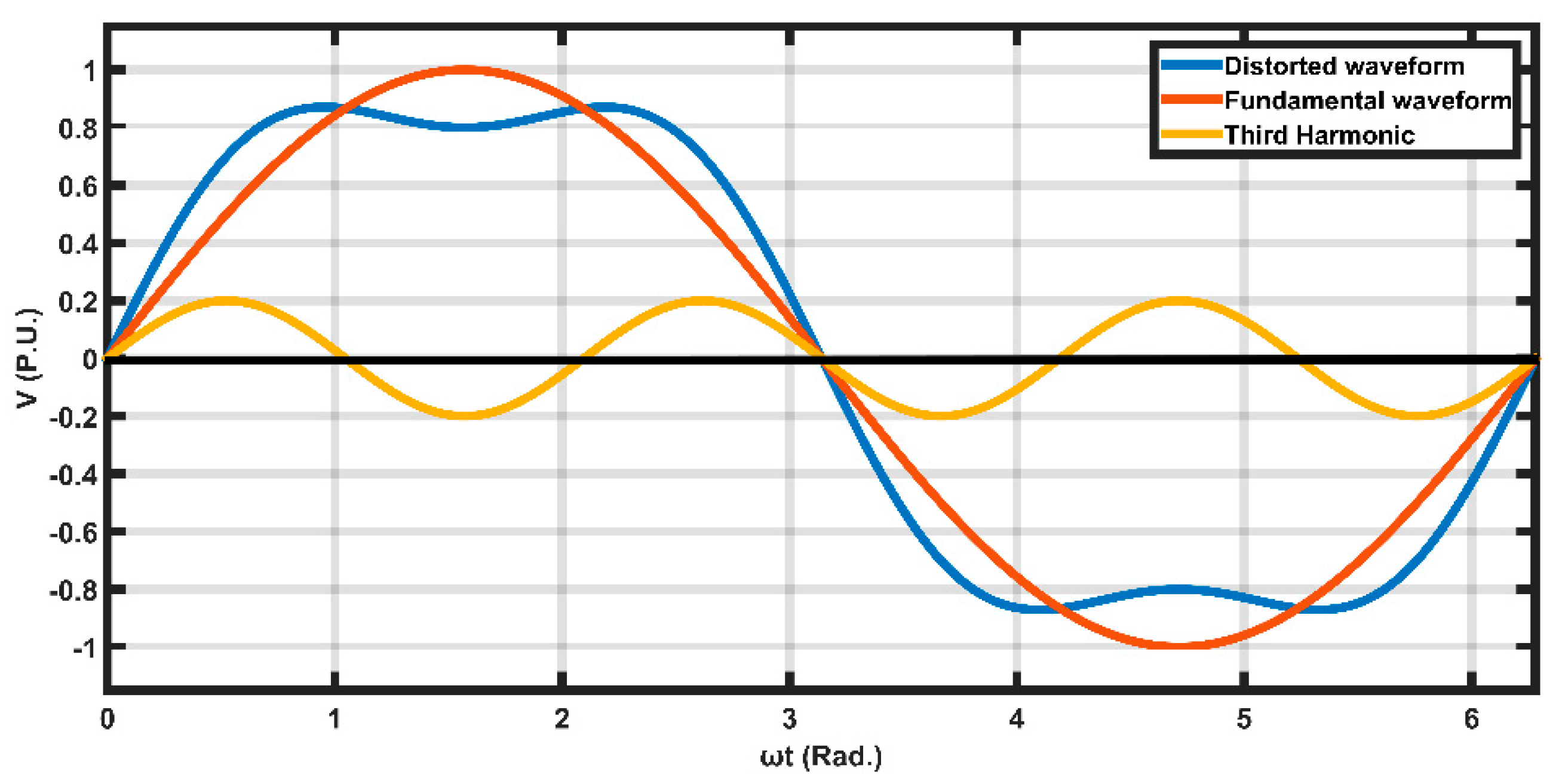

Figure 1.

First and third harmonics.

Figure 1.

First and third harmonics.

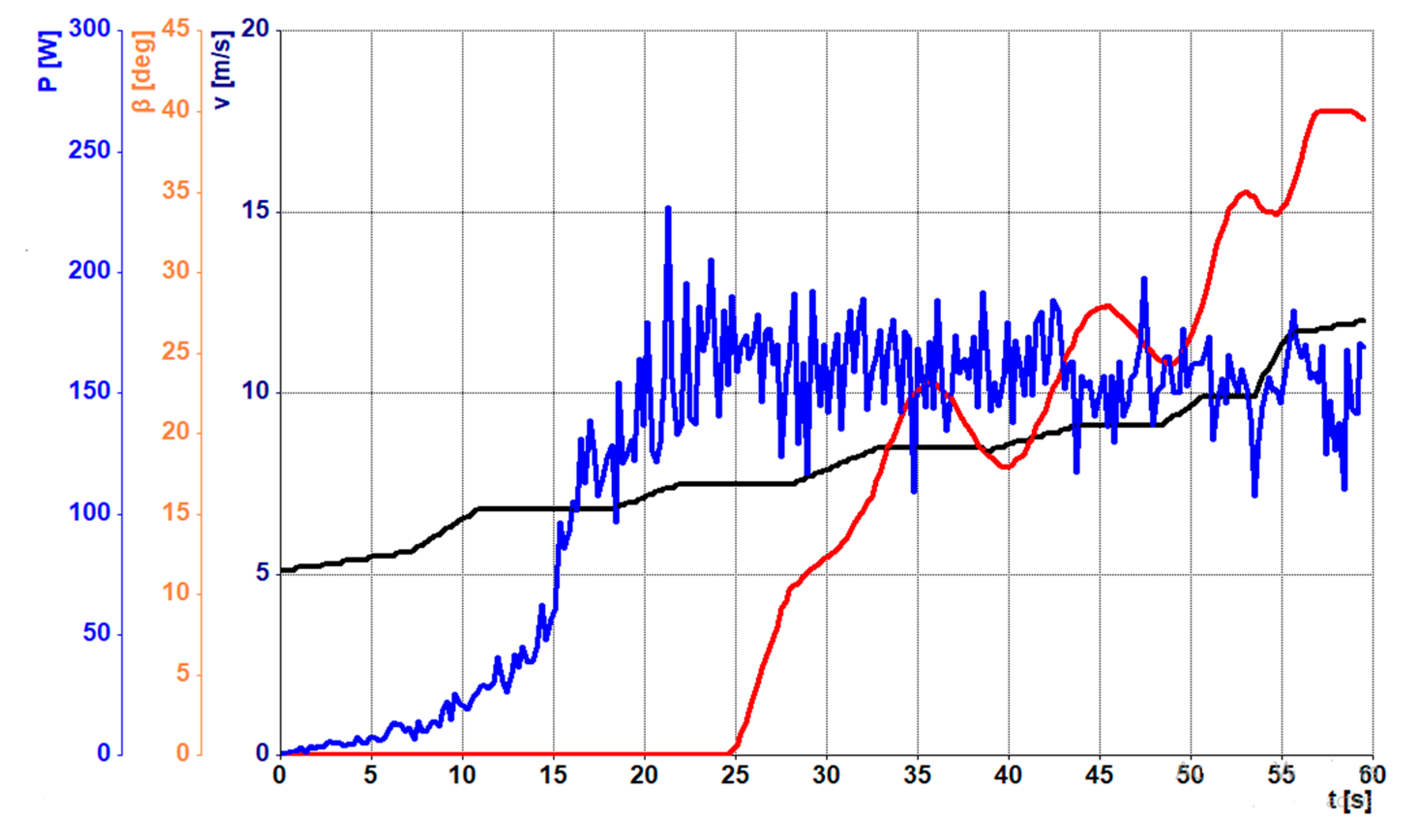

Figure 2.

Control regions of blade-angle controller.

Figure 2.

Control regions of blade-angle controller.

