Design and Implementation of Periodic Control for a Matrix Converter-Based Interior Permanent Magnet Synchronous Motor Drive System

Abstract

:1. Introduction

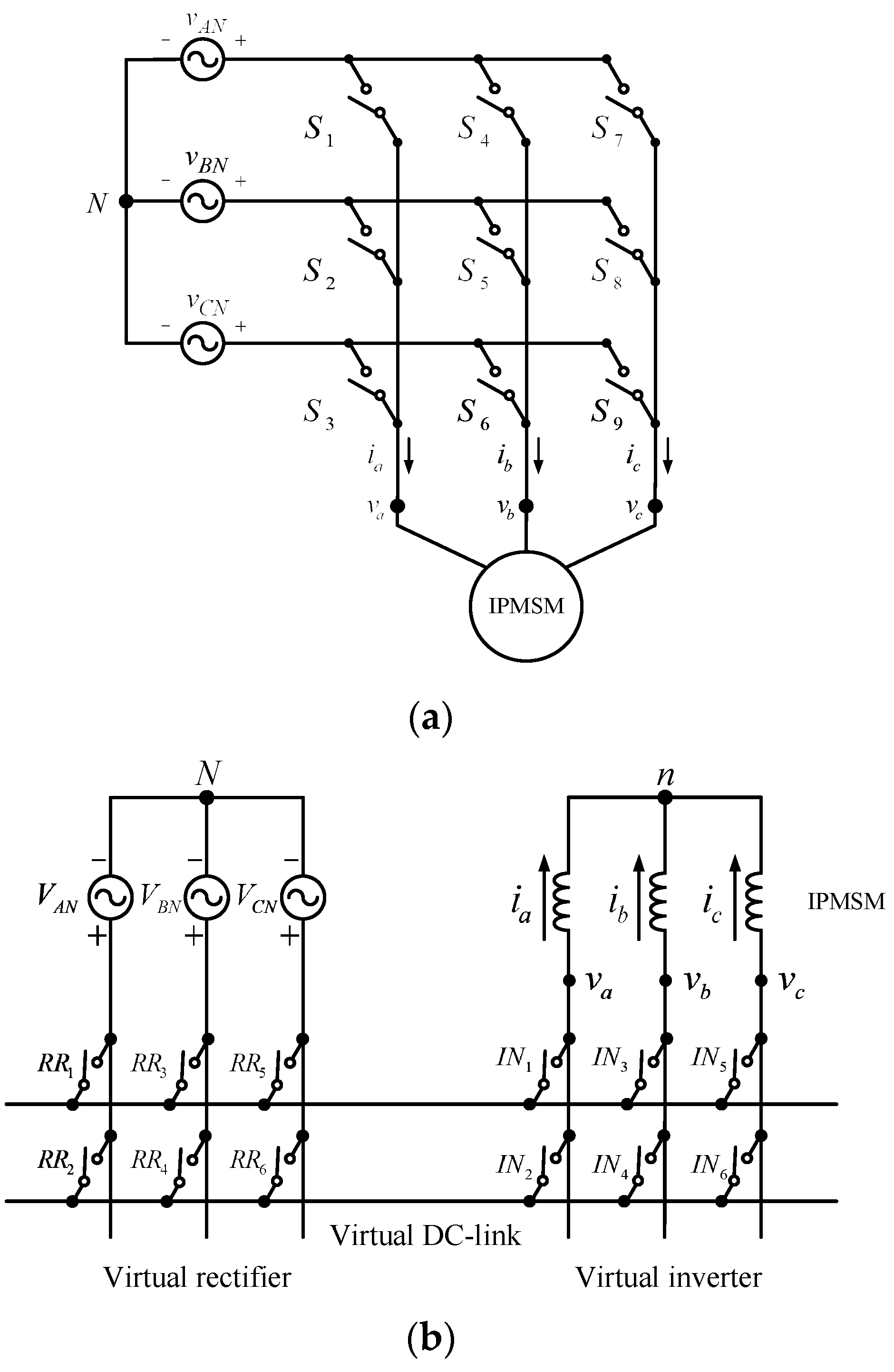

2. Matrix-Converter Based IPMSM Drives

2.1. Matrix Converter

2.2. Mathematical Model of an IPMSM

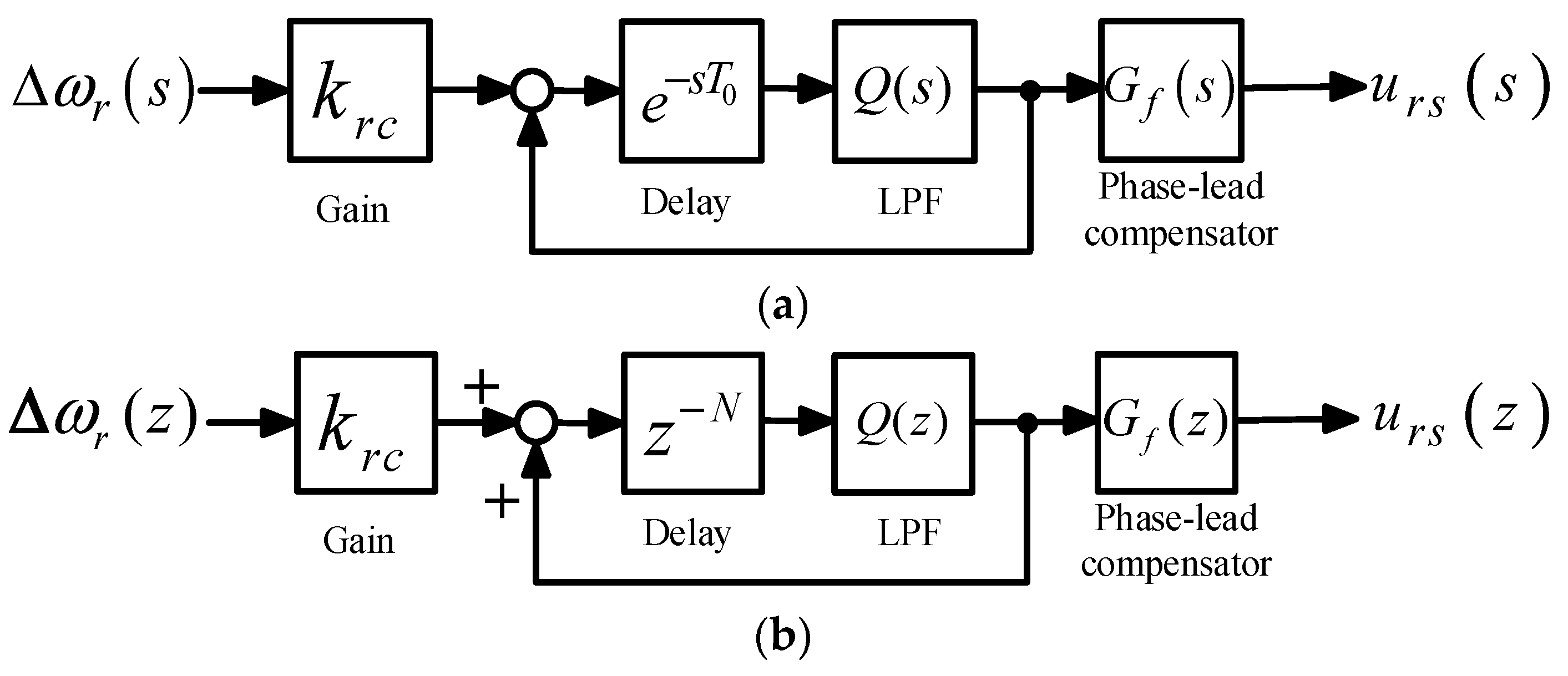

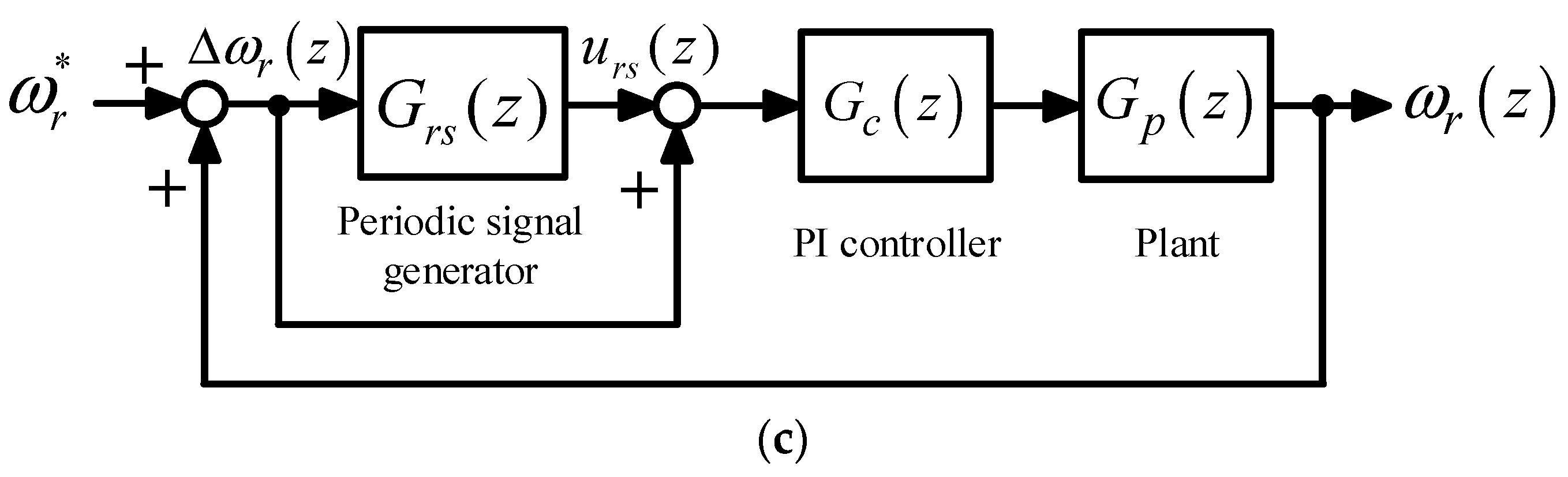

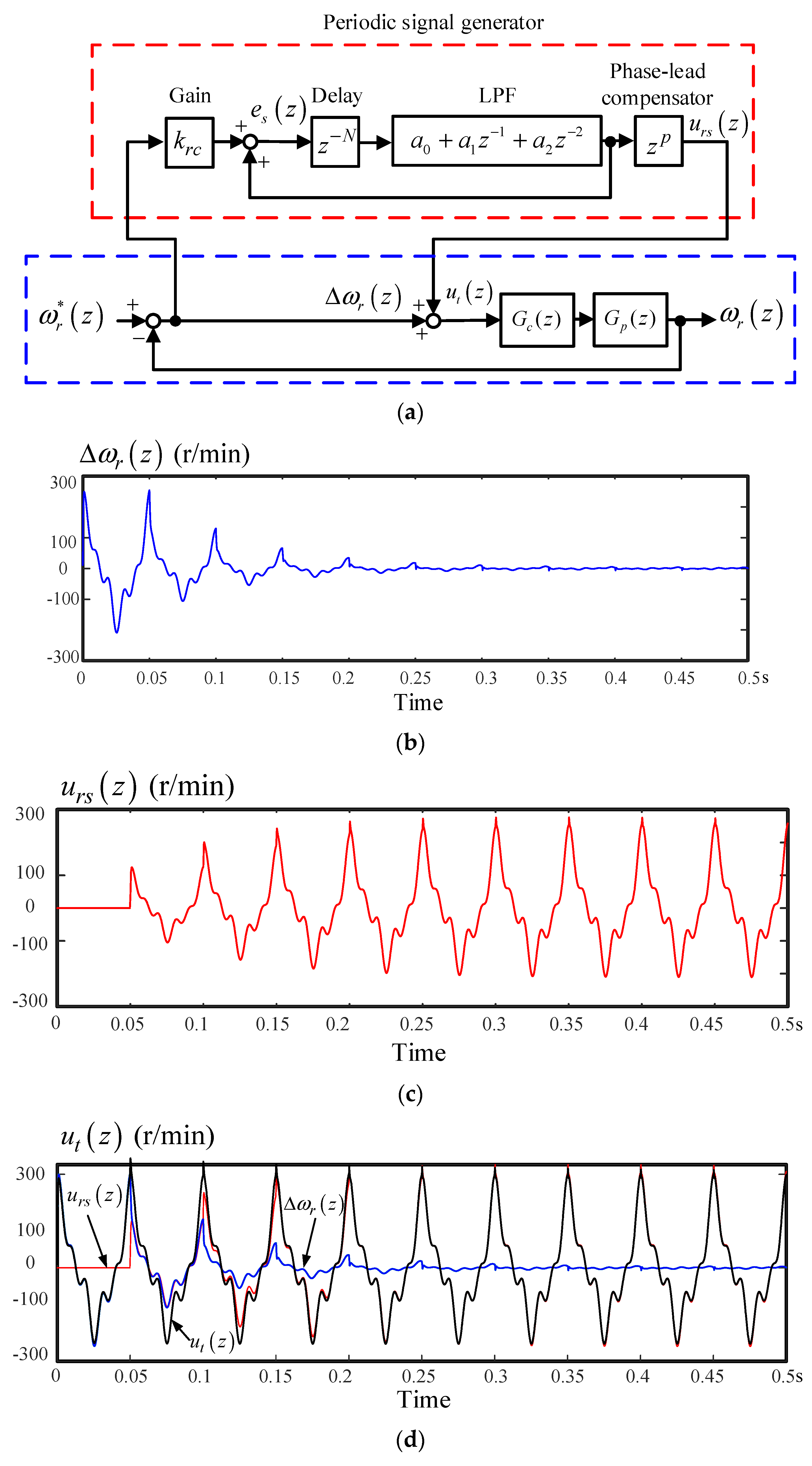

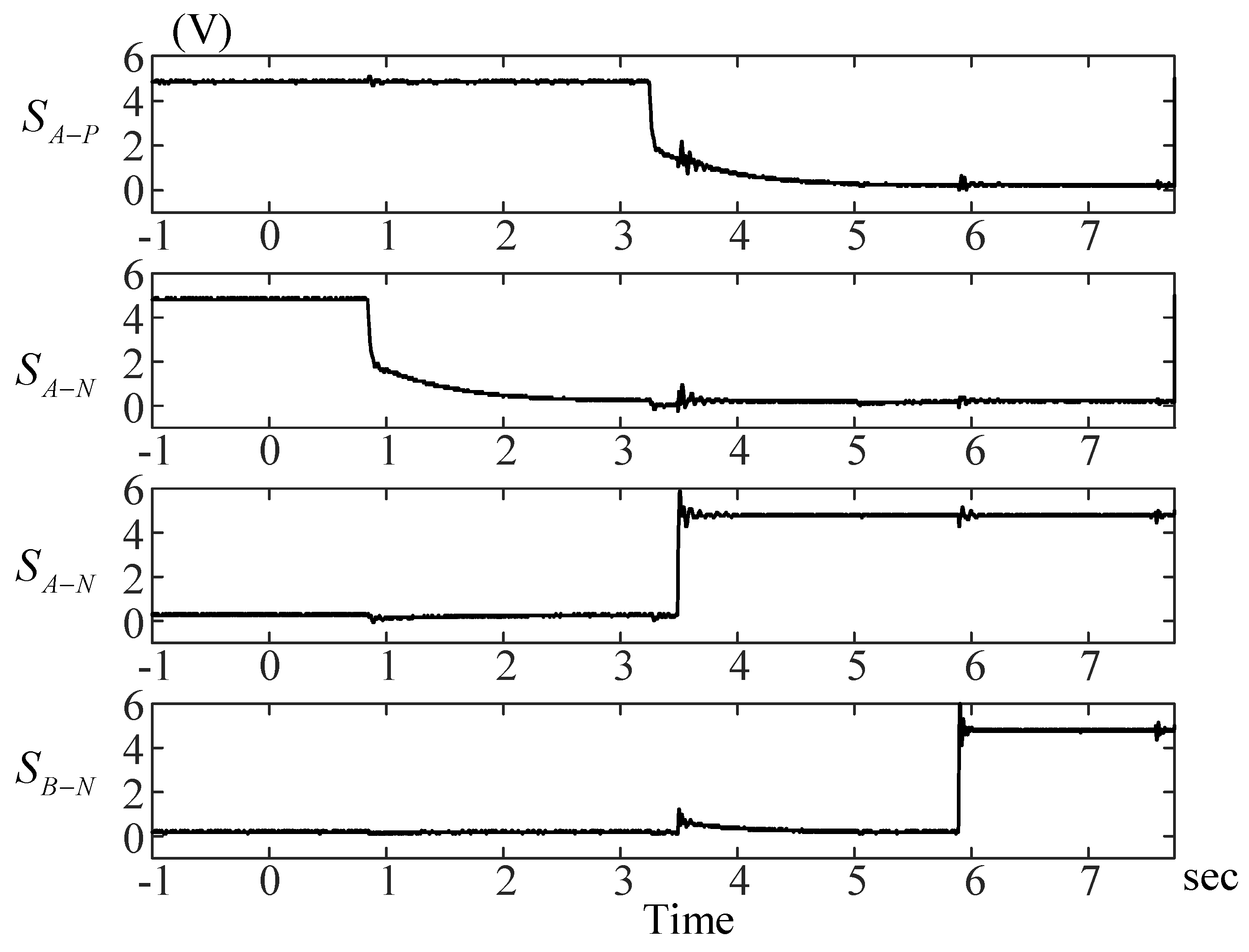

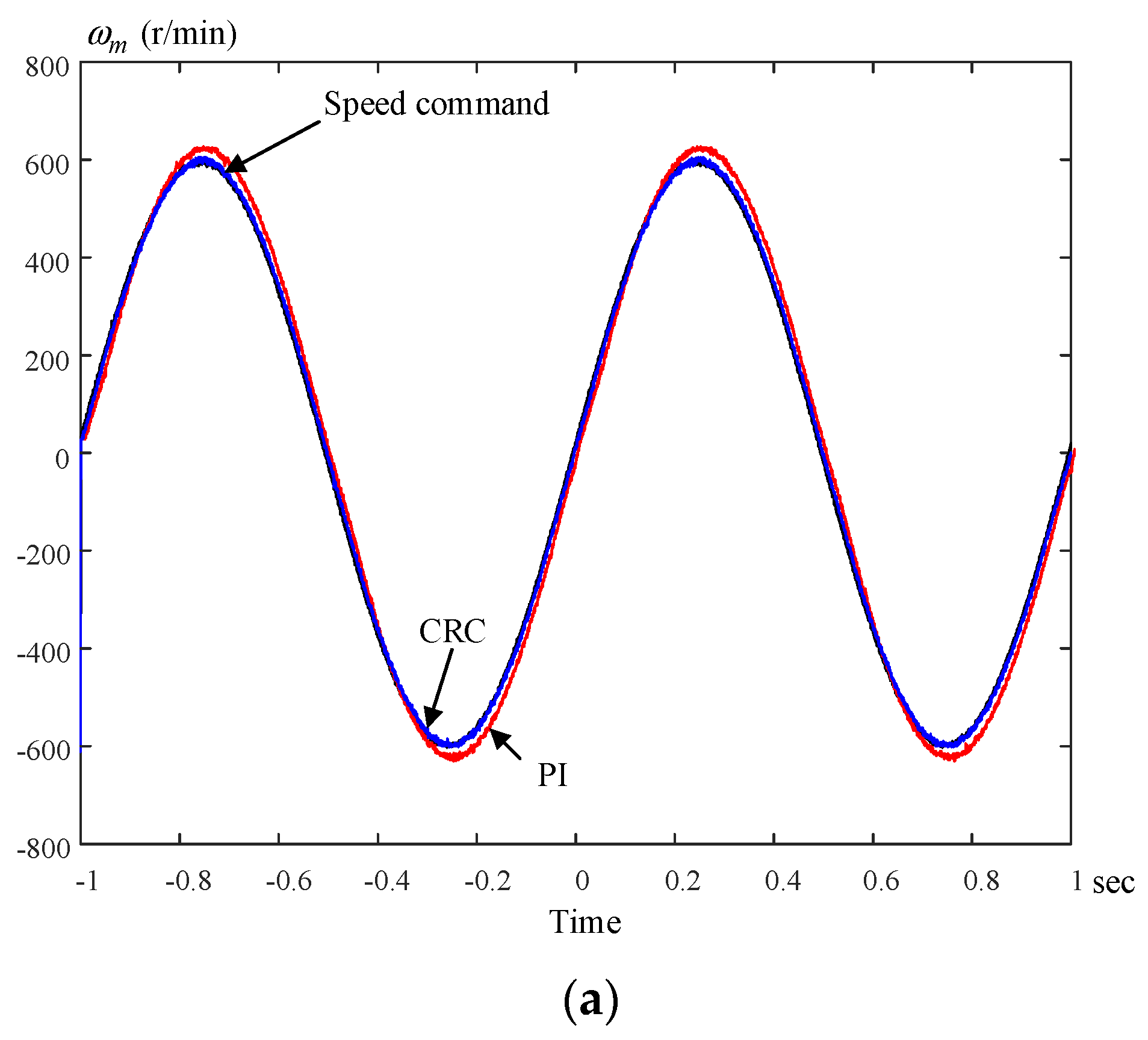

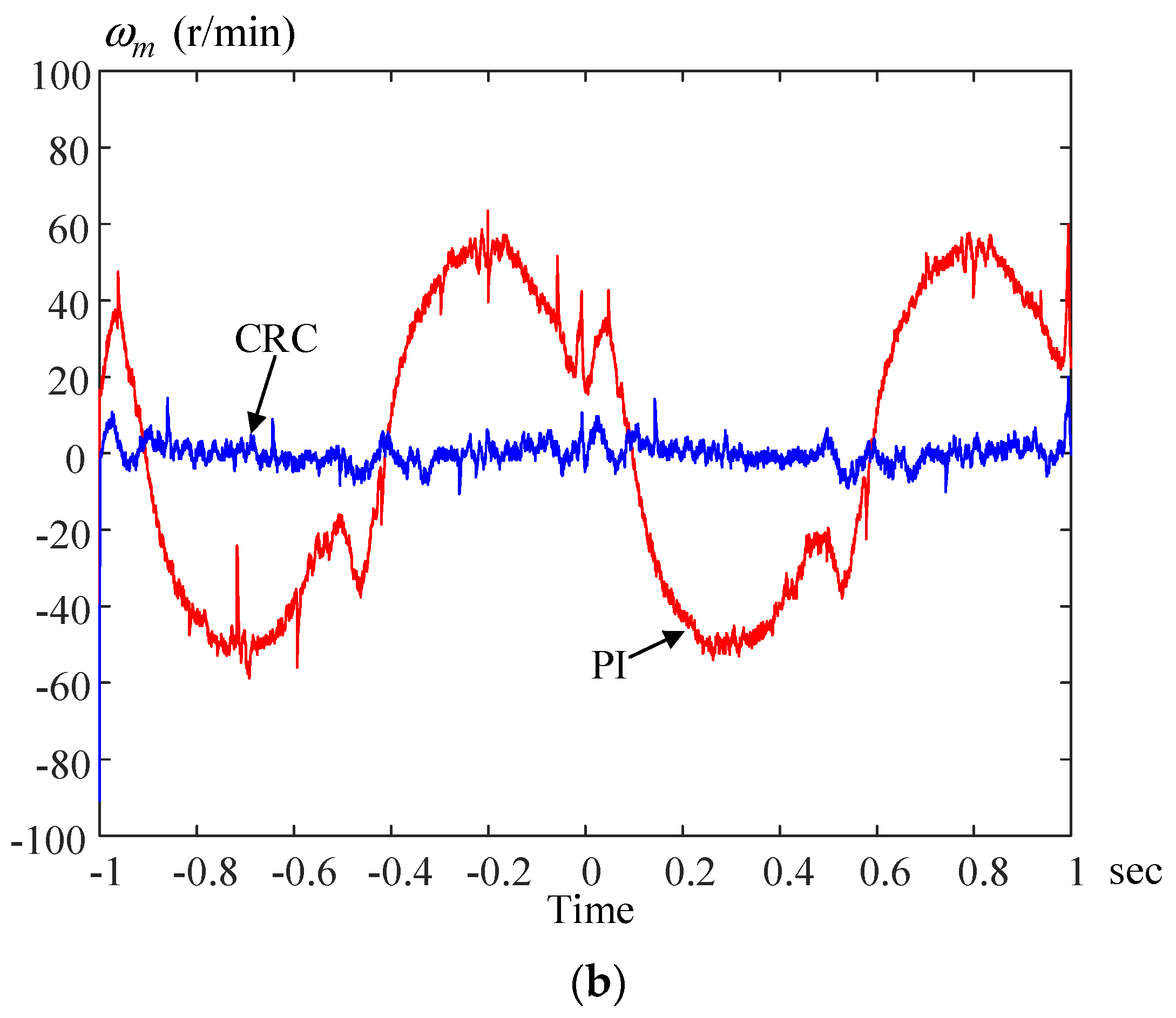

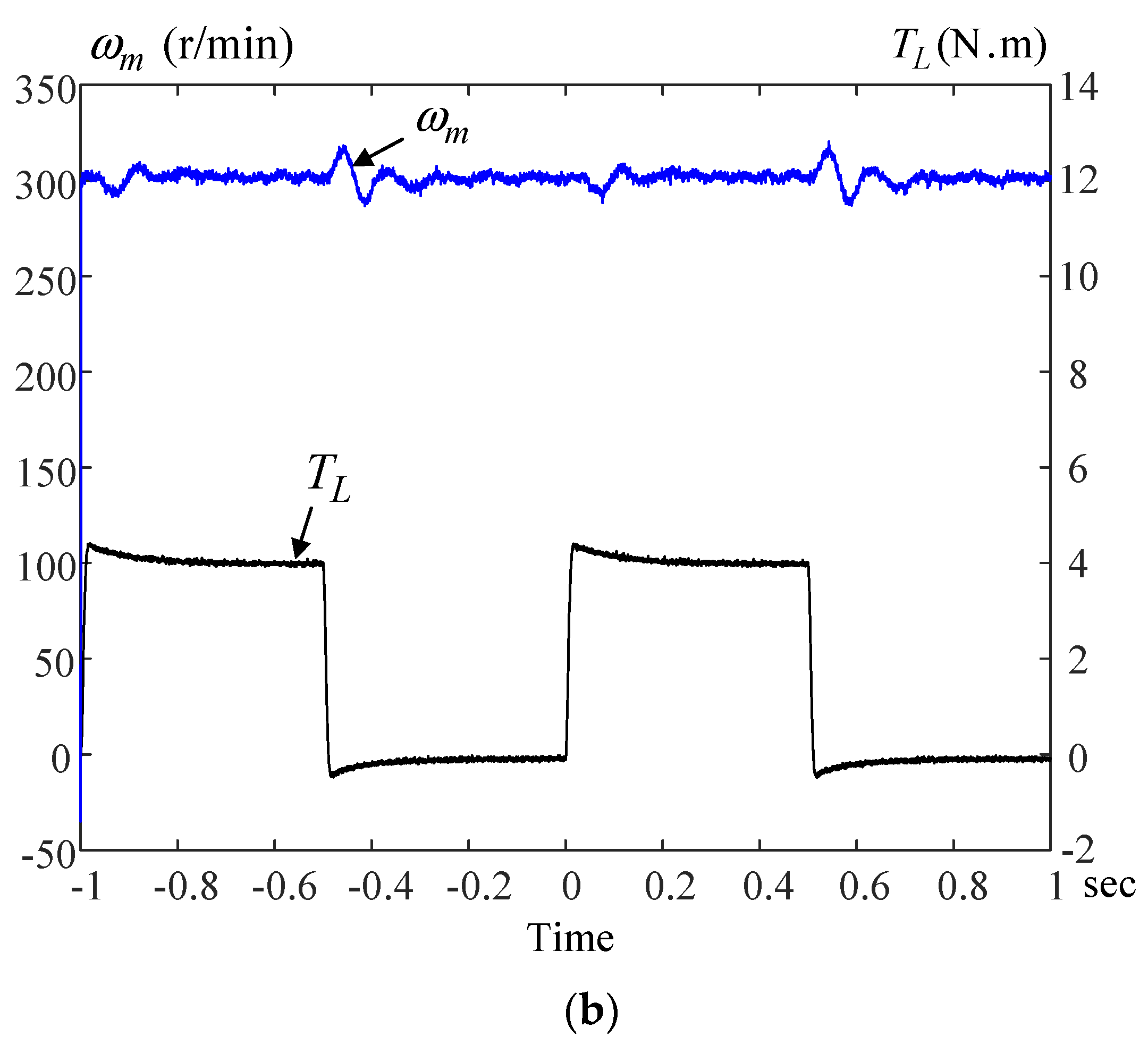

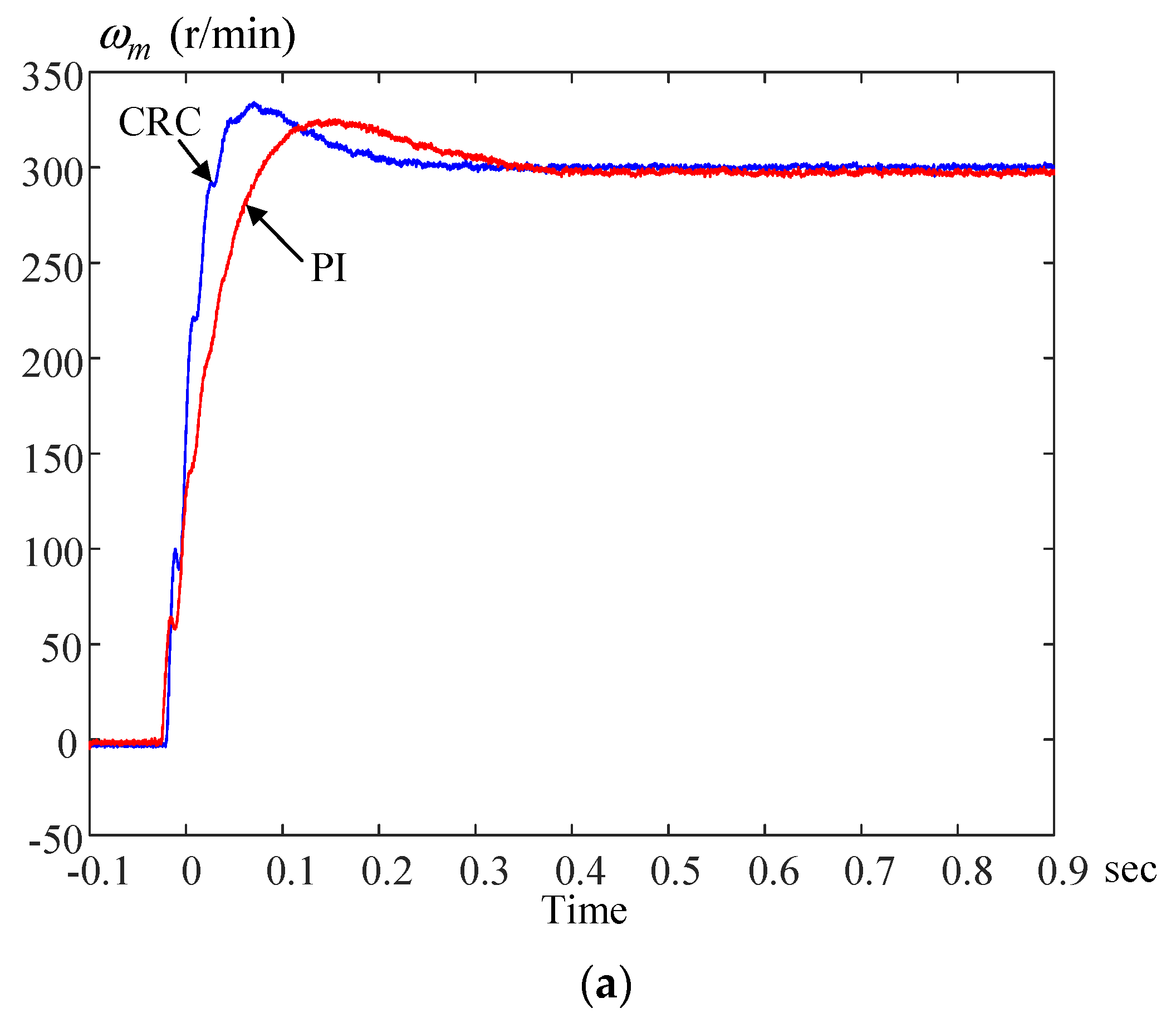

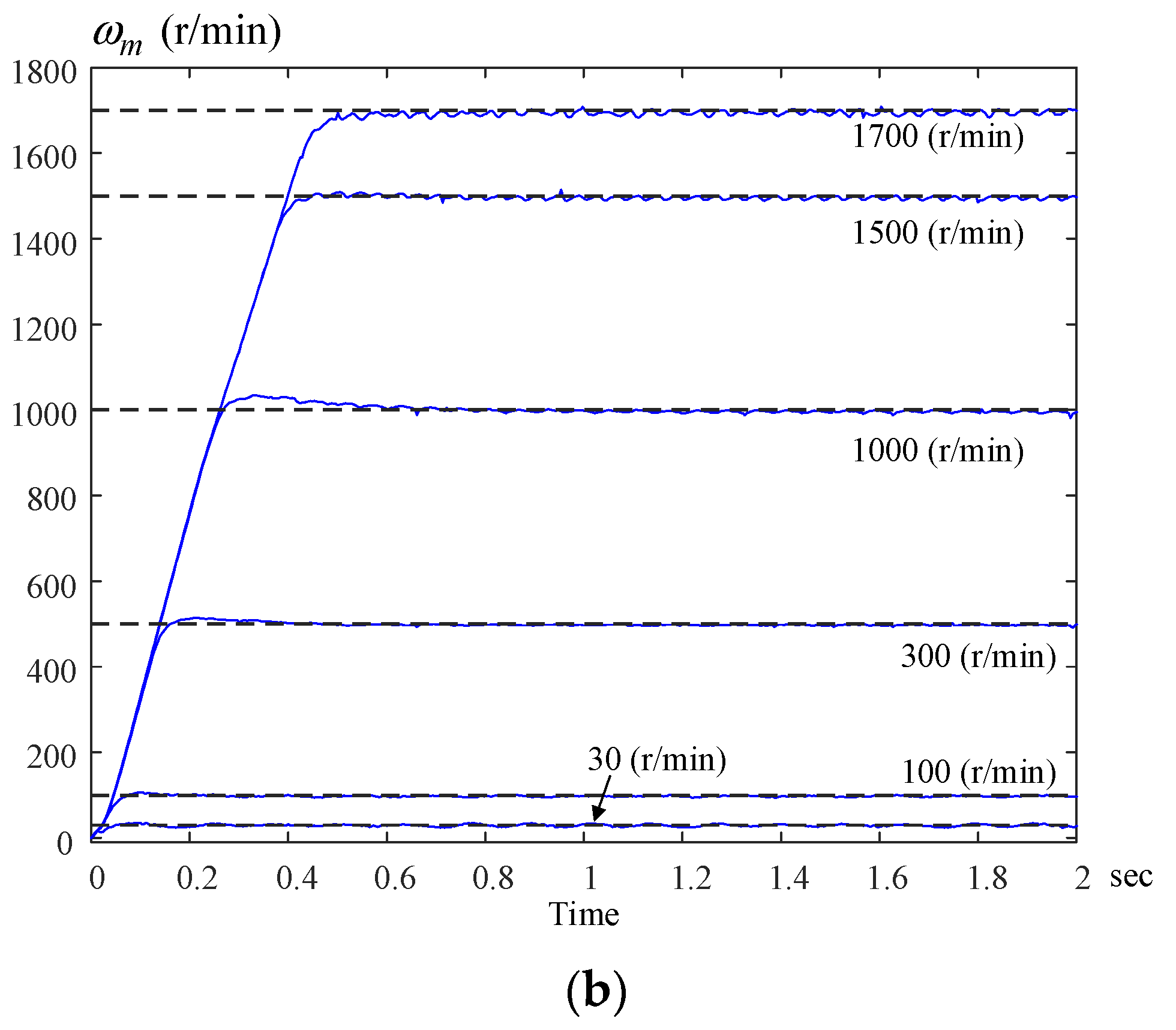

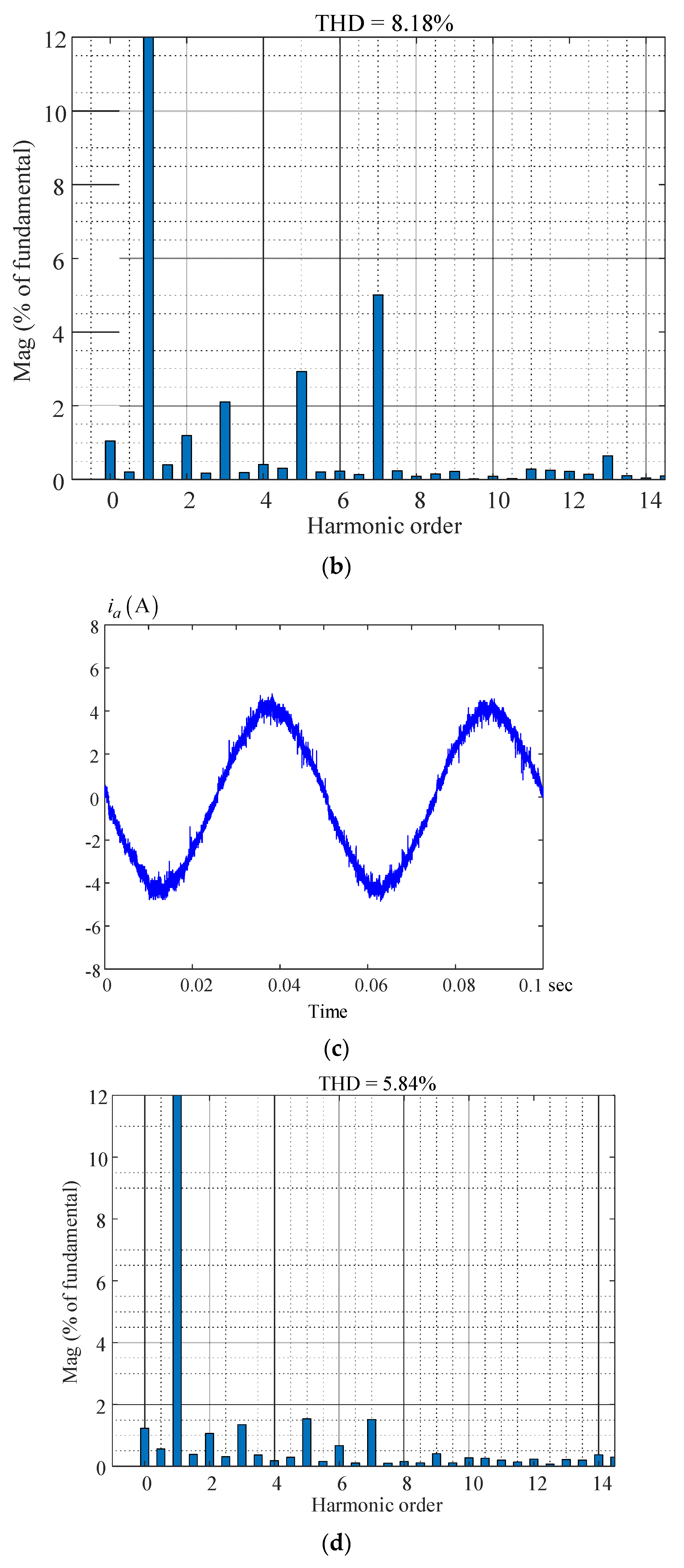

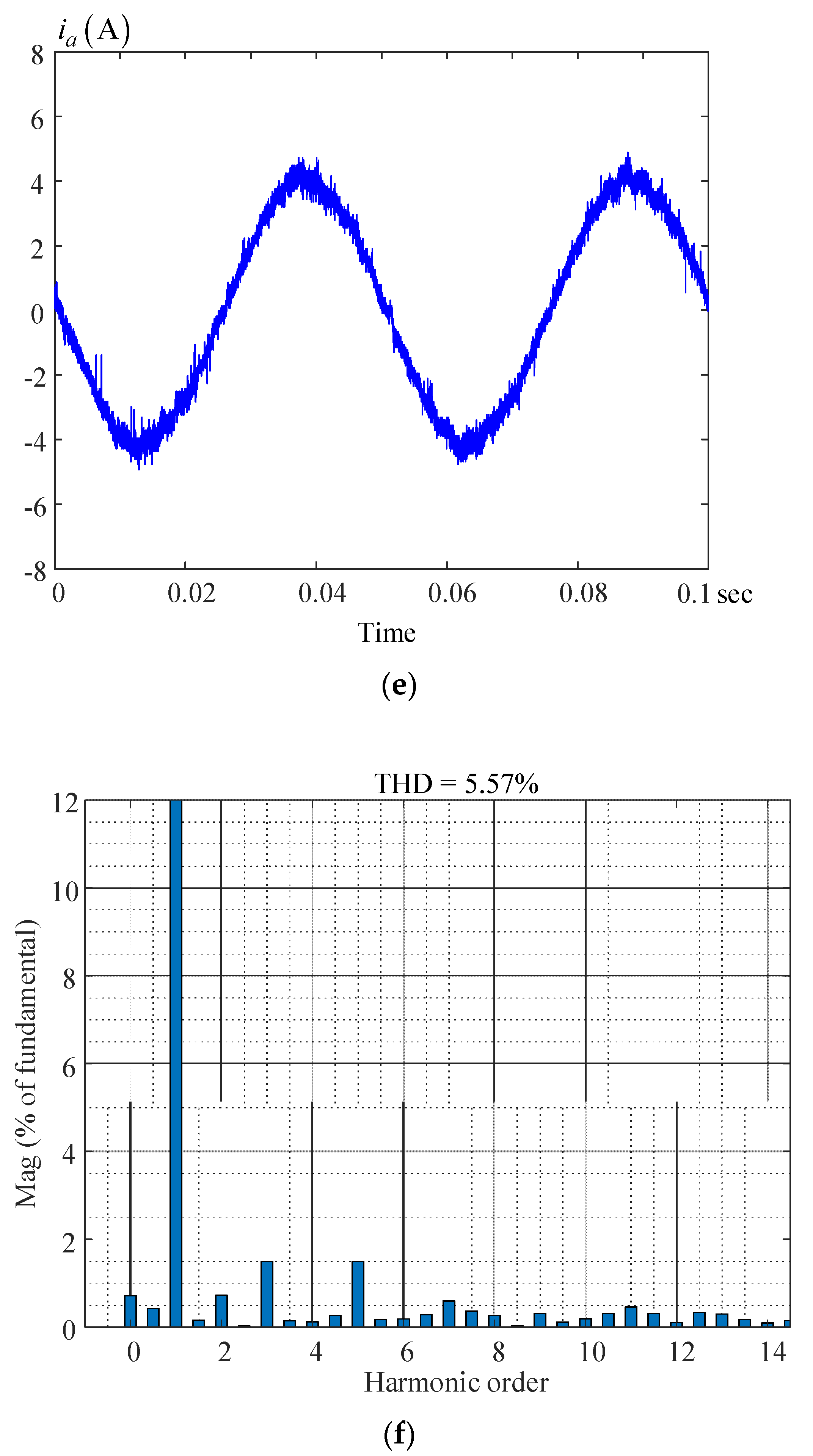

3. Speed-Loop Periodic Controller

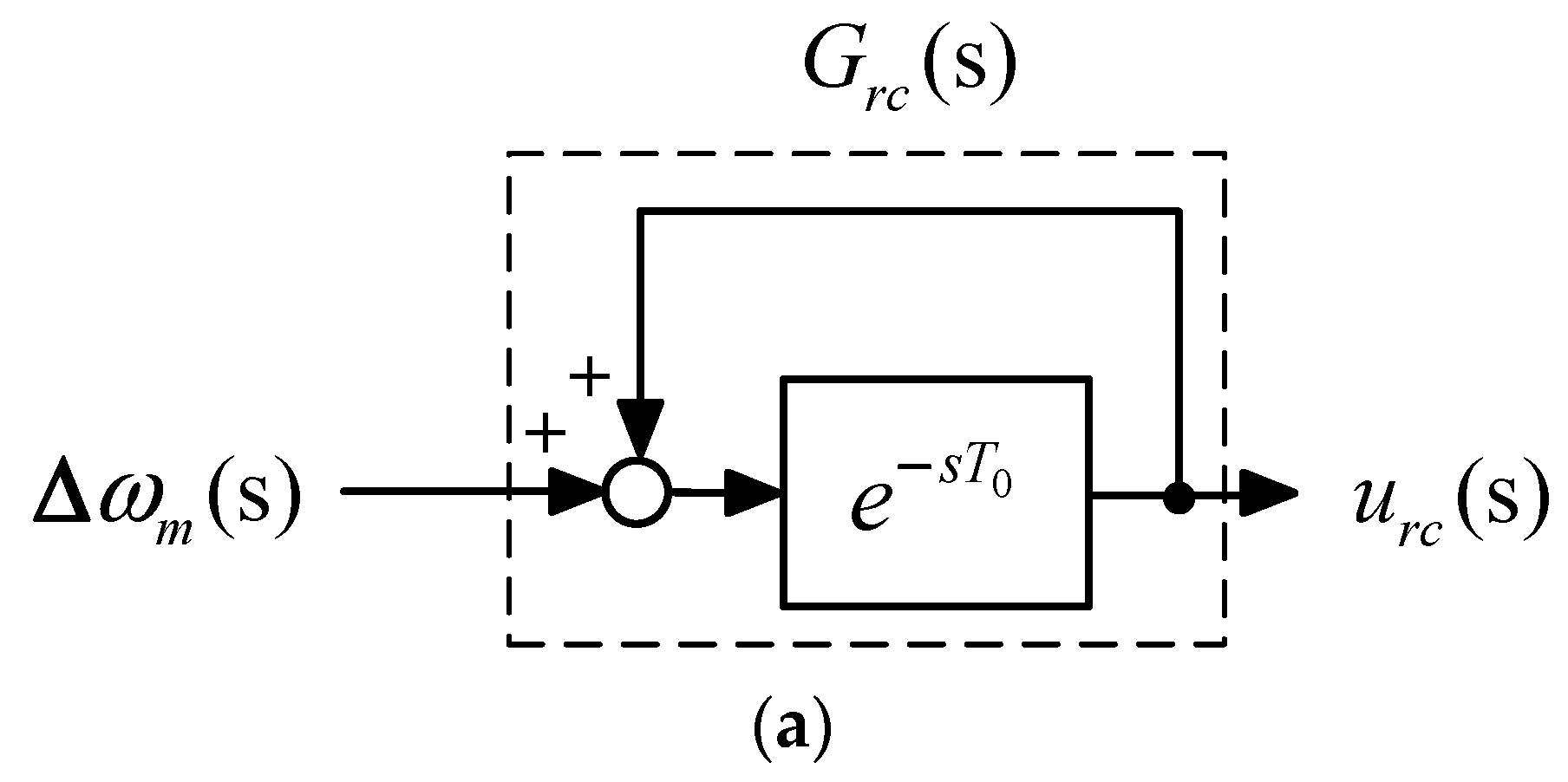

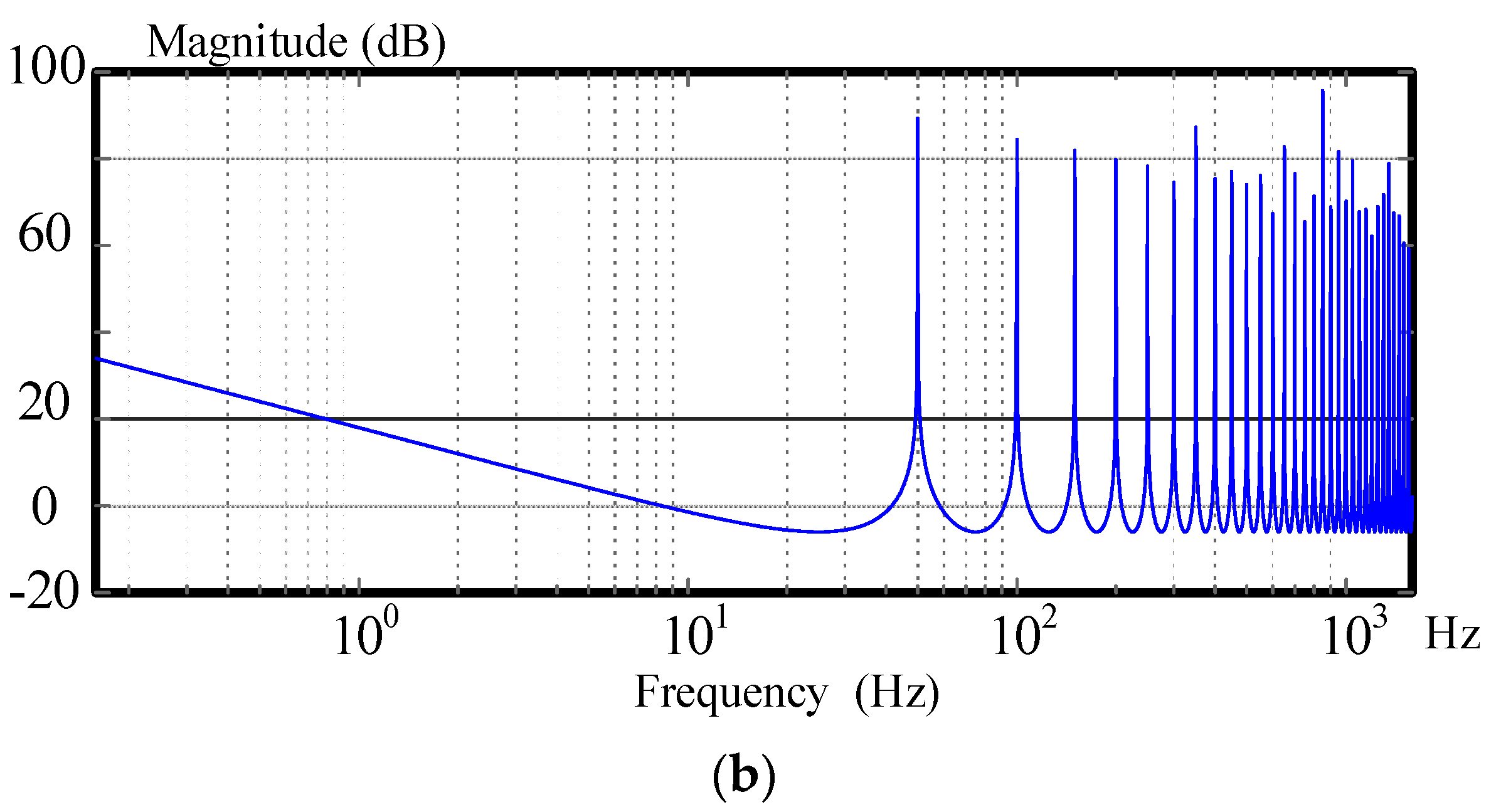

3.1. Classical Periodic Controller

3.1.1. Basic Principle

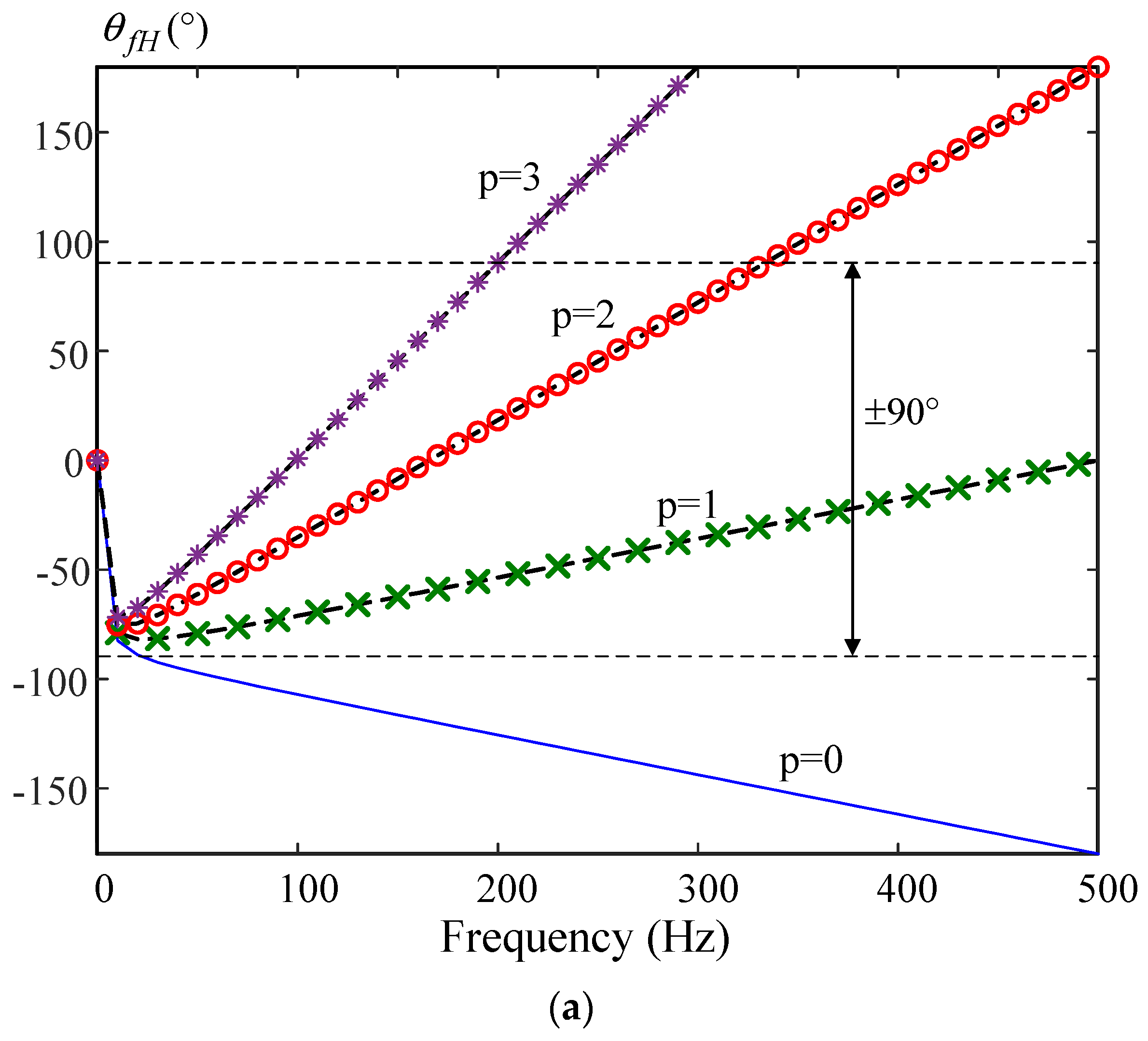

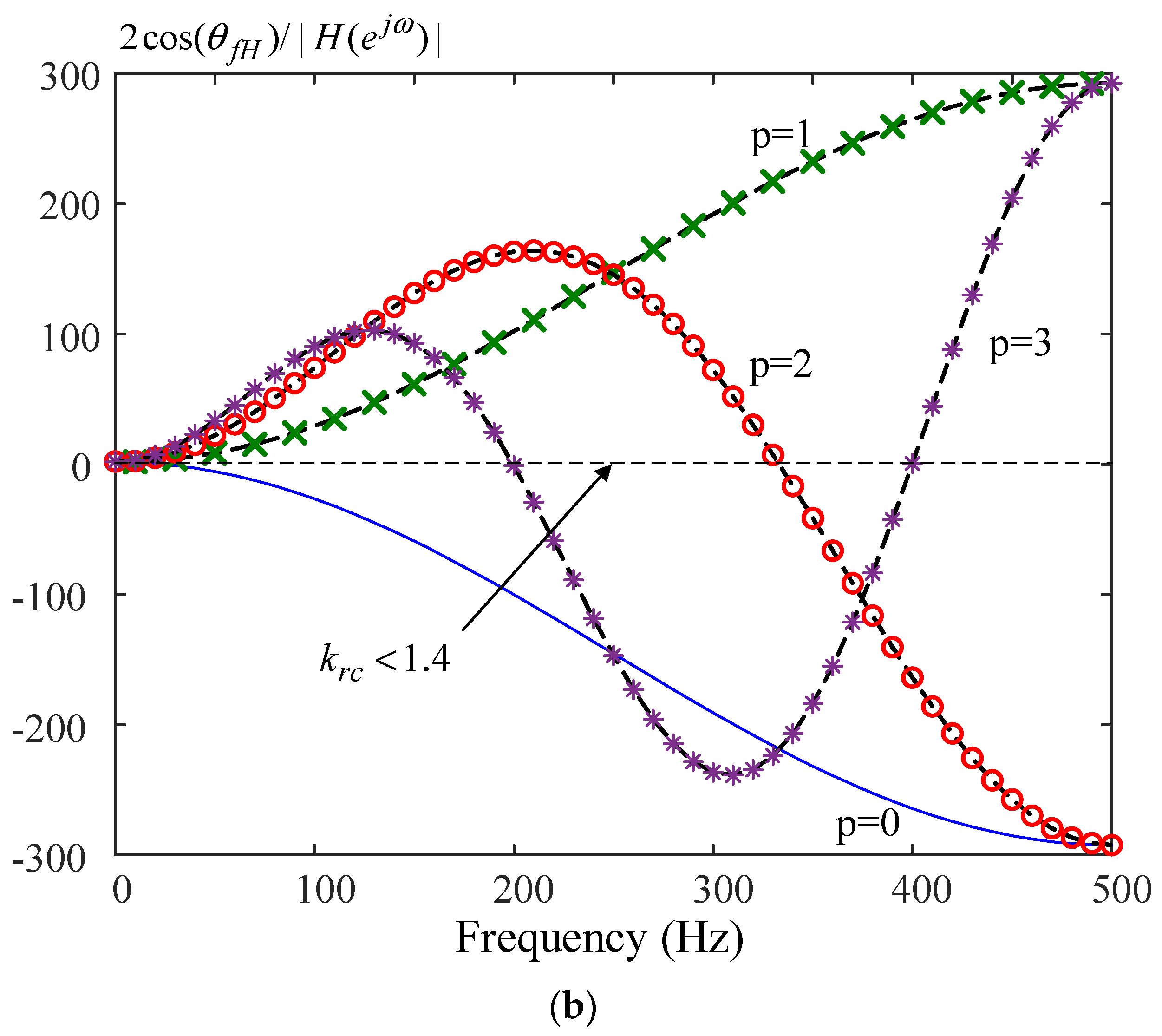

3.1.2. Stability Analysis and Control Parameter Determination

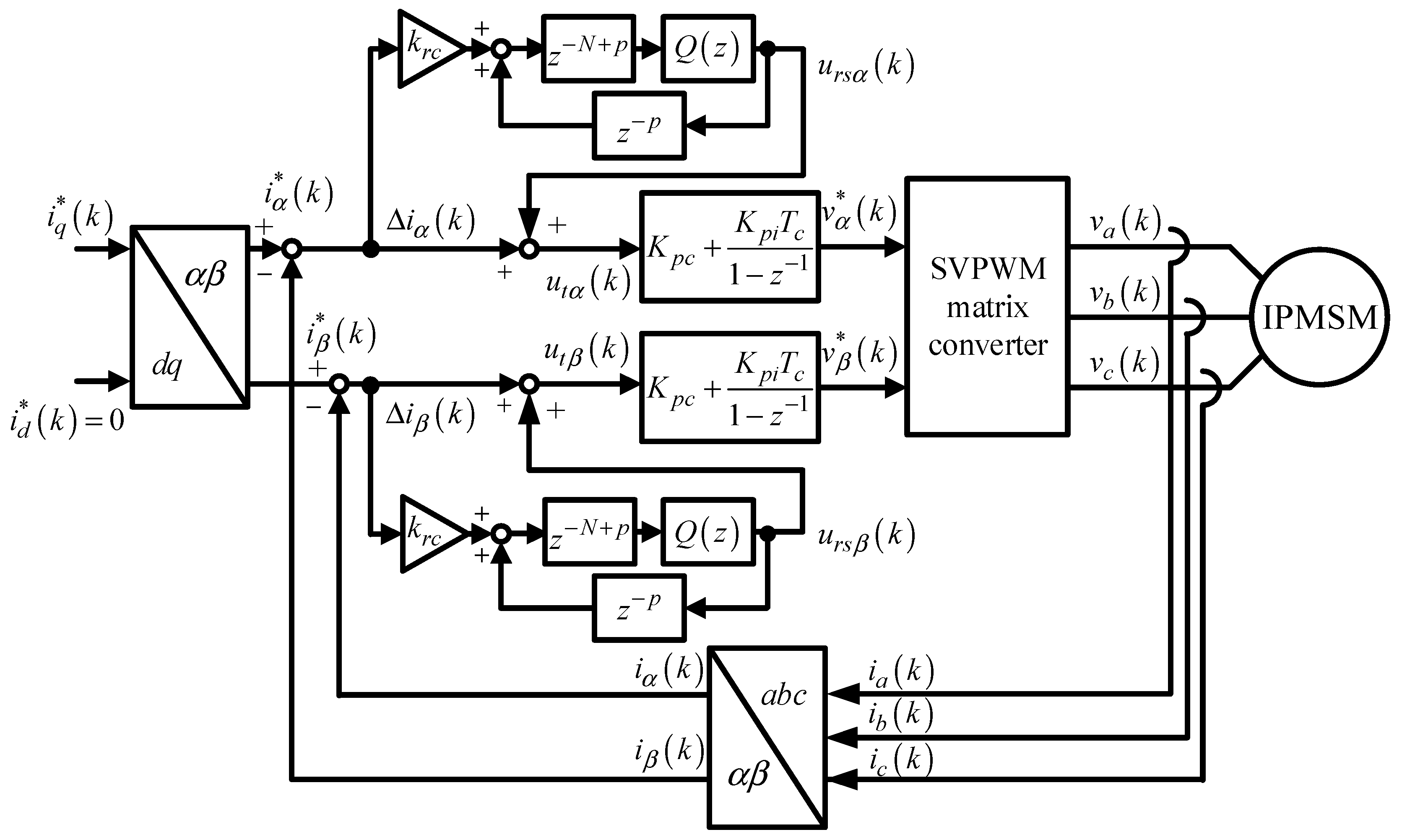

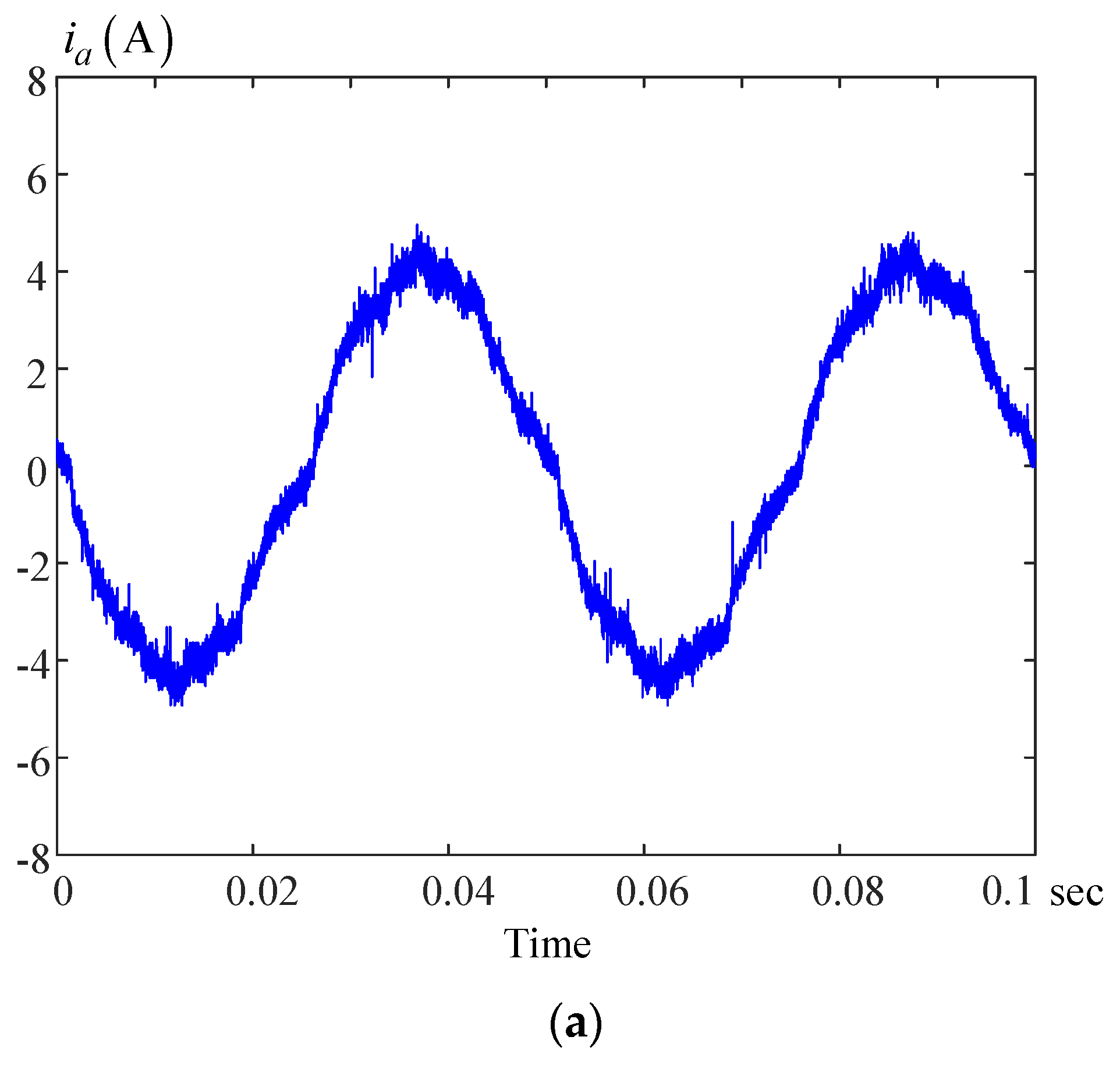

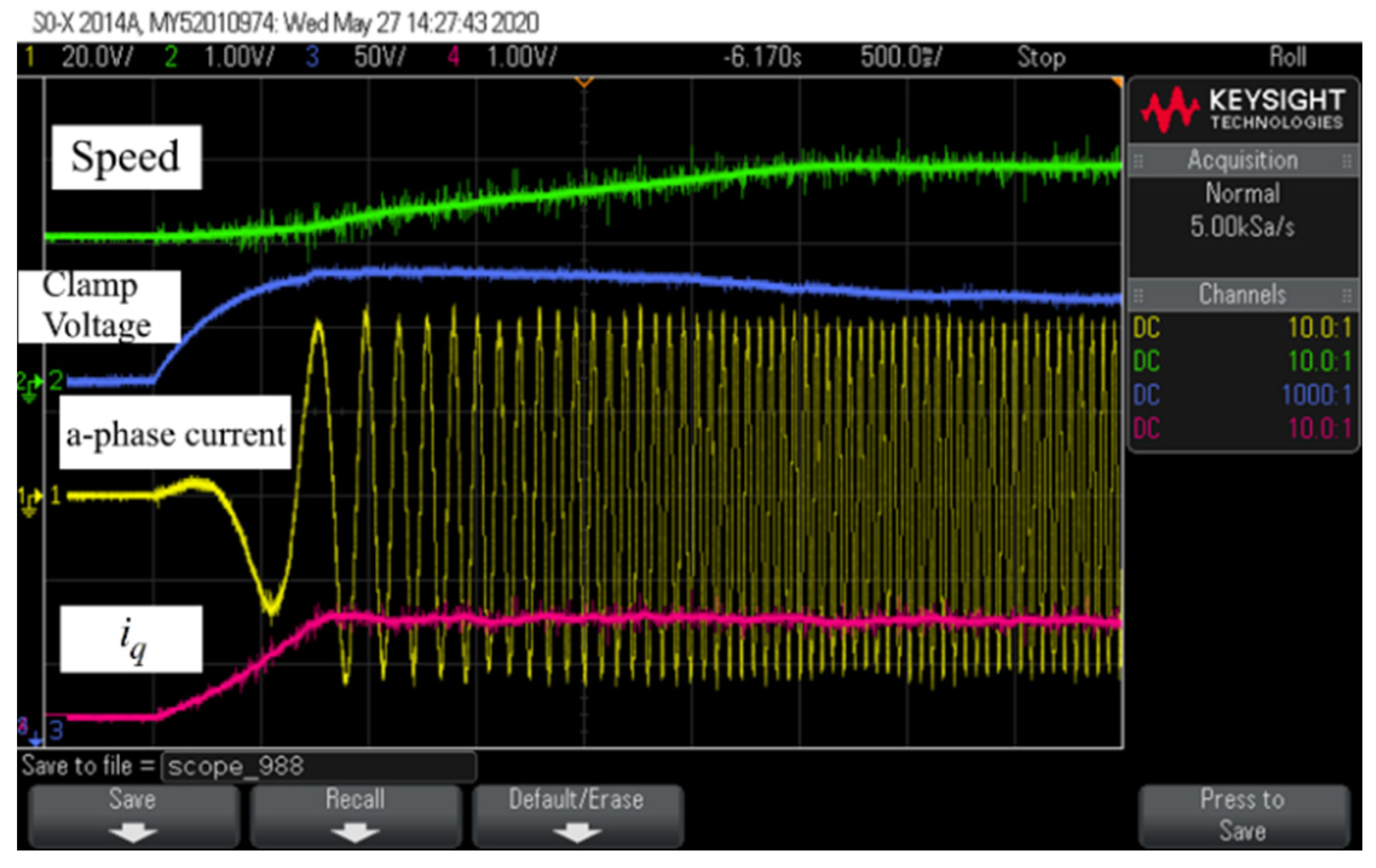

4. Current-Loop Periodic Controller

4.1. Conventional Periodic Current Controller

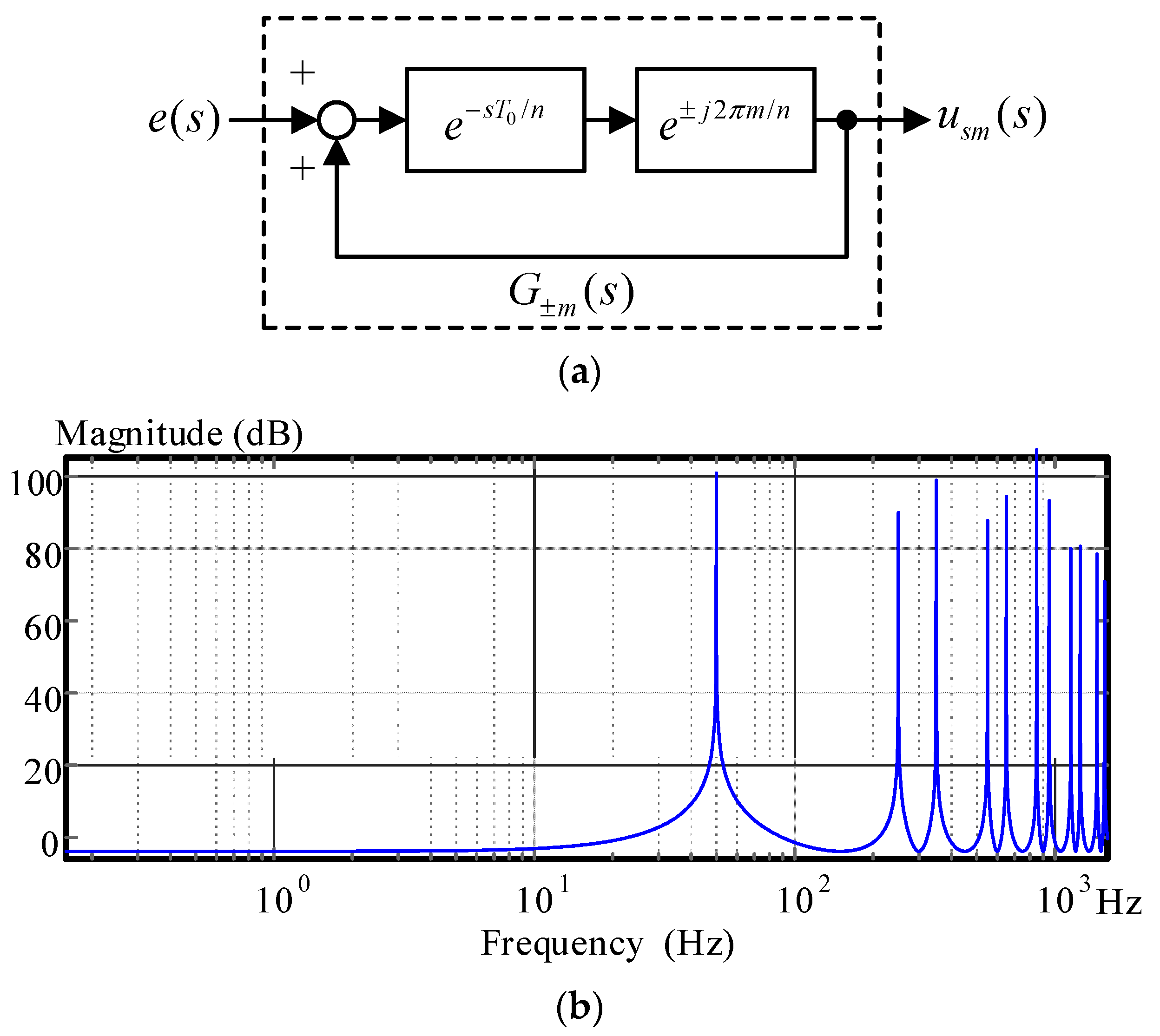

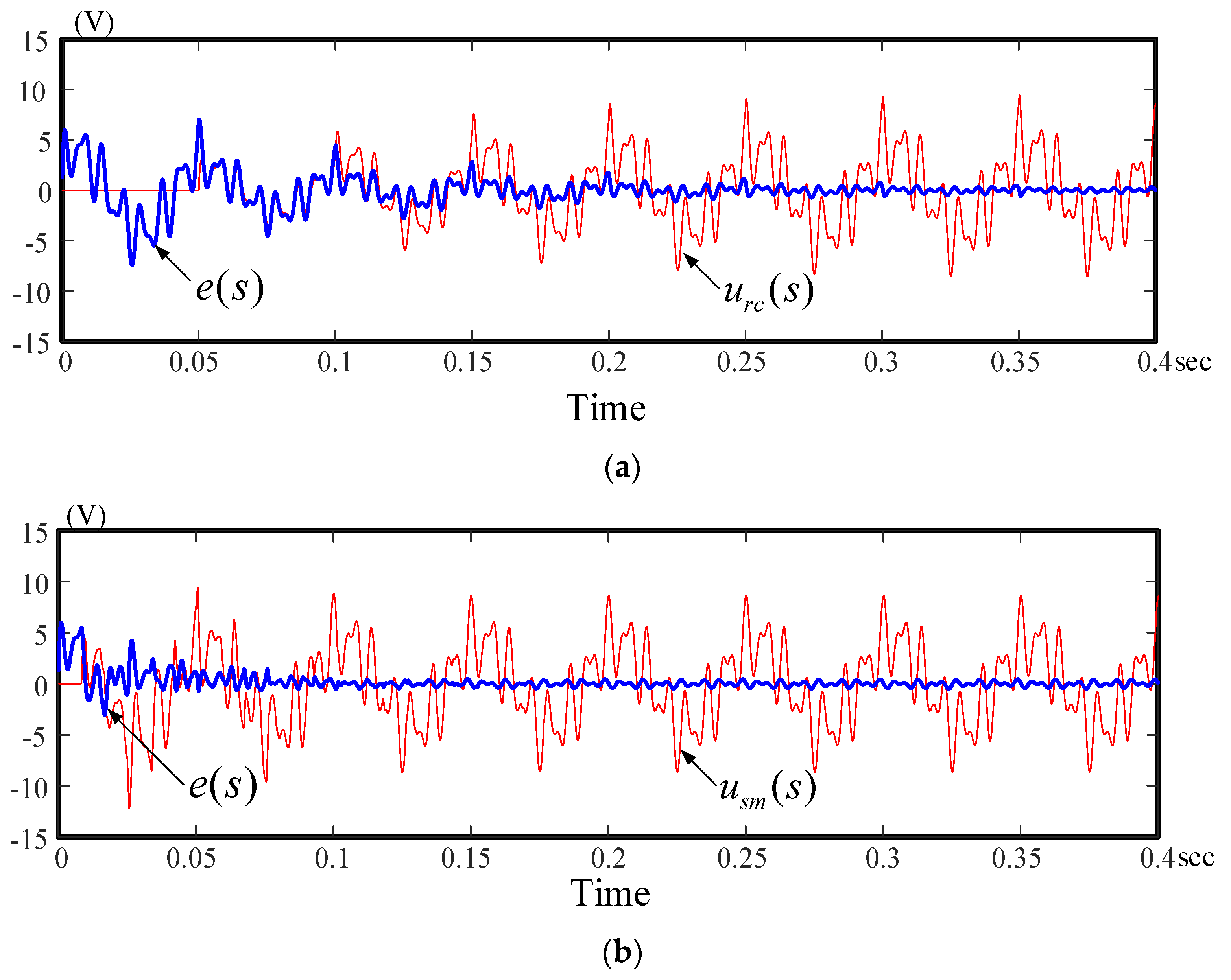

