Performance Improvement Plan of Air Circulation-Type Solar Heat-Storage System Using Ventilated Cavity of Roof

Abstract

1. Introduction

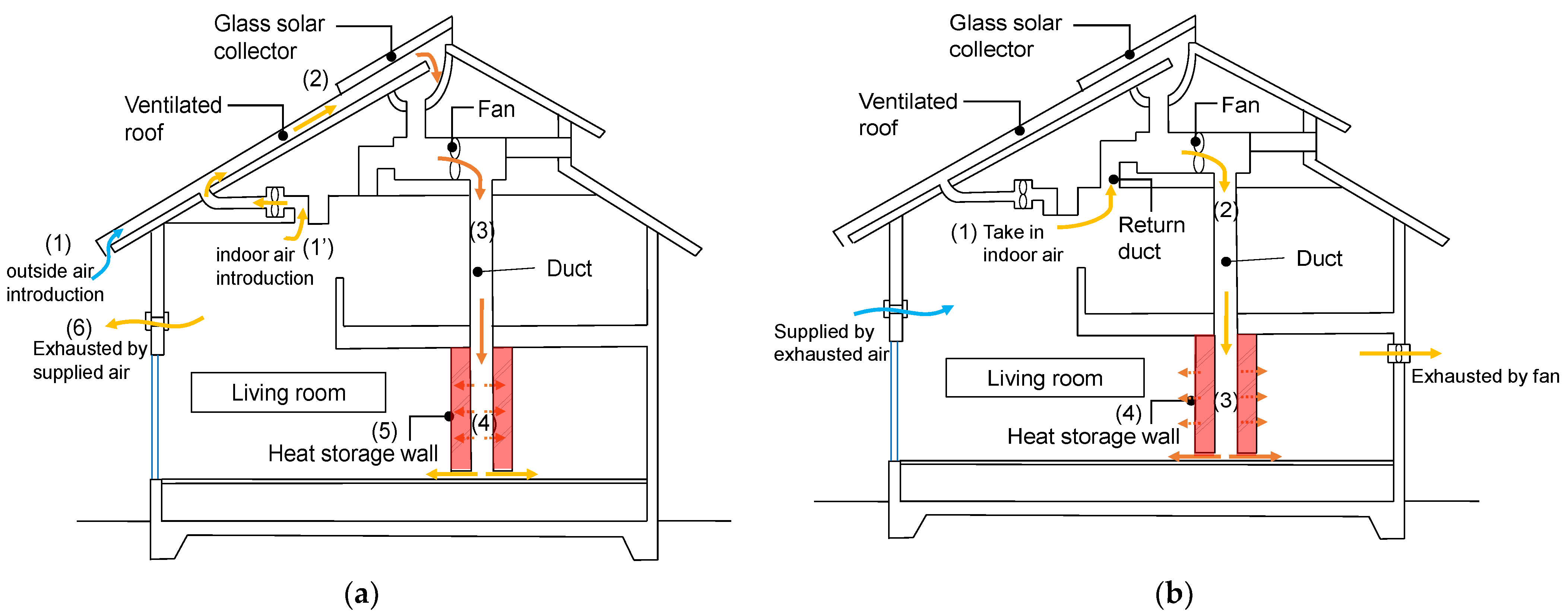

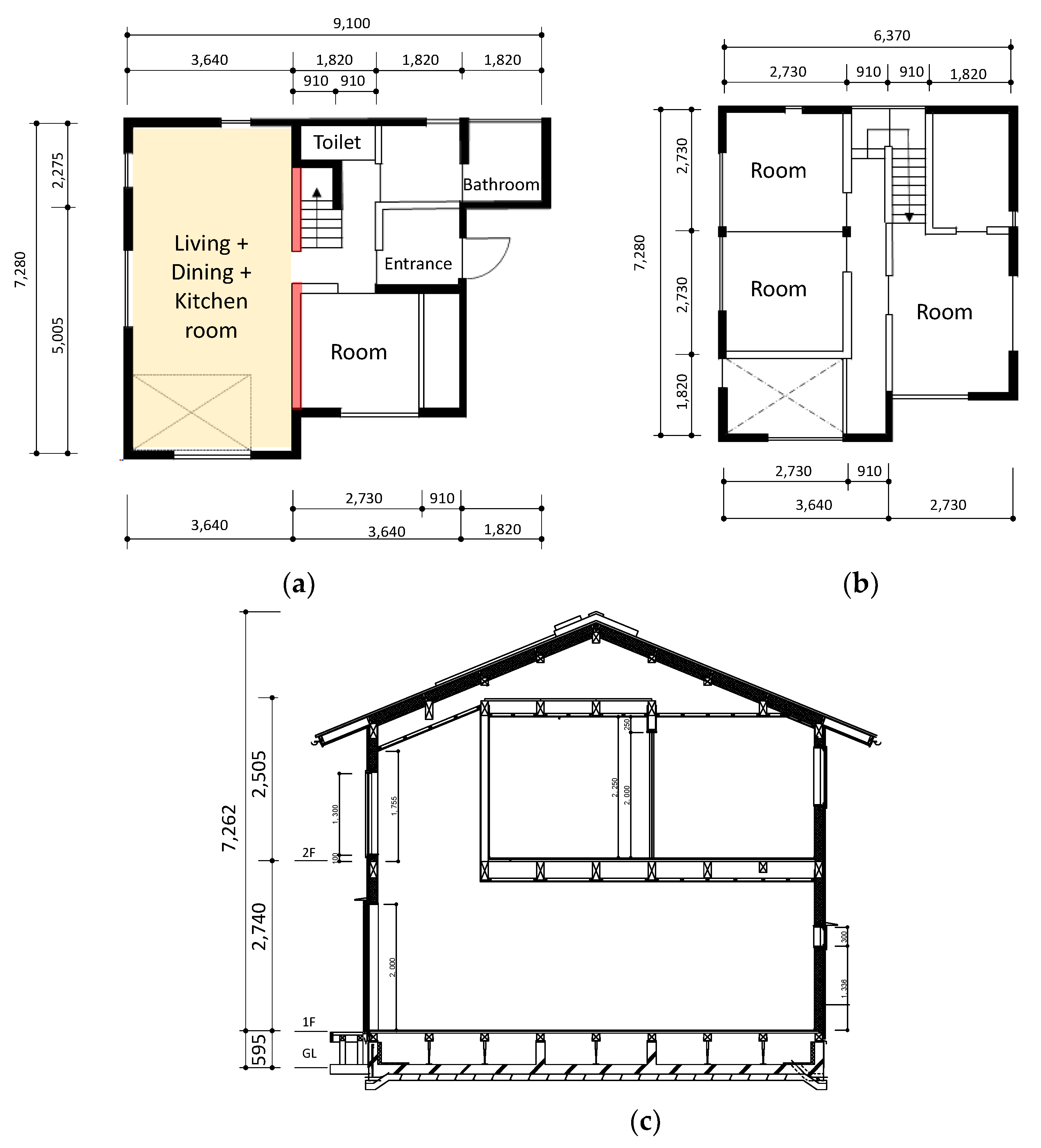

2. Overview of the System under Consideration

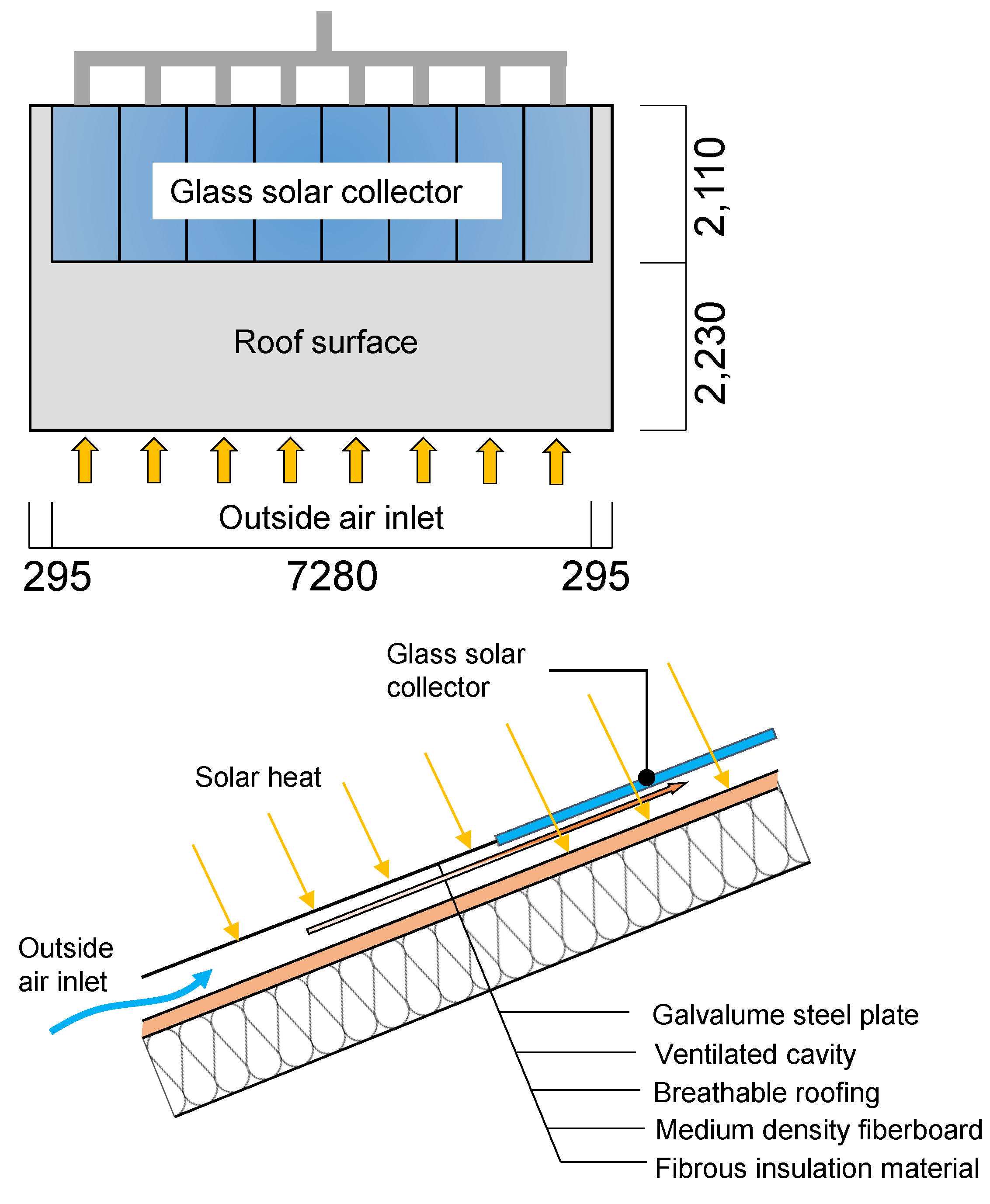

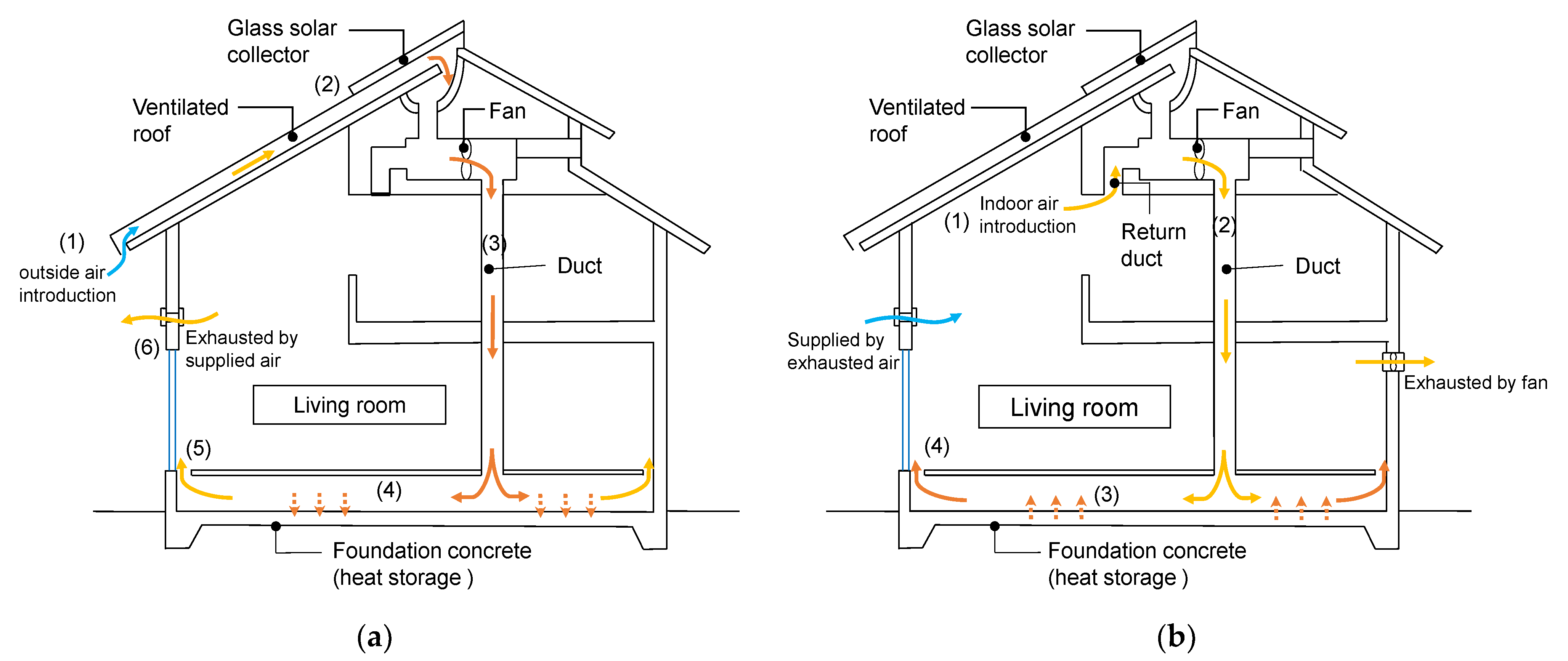