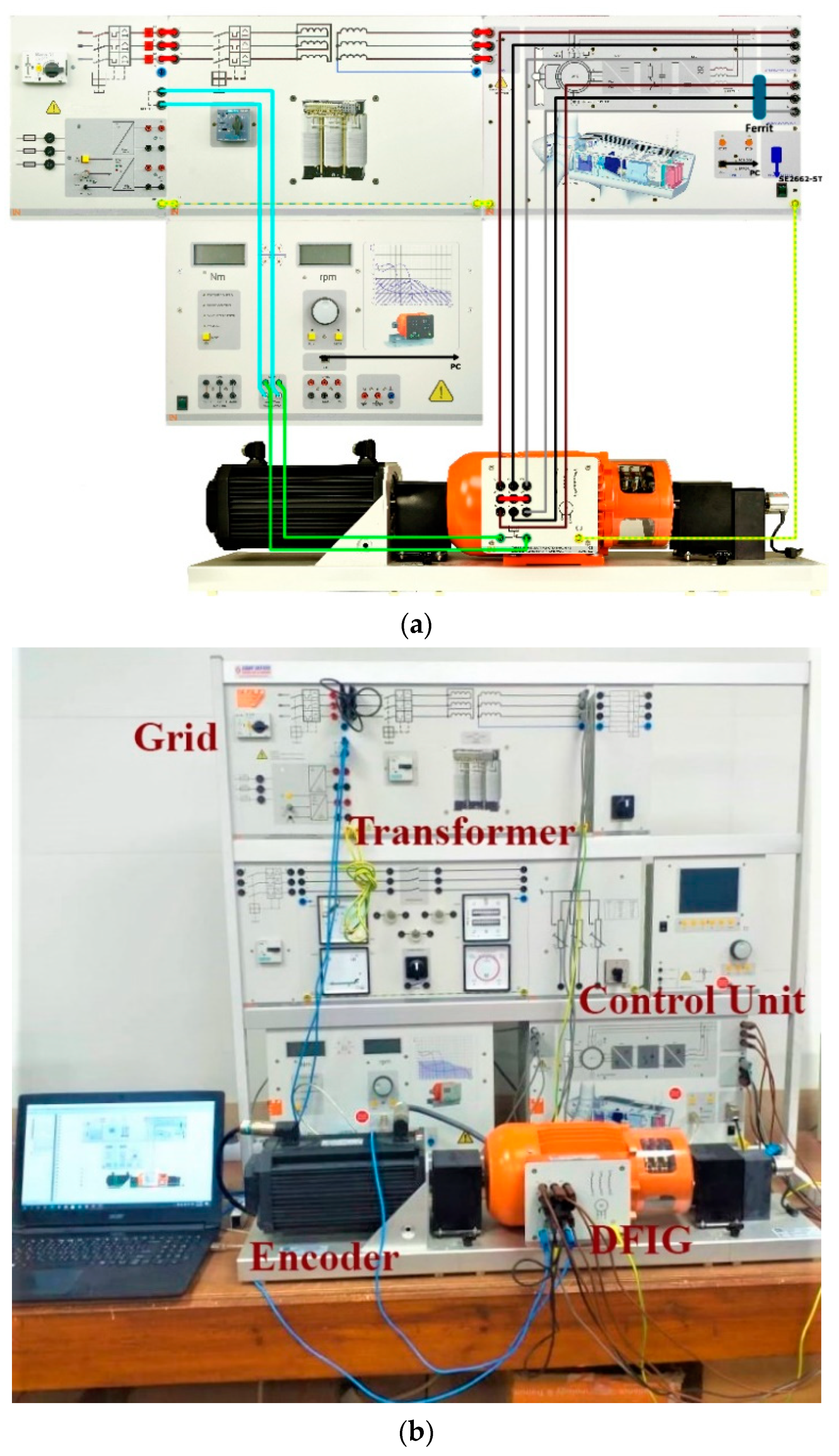

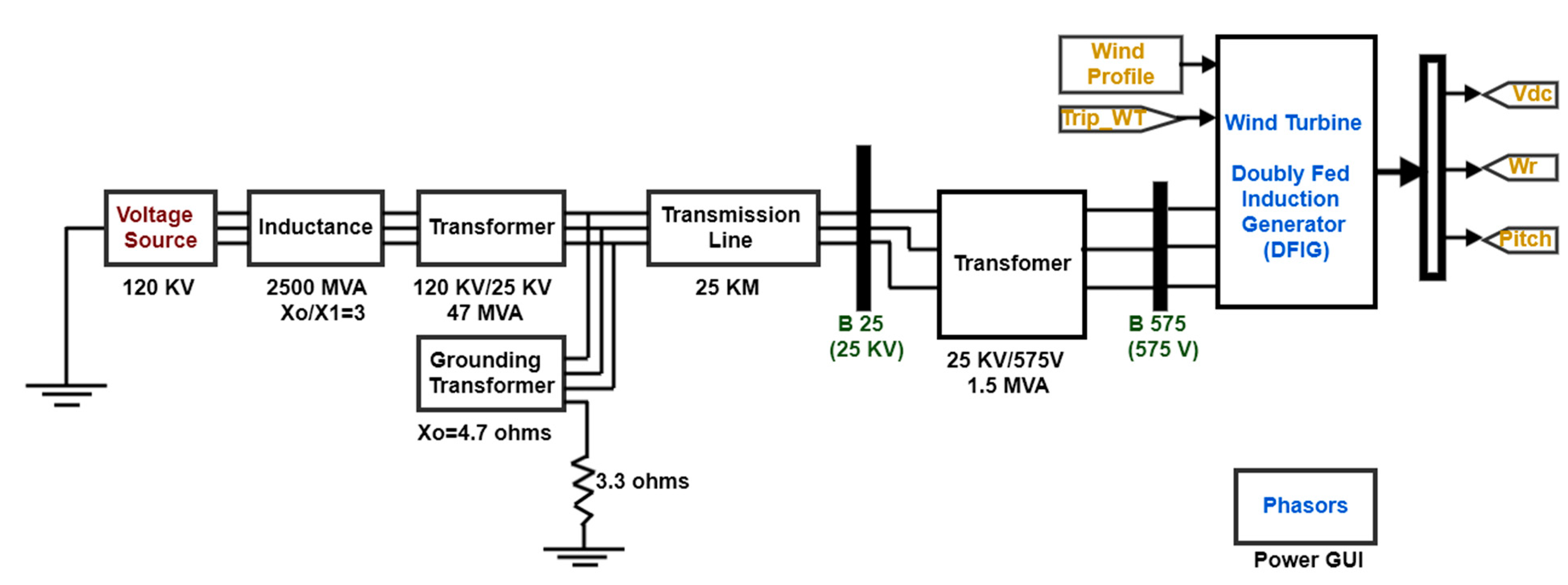

Figure 3.

(a) Connection diagram of wind power plant. (b) Laboratory setup of wind power plant.

Figure 3.

(a) Connection diagram of wind power plant. (b) Laboratory setup of wind power plant.

Figure 4.

(a) Active power responses for different blade angles at 5 m/s wind speed. (b) Active power responses for different blade angles at 6 m/s wind speed. (c) Active power responses for different blade angles at 7 m/s wind speed.

Figure 4.

(a) Active power responses for different blade angles at 5 m/s wind speed. (b) Active power responses for different blade angles at 6 m/s wind speed. (c) Active power responses for different blade angles at 7 m/s wind speed.

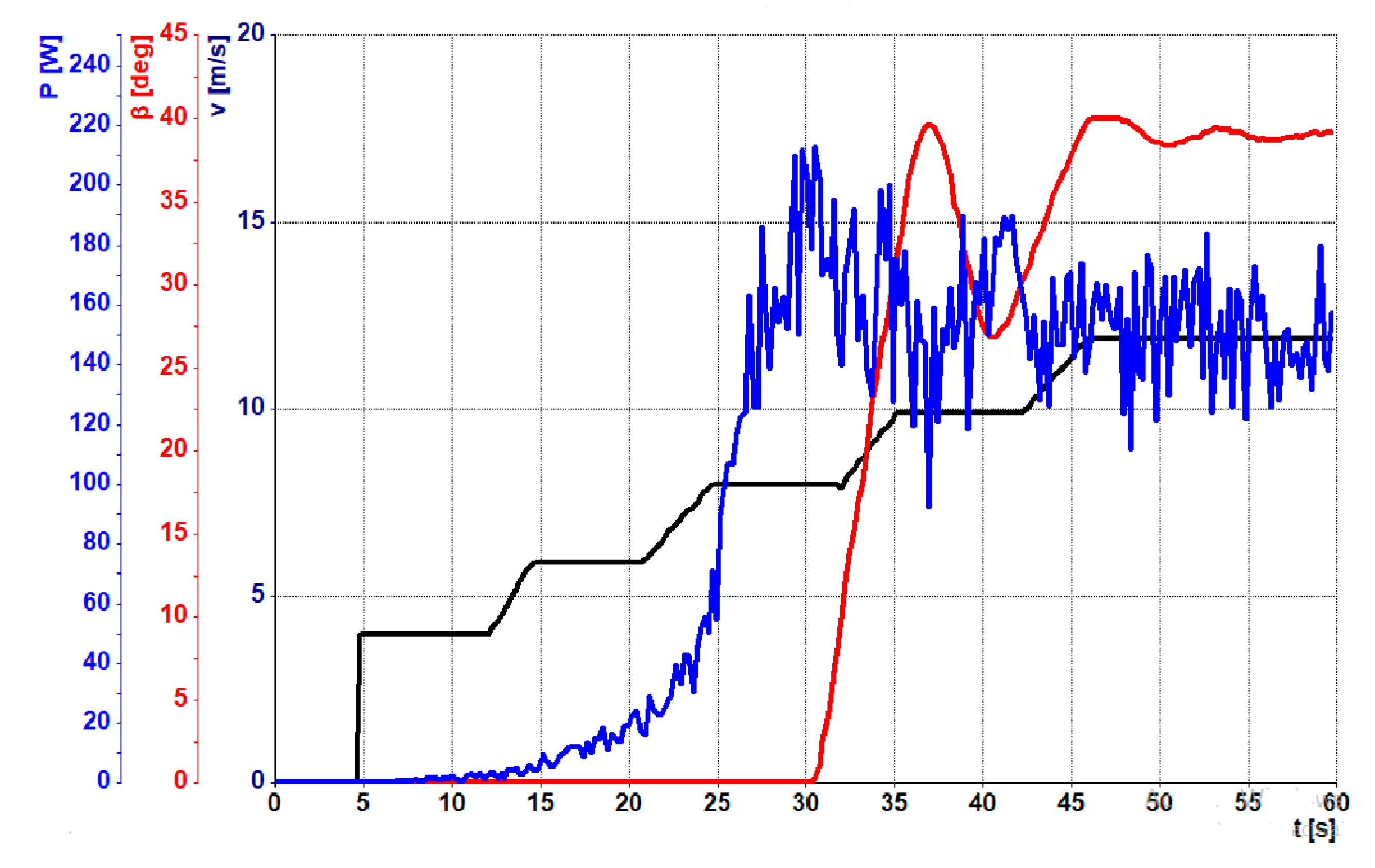

Figure 5.

