Conceptual Design and Hydrodynamic Performance of a Modular Hybrid Floating Foundation

Abstract

:1. Introduction

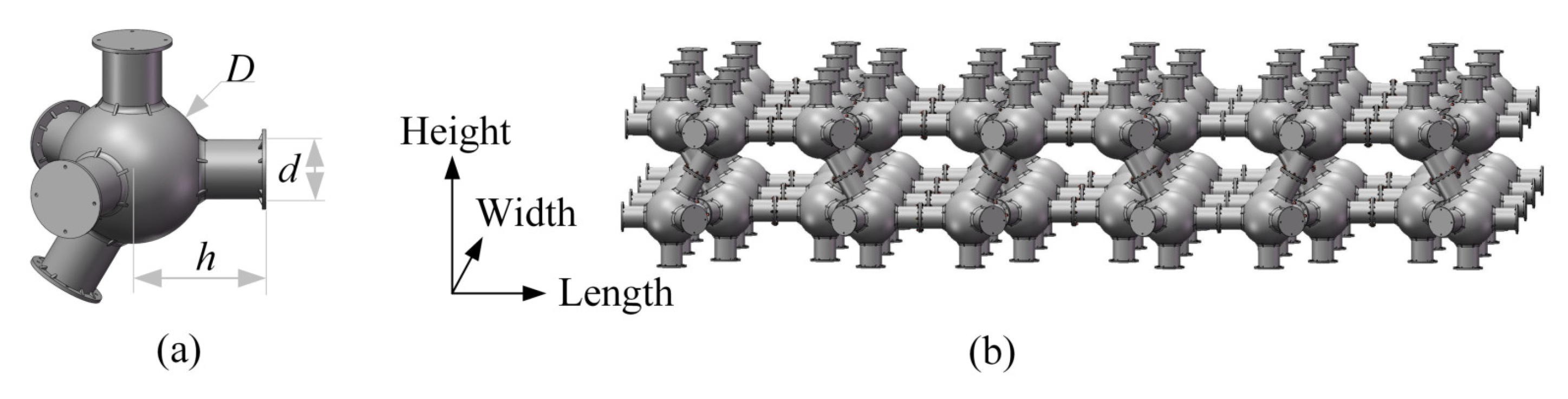

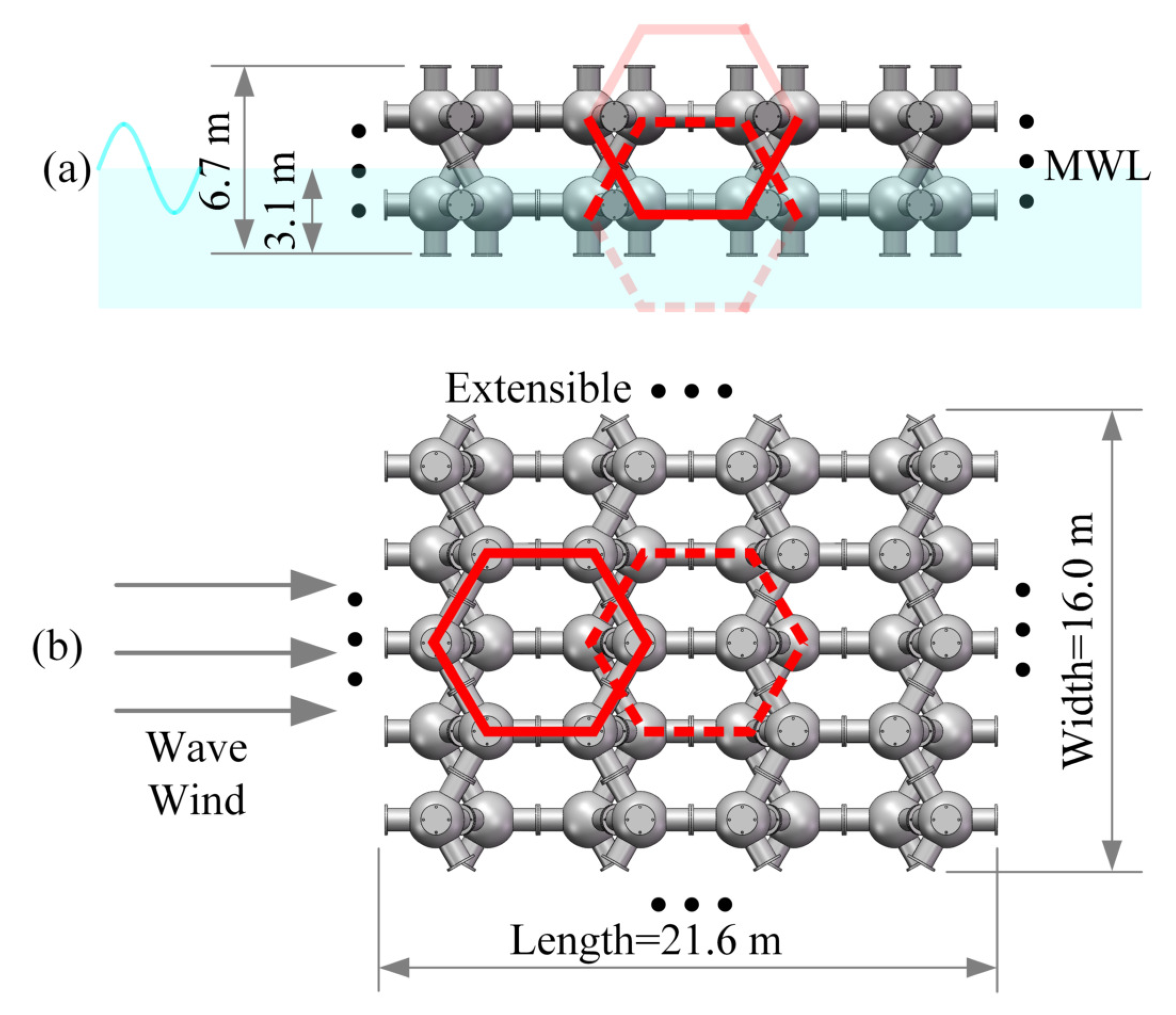

2. Model Descriptions

2.1. Modular Conception of Floating Foundation

- A minimalist design is mainly used to keep the BDFF as simple as possible;

- The unique module can be mass-produced in the factory and assembled near the harbor, which could significantly cut the manufacturing and installation cost while shortening the construction time of the platform;

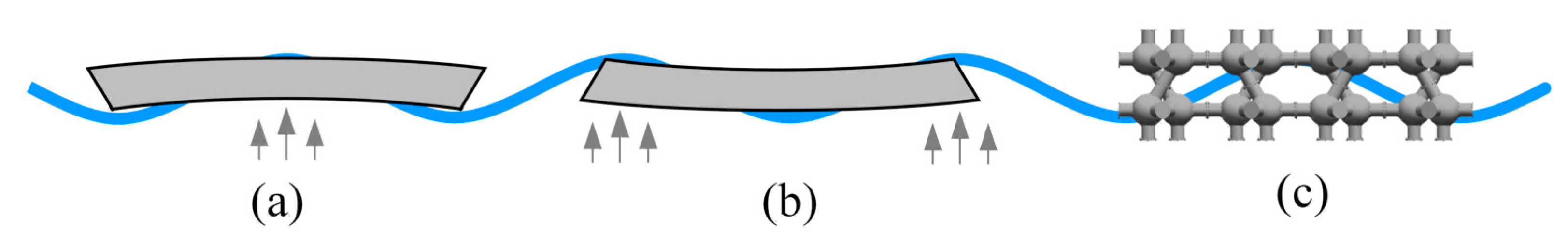

- The waves with various wavelengths can easily propagate through the BDFF without hogging and sagging as shown in Figure 3.

