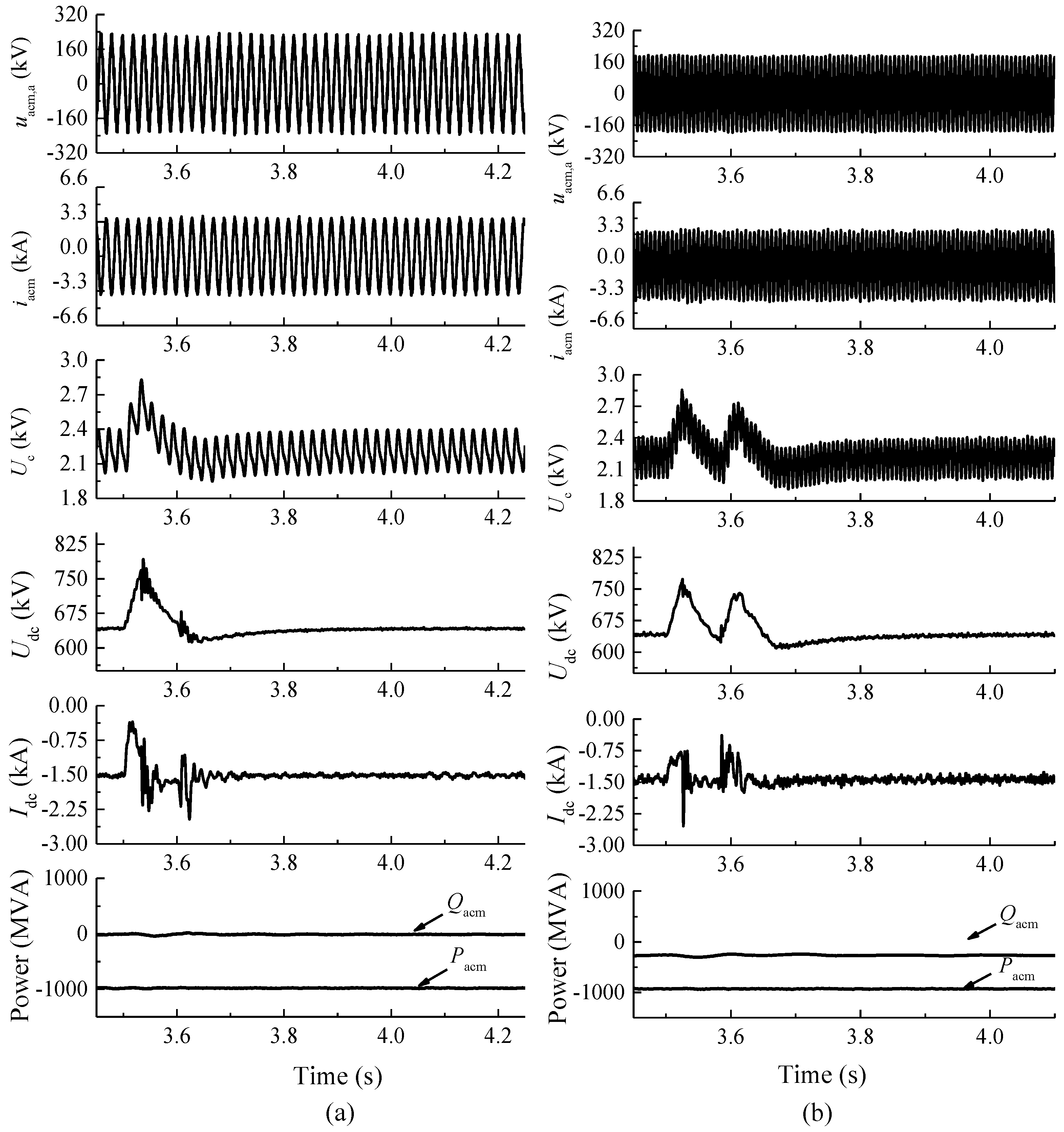

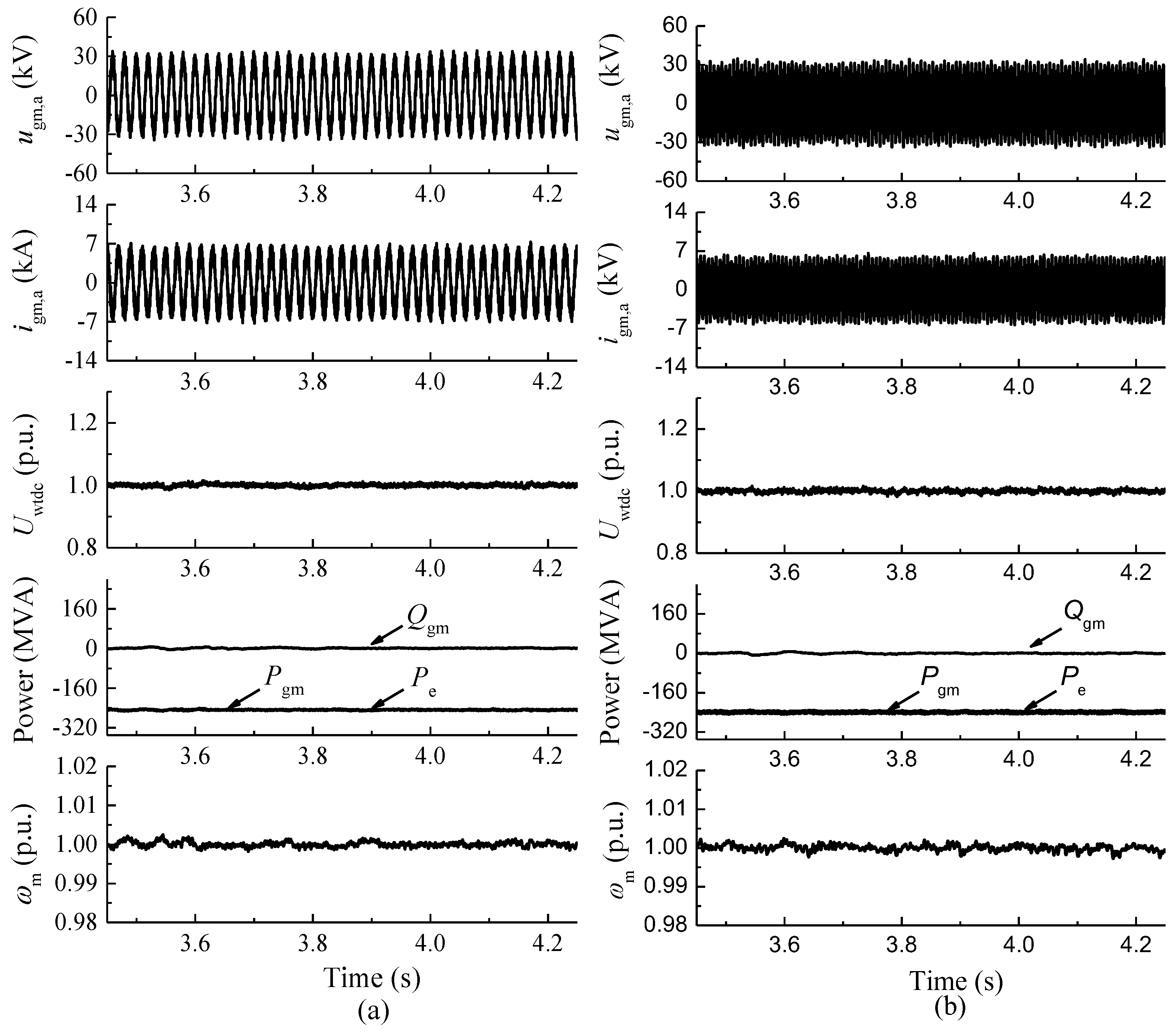

5.3.2. Wind Power Fluctuation

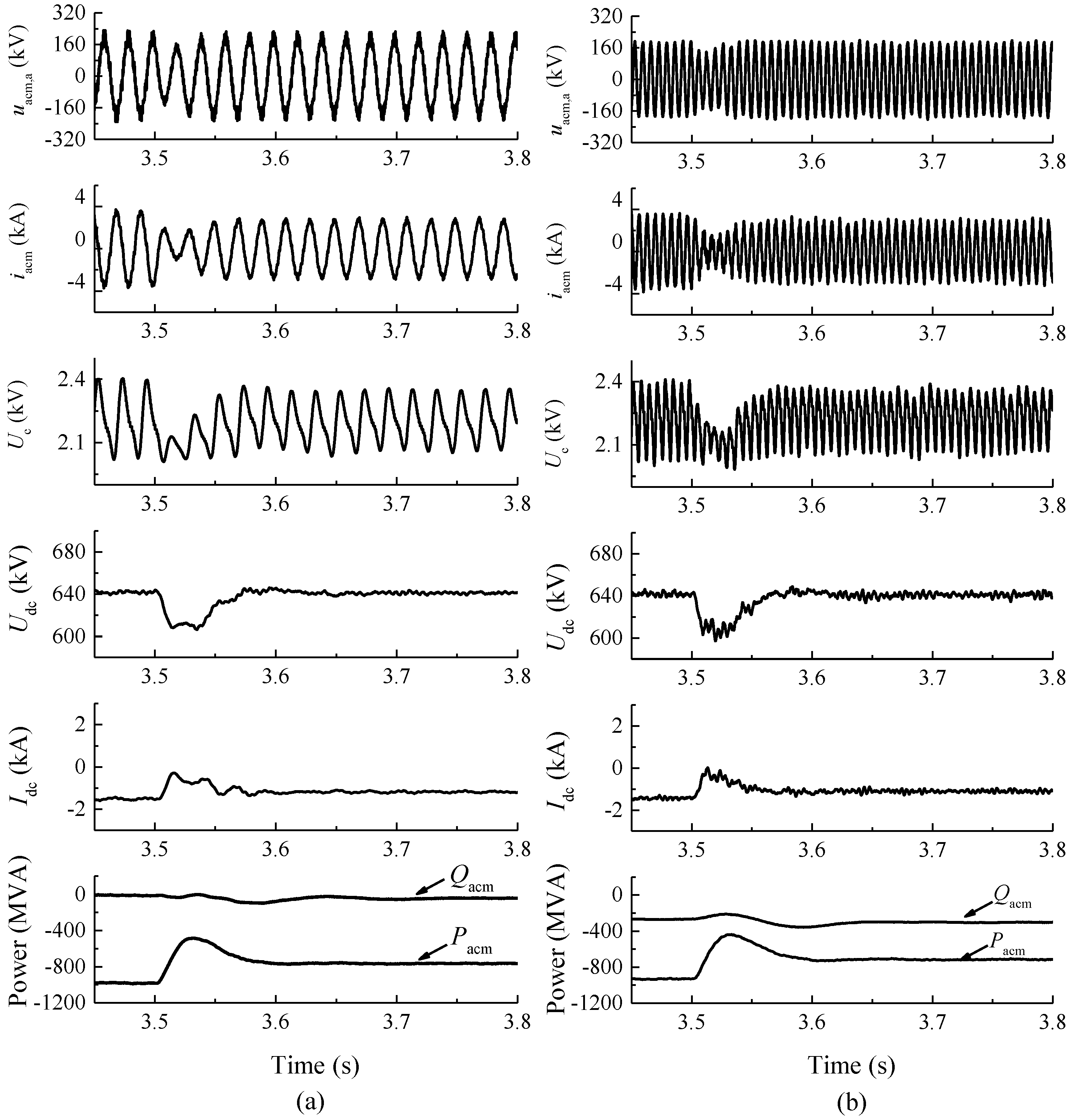

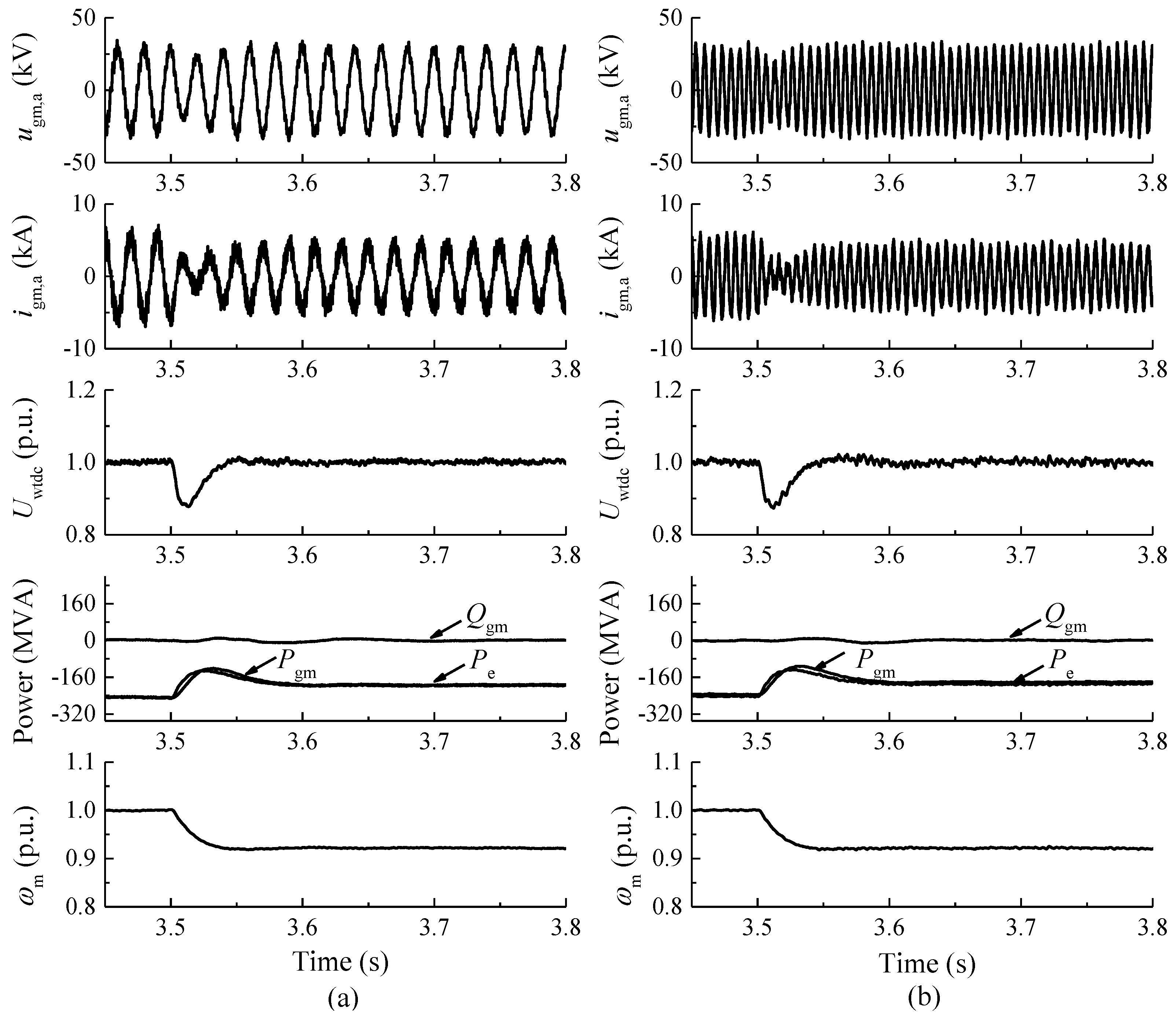

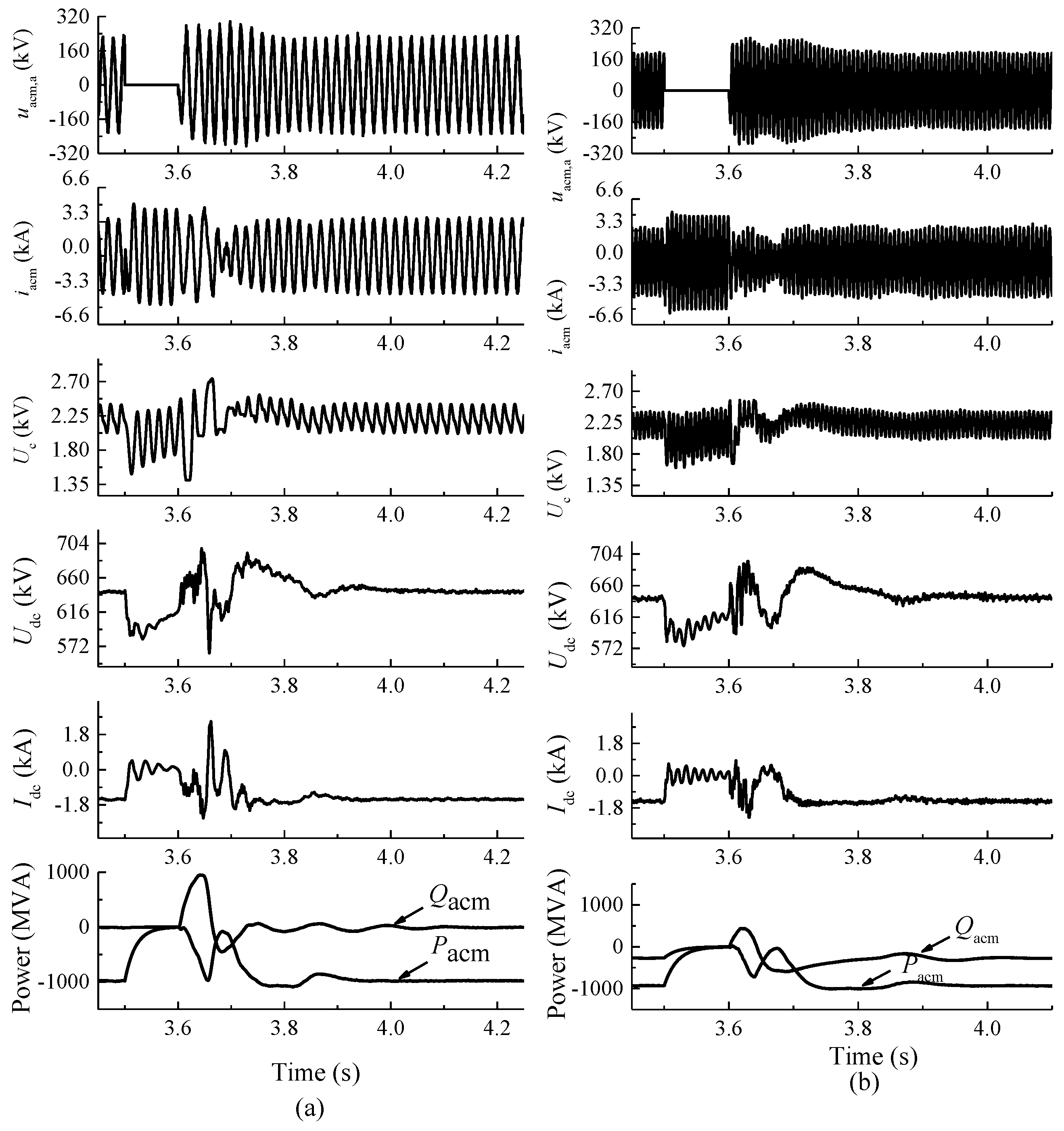

