Abstract

In this paper, the fault current limiting (FCL) characteristics of a flux-coupled type superconducting fault current limiter (SFCL) with parallel connection between two windings in a DC system were analyzed. The flux-coupled type SFCL was composed of two coils connected in parallel and a superconducting element (SE), which was connected in series with the secondary coil. The flux-coupled type SFCL works in DC systems similar to those in AC systems. Before a fault occurs, the respective magnetic fluxes generated by the two coils connected in parallel offset each other, maintaining the voltage induced in the two coils at zero. In case of a fault, however, resistance is generated in the SE, preventing the magnetic fluxes generated by the two coils from offsetting each other. Thus, some voltage is induced in the two coils, and this starts to limit the fault current. DC short circuit tests were conducted, and the test results confirmed that the flux-coupled type SFCL with the two parallel connected coils was effective in limiting the fault current in a DC system. Additionally, the effect of the wiring direction of the two coils on the SFCL’s FCL performance and operating current, limiting impedance, and instantaneous power load was further analyzed, and as a result, the performance conditions of the SFCL in a DC system were determined.

1. Introduction

The fault current of the system has inevitably increased due to the increase of power generation sources to respond to power demand and the system looping for reliable power supply. As a countermeasure to this, various studies on the development of superconducting fault current limiter (SFCL) applied to electric aircrafts, DC cables, shipboards, etc. have been conducted more competitively as the zero resistance and lossless properties of superconductors act as advantages over existing alternatives [1,2,3,4,5,6,7,8,9,10]. The fault current reduction is limited in value and time. SFCL can detect the fault current occurring in the power system tens of times within 1 ms and return it to the normal current within a few seconds. Even when the power load increases, operation is possible without increasing the capacity of the existing circuit breaker, thereby reducing the cost of replacing the circuit breaker and enormous cost loss due to electric quality problems. The acceptable capacity of each country or type of SFCL is somewhat different, but the capacity of resistive type SFCL is 220 kV class system of Russian SuperOx [11]. Recently, with the spread of smart grids to promote efficient distribution systems, a number of large-capacity distributed power sources have been adopted. Such systems may cause an increase in the fault current of the power system. In addition, they do not have a natural current zero point, as is typically observed in AC current, and thus, must be equipped with high-speed DC circuit breakers instead of existing mechanical circuit breakers, to accommodate the speed and level of DC fault current increases when the short circuit accident occurs [12,13,14,15].

In general, a circuit breaker opens and closes to allow or stop the flow of normal current in a normal state. However, when an abnormally large fault current flows, due to failures such as overload or short circuit, a circuit breaker can be used to cut off the current. These circuit breakers must be installed in a circuit with a high-voltage or higher to protect the entire power system in case of a failure. For DC circuit breakers (DCCBs), a special circuit breaker topology is available, which is designed to apply black-box arc models to the main circuit, to facilitate breaking simulations. Because DC currents do not have a natural current zero point, the arc holding time may be prolonged when the DCCB is tripped. A hybrid circuit breaker (HCB) is designed to have a mechanical high-speed switch in the conduction path and power semiconductor switch in the commutation path. This design not only reduces conduction losses under normal conditions, but also quickly cuts off fault currents when an accident occurs in the DC system. HCBs have the advantage of reducing the fault recovery time by effectively isolating the affected parts of the DC system, minimizing the overall effect of the accident [16,17,18,19]. However, when the rated capacity of the DC system increases, the performance and capacity of mechanical high-speed switches and power semiconductor switches must be increased in order to stably block the increased fault current. Accordingly, the cost and size of the DCCB will increase overall. For this reason, DC systems based solely on DCCBs are facing their limits, so research on current limiting technologies to limit fault current is urgently needed [20]. In Ref. [20], a simulation was performed to study the effect of resistive SFCL on real DC systems and to determine the appropriate SFCL parameters for the network. In particular, it differs from this work in that HTS tape tests were performed to demonstrate the current limiting ability of superconducting materials.

SFCL is one of the most widely used fault current limiting (FCL) technologies due to its beneficial features. Using the intrinsic rapid quenching nature of superconductors, when a short circuit accident occurs, SFCLs can distribute the fault current in a timely and proper manner and thus reduce it quickly and efficiently [21,22]. At present, most SFCL prototypes have been designed for AC distribution system applications [23,24,25,26,27,28,29]. In Ref. [23], the FCL and recovery characteristics in AC systems are analyzed for flux-lock type SFCL with an isolating transformer. There is a difference from this work in the experimental application of the AC system and the structure of the SFCL using the insulation transformer for the double core. Few studies have reported on the application of SFCLs in DC systems [30,31,32,33]. In Ref. [31], a conceptual design and electromagnetic design for a flux-coupling type SFCL were carried out to provide a large-scale protection scheme for shipboard medium voltage DC (MVDC). Here, there is a difference from this work in that the superconducting coil is used for the flux-coupling type SFCL and that it is applied to the shipboard MVDC. In order to conduct rapid research in DC systems, detailed information about the transient behavior and influence mechanisms of resistive SFCLs has been covered by adopting a completed DC micro-grid. The most important feature of the resistive SFCL, which was often discussed in AC systems, is its simple structure, and it is advantageous in terms of weight and cost compared to the inductive type. However, there are always problems with the occurrence of hot spots and the superconductor manufacturing technology that must be supported during the current limiting action [34].