Wind speed, active power, and blade angle of first experimental case study.

Figure 5.

Wind speed, active power, and blade angle of first experimental case study.

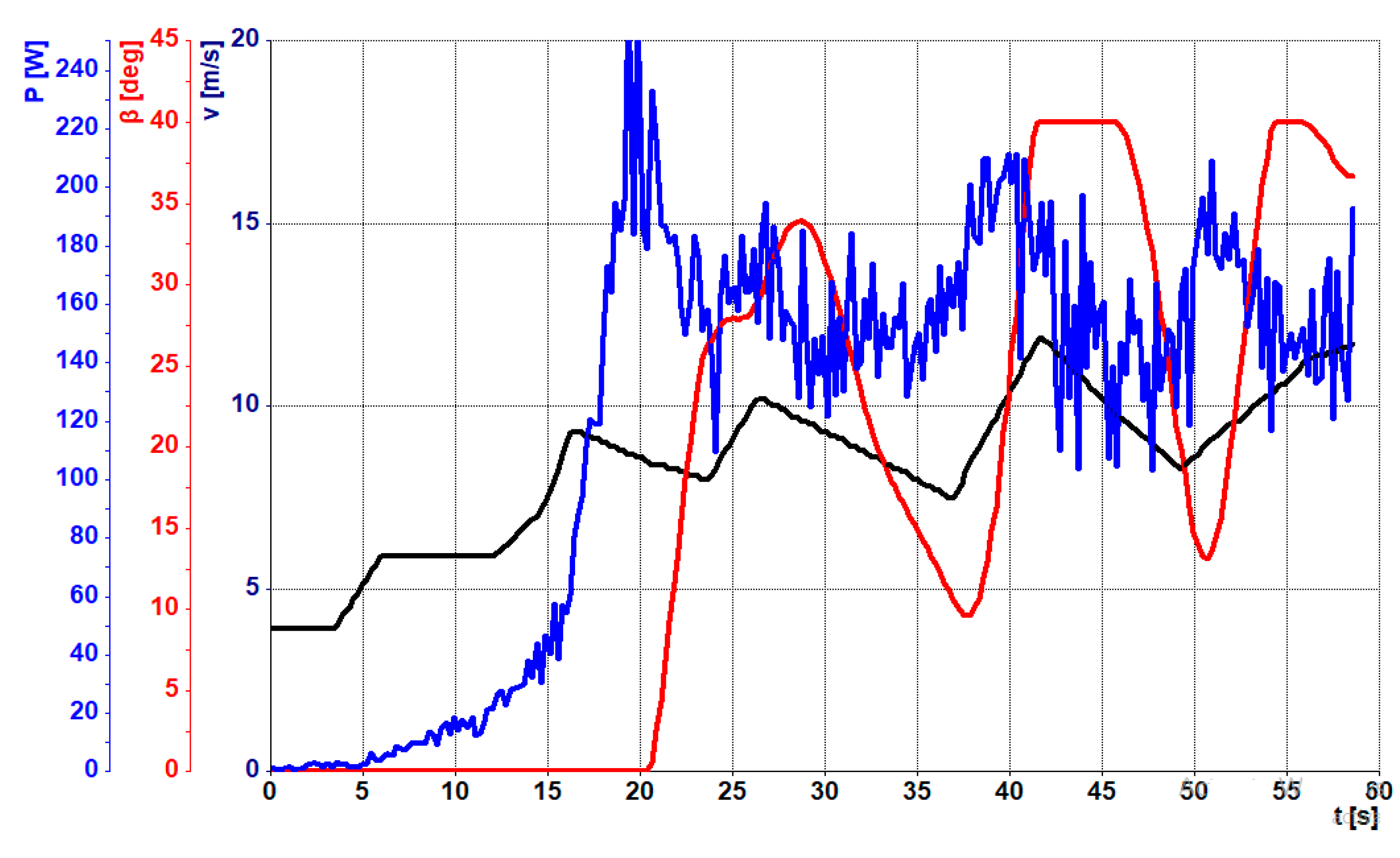

Figure 6.

Wind speed, active power, and blade angle of second experimental case study.

Figure 6.

Wind speed, active power, and blade angle of second experimental case study.

Figure 7.

Wind speed, active power, and blade angle of third experimental case study.

Figure 7.

Wind speed, active power, and blade angle of third experimental case study.

Figure 8.

Wind speed, active power, and blade angle of fourth experimental case study.

Figure 8.

Wind speed, active power, and blade angle of fourth experimental case study.

Figure 9.

MATLAB model of wind-turbine DFIG.

Figure 9.

MATLAB model of wind-turbine DFIG.

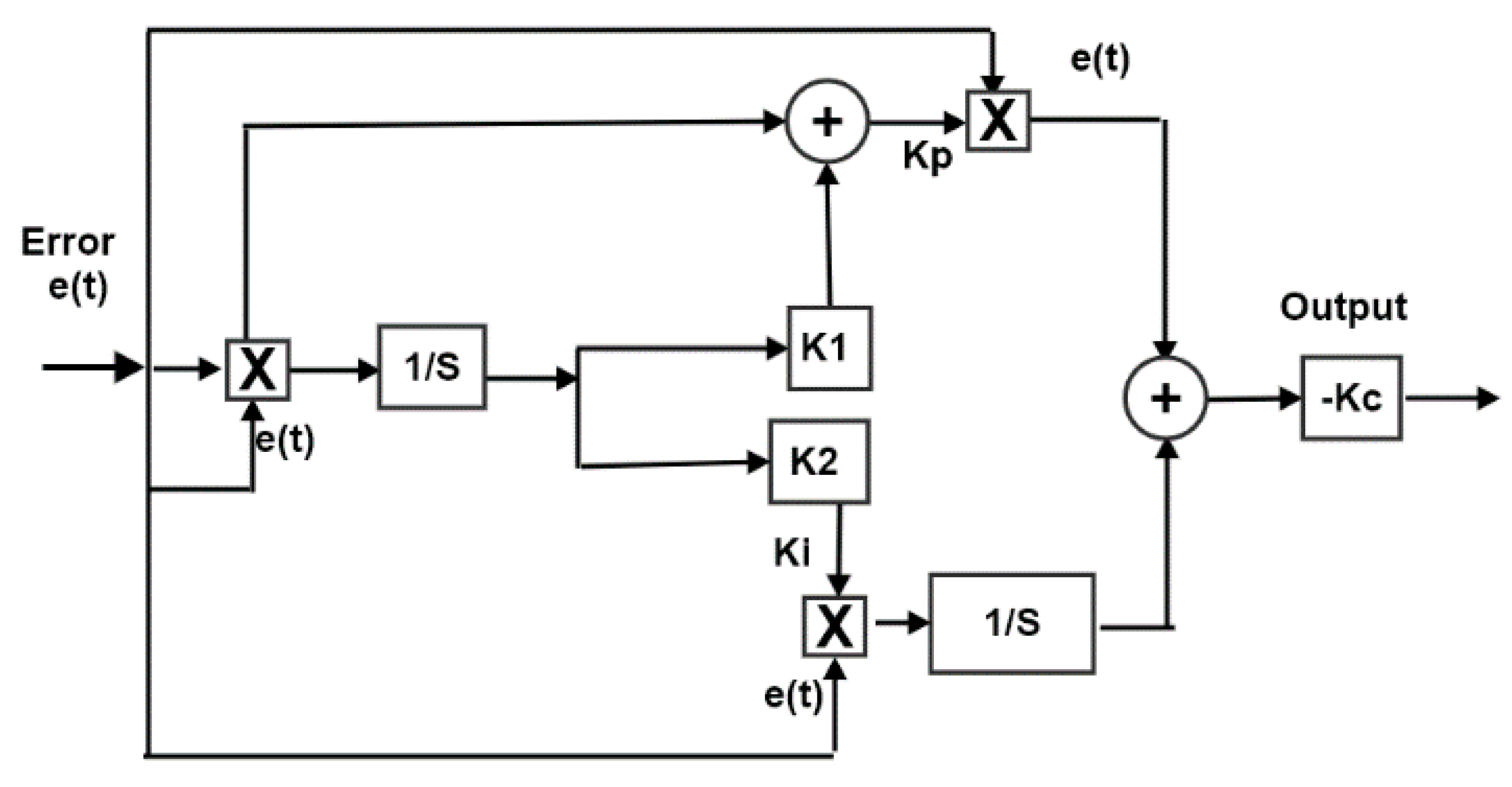

Figure 10.

Block diagram representation of the adaptive PI controller.

Figure 10.

Block diagram representation of the adaptive PI controller.