2.1. Conventional System with Glass Solar Thermal Collector

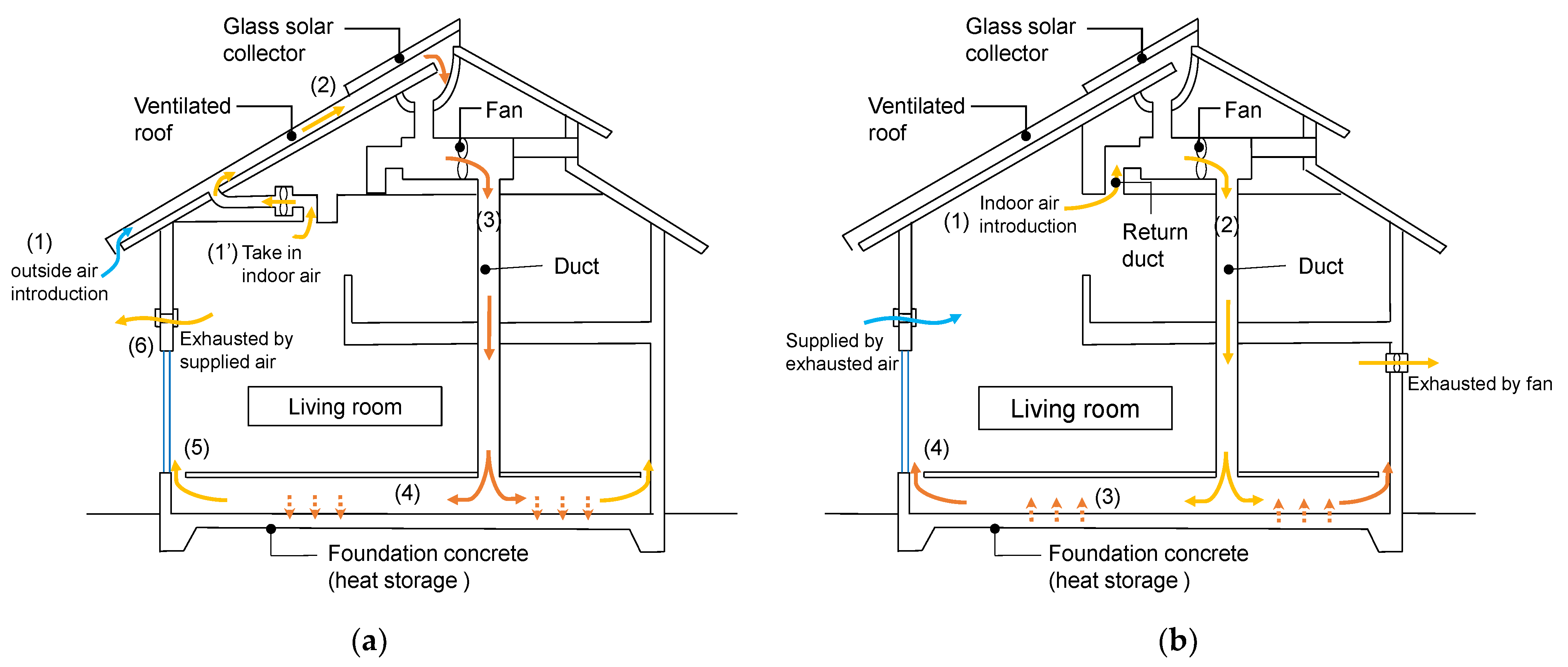

2.2. Improvement Plan 1: Type A (Indoor Air Intake)

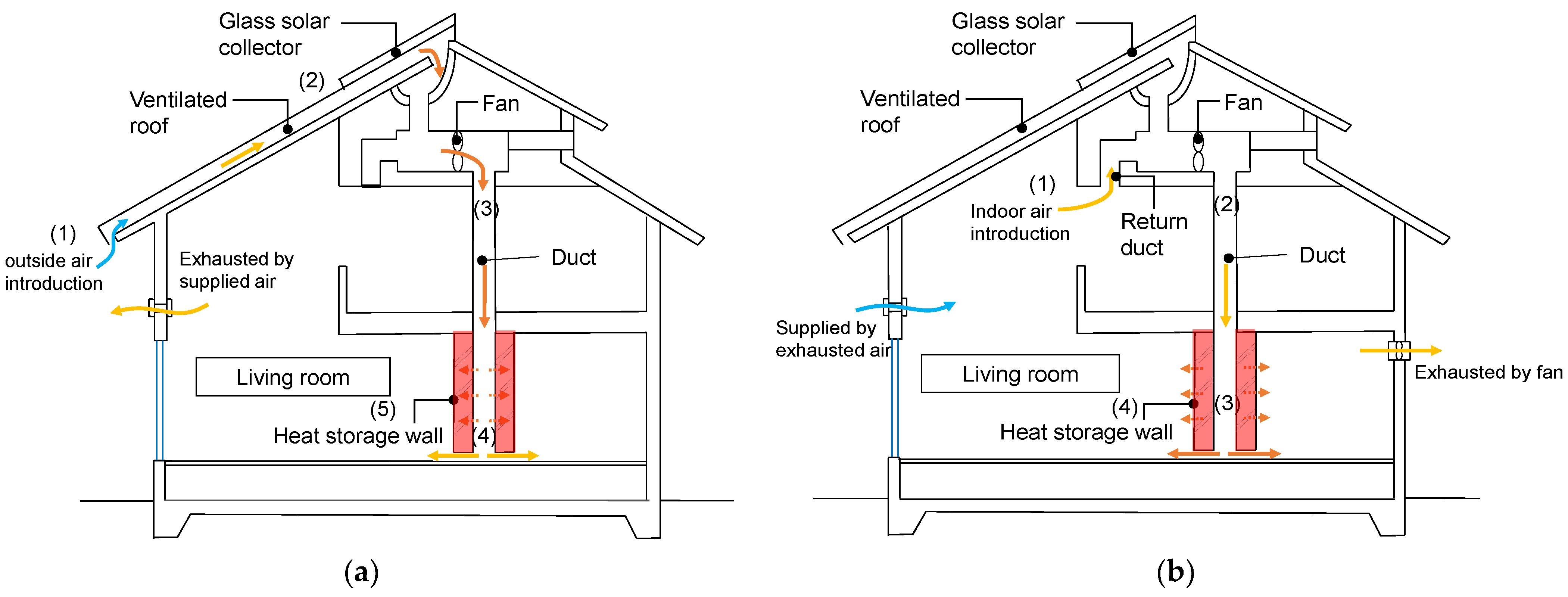

2.3. Improvement Plan 2: Type B (Heat Storage Wall + Indoor Ventilation)

2.4. Improvement Plan 3: Type C (Type A + Type B)

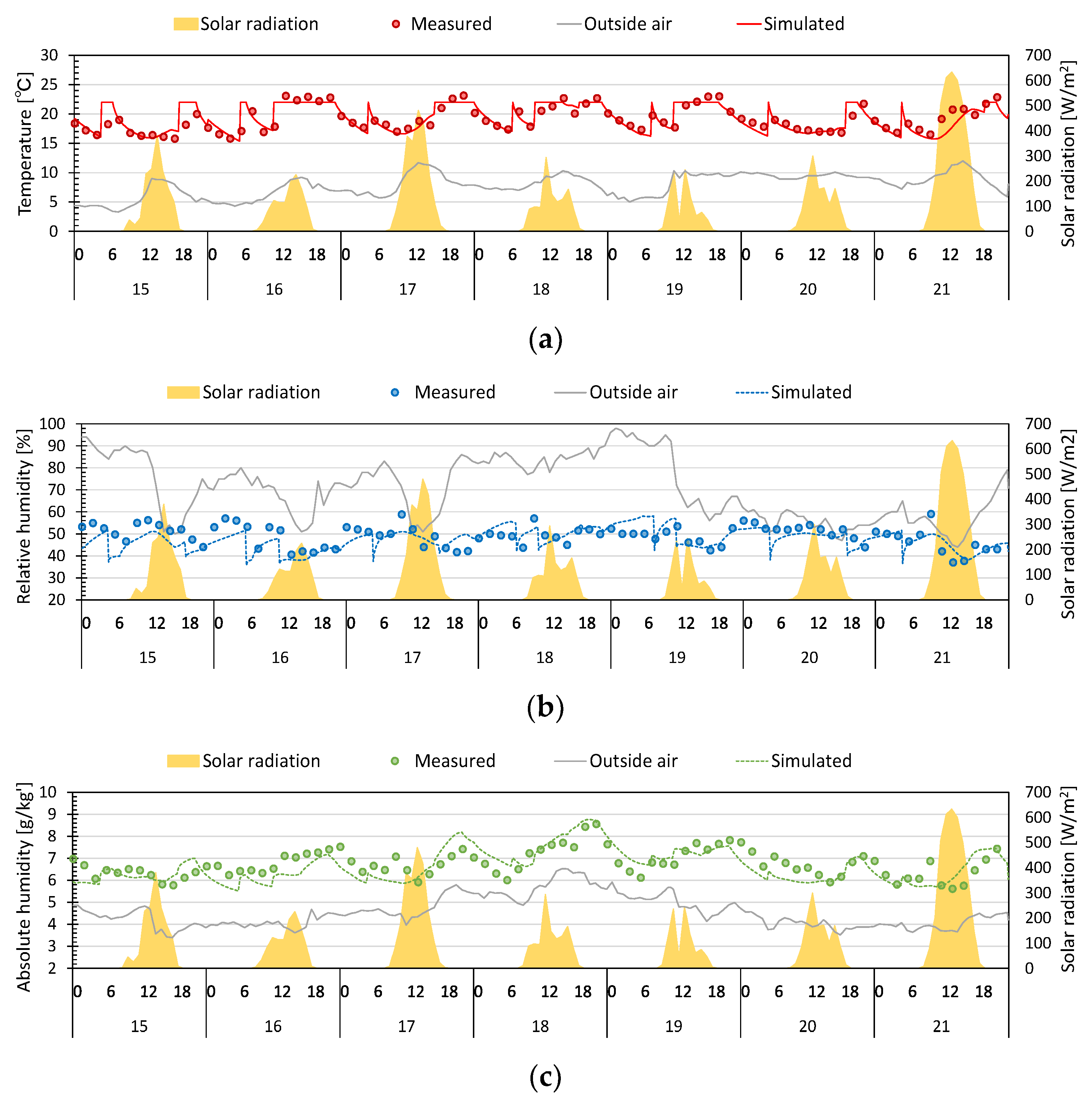

