Numerical Investigation on the Flame Structure and CO/NO Formations of the Laminar Premixed Biogas–Hydrogen Impinging Flame in the Wall Vicinity

Abstract

:1. Introduction

2. Numerical Methods

3. Results and Discussions

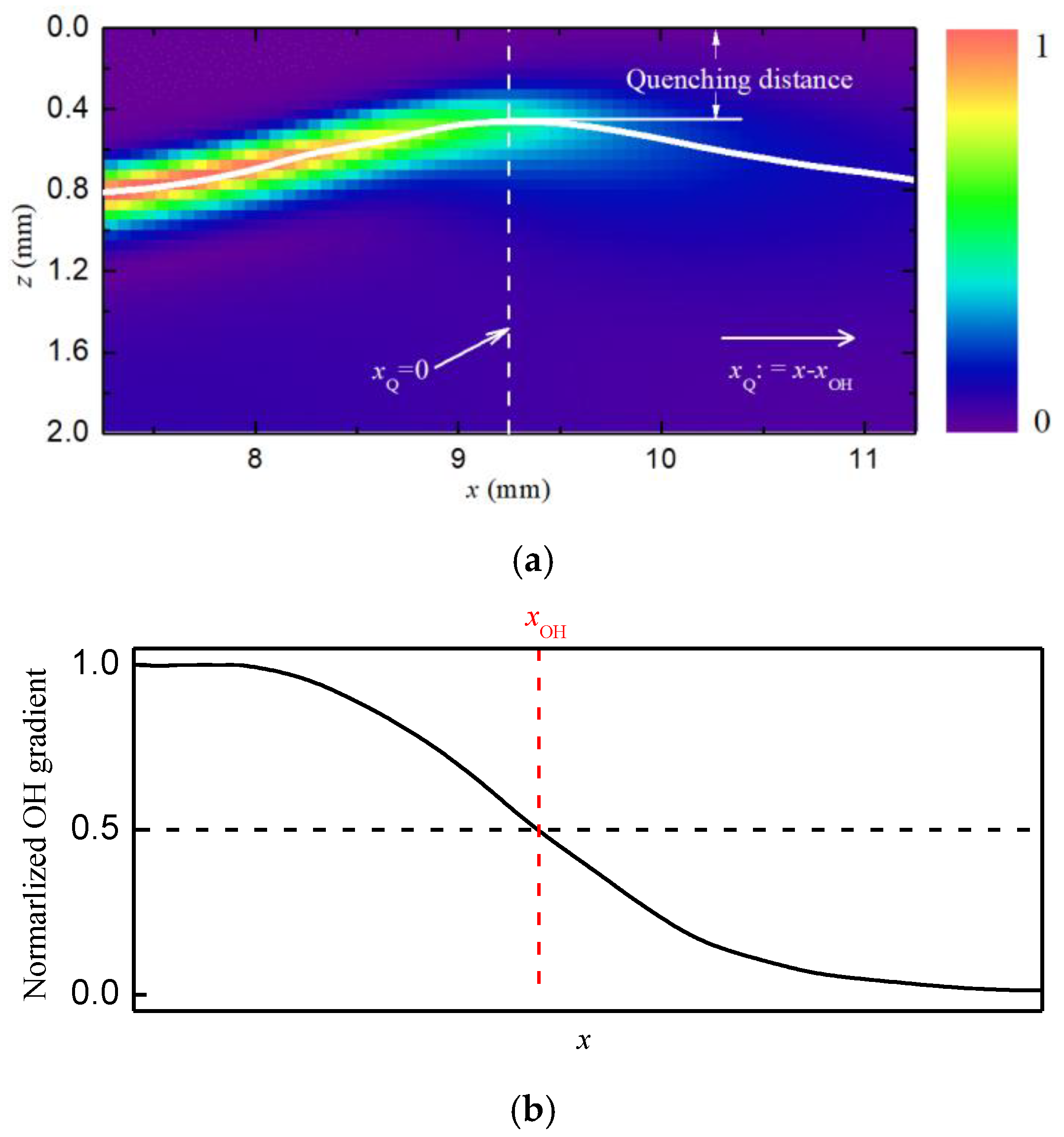

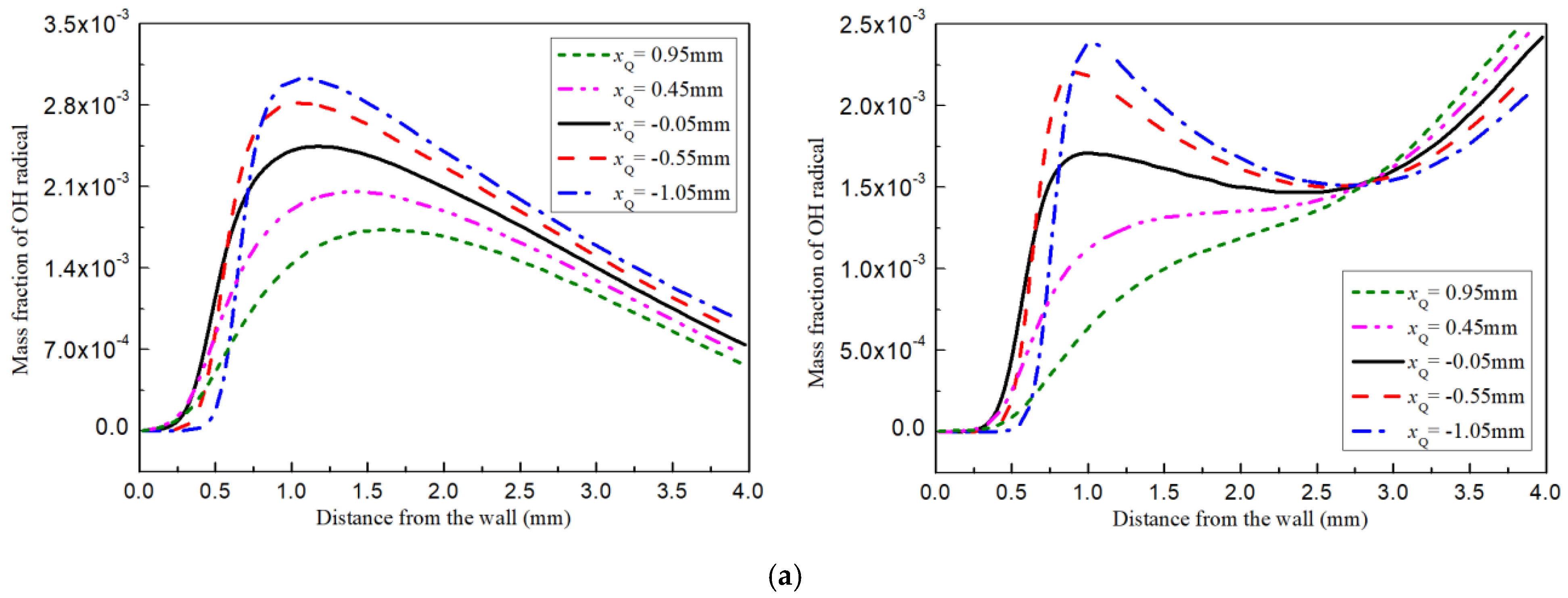

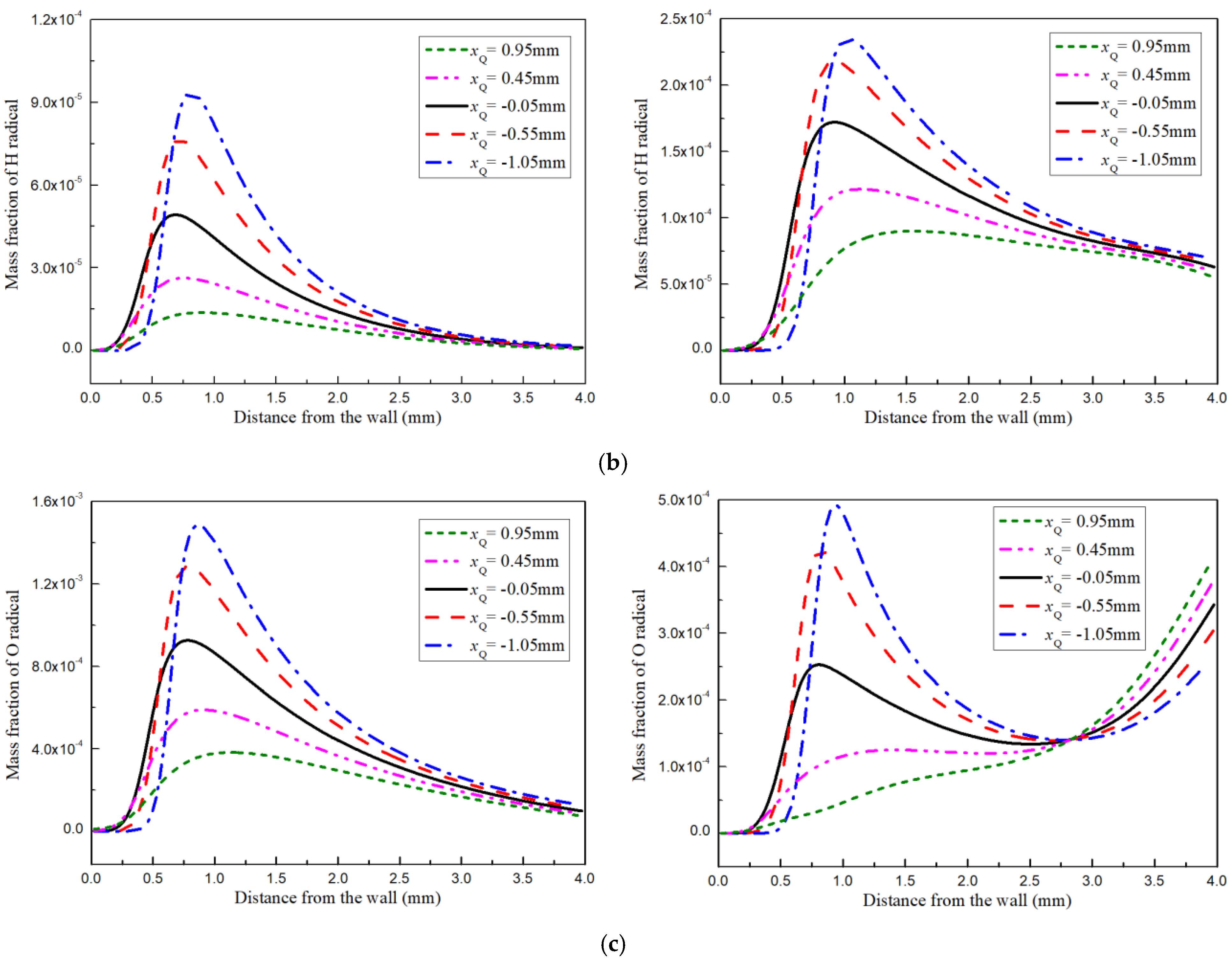

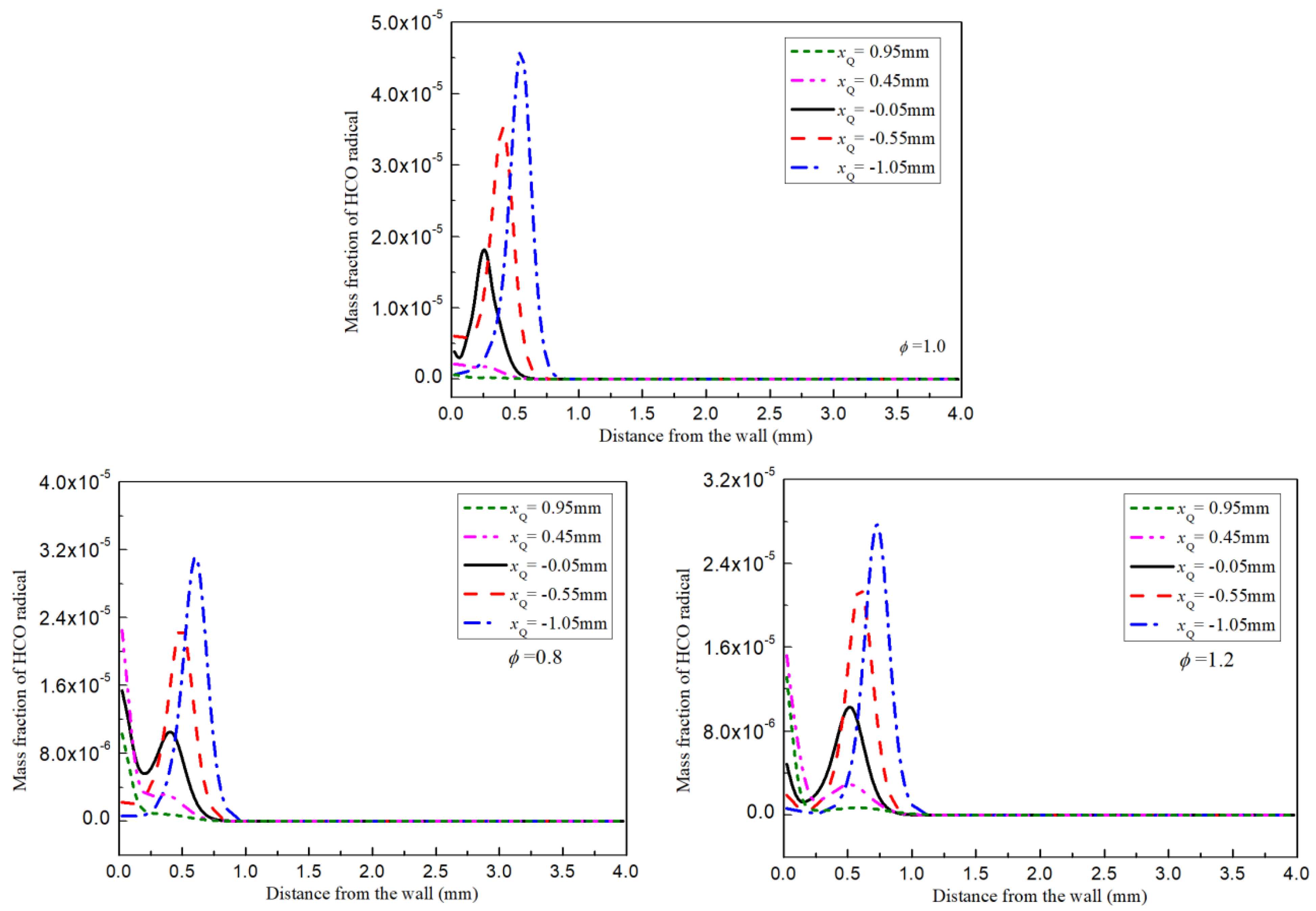

3.1. Near-Wall Flame Structure of the Laminar Premixed Biogas–Hydrogen Impinging Flame

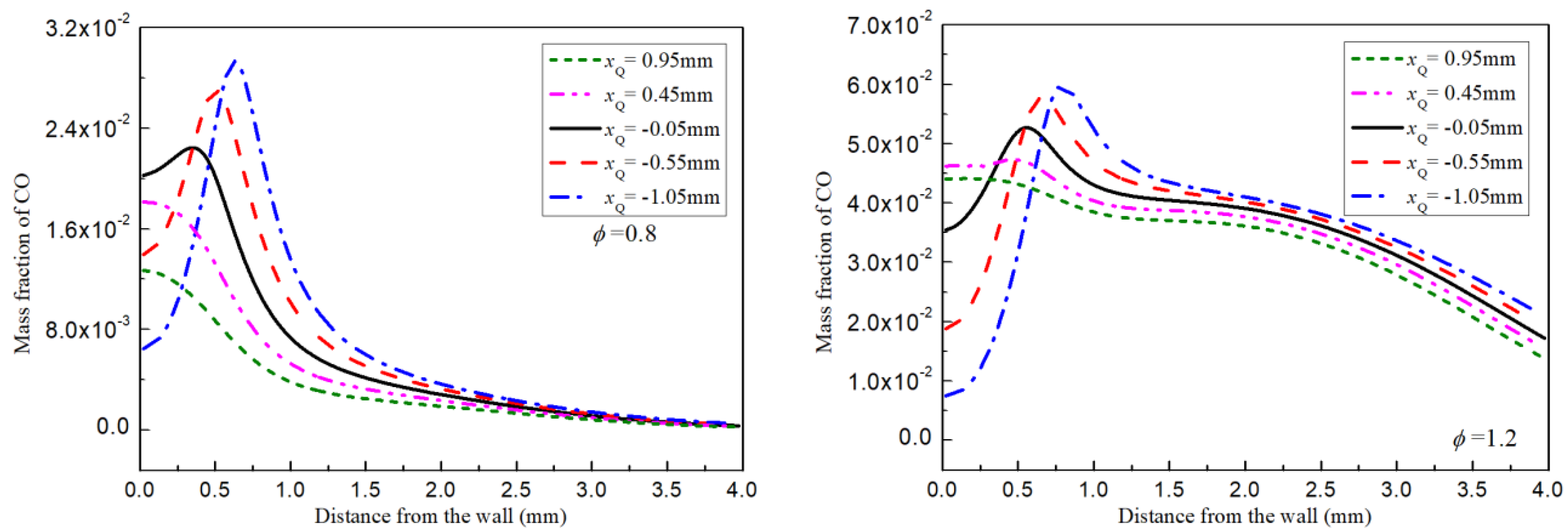

3.2. Near-Wall Spatial Profiles of CO in the Laminar Premixed Biogas–Hydrogen Impinging Flame

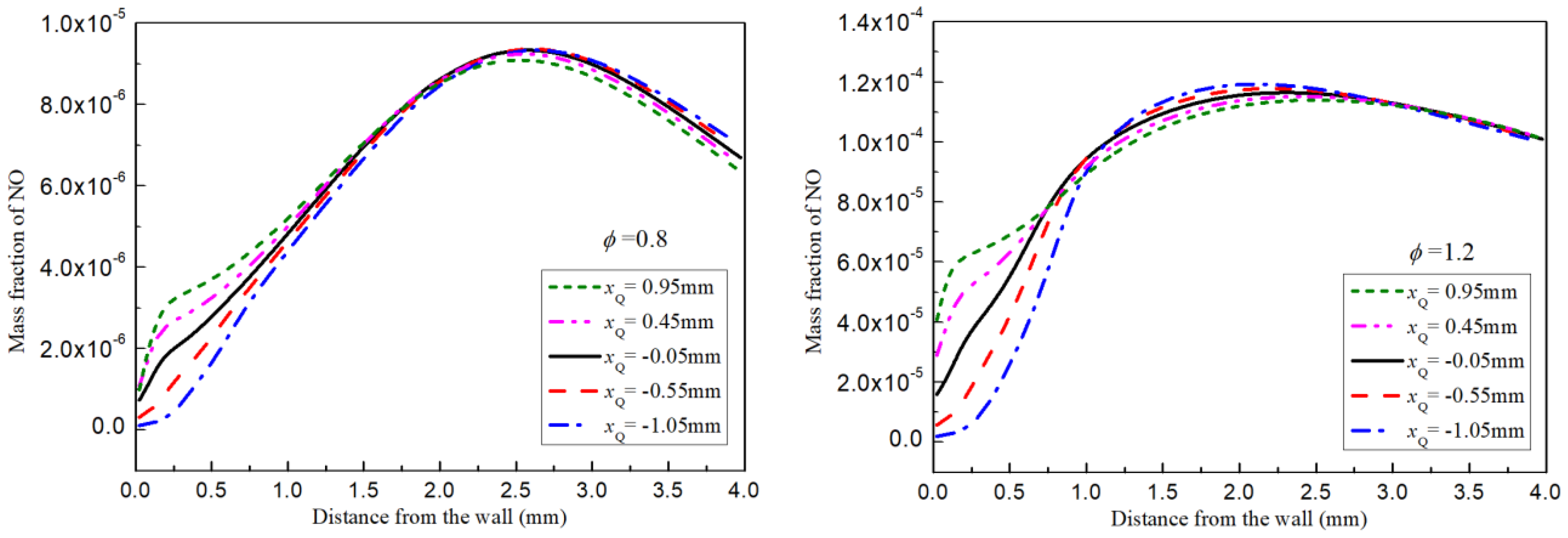

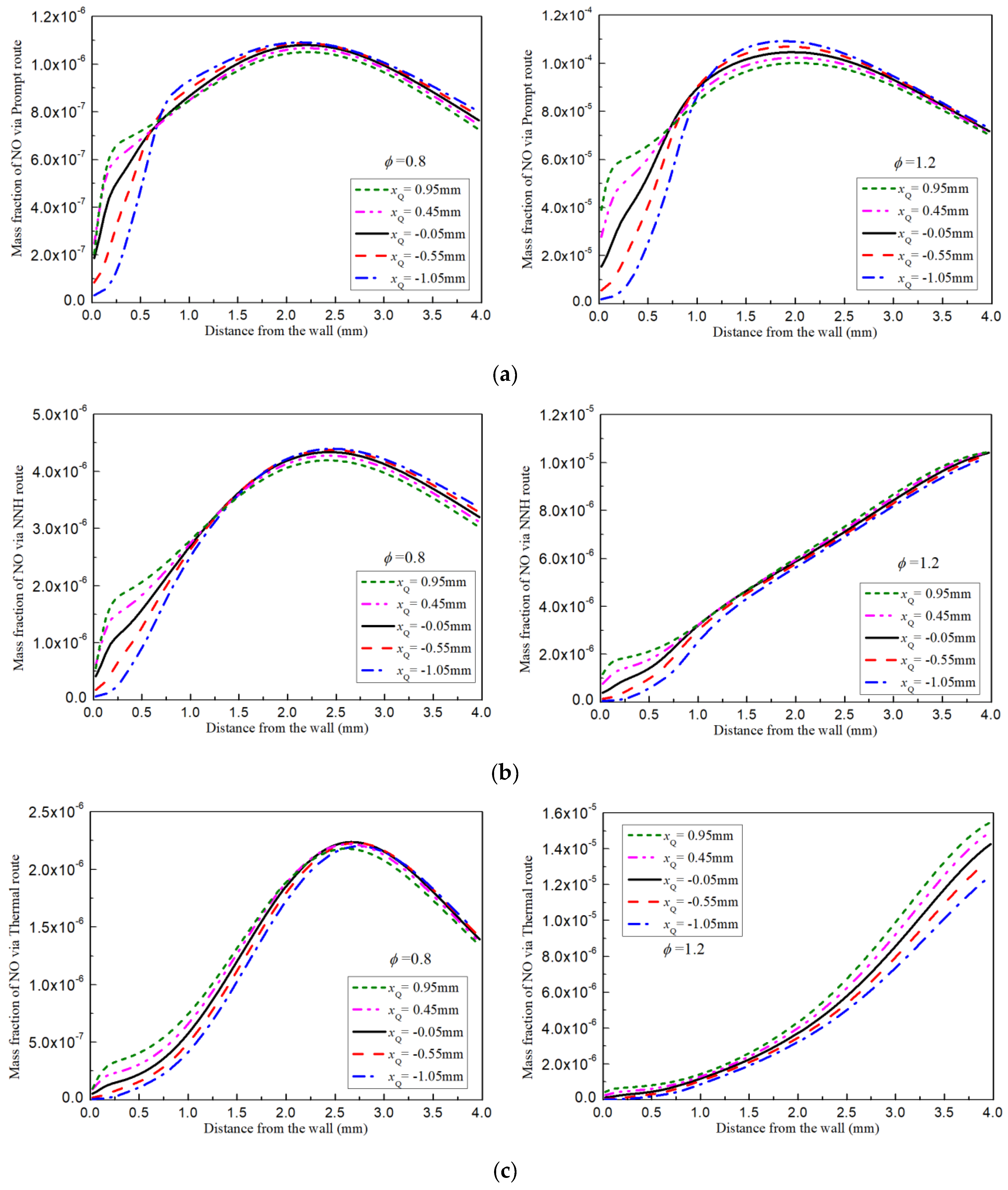

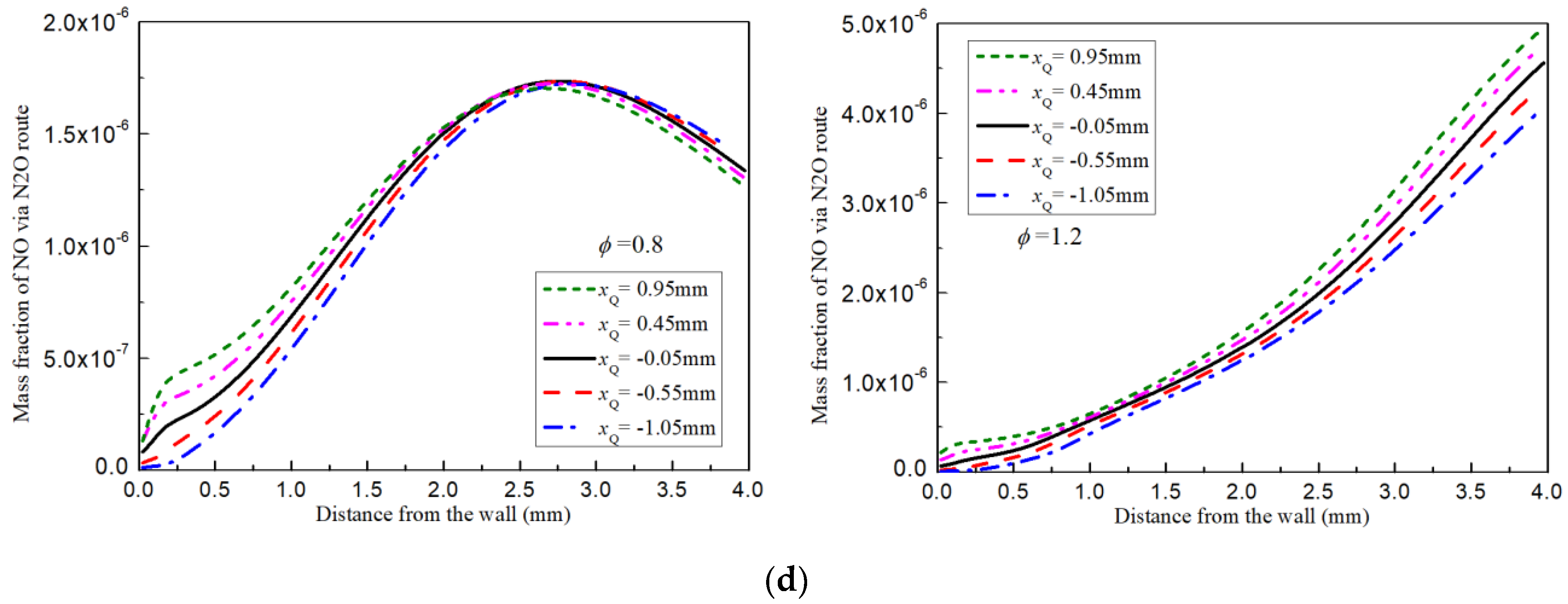

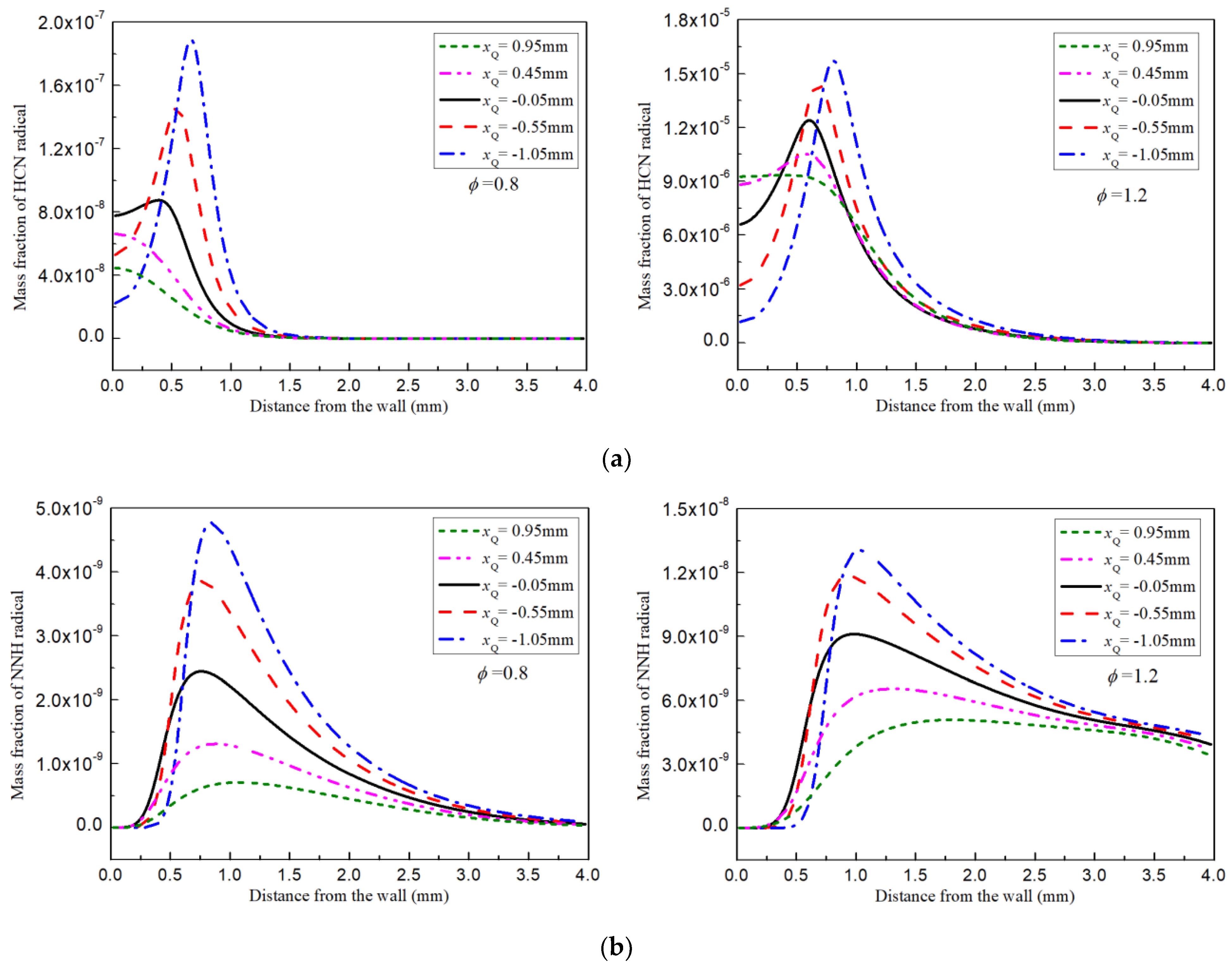

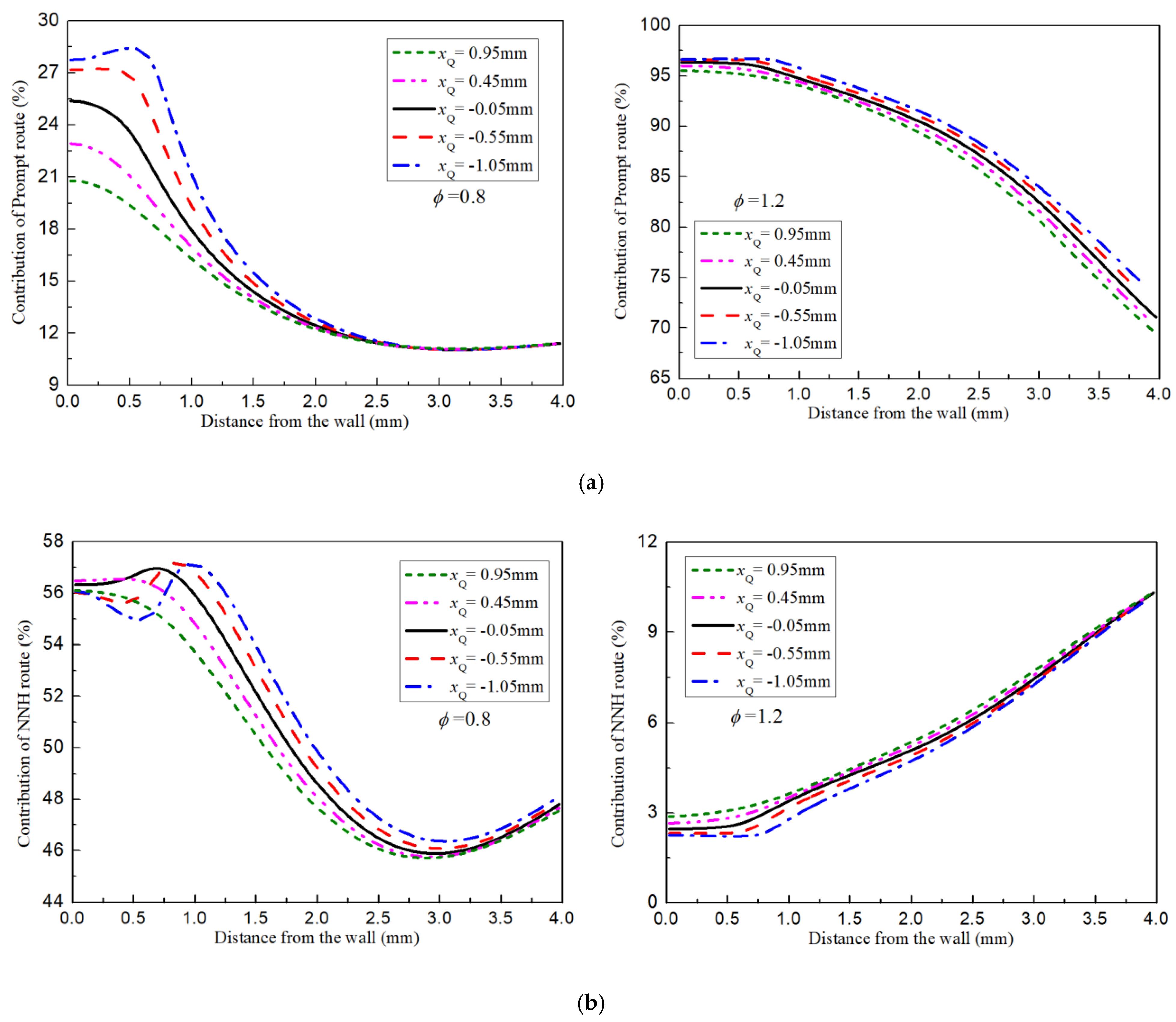

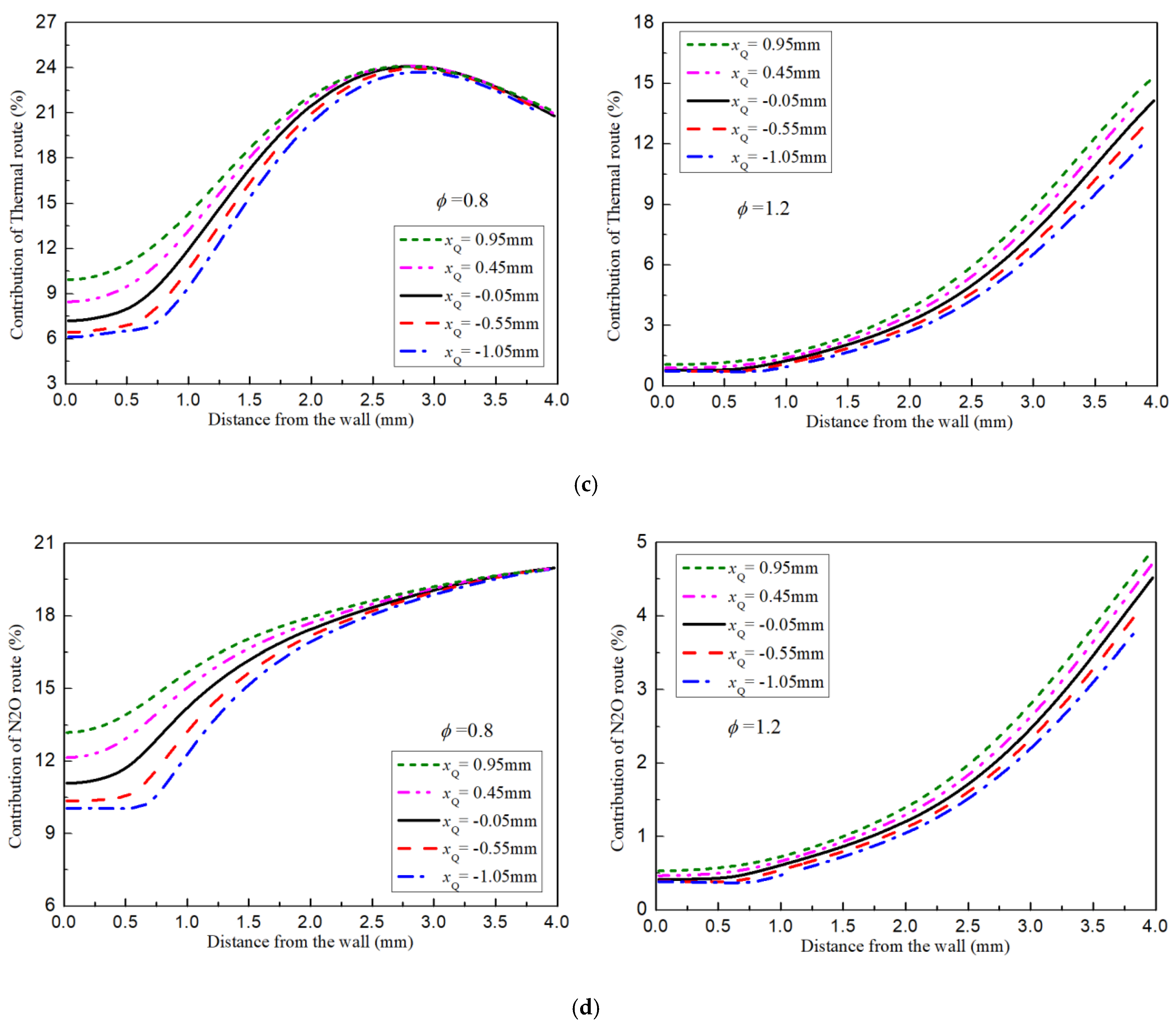

3.3. Near-Wall Spatial Profiles of NO in the Laminar Premixed Biogas–Hydrogen Impinging Flame

