A Steady State Model for Burning Coal Mine Methane in a Reverse Flow Burner

Abstract

:1. Introduction

2. Numerical Model

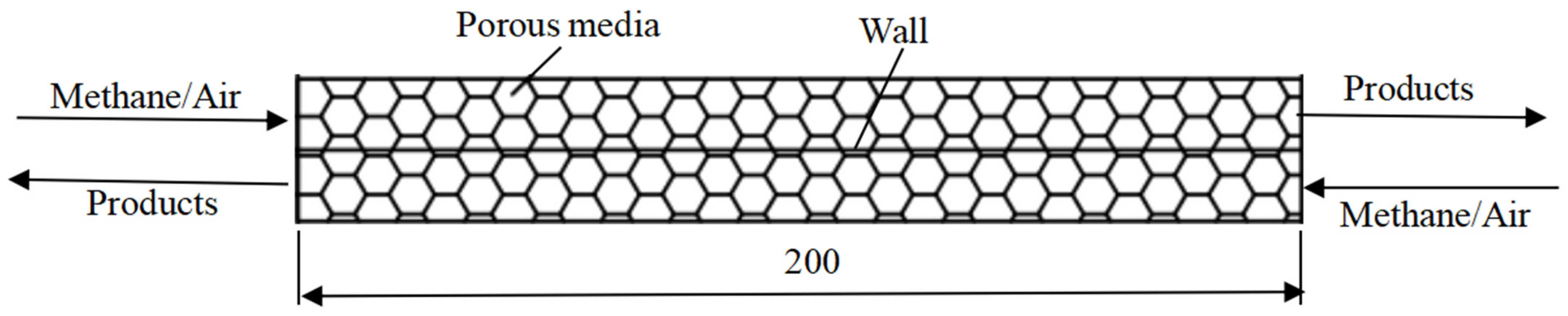

2.1. Geometry of the RFB

- (1)

- The gas flow in porous media is laminar and the working gas is non-radiating.

- (2)

- The packing bed is inert and has an optical thickness, and the solid radiation is computed by the Rosseland assumption.

- (3)

- Pressure drop in the packed bed is neglected.

2.2. Steady State Model

2.3. Boundary Conditions, Initial Condition and Solution Process

- (1)

- Inlet:

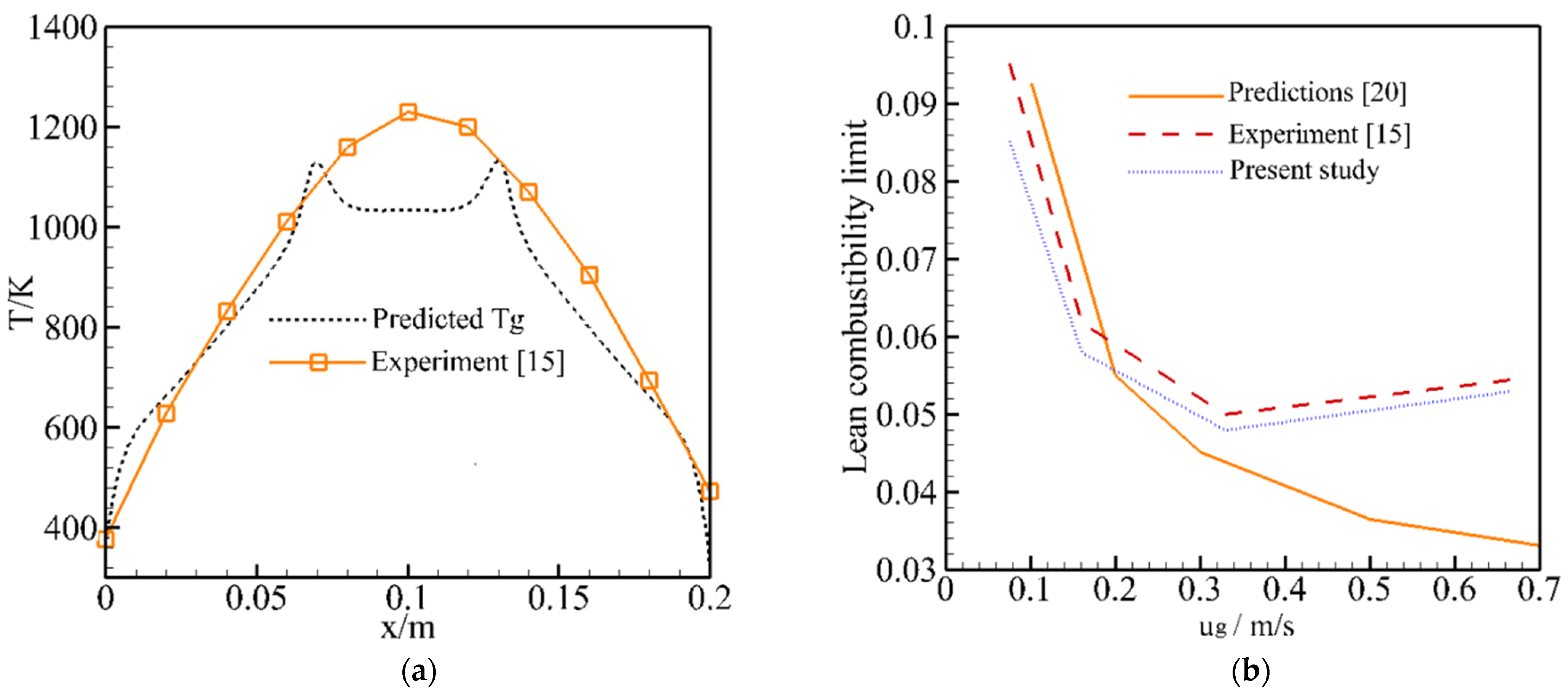

3. Model Verification

4. Results and Discussions

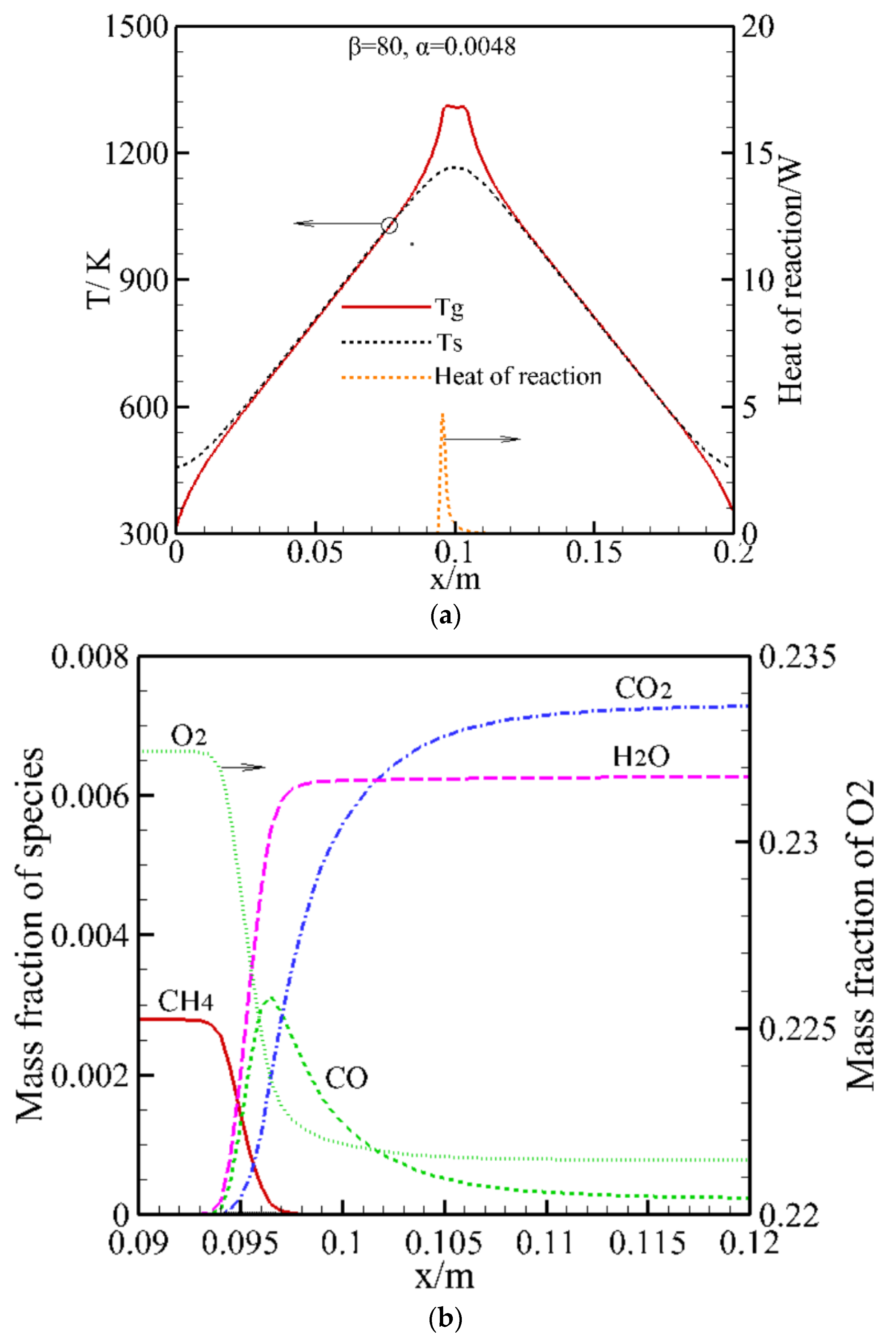

4.1. Temperature and Species Distribution at LCL

4.2. Effect of Heat Loss on Lean Combustibility Limit

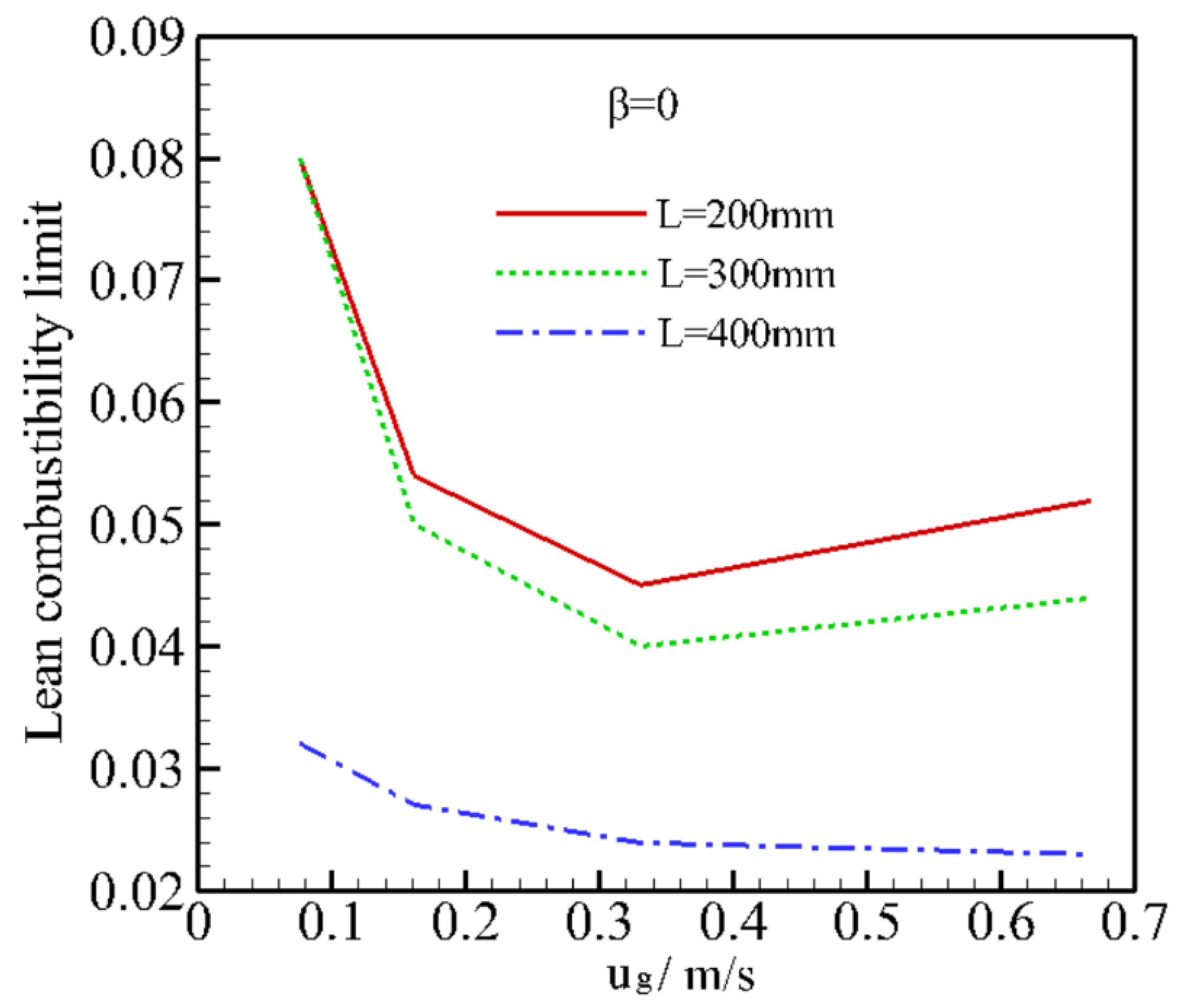

4.3. Effect of Burner Length on Lean Combustibility Limit

4.4. Computational Time Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| c | specific heat, |

| Di | diffusion coefficient of species i, cm2/s |

| hi | the molar enthalpy of species i, |

| T | temperature, K |

| ug | gas mixture velocity, m/s |

| x | coordinate, m |

| dpore | pore diameter of porous media, m |

| hv | convective heat transfer coefficient, |

| t | time, s |

| T0 | ambient temperature, K |