3. Simulation Accuracy Verification

4. Simulation Results

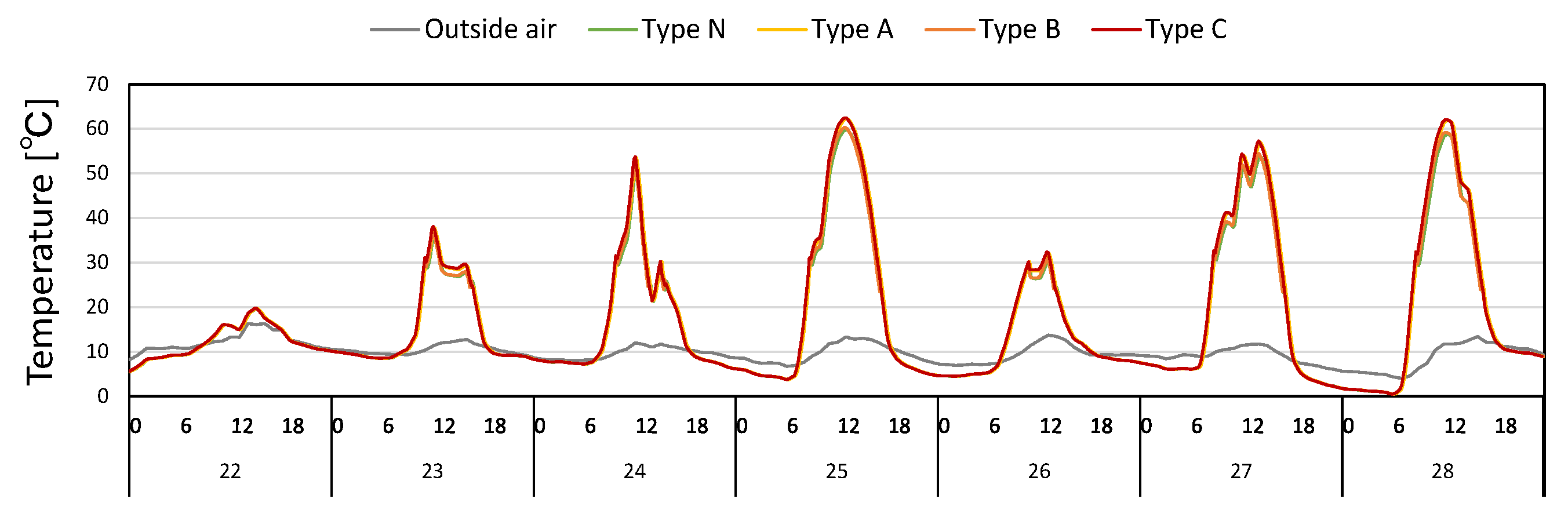

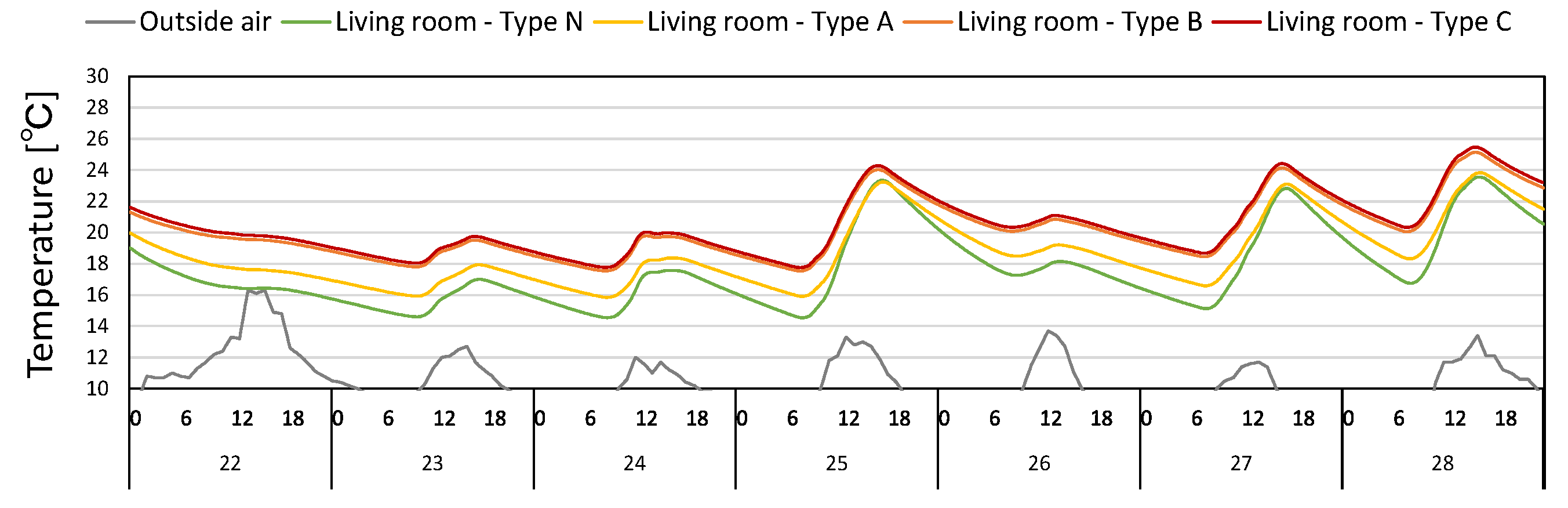

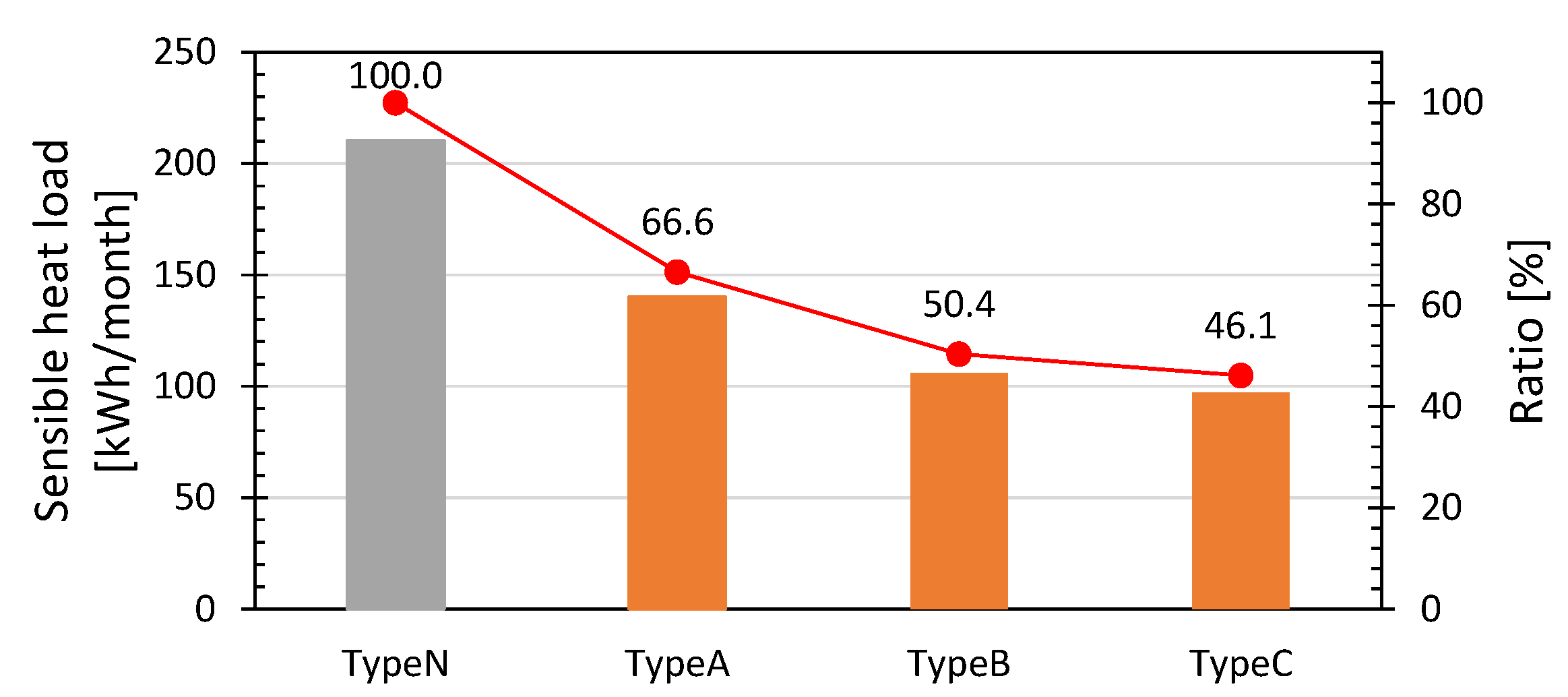

4.1. Comparison of Roof Ventilation Layer and Room Temperature

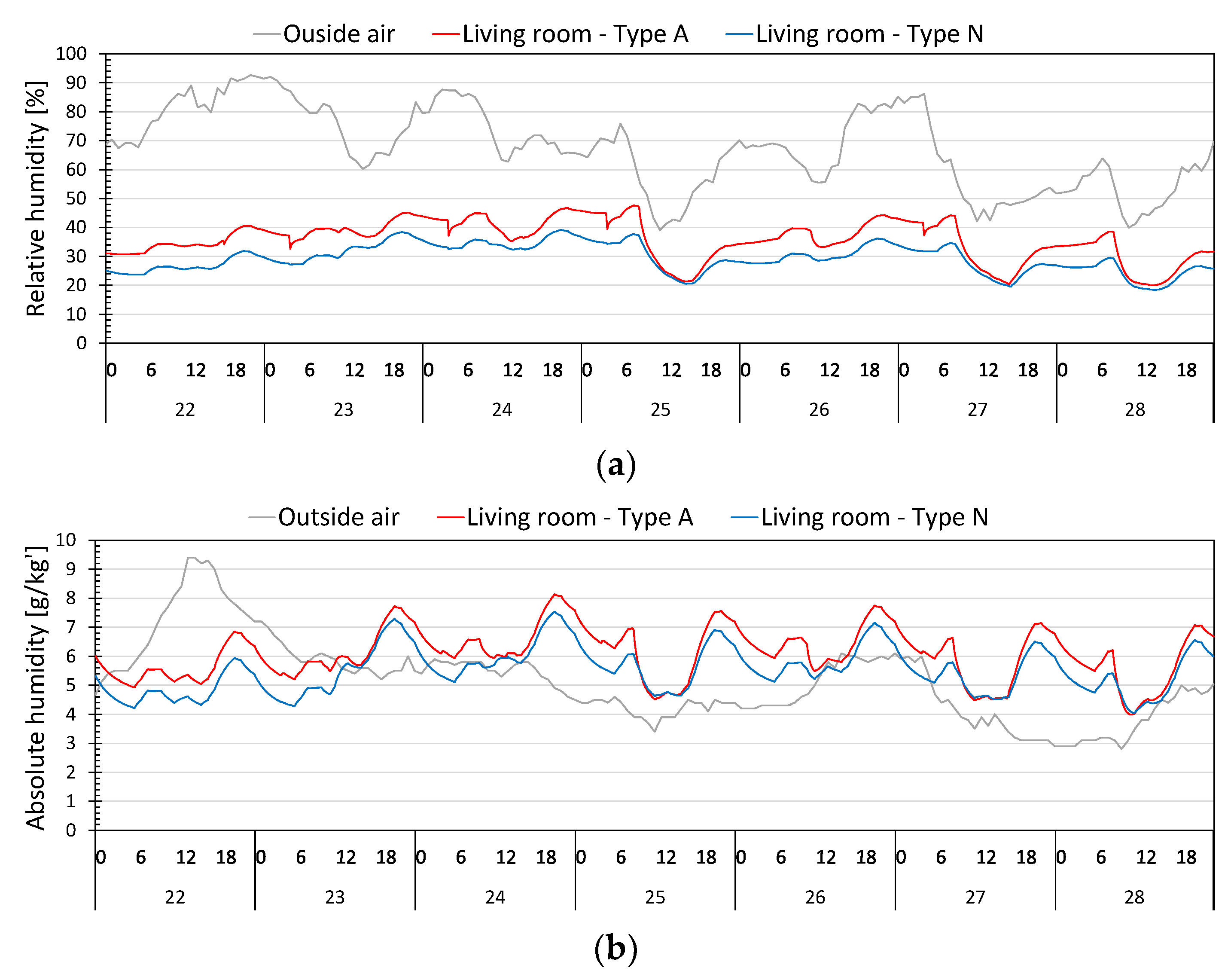

4.2. Examination of Overdrying Prevention Effect

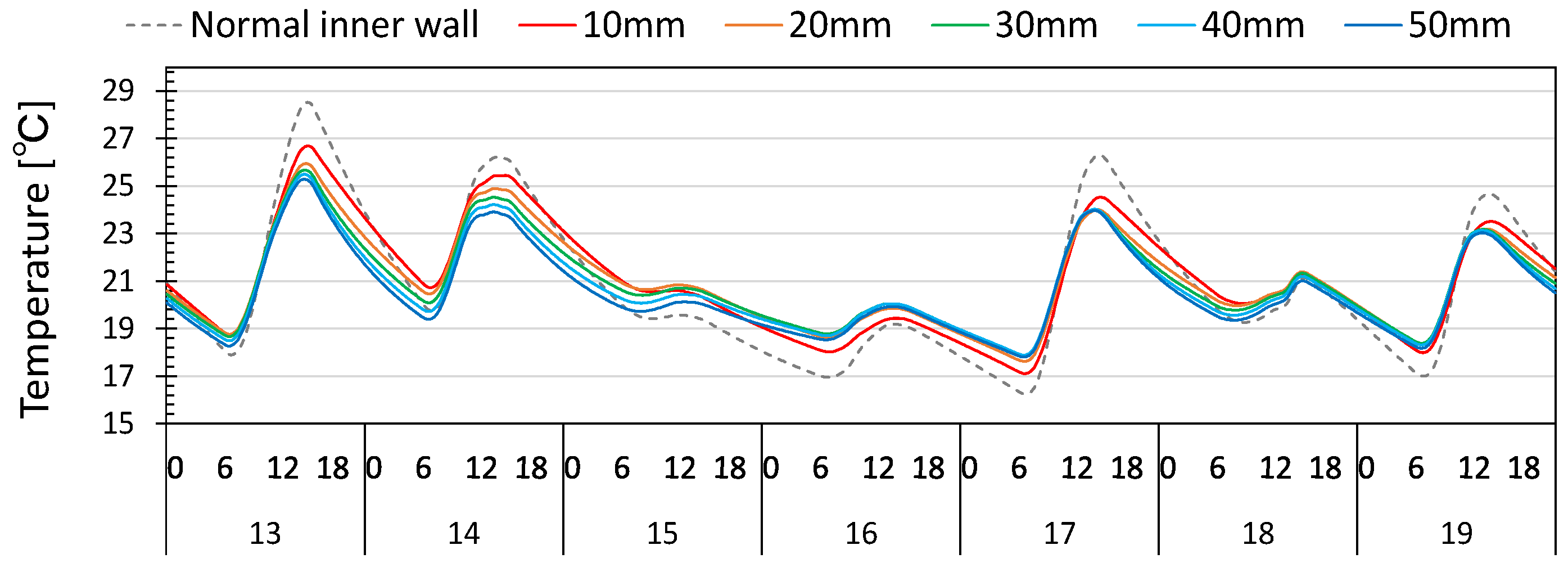

