Day-Ahead and Intra-Day Collaborative Optimized Operation among Multiple Energy Stations

Abstract

1. Introduction

- Combined with typical IES equipment models, the energy constraints of the pipe network, including electric, gas, heating, and cooling networks, are integrated toward a more detailed and comprehensive model for IES operation.

- Considering the uncertainty of the PV output, a day-ahead and intra-day collaborative robust optimization model of multiple energy stations is constructed, where the influence of electrical load participating in the demand response is also incorporated.

- The piecewise linearization method is used since the equipment and network model of an IES contains a large number of nonlinear terms. The whole optimization model is then converted to a mixed-integer linear programming model. Compared to other existing methods, a unified solution method for the optimal operation of equipment and the network in an IES is proposed.

2. Integrated Energy System Modeling

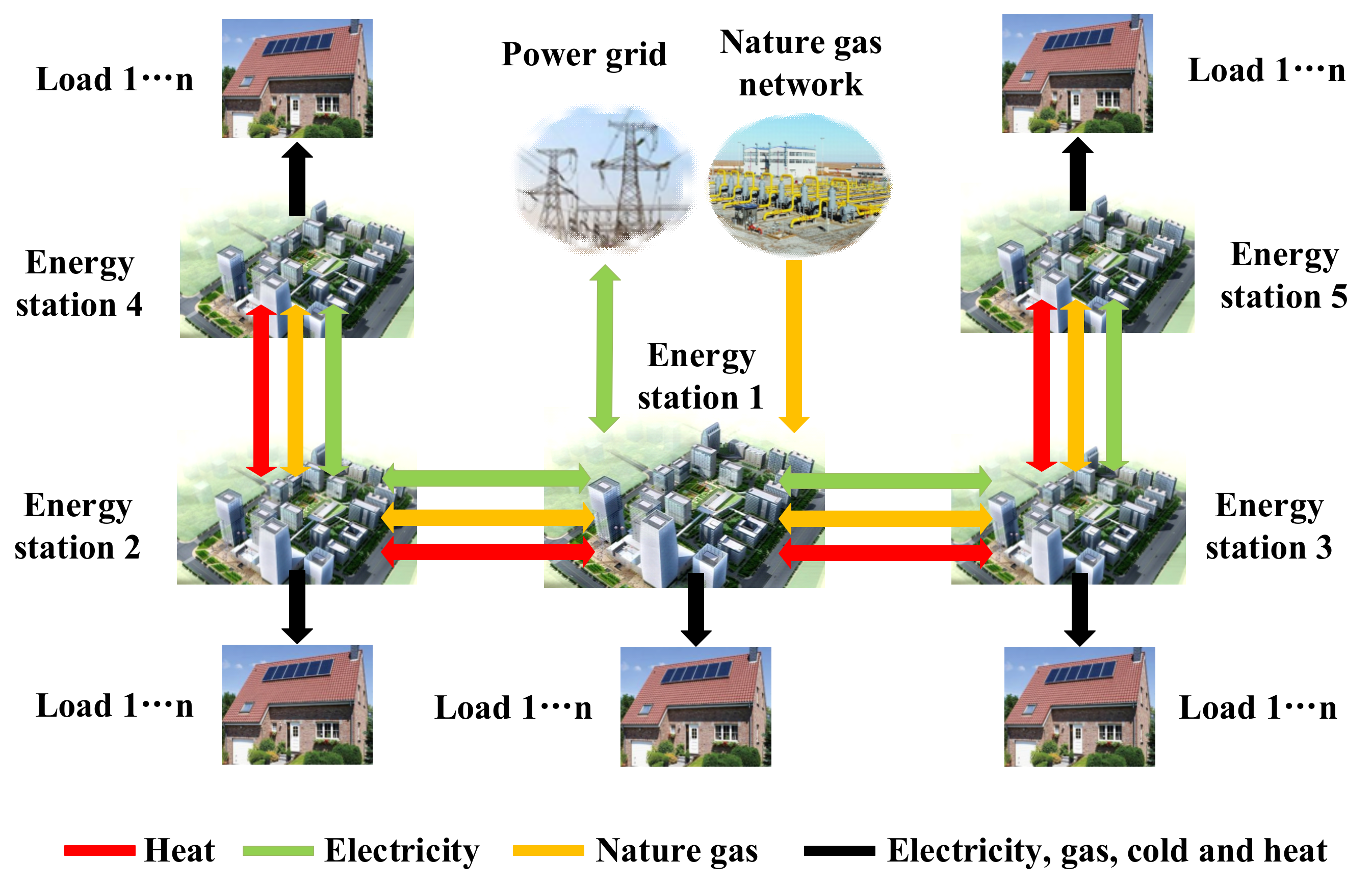

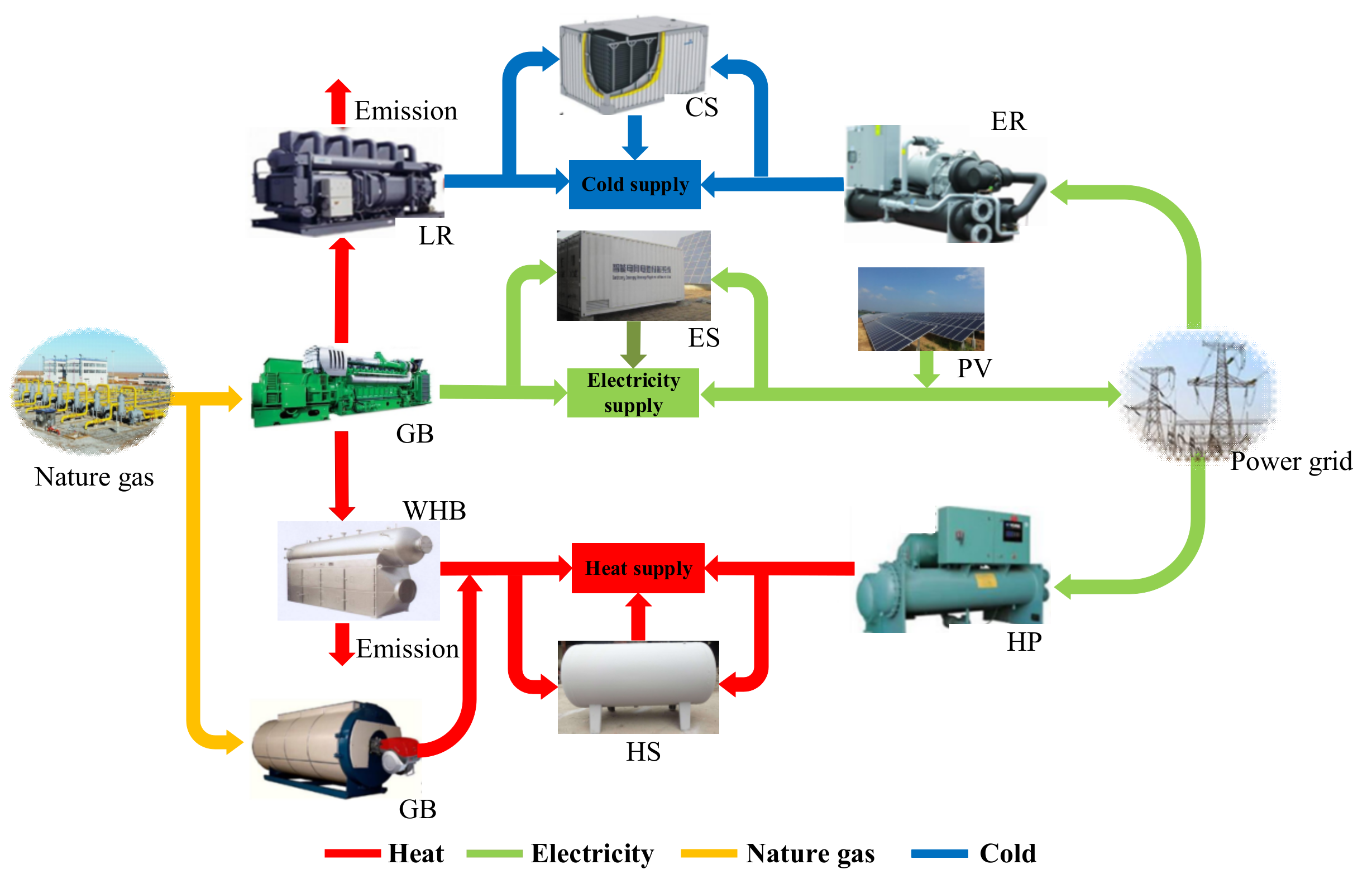

2.1. An Overview of Integrated Energy Systems

2.2. Equipment Modeling of an Integrated Energy System

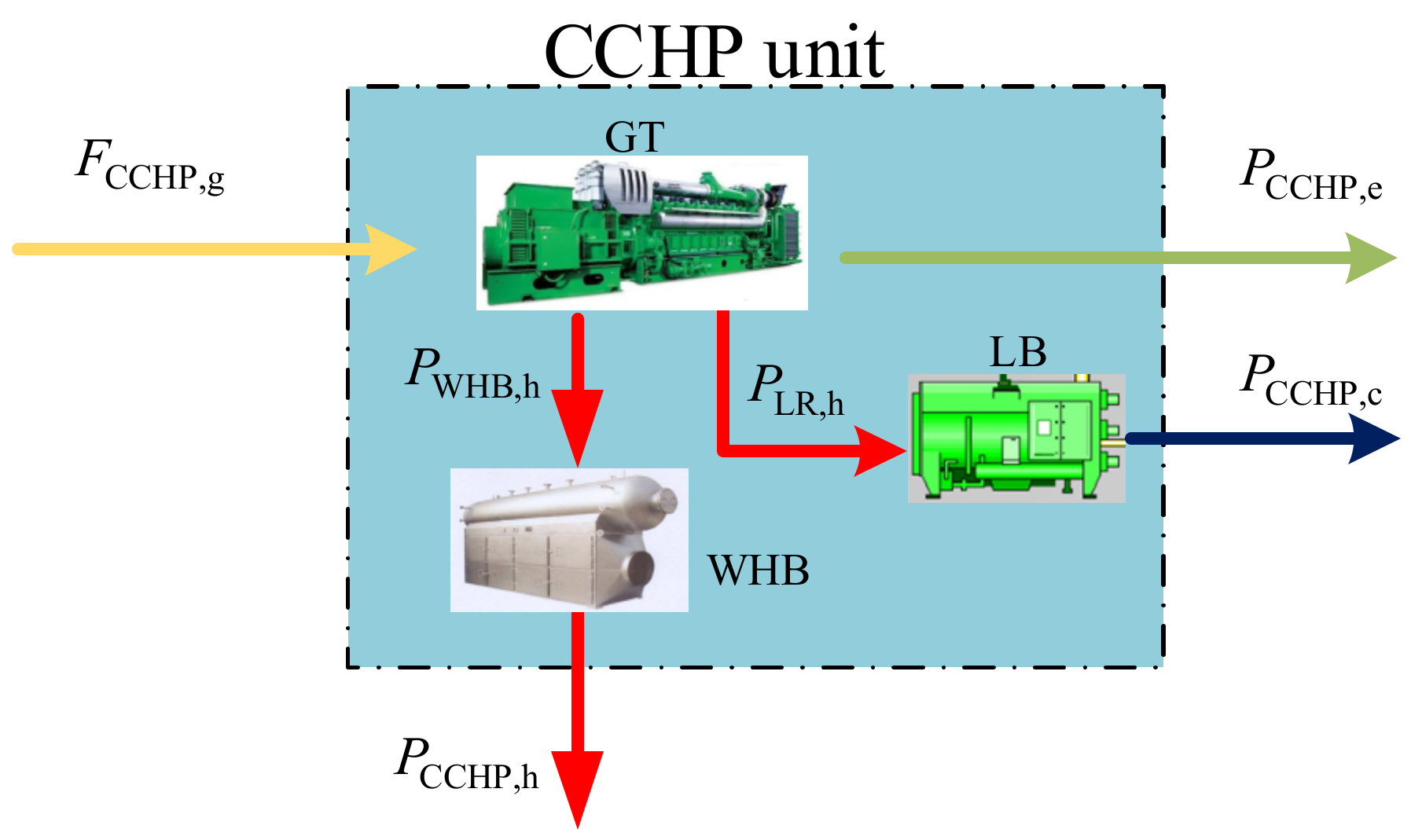

2.2.1. CCHP Unit of the Gas Turbine

2.2.2. Gas Boiler

2.2.3. Electric Refrigeration

2.2.4. Heat Pump

2.2.5. Multi-Energy Storage

2.3. Modeling of the Multi-Energy Network

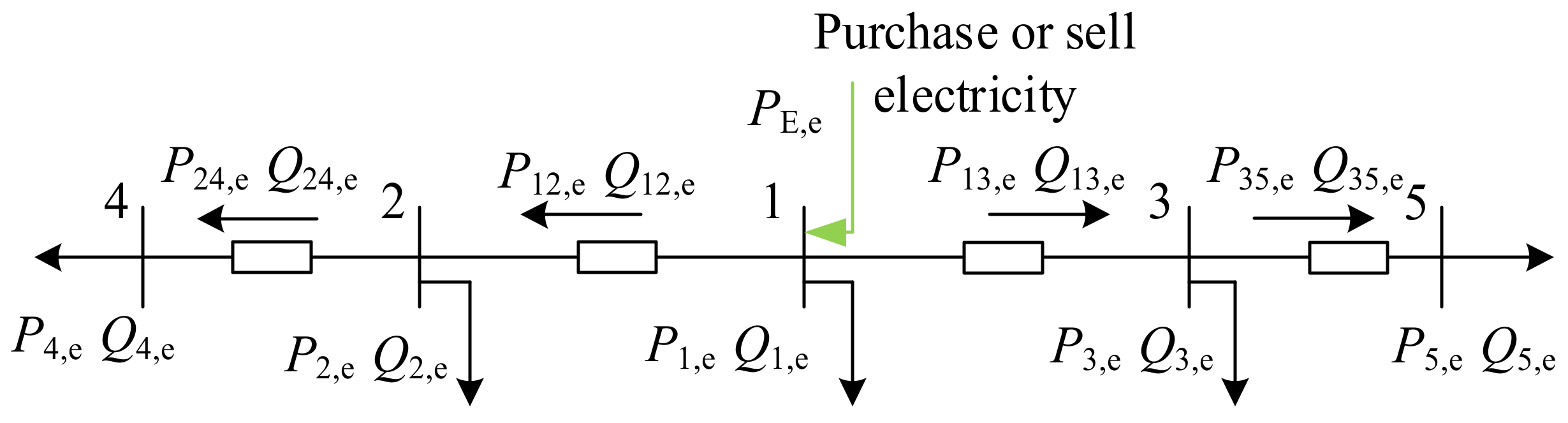

2.3.1. Electrical Power Network

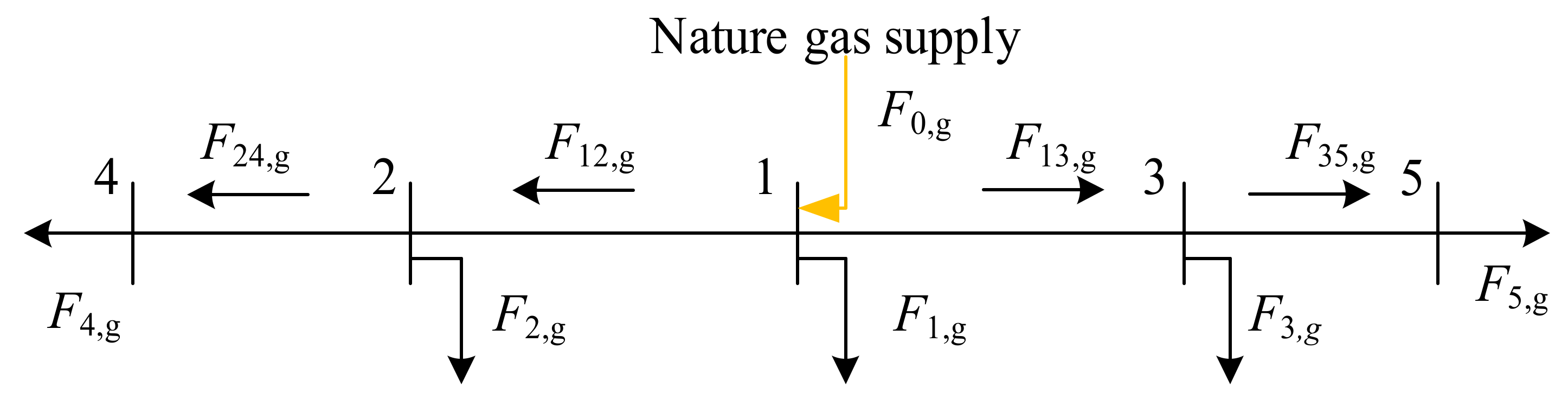

2.3.2. Natural Gas Network

2.3.3. Thermal Network

Thermodynamic Equations

Hydraulic Equations

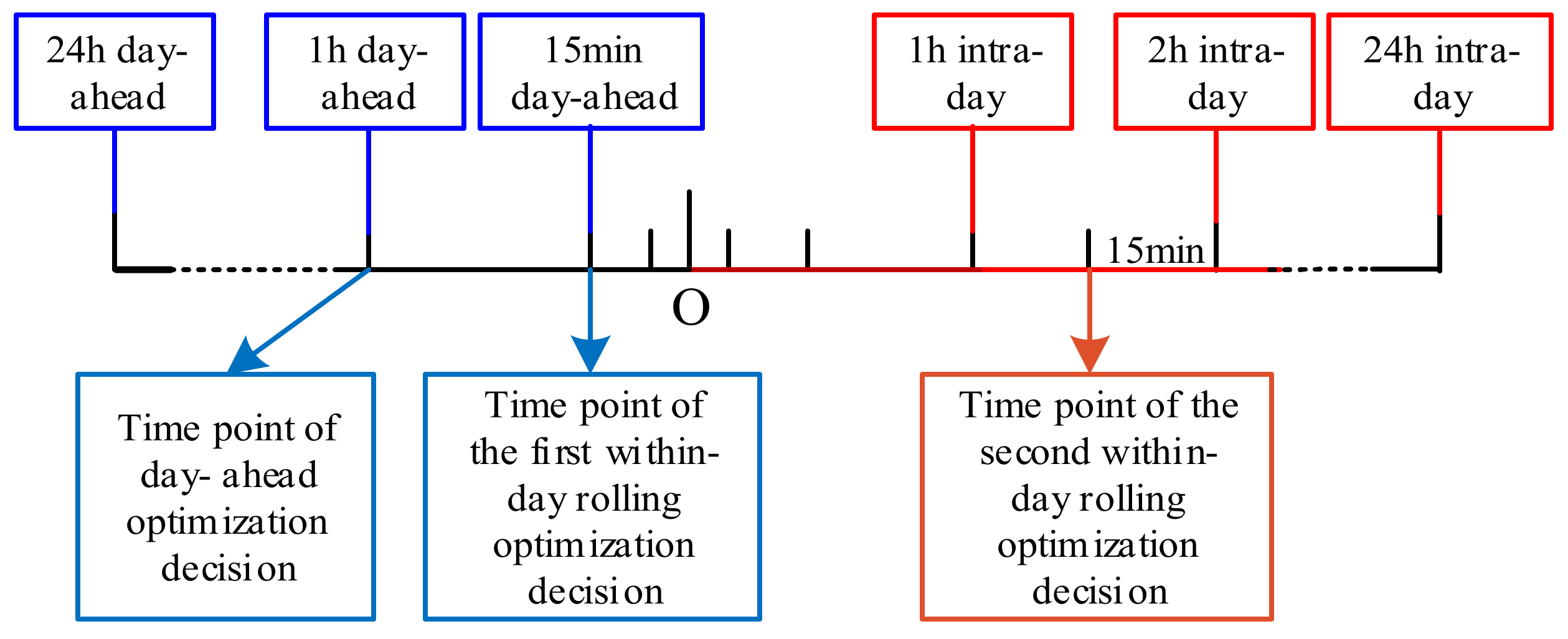

3. Day-Ahead and Intra-Day Collaborative Robust Optimization Model for an IES

3.1. Objective Functions

3.1.1. Objective Function of Day-Ahead Optimized Operation of the IES

3.1.2. Objective Function of Intra-Day Optimized Operation of an IES

3.2. Constraints

3.2.1. Equipment Operation Constraints

3.2.2. Energy Balance Constraints of an Energy Station

