Heating Performance and Ammonia Removal of a Single-Stage Bioscrubber Pilot Plant with Integrated Heat Exchanger under Field Conditions

Abstract

:1. Introduction

2. Materials and Methods

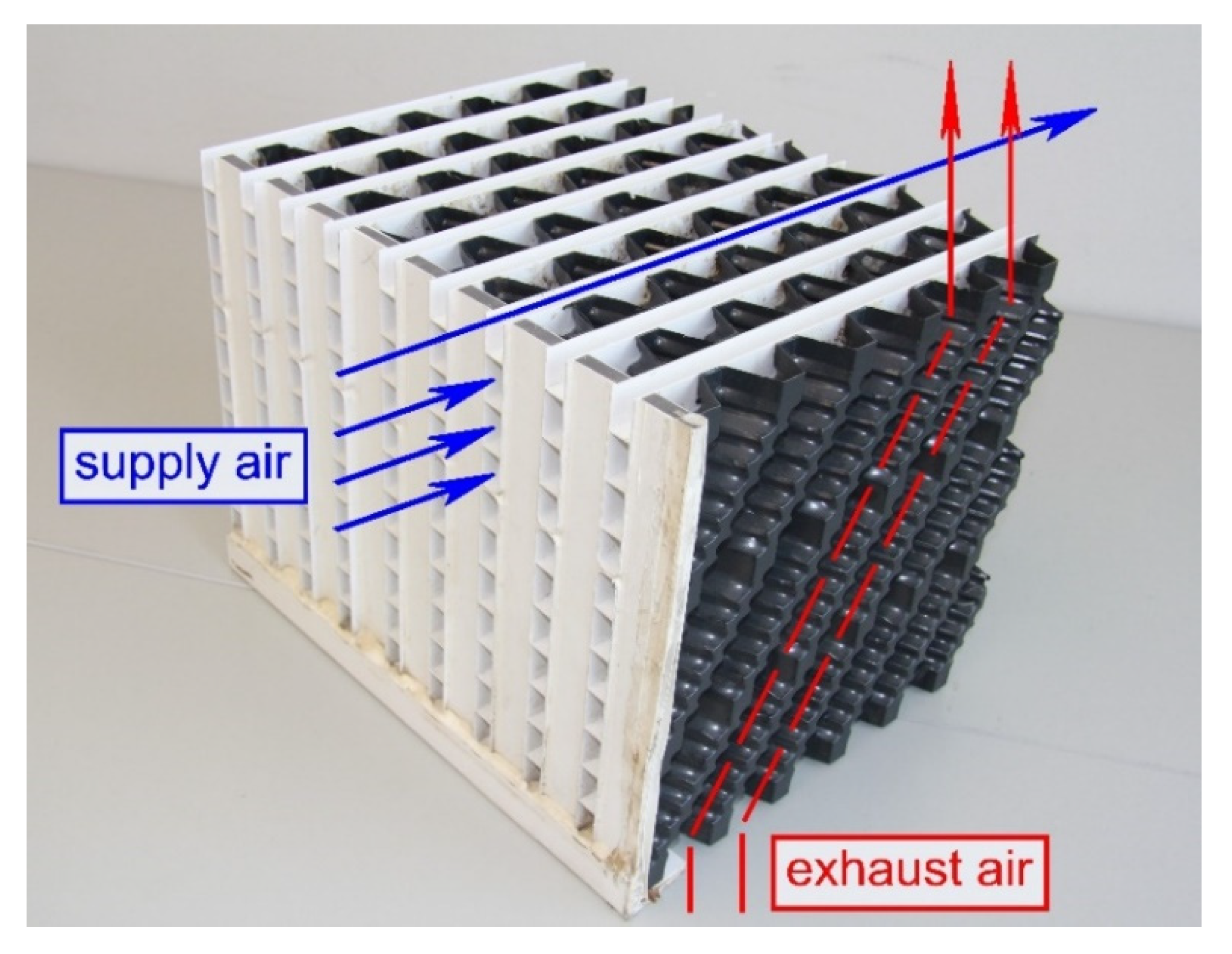

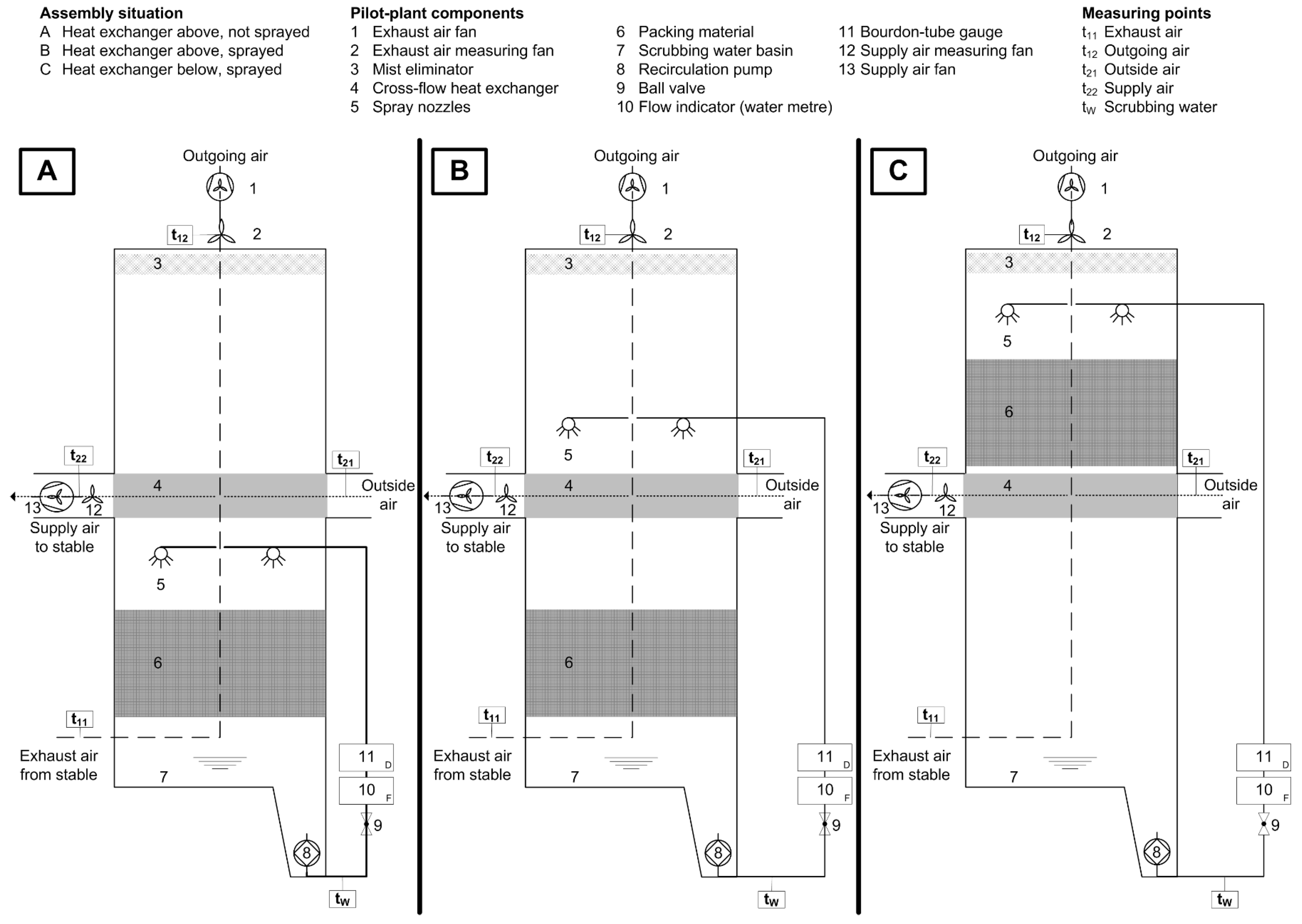

2.1. Description of the Small-Scale Exchange Scrubber Pilot Plant

2.2. Experimental Procedure

2.3. Measurement of Air Temperature and Humidity

2.4. Measurement and Calculation of Air Volume Flow

2.5. Calculation of the Heating Performance

- = heating performance of the exchange scrubber in kW

- = air mass flow in kg h−1

- = specific heat capacity of dry air in Wh kg−1 K−1 ( = 1.005 kJ kg−1 K−1 = 0.28 Wh kg−1 K−1)

- t21 = outside air temperature in °C

- t22 = supply air temperature in °C

2.6. Measurement of Electricity Consumption

2.7. Calculation of the Coefficient of Performance

- COP = coefficient of performance

- = heating performance of the exchange scrubber in kW

- = electrical power consumption of the exchange scrubber in kW

2.8. Measurement of the Ammonia Concentration of the Exhaust and Outgoing Air

2.9. Measurement of Scrubbing Water

2.10. Measurement Data Analysis

- Outside air temperature (t21): −3 °C ≤ t21 ≤ +3 °C.