4.2. Current-Loop Selective Harmonic Controller

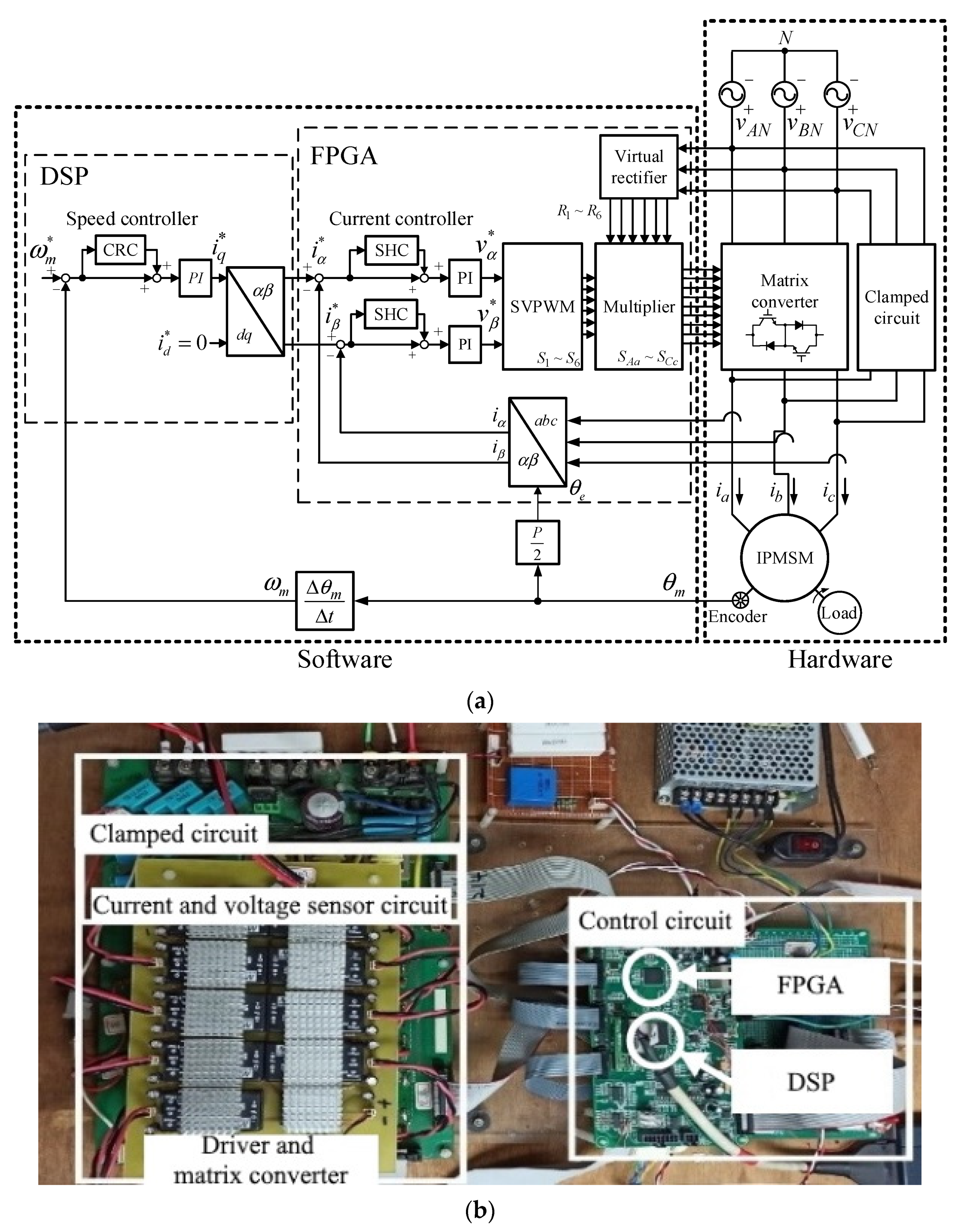

5. Implementation

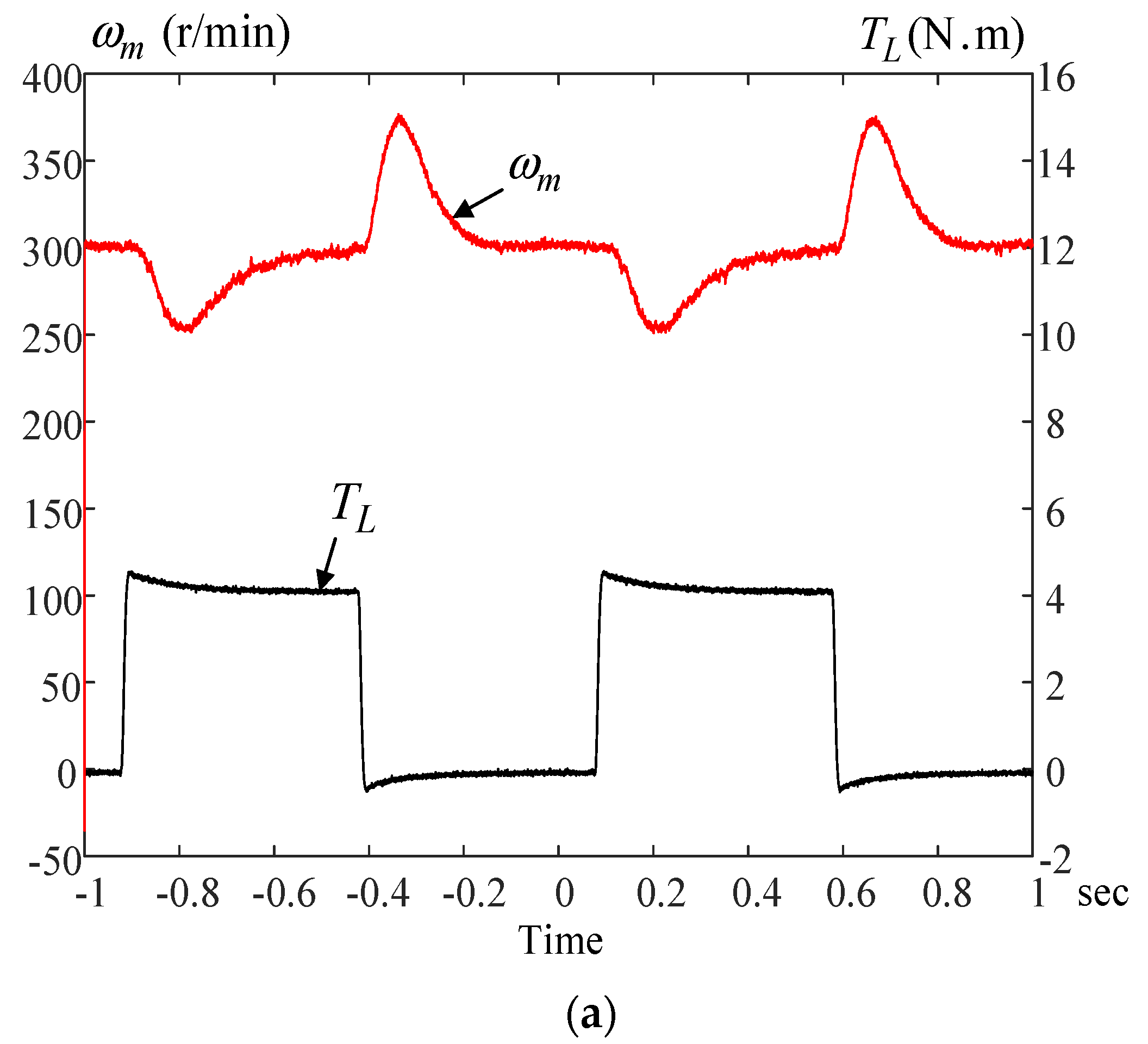

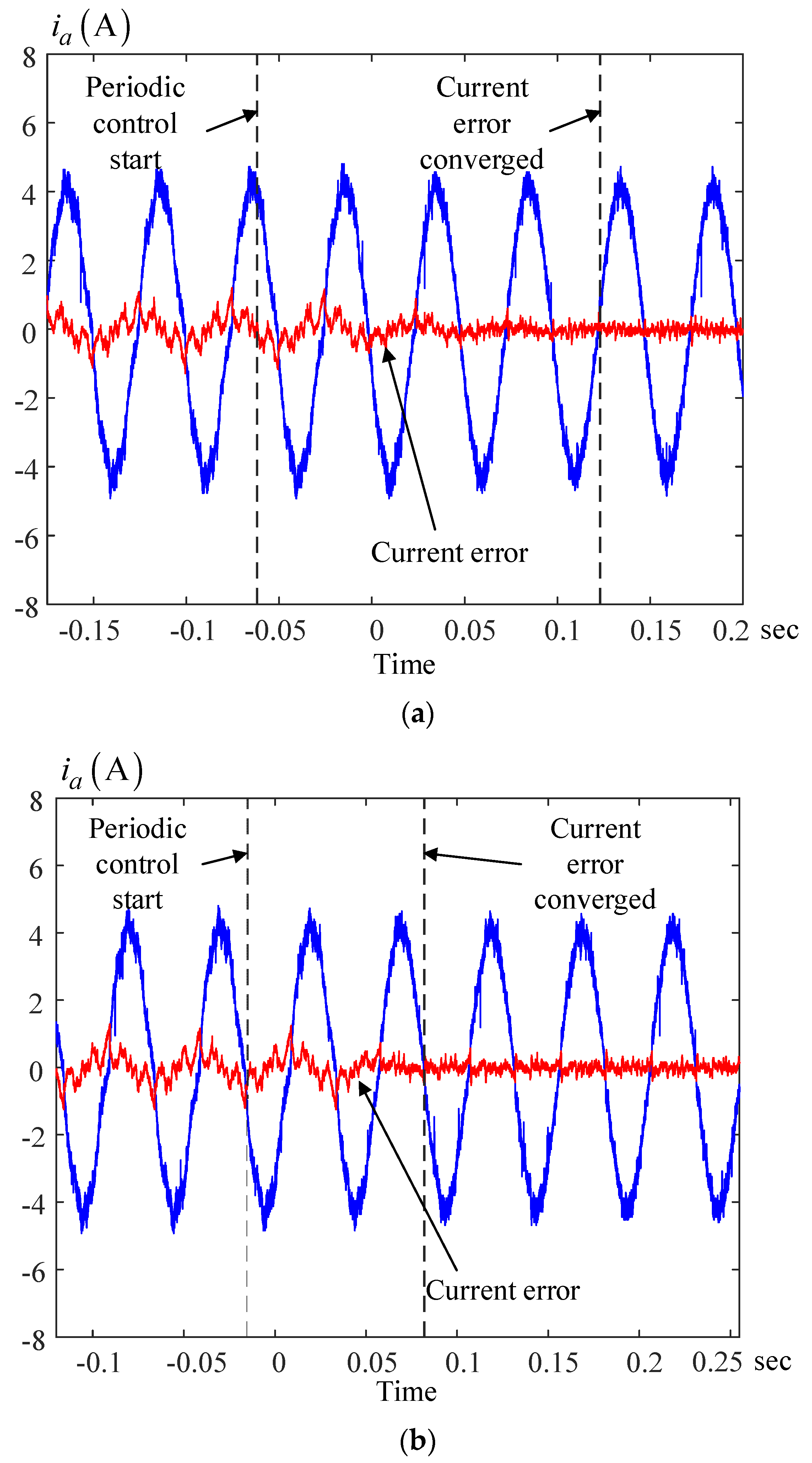

6. Experimental Results

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| bidirectional switches of matrix converter | |

| virtual DC-link voltage | |

| - | input three-phase voltages of matrix converter |

| - | output three-phase voltages of matrix converter |

| bidirectional switches of virtual rectifier | |

| unidirectional switches of virtual inverter | |

| differential operator | |

| , | d-q axis currents of IPMSM |

| , | d-q axis voltages of IPMSM |

| , | d-q axis inductances of IPMSM |

| resistance of IPMSM | |

| pole number of IPMSM | |

| flux linkage of permanent magnet material in IPMSM | |

| total torque | |

| mechanical rotor speed of IPMSM | |

| electrical rotor speed of IPMSM | |

| mechanical rotor position of IPMSM | |

| electrical rotor position of IPMSM | |

| polynomial of the multi sinusoids | |

| different frequencies | |

| L | Laplace transformation |

| control gain | |

| phase-lead angle | |

| s | s-domain |

| z | z-domain |

| resonant frequency | |

| h times of resonant frequency | |

| harmonic order | |

| transfer function of classical periodic controller | |

| period of high-frequency signal | |

| delay times | |

| constant gain of classical periodic controller | |