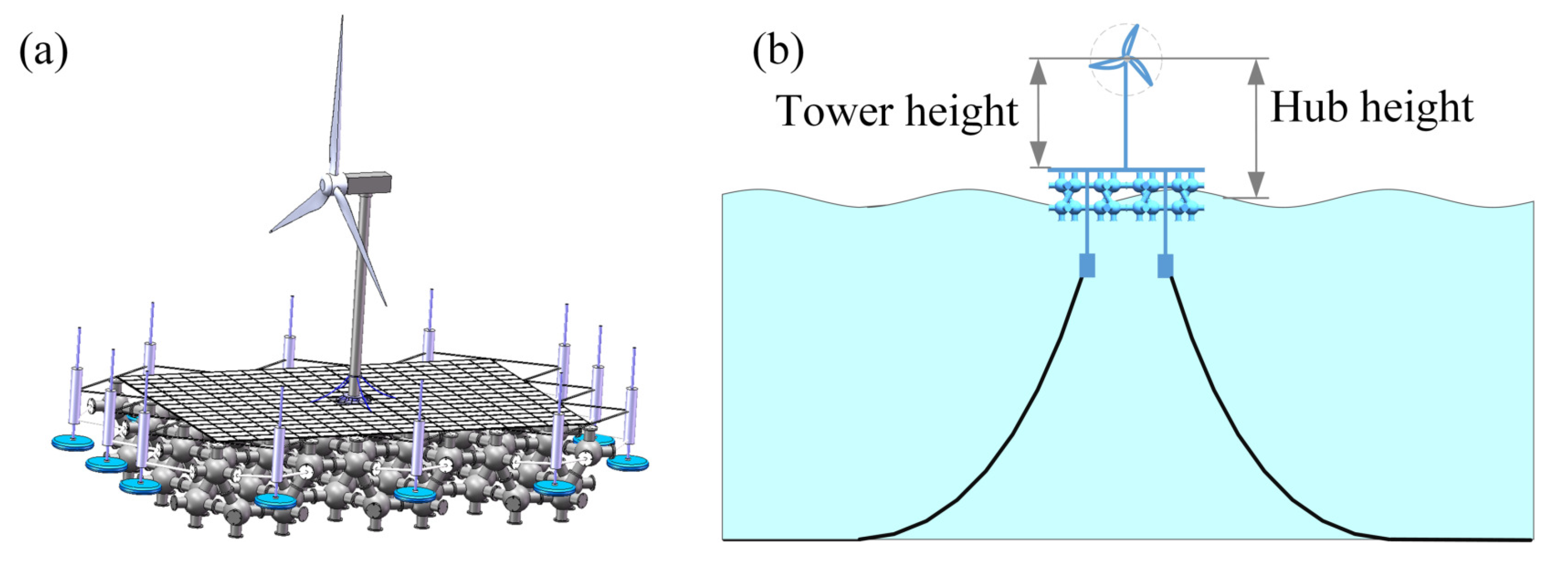

2.2. Specification of the Superstructures

2.3. Specification of the System

2.4. Specification of the Substructures

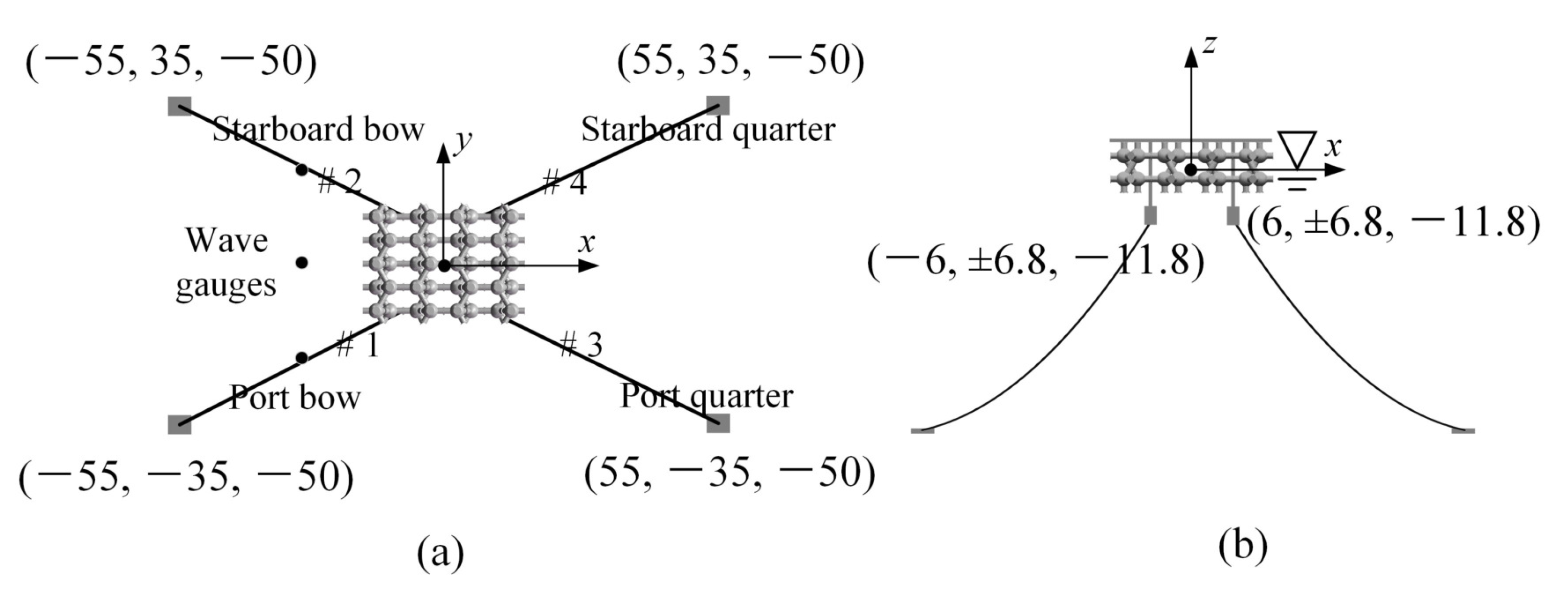

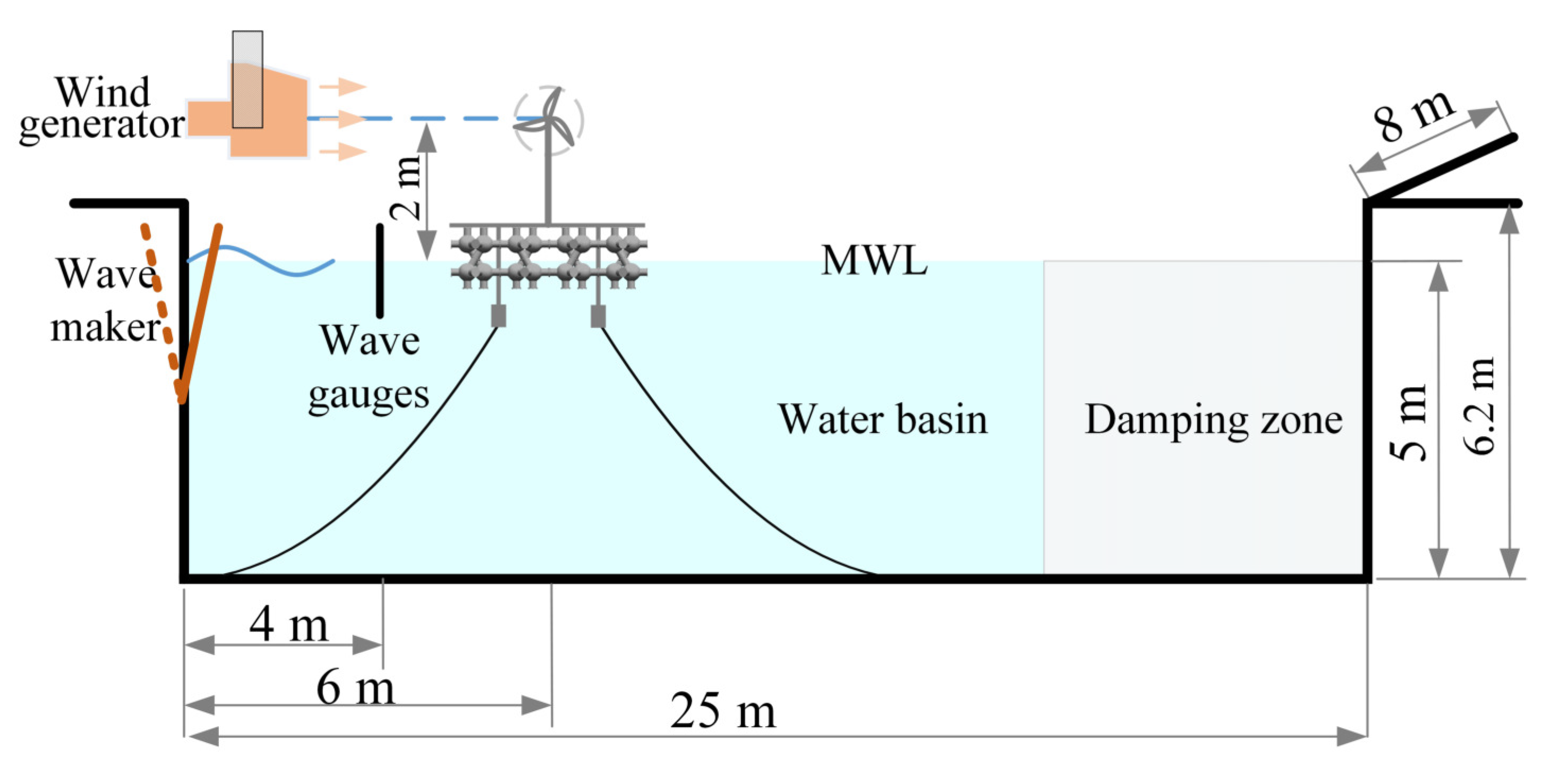

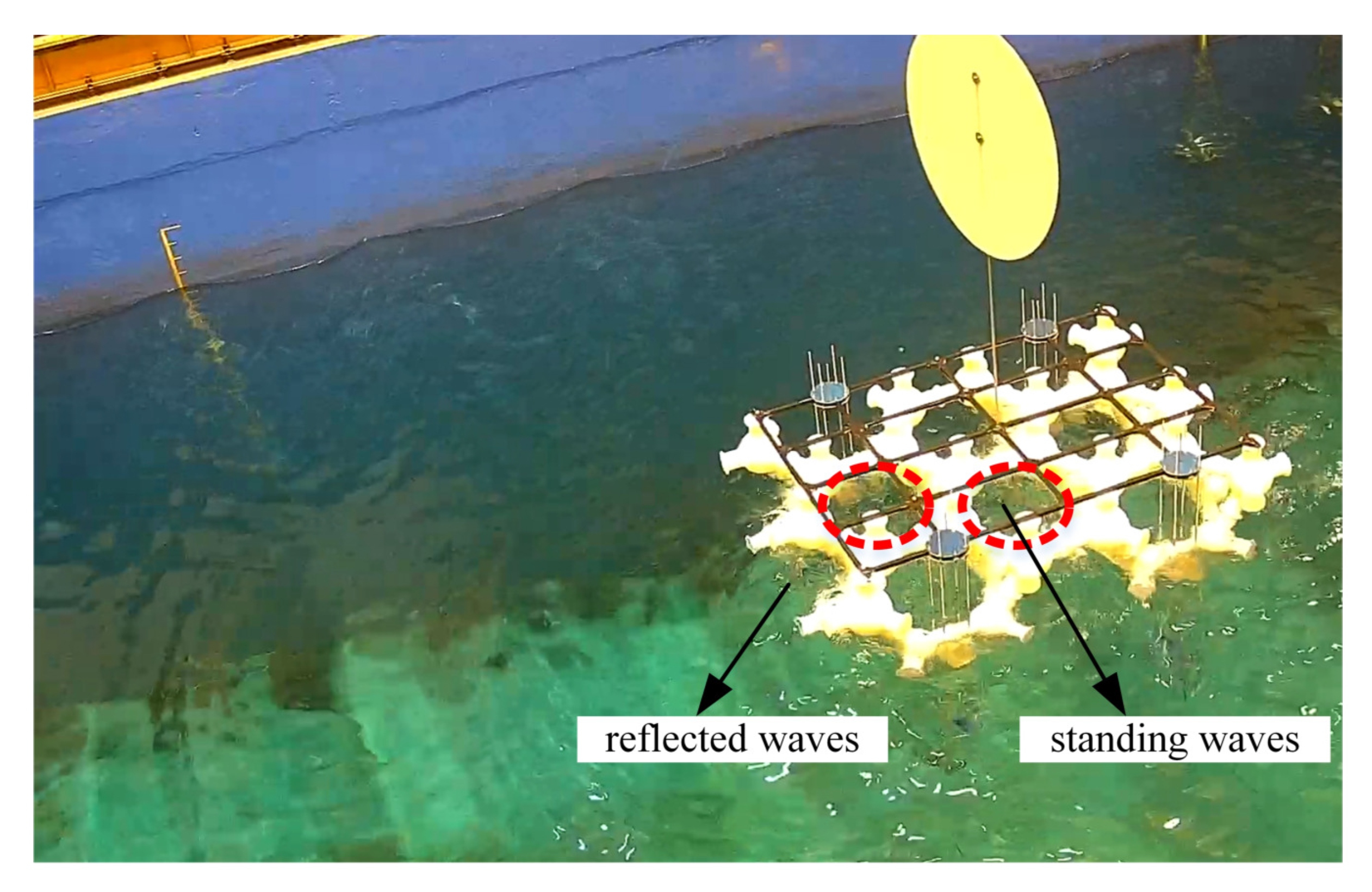

3. Experimental Set-Up

3.1. Water Basin

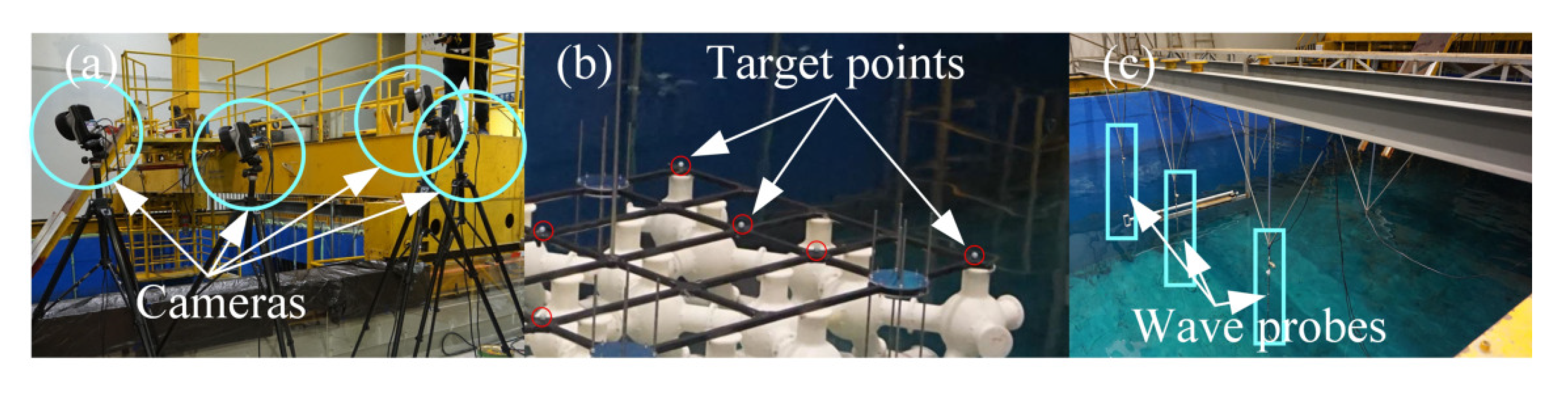

3.2. Measuring Instruments

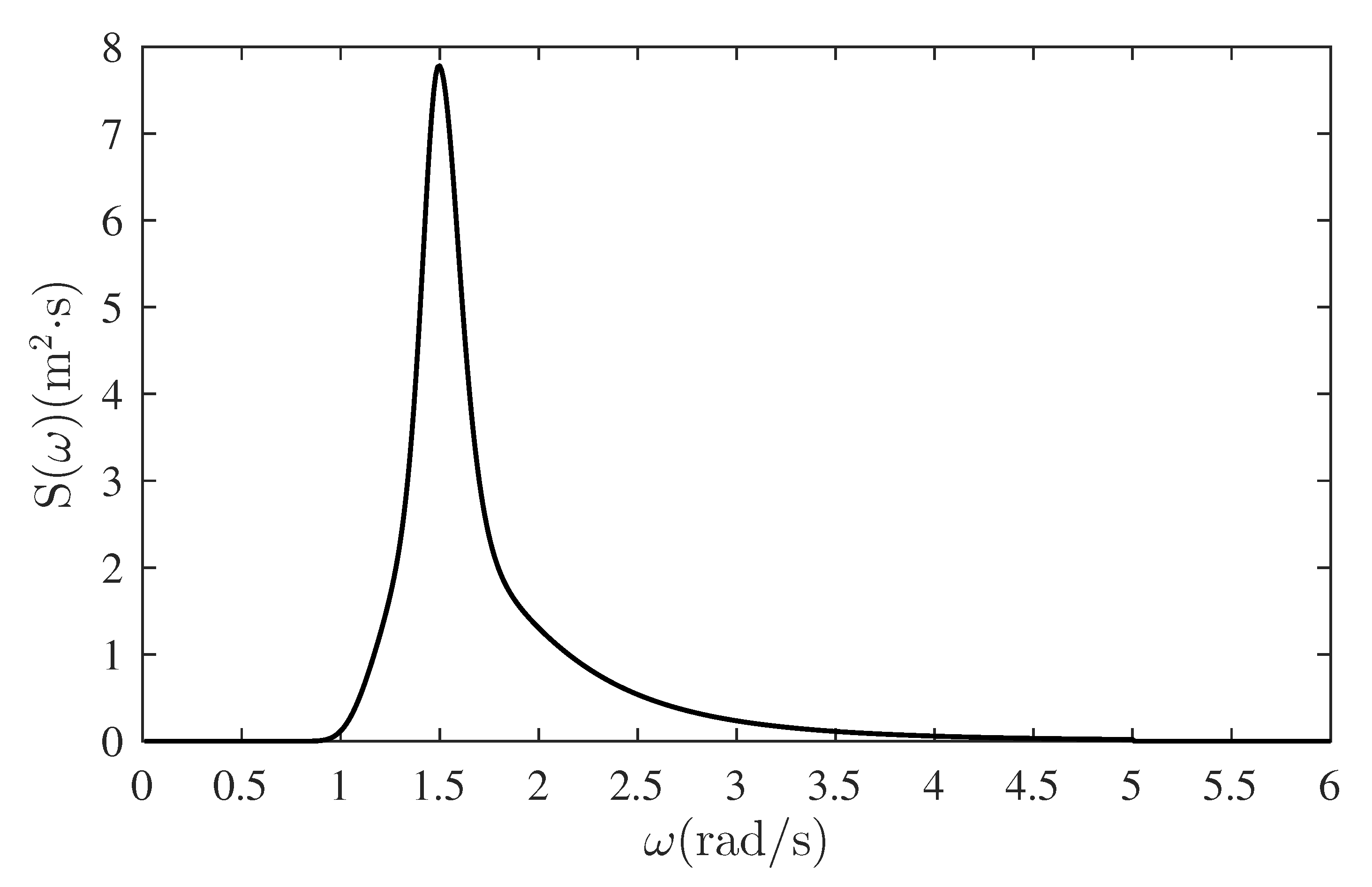

3.3. Incident Waves

4. Results

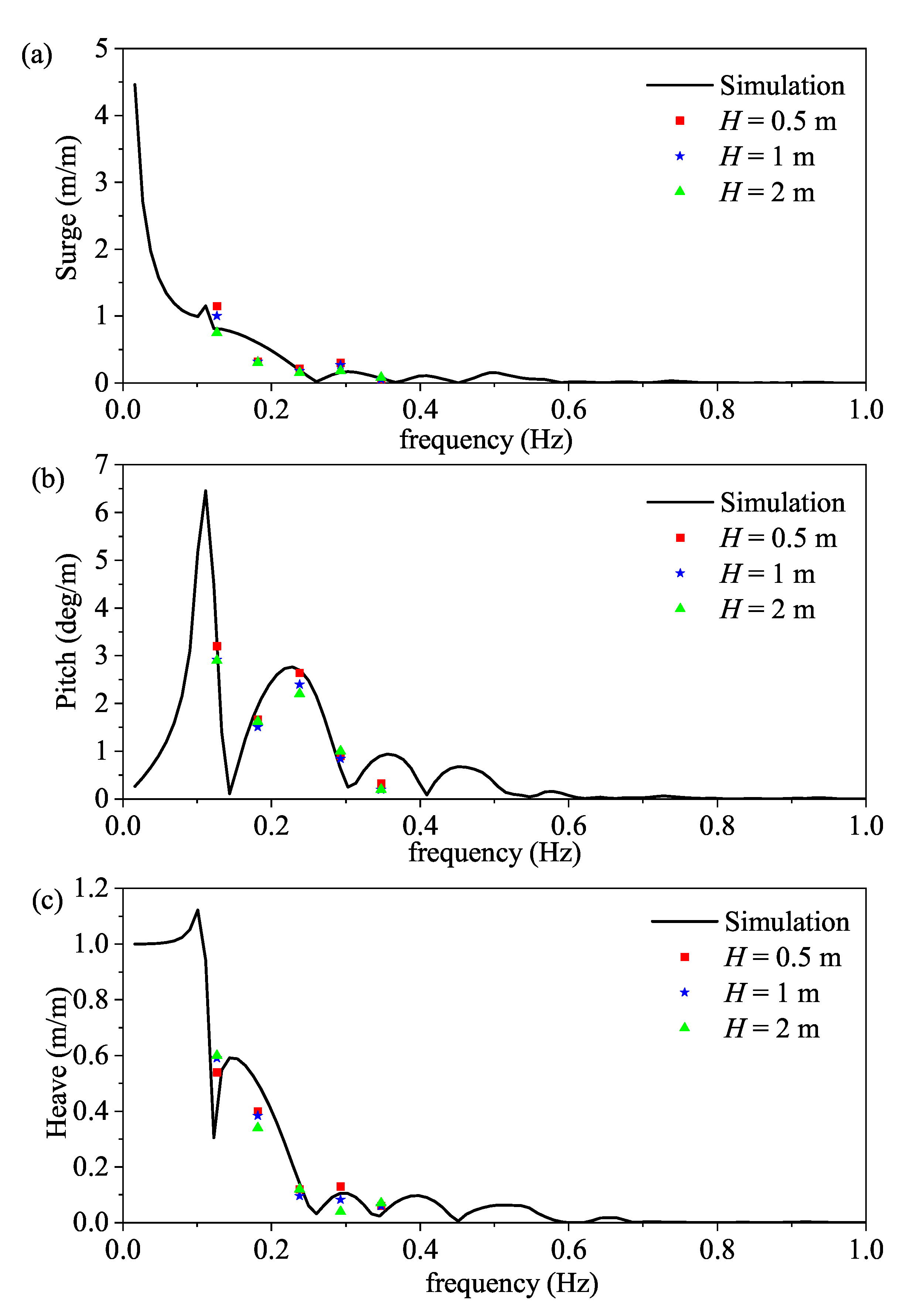

4.1. Response Amplitude Operator

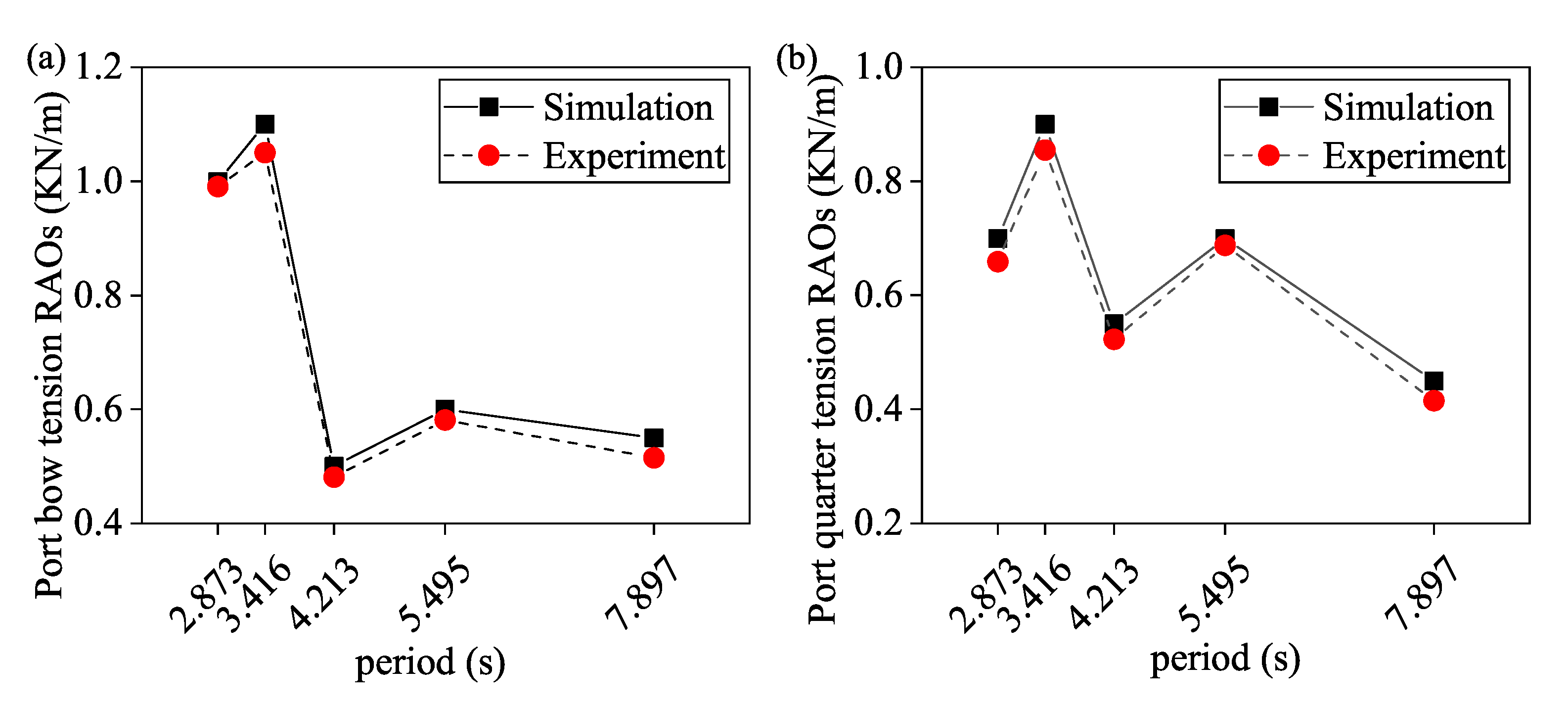

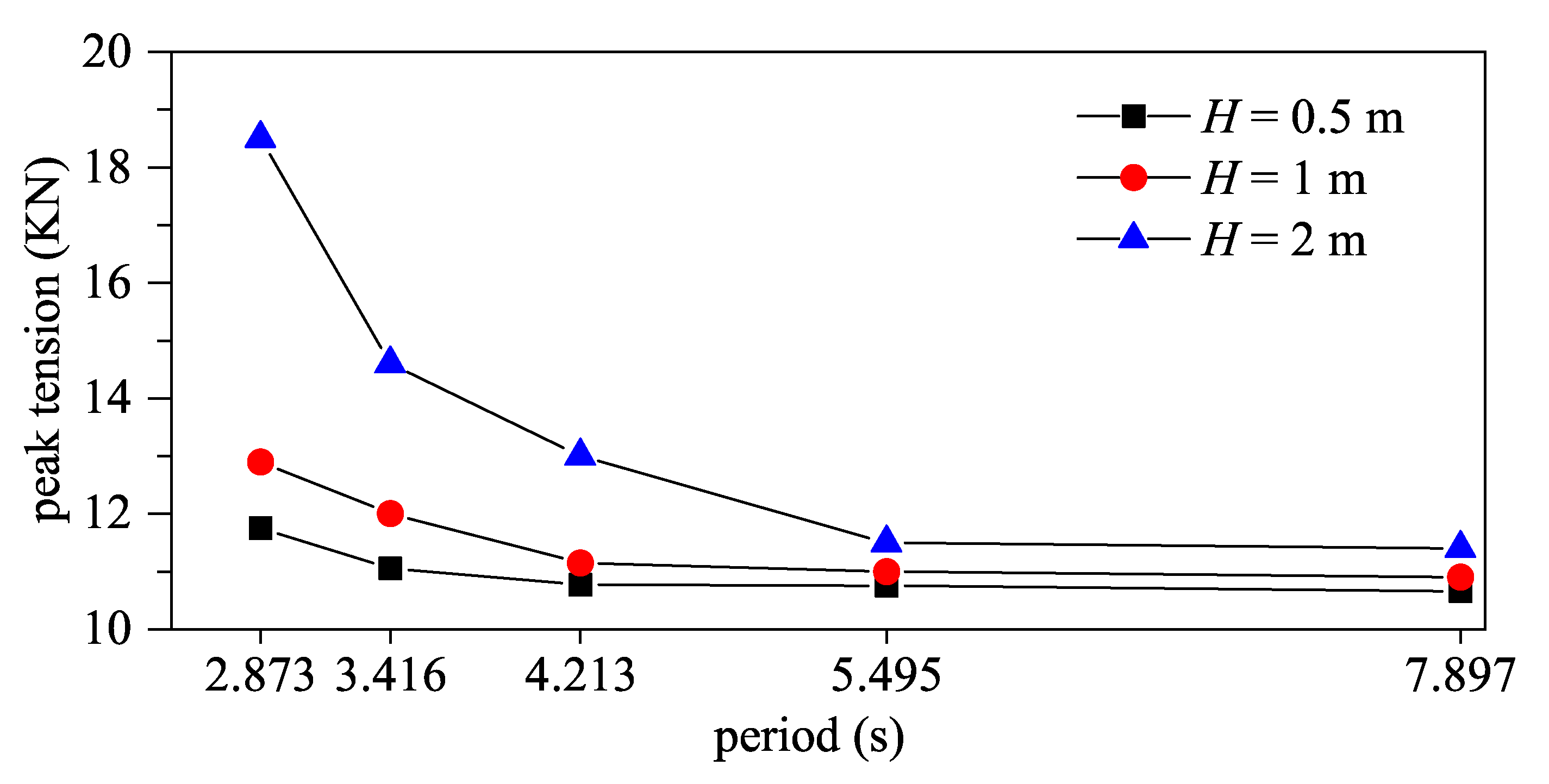

4.2. Mooring Force