3.2.3. Operation Constraints of Electricity, Heat, and Gas Energy Networks

3.2.4. Demand Response Constraints

3.2.5. Intra-Day Rolling Optimization Operation Constraints

- Energy storage output constraints

- Output adjustment constraint

- Spinning reserve constraints

- Equipment start-up and shut-down state constraints

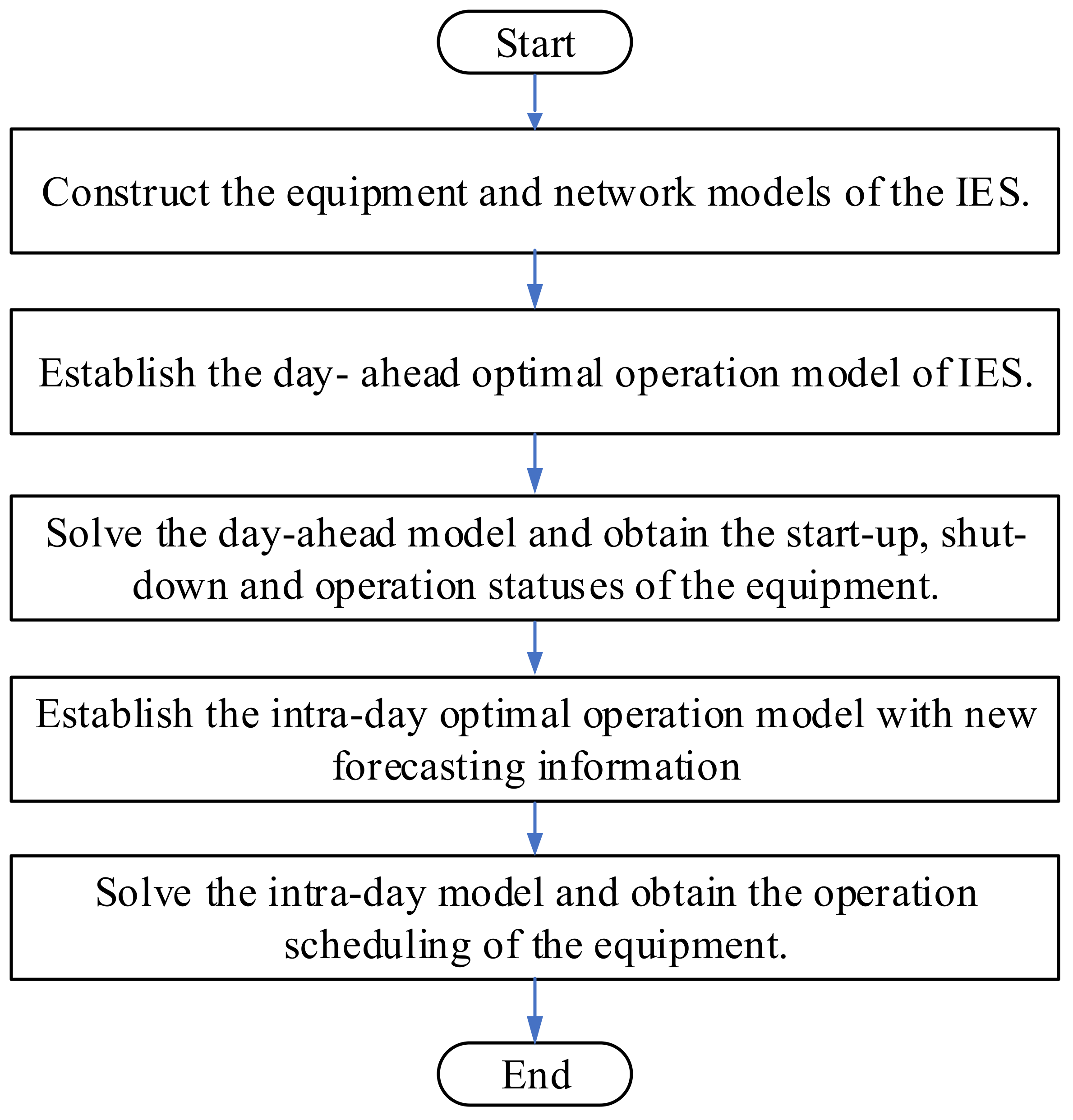

3.3. Optimal Operation Solution Method

- Step 1: Construct IES network and equipment models based on network construction and equipment parameters.

- Step 2: Establish the day-ahead optimal operation model of the IES with day-ahead PV and load forecast information.

- Step 3: Solve the day-ahead optimal operation model to obtain the start-up, shut-down, and operation status of the unit equipment.

- Step 5: Establish the intra-day collaborative optimization operation model based on day-ahead pre-dispatch results and updated forecasting information.

- Step 6: Solve the intra-day operation model to obtain the operation scheduling of equipment for the subsequent time periods.

