Concepts for Hydrogen Internal Combustion Engines and Their Implications on the Exhaust Gas Aftertreatment System

Abstract

:1. Introduction

2. Materials and Methods

3. Results

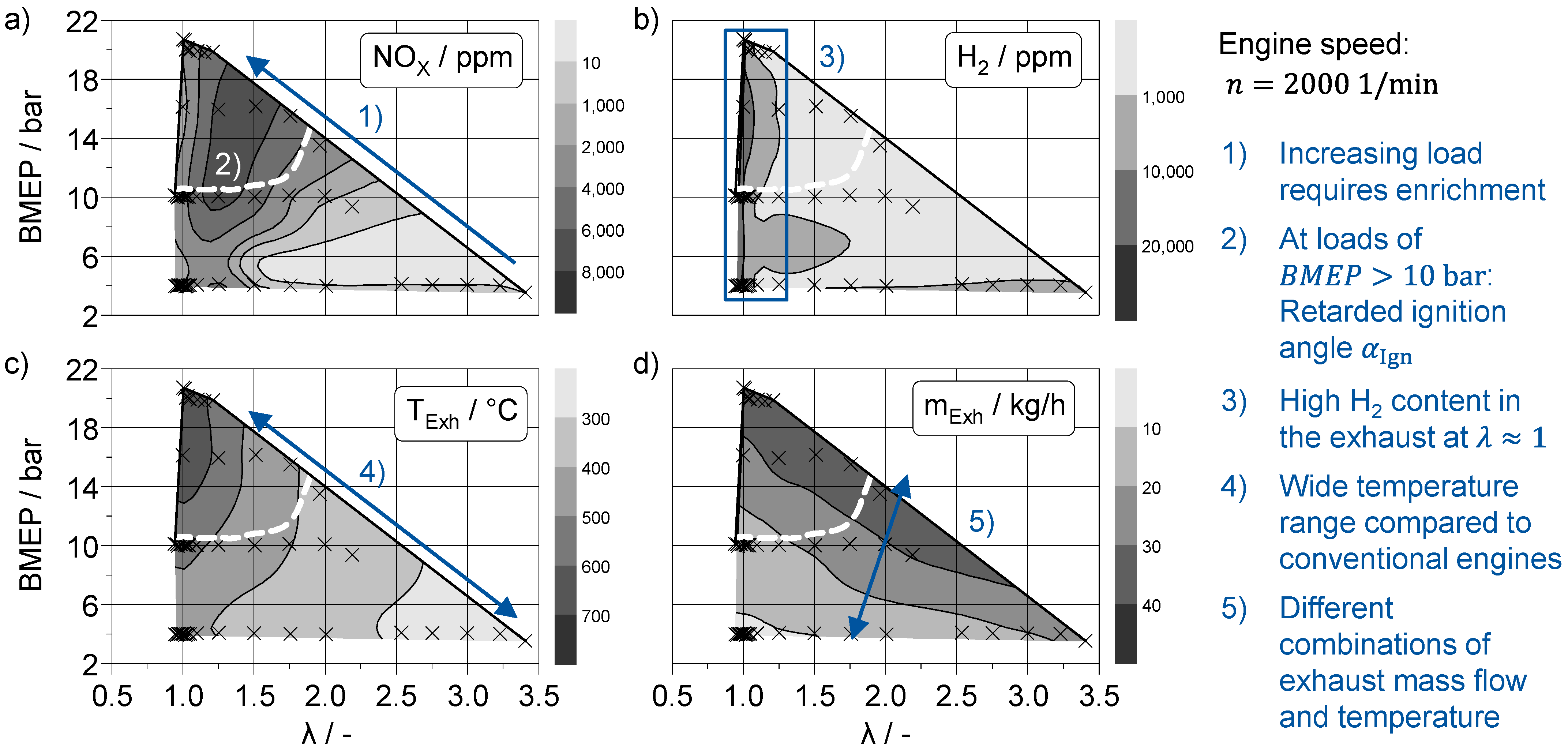

3.1. Gasoline Engine-Based Hydrogen Engine for Passenger Car Applications

3.2. Diesel Engine-Based Hydrogen Engine for Heavy Duty Applications

4. Discussion

5. Conclusions

- Lean operation is limited by the boosting system. Highest specific power is reached with stoichiometric combustion, which is accompanied by relatively high NOX emissions. Thus, the EATS has to include either a three-way catalyst (TWC) or a three-way NOX storage catalyst (TWNSC);