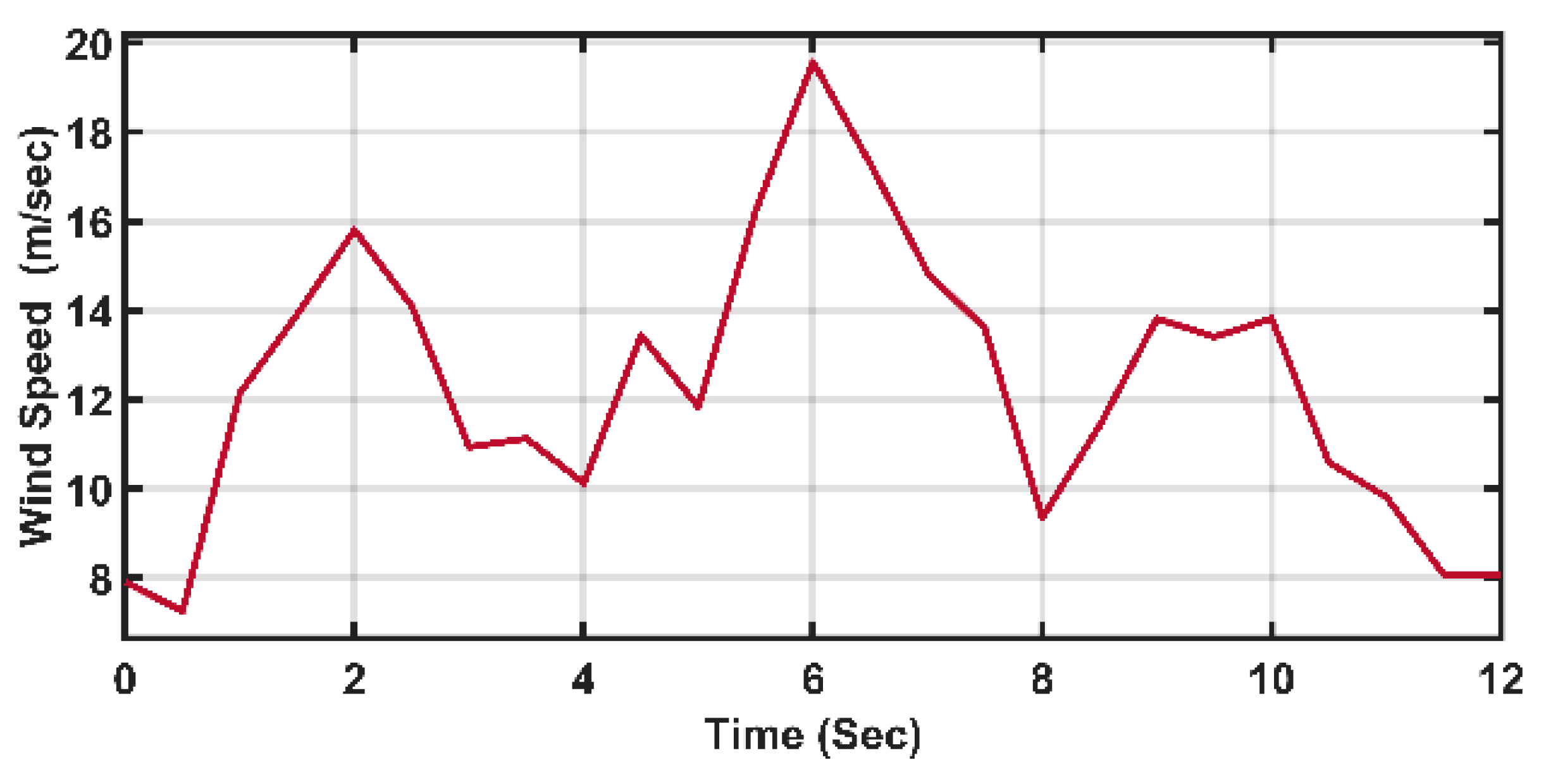

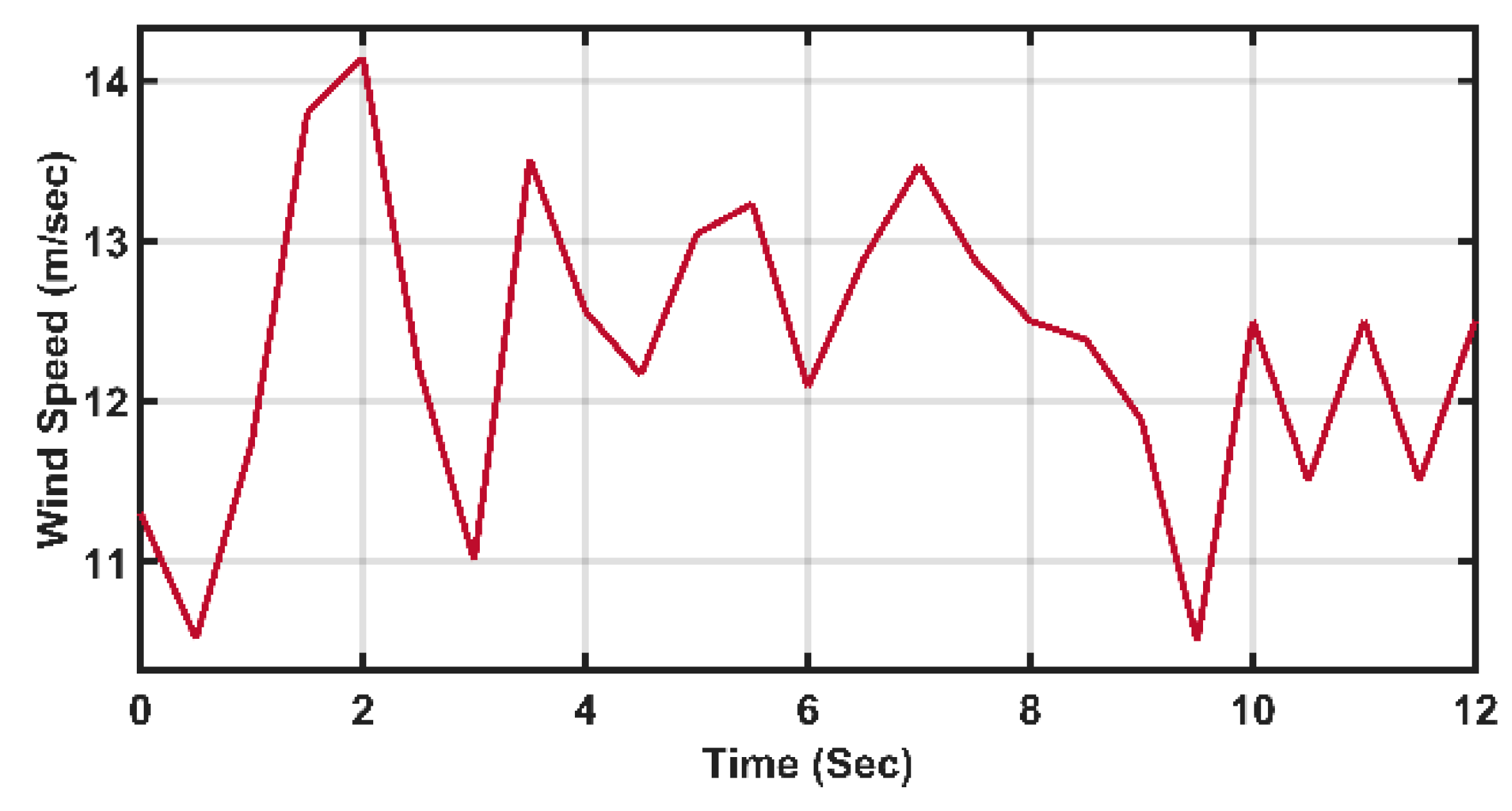

Figure 11.

Wind-speed profile of normal first case.

Figure 11.

Wind-speed profile of normal first case.

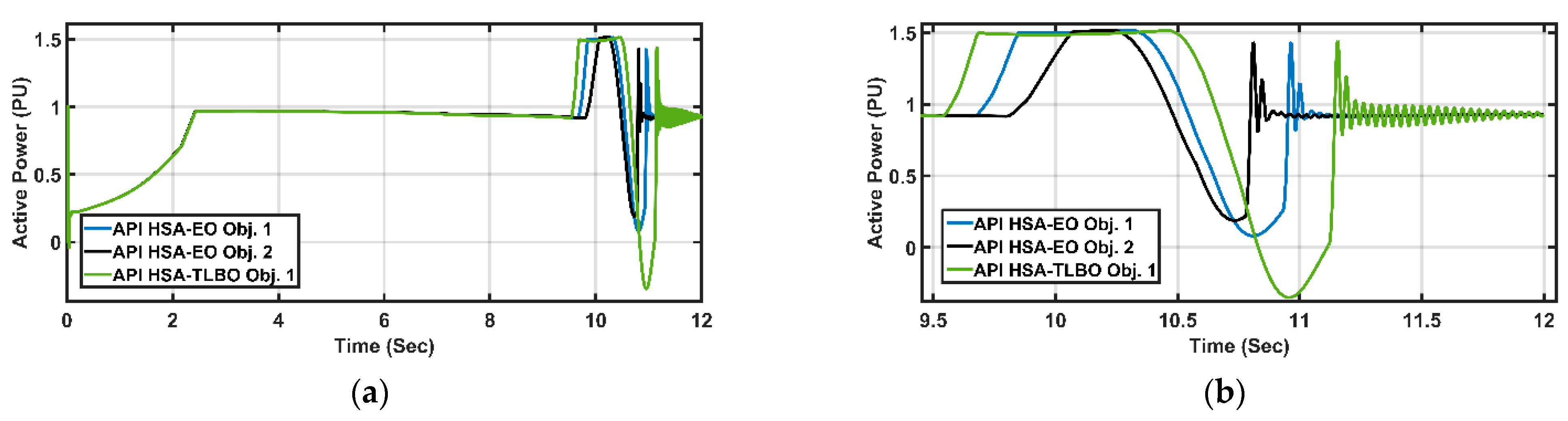

Figure 12.