4. The Example Analysis

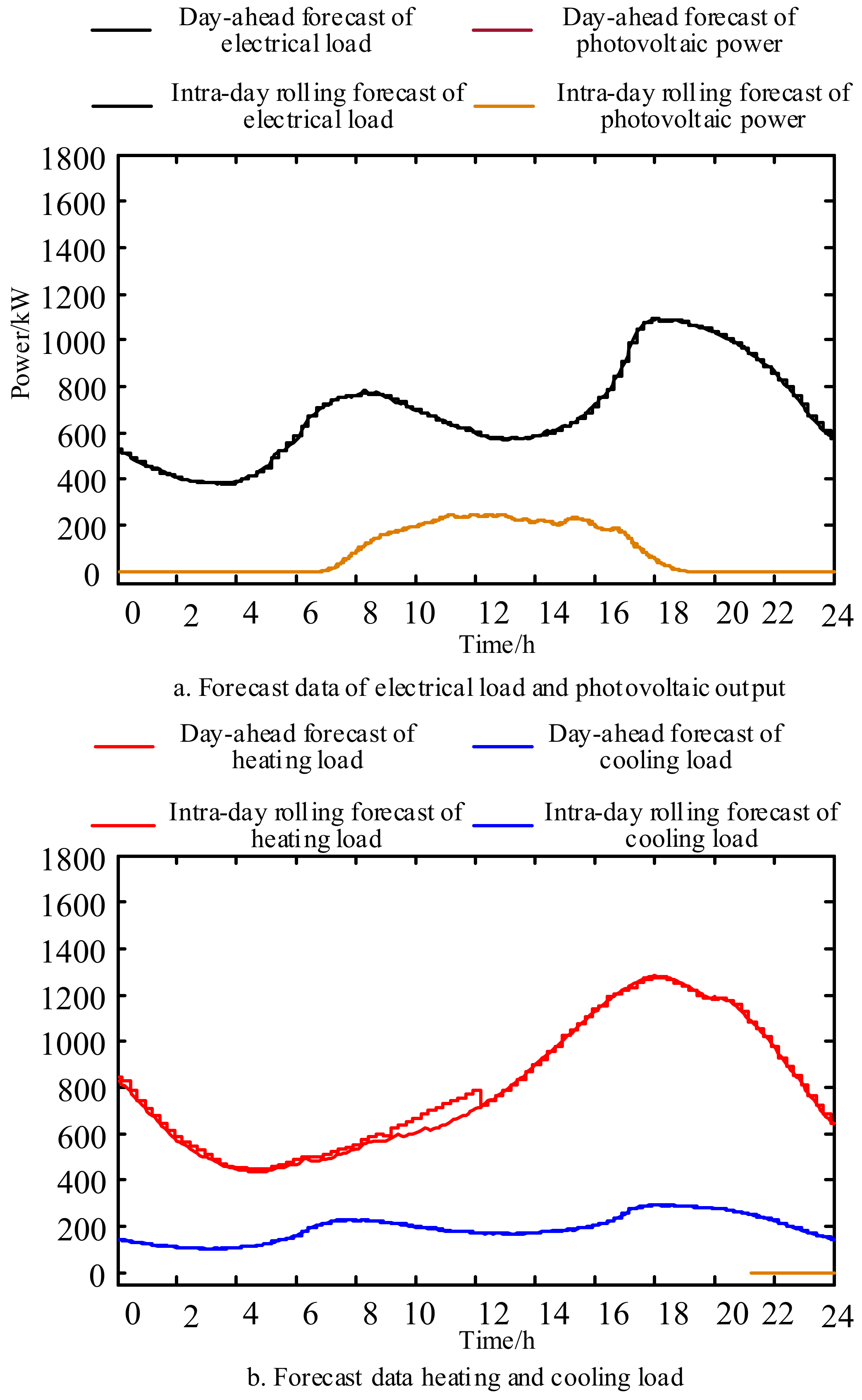

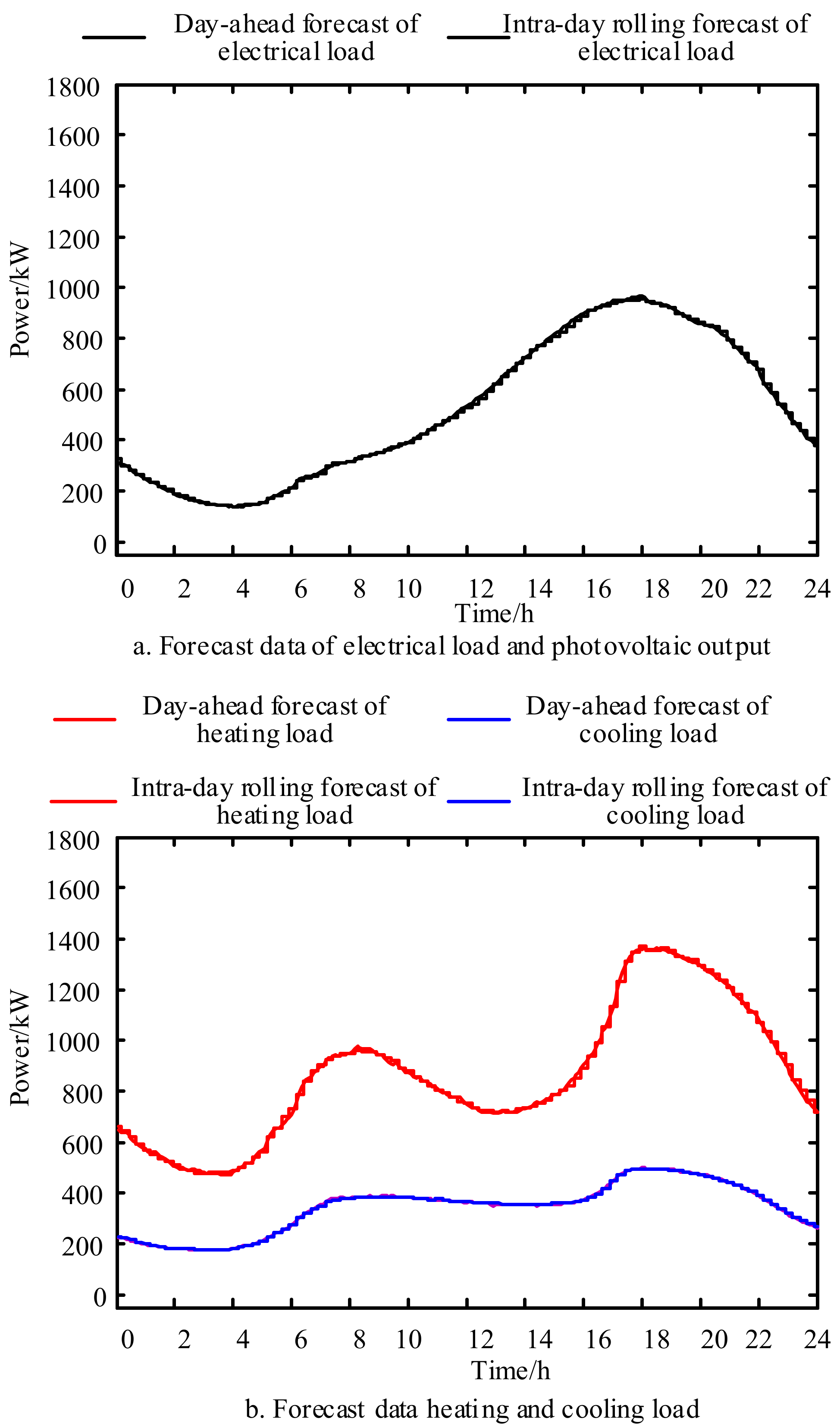

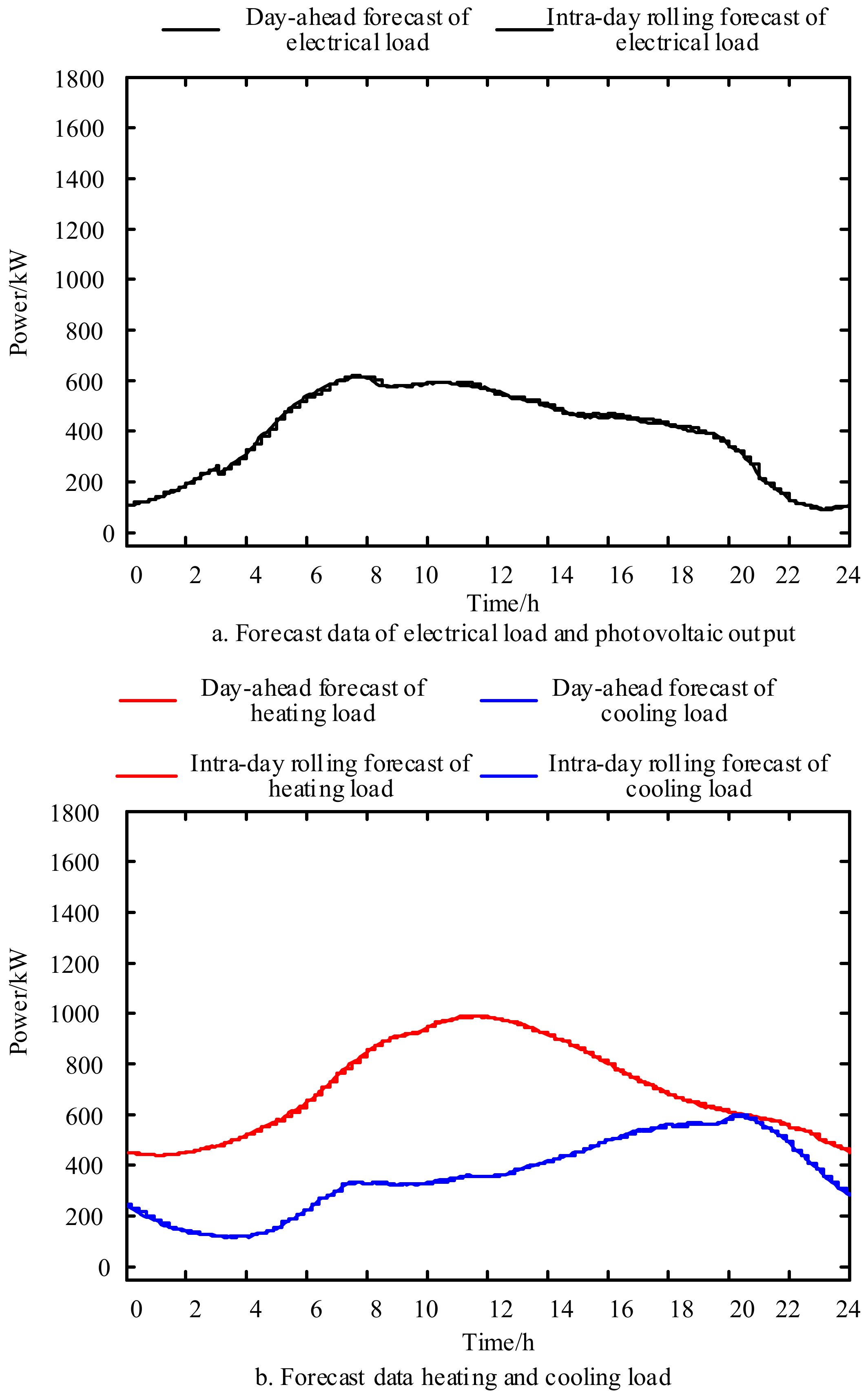

4.1. Example Data

4.2. Analysis of Simulation Results

4.2.1. The Impacts of Demand Response

- Case 1: The demand response and the uncertainty of PV power generation output are not considered.

- Case 2: The demand response is not considered, and the uncertainty of PV power generation output is 60%.

- Case 3: The demand response participation is 5% of the total electric load, and the uncertainty of the PV output is 60%.

- Case 4: The demand response participation is 10% of the total electric load, and the uncertainty of the PV output is 60%.

- Case 5: The demand response participation is 20% of the total electric load, and the uncertainty of the PV output is 60%.

4.2.2. The Impacts of Uncertainty of PV Power Output

- Case 1: The uncertainty of the PV output and the demand response are not taken into account.

- Case 2: The uncertainty of the PV output is not considered, while the power load demand response participation rate is 10%.

- Case 3: The uncertainty of the PV output is 30%, and the participation rate of the power load demand response is 10%.

- Case 4: The uncertainty of the PV output is 60%, and the participation rate of the power load demand response is 10%.

- Case 5: The uncertainty of the PV output is 90%, and the participation rate of the power load demand response is 10%.

