Application of Artificial Intelligence Technologies to Assess the Quality of Structures

Abstract

:1. Introduction

2. Related Works

3. Algorithm for Automating Metallographic Quality Control of Metals

- Step 1.

- Formation of an image of the metal microstructure in digital form f(x,y).

- Step 2.

- The image of the metal microstructure is analyzed. At the second stage, preliminary processing and analysis of the image of the metal microstructure is carried out. Many quantitative characteristics of the metal under study are formed, as well as many of its qualitative characteristics:

- Step 3.

- The definition of the metal grade is performed. At the third stage, based on the chemical composition of the metal and the obtained quantitative characteristics, the metal grade mr is determined.

- Step 4.

- The determination of the properties of the metal is performed based on the sets of its characteristics N, Q, and existing defects.

- Step 5.

- A conclusion on the metal for compliance with the requirements is formed, and the group of metal use is determined

- Step 6.

- Sending the result of metallographic analysis to the workshop for further decision-making.

4. Experimental Studies of the Developed Tools

- (1)

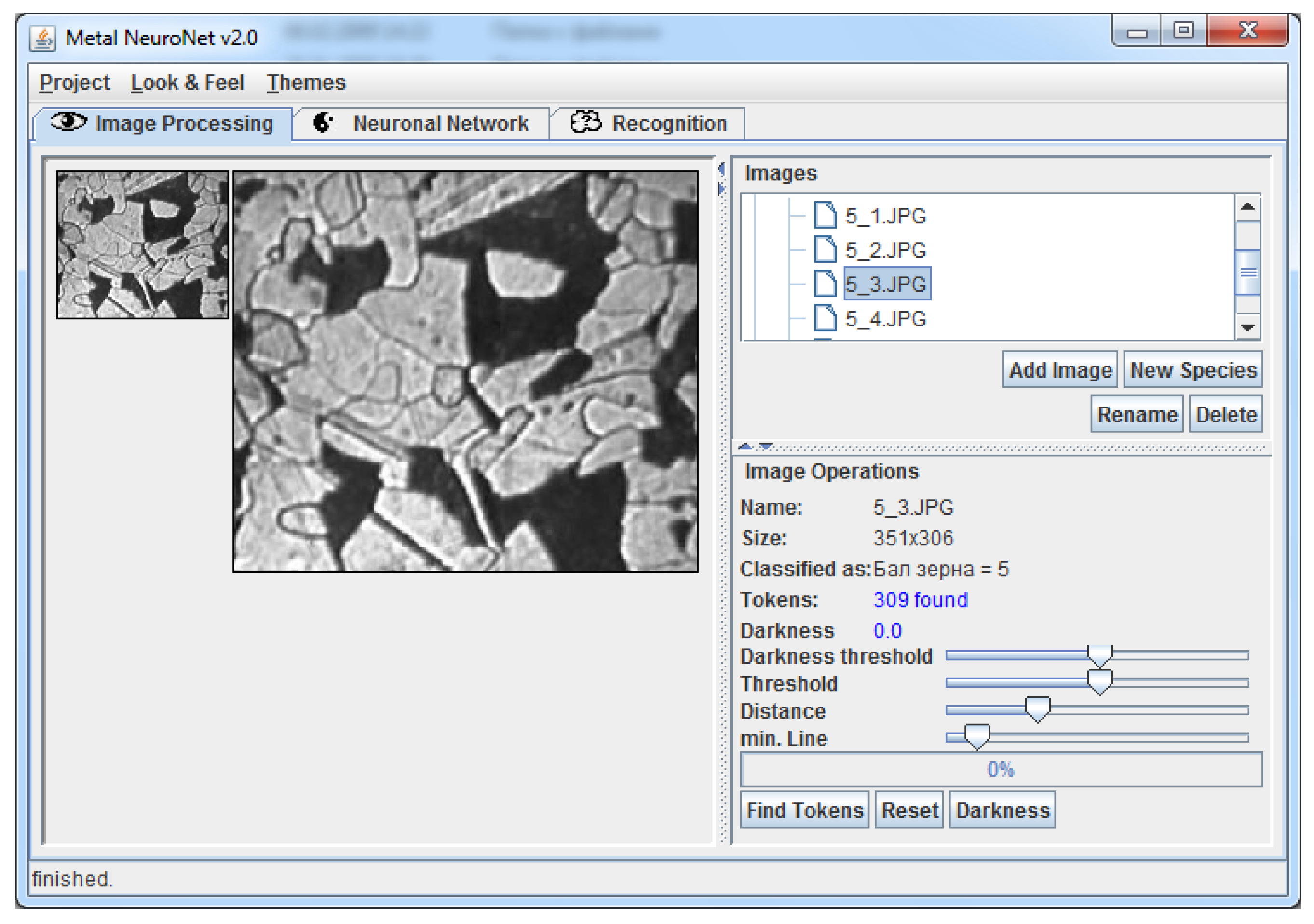

- setting by the user of the type of analysis of microstructures of alloys;

- (2)

- input of the image of the metal microstructure;

- (3)

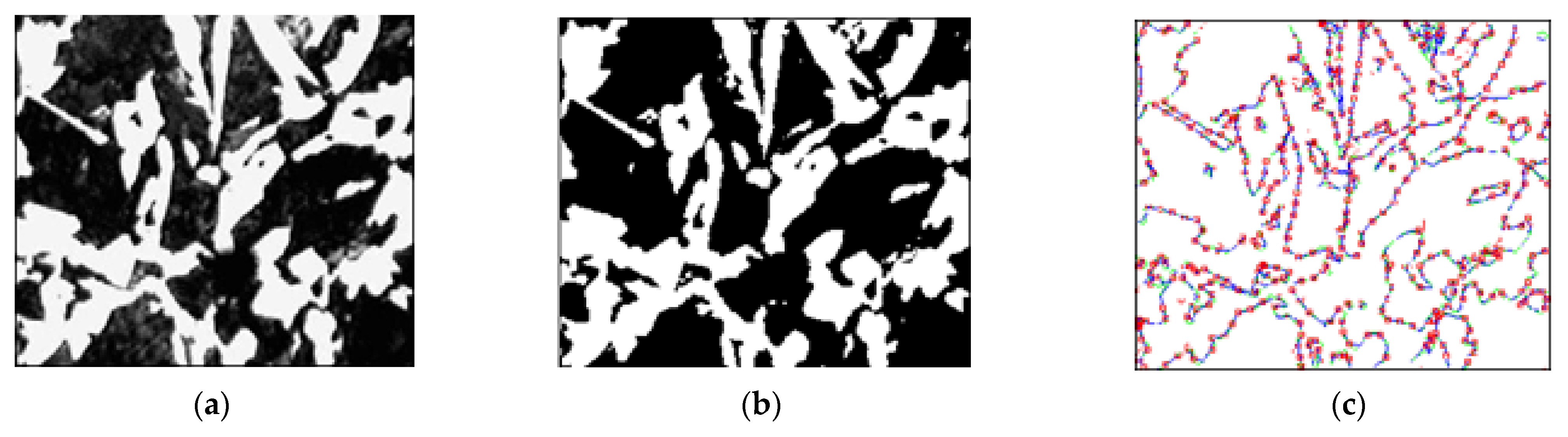

- preliminary processing of the image;

- (4)

- quantitative assessment of the metal;

- (5)

- determination of the grade and properties of the metal;

- (6)

- formation of a conclusion and producing recommendations regarding the analyzed metal sample;

- (7)

- Sending the analysis results to the workshop.

- (1)

- user input of the base of reference images of metal microstructures;

- (2)

- the choice of the architecture of the neural network for the recognition of images of metal microstructures;

- (3)