| transfer function of low-pass filter | |

| Phase-lead compensator | |

| H | closed-loop transfer function using PI controller |

| phase angle | |

| summation of and | |

| parameters of low-pass filter | |

| input of periodic controller | |

| -axis current | |

| -axis voltage | |

| -axis current | |

| -axis voltage | |

| transfer function of selective harmonic periodic controller | |

| combined transfer function | |

| DC gain of selective harmonic periodic controller | |

| proportional gain of PI controller | |

| integral gain of PI controller | |

| pole | |

| mechanical speed error | |

| initial value of mechanical speed error | |

| transfer function of plant | |

| transfer function of PI control | |

| transfer function of an IMP-based resonant controller |

References

- Gao, Q.; Asher, G.M.; Sumner, M.; Empringham, L. Position estimation of a matrix-converter-fed AC PM machine from zero to high speed using PWM excitation. IEEE Trans. Ind. Electron. 2009, 56, 2030–2038. [Google Scholar]

- Chen, Y.; Liu, T.H.; Cuong, N.M. Implementation of sensorless DC-link capacitorless inverter-based interior permanent magnet synchronous motor drive via measuring switching-state current ripples. IET J. 2016, 10, 197–207. [Google Scholar] [CrossRef]

- Dasika, J.D.; Saeedifard, M. A fault-tolerant strategy to control the matrix converter under an open-switch failure. IEEE Trans. Ind. Electron. 2015, 62, 680–691. [Google Scholar] [CrossRef]