4. Conclusions

- The temperature and OH, H, and O radicals can be affected considerably by the cold wall, which results in a large temperature gradient and quite low concentrations of OH, H, and O radicals in the wall vicinity. It should be noted that the cold wall can also influence the premixed combustion process in the flame front, which is close to the wall but does not touch the wall, and results in decreased concentrations of OH, H, and O radicals before flame quenching occurs. This means that, thanks to the effectively increased surface-to-volume ratio, the premixed combustion process in the downsized chamber will be suppressed more easily by the amplified cooling effects of the cold wall, which might contribute to the decreased combustion efficiency and increased pollutant emissions.

- After the flame quenching, the high CO concentration can be observed near the wall at both φ = 0.8 and 1.2. Compared with that at φ = 1.0, more unburned fuel is allowed to pass through the quenching zone and to generate CO after flame quenching near the wall at φ = 0.8 and 1.2 thanks to the suppressed fuel consumption rate and excess fuel in the unburned gases. Thus, the high concentration of CO near the wall in either the fuel-lean or fuel-rich condition is ascribed to the combined effects of CO production and transportation. By isolating the formation routes of NO production, it is found that the fast-rising trend of NO concentration near the wall in the post flame region at φ = 0.8 is attributed to the NO transportation from the NNH route primarily, while the high NO concentration at φ = 1.2 is resulted from the prompt NO production, which accounts for more than 90% of NO generation in the wall vicinity. It is thus known that the incomplete combustion and NO via the prompt and NNH routes might be improved in the downsized combustor due to the amplified cooling effects of the cold wall.