In this paper, a flux-coupled type SFCL was employed to reduce the effect of DC short circuit accidents in DC systems. This flux-coupled type SFCL was composed of two magnetically coupled coils connected in parallel and one superconducting element (SE). The FCL characteristics of this flux-coupled type SFCL were analyzed. The quench of the SE was measured while changing the direction of the additive wiring and subtractive wiring connections of the magnetic coupling winding of the proposed SFCL. Additionally, the current and voltage relationship of the SFCL and various properties of each winding were analyzed during the fault. Furthermore, the FCL performance and instantaneous power loss characteristics of the SE for each condition were compared and analyzed.

2. Experimental Methods

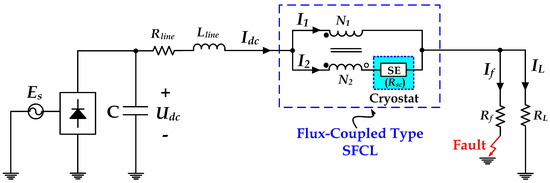

2.1. Performance of the Flux-Coupled Type SFCL in a DC Side Short Circuit Fault

The DC side short circuit error is one of the most serious failures that can occur in a DC system. In the early stages of the error, the voltage between the poles is higher than the maximum voltage between the AC phases, so the reverse voltage drop will block all diodes. Therefore, it is electrically open between AC and DC. However, the capacitor voltage on the DC side cannot change rapidly, and the voltage stabilization capacitor and the fault cable on the DC side form a discharge path, so most of the fault current occurs mainly from the discharge of the capacitor. Figure 1 presents a schematic circuit diagram of the flux-coupled type SFCL installed to respond to a DC side poles short circuit error. Here, Rline and Lline refer to the equivalent resistance and inductance of the DC cable, respectively. RL and Rf are the load resistance and fault resistance, respectively, while Rg is the composite resistance, which is expressed as . Es and C are the AC input voltage and filter capacitor. I1 and I2 are the currents that flow through the primary (N1) and secondary (N2) coils, respectively. If and IL are the respective currents that flow through the fault resistance (Rf) and the load resistance (RL).

Figure 1.

Schematic diagram of flux-coupled type superconducting fault current limiter (SFCL) in DC side poles short circuit error.

2.2. Operational Principles and Equivalent Circuit Analysis

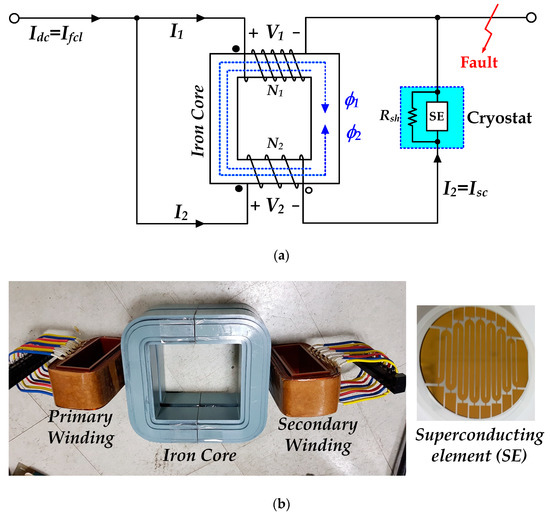

The configuration of the flux-coupled type SFCL with two coils connected in parallel is shown in Figure 2. The two coils are connected in parallel to a single iron core, and the SE is connected in series to the secondary coil. The winding direction of coils in the iron core is one of the most important parameters of SFCLs. The winding direction is divided into additive polarity and subtractive polarity types, depending on how the primary coil (N1) is connected to the secondary coil (N2). If two magnetically coupled coils have the same polarity, it means that they are wound in the same direction. If their polarity is opposite, it means that they are reverse-wound with respect to each other. As shown in Figure 2, the polarity of the primary and secondary coils is indicated as [●] or [○]. The additive wiring corresponds to when the two coils are wound in the same direction. This is a combination of the primary coil’s voltage V1 [●] and the secondary coil’s voltage V2 [●]. The subtractive wiring corresponds to when the two coils are reverse-wound. This is a combination of the primary coil’s voltage V1 [●] and the secondary coil’s voltage V2 [○].

Figure 2.

Structure of the SFCL with two parallel flux-coupled coils: (a) schematic configuration; (b) iron core, windings, and SE used for the test prototype.