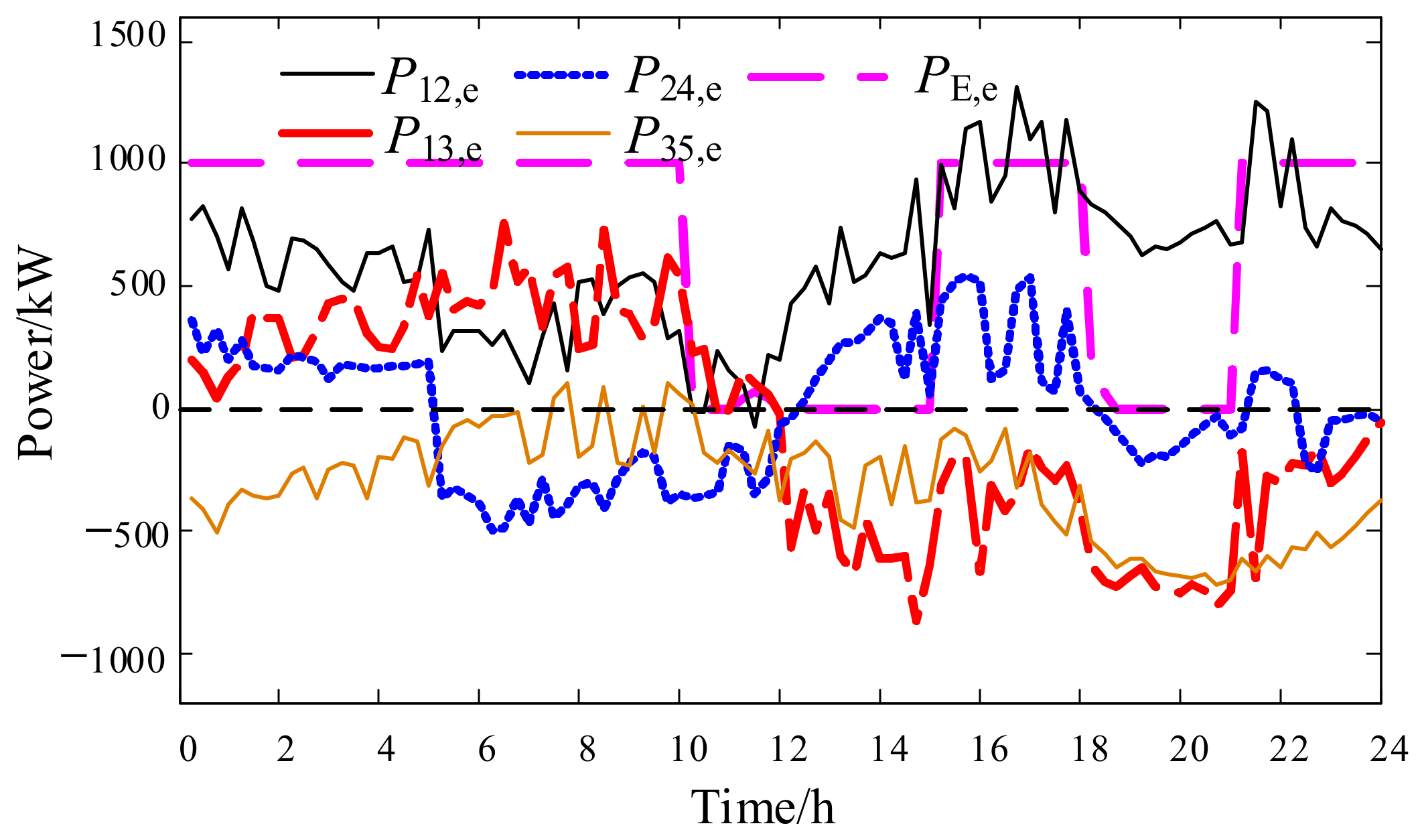

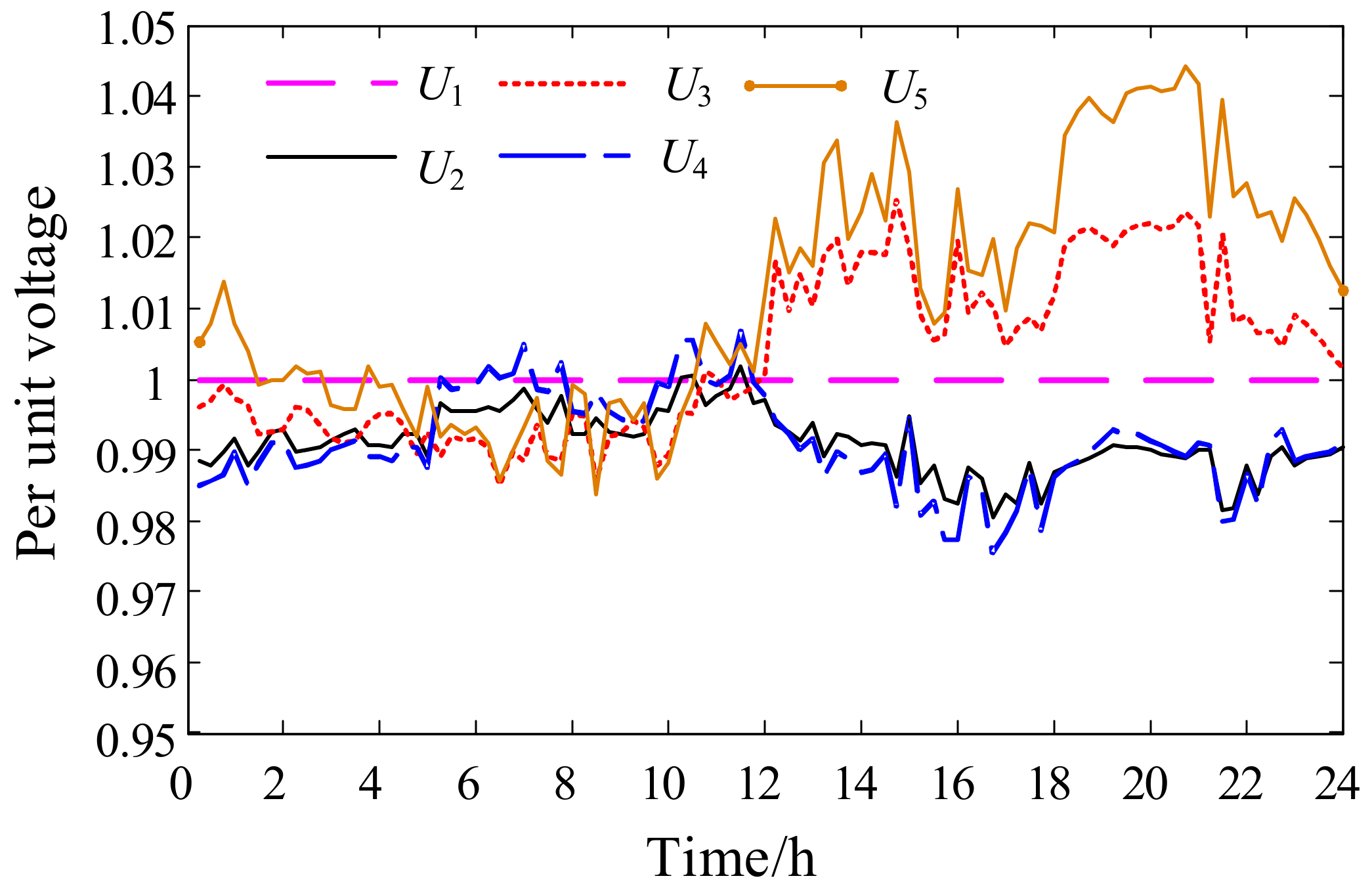

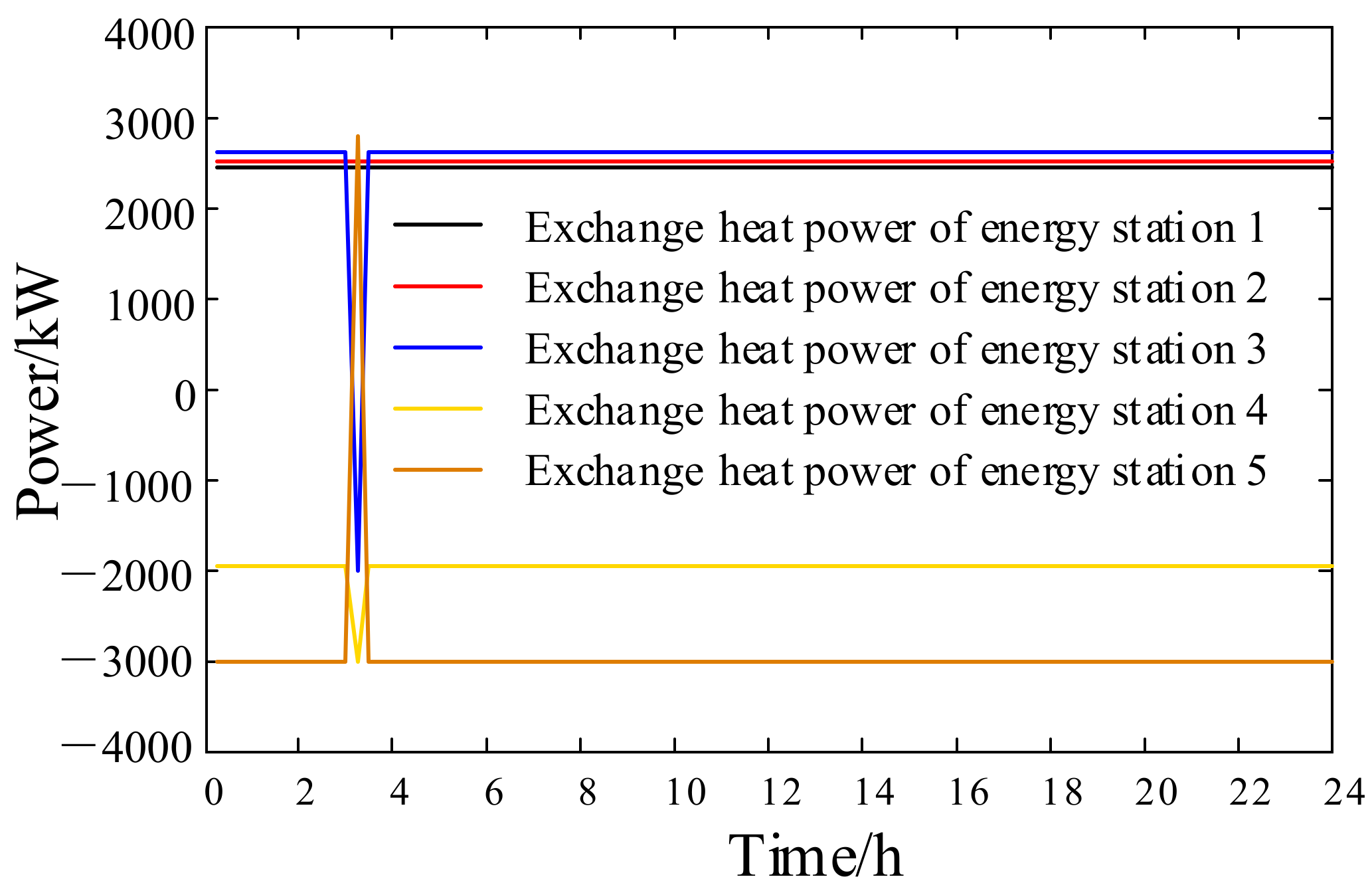

4.2.3. The Operation of Tie-Lines