4.3. Difference Caused by the Thickness of the Heat-Storage Wall

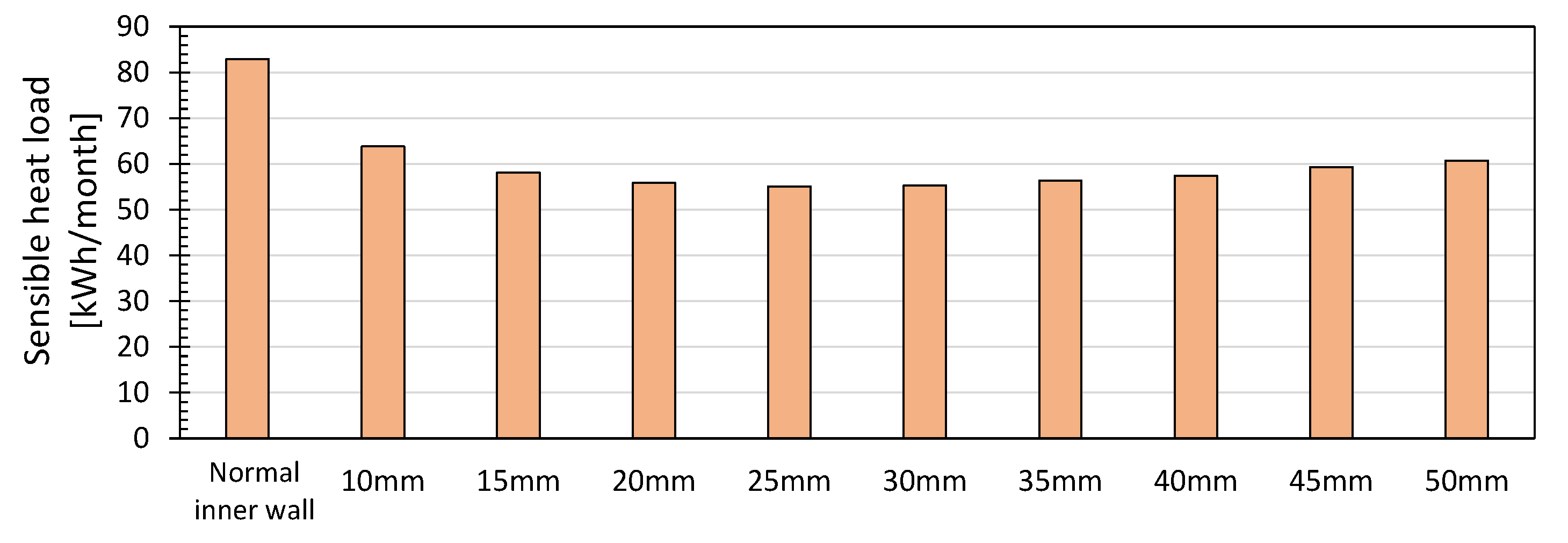

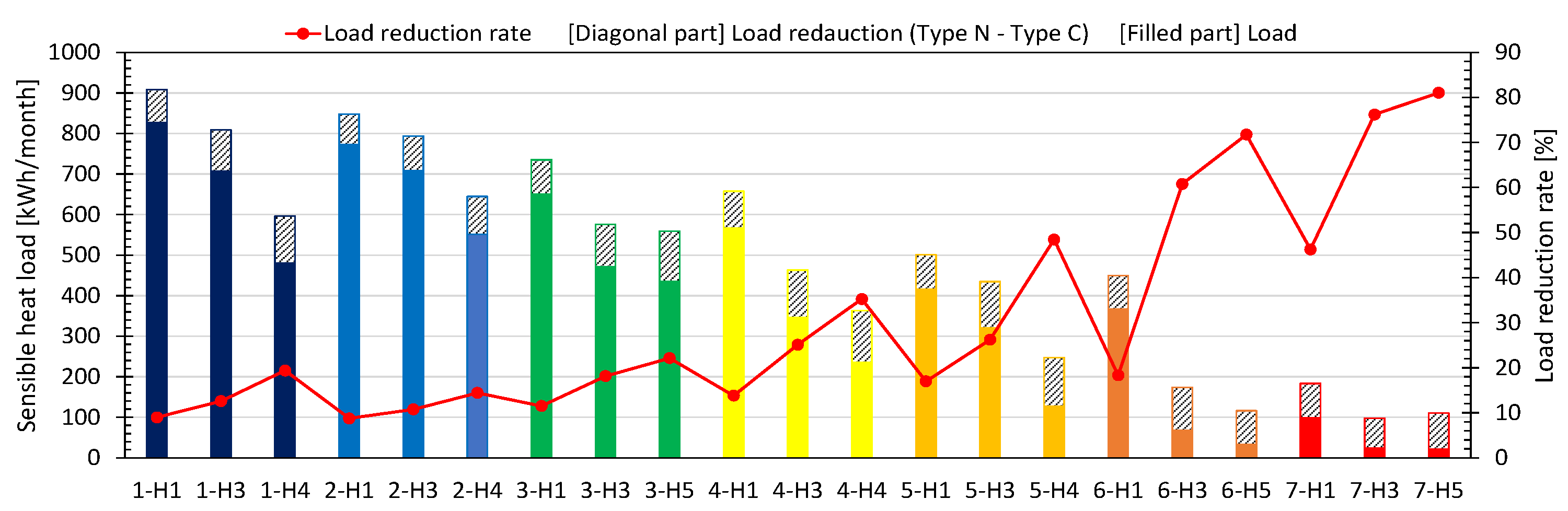

4.4. Difference Caused by the Thickness of the Heat-Storage Wall

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ibañez-Puy, M.; Vidaurre-Arbizu, M.; Sacristán-Fernández, J.A.; Martín-Gómez, C. Opaque