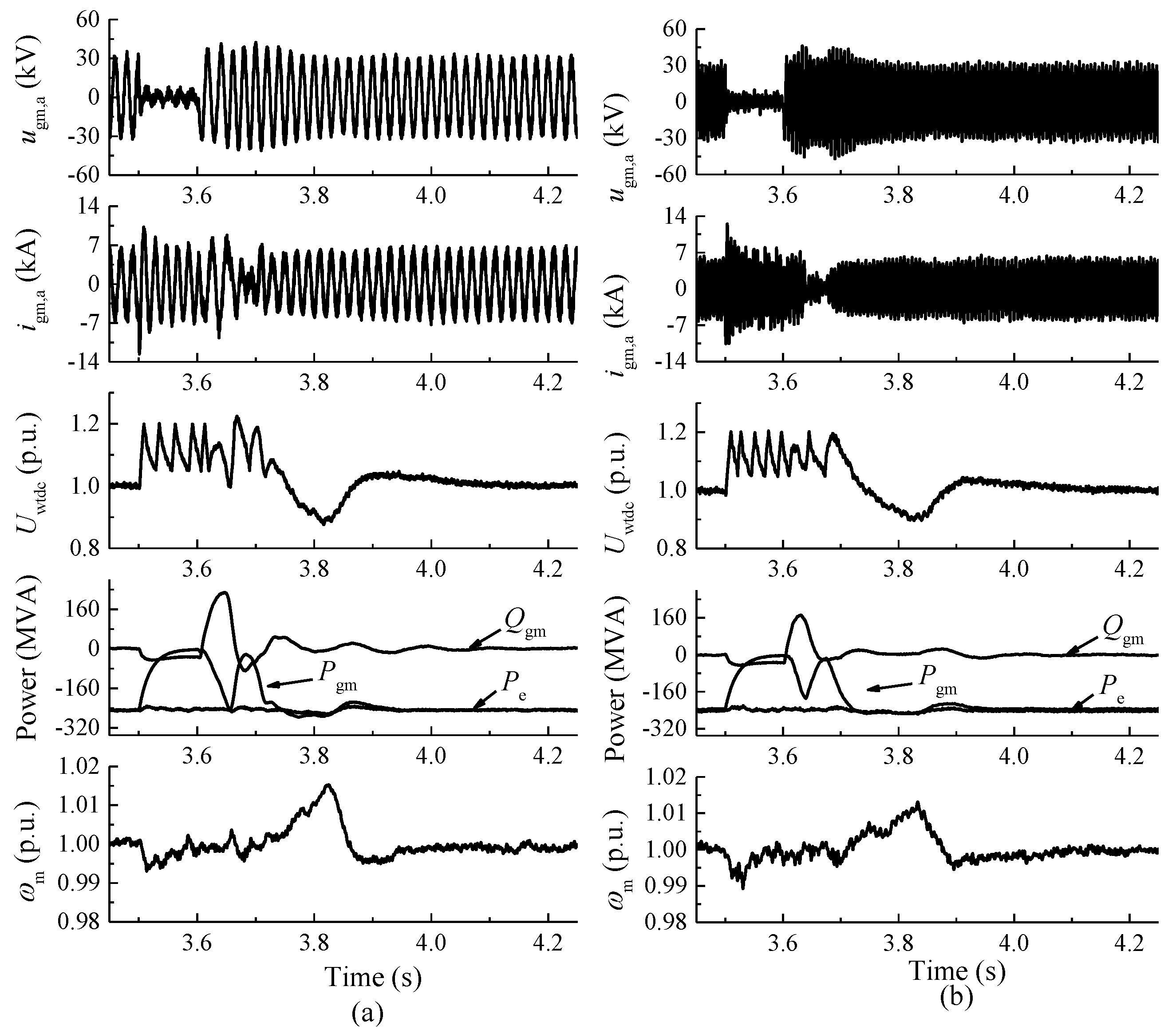

5.3.3. AC Faults in the Offshore Wind Farm

5.3.4. AC Faults in the Onshore Grid

6. Conclusions

- (1)

- Compared with the conventional 50/60 Hz MMC-HVDC scheme, the operating frequency of the offshore AC system is increased to the medium-frequency range in the proposed scheme. Consequently, the actual values of the electrical equipment are decreased inversely to the increased frequency, resulting in significantly reductions in the spatial volume, weight, and cost of the offshore platform;

- (2)

- Compared with the other offshore platform miniaturization schemes, such as the DRU-rectifier-based HVDC scheme, the AC voltage and frequency of the offshore AC system are controlled by the offshore MMC rectifier station in the proposed scheme. Therefore, the conventional grid control mode can be maintained in the offshore WTs, as well as in the offshore wind farm black start scheme.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DFIG-WT | Doubly-fed induction generator-based wind turbine |