A Y1Ba2Cu3O7−x (YBCO) thin-film with a critical temperature of 87 K and a critical current of 27 A was patterned and used as the SE (Refer to Figure 2b). The SE is immersed in 77 K liquid nitrogen. The YBCO thin-film used in SE was made from materials manufactured by THEVA, Germany. YBCO thin-film of 0.3 μm was deposited on sapphire substrate with its diameter of 2 inch and a 0.2 μm thick gold layer was covered on it for bypass against hotspots. The SE was fabricated by etching the YBCO thin-film into 2 mm wide and 420 mm long meander line using photolithography technique, which consisted of 14 stripes with different lengths, respectively. The normal state resistance of a SE with a gold layer was 85 Ω at room temperature. In addition, as shown in Figure 2a, in order to protect SE during quench, a shunt resistor (Rsh) was used by connecting to the SE in parallel [35,36].

The operating principle of the SFCL can be explained before and after failure. Before a fault occurs, i.e., in the normal condition, the SE is in a superconducting state, and thus, its resistance (Rsc) is zero. The magnetic fluxes (ϕ1, ϕ2) induced in each coil then offset each other, thereby maintaining the voltage induced in each coil at zero. After a fault, i.e., when a failure occurs on the DC side, the current flowing through the SE starts to exceed the critical current, thus causing the SE to undergo a transition into a normal conducting state. As a result, resistance is generated in the SE. This leads to the generation of voltage in the SE, thereby causing a voltage to be induced in the two coils and further generating current limiting impedance. This impedance then limits the fault current (Ifcl). When a fault occurs on the load side, the current (Idc) flowing through the DC side becomes the same as the fault current (Ifcl).

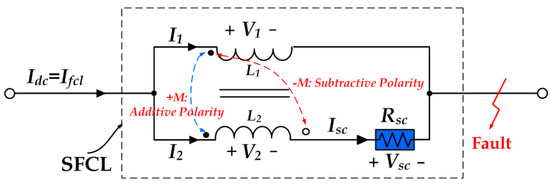

Figure 3 shows the electrical equivalent circuit of the flux-coupled type SFCL in which the primary and secondary coils are connected in parallel. Here, L1 and L2 refer to the inductance of the primary and secondary coils, respectively. Idc and I1 are the currents that flow through the DC side and the primary coil, respectively. I2 and Isc are the respective currents that flow through the secondary coil and the SE, and the two currents have the same magnitude. Rsc and Vsc refer to the resistance and voltage of the SE. It was assumed that, on both the primary and secondary sides, magnetic leakage flux did not exist, and only the mutual flux existed. The mutual induction flux was , and , and thus, it was assumed to be . Based on this electrical equivalent circuit, Kirchhoff’s voltage-current equation was derived as follows:

Figure 3.

Electrical equivalent circuit of the SFCL using two parallel flux-coupled coils.

Here, the mutual inductance and the secondary coil’s voltage polarity are indicated by (+) for the additive wiring and (−) for the subtractive wiring. Based on Equations (1)–(4), the fault current (Ifcl) of the SFCL, the operating current (Iop) of the SFCL, and the limiting impedance (Zfcl) can be inferred as follows:

In Equations (5)–(7), the top sign is used to indicate the additive wiring (−), and the bottom sign is used to indicated the subtractive wiring (+). Equation (6) was derived by defining the current limited in the early stage when the current generated in the SE reached the critical current as the operating current (Iop) and then substituting RSC = 0, Isc = Ic, and Ifcl = Iop. As can be seen in Equation (6) and Equation (7), the operating current and limiting impedance of the SFCL can be adjusted by varying the inductance ratio (L) of the two coils. Here, L refers to the inductance ratio of the two coils (L2/L1).

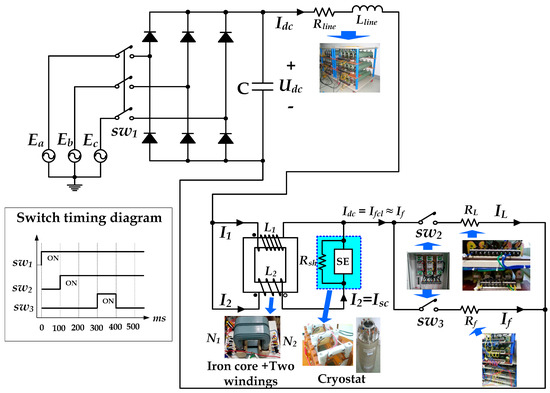

2.3. Experimental Design and Methods

Figure 4 shows the configuration of an experimental device designed to simulate the FCL characteristics of the SFCL with two flux-coupled coils. The AC input voltage was set to Eab = Ebc = Eca = 80 Vrms, 60 Hz. The system was designed to allow the DC power to be supplied through a three-phase diode and filter capacitor. The line resistance Rline and the line inductance Lline were 0.42 Ω and 0.18 mH, respectively, and the fault resistance Rf and the load resistance RL were set to 1.5 Ω and 10 Ω, respectively.

Figure 4.

Experimental circuit used to simulate a short circuit in the SFCL using two parallel flux-coupled coils.

The SFCL circuit was configured as follows: the two coils were connected in parallel to a single iron core, and the SE was connected in series to the secondary coil. This flux-coupled type SFCL was then connected between the power supply and the load terminal. The inductance of the primary and secondary coils used in the test were 1.3 mH and 60.9 mH, respectively. A YBCO thin-film was fabricated by the etching process and used as the SE (see the picture on the right in Figure 2b). As shown in Figure 4, in order to protect the SE during the quench, a shunt resistor (Rsh) was used by connecting to the SE in parallel.