Ventilated Façades: Thermal and energy performance review. Renew. Sustain. Energy Rev. 2017, 79, 180–191. [Google Scholar] [CrossRef]

- Balocco, C. A simple model to study ventilated facades energy performance. Energy Build. 2002, 34, 469–475. [Google Scholar] [CrossRef]

- Jiru, T.E.; Haghighat, F. Modeling ventilated double skin façade-A zonal approach. Energy Build. 2008, 40, 1567–1576. [Google Scholar] [CrossRef]

- Sanjuan, C.; Suárez, M.J.; González, M.; Pistono, J.; Blanco, E. Energy performance of an open-joint ventilated façade compared with a conventional sealed cavity façade. Sol. Energy 2011, 85, 1851–1863. [Google Scholar] [CrossRef]

- Suárez, M.J.; Sanjuan, C.; Gutiérrez, A.J.; Pistono, J.; Blanco, E. Energy evaluation of an horizontal open joint ventilated faade. Appl. Therm. Eng. 2012, 37, 302–313. [Google Scholar] [CrossRef]

- Sánchez, M.N.; Sanjuan, C.; Suárez, M.J.; Heras, M.R. Experimental assessment of the performance of open joint ventilated façades with buoyancy-driven airflow. Sol. Energy 2013, 91, 131–144. [Google Scholar] [CrossRef]