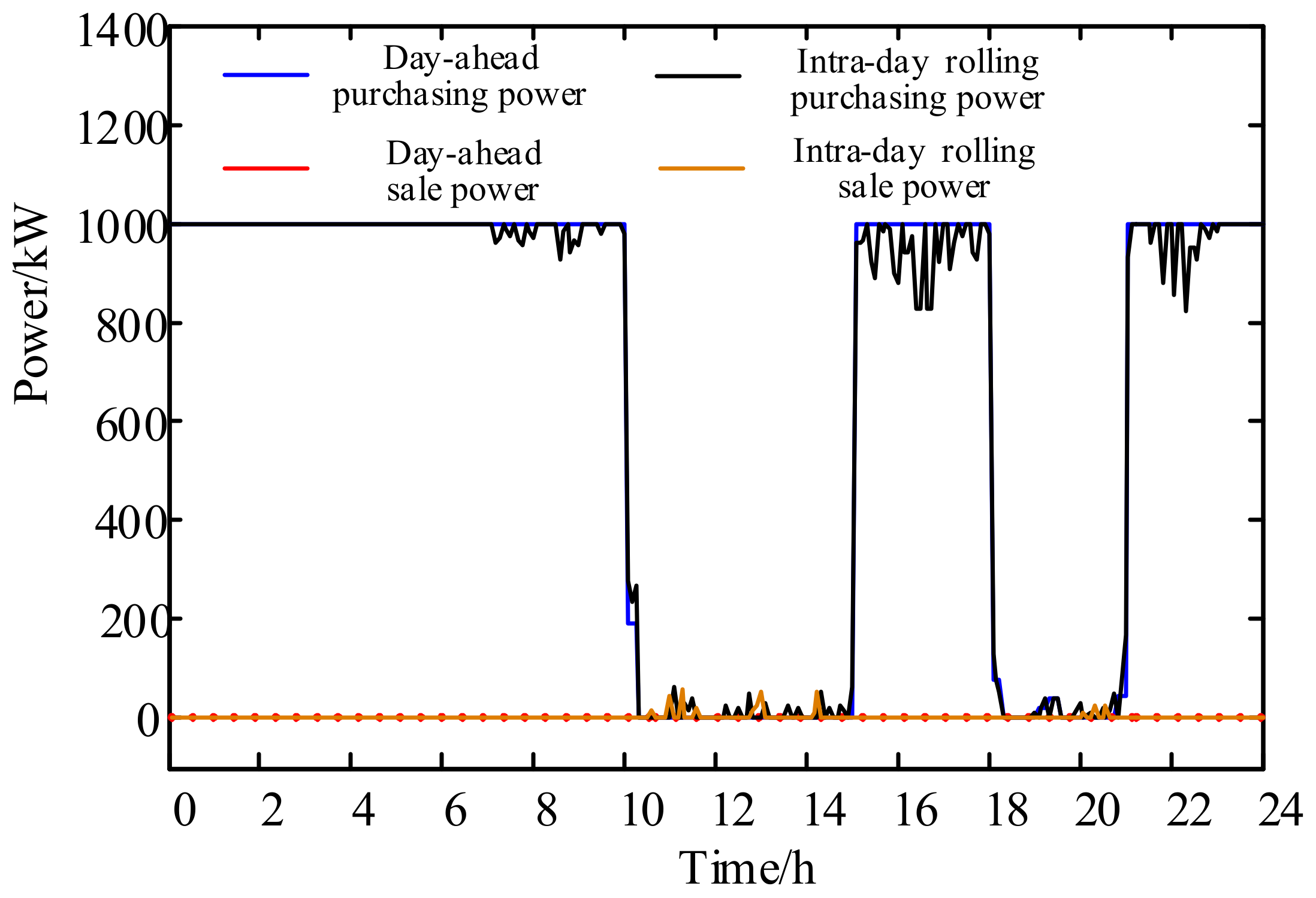

4.2.4. Power Exchange between the Main Grid and the IES

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCHP | combined cool heat and power |