A short circuit was simulated as follows. SW1 was turned on to supply DC power through the three-phase rectifier circuit while causing the capacitor to be charged with the DC voltage. Subsequently, SW2 was turned on at 100 ms, and then SW3 was kept turned on in the range between 300 and 400 ms to simulate the occurrence of a fault. Under the condition of fault occurrence on the load side, the current (Idc) flowing through the DC side becomes the same as the fault current (Ifcl). The fault current (Ifcl) flowing through the flux-coupled type SFCL is approximately equal to the short circuit current (If), caused by a short circuit accident on the load side. The current and voltage flowing through each coil, including the voltage at both ends of the SE, were measured using a current transformer (CT) and a potential transformer (PT). Table 1 shows the specifications of the components of the experimental devices used to simulate a short circuit, including the power supply on the AC side and the power system on the DC side, along with the specifications of each coil and SE that constituted the SFCL.

Table 1.

Experimental specifications of the DC system models, including the flux-coupled type SFCL.

3. Experimental Results

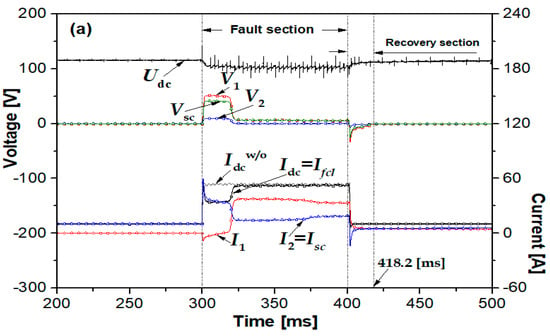

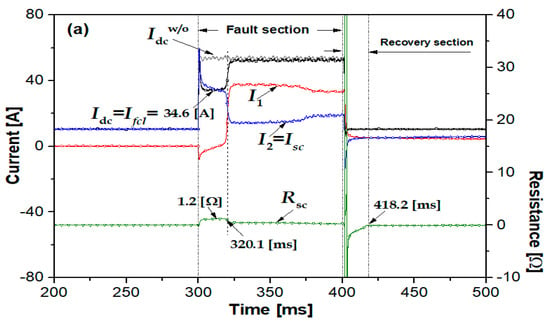

Figure 5 shows the FCL performance of the flux-coupled type SFCL with respect to the winding direction of the primary and secondary coils. Before a fault occurs, the magnetic fluxes inside the iron core offset each other, thereby maintaining the voltage of each coil at zero. Once a line fault occurs on the DC side, a quench immediately occurs in the SE, causing a voltage to be generated at both ends of the SE. Thus, some voltage is induced in the two coils. As can be seen from the changes in the magnitude of the DC line current immediately after the fault, the degree of current limiting was higher with the flux-coupled type SFCL than without it installed. Here, Idcw/o refers to the DC current passing through the DC line when the flux-coupled type SFCL is not installed.

Figure 5.

Current and voltage relationship curves of the DC system models, including the flux-coupled type SFCL, in accordance the wiring direction: (a) for additive wiring; (b) for subtractive wiring.

Figure 5a shows the case of additive wiring, where the magnetically coupled coils are wound in the same direction. Figure 5b shows the case of subtractive wiring, where the magnetically coupled coils are reverse wound. For both additive polarity and subtractive wirings, the respective voltages of the SE and the magnetically coupled coils sharply increased due to the quench of the SE immediately after the fault. The voltage increase observed in the SE right after the fault, in particular, was greater in magnitude and lasted longer in the subtractive wiring than in the additive wiring. The voltage of the primary coil (V1) in the additive wiring can be expressed as the sum of the voltage of the SE (Vsc) and the voltage of the secondary coil (V2), while the voltage of the primary coil (V1) in the subtractive wiring can be expressed as the difference between the voltage of the SE (Vsc) and the voltage of the secondary coil (V2). These relationships correspond to Equation (3). It was found that the degree of FCL immediately after the fault was higher in the additive wiring than in the subtractive wiring. Additionally, this FCL operation occurred only while the quench of the SE was underway. Transient voltage and transient current occurred in the reverse direction in the primary and secondary coils in the 400–418.2 ms (in case of additive wiring) and 400–414.8 ms (in case of subtractive wiring) at the end of the failure. When the switch SW3 was turned off at 400 ms as shown in Figure 4, instantaneous overvoltage and overcurrent occurred due to residual magnetism remaining in the iron core and coil. After 418.2 ms (for additive wiring) and 414.8 ms (for subtractive wiring), respectively, it can be observed that the residual magnetism disappears and maintains a steady state. This section was set as the recovery section of the flux-coupled SFCL including SE.