(a) Active power responses of normal first case. (b) Focusing of the active power response. (c) Blade−angle responses of normal first case.

Figure 12.

(a) Active power responses of normal first case. (b) Focusing of the active power response. (c) Blade−angle responses of normal first case.

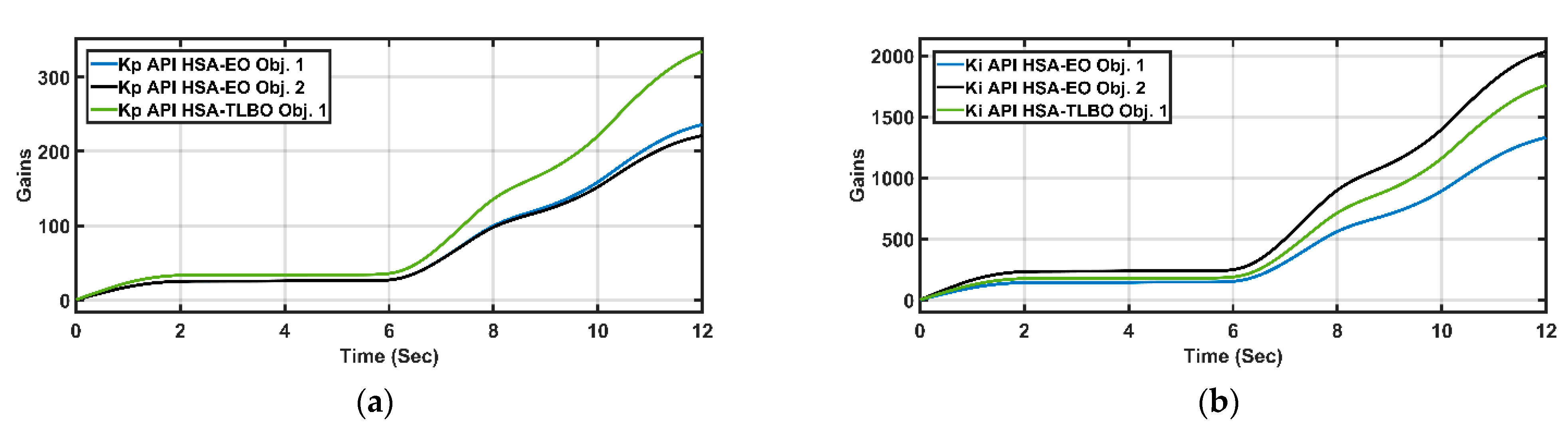

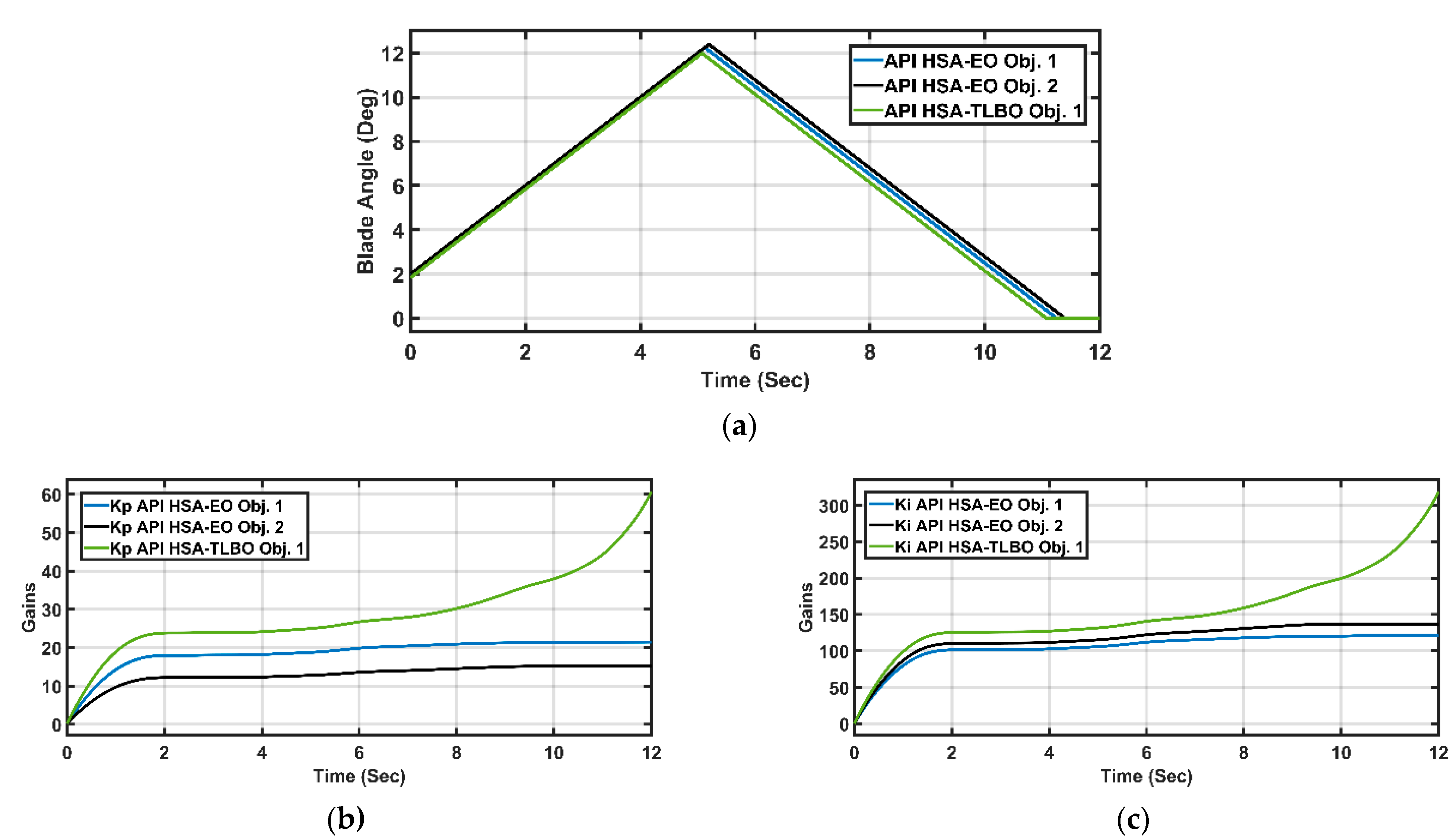

Figure 13.

(a) adaptive PI gain of normal first case. (b) adaptive PI gain of normal first case.

Figure 13.

(a) adaptive PI gain of normal first case. (b) adaptive PI gain of normal first case.