- At low loads, lean operation is still more efficient. Here, we see an SCR catalyst as the system of choice. Under these conditions, the upstream TWC/TWNSC can be used as oxidation catalyst to increase the NO2/NOX ratio. If hydrogen is available in the exhaust, the TWC/TWNSC will also produce ammonia, which reduces the required amount of urea injection;

- Switching between stoichiometric and lean operation will require dedicated engine operation strategies. Here, the avoidance of NOX, NH3 and N2O emissions will most likely require high attention.Main conclusions for the diesel engine-based hydrogen combustion engine with higher compression ratio (here ε = 13) targeting high efficiency are the following:

- Ultra-lean operation enables ultra-low NOX raw emissions down to the limit of detectability. However, the heavy enleanment comes along with very low exhaust gas temperatures that are below the light-off temperatures of currently available catalysts. As a result, the exhaust gas aftertreatment system is not instantly available in the event of a transient operating point change;

- From the exhaust gas aftertreatment point of view, less lean operation is beneficial. An engine operation, e.g., at an air/fuel ratio of λ = 2.3 still causes low NOX emissions, but increases the exhaust temperature to ensure catalyst activity;

- Under these operation conditions, the SCR catalyst is the most promising EATS component and can be directly transferred from diesel applications. For operation areas, where the SCR system is not fully active, a combination with an upstream NOX storage catalyst or H2-SCR system increases the overall NOX reduction performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Verhelst, S. Recent progress in the use of hydrogen as a fuel for internal combustion engines. Int. J. Hydrogen Energy 2014, 39, 1071–1085. [Google Scholar] [CrossRef] [Green Version]

- Candelaresi, D.; Valente, A.; Iribarren, D.; Dufour, J.; Spazzafumo, G. Comparative life cycle assessment of hydrogen-fuelled passenger cars. Int. J. Hydrogen Energy 2021, 46, 35961–35973. [Google Scholar] [CrossRef]

- Ma, D.-S.; Sun, Z.Y. Progress on the studies about NOx emission in PFI-H2ICE. Int. J. Hydrogen Energy 2020, 45, 10580–10591. [Google Scholar] [CrossRef]

- Thewes, M.; Balazs, A.; Yadla, S.K.; Walter, V.; Görgen, M.; Scharf, J.; Sterlepper, S.; Voßhall, T. Zero-Impact Combustion Engine. In Proceedings of the 28th Aachen Colloquium Automobile and Engine Technology, Aachen, Germany, 7–9 October 2019. [Google Scholar]

- Nagalingam, B.; Dübel, M.; Schmillen, K. Performance of the Supercharged Spark Ignition Hydrogen Engine. SAE Tech. Pap. Ser. 1983, 831688. [Google Scholar] [CrossRef]

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engines. Prog. Energy Combust. Sci. 2009, 35, 490–527. [Google Scholar] [CrossRef] [Green Version]

- Eichlseder, H.; Wallner, T.; Freymann, R.; Ringler, J. The Potential of Hydrogen Internal Combustion Engines in a Future Mobility Scenario. SAE Tech. Pap. Ser. 2003, 2003-01-2267. [Google Scholar] [CrossRef]

- Yamane, K. Hydrogen Fueled ICE, Successfully Overcoming Challenges through High Pressure Direct Injection Technologies: 40 Years of Japanese Hydrogen ICE Research and Development. SAE Tech. Pap. Ser. 2018, 2018-01-1145. [Google Scholar] [CrossRef]

- Kiesgen, G.; Klüting, M.; Bock, C.; Fischer, H. The New 12-Cylinder Hydrogen Engine in the 7 Series: The H2 ICE Age Has Begun. SAE Tech. Pap. Ser. 2006, 2006-01-0431. [Google Scholar] [CrossRef]

- Wallner, T.; Lohse-Busch, H.; Gurski, S.; Duoba, M.; Thiel, W.; Martin, D.; Korn, T. Fuel economy and emissions evaluation of BMW Hydrogen 7 Mono-Fuel demonstration vehicles. Int. J. Hydrogen Energy 2008, 33, 7607–7618. [Google Scholar] [CrossRef]