The degree of FCL was lower in the subtractive wiring than in the additive wiring, but the FCL operation lasted longer. In order to completely block the fault current in the DCCB after limiting the fault current, it is necessary to ensure that the current limiting operation of this SFCL lasts for a sufficient length of time. When a fault occurs in the DC system, the superconductor of SFCL is quenched to limit the fault current primarily. After that, it is a system that completely cuts off the fault current using a DCCB. DCCBs have different breaking times depending on the type of circuit breaker. It is possible to cut off at high speed within about 2 ms of cut-off time of semiconductor DCCB and HCB. However, the breaking speed of a mechanical DCCB is 30–50 ms on average, which is about 15–25 times slower than a circuit breaker with a semiconductor element. Therefore, if a mechanical DC CB is used behind the flux-coupled SFCL, the current limit time must be maintained to match the breaking speed of this circuit breaker. Factors influencing the fault current limit time include the winding wiring direction, number of windings, superconducting element capacity, and quench duration.

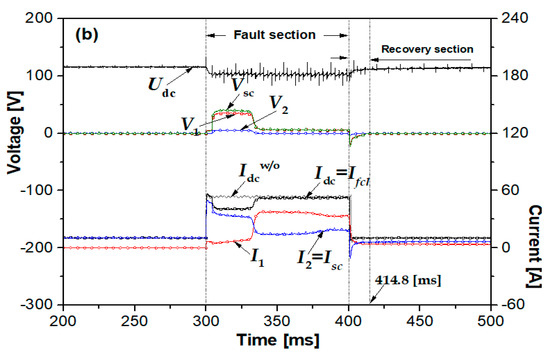

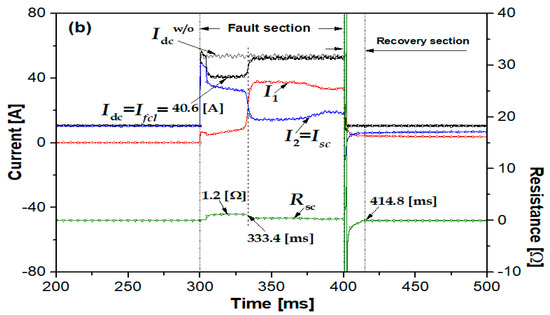

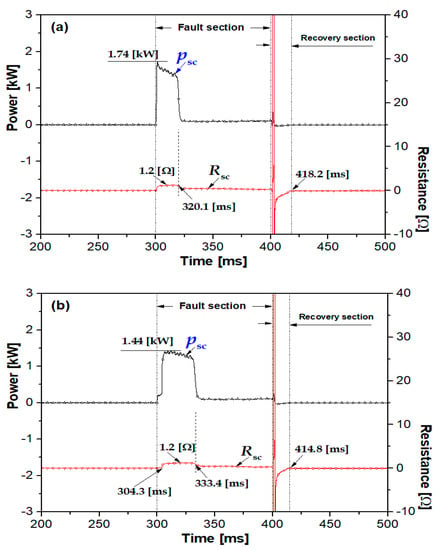

Figure 6 shows the relationship between the currents flowing through the primary and secondary coils and the resistance in the SE with respect to the wiring direction of the two coils. Figure 6a shows the characteristics of the currents flowing through the two magnetically coupled coils and the resistance of the SE in the additive wiring, where the two coils are wound in the same direction. In the time period between 300 and 320.1 ms immediately after the fault, the critical current of the SE was exceeded, thereby causing the quench of the SE to occur. As a result, resistance was generated in the SE. Here, the fault current (idc = ifcl) corresponds to the sum of the currents flowing through the primary and secondary coils. The current flowing through the secondary coil was greater than that flowing through the primary coil. This was because the number of windings in the primary coil was six times higher than that in the secondary coil, thus causing most of the current to flow towards the secondary coil. However, it was observed that, in the time period from 320.1 to 400 ms during which the fault occurred, more current flowed to the primary coil than to the secondary coil.

Figure 6.

Current and SE resistance relationship of the flux-coupled type SFCL in accordance the wiring direction: (a) for the additive wiring; (b) for the subtractive wiring.

Figure 6b shows the case of the subtractive wiring in which the two magnetically coupled windings are reverse wound. The resistance generated by the quench of the SE lasted 13.3 ms longer in the subtractive wiring than in the additive wiring. The currents flowing through the two coils immediately after the fault showed similar patterns compared to the additive wiring. The degree of FCL was lower in the subtractive wiring than in the additive wiring, but the current limiting operation lasted longer in the subtractive wiring.

Figure 7 shows the relationship between the SE resistance (Rsc) and the instantaneous power burden (psc) of the SE during the fault with respect to the winding direction of the two coils. As shown in Figure 2, the current (I2) flowing through SE is equal to Isc. The power burden consumed by SE is equal to the product of the square of Isc flowing through it while the SE is quenched to generate resistance. Therefore, most of the energy consumed in the SE is released as heat in the YBCO thin-film superconductor immersed in liquid nitrogen. During the period of occurrence of the Rsc resistance, the maximum instantaneous power consumed in the SE was higher in the additive wiring than in the subtractive wiring. The period during which the Rsc resistance was generated due to the quench of the SE was longer in the subtractive wiring than in the additive wiring, and the total power consumption during the fault period was greater in the subtractive wiring than in the additive wiring.