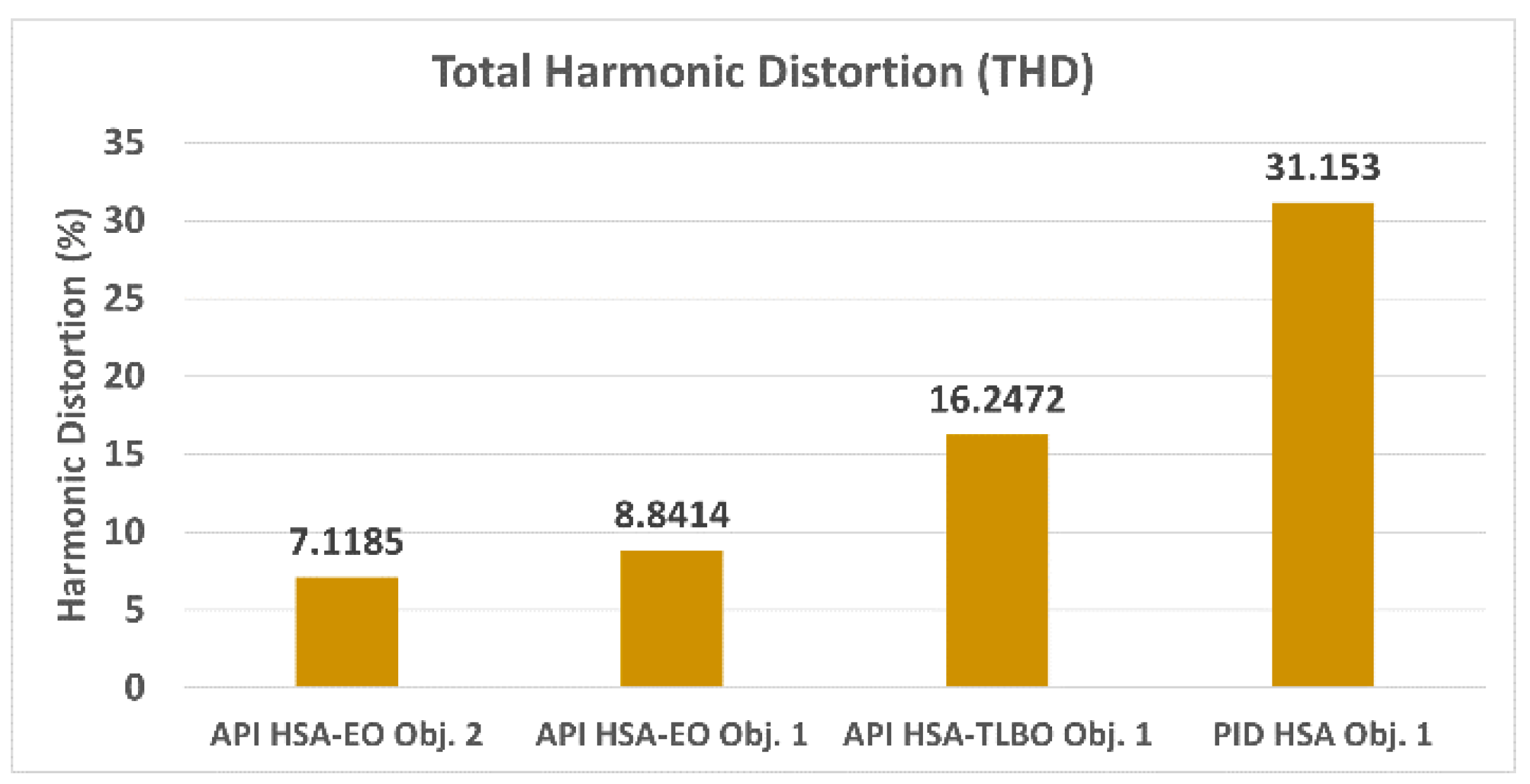

Figure 14.

Total harmonic distortion (THD) percentage of the four controllers under normal operation.

Figure 14.

Total harmonic distortion (THD) percentage of the four controllers under normal operation.

Figure 15.

Wind-speed profile of normal second case.

Figure 15.

Wind-speed profile of normal second case.

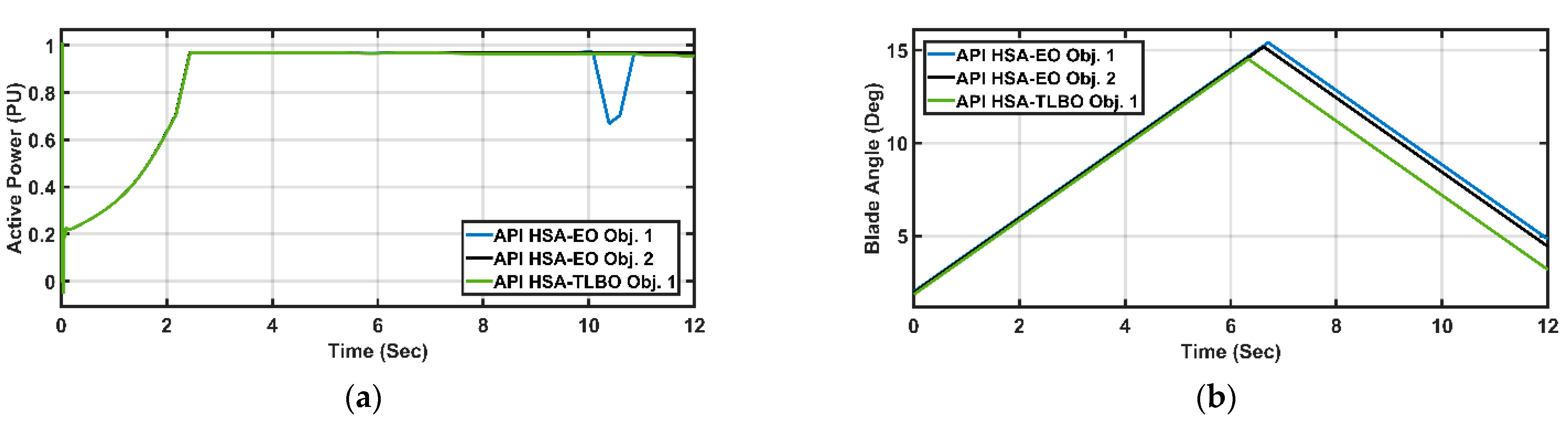

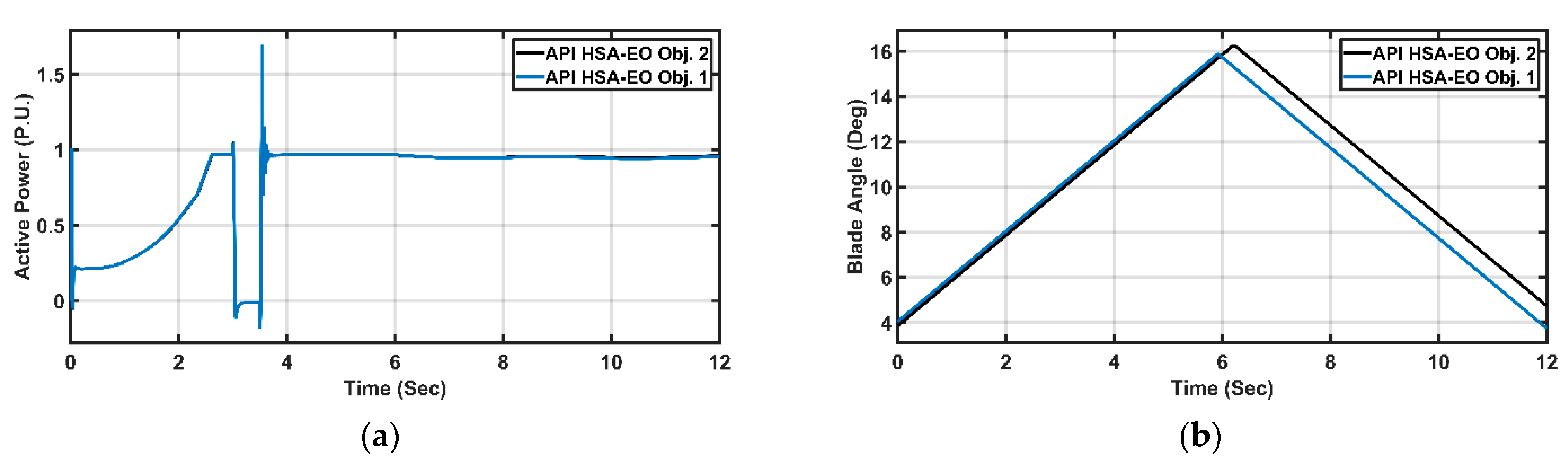

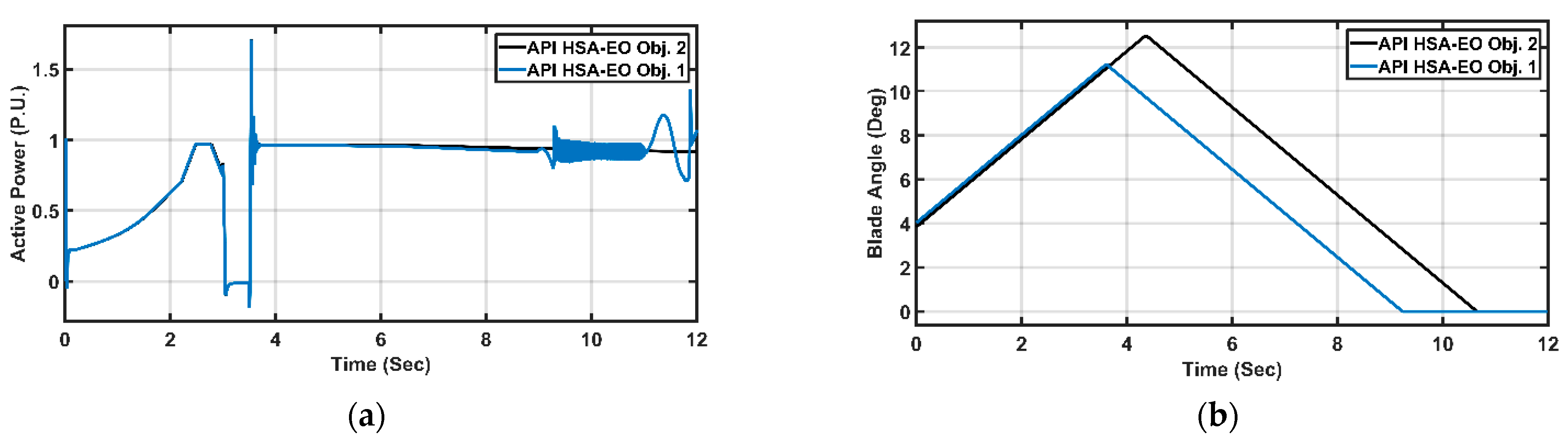

Figure 16.

(a) Active power responses of normal second case. (b) Blade-angle responses of normal second case.

Figure 16.

(a) Active power responses of normal second case. (b) Blade-angle responses of normal second case.

