A Study on the Possibility of Measuring Sludge Sedimentation Using Contrast Detection Characteristics of CdS Photoresistors

Abstract

:1. Introduction

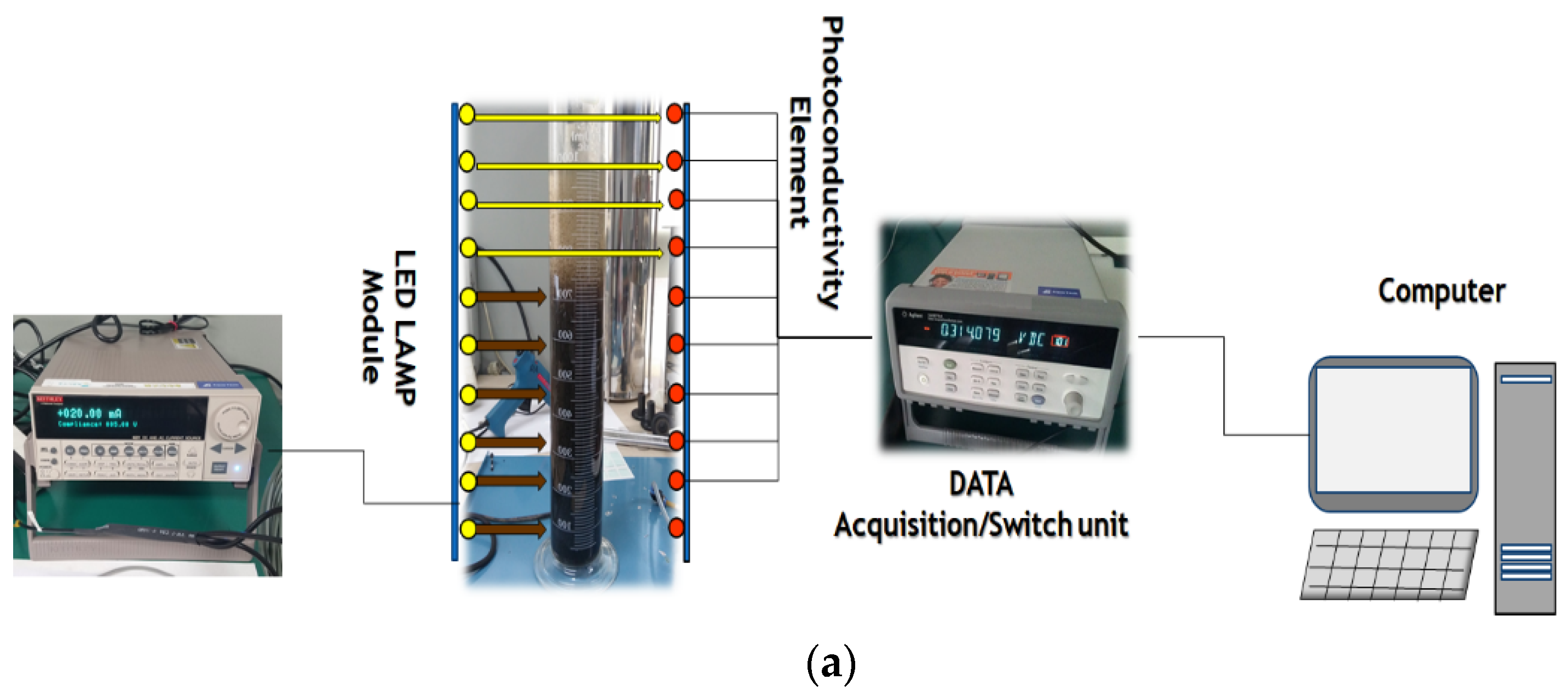

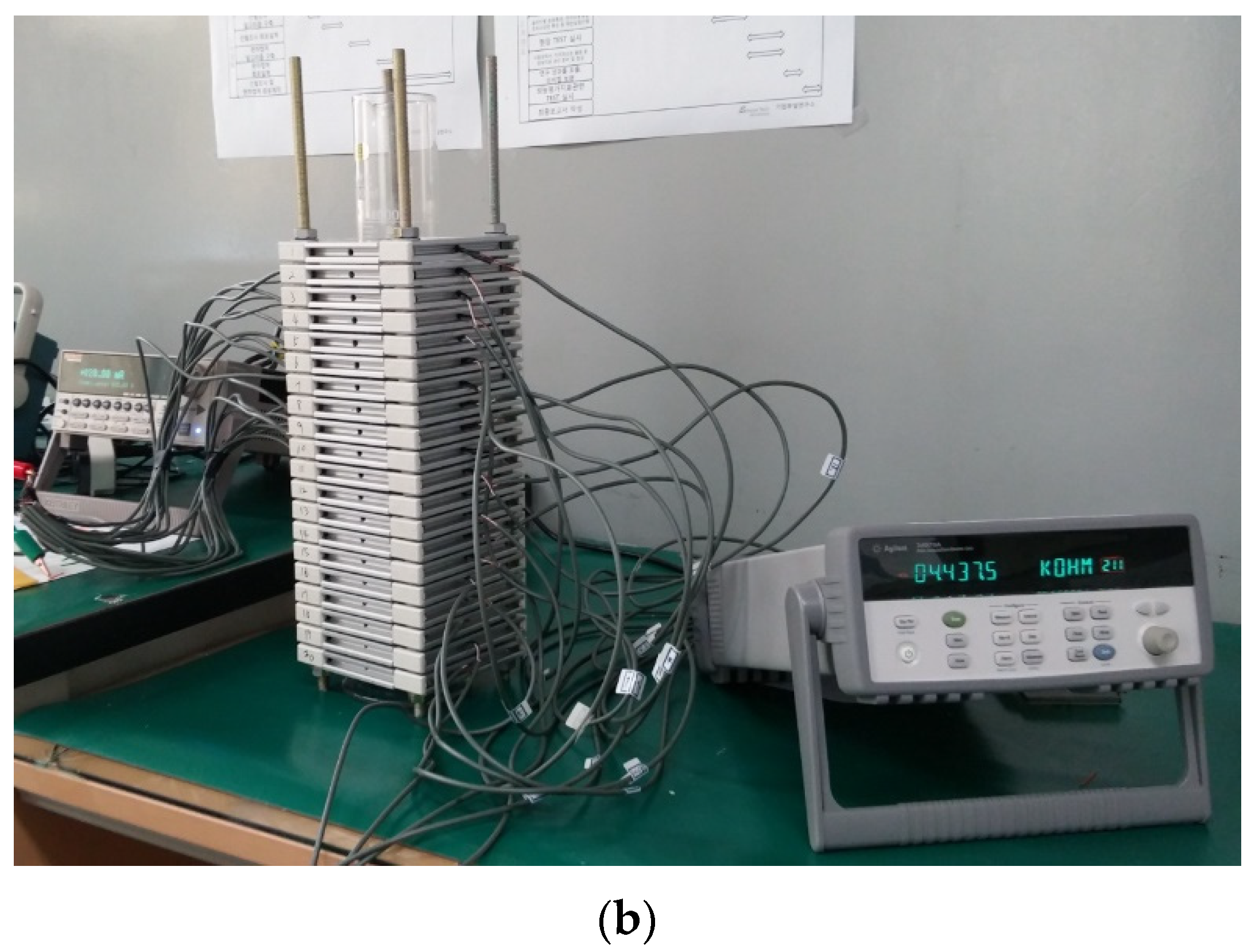

2. Materials and Methods

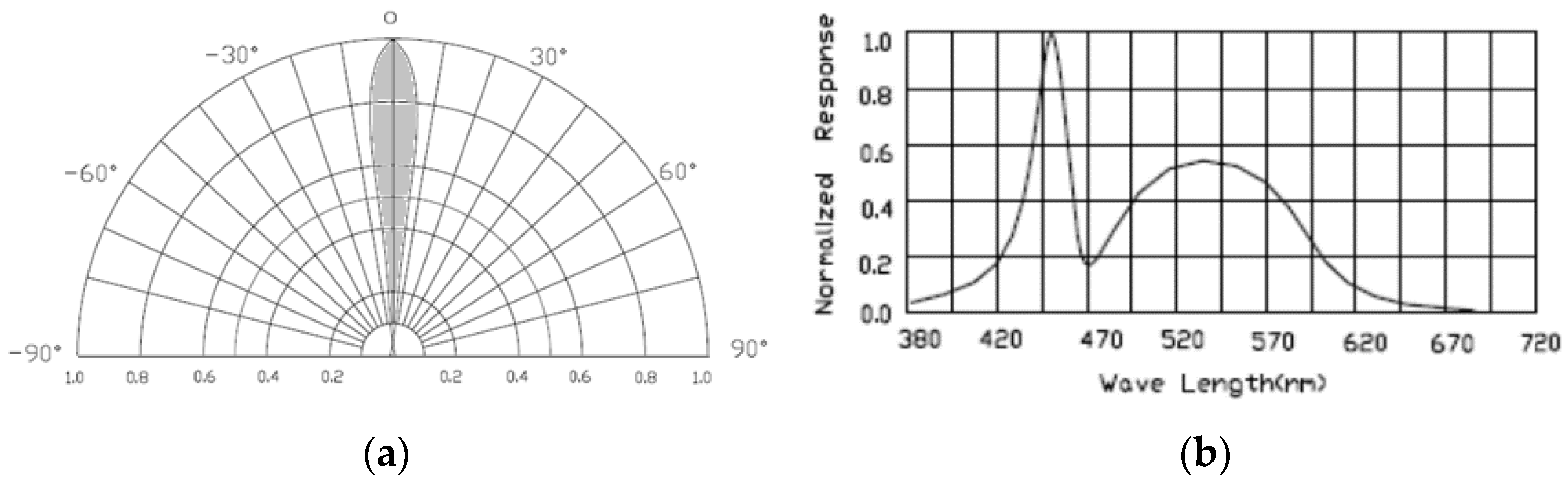

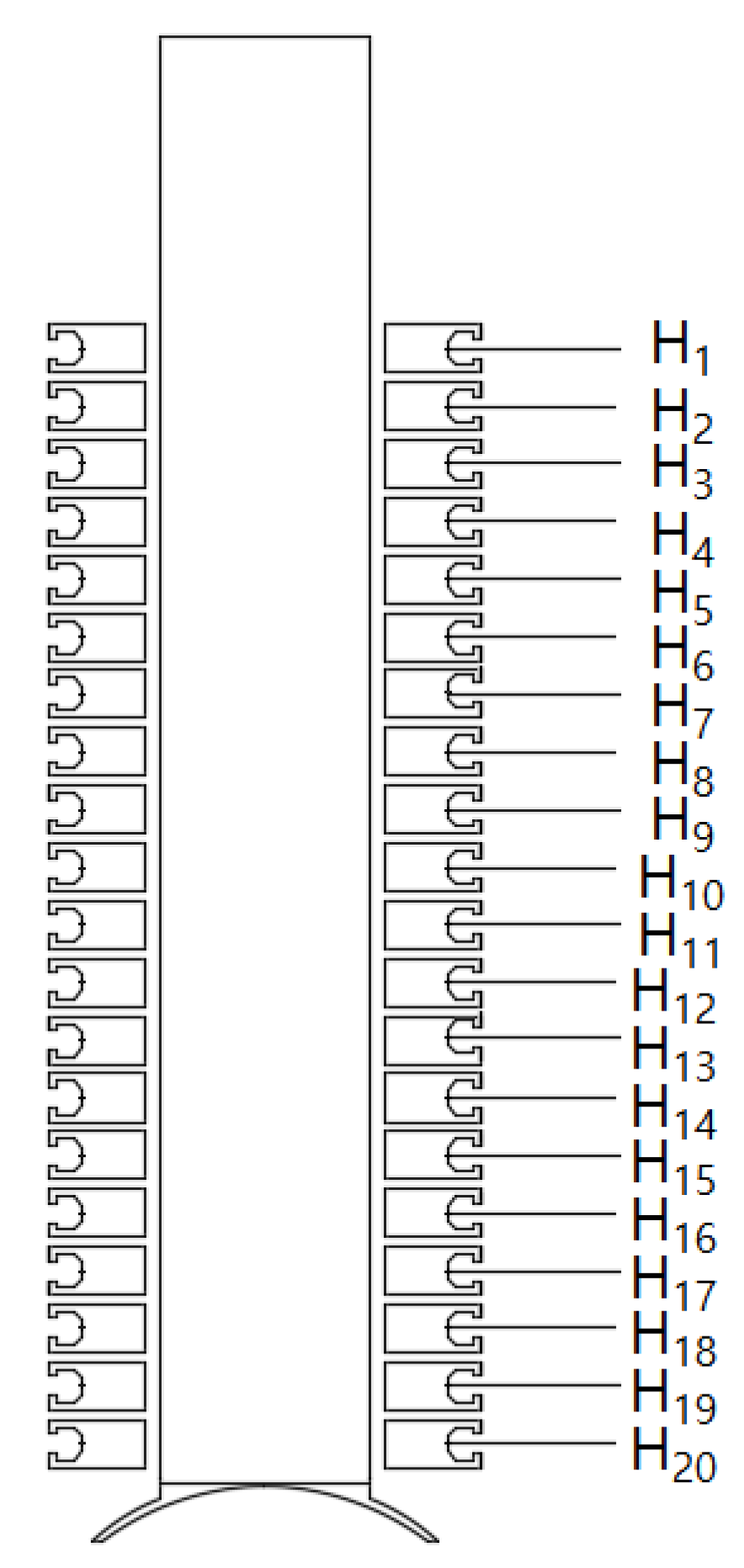

2.1. Test Devices

2.2. Material of Test

3. Result and Consideration

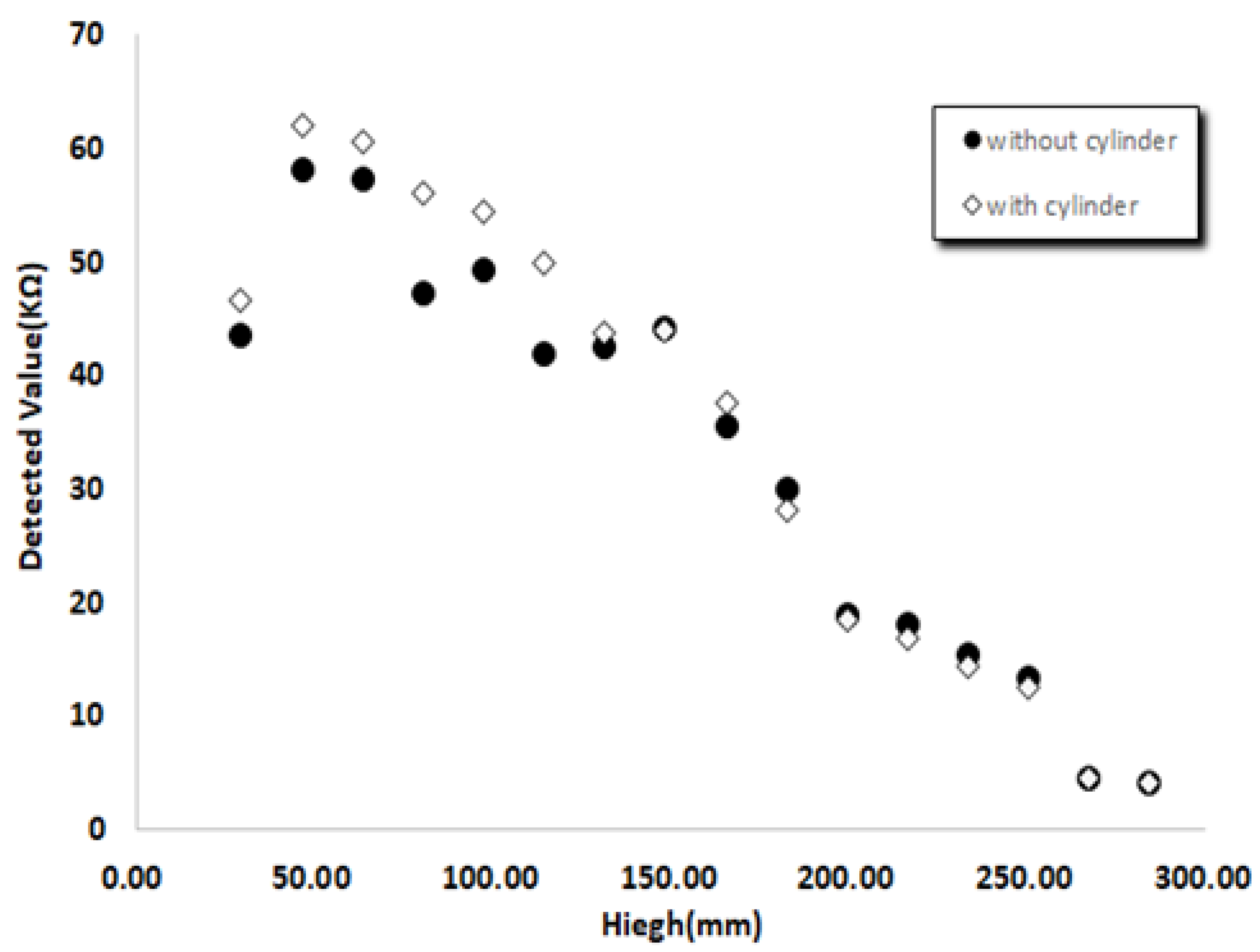