- Air mass flow (): 3500 kg h−1 ≤ ≤ 4500 kg h−1.

- Scrubbing water temperature (tW): 12.5 °C ≤ tW ≤ 16.5 °C.

3. Results and Discussion

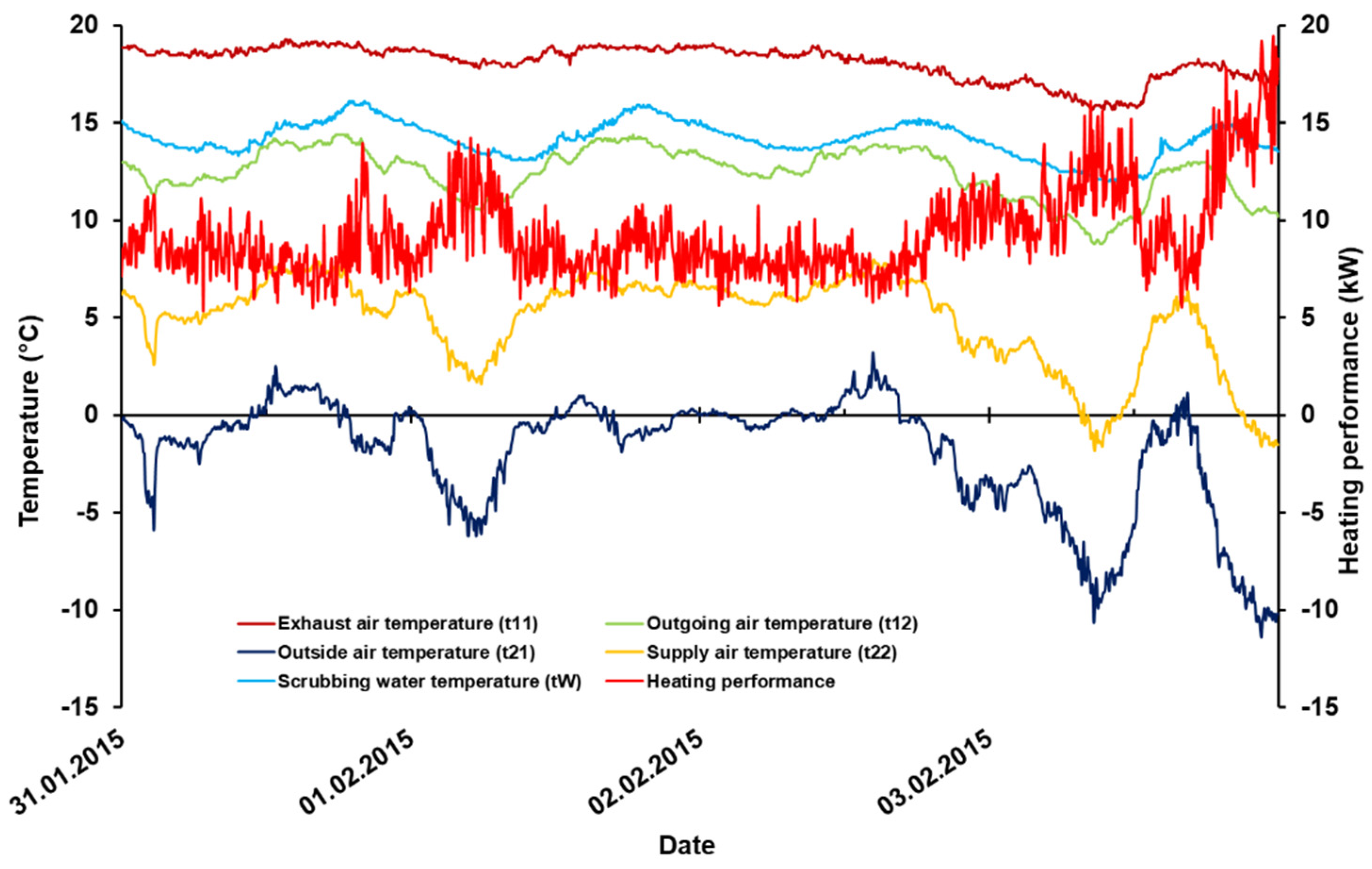

3.1. Temperature Profiles and Heating Performance

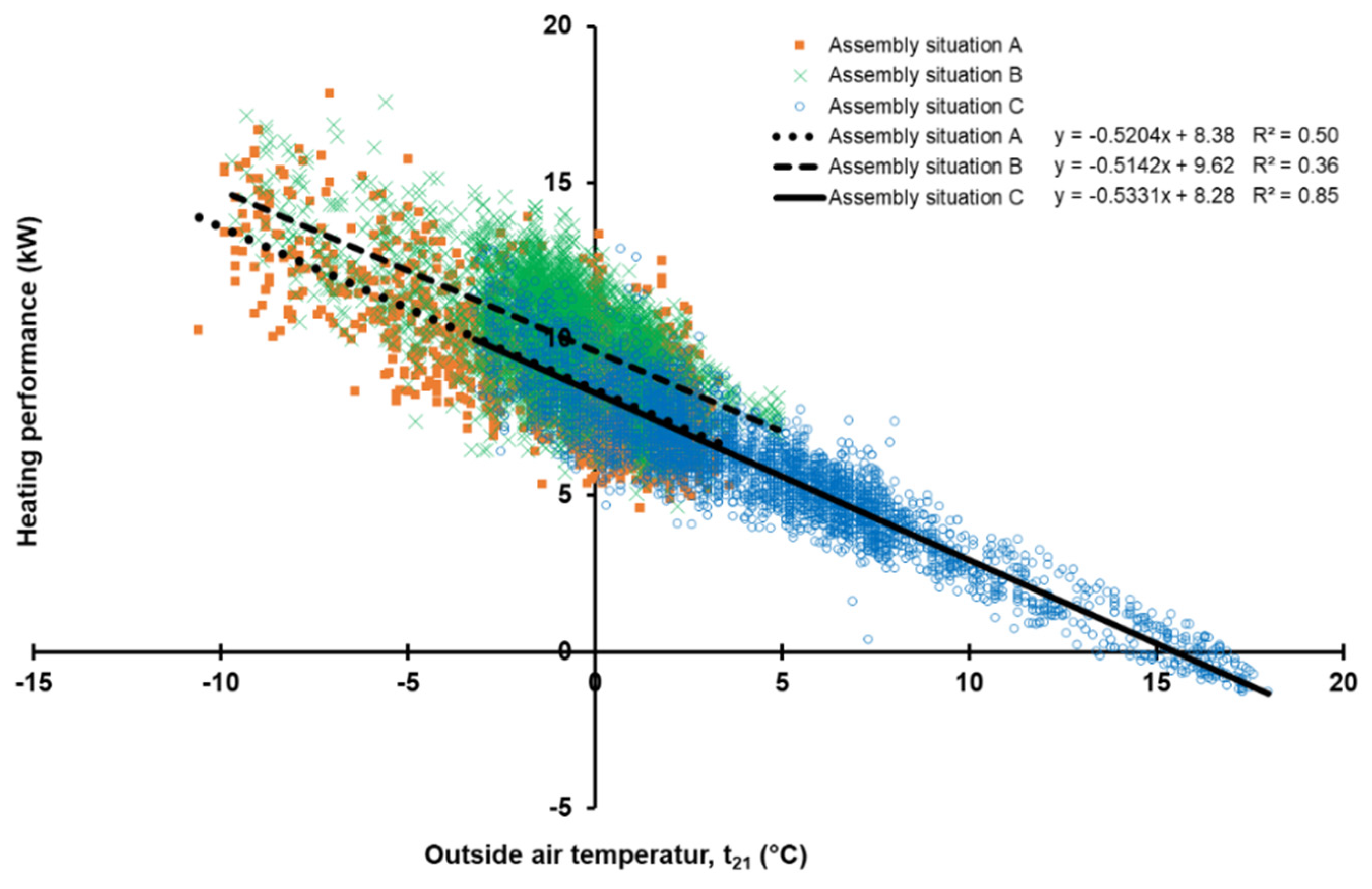

3.2. Influence of Outside Air and Scrubbing Water Temperature on Heating Performance

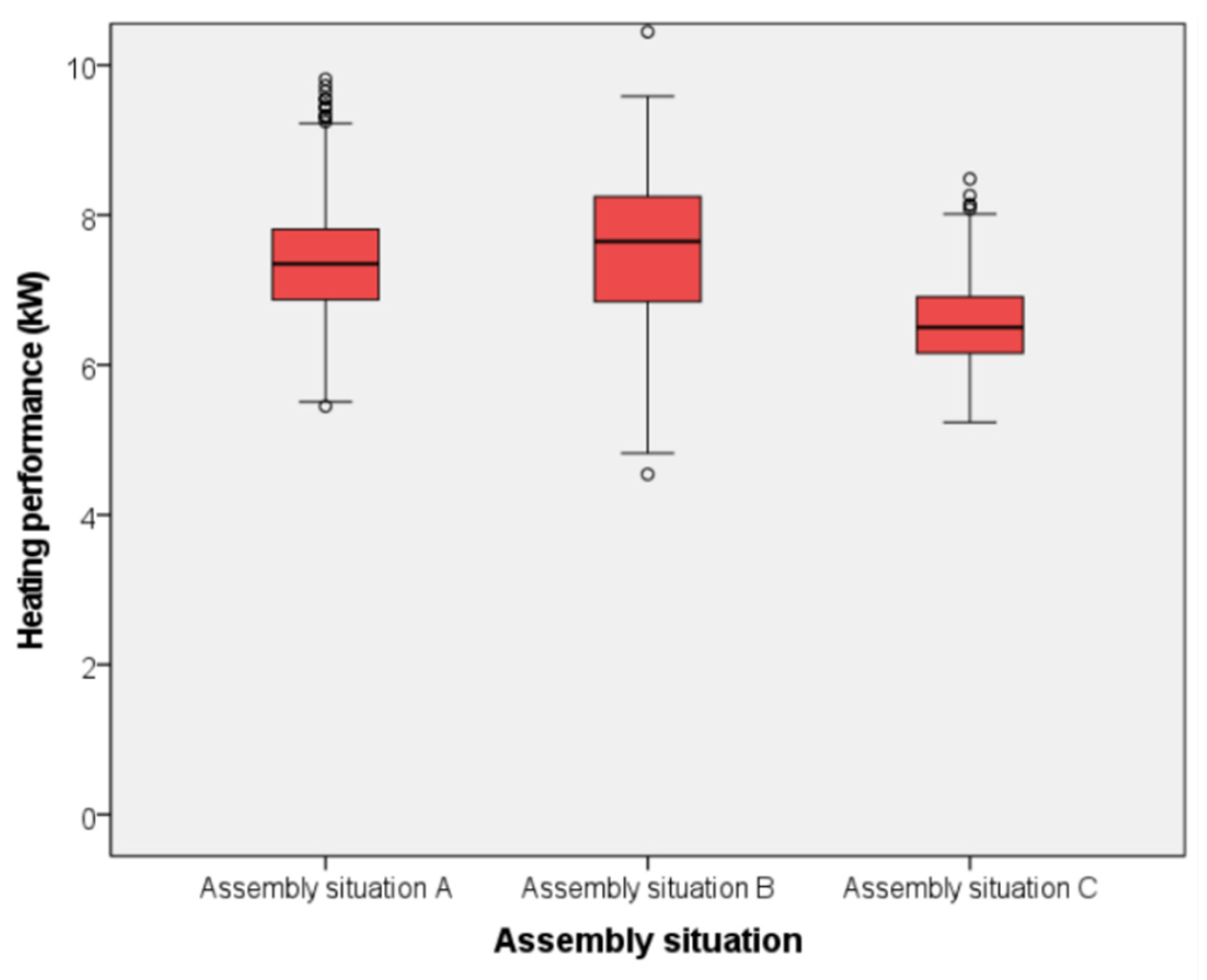

3.3. Most Effective Assembly Situation of Heat Exchanger

3.4. Energy Efficiency

3.5. Ammonia Removal Efficiency of Exchange Scrubber Pilot Plant

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Sensor Type | Unit | Measuring Range | Measuring Accuracy | Measuring Point |

|---|---|---|---|---|---|