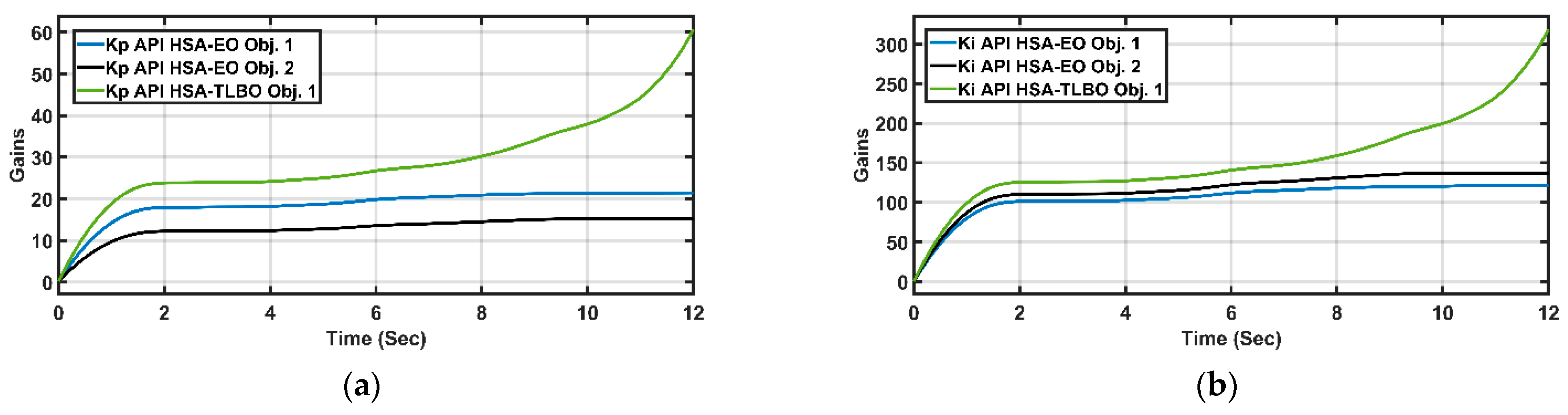

Figure 17.

(a) adaptive PI gain of normal second case. (b) adaptive PI gain of normal second case.

Figure 17.

(a) adaptive PI gain of normal second case. (b) adaptive PI gain of normal second case.

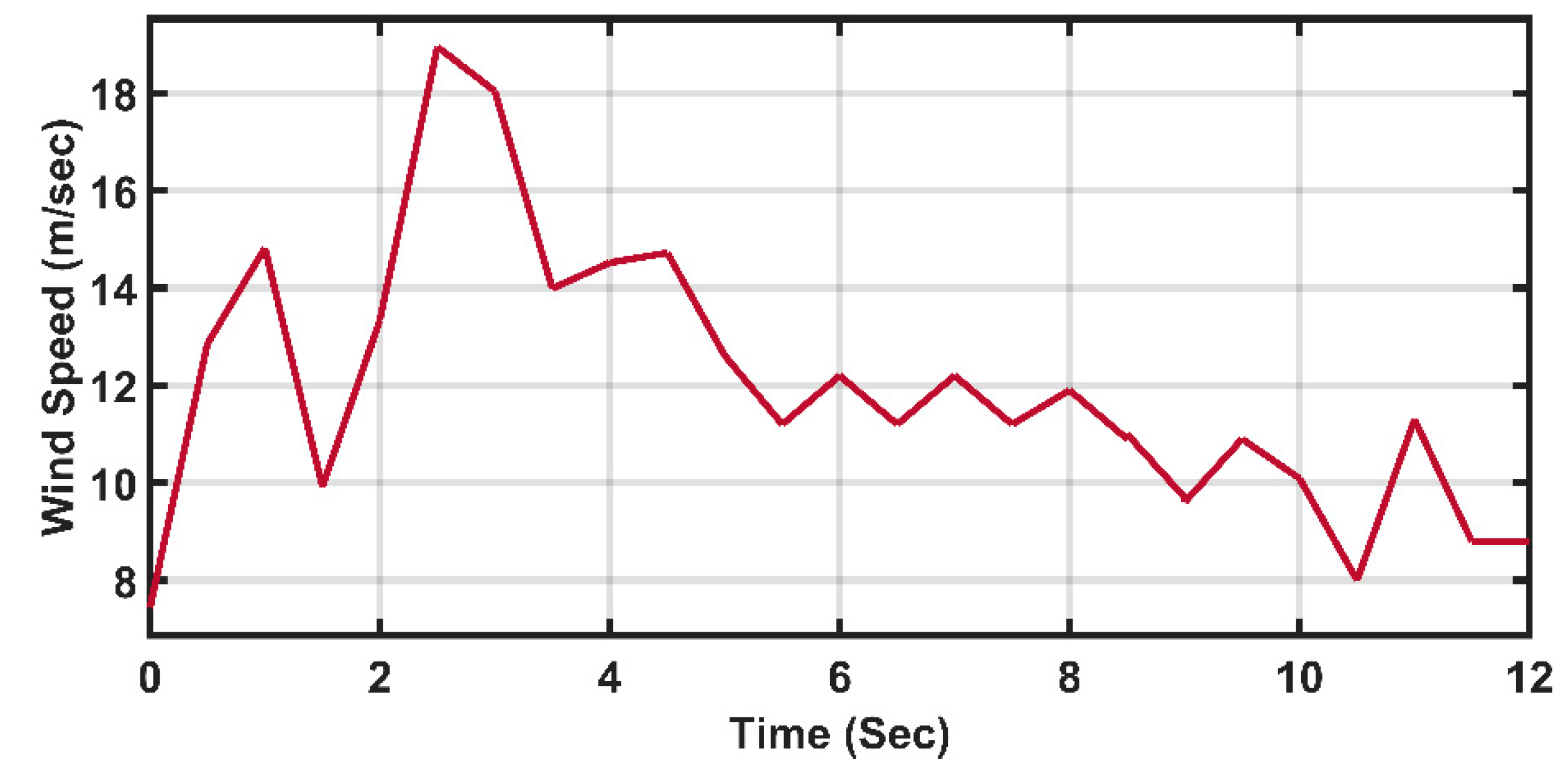

Figure 18.

The wind-speed profile of normal third case.

Figure 18.

The wind-speed profile of normal third case.

Figure 19.

(a) Active power responses of normal third case. (b) Focusing active power responses of normal third case.

Figure 19.

(a) Active power responses of normal third case. (b) Focusing active power responses of normal third case.

Figure 20.

(a) Blade-angle responses of normal third case. (b) adaptive PI gain of normal third case. (c) adaptive PI gain of normal third case.

Figure 20.

(a) Blade-angle responses of normal third case. (b) adaptive PI gain of normal third case. (c) adaptive PI gain of normal third case.

Figure 21.

Wind-speed profile of normal fourth case.

Figure 21.

Wind-speed profile of normal fourth case.

Figure 22.

(a) Active power responses of normal fourth case. (b) Focusing active power responses of normal fourth case.

Figure 22.

(a) Active power responses of normal fourth case. (b) Focusing active power responses of normal fourth case.

Figure 23.

Blade angle of the controllers at normal fourth case.

Figure 23.

Blade angle of the controllers at normal fourth case.

Figure 24.

(a) adaptive PI gain of normal second case. (b) adaptive PI gain of normal second case.

Figure 24.

(a) adaptive PI gain of normal second case. (b) adaptive PI gain of normal second case.

Figure 25.

(a) Active power responses of faulty first case. (b) Blade-angle responses of faulty first case.

Figure 25.

(a) Active power responses of faulty first case. (b) Blade-angle responses of faulty first case.

Figure 26.

(a) adaptive PI gain of faulty first case. (b) adaptive PI gain of faulty first case.

Figure 26.

(a) adaptive PI gain of faulty first case. (b) adaptive PI gain of faulty first case.

Figure 27.

THD percentage of the two controllers under faulty operation.

Figure 27.

THD percentage of the two controllers under faulty operation.

Figure 28.

Wind-speed profile of faulty second case.

Figure 28.

Wind-speed profile of faulty second case.

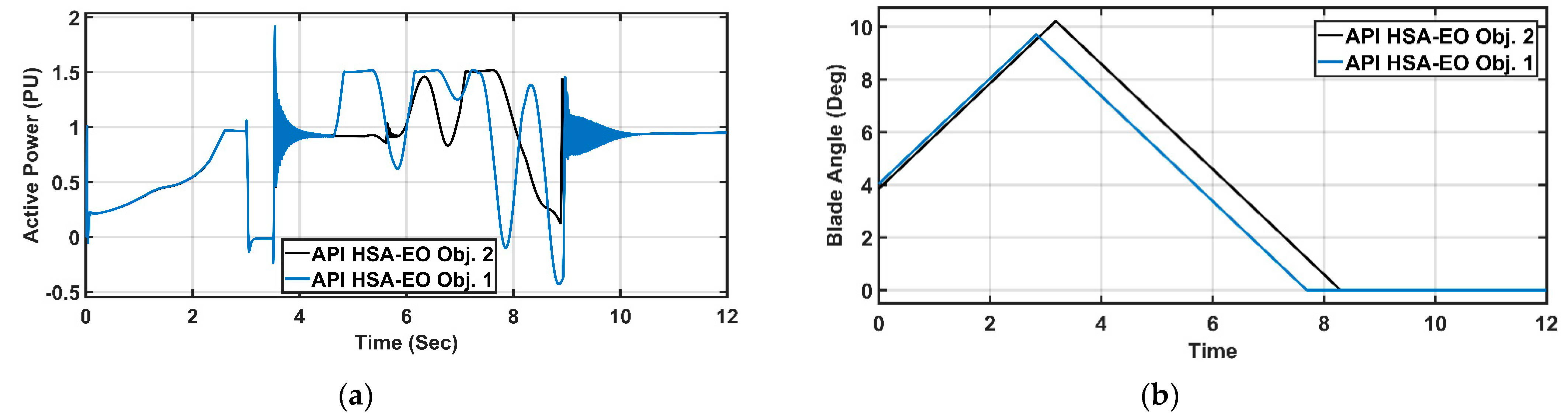

Figure 29.