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Alkidas, A. Combustion-chamber crevices: The major source of engine-out hydrocarbon emissions under fully warmed conditions. Prog. Energy Combust. Sci. 1999, 25, 253–273. [Google Scholar] [CrossRef]

- Dreizler, A.; Böhm, B. Advanced laser diagnostics for an improved understanding of premixed flame-wall interactions. Proc. Combust. Inst. 2015, 35, 37–64. [Google Scholar] [CrossRef]

- Wang, Y.; Trouvé, A. Direct numerical simulation of nonpremixed flame–wall interactions. Combust. Flame 2006, 144, 461–475. [Google Scholar] [CrossRef]

- Rivera, J.E.; Gordon, R.L.; Talei, M. Flame-wall interaction of a forced laminar premixed propane flame: Flame dynamics and exhaust CO emissions. Proc. Combust. Inst. 2019, 37, 5385–5392. [Google Scholar] [CrossRef]

- Tang, A.; Deng, J.; Cai, T.; Xu, Y.; Pan, J. Combustion characteristics of premixed propane/hydrogen/air in the micro-planar combustor with different channel-heights. Appl. Energy 2017, 203, 635–642. [Google Scholar] [CrossRef]

- Häber, T.; Suntz, R. Effect of different wall materials and thermal-barrier coatings on the flame-wall interaction of laminar premixed methane and propane flames. Int. J. Heat Fluid Flow 2018, 69, 95–105. [Google Scholar] [CrossRef]

- Poinsot, T.J.; Haworth, D.C.; Bruneaux, G. Direct simulation and modeling of flame-wall interaction for premixed turbulent combustion. Combust. Flame 1993, 95, 118–132. [Google Scholar] [CrossRef]

- Kosaka, H.; Zentgraf, F.; Scholtissek, A.; Bischoff, L.; Häber, T.; Suntz, R.; Albert, B.; Hasse, C.; Dreizler, A. Wall heat fluxes and CO formation/oxidation during laminar and turbulent side-wall quenching of methane and DME flames. Int. J. Heat Fluid Flow 2018, 70, 181–192. [Google Scholar] [CrossRef]

- Wei, Z.L.; Leung, C.W.; Cheung, C.S.; Huang, Z.H. Effects of H2 and CO2 addition on the heat transfer characteristics of laminar premixed biogas–hydrogen Bunsen flame. Int. J. Heat Mass Transf. 2016, 98, 359–366. [Google Scholar] [CrossRef]

