Performance and Exhaust Emissions of a Spark Ignition Internal Combustion Engine Fed with Butanol–Glycerol Blend

Abstract

:1. Introduction

1.1. Glycerol Specific Properties

1.2. Glycerol Combustion in the Compression Ignition Engine

1.3. Glycerol Combustion in the Spark-Ignition Engine

- Combustion tests on a mixture of glycerol and n-butanol in an internal combustion spark-ignition piston engine,

- Emission tests on this engine,

- A recommendation to use the glycerol–butanol blend (Glyc_But) at a mixing ratio of 1:3, as a complete and suitable substitute for the gasoline 95 in a modern spark-ignition engine.

2. Materials and Methods

- To obtain knowledge on possibilities of glycerol combustion in a spark-ignited reciprocating engine. As glycerol characterizes itself with relatively high viscosity, butanol was proposed to dilute it and decrease its kinematic viscosity in this way to a level at which the blend can be successfully sprayed by a typical port-fueled gasoline injector.

- To obtain knowledge on toxic emissions from the engine fueled glycerol–butanol blend. Hence, the tests were focused on exhaust gas toxic emissions as follows: NOx, CO, UHC, and smoke.

- n-butanol–glycerol blend at the ratio of 3:1. Hence, the blend contains n-butanol at a percentage of 75%, whereas glycerol is present at 25% by volume. Purity of glycerol used for tests was 99.5% in weight. The glycerol–butanol ratio was selected regarding its viscosity, which should provide conditions for spraying and vaporization. Finally, the dynamic viscosity of this blend was in the range 0.9–1.4 mPas at 50 °C.

- Pure n-butanol 99.9%.

- Gasoline 95. This is characterized with an octane rating of 95 and is commonly used in the European market.