| Wi | molecular weight of species i, |

| Y | mass fraction |

| Greek symbols | |

| equivalent ratio | |

| radiation conductivity, | |

| density, | |

| solid surface emissivity | |

| heat loss coefficient, | |

| thermal conductivity, | |

| thermal conductivity of packed bed, | |

| porosity | |

| reaction rate of species i, | |

| Stephan-Boltzmann constant, | |

| subscripts | |

| G | gas |

| S | solid |

References

- Gosiewski, K.; Pawlaczyk, A.; Jaschik, M. Energy recovery from ventilation air methane via reverse-flow reactors. Energy 2015, 92, 13–23. [Google Scholar] [CrossRef]

- U.S. EPA. U.S. Underground Coal Mine Ventilation Air Methane Exhaust Characterization. Coal mine ventilation air methane exhaust characterization. In Coal Bed Methane Outreach Program; U.S. EPA: Washington, DC, USA, 2010; pp. 1–16. [Google Scholar]

- Mao, M.; Shi, J.; Liu, Y.; Gao, M.; Chen, Q. Experimental investigation on control of temperature asymmetry and nonuniformity in a pilot scale thermal flow reversal reactor. Appl. Therm. Eng. 2020, 175, 115375. [Google Scholar] [CrossRef]

- Egerton, A.; Gugan, K.; Weinberg, F.J. The mechanism of smouldering in cigarettes. Combust. Flame 1963, 7, 37–73. [Google Scholar] [CrossRef]

- Weinberg, F.J. Combustion temperature: The future? Nature 1971, 233, 239–241. [Google Scholar] [CrossRef] [PubMed]

- Song, F.Q.; Wen, Z.; Dong, Z.Y.; Wang, E.Y.; Liu, X.L. Ultra-low calorific gas combustion in a gradually-varied porous burner with annular heat recirculation. Energy 2017, 119, 497–503. [Google Scholar] [CrossRef]