| Temperature | KTY81/210 | °C | −30–+150 | ±3% | t11, t12, t21, t22, tW |

| Relative humidity | DOL 114 | % | 0–100 | ±2% (40–85% RH) ±3% (10–95% RH) | t11, t12, t21, t22 |

| Air volume flow (supply air) | Measuring fan Reventa 650 | m3 h−1 | 560–13,300 | <5% (a) | t22 |

| Air volume flow (exhaust air) | Measuring fan Reventa 920 | m3 h−1 | 1220–25,190 | <5% (a) | t12 |

| Ammonia | Gas monitor Innova 1412 | ppm | 0.2–2000 | 2–3% | t11, t12 |

| Assembly Situation of Heat Exchanger | NO2−-N | NO3−-N | NH4+-N | Electric Conductivity | pH-Value |

|---|---|---|---|---|---|

| (mg L−1) | (mg L−1) | (mg L−1) | (mS cm−1) | (-) | |

| A | 696 | 12 | 2291 | 15.2 | 7.7 |

| B | 1399 | 71 | 1783 | 13.1 | 7.6 |

| C | 968 | 76 | 1159 | 9.1 | 7.6 |

References

- Arends, F. Exhaust Air Treatment Systems for Animal Housing Facilities: Techniques—Performance—Costs; Grimm, E., Ed.; KTBL: Darmstadt, Germany, 2008; ISBN 3939371602. [Google Scholar]

- Van der Heyden, C.; Demeyer, P.; Volcke, E.I. Mitigating emissions from pig and poultry housing facilities through air scrubbers and biofilters: State-of-the-art and perspectives. Biosyst. Eng. 2015, 134, 74–93. [Google Scholar] [CrossRef]

- EC. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control) [Online]. 2017. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC107189/jrc107189_01_irpp_bref_07_2017.pdf (accessed on 24 September 2021).