- Brunson, C.; Empringham, L.; Lillo, L.D. Open-circuit fault detection and diagnosis in matrix converters. IEEE Trans. Power Elecron. 2015, 30, 2840–2847. [Google Scholar]

- Wheeler, P.W.; Clare, J.; Empringham, L. Enhancement of matrix converter output waveform quality using minimized commutation times. IEEE Trans. Electron. 2004, 51, 240–244. [Google Scholar] [CrossRef]

- Wheeler, P.W.; Clare, J.C.; Empringham, L.; Bland, M.; Apap, M. Gate drive level intelligence and current sensing for matrix converter current commutation. IEEE Trans. Ind. Electron. 2002, 49, 382–389. [Google Scholar] [CrossRef]

- Xiao, D.; Rahman, M.F. Sensorless direct torque and flux controlled IPM synchronous machine fed by matrix converter over a wide speed range. IEEE Trans. Ind. Inform. 2013, 9, 1855–1867. [Google Scholar] [CrossRef]

- Gong, Z.; Zheng, X.; Zhang, H.; Dai, P.; Wu, X.; Li, M. A QPR-based low-complexity input current control strategy for the indirect matrix cinverters with unity grid power factor. IEEE Access 2019, 2019, 38766–38777. [Google Scholar] [CrossRef]

- Wisniewski, R.; Bazydlo, G.; Szczesniak, P.; Wojnakowski, M. Petri net-based specification of cyber-physical systems oriented to control direct matrix converters with space vector modulation. IEEE Access 2019, 2019, 23407–23420. [Google Scholar] [CrossRef]