3.1. Variation of CdS Photoresistors in Ambient Light

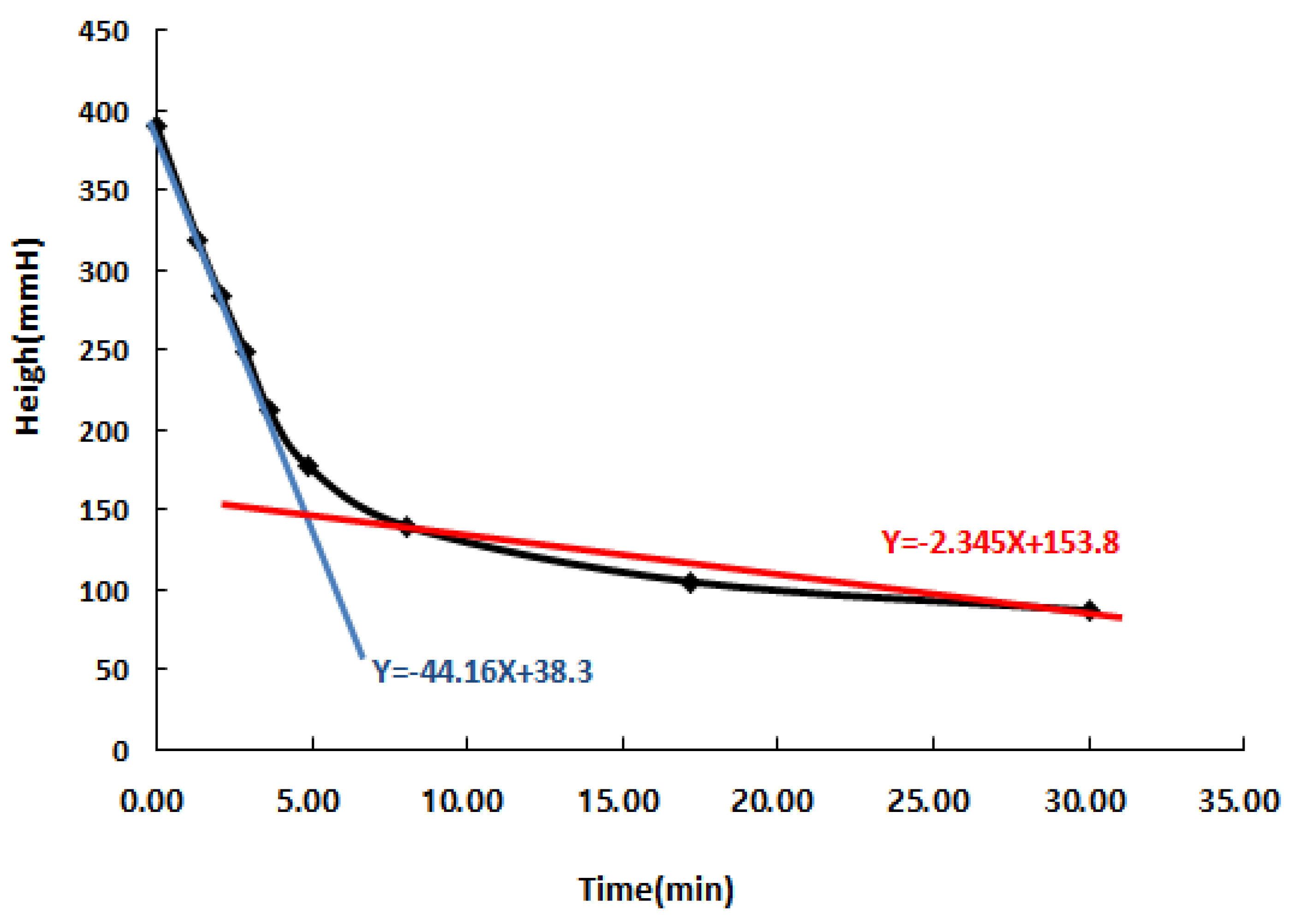

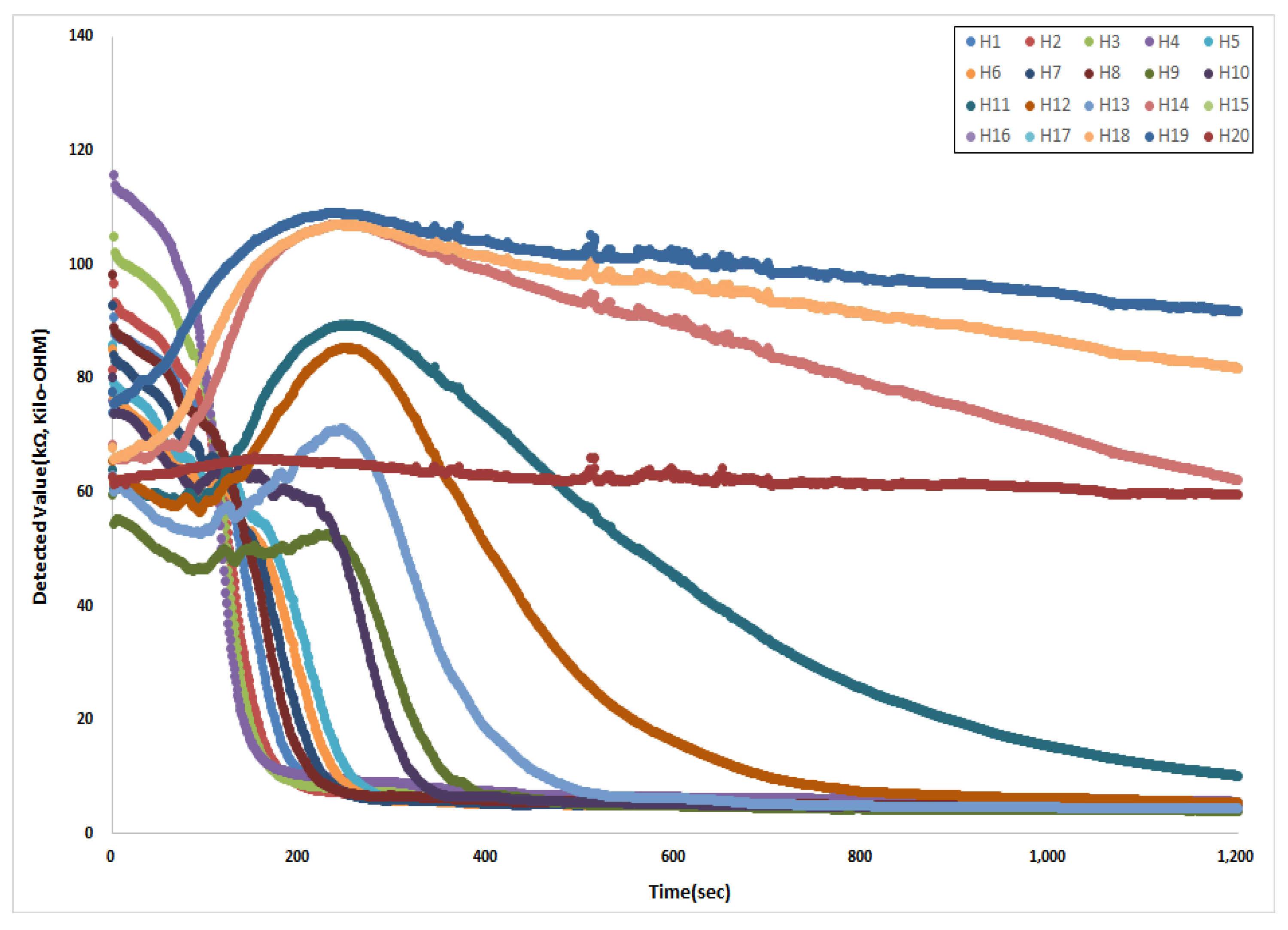

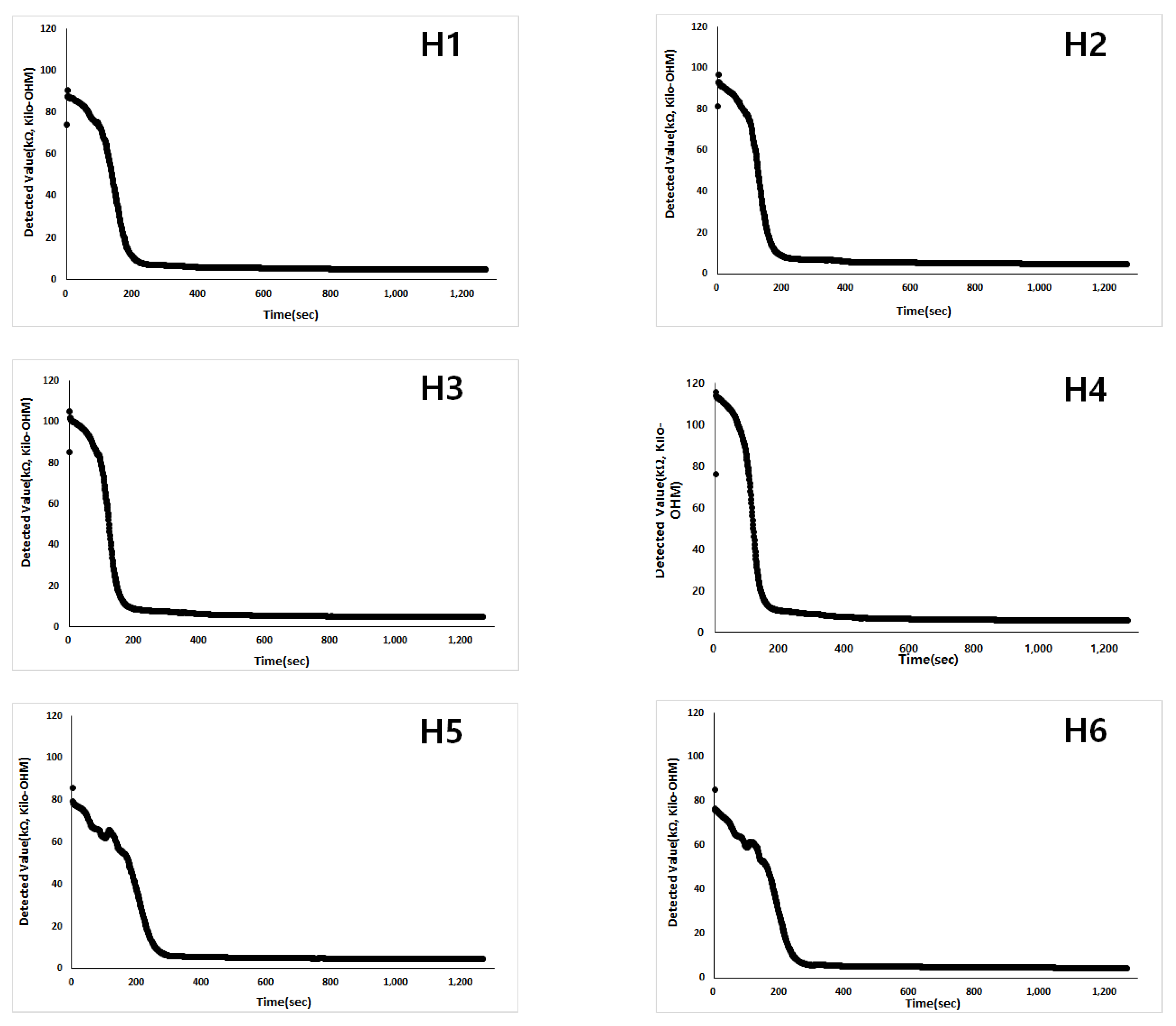

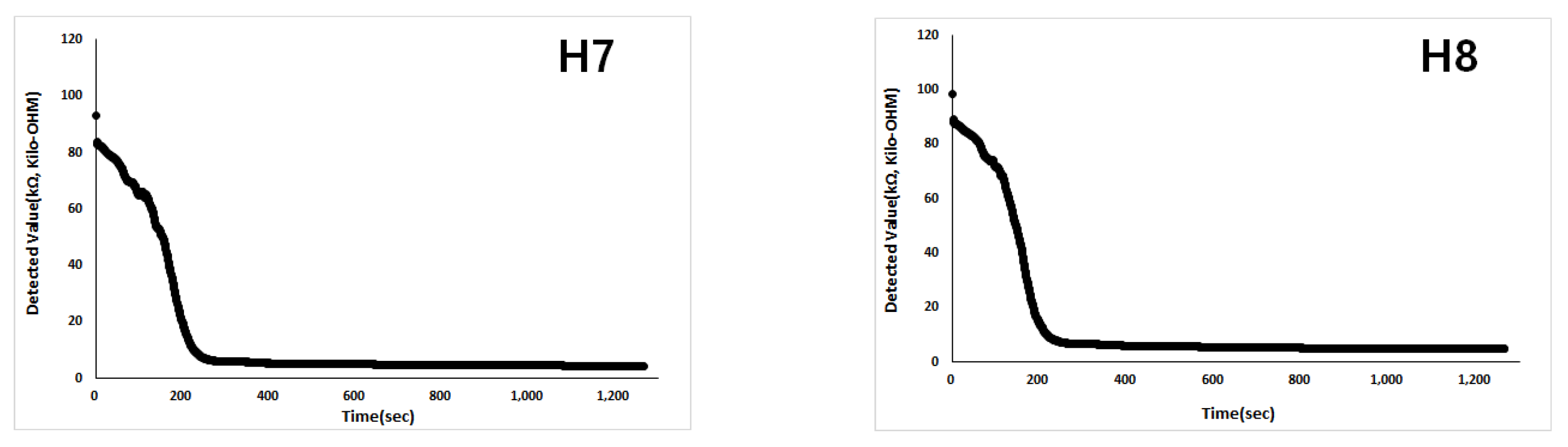

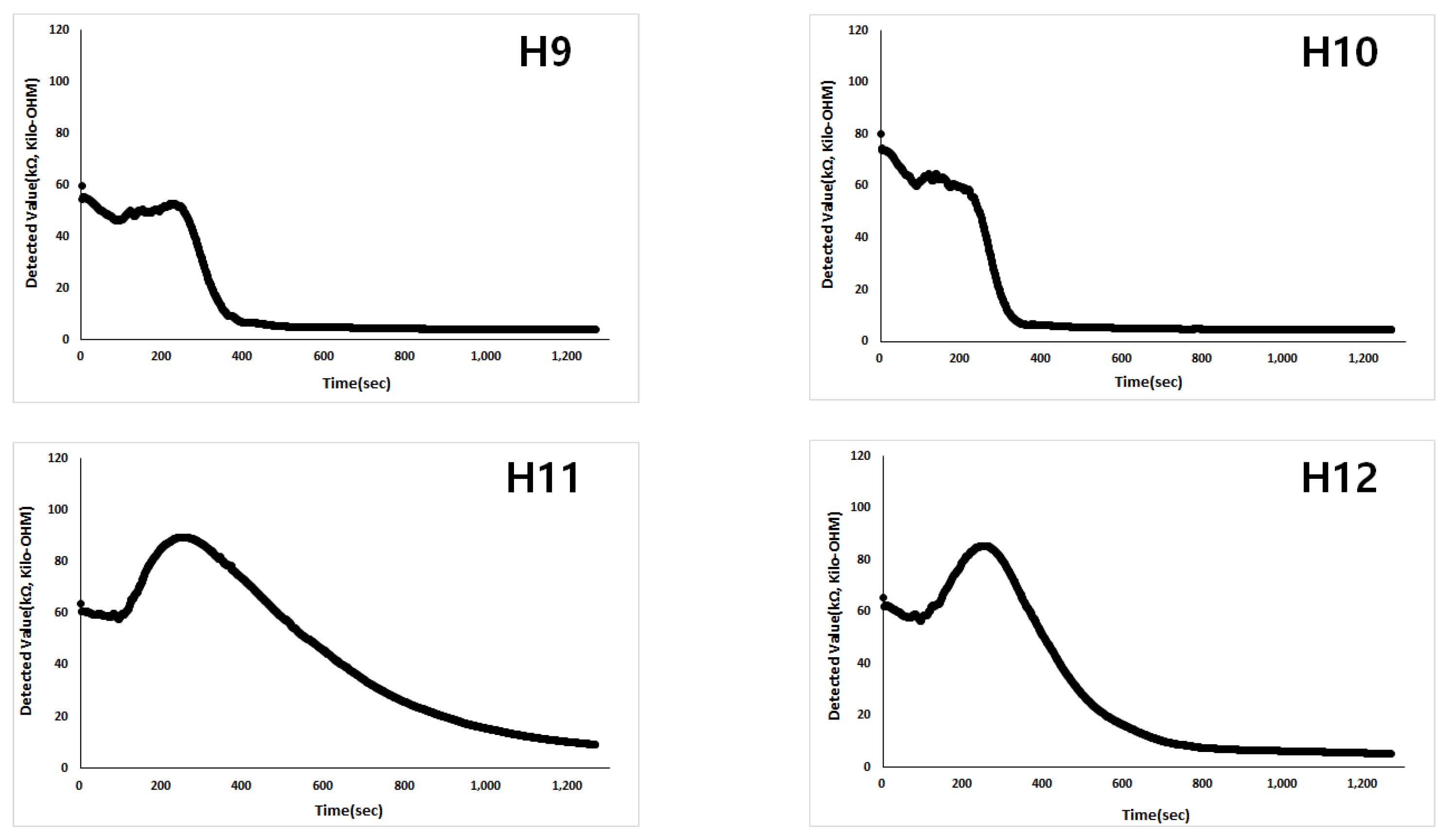

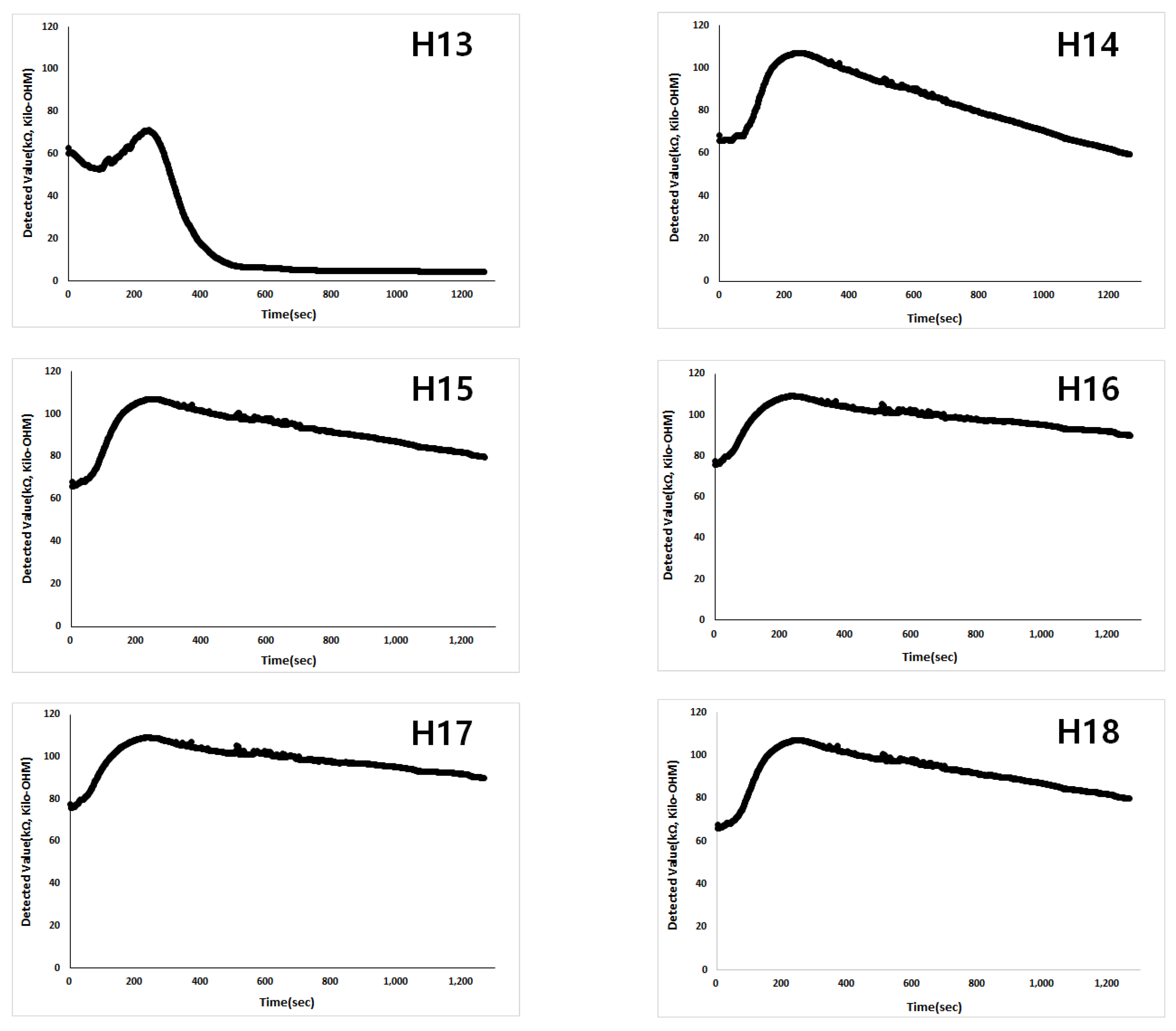

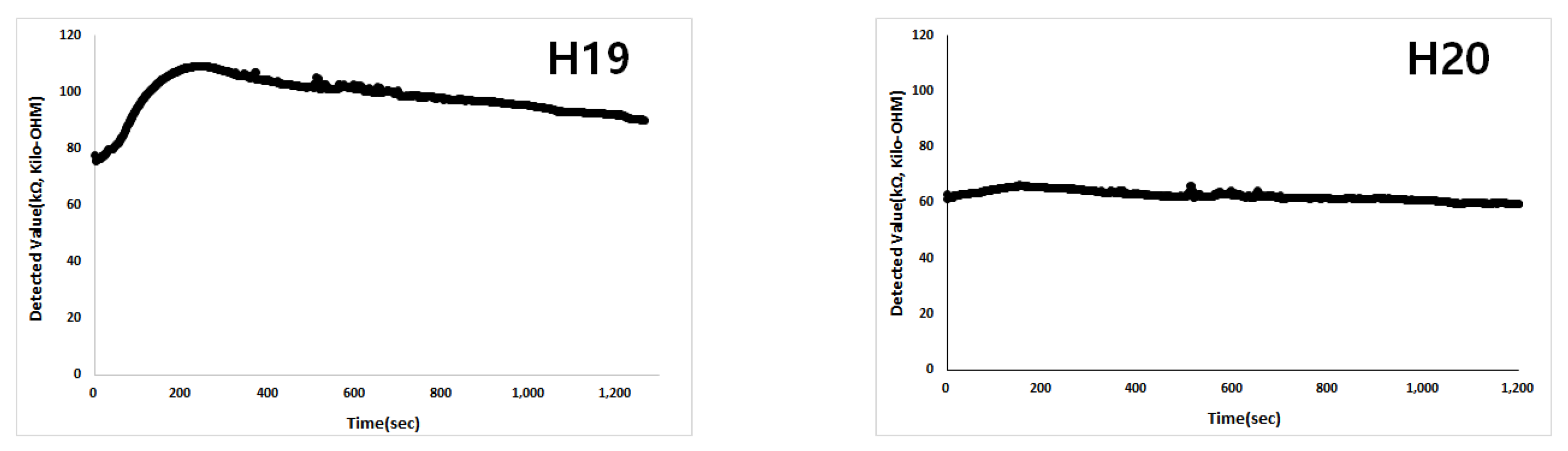

3.2. Comparison of CdS Resistors Variation Detected Data and Classical Test Results