| DRU | Diode-rectifier unit |

| DRU-HVDC | Diode-rectifier unit-based high-voltage direct current |

| GSC | Grid side converter |

| HVAC | High-voltage alternating current |

| HVDC | High-voltage direct current |

| LFAC | Low frequency alternating current |

| MMC | Modular multilevel converter |

| MMC-HVDC | Modular multilevel converter-based high-voltage direct current |

| MPPT | Maximum power point tracking |

| MSC | Machine side converter |

| PAG | Phase angle generator |

| PLL | Phase-locker loop |

| PMSG-WT | Permanent magnet synchronous generator-based wind turbine |

| SM | Submodules |

| 2L-VSCs | Two level voltage sourced converter |

| Cg | The cable shunt capacitance |

| C0 | The SM capacitor capacitance |

| Et | The excitation voltage |

| H | The equivalent capacity discharging time constant |

| iacm,abc | The AC-side current measurements of the MMC |

| imm,abc, igm,abc | The AC-side current measurements of the MSC and GSC, respectively |

| Iacref,dq, Ucref,dq | The control system output reference current and voltage, respectively |

| Iacm,dq, Uacm,dq, ucref,abc | The current and voltage variables obtained from the coordinate transformation, respectively |

| Icab | The capacitive charging current |

| Iamp | The cable capacity |

| Igcref,dq, Ugcref,dq | The output current references and voltage references from the GSC control system, respectively |

| Imcref,dq, Umcref,dq | The output current references and voltage references from the MSC control system, respectively |

| Ip | The active power current |

| L0 | The arm inductor inductance |

| Lt | The transformer leakage inductance |

| l, lac, ldc | The cable lengths of the AC and DC cable segments, respectively |

| Nc | The number of cascaded SMs in an arm |

| Nt | The winding turns |

| Pc, Pon, Psw | The total converter losses, the converter conduction losses, and the converter switching losses, respectively |

| Pe | The generator’s electromagnetic power |

| Phys, Pedd | The hysteresis loss and the eddy current losses, respectively |

| PL | The transmission line losses |

| Pt, Pwin, Pcor | The total transformer losses, the winding losses, and the core losses, respectively |

| RL,ac, RL,dc | The AC cable resistance and DC cable resistance per unit length, respectively |

| SvN | The converter’s rated capacity |

| ugcref,abc, ugm,dq, Igm,dq | Voltage and current variables obtained after coordinate transformation at the GSC |

| umcref,abc, Imm,dq | Voltage and current variables obtained after coordinate transformation at the MSC |

| Uac | The AC transmission voltage |

| UacN, Uacm,abc | The AC-side voltage rating and measurements of the MMC, respectively |

| Uc, Uc0, Δuc(t) | The SM capacitor voltage, the DC component of the SM capacitor voltage, and the time-dependent fluctuation in the SM capacitor voltage, respectively |

| Udc | The DC voltage of the MMC |

| UdcN, Udcm | The DC-side voltage rating and measurement of the MMC |

| UtN, StN | The transformer’s rated voltage and capacity, respectively |

| UwtdcN, Uwtdcm | The DC link voltage rating and measurement, respectively |

| Xd, Xq | The d-axis and q-axis reactance of the generator stator windings, respectively |

| XL | The coefficient of the compensation term in the decoupled current control loop |

| Xt | The percentage of the transformer to the equivalent base impedance |

| αR, δ | The skin factor and the skin depth, respectively |

| εc | The capacitor voltage fluctuation ratio |

| μ, σ | The conductor permeability and conductivity, respectively |

| ω0, f0 | The operating frequency |

| ωref, ωm | The rotor rotation speed reference and measurement, respectively |

References

- Erlich, I.; Shewarega, F.; Feltes, C.; Koch, F.W.; Fortmann, J. Offshore Wind Power Generation Technologies. Proc. IEEE 2013, 101, 891–905. [Google Scholar] [CrossRef]

- Friedrich, K. Modern HVDC PLUS application of VSC in Modular Multilevel Converter topology. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 3807–3810. [Google Scholar]

- Apostolaki-Iosifidou, E.; Mccormack, R.; Kempton, W.; Mccoy, P.; Ozkan, D. Transmission Design and Analysis for Large-Scale Offshore Wind Energy Development. IEEE Power Energy Technol. Syst. J. 2019, 6, 22–31. [Google Scholar] [CrossRef]

- Andersson, D.; Petersson, A.; Agneholm, E.; Karlsson, D. “Kriegers Flak 640 MW Off-Shore Wind Power Grid Connection—A Real Project Case Study. IEEE Trans. Energy Convers. 2007, 22, 79–85. [Google Scholar] [CrossRef]

- Qin, N.; You, S.; Xu, Z.; Akhmatov, V. Offshore wind farm connection with low frequency AC transmission technology. In Proceedings of the 2009 IEEE Power & Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009; pp. 1–8. [Google Scholar]

- Xiang, X.; Merlin, M.M.C.; Green, T.C. Cost analysis and comparison of HVAC, LFAC and HVDC for offshore wind power connection. In Proceedings of the 12th IET International Conference on AC and DC Power Transmission (ACDC 2016), Beijing, China, 28–29 May 2016; pp. 1–6. [Google Scholar]

- Berkani, A.; Pourkeivannour, S.; Negadi, K.; Boumediene, B.; Allaoui, T.; Ertan, H.B. Integration of Offshore Wind Farm Plants to the Power Grid using an HVDC line Transmission. In Proceedings of the 2019 International Aegean Conference on Electrical Machines and Power Electronics (ACEMP) & 2019 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Istanbul, Turkey, 2–4 September 2019; pp. 486–492. [Google Scholar]