- Banerjee, A.; Saveliev, A.V. High temperature heat extraction from counterflow porous burner. Int. J Heat Mass Transf. 2018, 127, 436–443. [Google Scholar] [CrossRef]

- Liu, H.S.; Wu, D.; Xie, M.Z.; Liu, H.; Xu, Z.J. Experimental and numerical study on the lean premixed filtration combustion of propane/air in porous medium. Appl. Therm. Eng. 2019, 150, 445–455. [Google Scholar] [CrossRef]

- Bubnovich, V.; Toledo, M. Analytical modelling of filtration combustion in inert porous media. Appl. Therm. Eng. 2007, 27, 1144–1149. [Google Scholar] [CrossRef]

- Shi, J.R.; Xie, M.Z.; Liu, H.; Li, G.; Zhou, L. Numerical simulation and theoretical analysis of low-velocity filtration combustion of lean mixture. Int. J. Heat Mass Trans. 2008, 51, 1818–1829. [Google Scholar] [CrossRef]

- Vahid, V.; Chanwoo, P. Analytical solutions of superadiabatic filtration combustion. Int. J. Heat Mass Trans. 2018, 117, 740–747. [Google Scholar]

- Liu, C.; Pan, M.; Zheng, L.; Lin, P. Effects of heterogeneous catalysis in porous media on nanofluid-based Reactions. Int. Commun. Heat Mass Transf. 2020, 110, 104434. [Google Scholar] [CrossRef]

- Yakovlev, I.; Zambalov, S. Three-dimensional pore-scale numerical simulation of methane-air combustion in inert porous media under the conditions of upstream and downstream combustion wave propagation through the media. Combust. Flame 2019, 209, 74–98. [Google Scholar] [CrossRef]

- Jiang, L.S.; Liu, H.S.; Suo, S.Y.; Xie, M.Z.; Bai, M.L. Simulation of propane-air premixed combustion process in randomly packed beds. Appl. Therm. Eng. 2018, 14, 153–163. [Google Scholar] [CrossRef]

- Hoffmann, J.G.; Echigom, R.; Yoshida, H.; Tada, S. Experimental study on combustion in porous media with a reciprocating flow system. Combust. Flame 1997, 111, 32–46. [Google Scholar] [CrossRef]

- Barcellos, W.M.; Carlos, L.; Souza, E.O.; Saveliev, V.A.; Kennedy, L.A. Ultra-low-emission steam boiler constituted of reciprocal flow porous burner. Exp. Therm. Fluid Sci. 2011, 35, 570–580. [Google Scholar] [CrossRef]

- Zeng, H.Y.; Wang, Y.Q.; Gong, S.Q.; Shi, Y.X.; Cai, N.S. Catalytically enhanced methane-rich combustion by porous media reactor. Fuel 2019, 248, 65–75. [Google Scholar] [CrossRef]

- Oliveira, M.; Kaviany, M. Nonequilibrium in the transport of heat and mass reactants in combustion in porous media. Prog. Energy Combust. Sci. 2001, 27, 523–545. [Google Scholar] [CrossRef]

- Hanamura, K.; Echigo, R.; Zhdanok, S.A. Superadiabatic combustion in a porous media. Int. J. Heat Mass Trans. 1993, 36, 3201–3209. [Google Scholar] [CrossRef]

- Dobrego, K.V.; Gnesdilov, N.N.; Lee, S.H.; Chol, H.K. Lean combustibility limit of methane in reciprocal flow filtration combustion reactor. Int. J. Heat Mass Trans. 2008, 51, 2190–2198. [Google Scholar] [CrossRef]

- Bubnovich, V.; Henríquez, L.; Díaz, C.; Maiza, M. Diameter of alumina balls effect on stabilization operation region for a reciprocal flow burner. Int. J. Heat Mass Trans. 2011, 54, 2026–2033. [Google Scholar] [CrossRef]

- Henríquez-Vargas, L.; Valeria, M.; Bubnovich, V. Numerical study of lean combustibility limits extension in a reciprocal flow porous media burner for ethanol/air mixtures. Int. J. Heat Mass Transf. 2015, 89, 1155–1163. [Google Scholar] [CrossRef]