Figure 7.

Power burden and SE resistance relationship of the flux-coupled type SFCL in accordance with the wiring direction: (a) for the additive wiring; (b) for the subtractive wiring.

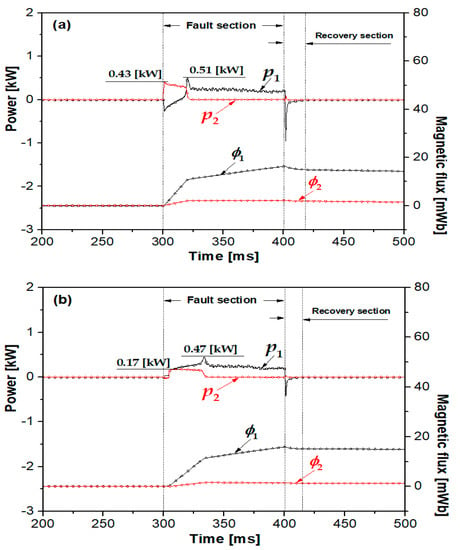

Figure 8 shows the magnetic flux () and instantaneous power () load of the two coils during the fault for both the additive wiring and subtractive wiring cases. It was found that the magnetic fluxes () of the primary and secondary coils were at similar levels regardless of the winding direction. The magnetic flux () of the primary coil was greater than that of the secondary coil (). The maximum instantaneous power consumed in the primary and secondary coils immediately after the fault was slightly larger in the additive wiring than in the subtractive wiring. Additionally, the instantaneous power consumed in the secondary coil during the fault period was found to be larger in the additive wiring than in the subtractive wiring.

Figure 8.

Instantaneous power burden and magnetic flux in each coil of the flux-coupled type SFCL in accordance the wiring direction: (a) for the additive wiring; (b) for the subtractive wiring.

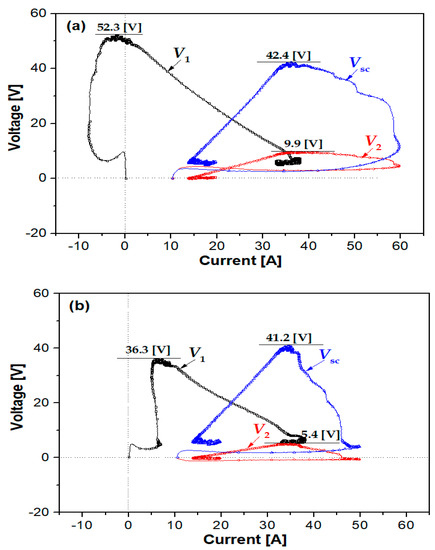

Figure 9 shows a comparison of the current and voltage trajectories of each device of the flux-coupled type SFCL during the 300–400 ms fault period, for both the additive wiring and subtractive wiring cases. The results showed that the voltage and current trajectories of each device during the fault were larger in the additive wiring than in the subtractive wiring. The size of the voltage and current trajectory of each device of the flux-coupled type SFCL differed according to the wiring direction. In the case of additive polarity winding, the trajectory pattern was similar, except that the current trajectory of the primary winding in the initial section of the failure was a negative value. It was confirmed that the flux-coupled SFCL operates in the same trajectory, even if the fault time increases from the beginning of the failure.

Figure 9.

Voltage and current trajectories in each device of the flux-coupled type SFCL during the fault: (a) for the additive wiring; (b) for the subtractive wiring.

4. Conclusions

In this paper, a prototype flux-coupled type SFCL with two coils connected in parallel is proposed as a device to limit a DC fault current in a DC system. An experimental device to simulate a DC short circuit accident was configured and used to analyze and compare the FCL characteristics of the proposed SFCL during a fault, relative to the winding direction of the two coils. The degree of FCL was higher in the additive wiring than in the subtractive wiring, but the FCL operation lasted a shorter time in the additive wiring. The period during which the SE resistance was generated due to the quenching of the SE was longer in the subtractive wiring than in the additive wiring, and the total power consumption during the DC fault period was greater in the subtractive wiring than in the additive wiring. This means that the total power burden characteristics of the SE were better in the additive wiring than in the subtractive wiring. The voltage and current trajectories of each device during the fault were larger in the additive wiring than in the subtractive wiring. It was also confirmed that the SFCL operated with similar-shaped trajectories during the fault regardless of the wiring direction of the two coils. A future study should focus on ensuring that the FCL operation of the SFCL can last for a sufficient amount of time so that the fault current can be completely blocked in a DCCB. Additionally, further research is required to find a way to remove the remanent fluxes from the two coils after the fault current is removed.