- Li, W.; Zhu, M.; Chao, P.; Liang, X.; Xu, D. Enhanced FRT and Postfault Recovery Control for MMC-HVDC Connected Offshore Wind Farms. IEEE Trans. Power Syst. 2019, 35, 1606–1617. [Google Scholar] [CrossRef]

- Blasco-Gimenez, R.; Añó-Villalba, S.; Rodríguez-D’Derlée, J.; Morant, F.; Bernal-Perez, S. Distributed Voltage and Frequency Control of Offshore Wind Farms Connected with a Diode-Based HVdc Link. IEEE Trans. Power Electron. 2010, 25, 3095–3105. [Google Scholar] [CrossRef]

- Blasco-Gimenez, R.; Anó-Villalba, S.; Rodriguez-D’Derlée, J.; Bernal-Perez, S.; Morant, F. Diode-Based HVdc Link for the Connection of Large Offshore Wind Farms. IEEE Trans. Energy Convers. 2011, 26, 615–626. [Google Scholar] [CrossRef]

- Bernal-Perez, S.; Ano-Villalba, S.; Blasco-Gimenez, R.; Rodriguez-D’Derlee, J. Efficiency and Fault Ride-Through Performance of a Diode-Rectifier- and VSC-Inverter-Based HVDC Link for Offshore Wind Farms. IEEE Trans. Ind. Electron. 2013, 60, 2401–2409. [Google Scholar] [CrossRef]

- Hoffmann, M.; Rathke, C.; Menze, A.; Hemdan, N.G.A.; Kurrat, M. Parallel operation of HVDC DRU and VSC converters for offshore wind farm connection: Technical and economic feasibility. In Proceedings of the 15th IET International Conference on AC and DC Power Transmission (ACDC 2019), Coventry, UK, 5–7 February 2019; pp. 1–6. [Google Scholar]

- Blasco-Gimenez, R.; Aparicio, N.; Ano-Villalba, S.; Bernal-Perez, S. LCC-HVDC Connection of Offshore Wind Farms With Reduced Filter Banks. IEEE Trans. Ind. Electron. 2012, 60, 2372–2380. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Li, R.; Xu, L. Distributed PLL-Based Control of Offshore Wind Turbines Connected With Diode-Rectifier-Based HVDC Systems. IEEE Trans. Power Deliv. 2018, 33, 1328–1336. [Google Scholar] [CrossRef] [Green Version]

- Cardiel-Álvarez, M.Á.; Arnaltes, S.; Rodriguez-Amenedo, J.L.; Nami, A. Decentralized Control of Offshore Wind Farms Connected to Diode-Based HVdc Links. IEEE Trans. Energy Convers. 2018, 33, 1233–1241. [Google Scholar] [CrossRef]

- Ramachandran, R.; Poullain, S.; Benchaib, A.; Bacha, S.; Francois, B. On the Black Start of Offshore Wind Power Plants with Diode Rectifier based HVDC Transmission. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE ‘19 ECCE Europe), Genova, Italy, 2–5 September 2019; pp. 1–10. [Google Scholar]

- Cai, L.; Karaagac, U.; Mahseredjian, J. Simulation of Startup Sequence of an Offshore Wind Farm With MMC-HVDC Grid Connection. IEEE Trans. Power Deliv. 2017, 32, 638–646. [Google Scholar] [CrossRef]

- Chakraborty, S.; Simoes, M.G. Advanced Active Filtering in a Single Phase High Frequency AC Microgrid. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Dresden, Germany, 16 June 2005; pp. 191–197. [Google Scholar]

- Chakraborty, S.; Simoes, M.G. Experimental Evaluation of Active Filtering in a Single-Phase High-Frequency AC Microgrid. IEEE Trans. Energy Convers. 2009, 24, 673–682. [Google Scholar] [CrossRef]

- Domínguez-García, J.L.; Rogers, D.J.; Ugalde-Loo, C.E.; Liang, J.; Gomis-Bellmunt, O. Effect of non-standard operating frequencies on the economic cost of offshore AC networks. Renew. Energy 2012, 44, 267–280. [Google Scholar] [CrossRef]

- Gierschner, S.; Eckel, H.; Bakran, M. A competitive medium frequency AC distribution grid for offshore wind farms using HVDC. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–10. [Google Scholar]

- Wu, B.; Lang, Y.; Zargari, N.; Kouro, S. Power Conversion and Control of Wind Energy Systems; Wiley-IEEE Press: Piscateway, NJ, USA, 2011. [Google Scholar]

- Xia, Y.; Ahmed, K.H.; Williams, B.W. A New Maximum Power Point Tracking Technique for Permanent Magnet Synchronous Generator Based Wind Energy Conversion System. IEEE Trans. Power Electron. 2011, 26, 3609–3620. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Zhang, Z.; Xu, Z. DRU Based Low Frequency AC Transmission Scheme for Offshore Wind Farm Integration. IEEE Trans. Sustain. Energy 2021, 1. [Google Scholar] [CrossRef]