| CHP | combined heat and power |

| CNY | Chinese yuan |

| CS | cold energy storage |

| ER | electric refrigerator |

| ES | electric energy storage |

| GB | gas boiler |

| GT | gas turbine |

| HP | heat pump |

| HS | heat energy storage |

| IES | integrated energy system |

| LR | lithium bromide refrigeration |

| MILP | mixed integer linear programming |

| PV | photovoltaic |

| SOC | state of charge |

| WHB | waste heat boiler |

Appendix A

References

- Wang, Y.; Wang, X.; Yu, H.; Huang, Y.; Dong, H.; Qi, C.; Baptiste, N. Optimal Design of Integrated Energy System Considering Economics, Autonomy and Carbon Emissions. J. Clean. Prod. 2019, 225, 563–578. [Google Scholar] [CrossRef]

- Fang, S.; Xu, Y.; Wen, S.; Zhao, T.; Wang, H.; Liu, L. Data-Driven Robust Coordination of Generation and Demand-Side in PV Integrated All-Electric Ship Microgrids. IEEE Trans. Power Syst. 2020, 35, 1783–1795. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, N.; Zhang, B.; Kang, C.; Xi, W.; Feng, M. Low-Carbon Operation of Multiple Energy Systems Based on Energy-Carbon Integrated Prices. IEEE Trans. Smart Grid 2020, 11, 1307–1318. [Google Scholar] [CrossRef]

- Ponocko, J.; Milanovic, J.V. Multi-objective Demand Side Management at Distribution Network Level in Support of Transmission Network Operation. IEEE Trans. Power Syst. 2020, 35, 1822–1833. [Google Scholar] [CrossRef]

- Ju, C.; Wang, P.; Goel, L.; Xu, Y. A Two-Layer Energy Management System for Microgrids with Hybrid Energy Storage Considering Degradation Costs. IEEE Trans. Smart Grid 2018, 9, 6047–6057. [Google Scholar] [CrossRef]

- Pan, Z.; Guo, Q.; Sun, H. Feasible Region Method Based Integrated Heat and Electricity Dispatch Considering Building Thermal Inertia. Appl. Energy 2017, 192, 395–407. [Google Scholar] [CrossRef]

- Tan, X.; Li, Q.; Wang, H. Advances and Trends of Energy Storage Technology in Microgrid. Int. J. Electr. Power Energy Syst. 2013, 44, 179–191. [Google Scholar] [CrossRef]

- Teng, Y.; Wang, Z.; Li, Y.; Ma, Q.; Hui, Q.; Li, S. Multi-Energy Storage System Model Based on Electricity Heat and Hydrogen Coordinated Optimization for Power Grid Flexibility. CSEE J. Power Energy Syst. 2019, 5, 266–274. [Google Scholar]

- Zeng, Z.; Ding, T.; Xu, Y.; Yang, Y.; Dong, Z. Reliability Evaluation for Integrated Power-Gas Systems with Power-to-Gas and Gas Storages. IEEE Trans. Power Syst. 2020, 35, 571–583. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, W.; Liu, F.; Mei, S. A Multi-Lateral Trading Model for Coupled Gas-Heat-Power Energy Networks. Appl. Energy 2017, 200, 180–191. [Google Scholar] [CrossRef]

- Fan, F.; Tai, N.; Zheng, X.; Huang, W.; Shi, J. Equalization Strategy for Multi-Battery Energy Storage Systems Using Maximum Consistency Tracking Algorithm of the Conditional Depreciation. IEEE Trans. Energy Convers. 2018, 33, 1242–1254. [Google Scholar] [CrossRef]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Liu, C.; Sun, R.; Wang, W.; Li, H. Increasing the Flexibility of Combined Heat and Power for Wind Power Integration in China: Modeling and Implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Li, J.; Fang, J.; Zeng, Q.; Chen, Z. Optimal Operation of the Integrated Electrical and Heating Systems to Accommodate the Intermittent Renewable Sources. Appl. Energy 2016, 16, 244–254. [Google Scholar] [CrossRef]

- Zhou, H.; Li, Z.; Zheng, J.H.; Wu, Q.H.; Zhang, H. Robust Scheduling of Integrated Electricity and Heating System Hedging Heating Network Uncertainties. IEEE Trans. Smart Grid 2020, 11, 1543–1555. [Google Scholar] [CrossRef]

- Liu, G.; Starke, M.; Xiao, B.; Zhang, X.; Tomsovic, K. Microgrid Optimal Scheduling with Chance-Constrained Islanding Capability. Electr. Power Syst. Res. 2017, 145, 197–206. [Google Scholar] [CrossRef]

- Peng, C.; Hou, Y.; Yu, N.; Wang, W. Risk-Limiting Unit Commitment in Smart Grid with Intelligent Periphery. IEEE Trans. Power Syst. 2017, 32, 4696–4707. [Google Scholar] [CrossRef]

- Mieth, R.; Dvorkin, Y. Distribution Electricity Pricing under Uncertainty. IEEE Trans. Power Syst. 2020, 35, 2325–2338. [Google Scholar] [CrossRef]

- Wang, B.; Dehghanian, P.; Zhao, D. Chance-Constrained Energy Management System for Power Grids with High Proliferation of Renewables and Electric Vehicles. IEEE Trans. Smart Grid 2020, 11, 2324–2336. [Google Scholar] [CrossRef]

- Baringo, L.; Conejo, A.J. Offering Strategy of Wind-Power Producer: A Multi-Stage Risk-Constrained Approach. IEEE Trans. Power Syst. 2016, 31, 1420–1429. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, H.; Xia, Q.; Kang, C.; Du, E. Optimal Joint-Dispatch of Energy and Reserve for CCHP-Based Microgrids. IET Gener. Transm. Distrib. 2017, 11, 785–794. [Google Scholar] [CrossRef]

- Pazouki, S.; Haghifam, M.R.; Moser, A. Uncertainty Modeling in Optimal Operation of Energy Hub in Presence of Wind, Storage and Demand Response. Int. J. Electr. Power Energy Syst. 2014, 61, 335–345. [Google Scholar] [CrossRef]

- Moreira, A.; Street, A.; Arroyo, J.M. An Adjustable Robust Optimization Approach for Contingency- Constrained Transmission Expansion Planning. IEEE Trans. Power Syst. 2015, 30, 2013–2022. [Google Scholar] [CrossRef]

- Baringo, L.; Baringo, A. A Stochastic Adaptive Robust Optimization Approach for the Generation and Transmission Expansion Planning. IEEE Trans. Power Syst. 2018, 33, 792–802. [Google Scholar] [CrossRef]

- Wu, H.; Krad, I.; Florita, A.; Hodge, B.M.; Ibanez, E.; Zhang, J.; Ela, E. Stochastic Multi-Timescale Power System Operations with Variable Wind Generation. IEEE Trans. Power Syst. 2016, 32, 3325–3337. [Google Scholar] [CrossRef]

- Rong, S.; Li, Z.; Li, W. Investigation of the Promotion of Wind Power Consumption Using the Thermal-Electric Decoupling Techniques. Energies 2015, 8, 8613–8629. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Wang, J.; Zhang, B.; Zheng, T. Transmission-Constrained Unit Commitment Considering Combined Electricity and District Heating Networks. IEEE Trans. Sustain. Energy 2016, 7, 480–492. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Shahidehpour, M.; Wang, J.; Zhang, B. Combined Heat and Power Dispatch Considering Pipeline Energy Storage of District Heating Network. IEEE Trans. Sustain. Energy 2016, 7, 12–22. [Google Scholar] [CrossRef]

- Shao, C.; Wang, X.; Shahidehpour, M.; Wang, X.; Wang, B. A MILP-based Optimal Power Flow in Multicarrier Energy Systems. IEEE Trans. Sustain. Energy 2017, 8, 239–248. [Google Scholar] [CrossRef]

- Wu, C.; Gu, W.; Jiang, P.; Li, Z.; Cai, H.; Li, B. Combined Economic Dispatch Considering the Time-Delay of A District Heating Network and Multi-Regional Indoor Temperature Control. IEEE Trans. Sustain. Energy 2018, 9, 118–127. [Google Scholar] [CrossRef]

- Duquette, J.; Rowe, A.; Wild, P. Thermal Performance of A Steady State Physical Pipe Model for simulating District Heating Grids with Variable Flow. Appl. Energy 2016, 178, 383–393. [Google Scholar] [CrossRef]