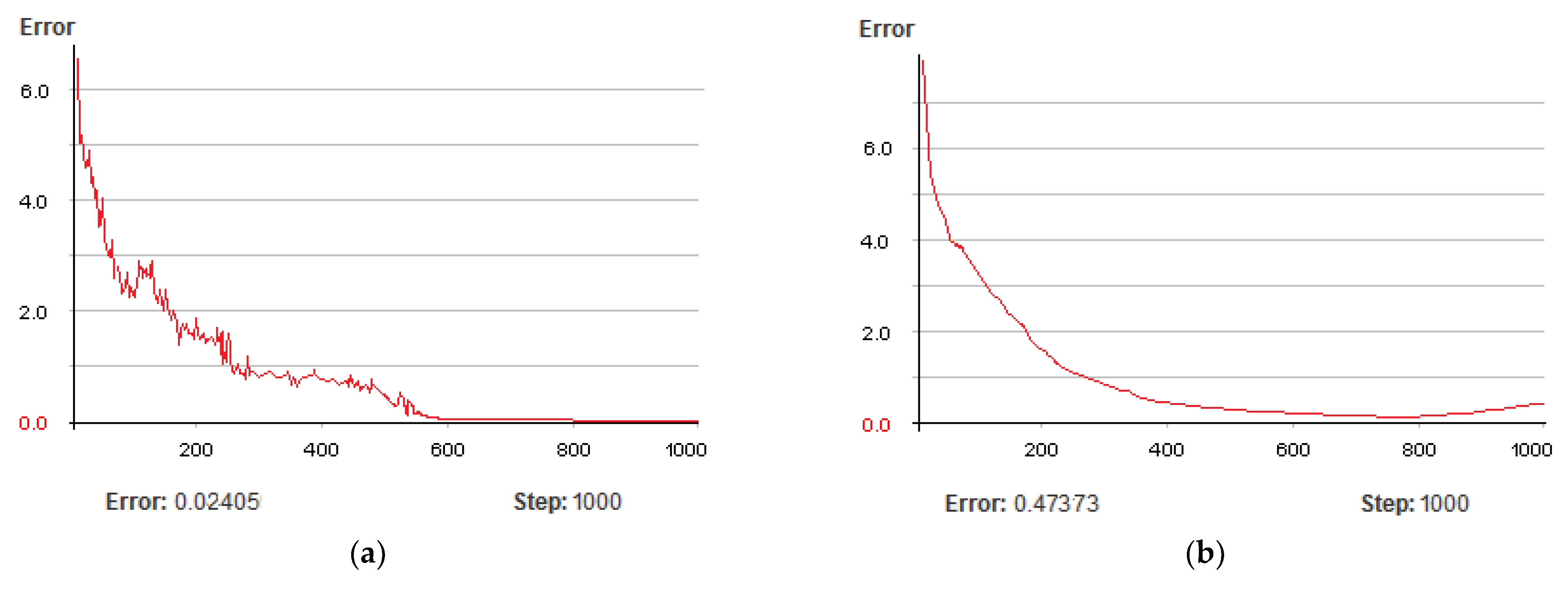

- learning a neural network based on the introduced standards of metal microstructures;

- (4)

- saving the parameters of the learnt neural network for further recovery on demand and analysis based on this network.

5. Discussion

6. Conclusions

- An algorithm for the automation of diagnostics of the state of metals has been proposed and described. The proposed algorithm implies the use of neural networks and precedent theory, which allows, due to the learning property, to adapt the proposed metallographic analysis tools for any enterprise.

- Developed software for metallographic images recognition. The developed software makes it possible to automatically determine the grade and quantitative characteristics of metals.

- The use of the developed tools made it possible to reduce the analysis time of metallographic images by three times, as well as to increase the accuracy of determining the quantitative characteristics of metals.

Author Contributions

Funding

Conflicts of Interest

References

- Smallman, R.E.; Ashbee, K.H.G. Modern Metallography: The Commonwealth and International Library: Metallurgy Division; Elsevier: Amsterdam, The Netherlands, 2013; 224p. [Google Scholar]

- Gordon, Y.; Kumar, S.; Freislich, M.; Yaroshenko, Y. The modern technology of iron and steel production and possible ways of their development. Steel Transl. 2015, 45, 627–634. [Google Scholar] [CrossRef] [Green Version]

- Colpaert, H. Metallography of Steels: Interpretation of Structure and the Effects of Processing; ASM International: Russell Township, OH, USA, 2018; 699p. [Google Scholar]

- Martyushev, N.; Skeeba, V. The method of quantitative automatic metallographic analysis. J. Phys. Conf. Ser. 2017, 803, 012094. [Google Scholar] [CrossRef]

- DeCost, B.L.; Holm, E.A. A computer vision approach for automated analysis and classification of microstructural image data. Comput. Mater. Sci. 2015, 110, 126–133. [Google Scholar] [CrossRef] [Green Version]