- Xu, Z.; Xiao, H.; Zhang, Z. Selection methods of main circuit parameters for modular multilevel converters. IET Renew. Power Gener. 2016, 10, 788–797. [Google Scholar] [CrossRef]

- Chakraborty, S.; Weiss, M.D.; Simoes, M.G. Distributed Intelligent Energy Management System for a Single-Phase High-Frequency AC Microgrid. IEEE Trans. Ind. Electron. 2007, 54, 97–109. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wang, L.; Meng, L. An Analytical AC Resistance Calculation Method for Multiple-Conductor Feeder Cables in Aircraft Electric Power Systems. IEEE Trans. Ind. Electron. 2019, 67, 3340–3349. [Google Scholar] [CrossRef]

- Hasan, S.; Taib, S.; Hardi, S.; AR, A.R.; Shukri, A. Core loss characteristics analysis of power transformer under different frequencies excitation. In Proceedings of the 2013 IEEE 7th International Power Engineering and Optimization Conference (PEOCO), Langkawi, Malaysia, 3–4 June 2013; pp. 619–623. [Google Scholar]

- Lüth, T.; Merlin, M.M.C.; Green, T.C.; Hassan, F.; Barker, C.D. High-Frequency Operation of a DC/AC/DC System for HVDC Applications. IEEE Trans. Power Electron. 2014, 29, 4107–4115. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Xu, Z.; Xue, Y. Valve losses evaluation based on piecewise analytical method for MMC–HVDC links. IEEE Trans. Power Deliv. 2014, 29, 1354–1362. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, Y.; Xu, Z. Medium frequency diode rectifier unit based HVDC transmission for offshore wind farm integration. IET Renew. Power Gener. 2021, 15, 717–730. [Google Scholar] [CrossRef]

| Subsystem | Element | Parameter | Value | |

|---|---|---|---|---|

| 50 Hz | 150 Hz | |||

| Land grid | Voltage source | Line voltage (kV) | 220 | 220 |

| Impedance | Inductance (H) | 0.019 | 0.19 | |

| Resistance (Ω) | 0.75 | 0.75 | ||

| HVDC system | Converter transformer | Rated capacity (MVA) | 1200 | 1200 |

| Rated line voltage (kV) | 230/336 | 230/336 | ||

| Leakage reactance (p.u.) | 0.16 | 0.16 | ||

| MMC | SMs per arm | 291 | 291 | |

| Capacitor (uF) | 9423 | 3141 | ||

| Arm inductors (H) | 0.09 | 0.03 | ||

| DC cable | Rated voltage (kV) | ±320 | ±320 | |

| Rated current (kA) | 1.56 | 1.56 | ||

| Length (kM) | 200 | 200 | ||

| Offshore AC system | AC feeder | Ground capacitance (uF) | 0.32 | 0.32 |

| Series inductance (H/m) | 3.23 × 10−7 | 3.23 × 10−7 | ||

| Series resistance (Ω/m) | 4.76 × 10−5 | 4.76 × 10−5 | ||

| Length (kM) | 2 × 3 + 2 × 4 | 2 × 3 + 2 × 4 | ||

| Step-up transformer | Rated capacity (MVA) | 300 | 300 | |

| Rated line voltage (kV) | 230/35 | 230/35 | ||

| Leakage reactance (p.u.) | 0.16 | 0.16 | ||

| Equivalent wind turbine | Wind turbine transformer’s rated capacity (MVA) | 300 | 300 | |

| Wind turbine transformer’s rated line voltage (kV) | 35/0.69 | 35/0.69 | ||

| Wind turbine transformer leakage reactance (p.u.) | 0.16 | 0.16 | ||

| Rated wind power (MW) | 250 | 250 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Tang, Y.; Xu, Z. Miniaturization of an Offshore Platform with Medium-Frequency Offshore Wind Farm and MMC-HVDC Technology. Energies 2021, 14, 2058. https://doi.org/10.3390/en14082058

Zhang Z, Tang Y, Xu Z. Miniaturization of an Offshore Platform with Medium-Frequency Offshore Wind Farm and MMC-HVDC Technology. Energies. 2021; 14(8):2058. https://doi.org/10.3390/en14082058

Chicago/Turabian StyleZhang, Zheren, Yingjie Tang, and Zheng Xu. 2021. "Miniaturization of an Offshore Platform with Medium-Frequency Offshore Wind Farm and MMC-HVDC Technology" Energies 14, no. 8: 2058. https://doi.org/10.3390/en14082058

APA StyleZhang, Z., Tang, Y., & Xu, Z. (2021). Miniaturization of an Offshore Platform with Medium-Frequency Offshore Wind Farm and MMC-HVDC Technology. Energies, 14(8), 2058. https://doi.org/10.3390/en14082058