- Susanti, L.; Homma, H.; Matsumoto, H.; Suzuki, Y.; Shimizu, M. A laboratory experiment on natural ventilation through a roof cavity for reduction of solar heat gain. Energy Build. 2008, 40, 2196–2206. [Google Scholar] [CrossRef]

- Bunkholt, N.S.; Säwén, T.; Stockhaus, M.; Kvande, T.; Gullbrekken, L.; Wahlgren, P.; Lohne, J. Experimental study of thermal buoyancy in the cavity of ventilated roofs. Buildings 2020, 10, 8. [Google Scholar] [CrossRef]

- Lee, S.; Park, S.H.; Yeo, M.S.; Kim, K.W. An experimental study on airflow in the cavity of a ventilated roof. Build. Environ. 2009, 44, 1431–1439. [Google Scholar] [CrossRef]

- Maurer, C.; Baumann, T.; Hermann, M.; Di Lauro, P.; Pavan, S.; Michel, L.; Kuhn, T.E. Heating and cooling in high-rise buildings using facade-integrated transparent solar thermal collector systems. J. Build. Perform. Simul. 2013, 6, 449–457. [Google Scholar] [CrossRef]

- KoŚny, J.; Biswas, K.; Miller, W.; Kriner, S. Field thermal performance of naturally ventilated solar roof with PCM heat sink. Sol. Energy 2012, 86, 2504–2514. [Google Scholar] [CrossRef]

- Lee, H.; Ozaki, A.; Lee, M. Energy saving effect of air circulation heat storage system using natural energy. Build. Environ. 2017, 124, 104–117. [Google Scholar] [CrossRef]

- Lee, H.; Ozaki, A. Sensitivity analysis for optimization of renewable-energy-based air-circulation-type temperature-control system. Appl. Energy 2018, 230, 317–329. [Google Scholar] [CrossRef]

- Lee, H.; Ozaki, A.; Lee, M.; Cho, W. A fundamental study of intelligent building envelope systems capable of passive dehumidification and solar heat collection utilizing renewable energy. Energy Build. 2019, 195, 139–148. [Google Scholar] [CrossRef]

- Lee, H.; Ozaki, A. Housing design methodology for passive hygrothermal control and effect verification via field measurements. Build. Environ. 2020, 185, 107241. [Google Scholar] [CrossRef]

- Martin-Escudero, K.; Salazar-Herran, E.; Campos-Celador, A.; Diarce-Belloso, G.; Gomez-Arriaran, I. Solar energy system for heating and domestic hot water supply by means of a heat pump coupled to a photovoltaic ventilated façade. Sol. Energy 2019, 183, 453–462. [Google Scholar] [CrossRef]

- Mingotti, N.; Chenvidyakarn, T.; Woods, A.W. The fluid mechanics of the natural ventilation of a narrow-cavity double-skin facade. Build. Environ. 2011, 46, 807–823. [Google Scholar] [CrossRef]

- Okumura, A. The present and future OM solar system. PLEA 1997, 1, 69–74. [Google Scholar]

- Kuwasawa, Y.; Akamine, Y.; Mae, M.; Nakamura, S.; Roh, H. Study on Energy Saving Effect of Air-Based Solar Heating System Part 1 Outline of Field-Survey and Measurement Results in Summer and Winter. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 2010, 2063–2066. (In Japanese) [Google Scholar] [CrossRef]

- Choi, Y.; Takase, K.; Mae, M. System performance of a residential building using the air-based solar heating system. Sol. Energy 2018, 171, 47–63. [Google Scholar] [CrossRef]

- Choi, Y.; Mae, M.; Bae Kim, H. Thermal performance improvement method for air-based solar heating systems. Sol. Energy 2019, 186, 277–290. [Google Scholar] [CrossRef]

- Ozaki, A.; Tsujimaru, T. Prediction of hygrothermal environment of buildings based upon combined simulation of heat and moisture transfer and airflow. IBPSA 2005—Int. Build. Perform. Simul. Assoc 2005, 899–906. [Google Scholar]

- Calculation Conditions of the Housing Scenario for Energy Saving. Available online: http://www.heat20.jp/grade/manu_rev2.pdf (accessed on 1 February 2021). (In Japanese).

| Normal Wall (Type N) | Heat-Storage Wall (Types B and C) | |

|---|---|---|

| Thickness [mm] | 12 | 20 |

| Conductivity [W/m K] | 0.105 | 1.2 |

| Specific heat [J/kg K] | 1880 | 840 |

| Specific weight [kg/m3] | 724 | 2220 |

| Moisture conductivity [kg/m∙s∙Pa] | 7.610 × 10−12 | 7.610 × 10−12 |

| Moisture capacity [kg/m3(kJ/kg)] | 1.910 × 10−2 | 1.905 × 10−2 |

| Overview | |

|---|---|

| Target area | Fukuoka, Japan |

| Total floor area [m2] | 92.82 |

| Structure | Wooden construction |

| Year of completion | 2018 |

| Family structure [people] | four people |

| Building Envelope Overview | Roof Overview |

|---|---|

| Siding (14 mm) | Galvalume steel plate (0.4 mm) |

| Ventilated cavity (21 mm) | Ventilated cavity (45 mm) |

| Moisture-permeable sheet | Moisture-permeable sheet |

| Plywood (9 mm) | Plywood (9.2 mm) |

| Cellulose fiber insulation (120 mm, 55 kg/m3) | Moisture-permeable sheet |

| Moisture-permeable sheet | Cellulose fiber insulation (185 mm, 55 kg/m3) |

| Moisture-permeable sheet |

| Condition | |

|---|---|

| Target area | Fukuoka, Japan |

| Weather condition | EA weather data 1 |

| Air-flow rate of ventilated roof | 250 m3/h |

| Roof ventilation start temperature | 30 ℃ |

| Roof ventilation stop temperature | 25 ℃ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Ozaki, A.; Choi, Y.; Iqbal, M. Performance Improvement Plan of Air Circulation-Type Solar Heat-Storage System Using Ventilated Cavity of Roof. Energies 2021, 14, 1606. https://doi.org/10.3390/en14061606

Lee H, Ozaki A, Choi Y, Iqbal M. Performance Improvement Plan of Air Circulation-Type Solar Heat-Storage System Using Ventilated Cavity of Roof. Energies. 2021; 14(6):1606. https://doi.org/10.3390/en14061606

Chicago/Turabian StyleLee, Haksung, Akihito Ozaki, Younhee Choi, and Muhammad Iqbal. 2021. "Performance Improvement Plan of Air Circulation-Type Solar Heat-Storage System Using Ventilated Cavity of Roof" Energies 14, no. 6: 1606. https://doi.org/10.3390/en14061606

APA StyleLee, H., Ozaki, A., Choi, Y., & Iqbal, M. (2021). Performance Improvement Plan of Air Circulation-Type Solar Heat-Storage System Using Ventilated Cavity of Roof. Energies, 14(6), 1606. https://doi.org/10.3390/en14061606