- Wagner, S.; Angenendt, E.; Beletskaya, O.; Zeddies, J. Costs and benefits of ammonia and particulate matter abatement in German agriculture including interactions with greenhouse gas emissions. Agric. Syst. 2015, 141, 58–68. [Google Scholar] [CrossRef]

- DIN 18910. Wärmeschutz Geschlossener Ställe—Wärmedämmung und Lüftung—Planungs- und Berechnungsgrundlagen für Geschlossene Zwangsbelüftete Ställe; Beuth Verlag: Berlin, Germany, 2017; (DIN 18910:2017-08). [Google Scholar]

- Krommweh, M.S.; Büscher, W. Heating performance of a laboratory pilot-plant combining heat exchanger and air scrubber for animal houses. Sci. Rep. 2021, 11, 6872. [Google Scholar] [CrossRef] [PubMed]

- DLG. Luft-Luft-Wärmetauscher WVTL 480. Wärmerückgewinnungseffizienz unter Praxisbedingungen. Schönhammer GmbH: DLG-Prüfbericht 5971F, 2011. Available online: https://pruefberichte.dlg.org/filestorage/pbdocs/5971F.pdf (accessed on 24 September 2021).

- Rösmann, P.; Büscher, W. Rating of an air-to-air heat exchanger in practise. Landtechnik 2010, 65, 418–420. [Google Scholar] [CrossRef]

- DLG. 1-stufiger biologischer Abluftwäscher System RIMU für die Schweinehaltung: RIMU—Agrartechnologie GmbH: DLG-Prüfbericht 6284. 2015. Available online: http://www.dlg-test.de/tests/6284.pdf (accessed on 24 September 2021).

- Hahne, J.; Schirz, S.; Schumacher, W. Leitfaden des Landkreises Cloppenburg zur Feststellung der Eignung von Abluftreinigungsanlagen in der Tierhaltung zur Anwendung in der Genehmigungspraxis und bei der Überwachung. 2002. Available online: https://lkclp.de/uploads/files/ara_leitfaden_zur_feststellung_der_eignung_mit_anlage.pdf (accessed on 24 September 2021).

- Calvet, S.; Gates, R.S.; Zhang, G.; Estellés, F.; Ogink, N.W.; Pedersen, S.; Berckmans, D. Measuring gas emissions from livestock buildings: A review on uncertainty analysis and error sources. Biosyst. Eng. 2013, 116, 221–231. [Google Scholar] [CrossRef] [Green Version]

- Maghirang, R.G.; Liu, Y.; Chung, D.S. Evaluation of a freely rotating impeller to measure fan airflow rates in livestock buildings. Trans. ASAE 1998, 41, 819–824. [Google Scholar] [CrossRef]

- Büscher, W.; Neser, S.; Gronauer, A. Messmethoden zur Luftvolumenstromermittlung in zwangsbelüfteten Ställen. In Messmethoden für Ammoniak-Emissionen aus der Tierhaltung; KTBL, Ed.; Landwirtschaftsverlag: Münster-Hiltrup, Germany, 2001; pp. 110–121. ISBN 3-7843-2130-5. [Google Scholar]

- DIN EN 13053. Ventilation for Buildings—Air Handling Units—Rating and Performance for Units, Components and Sections, German version EN 13053:2019; Beuth Verlag: Berlin, Germany, 2020. [Google Scholar]

- VDI 3803-5. Air-Conditioning, System Requirements. Part 5: Heat Recovery Systems (VDI Ventilation Code of Practice); Beuth Verlag: Berlin, Germany, 2013. [Google Scholar]

- Hassouna, M.; Robin, P.; Charpiot, A.; Edouard, N.; Méda, B. Infrared photoacoustic spectroscopy in animal houses: Effect of non-compensated interferences on ammonia, nitrous oxide and methane air concentrations. Biosyst. Eng. 2013, 114, 318–326. [Google Scholar] [CrossRef]