- Bezyazychnyi, V.F.; Palamar, I.N.; Azikov, N.S. Automation of Analysis of the Structure of a Material with Details Based on Controlled Functional Systems. J. Mach. Manuf. Reliab. 2020, 49, 341–346. [Google Scholar] [CrossRef]

- Wu, W.-H.; Lee, J.-C.; Wang, Y.-M. A Study of Defect Detection Techniques for Metallographic Images. Sensors 2020, 20, 5593. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Liu, Y.; Liu, S.; Liu, F.; Chen, Y. Framework of Specific Description Generation for Aluminum Alloy Metallographic Image Based on Visual and Language Information Fusion. Symmetry 2020, 12, 771. [Google Scholar] [CrossRef]

- Niezgoda, S.R.; Kanjarla, A.K.; Kalidindi, S.R. Novel microstructure quantification framework for databasing, visualization, and analysis of microstructure data. Integr. Mater. Manuf. Innov. 2013, 2, 54–80. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Ma, L.; Yao, Y. Segmentation of casting defect regions for the extraction of microstructural properties. Eng. Appl. Artif. Intell. 2019, 85, 150–163. [Google Scholar] [CrossRef]

- Long, J.; Shelhamer, E.; Darrell, T. Fully convolutional networks for semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 3431–3440. [Google Scholar]

- Azimi, S.M.; Britz, D.; Engstler, M.; Fritz, M.; Mücklich, F. Advanced steel microstructure classification by deep learning methods. Sci. Rep. 2018, 8, 2128. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Ban, X.; Huang, H.; Chen, Y.; Liu, W.; Zhi, Y. Deep learning-based image segmentation for al-la alloy microscopic images. Symmetry 2018, 10, 107. [Google Scholar] [CrossRef] [Green Version]

- De Albuquerque, V.H.; Silva, C.C.; Menezes, T.I.; Farias, J.P.; Tavares, J.M. Automatic evaluation of nickel alloy secondary phases from SEM images. Microsc. Res. Tech. 2011, 74, 36–46. [Google Scholar] [CrossRef] [PubMed]

- Vijayalakshmi, D. Malaya Kumar Nath Taxonomy of Performance Measures for Contrast Enhancement. Pattern Recognit. Image Anal. 2020, 30, 691–701. [Google Scholar] [CrossRef]

- Dougherty, G. Pattern Recognition and Classification; Springer: Berlin/Heidelberg, Germany, 2013; 206p. [Google Scholar]

- Kenji, S. Artificial Neural Networks: Architectures and Applications; IntechOpen Limited 5 Princes Gate Court; SW7 2QJ: London, UK, 2013; 264p. [Google Scholar]

- Suresh Kumar, P.; Behera, H.S.; Anisha Kumari, K.; Nayak, J.; Naik, B. Advancement from neural networks to deep learning in software effort estimation: Perspective of two decades. Comput. Sci. Rev. 2020, 38, 100288. [Google Scholar] [CrossRef]

- Richter, M.M.; Weber, R. Case-Based Reasoning; Springer: Berlin/Heidelberg, Germany, 2013; 546p. [Google Scholar]

- Alqurashi, T.; Wang, W. Clustering ensemble method. Int. J. Mach. Learn. Cybern. 2019, 10, 1227–1246. [Google Scholar] [CrossRef] [Green Version]

- Emelianov, V.; Emelianova, N.; Zhilenkov, A.; Chernyi, S. Application of Information Technologies and Programming Methods of Embedded Systems for Complex Intellectual Analysis. Entropy 2021, 23, 94. [Google Scholar] [CrossRef] [PubMed]

- Yemelyanov, V.; Chernyi, S.; Yemelyanova, N.; Varadarajan, V. Application of neural networks to forecast changes in the technical condition of critical production facilities. Comput. Electr. Eng. 2021, 93, 107225. [Google Scholar] [CrossRef]