(a) Active power responses of faulty second case. (b) Blade-angle responses of faulty second case.

Figure 29.

(a) Active power responses of faulty second case. (b) Blade-angle responses of faulty second case.

Figure 30.

(a) adaptive PI gain of faulty second case. (b) adaptive PI gain of faulty second case.

Figure 30.

(a) adaptive PI gain of faulty second case. (b) adaptive PI gain of faulty second case.

Figure 31.

Wind-speed profile of faulty third case.

Figure 31.

Wind-speed profile of faulty third case.

Figure 32.

(a) Active power responses of faulty third case. (b) Blade-angle responses of faulty third case.

Figure 32.

(a) Active power responses of faulty third case. (b) Blade-angle responses of faulty third case.

Figure 33.

(a) adaptive PI gain of faulty third case. (b) adaptive PI gain of faulty third case.

Figure 33.

(a) adaptive PI gain of faulty third case. (b) adaptive PI gain of faulty third case.

Figure 34.

Wind-speed profile of faulty fourth case.

Figure 34.

Wind-speed profile of faulty fourth case.

Figure 35.

(a) Active power responses of faulty fourth case. (b) Blade-angle responses of faulty fourth case.

Figure 35.

(a) Active power responses of faulty fourth case. (b) Blade-angle responses of faulty fourth case.

Figure 36.

(a) adaptive PI gain of faulty third case. (b) adaptive PI gain of faulty third case.

Figure 36.

(a) adaptive PI gain of faulty third case. (b) adaptive PI gain of faulty third case.

Table 1.

Controller parameters in normal operation.

Table 1.

Controller parameters in normal operation.

| CONTROLLERS | Parameters |

|---|

| PID HSA Obj. 1 [39] | | | |

| 68 | 13.7 | 72 |

| API HSA Hybrid TLBO Obj. 1 [40] | | | |

| 155.25 | 817.54 | 26.63 |

| API HSA-EO Obj. 1 | 117 | 660 | 28.83 |

| API HSA-EO Obj. 2 | 117 | 1078.2 | 29 |

Table 2.

Numerical comparison between the controllers at normal first case.

Table 2.

Numerical comparison between the controllers at normal first case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| PID | 2.05 s | 9 s | 1.51 pu | −0.85 pu |

| API HSA-TLBO | 2.72 s | 5.35 s | 0.975 pu | −0.625 pu |

| API HSA-EO Obj. 1 | 2.715 s | 5.34 s | 0.975 pu | −0.619 pu |

| API HSA-EO Obj. 2 | 2.714 s | 5.34 s | 0.975 pu | −0.619 pu |

Table 3.

Statistical analysis of the active power—normal first case.

Table 3.

Statistical analysis of the active power—normal first case.

| Controllers | Standard Deviation (SD) | Root Mean Square Error (RMSE) |

|---|

| PID | 0.4039 | 0.4447 |

| API HSA-TLBO | 0.3245 | 0.4293 |

| API HSA-EO Obj. 1 | 0.3243 | 0.4205 |

| API HSA-EO Obj. 2 | 0.3268 | 0.4205 |

Table 4.

Numerical comparison between the controllers at normal second case.

Table 4.

Numerical comparison between the controllers at normal second case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-TLBO | 2.45 s | 2.45 s | 0.975 pu | 0.975 pu |

| API HSA-EO Obj. 1 | 2.45 s | 10.9 s | 0.975 pu | 0.667 pu |

| API HSA-EO Obj. 2 | 2.45 s | 2.45 s | 0.975 pu | 0.975 pu |

Table 5.

Statistical analysis of the active power—normal second case.

Table 5.

Statistical analysis of the active power—normal second case.

| Controllers | SD | RMSE |

|---|

| API HSA-TLBO | 0.3297 | 0.4044 |

| API HSA-EO Obj. 1 | 0.3207 | 0.3965 |

| API HSA-EO Obj. 2 | 0.3251 | 0.3961 |

Table 6.

Numerical comparison between the controllers at normal third case.

Table 6.

Numerical comparison between the controllers at normal third case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-TLBO | 2.445 s | 12 s | 1.515 pu | −0.355 pu |

| API HSA-EO Obj. 1 | 2.435 s | 11.4 s | 1.515 pu | 0.081 pu |

| API HSA-EO Obj. 2 | 2.435 s | 11.1 s | 1.515 pu | 0.188 pu |

Table 7.

Statistical analysis of the active power—normal third case.

Table 7.

Statistical analysis of the active power—normal third case.

| Controllers | SD | RMSE |

|---|

| API HSA-TLBO | 0.3718 | 0.4143 |

| API HSA-EO Obj. 1 | 0.361 | 0.4013 |

| API HSA-EO Obj. 2 | 0.3449 | 0.3868 |

Table 8.

Numerical comparison between the controllers at normal fourth case.

Table 8.

Numerical comparison between the controllers at normal fourth case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-TLBO | 2.66 s | 10.035 s | 1.501 pu | −0.02 pu |

| API HSA-EO Obj. 1 | 2.65 s | 10.005 s | 1.515 pu | −0.01 pu |

| API HSA-EO Obj. 2 | 2.65 s | 10.005 s | 1.515 pu | 0.133 pu |

Table 9.

Statistical analysis of the active power—normal fourth case.

Table 9.

Statistical analysis of the active power—normal fourth case.

| Controllers | SD | RMSE |

|---|

| API HSA-TLBO | 0.3303 | 0.3658 |

| API HSA-EO Obj. 1 | 0.3318 | 0.3642 |

| API HSA-EO Obj. 2 | 0.317 | 0.3487 |

Table 10.

Controller parameters used in faulty operation cases.

Table 10.

Controller parameters used in faulty operation cases.

| Controllers | Parameters |

|---|

| K1 | K2 | Kc |

|---|

| API HSAEO Obj. 1 | 50.830 | 48.538 | 58.551 |

| API HSAEO Obj. 2 | 41 | 193.568 | 55.838 |

Table 11.

Numerical comparison between the controllers at faulty first case.

Table 11.

Numerical comparison between the controllers at faulty first case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-EO Obj. 1 | 2.65 s | 3.81 s | 1.69 pu | −0.185 pu |

| API HSA-EO Obj. 2 | 2.65 s | 3.81 s | 1.69 pu | −0.185 pu |

Table 12.

Statistical analysis of the active power—faulty first case.

Table 12.

Statistical analysis of the active power—faulty first case.

| Controllers | SD | RMSE |

|---|

| API HSA-EO Obj. 1 | 0.3966 | 0.4962 |

| API HSA-EO Obj. 2 | 0.3943 | 0.4922 |

Table 13.

Numerical comparison between the controllers at faulty second case.

Table 13.

Numerical comparison between the controllers at faulty second case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-EO Obj. 1 | 2.49 s | 12 S | 1.71 pu | −0.188 pu |

| API HSA-EO Obj. 2 | 2.49 s | 3.81 S | 1.71 pu | −0.188 pu |

Table 14.

Statistical analysis of the active power—faulty second case.

Table 14.

Statistical analysis of the active power—faulty second case.

| Controllers | SD | RMSE |

|---|

| API HSA-EO Obj. 1 | 0.3214 | 0.3785 |

| API HSA-EO Obj. 2 | 0.3781 | 0.4759 |

Table 15.

Numerical comparison between the controllers at faulty third case.

Table 15.

Numerical comparison between the controllers at faulty third case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-EO Obj. 1 | 2.605 s | 12 s | 1.725 pu | −1.439 pu |

| API HSA-EO Obj. 2 | 2.605 s | 3.81 s | 1.725 pu | −0.191 pu |

Table 16.

Statistical analysis of the active power—faulty third case.

Table 16.

Statistical analysis of the active power—faulty third case.

| Controllers | SD | RMSE |

|---|

| API HSA-EO Obj. 1 | 0.596 | 0.6236 |

| API HSA-EO Obj. 2 | 0.4001 | 0.5040 |

Table 17.

Numerical comparison between the controllers at faulty fourth case.

Table 17.

Numerical comparison between the controllers at faulty fourth case.

| Controllers | Rising Time | Settling Time | Positive Peak | Negative Peak |

|---|

| API HSA-EO Obj. 1 | 2.615 s | 10.3 s | 1.910 pu | −0.234 pu |

| API HSA-EO Obj. 2 | 2.615 s | 10.1 s | 1.915 pu | −0.232 pu |

Table 18.

Statistical analysis of the active power—faulty fourth case.

Table 18.

Statistical analysis of the active power—faulty fourth case.

| Controllers | SD | RMSE |

|---|

| API HSA-EO Obj. 1 | 0.4226 | 0.4568 |

| API HSA-EO Obj. 2 | 0.3859 | 0.4291 |