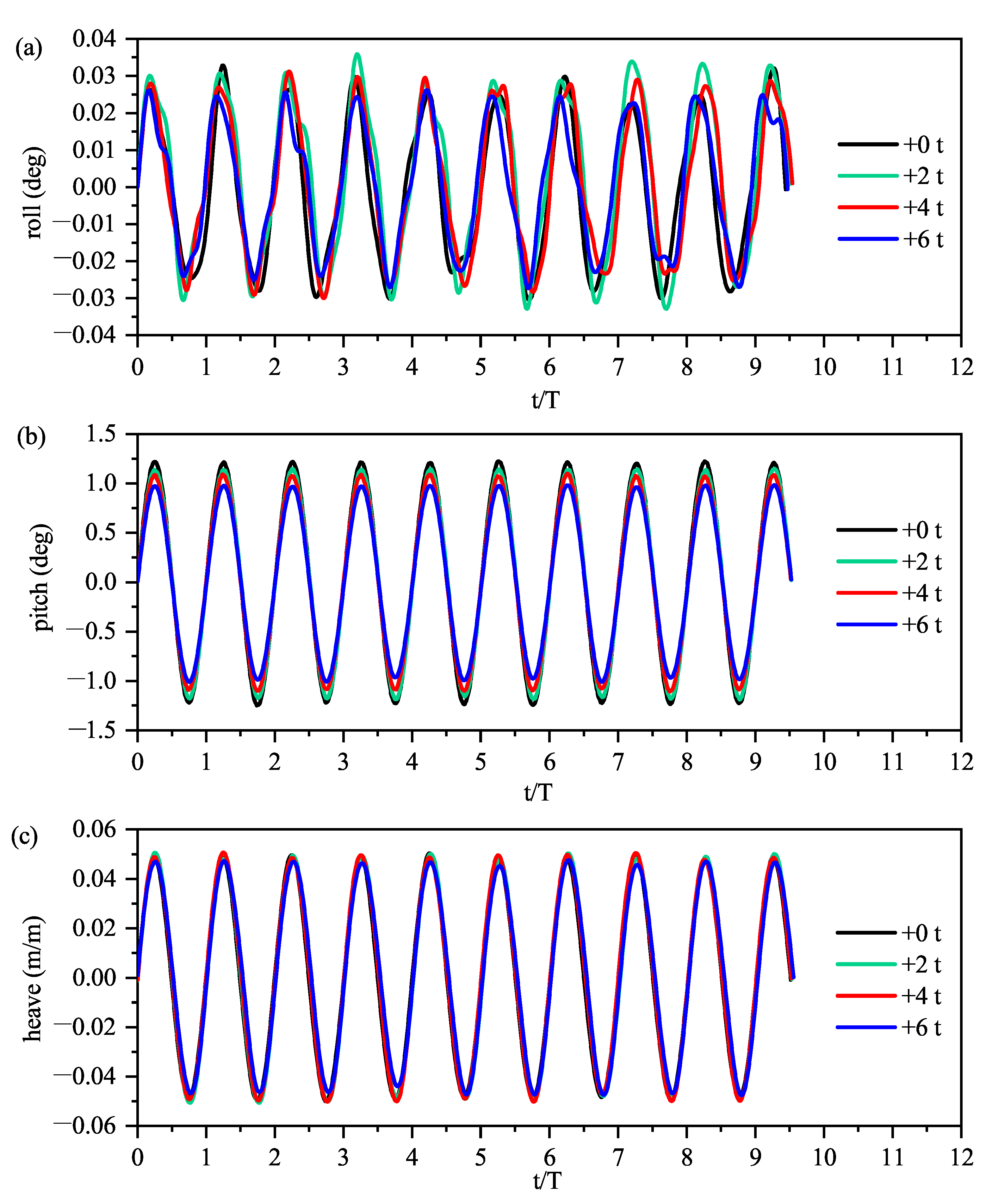

4.3. Influence of Platform Weights

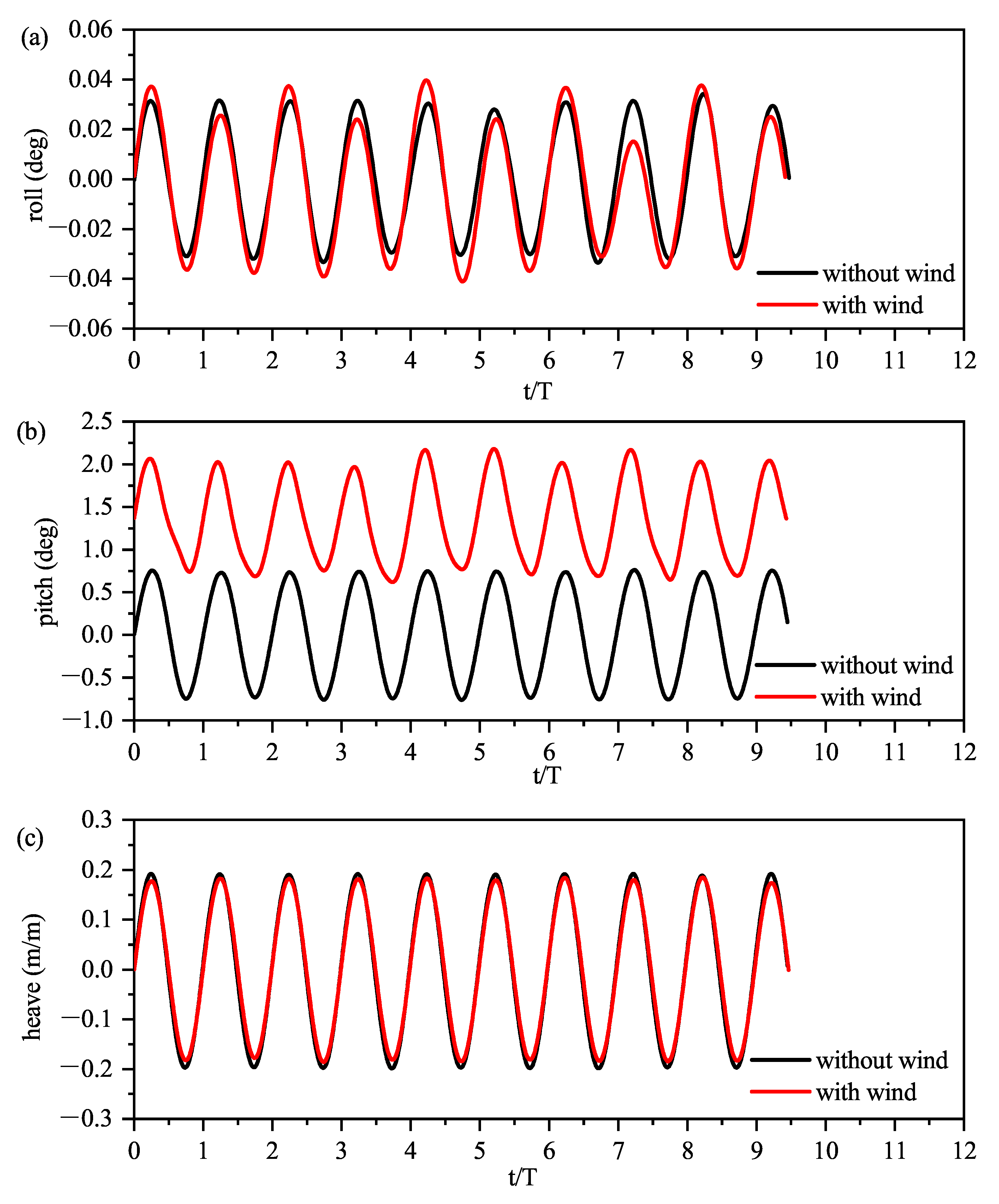

4.4. Influence of Winds

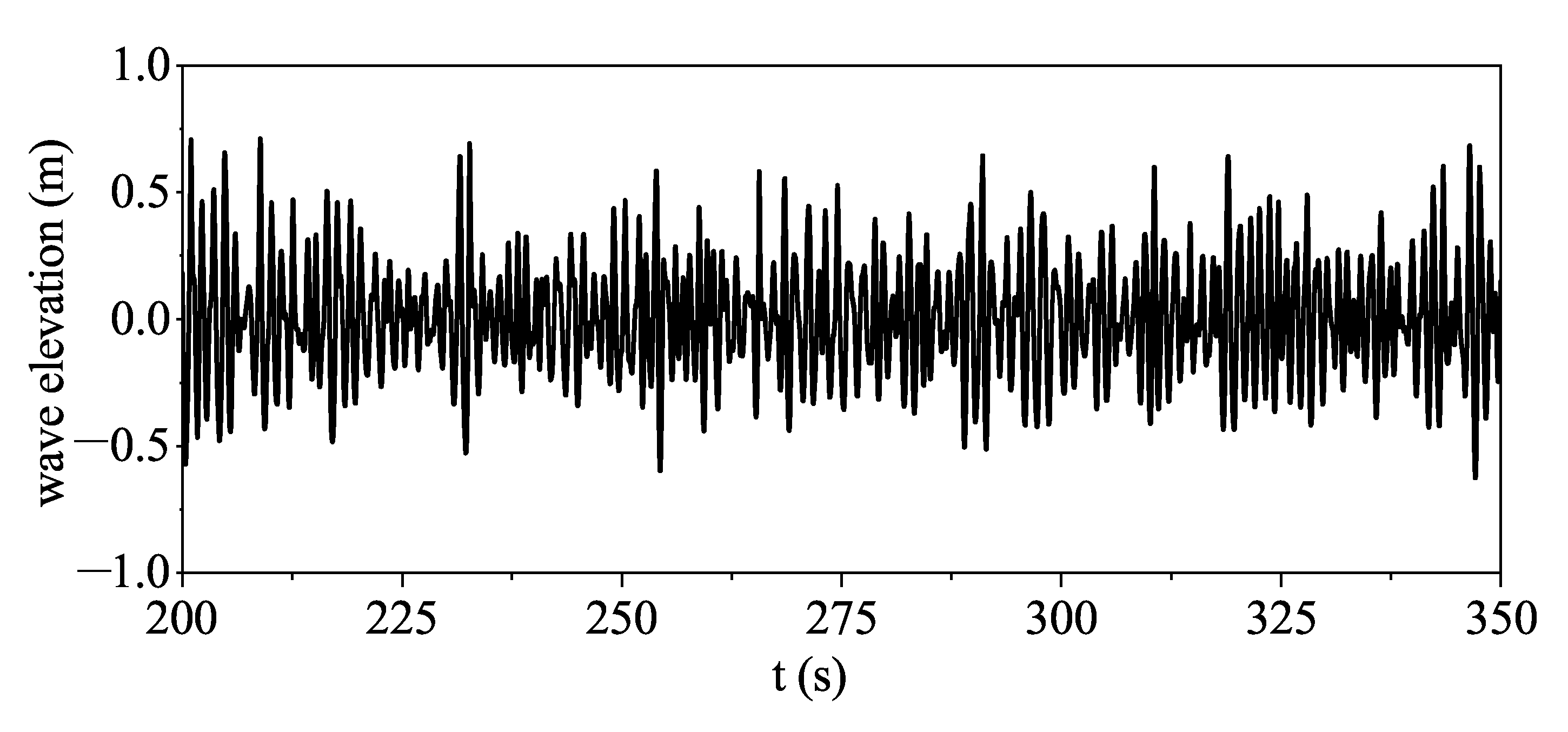

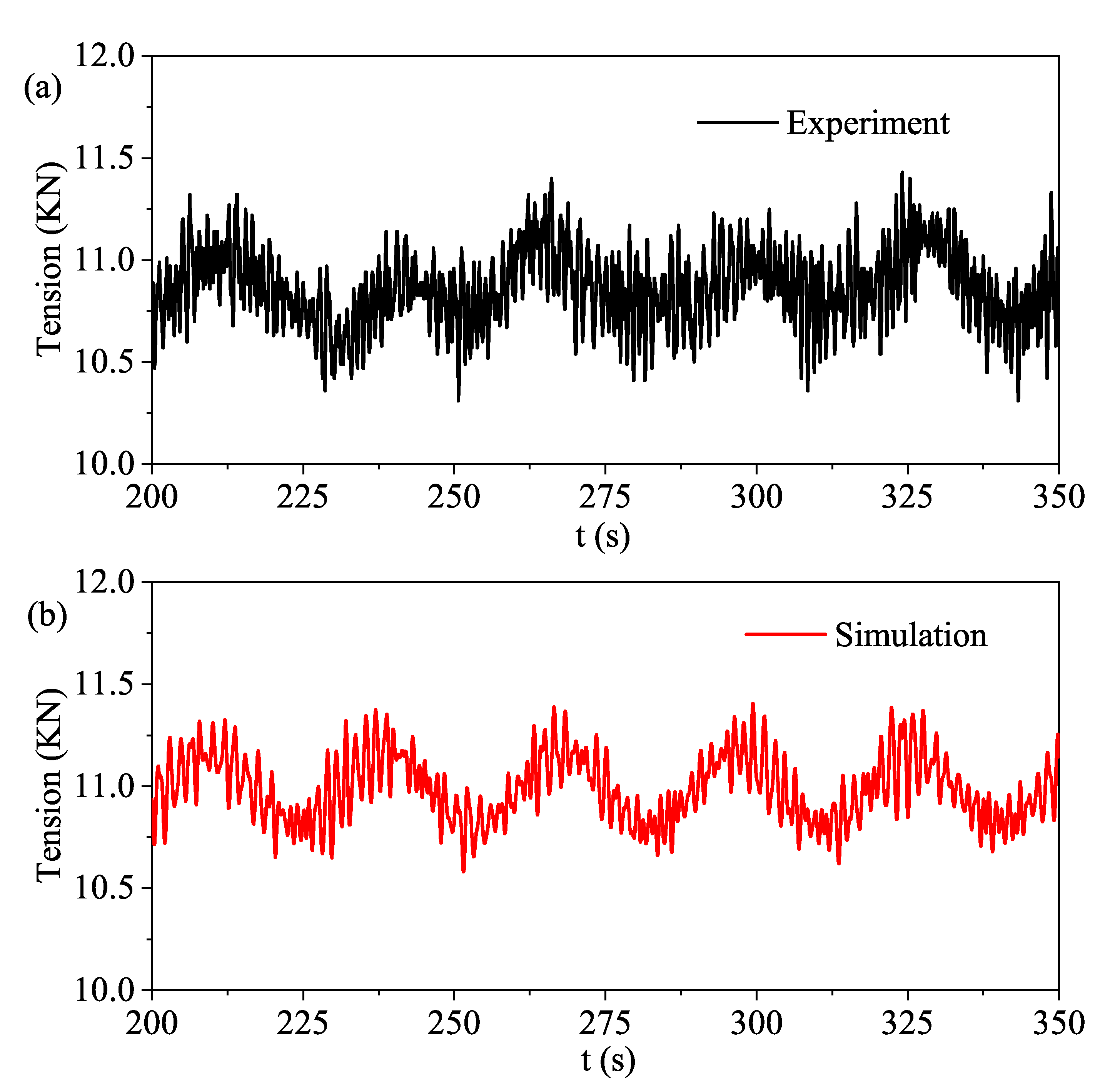

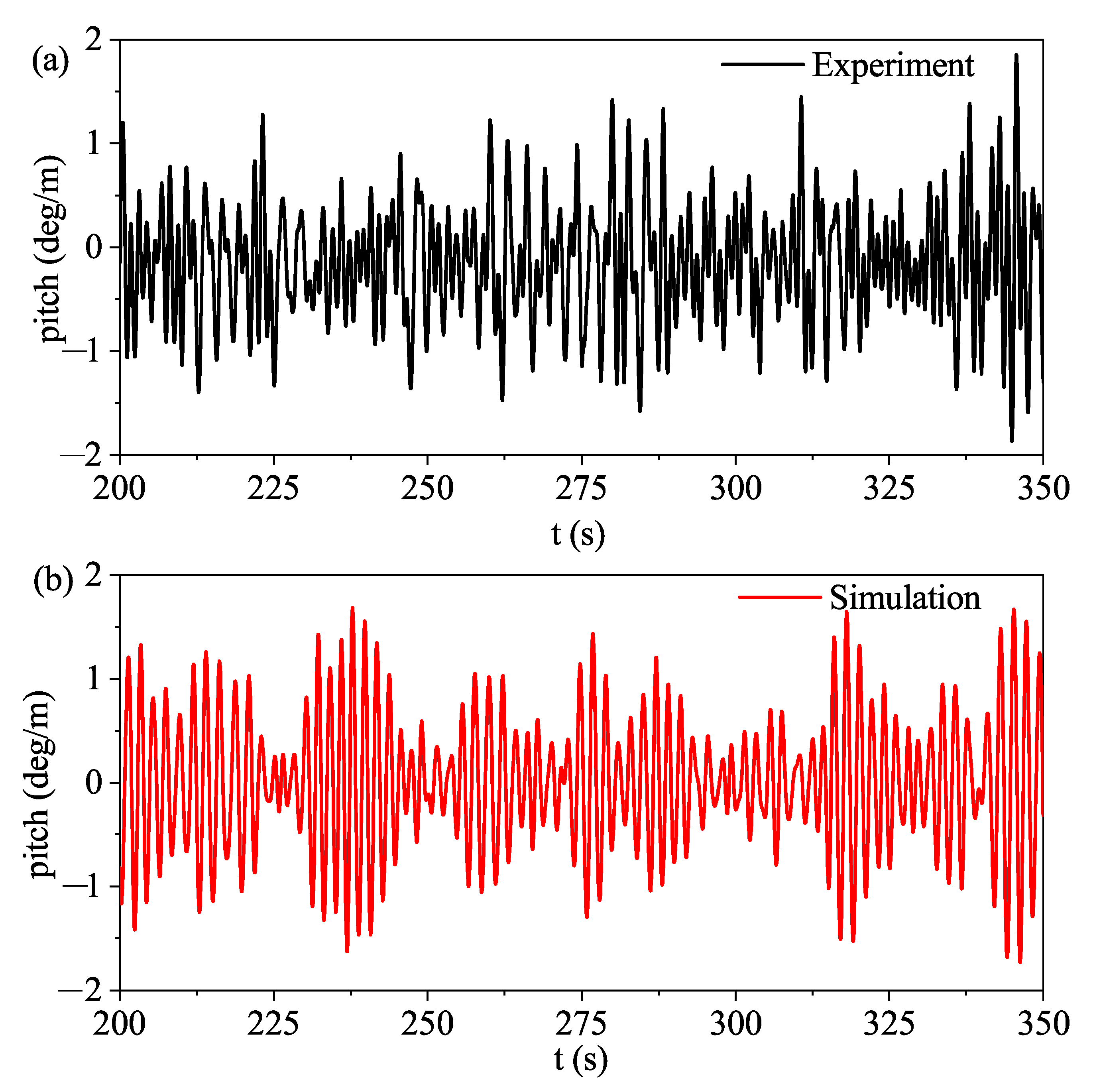

4.5. Irregular Waves

5. Conclusions

- Fifteen wave conditions are used to evaluate the hydrodynamic performance. The numerical results based on the potential theory are generally in good agreement with those of experiments. The maximum pitch angle is acceptable under the long-wave excitation.