- Kumar, V.; Joshi, R.R.; Bansal, R.C. Optimal control of matrix-converter-based WECS for performance enhancement and efficiency optimization. IEEEE Trans. Energy Conver. 2009, 24, 264–273. [Google Scholar] [CrossRef]

- Xia, C.; Yan, Y.; Song, P.; Shi, T. Voltage disturbance rejection for matrix converter-based PMSM drive system using internal model control. IEEE Trans. Ind. Electron. 2012, 59, 361–372. [Google Scholar]

- Yao, W.; Liu, J.; Lu, Z. Distributed control for the modular multilevelmatrix converter. IEEE Trans. Power Electron. 2019, 34, 3775–3788. [Google Scholar] [CrossRef]

- Monteiro, J.; Silva, J.F.; Pinto, S.F.; Palma, J. Linear and sliding-mode controller matrix converter-base unified power controllers. IEEE Trans. Power Electron. 2014, 29, 3357–3367. [Google Scholar]

- Formentini, A.; Trentin, A.; Marchesoni, M.; Zanchetta, P.; Wheeler, P. Speed finite control set model predictive control of a PMSM fed by matrix converter. IEEE Trans. Ind. Electron. 2015, 62, 6786–6796. [Google Scholar] [CrossRef]

- Shigeuchi, K.; Xu, J.; Shimosato, N.; Sato, Y. A modulation method to realize sinusoidal line current for bidirectional isolated three-phase AC/DC dual-active-bridge converter based on matrix converter. IEEE Trans. Power Electron. 2020, 36, 6015–6029. [Google Scholar] [CrossRef]