- Kramar, V.; Rodkina, A.; Ivanova, O.; Chernyi, S.; Zinchenko, A. Analysis Technology and Cathodic Protection for Hull Structures of Ships and Floating Facilities. Inventions 2021, 6, 74. [Google Scholar] [CrossRef]

| Standard and Characteristics of the Alloy | Structure of the Neural Network | Recognition Error | Optimal Number of the Learning Epochs | Total Amount of the Alloy Analyzed Images | A Number of Correctly Recognized Images | |

|---|---|---|---|---|---|---|

| GOST 5639-82 | Grain amount | 510-170-10 | 0.0243 | 800 | 231 | 224 |

| GOST 8233-56 | Ratio Ferrite/Perlite | 375-125-10 | 0.0384 | 950 | 121 | 119 |

| Ratio Martensite/Troostite | 375-125-10 | 0.0351 | 1300 | 121 | 118 | |

| Size of carbide network | 210-70-6 | 0.0259 | 850 | 121 | 118 | |

| GOST 1778-70 | Grade of line nitrides | 210-70-5 | 0.0163 | 700 | 142 | 134 |

| Grade of sulphides | 210-70-5 | 0.0095 | 850 | 142 | 133 | |

| ASTME1382 | Size of ferrite grain | 600-200-19 | 0.0573 | 1300 | 231 | 217 |

| Types of Steel | Values of the Metal Characteristics—Xi (the Situation to Be Solved—si), | The Number of the Use Case in the Use Case Base | Steel Grade —the Situation to Be Solved is ri |

|---|---|---|---|

| Carbon Tool Steel | 0.7C; 0.18Cr; 0.2Mn; 0.024S; 0.018P | 25 | У7(C 70W2) |

| Carbon Tool Steel | 0.87C; 0.22Cr; 0.27Mn; 0.02S; 0.023P | 33 | У9A(C 70W1) |

| Structural Steel | 0.1C; 0.09Cr; 0.35Mn; 0.01S; 0.03P | 12 | 08кп(A 622) |

| Structural Steel | 0.2C; 0.24Cr; 0.6Mn; 0.02S; 0.02P | 19 | 20пc(A 29 1020) |

| Structural Steel | 0.09C; 0.2 Si; 0.43 Mn; 0.03S; 0.03P | 3 | Cт1cп(A192 Gr A) |

| Structural Steel | 0.18C; 0.2Cr; 0.3Mn; 0.03Si; 0.04S | 6 | Cт3кп (A 107) |

| Microstructure | Processing Time, Min | Structural Component | Carbon, % (C) | The Form of Inclusion | Non-Metal Inclusions | Resistance to Rupture, MPa |

|---|---|---|---|---|---|---|

| <1 | Ferrite, Perlite | 0.21 | Grain | Oxides (amount = 2) | 520 |

| <1 | Ferrite, Perlite | 0.53 | Grain | Oxides (amount = 3) | 540 |

| <1 | Ferrite, Perlite | 0.78 | Grain | Oxides (amount = 3) | 450 |

| Evaluated Metallographic System | Average Time of Metallographic Image Analysis (Including Image Recognition Time), Min | Deviation of Grain Parameters in the Analyzed Metallographic Image, % |

|---|---|---|

| Metallographic analysis system prior to the implementation of the proposed tools (based on classical approaches for recognizing images of metal microstructures) | 18 | 5–10 |

| Upgraded metallographic system after the implementation of the proposed tools (based on neural networks and precedent theory) | 5 | 3–4 |

| Existing metallographic systems (SPECTR MET, SIAMS, etc.) | 7 | 5–8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhilenkov, A.; Chernyi, S.; Emelianov, V. Application of Artificial Intelligence Technologies to Assess the Quality of Structures. Energies 2021, 14, 8040. https://doi.org/10.3390/en14238040

Zhilenkov A, Chernyi S, Emelianov V. Application of Artificial Intelligence Technologies to Assess the Quality of Structures. Energies. 2021; 14(23):8040. https://doi.org/10.3390/en14238040

Chicago/Turabian StyleZhilenkov, Anton, Sergei Chernyi, and Vitalii Emelianov. 2021. "Application of Artificial Intelligence Technologies to Assess the Quality of Structures" Energies 14, no. 23: 8040. https://doi.org/10.3390/en14238040

APA StyleZhilenkov, A., Chernyi, S., & Emelianov, V. (2021). Application of Artificial Intelligence Technologies to Assess the Quality of Structures. Energies, 14(23), 8040. https://doi.org/10.3390/en14238040