- Li, H.; Zhang, C.; Xin, H. Performance of an Infrared Photoacoustic Single Gas Analyzer in Measuring Ammonia from Poultry Houses. Appl. Eng. Agric. 2015, 31, 471–477. [Google Scholar] [CrossRef] [Green Version]

- Schmithausen, A.J.; Trimborn, M.; Büscher, W. Methodological Comparison between a Novel Automatic Sampling System for Gas Chromatography versus Photoacoustic Spectroscopy for Measuring Greenhouse Gas Emissions under Field Conditions. Sensors 2016, 16, 1638. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schmithausen, A.J.; Schiefler, I.; Trimborn, M.; Gerlach, K.; Südekum, K.-H.; Pries, M.; Büscher, W. Quantification of Methane and Ammonia Emissions in a Naturally Ventilated Barn by Using Defined Criteria to Calculate Emission Rates. Animals 2018, 8, 75. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hahne, J. Eigenkontrolle und Überwachung von Abluftreinigungsanlagen in der Schweinehaltung: Self-monitoring and control of exhaust air treatment systems in pig keeping. In 14. Tagung Bau Technik und Umwelt in der Landwirtschaftlichen Nutztierhaltung, Proceedings of the 14th Conference Construction, Engineering and Environment in Livestock Farming, Bonn, Germany, 24–26 September 2019; KTBL, Ed.; Kuratorium für Technik und Bauwesen in der Landwirtschaft: Darmstadt, Germany, 2019; pp. 15–20. ISBN 9783945088692. [Google Scholar]

- Ogawa, H.; Dahl, P.; Suzuki, T.; Kai, P.; Takai, H. A microbiological-based air cleaning system using a two-step process for removal of ammonia in discharge air from a pig rearing building. Biosyst. Eng. 2011, 109, 108–119. [Google Scholar] [CrossRef]

- Krommweh, M.S.; Rösmann, P.; Büscher, W. Investigation of heating and cooling potential of a modular housing system for fattening pigs with integrated geothermal heat exchanger. Biosyst. Eng. 2014, 121, 118–129. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Erlbaum: Hillsdale, NJ, USA, 1988; ISBN 0-8058-0283-598 5. [Google Scholar]

- Caputo, A.C.; Pelagagge, P.M.; Salini, P. Joint economic optimization of heat exchanger design and maintenance policy. Appl. Therm. Eng. 2011, 31, 1381–1392. [Google Scholar] [CrossRef] [Green Version]

- Characklis, W.G. Bioengineering Report. Fouling Biofilm Development: A Process Analysis. Biotechnol. Bioeng. 1981, 23, 1923–1960. [Google Scholar] [CrossRef]

- Müller-Steinhagen, H.; Malayeri, M.R.; Watkinson, A.P. Heat Exchanger Fouling: Mitigation and Cleaning Strategies. Heat Transf. Eng. 2011, 32, 189–196. [Google Scholar] [CrossRef]

- Kazi, S.N. Fouling and Fouling Mitigation on Heat Exchanger Surfaces. In Heat Exchangers—Basics Design Applications; Mitrovic, J., Ed.; InTech: London, UK, 2012; ISBN 978-953-51-0278-6. [Google Scholar]

- Rösmann, P. Einsatz von Regenerativen Energiequellen Zum Heizen und Kühlen von Zwangsbelüfteten Tierställen. Ph.D. Thesis, Rheinische Friedrich-Wilhelms-Universität Bonn, Bonn, Germany, 2012. [Google Scholar]

- DLG. Big Dutchman International GmbH—Heat Exchanger Earny Type 40.000—Efficiency of Heat Recovery under Practical Conditions: DLG Test Report 6140F. 2014. Available online: http://www.dlg-test.de/tests/6140F_e.pdf (accessed on 24 September 2021).

- Licharz, H.; Rösmann, P.; Krommweh, M.S.; Mostafa, E.; Büscher, W. Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses. Energies 2020, 13, 662. [Google Scholar] [CrossRef] [Green Version]

- Mun, H.S.; Dilawar, M.A.; Jeong, M.G.; Rathnayake, D.; Won, J.S.; Park, K.W.; Lee, S.R.; Ryu, S.B.; Yang, C.J. Effect of a Heating System Using a Ground Source Geothermal Heat Pump on Production Performance, Energy-Saving and Housing Environment of Pigs. Animals 2020, 10, 2075. [Google Scholar] [CrossRef] [PubMed]

- Decius, M.; Hartung, J.; Naim, H.Y. Prüfung der Funktionsweise und Effizienz Einer Biologischen Abluftreinigungsanlage Unter Praxisbedingungen im Hinblick auf das Rückhaltevermögen für Bioaerosole; Tierärztliche Hochschule: Hannover, Germany, 2016. [Google Scholar]