- Lei, J.; Feng, S.; Zhou, B.; Nguyen, H.N.; Zhao, J.; Chen, W. A simple modulation scheme with zero common-mode voltage and improved efficiency for direct matrix converter-fed PMSM drives. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 3712–3722. [Google Scholar] [CrossRef]

- Szczepankowski, P.; Wheeler, P.; Bajdecki, T. Application of analytic signal and smooth interpolation in pulsewidth modulation for conventional matrix converters. IEEE Trans. Ind. Electron. 2020, 67, 10011–10023. [Google Scholar] [CrossRef]

- Li, Y.; Qiu, L.; Zhi, Y.; Yan, G.; Zhang, J.; Ma, J.; Fang, Y. An overmodulation strategy for matrix converter under unbalanced input voltages. IEEE Access 2021, 2021, 2345–2356. [Google Scholar] [CrossRef]

- Deng, W.; Li, S. Direct torque control of matrix converter-fed PMSM drives using multidimensional switching table for common-mode voltage minimization. IEEE Trans. Power Electron. 2021, 36, 683–690. [Google Scholar] [CrossRef]

- Fang, F.; Tian, H.; Li, Y. Coordination control of modulation index and phase shift angle for current stress reduction in isolated AC-DC matrix converter. IEEE Trans. Power Electron. 2021, 36, 4585–4596. [Google Scholar] [CrossRef]

- Urrutia, M.; Cardenas, R.; Clare, J.C.; Watson, A. Circulating current control for the modular multilevel matrix converter based on model predictive control. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6069–6085. [Google Scholar] [CrossRef]