- The simulation and experimental results of mooring tension RAOs have the same trend. The peak mobilized tensions of fore and rear mooring lines are far less than the breaking load.

- As concerns the influence of platform weights, the pitch motion can be reduced effectively by properly adding mass blocks on the deck of the BDFF. Meanwhile, the corresponding heave motion is independent of the additional loads.

- The experiment indicates that at a constant wind speed of 10 m/s, the wind substantially influences the pitch motion. The balance position has a tilt angle of 1.4 degrees. However, the influence on the heave motion is limited.

- It can also be found that the coupling effect of the roll, pitch, and heave motion is weak due to the symmetrical design.

- Regarding the irregular wave tests, the mooring tensions and instantaneous motion responses are compared with simulation results, showing similar characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BDFF | Buoyancy-distributed floating foundation |

| COG | Center of gravity |

| DOF | Degree of freedom |

| HFS | Hybrid floating system |

| MWL | Mean water line |

| RAOs | Response amplitude operators |

| SPAR | Single Point Anchor Reservoir |

| SSFF | Semi-submersible floating foundation |

| TLP | Tension-leg platform |

| WEC | Wave energy convertor |

References

- Wu, X.N.; Hu, Y.; Li, Y.; Yang, J.; Duan, L.; Wang, T.G.; Adcock, T.; Jiang, Z.Y.; Gao, Z.; Lin, Z.L.; et al. Foundations of offshore wind turbines: A review. Renew. Sustain. Energy Rev. 2019, 104, 379–393. [Google Scholar] [CrossRef] [Green Version]

- Oh, K.Y.; Nam, W.; Ryu, M.S.; Kim, J.Y.; Epureanu, B.I. A review of foundations of offshore wind energy convertors: Current status and future perspectives. Renew. Sustain. Energy Rev. 2018, 88, 16–36. [Google Scholar] [CrossRef]

- Maienza, C.; Avossa, M.A.; Ricciardelli, F.; Scherillo, F.; Georgakis, C.T. A Comparative Analysis of Construction Costs of Onshore and Shallow- and Deep-Water Offshore Wind Farms. In Proceedings of the XV Conference of the Italian Association for Wind Engineering, Naples, Campania, Italy, 9–12 September 2018; Ricciardelli, F., Avossa, M.A., Eds.; Springer: Cham, Switzerland, 2019; pp. 440–453. [Google Scholar] [CrossRef]

- Wang, X.F.; Zeng, X.W.; Li, J.L.; Yang, X.; Wang, H.J. A review on recent advancements of substructures for offshore wind turbines. Energy Convers. Manag. 2018, 158, 103–119. [Google Scholar] [CrossRef]

- Butterfield, S.; Musial, W.; Jonkman, J.; Sclavounos, P. Engineering Challenges for Floating Offshore Wind Turbines (No. NREL/CP-500-38776); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2007.