- Zhen, H.S.; Leung, C.W.; Cheung, C.S.; Huang, Z.H. Combustion characteristic and heating performance of stoichiometric biogas–hydrogen–air flame. Int. J. Heat Mass Transf. 2016, 92, 807–814. [Google Scholar] [CrossRef]

- Yousefi-Asli, V.; Houshfar, E.; Beygi-Khosroshahi, F.; Ashjaee, M. Experimental investigation on temperature field and heat transfer distribution of a slot burner methane/air flame impinging on a curved surface. Appl. Therm. Eng. 2018, 129, 761–771. [Google Scholar] [CrossRef]

- Kiani, M.; Houshfar, E.; Ashjaee, M. Experimental investigations on the flame structure and temperature field of landfill gas in impinging slot burners. Energy 2019, 170, 507–520. [Google Scholar] [CrossRef]

- Raj, V.C.; Kuntikana, P.; Sreedhara, S.; Prabhu, S.V. Separation of heat transfer components from impinging methane diffusion flames. Int. J. Heat Mass Transf. 2018, 126, 123–138. [Google Scholar] [CrossRef]

- Singh, A.; Mann, M.; Kissel, T.; Brübach, J.; Dreizler, A. Simultaneous measurements of temperature and CO concentration in stagnation stabilized flames. Flow Turbul. Combust. 2013, 90, 723–739. [Google Scholar] [CrossRef]

- Mann, M.; Jainski, C.; Euler, M.; Böhm, B.; Dreizler, A. Transient flame–wall interactions: Experimental analysis using spectroscopic temperature and CO concentration measurements. Combust. Flame 2014, 161, 2371–2386. [Google Scholar] [CrossRef]

- Jainski, C.; Rißmann, M.; Böhm, B.; Janicka, J.; Dreizler, A. Sidewall quenching of atmospheric laminar premixed flames studied by laser-based diagnostics. Combust. Flame 2017, 183, 271–282. [Google Scholar] [CrossRef]

- Ganter, S.; Heinrich, A.; Meier, T.; Kuenne, G.; Jainski, C.; Rißmann, M.C.; Dreizler, A.; Janicka, J. Numerical analysis of laminar methane–air side-wall-quenching. Combust. Flame 2017, 186, 299–310. [Google Scholar] [CrossRef]