Author Contributions

Writing—original draft preparation, Y.-P.K.; Analysis of the experimental data and Writing—review and editing, S.-C.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), funded by the Ministry of education (2018R1D1A1B07040471).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alam, M.S.; Abido, M.A.Y.; El-Amin, I. Fault current limiters in power systems: A comprehensive review. Energies 2018, 11, 1025. [Google Scholar] [CrossRef]

- Park, D.K.; Chang, K.S.; Yang, S.E.; Kim, Y.J.; Ahn, M.C.; Yoon, Y.S.; Kim, H.M.; Park, J.W.; Ko, T.K. Analytical and experimental studies on the hybrid fault current limiter employing asymmetric non-inductive coil and fast switch. IEEE Trans. Appl. Supercond. 2009, 19, 1896–1899. [Google Scholar] [CrossRef]

- Hyun, O.B.; Yim, S.W.; Yu, S.D.; Yang, S.E.; Kim, W.S.; Kim, H.R.; Lee, G.H.; Sim, J.; Park, K.B. Long-term operation and fault tests of a 22.9 kV hybrid SFCL in the KEPCO test grid. IEEE Trans. Appl. Supercond. 2011, 21, 21312134. [Google Scholar] [CrossRef]

- Kim, W.S.; Hyun, O.; Park, C.R.; Yim, S.W.; Yu, S.D.; Yang, S.E.; Kim, H.S.; Kim, H.R. Dynamic characteristics of a 22.9 kV hybrid SFCL for short circuit test considering a simple coordination of protection system in distribution networks. IEEE Trans. Appl. Supercond. 2012, 22, 5601404. [Google Scholar]

- Lim, S.H.; Kim, J.C. Analysis on protection coordination of protective devices with a SFCL due to the application location of a dispersed generation in a power distribution system. IEEE Trans. Appl. Supercond. 2012, 22, 5601104. [Google Scholar]

- Deng, C.H.; Zheng, F.; Chen, L.; Li, M.; Xia, P.; Li, S.; Lomg, Z.; Zhu, L.; Guo, F. Study of a modified flux-coupling-type superconducting fault current limiter for mitigating the effect of DC short circuit in a VSC-HVDC system. J. Supercond. Nov. Magn. 2015, 28, 1525–1534. [Google Scholar] [CrossRef]

- Song, W.; Pei, X.; Xi, J.; Zeng, X. A Novel Helical Superconducting Fault Current Limiter for Electric Propulsion Aircraft. IEEE Trans. Transp. Electrif. 2021. [Google Scholar] [CrossRef]

- Song, W.; Pei, X.; Xi, J.; Zeng, X.; Yazdani-Asrami, M.; Fang, X.; Fang, J.; Jiang, Z. AC losses in noninductive SFCL solenoidal coils wound by parallel conductors. IEEE Trans. Appl. Supercond. 2020, 30, 5602509. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Staines, M.; Sidorov, G.; Eieher, A. Heat transfer and recovery performance enhancement of metal and superconducting tapes under high current pulses for improving fault current-limiting behavior of HTS transformers. Supercon. Sci. Techno. 2020, 33, 095014. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Staines, M.; Sidorov, G.; Davies, M.; Bailey, J.; Allpress, N.; Glasson, N.; Gholamian, S.A. Fault current limiting HTS transformer with extended fault withstand time. Supercon. Sci. Techno. 2019, 32, 035006. [Google Scholar] [CrossRef]

- Hyun, O.B. Brief review of the field test and application of a superconducting fault current limiter. Prog. Supercond. Cryog. 2017, 19, 1–11. [Google Scholar]

- Lee, H.Y. A Study on Fault Protection Scheme Using Fault Current Limiter and Circuit Breaker Considering Fault Current Characteristics of Voltage Source Converter HVDC System. Ph.D. Thesis, Hanyang Unversity, Seoul, Korea, 2020; pp. 1–172. [Google Scholar]

- Franck, C.M. HVDC circuit breakers: A review identifying future research needs. IEEE Trans. Power Deliv. 2011, 26, 998–1007. [Google Scholar] [CrossRef]

- Flourentzou, N.; Agelidis, V.G.; Demetriades, G.D. VSC-based HVDC power transmission systems: An overview. IEEE Trans. Power Electron. 2009, 24, 592–602. [Google Scholar] [CrossRef]

- Bucher, M.K.; Franck, C.M. Contribution of fault current sources in multi-terminal HVDC cable networks. IEEE Trans. Power Delivery 2013, 28, 1796–1803. [Google Scholar] [CrossRef]

- Hafner, J.; Jacobson, B. Proactive hybrid HVDC breakers: A key innovation for reliable HVDC grids. In Proceedings of the CIGRE The Electric Power System of the Future: Integrating Supergrids and Microgrids International Symposium, Bologna, Italy, 13–15 September 2011; pp. 1–8. [Google Scholar]

- Li, Y.; Xia, K.; Liu, W.; Li, D. Design and simulation analysis of electromagnetic repulsion mechanism. In Proceedings of the 2010 IEEE International Conference on Industrial Technology (ICIT 2010), Via del Mar, Chile, 14–17 March 2010; pp. 914–918. [Google Scholar]

- Dordizadeh, P.; Gharghabi, P.; Niayesh, K. Dynamic analysis of a fast-acting circuit breaker (Thompson) drive mechanism. J. Korean Phys. Soc. 2011, 59, 3547–3554. [Google Scholar] [CrossRef]