- Mir, T.N.; Singh, B.; Bhat, A.H. FS-MPC-Based speed sensorless control of matrix converter fed induction motor drive with zero common mode voltage. IEEE Trans. Ind. Electron. 2021, 68, 9185–9195. [Google Scholar] [CrossRef]

- Fang, F.; Tian, H.; Li, Y. Finite control set model predictive control for AC-DC matrix converter with virtual space vectors. IEEE Jour. Emerg. Select. Top. Power Electron. 2021, 9, 616–628. [Google Scholar] [CrossRef]

- Trzynadlowski, A.M. Introduction to Modern Power Electronics, 2nd ed.; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Rogers, E.; Galkowski, K.; Owens, D.H. Control Systems Theory and Applications for Linear Repetitive Processes; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Goodwin, G.C.; Graebe, S.F.; Salgado, M.E. Control System Design; Prentice-Hall: Hoboken, NJ, USA, 2001. [Google Scholar]

- Zhou, K.; Wang, D.; Yang, Y.; Blaabjerg, F. Periodic Control of Power Electronic Converters; The Institute of Engineering and Technology: London, UK, 2016. [Google Scholar]

- Unsalan, C.; Tar, B. Digital System Design with FPGA-Implementation Using Verilog and VHDL; McGraw Hill: New York, NY, USA, 2017. [Google Scholar]

- Toliyat, H.A.; Compbell, S. DSP-Based Electromechanical Motion Control; CRC Press: New York, NY, USA, 2004. [Google Scholar]

| Authors | Reference Numbers | Control Methods | Published Years |

|---|---|---|---|

| Kumar et al. | [10] | Optimal control | 2009 |