- Stockhausen, W.F.; Natkin, R.J.; Kabat, D.M.; Reams, L.; Tang, X.; Hashemi, S.; Szwabowski, S.J.; Zanardelli, V.P. Ford P2000 Hydrogen Engine Design and Vehicle Development Program. SAE Tech. Pap. Ser. 2002, 2002-01-0240. [Google Scholar] [CrossRef]

- Natkin, R.J.; Denlinger, A.R.; Younkins, M.A.; Weimer, A.Z.; Hashemi, S.; Vaught, A.T. Ford 6.8L Hydrogen IC Engine for the E-450 Shuttle Van. SAE Tech. Pap. Ser. 2007, 2007-01-4096. [Google Scholar] [CrossRef]

- Virnich, L.; Lindemann, B.; Müther, M.; Schaub, J.; Huth, V.; Geiger, J. How to Improve Transient Engine Performance of HD Hydrogen Engines while Maintaining Lowest NOx Emissions. In Proceedings of the 42th International Vienna Motor Symposium, Vienna, Austria, 28–30 April 2021; ISBN 978-3-9504969-0-1. [Google Scholar]

- Pauer, T.; Weller, H.; Schünemann, E.; Eichlseder, H.; Grabner, P.; Schaffer, K. H2ICE for Future Passenger Cars and Light Commercial Vehicles. In Proceedings of the 41th International Vienna Motor Symposium, Vienna, Austria, 22–24 April 2020; ISBN 978-3-18-381312-4. [Google Scholar]

- Dreisbach, R.; Arnberger, A.; Zukancic, A.; Wieser, M.; Kunder, N.; Plettenberg, M.; Raser, B.; Eichlseder, H. The Heavy-Duty Hydrogen Engine and its Realization until 2025. In Proceedings of the 42th International Vienna Motor Symposium, Vienna, Austria, 28–30 April 2021; ISBN 978-3-9504969-0-1. [Google Scholar]

- Korn, T.; Nobile, R.-F.; Grassinger, D. Zero-Emission, Maximum Performance—The Latest Generation of Hydrogen Combustion Engines. In Proceedings of the 42th International Vienna Motor Symposium, Vienna, Austria, 28–30 April 2021; ISBN 978-3-9504969-0-1. [Google Scholar]

- Walter, L.; Sommermann, A.; Hyna, D.; Malischewski, T.; Leistner, M.; Hinrichsen, F.; Wöhner, P.; Schmitt, J.; McMackin, M. The H2 Combustion Engine—The Forerunner of a Zero Emissions Future. In Proceedings of the 42th International Vienna Motor Symposium, Vienna, Austria, 28–30 April 2021; ISBN 978-3-9504969-0-1. [Google Scholar]

- Wang, X.; Sun, B.; Luo, Q. Energy and exergy analysis of a turbocharged hydrogen internal combustion engine. Int. J. Hydrogen Energy 2019, 44, 5551–5563. [Google Scholar] [CrossRef]

- Li, Y.; Gao, W.; Zhang, P.; Ye, Y.; Wei, Z. Effects study of injection strategies on hydrogen-air formation and performance of hydrogen direct injection internal combustion engine. Int. J. Hydrogen Energy 2019, 44, 26000–26011. [Google Scholar] [CrossRef]

- Yip, H.L.; Srna, A.; Liu, X.; Kook, S.; Hawkes, E.R.; Chan, Q.N. Visualization of hydrogen jet evolution and combustion under simulated direct-injection compression-ignition engine conditions. Int. J. Hydrogen Energy 2020, 45, 32562–32578. [Google Scholar] [CrossRef]

- Yip, H.L.; Srna, A.; Yuen, A.C.Y.; Kook, S.; Taylor, R.A.; Yeoh, G.H.; Medwell, P.R.; Chan, Q.N. A Review of Hydrogen Direct Injection for Internal Combustion Engines: Towards Carbon-Free Combustion. Appl. Sci. 2019, 9, 4842. [Google Scholar] [CrossRef] [Green Version]

- Sterlepper, S.; Claßen, J.; Pischinger, S.; Görgen, M.; Cox, J.; Nijs, M.; Scharf, J. Relevance of Exhaust Aftertreatment System Degradation for EU7 Gasoline Engine Applications. SAE Tech. Pap. Ser. 2020, 2020-01-0382. [Google Scholar] [CrossRef]