- Vourliotakis, G.; Skevis, G.; Founti, M.A.; Al-Hamamre, Z.; Trimis, D. Detailed kinetic modelling of the T-POX reforming process using a reactor network approach. Int. J. Hydrog. Energy 2008, 33, 2816–2825. [Google Scholar] [CrossRef]

- Shi, J.R.; Mao, M.M.; Li, H.L.; Liu, Y.Q.; Sun, Y.S. Pore-level study of syngas production from fuel-rich partial oxidation in a simplified two-Layer burner. Front. Chem. 2019, 7, 793–798. [Google Scholar] [CrossRef] [PubMed]

- Dixon, A.G. Local transport and reaction rates in a fixed bed reactor tube: Endothermic steam methane reforming. Chem. Eng. Sci. 2017, 168, 156–177. [Google Scholar] [CrossRef]

- Pope, S.B. Computationally efficient implementation of combustion chemistry using in situ adaptive tabulation. Combust. Theor. Model. 1997, 1, 41–63. [Google Scholar] [CrossRef]

- Koren, C.; Vicquelin, R.; Gicquel, O. Self-adaptive coupling frequency for unsteady coupled conjugate heat transfer simulations. Int. J. Therm. Sci. 2017, 118, 340–354. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.R.; Xie, M.Z.; Li, G. Approximate solutions of lean premixed combustion in porous media with reciprocating flow. Int. J. Heat Mass Trans. 2009, 52, 702–708. [Google Scholar] [CrossRef]

- Dobrego, K.V.; Gnezdilov, N.N.; Lee, S.H.; Choi, H.K. Partial oxidation of methane in a reverse flow porous media reactor: Water admixing optimization. Int. J. Hydrog. Energy 2008, 33, 5534–5544. [Google Scholar] [CrossRef]

- Zheng, C.H.; Cheng, L.M.; Cen, K.F.; Bingue, J.P.; Savelieva, A. Partial oxidation of methane in a reciprocal flow porous burner with an external heat source. Int. J. Hydrog. Energy 2012, 37, 4119–4126. [Google Scholar] [CrossRef]

- Yao, Z.X.; Saveliev, A.V. High efficiency high temperature heat extraction from porous media reciprocal flow burner: Time-averaged model. Appl. Therm. Eng. 2018, 143, 614–620. [Google Scholar] [CrossRef]

- Bowman, C.T.; Hanson, R.K.; Davidson, D.F.; Gardiner, W.C.; Lissianski, J.V.; Smith, G.P.; Golden, D.M.; Frenklach, M.; Goldenberg, M. Available online: http://www.me.berkeley.edu/gri_mech/ (accessed on 5 July 1995).

- Younis, L.B.; Viskanta, R. Experimental determination of the volumetric heat transfer coefficient between stream of air and ceramic foam. Int. J. Heat Mass Trans. 1993, 36, 1425–1434. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, J.; Shi, J.; Mao, M.; Kong, X.; Zhou, D. A Steady State Model for Burning Coal Mine Methane in a Reverse Flow Burner. Energies 2021, 14, 7957. https://doi.org/10.3390/en14237957

Lv J, Shi J, Mao M, Kong X, Zhou D. A Steady State Model for Burning Coal Mine Methane in a Reverse Flow Burner. Energies. 2021; 14(23):7957. https://doi.org/10.3390/en14237957

Chicago/Turabian StyleLv, Jinsheng, Junrui Shi, Mingming Mao, Xiangjin Kong, and Dan Zhou. 2021. "A Steady State Model for Burning Coal Mine Methane in a Reverse Flow Burner" Energies 14, no. 23: 7957. https://doi.org/10.3390/en14237957

APA StyleLv, J., Shi, J., Mao, M., Kong, X., & Zhou, D. (2021). A Steady State Model for Burning Coal Mine Methane in a Reverse Flow Burner. Energies, 14(23), 7957. https://doi.org/10.3390/en14237957