| Xia et al. | [11] | Internal model control | 2012 |

| Monteiro et al. | [13] | Sliding mode control | 2014 |

| Formentini et al. | [14] | Predictive control | 2015 |

| Gong et al. | [8] | Quasi-proportional resonance | 2019 |

| Urrutia et al. | [21] | Predictive control | 2021 |

| Mir et al. | [22] | Predictive control | 2021 |

| Fang et al. | [23] | Predictive control | 2021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.-H.; Chang, K.-H.; Li, J.-H. Design and Implementation of Periodic Control for a Matrix Converter-Based Interior Permanent Magnet Synchronous Motor Drive System. Energies 2021, 14, 8073. https://doi.org/10.3390/en14238073

Liu T-H, Chang K-H, Li J-H. Design and Implementation of Periodic Control for a Matrix Converter-Based Interior Permanent Magnet Synchronous Motor Drive System. Energies. 2021; 14(23):8073. https://doi.org/10.3390/en14238073

Chicago/Turabian StyleLiu, Tian-Hua, Kai-Hsiang Chang, and Jia-Han Li. 2021. "Design and Implementation of Periodic Control for a Matrix Converter-Based Interior Permanent Magnet Synchronous Motor Drive System" Energies 14, no. 23: 8073. https://doi.org/10.3390/en14238073

APA StyleLiu, T.-H., Chang, K.-H., & Li, J.-H. (2021). Design and Implementation of Periodic Control for a Matrix Converter-Based Interior Permanent Magnet Synchronous Motor Drive System. Energies, 14(23), 8073. https://doi.org/10.3390/en14238073