4. Conclusions

- The average deviation of the effect of ambient light using the CdS photoresistors with and without the transparent cylindrical cylinder made of glass was found to be 2.3%, indicating no significant difference.

- In the CdS photoresistor installation height range of H1–H8, the sludge sedimentation velocity was calculated to be 0.594 mm/s in the section where the discrete particle settling occurred for 200 s. In the classical test, the sludge interface height changed from 390 mm to 140 mm in 480 s and, hence, the sludge sedimentation velocity was calculated to be 0.521 mm/s, indicating a similar trend to the sludge sedimentation velocity of the Class Ⅰ type obtained using the CdS photoresistors measuring values.

- The CdS photoresistor installation height of H9 to H12 was 165 mm (H9)–216 mm (H12), and the average value of 67.3 kΩ detected to 60.3 kΩ in 280 s, diminishing by 7.0 kΩ. The average change rate of measured values of CdS photoresistor was low (−0.025 kΩ/s) in the H9 to H12 section, demonstrating the characteristics of flocculent particle settling (Class II) where the particulate solids flocculated into floc as sedimentation velocity 0.183 mm/s.

- Comparing measured values of the CdS photoresistors installed at different heights of H1–H20 with the sludge sedimentation interface changing over time and sedimentation velocities obtained via classical tests, the velocity from flocculent particle settling to compression settling was found to be 0.056 mm/s and 0.068 mm/s, respectively.

- This study verified that the SVI measurement using CdS photoresistors could measure the change over time more objectively compared to that measured by the subjective tests (classical tests).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C.M.; Xu, L.M.; Xu, P.C.; Wang, X.C. Elimination of virus from domestic wastewater: Requirements and technologies. World J. Microbio. Biolo. 2016, 32, 69. [Google Scholar]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering Treatment and Reuse, 4th ed.; Metcalf & Eddy Inc.: New York, NY, USA, 2003; Volume 1469, pp. 1–2. [Google Scholar]

- Activated Sludge Process. Available online: Iwapublishing.com/news/acivited-sludge-pro (accessed on 10 August 2021).