- Jiang, B.; Gordon, R.L.; Talei, M. Head-on quenching of laminar premixed methane flames diluted with hot combustion products. Proc. Combust. Inst. 2019, 37, 5095–5103. [Google Scholar] [CrossRef]

- Wei, Z.; Zhen, H.; Leung, C.; Cheung, C.; Huang, Z. Effects of H2 addition on the formation and emissions of CO/NO2/NOx in the laminar premixed biogas-hydrogen flame undergoing the flame-wall interaction. Fuel 2020, 259, 116257. [Google Scholar] [CrossRef]

- Wei, Z.; Zhen, H.; Leung, C.; Cheung, C.; Huang, Z. Effects of unburned gases velocity on the CO/NO2/NOx formations and overall emissions of laminar premixed biogas-hydrogen impinging flame. Energy 2020, 196, 117146. [Google Scholar] [CrossRef]

- Wei, Z.; Zhen, H.; Leung, C.; Cheung, C.; Huang, Z. Formations and emissions of CO/NO2/NOx in the laminar premixed biogas-hydrogen flame undergoing the flame-wall interaction: Effects of the variable CO2 proportion. Fuel 2020, 276, 118096. [Google Scholar] [CrossRef]

- Wei, Z.L.; Zhen, H.S.; Leung, C.W.; Cheung, C.S.; Huang, Z.H. Experimental and numerical study on the emission characteristics of laminar premixed biogas-hydrogen impinging flame. Fuel 2017, 195, 1–11. [Google Scholar] [CrossRef]

- Wehrfritz, A.; Wang, H.; Hawkes, E.R.; Gao, Y.; Lu, T. Wall-impinging laminar premixed n-dodecane flames under autoignitive conditions. Proc. Combust. Inst. 2019, 37, 1647–1654. [Google Scholar] [CrossRef]

- Divya, D.; Gopinath, L.R.; Merlin Christy, P. A review on current aspects and diverse prospects for enhancing biogas production in sustainable means. Renew. Sustain. Energy Rev. 2015, 42, 690–699. [Google Scholar] [CrossRef]

- Lim, C.; Kim, D.; Song, C.; Kim, J.; Han, J.; Cha, J.-S. Performance and emission characteristics of a vehicle fueled with enriched biogas and natural gases. Appl. Energy 2015, 139, 17–29. [Google Scholar] [CrossRef]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef] [Green Version]

- Habib, R.; Yadollahi, B.; Saeed, A.; Doranehgard, M.H.; Li, L.K.B.; Karimi, N. Unsteady ultra-lean combustion of methane and biogas in a porous burner—An experimental study. Appl. Therm. Eng. 2021, 182, 116099. [Google Scholar] [CrossRef]

- Bauer, C.; Forest, T. Effect of hydrogen addition on the performance of methane-fueled vehicles. Part I: Effect on SI engine performance. Int. J. Hydrogen Energy 2001, 26, 55–70. [Google Scholar] [CrossRef]

- Du, Y.; Yu, X.; Wang, J.; Wu, H.; Dong, W.; Gu, J. Research on combustion and emission characteristics of a lean burn gasoline engine with hydrogen direct-injection. Int. J. Hydrogen Energy 2016, 41, 3240–3248. [Google Scholar] [CrossRef]

- Wu, L.; Kobayashi, N.; Li, Z.; Huang, H. Experimental study on the effects of hydrogen addition on the emission and heat transfer characteristics of laminar methane diffusion flames with oxygen-enriched air. Int. J. Hydrogen Energy 2016, 41, 2023–2036. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Xia, H.; Ju, R.; Zhang, M.; Mu, H.; Huang, Z. Effect of hydrogen enrichment and electric field on lean CH4/air flame propagation at elevated pressure. Int. J. Hydrogen Energy 2019, 44, 15962–15972. [Google Scholar] [CrossRef]

- Guo, S.; Wang, J.; Zhang, W.; Zhang, M.; Huang, Z. Effect of hydrogen enrichment on swirl/bluff-body lean premixed flame stabilization. Int. J. Hydrogen Energy 2020, 45, 10906–10919. [Google Scholar] [CrossRef]

- Peters, N.; Rogg, B. Reduced Kinetic Mechanisms for Applications in Combustion Systems; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- UCSD. San Diego Mechanism. Chemical-Kinetic Mechanisms for Combustion, ApplicationsSan Diego Mechanism Web Page, Mechanical and Aerospace Engineering (Combustion Research), University of California at San Diego. Available online: http://combustion.ucsd.edu (accessed on 1 September 2021).

- Guo, H.; Smallwood, G.; Liu, F.; Ju, Y.; Gulder, O. The effect of hydrogen addition on flammability limit and NOx emission in ultra-lean counterflow CH4/air premixed flames. Proc. Combust. Inst. 2005, 30, 303–311. [Google Scholar] [CrossRef] [Green Version]

- Palulli, R.; Talei, M.; Gordon, R.L. Unsteady flame–wall interaction: Impact on CO emission and wall heat flux. Combust. Flame 2019, 207, 406–416. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Z.; Wang, L.; Liu, H.; Liu, Z.; Zhen, H. Numerical Investigation on the Flame Structure and CO/NO Formations of the Laminar Premixed Biogas–Hydrogen Impinging Flame in the Wall Vicinity. Energies 2021, 14, 7308. https://doi.org/10.3390/en14217308

Wei Z, Wang L, Liu H, Liu Z, Zhen H. Numerical Investigation on the Flame Structure and CO/NO Formations of the Laminar Premixed Biogas–Hydrogen Impinging Flame in the Wall Vicinity. Energies. 2021; 14(21):7308. https://doi.org/10.3390/en14217308

Chicago/Turabian StyleWei, Zhilong, Lei Wang, Hu Liu, Zihao Liu, and Haisheng Zhen. 2021. "Numerical Investigation on the Flame Structure and CO/NO Formations of the Laminar Premixed Biogas–Hydrogen Impinging Flame in the Wall Vicinity" Energies 14, no. 21: 7308. https://doi.org/10.3390/en14217308

APA StyleWei, Z., Wang, L., Liu, H., Liu, Z., & Zhen, H. (2021). Numerical Investigation on the Flame Structure and CO/NO Formations of the Laminar Premixed Biogas–Hydrogen Impinging Flame in the Wall Vicinity. Energies, 14(21), 7308. https://doi.org/10.3390/en14217308