- Lu, S.; Gu, W.; Meng, K.; Yao, S.; Liu, B.; Dong, Z.Y. Thermal Inertial Aggregation Model for Integrated Energy Systems. IEEE Trans. Power Syst. 2020, 35, 2374–2387. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, J.; Qiu, J.; Zhang, S.; Lai, M.; Dong, Z.Y. Practical Pricing Approach to Smart Grid Demand Response Based on Load Classification. IEEE Trans. Smart Grid 2017, 9, 179–190. [Google Scholar] [CrossRef]

- Geramifar, H.; Shahabi, M.; Barforoshi, T. Coordination of Energy Storage Systems and Demand Response Resources for Optimal Scheduling of Microgrids under Uncertainties. IET Renew. Power Gener. 2017, 11, 377–388. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Le, L.B. Joint Optimization of Electric Vehicle and Home Energy Scheduling Considering User Comfort Preference. IEEE Trans. Smart Grid 2014, 5, 188–199. [Google Scholar] [CrossRef]

- Tabar, V.S.; Jirdehi, M.A.; Hemmati, R. Energy Management in Microgrid Based on the Multi Objective Stochastic Programming Incorporating Portable Renewable Energy Resource as Demand Response Option. Energy 2017, 118, 827–839. [Google Scholar] [CrossRef]

- Lei, S.; Hou, Y.; Qiu, F.; Yan, J. Identification of Critical Switches for Integrating Renewable Distributed Generation by Dynamic Network Reconfiguration. IEEE Trans. Sustain. Energy 2018, 9, 420–432. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.; Hou, Y.; Ma, K. Dynamic Game-Based Maintenance Scheduling of Integrated Electric and Natural Gas Grids with A Bilevel Approach. IEEE Trans. Power Syst. 2018, 33, 4958–4971. [Google Scholar] [CrossRef]

- Alipour, M.; Zare, K.; Mohammadi-Ivatloo, B. Short-Term Scheduling of Combined Heat and Power Generation Units in the Presence of Demand Response Programs. Energy 2014, 71, 289–301. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, P.; Liu, X. Collaborative Autonomous Optimization of Interconnected Multi-Energy Systems with Two-Stage Transactive Control Framework. Energies 2019, 13, 1. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Ma, J.; Bie, Z. A Mixed-Integer Linear Programming Approach to Security-Constrained Co-Optimization Expansion Planning of Natural Gas and Electricity Transmission Systems. IEEE Trans. Power Syst. 2018, 33, 6368–6378. [Google Scholar] [CrossRef]

- Zhai, J.; Wu, X.; Zhu, S.; Yang, B.; Liu, H. Optimization of Integrated Energy System Considering Photovoltaic Uncertainty and Multi-Energy Network. IEEE Access 2020, 8, 141558–141568. [Google Scholar] [CrossRef]

| Variable Type | Before Linearization | After Linearization |

|---|---|---|

| Continuous variable | (5 × 17 + 8) × 96 = 9696 | (5 × 26 + 8 + 4 × 10) × 96 = 17,088 |

| 0–1 variable | 5 × 8 × 96 = 3840 | (5 × 18 + 4 × 10) × 96 = 12,480 |

| Equipment | ES1 | ES2 | ES3 | ES4 | ES5 |

|---|---|---|---|---|---|

| Combined cool heat and power (CCHP) | √ | √ | √ | √ | √ |

| Gas boiler (GB) | √ | √ | √ | √ | × |

| Electric refrigerator (ER) | √ | √ | √ | √ | √ |

| Heat pump (HP) | √ | √ | √ | × | √ |

| Photovoltaic (PV) | √ | √ | √ | × | × |

| Electric energy storage (ES) | √ | √ | × | × | × |

| Heat energy storage (HS) | √ | √ | × | × | × |

| Cold energy storage (CS) | √ | × | × | √ | √ |

| Equipment | Minimum Power (kW) | Minimum Power (kW) | Up/Down Ramp Rate (kW∙h−1) | Maintenance Cost (CNY∙kW−1) | |

|---|---|---|---|---|---|

| CCHP | Generation () | 500 | 1000 | 200 | 0.1 |

| Waste heat () | 750 | 1500 | – | – | |

| Lithium bromide () | 0 | 1000 | – | 0.02 | |

| GB () | 100 | 500 | 100 | 0012 | |

| ER () | 0 | 100 | – | 0.015 | |

| HP () | 0 | 200 | – | 0.006 | |

| PV () | 0 | 400 | – | 0.0235 | |

| Energy Storage | ES | HS | CS |

|---|---|---|---|

| Capacity (kWh) | 800 | 200 | 200 |

| Maximum charging and discharging ratio | 0.2 | 0.2 | 0.2 |

| Charging and discharging efficiency | 0.90 | 0.98 | 0.95 |

| Minimum SOC | 0.2 | 0.2 | 0.2 |

| Maximum SOC | 0.9 | 0.9 | 0.9 |

| Node Number | Line Number | Length (km) | |

|---|---|---|---|

| Beginning | End | ||

| 1 | 2 | 1 | 1 |

| 1 | 3 | 2 | 1.5 |

| 2 | 4 | 3 | 2 |

| 3 | 5 | 4 | 1 |

| Categories | Independent Operation (CNY) | Collaborative Operation (CNY) | |

|---|---|---|---|

| Electrical Cost | Purchasing | 6880 | 5865.7 |

| Sale | 8952 | 0 | |

| Total | −2072 | 5865.7 | |

| Fuel cost | 56,497 | 38,860 | |

| Start-up and shut-down cost | 35 | 9 | |

| Maintenance cost | 8244 | 6335.8 | |

| Demand response revenue | 764 | 384.1 | |

| Total | 61,940 | 50,686 | |

| Categories | Case 1 (CNY) | Case 2 (CNY) | Case 3 (CNY) | Case 4 (CNY) | Case 5 (CNY) | |

|---|---|---|---|---|---|---|

| Electrical Cost | Purchasing | 6468.6 | 6382.9 | 5448.1 | 5357.3 | 5362.6 |

| Sale | 0 | 0 | 0 | 0 | 0 | |

| Total | 6468.6 | 6382.9 | 5448.1 | 5357.3 | 5362.6 | |

| Fuel cost | 38,350 | 38,638 | 39,440 | 39,519 | 39,514 | |

| Start-up and shut-down cost | 15 | 15 | 15 | 15 | 6 | |

| Maintenance cost | 6267.9 | 6307.1 | 6416.3 | 6427.2 | 6426.5 | |

| Demand response revenue | 0 | 0 | 190.8 | 384.8 | 771.9 | |

| Total | 51,101 | 51,343 | 51,129 | 50,933 | 50,537 | |

| Categories | Case 1 (CNY) | Case 2 (CNY) | Case 3 (CNY) | Case 4 (CNY) | Case 5 (CNY) | |

|---|---|---|---|---|---|---|

| Electrical Cost | Purchasing | 6468.6 | 5865.7 | 5872.7 | 5357.3 | 5477.3 |

| Sale | 0 | 0 | 0 | 0 | 0 | |

| Total | 6468.6 | 5865.7 | 5872.7 | 5357.3 | 5477.3 | |

| Fuel cost | 38,350 | 38,860 | 38,964 | 39,519 | 39,626 | |

| Start-up and shut-down cost | 15 | 9 | 9 | 15 | 15 | |

| Maintenance cost | 6267.9 | 6335.8 | 6350.3 | 6427.2 | 6442 | |

| Demand response revenue | 0 | 384.1 | 384.5 | 384.8 | 385.4 | |

| Total | 51,101 | 50,686 | 50,812 | 50,933 | 51,175 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, J.; Wu, X.; Li, Z.; Zhu, S.; Yang, B.; Liu, H. Day-Ahead and Intra-Day Collaborative Optimized Operation among Multiple Energy Stations. Energies 2021, 14, 936. https://doi.org/10.3390/en14040936

Zhai J, Wu X, Li Z, Zhu S, Yang B, Liu H. Day-Ahead and Intra-Day Collaborative Optimized Operation among Multiple Energy Stations. Energies. 2021; 14(4):936. https://doi.org/10.3390/en14040936

Chicago/Turabian StyleZhai, Jingjing, Xiaobei Wu, Zihao Li, Shaojie Zhu, Bo Yang, and Haoming Liu. 2021. "Day-Ahead and Intra-Day Collaborative Optimized Operation among Multiple Energy Stations" Energies 14, no. 4: 936. https://doi.org/10.3390/en14040936

APA StyleZhai, J., Wu, X., Li, Z., Zhu, S., Yang, B., & Liu, H. (2021). Day-Ahead and Intra-Day Collaborative Optimized Operation among Multiple Energy Stations. Energies, 14(4), 936. https://doi.org/10.3390/en14040936