- Floating Wind Systems. Available online: https://www.bluewater.com/products-technology/floating-wind-systems/ (accessed on 20 October 2021).

- Amate, J.; Nchez, G.D.S.A.; Lez, G.G.A. Development of a Semi-submersible Barge for the installation of a TLP floating substructure. TLPWIND® case study. J. Phys. Conf. Ser. 2016, 749, 012016. [Google Scholar] [CrossRef]

- Vita, L.; Ramachandran, G.; Krieger, A.; Kvittem, M.I.; Merino, D.; Cross-Whiter, J.; Ackers, B.B. Comparison of numerical models and verification against experimental data, using Pelastar TLP concept. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Ocean Renewable Energy, St. John’s, NL, Canada, 31 May–5 June 2015; Volume 9. [Google Scholar] [CrossRef]

- The Future of Offshore Wind Is Afloat. Available online: https://www.equinor.com/en/what-we-do/floating-wind.html (accessed on 20 October 2021).

- Díaz, H.; Soares, C.G. Review of the current status, technology and future trends of offshore wind farms. Ocean Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Henderson, A.R.; Zaaijer, M.B.; Bulder, B.; Pierik, J.; Huijsmans, R.; van Hees, M.; Snijders, E.; Wijnants, G.H.; Wolf, M.J. Floating windfarms for shallow offshore sites. In Proceedings of the Fourteenth International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004. [Google Scholar]

- Liu, Y.; Li, S.; Yi, Q.; Chen, D. Developments in semi-submersible floating foundations supporting wind turbines: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 60, 433–449. [Google Scholar] [CrossRef]

- Roddier, D.; Cermelli, C.; Aubault, A.; Weinstein, A. WindFloat: A floating foundation for offshore wind turbines. J. Renew. Sustain. Energy 2010, 2, 033104. [Google Scholar] [CrossRef]

- Robertson, A.; Jonkman, J.; Masciola, M.; Song, H.; Goupee, A.; Coulling, A.; Luan, C. Definition of the Semisubmersible Floating System for Phase II of OC4; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2014.

- Mahfouz, M.; Faerron-Guzmán, R.; Müller, K.; Lemmer, F.; Cheng, P. Validation of drift motions for a semi-submersible floating wind turbine and associated challenges. J. Phys. Conf. Ser. 2020, 1669, 012011. [Google Scholar] [CrossRef]

- Roy, A.; Auger, F.; Dupriez-Robin, F.; Bourguet, S.; Tran, Q.T. Electrical power supply of remote maritime areas: A review of hybrid systems based on marine renewable energies. Energies 2018, 11, 1904. [Google Scholar] [CrossRef] [Green Version]

- Yde, A.; Bellew, S.B.; Clausen, R.S.; Nielsen, A.W. Report: Experimental and Theoretical Analysis of a Combined Floating Wave and Wind Energy Conversion Platform; DTU Wind Energy: Roskilde, Denmark, 2014. [Google Scholar]

- Technical Overview. Available online: https://bomborawave.com/mwave/ (accessed on 20 October 2021).

- Hanssen, J.E.; Margheritini, L.; O’Sullivan, K.; Mayorga, P.; Martinez, I.; Arriaga, A.; Agos, I.; Steynor, J.; Ingram, D.; Hezari, R.; et al. Design and performance validation of a hybrid offshore renewable energy platform. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Grimaldi Forum, Monaco, 31 March–2 April 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Ohya, Y.; Karasudani, T.; Nagai, T.; Watanabe, K. Wind lens technology and its application to wind and water turbine and beyond. Renew. Energy Environ. Sustain. 2017, 2, 2. [Google Scholar] [CrossRef] [Green Version]

- Our Unique Approach to Marine Renewable Electricity Production. Available online: https://www.sinnpower.com/ (accessed on 20 October 2021).

- Ahamed, R.; McKee, K.; Howard, I. Advancements of wave energy converters based on power take off (PTO) systems: A review. Ocean Eng. 2020, 204, 107248. [Google Scholar] [CrossRef]

- Koundouri, P.; Giannouli, A.; Souliotis, I. An integrated approach for sustainable environmental and socio-economic development using offshore infrastructure. In Renewable and Alternative Energy: Concepts, Methodologies, Tools, and Applications; Erdoğdu, M.M., Thankom, A., Imran, H.A., Eds.; IGI Global: Hershey, PA, USA, 2016; pp. 44–64. [Google Scholar]

- Papandroulakis, N.; Thomsen, C.; Mintenbeck, K.; Mayorga, P.; Hernández-Brito, J.J. The EU-Project “TROPOS”. In Aquaculture Perspective of Multi-Use Sites in the Open Ocean: The Untapped Potential for Marine Resources in the Anthropocene; Buck, B.H., Langan, R., Eds.; Springer: Cham, Switzerland, 2017; pp. 355–374. [Google Scholar]

- Krüner, S.; Hackl, C.M. Experimental Identification of the Optimal Current Vectors for a Permanent-Magnet Synchronous Machine in Wave Energy Converters. Energies 2019, 12, 862. [Google Scholar] [CrossRef] [Green Version]

- Yi, F.; Feng, W.b.; Cao, H.J. Wave analysis based on ERA-Interim reanalysis data in the South China Sea. Mar. Forecast. 2018, 35, 44–51. (In Chinese) [Google Scholar]

- Zhai, F.; Wu, W.; Gu, Y.; Li, P.; Liu, Z. Dynamics of the seasonal wave height variability in the South China Sea. Int. J. Climatol. 2021, 41, 934–951. [Google Scholar] [CrossRef]

| Energy Type | Applications |

|---|---|

| TLP: Bluewater, TLPWIND, PelaStar; | |

| Wind | SPAR: Hywind; |

| SSFF: Dutch Tri-floater, WindFloat, OC4-DeepCWind, NAUTILUS | |

| Wind + Wave | Poseidon P37, InSPIRE, W2Power, H2Ocean |

| Wind + Solar | OEFP |

| Wind + Wave + Solar | OHP |

| Comprehensive | TROPOS, MERMAID |

| Item | Value | Unit |

|---|---|---|

| Mass of rotors and hub | kg | |

| Mass of tower | kg | |

| Total mass including wind turbine and ballast | kg | |

| Depth of Center of gravity (COG) below the MWL | 3.5 | m |

| Roll Inertia relative to COG | kg·m | |

| Pitch Inertia relative to COG | kg·m | |

| Yaw Inertia relative to COG | kg·m |

| Case | Wave Periods, s | Wave Height, m | Winds |

|---|---|---|---|

| 1 | 2.873, 3.416, 4.213, 5.495, 7.897 | 0.5, 1, 2 | Without winds |

| 2 | 2.873, 3.416, 4.213, 5.495, 7.897 | 1 | With winds |

| Direction | Expression | RAO |

|---|---|---|

| Surge | ||

| Pitch | ||

| Heave |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, X.; Yao, Y.; Du, J. Conceptual Design and Hydrodynamic Performance of a Modular Hybrid Floating Foundation. Energies 2021, 14, 7605. https://doi.org/10.3390/en14227605

Qu X, Yao Y, Du J. Conceptual Design and Hydrodynamic Performance of a Modular Hybrid Floating Foundation. Energies. 2021; 14(22):7605. https://doi.org/10.3390/en14227605

Chicago/Turabian StyleQu, Xiaobin, Yingxue Yao, and Jianjun Du. 2021. "Conceptual Design and Hydrodynamic Performance of a Modular Hybrid Floating Foundation" Energies 14, no. 22: 7605. https://doi.org/10.3390/en14227605

APA StyleQu, X., Yao, Y., & Du, J. (2021). Conceptual Design and Hydrodynamic Performance of a Modular Hybrid Floating Foundation. Energies, 14(22), 7605. https://doi.org/10.3390/en14227605