- Wunsch, R.; Schön, C.; Frey, M.; Tran, D.; Proske, S.; Wandrey, T.; Kalogirou, M.; Schäffner, J. Detailed experimental investigation of the NOx reaction pathways of three-way catalysts with focus on intermediate reactions of NH3 and N2O. Appl. Catal. B 2020, 272, 118937. [Google Scholar] [CrossRef]

- Claßen, J.; Pischinger, S.; Krysmon, S.; Sterlepper, S.; Dorscheidt, F.; Doucet, M.; Reuber, C.; Görgen, M.; Scharf, J.; Nijs, M.; et al. Statistically supported real driving emission calibration: Using cycle generation to provide vehicle-specific and statistically representative test scenarios for Euro 7. Int. J. Engine Res. 2020, 21, 1783–1799. [Google Scholar] [CrossRef]

- Claßen, J.; Krysmon, S.; Dorscheidt, F.; Sterlepper, S.; Pischinger, S. Real Driving Emission Calibration—Review of Current Validation Methods against the Background of Future Emission Legislation. Appl. Sci. 2021, 11, 5429. [Google Scholar] [CrossRef]

- Kawamura, A.; Yanai, T.; Sato, Y.; Naganuma, K.; Yamane, K.; Takagi, Y. Summary and Progress of the Hydrogen ICE Truck Development Project. SAE Int. J. Commer. Veh. 2009, 2, 110–117. [Google Scholar] [CrossRef]

- Savva, P.G.; Costa, C.N. Hydrogen Lean-DeNOx as an Alternative to the Ammonia and Hydrocarbon Selective Catalytic Reduction (SCR). Catal. Rev. 2011, 53, 91–151. [Google Scholar] [CrossRef]

- Leicht, M.; Schott, F.J.; Bruns, M.; Kureti, S. NOx reduction by H2 on WOx/ZrO2-supported Pd catalysts under lean conditions. Appl. Catal. B 2012, 117–118, 275–282. [Google Scholar] [CrossRef]

- Hahn, C.; Endisch, M.; Schott, F.J.; Kureti, S. Kinetic modelling of the NOx reduction by H2 on Pt/WO3/ZrO2 catalyst in excess of O2. Appl. Catal. B 2015, 168–169, 429–440. [Google Scholar] [CrossRef]

- Schott, F.J.P.; Balle, P.; Adler, J.; Kureti, S. Reduction of NOx by H2 on Pt/WO3/ZrO2 catalysts in oxygen-rich exhaust. Appl. Catal. B 2009, 87, 18–29. [Google Scholar] [CrossRef]

- Olympiou, G.G.; Efstathiou, A.M. Industrial NOx control via H2-SCR on a novel supported-Pt nanocatalyst. Chem. Eng. J. 2011, 170, 423–432. [Google Scholar] [CrossRef]

- Hamada, H.; Haneda, M. A review of selective catalytic reduction of nitrogen oxides with hydrogen and carbon monoxide. Appl. Catal. A 2012, 421–422, 1–13. [Google Scholar] [CrossRef]

- Luo, Q.; Hu, J.-B.; Sun, B.; Liu, F.; Wang, X.; Li, C.; Bao, L. Effect of equivalence ratios on the power, combustion stability and NOx controlling strategy for the turbocharged hydrogen engine at low engine speeds. Int. J. Hydrogen Energy 2019, 44, 17095–17102. [Google Scholar] [CrossRef]

- Lee, J.; Park, C.; Bae, J.; Kim, Y.; Choi, Y.; Lim, B. Effect of different excess air ratio values and spark advance timing on combustion and emission characteristics of hydrogen-fueled spark ignition engine. Int. J. Hydrogen Energy 2019, 44, 25021–25030. [Google Scholar] [CrossRef]

- Li, Y.; Gao, W.; Zhang, P.; Fu, Z.; Cao, X. Influence of the equivalence ratio on the knock and performance of a hydrogen direct injection internal combustion engine under different compression ratios. Int. J. Hydrogen Energy 2021, 46, 11982–11993. [Google Scholar] [CrossRef]

- Zhu, H.; Duan, J. Research on emission characteristics of hydrogen fuel internal combustion engine based on more detailed mechanism. Int. J. Hydrogen Energy 2019, 44, 5592–5598. [Google Scholar] [CrossRef]