- Liu, F.; Fiencke, C.; Guo, J.; Lyu, T.; Dong, R.; Pfeiffer, E.-M. Optimisation of bioscrubber systems to simultaneously remove methane and purify wastewater from intensive pig farms. Environ. Sci. Pollut. Res. 2019, 26, 15847–15856. [Google Scholar] [CrossRef] [PubMed]

- VDI 3478-2. Biological Waste Gas Purification: Part 2: Biological Trickle Bed-Reactors; Beuth Verlag: Berlin, Germany, 2008. [Google Scholar]

- Liu, F.; Fiencke, C.; Guo, J.; Rieth, R.; Cuhls, C.; Dong, R.; Pfeiffer, E.-M. Bioscrubber treatment of exhaust air from intensive pig production: Case study in northern Germany at mild climate condition. Eng. Life Sci. 2017, 17, 458–466. [Google Scholar] [CrossRef] [PubMed]

| Unit | Assembly Situation of Heat Exchanger | ||||

|---|---|---|---|---|---|

| A | B | C | |||

| Test days | d | 13 | 13 | 13 | |

| Test hours | h | 312 | 312 | 308 | |

| Total electricity consumption (kWhel) | kWh | 265.6 | 272.7 | 261.0 | |

| of that | exhaust air fan | kWh | 54.4 | 56.5 | 54.9 |

| supply air fan | kWh | 22.2 | 24.4 | 23.6 | |

| recirculation pump and sludge removal pump | kWh | 189.0 | 191.8 | 182.5 | |

| Average heating performance | kW | 8.5 | 10.0 | 6.0 | |

| Total transferred thermal energy (kWhth) | kWh | 2641 | 3132 | 1860 | |

| COP | - | 9.9 | 11.5 | 7.1 | |

| Assembly Situation of Heat Exchanger | A | B | C | |

|---|---|---|---|---|

| Period of ammonia measurement | 2015-02-04, 7:00 p.m. to 2015-02-05, 9:00 a.m. | 2015-02-18, 10:30 p.m. to 2015-02-19, 12:30 p.m. | 2015-03-04, 10:15 p.m. to 2015-03-05, 8:15 p.m. | |

| Test duration (h) | 14 | 14 | 22 | |

| Ammonia concentration in raw gas (ppm) | xmin | 19.9 | 17.3 | 22.7 |

| mean ± SD | 25.2 ± 2.9 | 18.3 ± 0.7 | 25.7 ± 1.7 | |

| xmax | 33.5 | 19.8 | 28.7 | |

| Ammonia concentration in clean gas (ppm) | xmin | 12.6 | 7.4 | 7.6 |

| mean ± SD | 13.9 ± 0.9 | 7.9 ± 0.2 | 9.2 ± 1.0 | |

| xmax | 16.2 | 8.3 | 10.4 | |

| Removal efficiency | xmin | 0.34 | 0.55 | 0.58 |

| mean ± SD | 0.44 ± 0.05 | 0.57 ± 0.01 | 0.64 ± 0.03 | |

| xmax | 0.52 | 0.61 | 0.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krommweh, M.S.; Deeken, H.F.; Licharz, H.; Büscher, W. Heating Performance and Ammonia Removal of a Single-Stage Bioscrubber Pilot Plant with Integrated Heat Exchanger under Field Conditions. Energies 2021, 14, 6484. https://doi.org/10.3390/en14206484

Krommweh MS, Deeken HF, Licharz H, Büscher W. Heating Performance and Ammonia Removal of a Single-Stage Bioscrubber Pilot Plant with Integrated Heat Exchanger under Field Conditions. Energies. 2021; 14(20):6484. https://doi.org/10.3390/en14206484

Chicago/Turabian StyleKrommweh, Manuel S., Hauke F. Deeken, Hannah Licharz, and Wolfgang Büscher. 2021. "Heating Performance and Ammonia Removal of a Single-Stage Bioscrubber Pilot Plant with Integrated Heat Exchanger under Field Conditions" Energies 14, no. 20: 6484. https://doi.org/10.3390/en14206484

APA StyleKrommweh, M. S., Deeken, H. F., Licharz, H., & Büscher, W. (2021). Heating Performance and Ammonia Removal of a Single-Stage Bioscrubber Pilot Plant with Integrated Heat Exchanger under Field Conditions. Energies, 14(20), 6484. https://doi.org/10.3390/en14206484