- Nabaterega, R.; Kumar, V.; Khoei, S.; Eskicioglu, C. A review on Two-stage anerobic digestion options for optimizing municipal wastewater sludge treatment process. J. Environ. Chem. Eng. 2021, 9, 105502. [Google Scholar] [CrossRef]

- Jenkins, D.; Richard, M.G.; Diaigger, G.T. Manual on the Case and Control of Activated Sludge Bulking, Foaming, and Other Solid Separation Problems, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–7. [Google Scholar]

- Dewil, R.; Baeyensa, J.; Goutrind, R. The use of ultrasonics in the treatment of waste activated sludge. Chin. J. Chem. Eng. 2006, 141, 105–113. [Google Scholar] [CrossRef]

- Kotzapetros, A.D.; Paraskevas, P.A.; Stasinakis, A.S. Design of a modern auto matric control system for the activated sludge process in wastewater treatment. Chin. J. Chem. Eng 2015, 23, 1340–1349. [Google Scholar] [CrossRef]

- Flores-Alsina, X.; Comas, J.; Rodriguez-Roda, I.; Gernaey, K.V.; Rosen, C. Including the effects of filamentous bulking sludge during the simulation of wastewater treatment plants using a risk assessment model. Water Res. 2009, 43, 4527–4538. [Google Scholar] [CrossRef] [PubMed]

- Dick, R.I.; Vesilind, P.A. The sludge volume index: What is it? J. Water Pollut. Control. Fed. 1969, 41, 1285–1291. [Google Scholar]

- Banadda, E.N.; Jenne, R.; Smets, I.Y.; Gins, G.; Mys, M.; Van Impe, J.F. Identification and modeling of the sludge volume index by exploiting image analysis information. IFAC Proc. Vol. 2004, 37, 85–90. [Google Scholar] [CrossRef]

- Kim, Y.; Yeom, H.S.; Choi, S.J.; Bae, H.Y.; Kim, C.W. Sludge settleability detecting using automated SV30 measurement and comparisons of feature extraction methods. Korean J. Chem. Eng. 2010, 27, 886–892. [Google Scholar] [CrossRef]

- Sun, K.; Artan, N.S.; Dong, Z. CALC: Calibration for ambient light correction in screen to camera visible light communication. Results Opt. 2021, 5, 100122. [Google Scholar] [CrossRef]

- Xiong, N.N.; Shen, Y.; Yang, K.; Lee, C.; Wu, C. Color sensors and their applications based on real-time color image segmentation for cyber physical systems. EURASIP J. Image Video Process. 2018, 2018, 23. [Google Scholar] [CrossRef]

- Sinclair, I. Passive Components for Circuit Design, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Christenson, J. Sensor and Transducers, Hand Book of Biomechatronics; Academic Press: London, UK, 2019; pp. 61–93. [Google Scholar]

- Photoresistor, Chapter 3. Resistor Type. Available online: https://eepower.comresistor-types/photo-resistor/# (accessed on 15 September 2021).

- FYL-5014UMIC Data Sheet. Available online: Unisystem-displays.com/en/foryard.html (accessed on 15 September 2021).

- Photocells A 9050 Data Sheet. Available online: www.perkinelmer.com/opto (accessed on 15 September 2021).

- Fang, F.; Qiao, L.L.; Cao, J.S.; Li, Y.; Xie, W.M.; Sheng, G.P.; Yu, H.Q. Quantitative evaluation of A2O and reversed A2O process for biological municipal wastewater treatment using a projection pursuit method. Sep. Purif. Technol. 2016, 166, 164–170. [Google Scholar] [CrossRef]

- Rice, E.W.; Baird, R.B.; Eaton, A.D. Standard Method for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Choi, J.H.; Kim, J.S.; Jung, G.I.; Lee, T.H.; Kim, A.H.; Oh, H.B.; Park, H.J.; Kim, K.S.; Jun, J.H. Estimation of the light intensity by using bright-chip LED sensor system. Trans. Korean Inst. Electr. Eng. 2013, 62, 290–1296. [Google Scholar]

- Liu, J.; Liang, Y.; Wang, L.; Wang, B.; Zhang, T.; Yi, F. Fabrication and photosensitivity of CdS photoresistor on silica nanopillars substrate. Mater. Semicond. Process. 2016, 56, 217–221. [Google Scholar] [CrossRef]

| Parameter | Operating Value | Unit | |

|---|---|---|---|

| Luminous Intensity | 27,000 | mcd (a) | |

| View angle | 15 | Deg. (b) | |

| Chromaticity coordinates (c) | X | 0.29 | - |

| Y | 0.29 | - | |

| Color temperature (d) | 9500 | K | |

| List | Organic Load Applied to Bioreactor (kg-COD (a)/kg-MLSS/Day) | MLSS (mg/L) | DO (mg/L) | pH |

|---|---|---|---|---|

| Bioreactor sludge | 1.0 | 3800.0 | 1.2 | 6.9 |

| Part No. | R10 Range (kΩ) | R100 Typ. (kΩ) | R10 min. (MΩ) | R05 min. (MΩ) | γ10/100 | λpeak (nm) |

|---|---|---|---|---|---|---|

| A905012 | 18–14 | 7 | 0.15 | 0.45 | 0.65 | 530 |

| R10 Resistance at E = 10 lux light intensity | Tst Storage Temperature TC Thermal Coefficient | |||||

| R100 Resistance at E = 100 lux light intensity | ||||||

| R01 Dark Resistance after 1 s (E = 0) | ton Rise time to 63% of final I (R10) | |||||

| R05 Dark Resistance after 5 s (E = 0) | toff Decay time to 37% of initial I (R10) | |||||

| γ10/100 Sensitivity log (R10/R100)/log (100 lux/10 lux) | Vmax Maximum operating voltage at E = 0 lux | |||||

| λpeak Peak spectral sensitivity | Pmax Power dissipation at 25 °C Ambient Temperature | |||||

| Top Operating temperature | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, S.-M.; Kim, H.-O.; Kim, C.-G. A Study on the Possibility of Measuring Sludge Sedimentation Using Contrast Detection Characteristics of CdS Photoresistors. Energies 2021, 14, 7817. https://doi.org/10.3390/en14227817

Hong S-M, Kim H-O, Kim C-G. A Study on the Possibility of Measuring Sludge Sedimentation Using Contrast Detection Characteristics of CdS Photoresistors. Energies. 2021; 14(22):7817. https://doi.org/10.3390/en14227817

Chicago/Turabian StyleHong, Seong-Min, Hyun-Ook Kim, and Choong-Gon Kim. 2021. "A Study on the Possibility of Measuring Sludge Sedimentation Using Contrast Detection Characteristics of CdS Photoresistors" Energies 14, no. 22: 7817. https://doi.org/10.3390/en14227817

APA StyleHong, S.-M., Kim, H.-O., & Kim, C.-G. (2021). A Study on the Possibility of Measuring Sludge Sedimentation Using Contrast Detection Characteristics of CdS Photoresistors. Energies, 14(22), 7817. https://doi.org/10.3390/en14227817