- Abdulhamid, H.; Fridell, E.; Skoglundh, M. Influence of the Type of Reducing Agent (H2, CO, C3H6 and C3H8) on the Reduction of Stored NOX in a Pt/BaO/Al2O3 Model Catalyst. Top. Catal. 2004, 30–31, 161–168. [Google Scholar] [CrossRef]

- Ling-zhi, B.; Bai-gang, S.; Qing-he, L.; Yong-li, G.; Xi, W.; Fu-shui, L.; Chao, L. Simulation and experimental study of the NOx reduction by unburned H2 in TWC for a hydrogen engine. Int. J. Hydrogen Energy 2020, 45, 20491–20500. [Google Scholar] [CrossRef]

- Lindholm, A.; Currier, N.; Fridell, E.; Yezerets, A.; Olsson, L. NOx storage and reduction over Pt based catalysts with hydrogen as the reducing agentInfluence of H2O and CO2. Appl. Catal. B 2007, 75, 78–87. [Google Scholar] [CrossRef]

- Krishnan Unni, J.; Bhatia, D.; Dutta, V.; Das, L.M.; Jilakara, S.; Subash, G.P. Development of Hydrogen Fuelled Low NOx Engine with Exhaust Gas Recirculation and Exhaust after Treatment. SAE Tech. Pap. Ser. 2017, 2017-26-0074. [Google Scholar] [CrossRef]

- Schmieg, S.J.; Lee, J.-H. Evaluation of Supplier Catalyst Formulations for the Selective Catalytic Reduction of NOx With Ammonia. SAE Tech. Pap. Ser. 2005, 2005-01-3881. [Google Scholar] [CrossRef]

- Malamis, S.A.; Li, M.; Epling, W.S.; Harold, M.P. Steady state and lean-rich cycling study of a three-way NOX storage catalyst: Experiments. Appl. Catal. B 2018, 237, 588–602. [Google Scholar] [CrossRef]

- Li, M.; Malamis, S.A.; Epling, W.; Harold, M.P. Steady state and lean-rich cycling study of a three-way NOX storage catalyst: Modeling. Appl. Catal. B 2019, 242, 469–484. [Google Scholar] [CrossRef]

- Klell, M.; Eichlseder, H.; Sartory, M. Mixtures of hydrogen and methane in the internal combustion engine—Synergies, potential and regulations. Int. J. Hydrogen Energy 2012, 37, 11531–11540. [Google Scholar] [CrossRef]

- Singh, A.P.; Pal, A.; Agarwal, A.K. Comparative particulate characteristics of hydrogen, CNG, HCNG, gasoline and diesel fueled engines. Fuel 2016, 185, 491–499. [Google Scholar] [CrossRef]

- Sterlepper, S.; Claßen, J.; Pischinger, S.; Schernus, C.; Görgen, M.; Cox, J.; Nijs, M.; Scharf, J.; Rose, D.; Boger, T. Analysis of the Emission Conversion Performance of Gasoline Particulate Filters Over Lifetime. SAE Int. J. Adv. Curr. Prac. Mobil. 2020, 2, 710–720. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sterlepper, S.; Fischer, M.; Claßen, J.; Huth, V.; Pischinger, S. Concepts for Hydrogen Internal Combustion Engines and Their Implications on the Exhaust Gas Aftertreatment System. Energies 2021, 14, 8166. https://doi.org/10.3390/en14238166

Sterlepper S, Fischer M, Claßen J, Huth V, Pischinger S. Concepts for Hydrogen Internal Combustion Engines and Their Implications on the Exhaust Gas Aftertreatment System. Energies. 2021; 14(23):8166. https://doi.org/10.3390/en14238166

Chicago/Turabian StyleSterlepper, Stefan, Marcus Fischer, Johannes Claßen, Verena Huth, and Stefan Pischinger. 2021. "Concepts for Hydrogen Internal Combustion Engines and Their Implications on the Exhaust Gas Aftertreatment System" Energies 14, no. 23: 8166. https://doi.org/10.3390/en14238166

APA StyleSterlepper, S., Fischer, M., Claßen, J., Huth, V., & Pischinger, S. (2021). Concepts for Hydrogen Internal Combustion Engines and Their Implications on the Exhaust Gas Aftertreatment System. Energies, 14(23), 8166. https://doi.org/10.3390/en14238166