- Bissal, A.; Magnusson, J.; Engdahl, G. Comparison of two ultra-fast actuator concepts. IEEE Trans. Magn. 2012, 48, 3315–3318. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Sheng, J.; Cai, L.; Jin, Z.; Gu, J.; An, Z.; Yang, X.; Hong, Z. Design and application of a superconducting fault current limiter in DC systems. IEEE Trans. Appl. Supercond. 2014, 24, 5601305. [Google Scholar] [CrossRef]

- Manohar, P.; Ahmed, W. Superconducting fault current limiter to mitigate the effect of DC line fault in VSC-HVDC system. In Proceedings of the 2012 International Conference on Power, Signals, Controls and Computation, Thrissur, India, 3–6 January 2012; pp. 1–6. [Google Scholar]

- Endo, M.; Hori, T.; Koyama, T.; Kaiho, K.; Yamaguchi, I.; Arai, K.; Mizoguchi, H.; Yanabu, S. Development of a superconducting fault current limiter using various high-speed circuit breakers. IET Electr. Power Appl. 2009, 3, 363–370. [Google Scholar] [CrossRef]

- Ko, S.C.; Lim, S.H.; Han, T.H. Analysis on fault current limiting and recovery characteristics of a flux-lock type SFCL with an isolated transformer. Phys. C 2012, 484, 263–266. [Google Scholar] [CrossRef]

- Lim, S.H.; Ko, S.C.; Han, T.H. Analysis on current limiting characteristics of a transformer type SFCL with two triggering current levels. Phys. C 2012, 484, 253–257. [Google Scholar] [CrossRef]

- Lim, S.H.; Kim, Y.P.; Ko, S.C. Effect of peak current limiting in series-connection SFCL with two magnetically coupled circuits using E-I core. IEEE Trans. Appl. Supercond. 2016, 26, 5600404. [Google Scholar] [CrossRef]

- Lim, S.H.; Ko, S.C. Comparison of peak current limiting in two magnetically coupled SFCLs using dual iron cores. IEEE Trans. Appl. Supercond. 2016, 26, 5600304. [Google Scholar] [CrossRef]

- Ko, S.C.; Han, T.H.; Lim, S.H. Analysis on current limiting characteristics according to the Influence of the magnetic flux for SFCL with two magnetic paths. J. Electr. Eng. Technol. 2014, 9, 1909–1913. [Google Scholar] [CrossRef]

- Ko, S.C.; Han, T.H.; Lim, S.H. Current-limiting and recovery characteristics of a flux-lock-type SFCL with two adjustable operational currents. J. Korean Phys. Soc. 2014, 65, 253–256. [Google Scholar] [CrossRef]

- Han, T.H.; Ko, S.C.; Lee, B.J.; Lim, S.H. Study on current limiting characteristics of a flux-lock type SFCL using series connected two coils with twice triggering operation. J. Electr. Eng. Technol. 2014, 9, 777–781. [Google Scholar] [CrossRef][Green Version]

- Qiu, Q.; Xiao, L.; Zhang, Z.; Jing, L.; Liu, Q.; Zhang, G.; Xia, D. Design and test of 10kV/400A flux-coupling–typesuperconducting fault current limiting module. IEEE Trans. Appl. Supercond. 2018, 28, 5601806. [Google Scholar] [CrossRef]

- Li, Z.; Liang, S.; Ren, L.; Tan, X.; Xu, Y.; Tang, Y.; Li, J.; Shi, J. Application of flux-coupling-type superconducting fault current limiter on shipboard MVDC integrated power systems. IEEE Trans. Appl. Supercond. 2020, 30, 5601908. [Google Scholar] [CrossRef]

- Shu, J.; Wang, S.; Liu, T.; Jiao, N.; Wang, Y. A novel current-limiting circuit based on resistive-type SFCL for fault in DC power system. Microelectron. Reliab. 2018, 88, 1201–1205. [Google Scholar] [CrossRef]

- Lee, J.G.; Khan, U.A.; Hwang, J.S.; Seong, J.K.; Shin, W.J.; Park, B.B.; Lee, B.W. Assessment on the influence of resistive superconducting fault current limiter in VSC-HVDC system. Phys. C. 2014, 504, 163–166. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Qin, Y.; Chen, H.; Shen, Q.S.; Xu, Y.; Ren, L.; Tang, Y. Application and design of a resistive-type superconducting fault current limiter for efficient protection of a DC microgrid. IEEE Trans. Appl. Supercond. 2019, 29, 5600607. [Google Scholar] [CrossRef]

- Kim, H.R.; Choi, H.S.; Lim, H.R.; Kim, I.S.; Hyun, O.B. Initial quench development in uniform Au/Y-Ba-Cu-O thin films. IEEE Trans. Appl. Supercond. 2001, 11, 2414–2417. [Google Scholar]

- Choi, H.S.; Hyun, O.B.; Kim, H.R.; Park, K.B. Switching properties of a hybrid type superconducting fault current limiter using YBCO stripes. IEEE Trans. Appl. Supercond. 2002, 14, 1833–1838. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).