2.1. Test Matrix

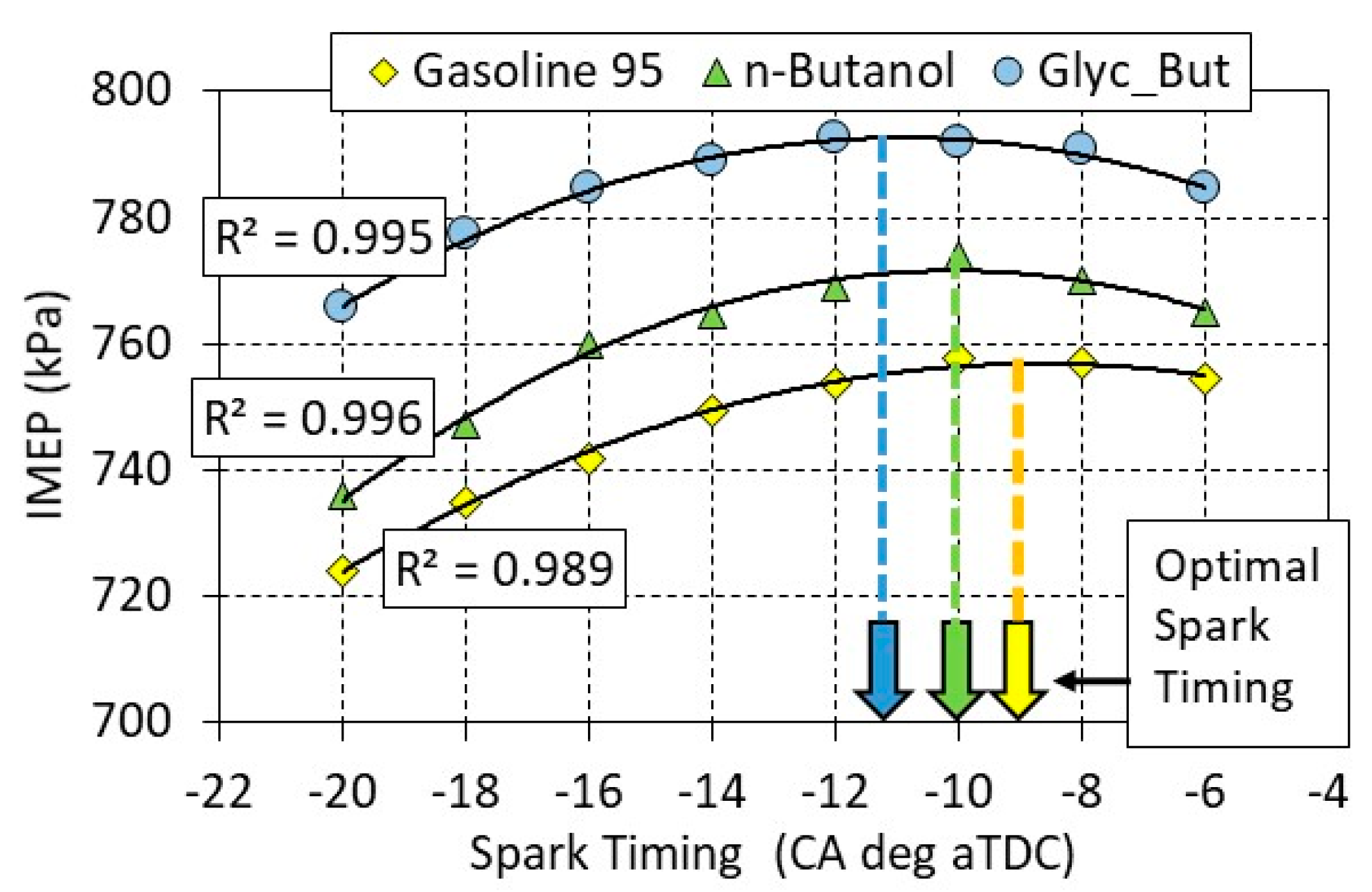

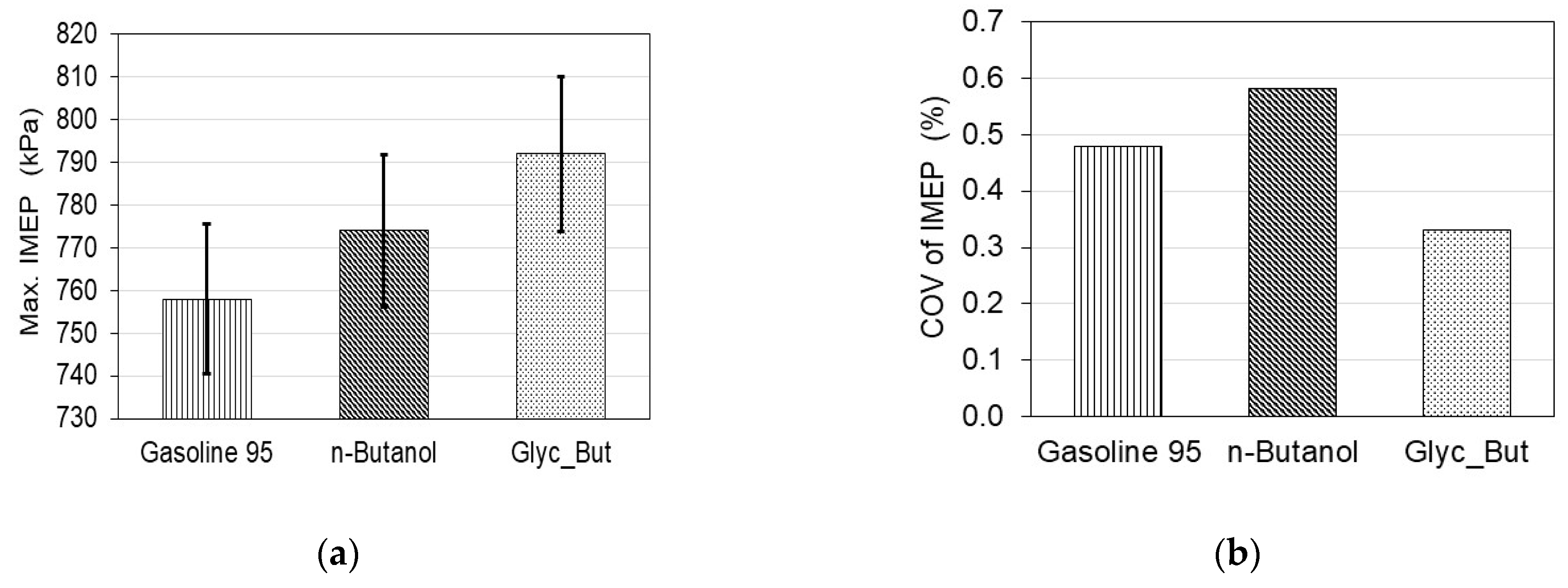

- Investigation of optimal spark timing to obtain maximum brake torque (MBT) and maximum indicated mean effective pressure (IMEP). Additionally, the coefficient of variation (COV) of IMEP was introduced to express the smoothness of engine run.

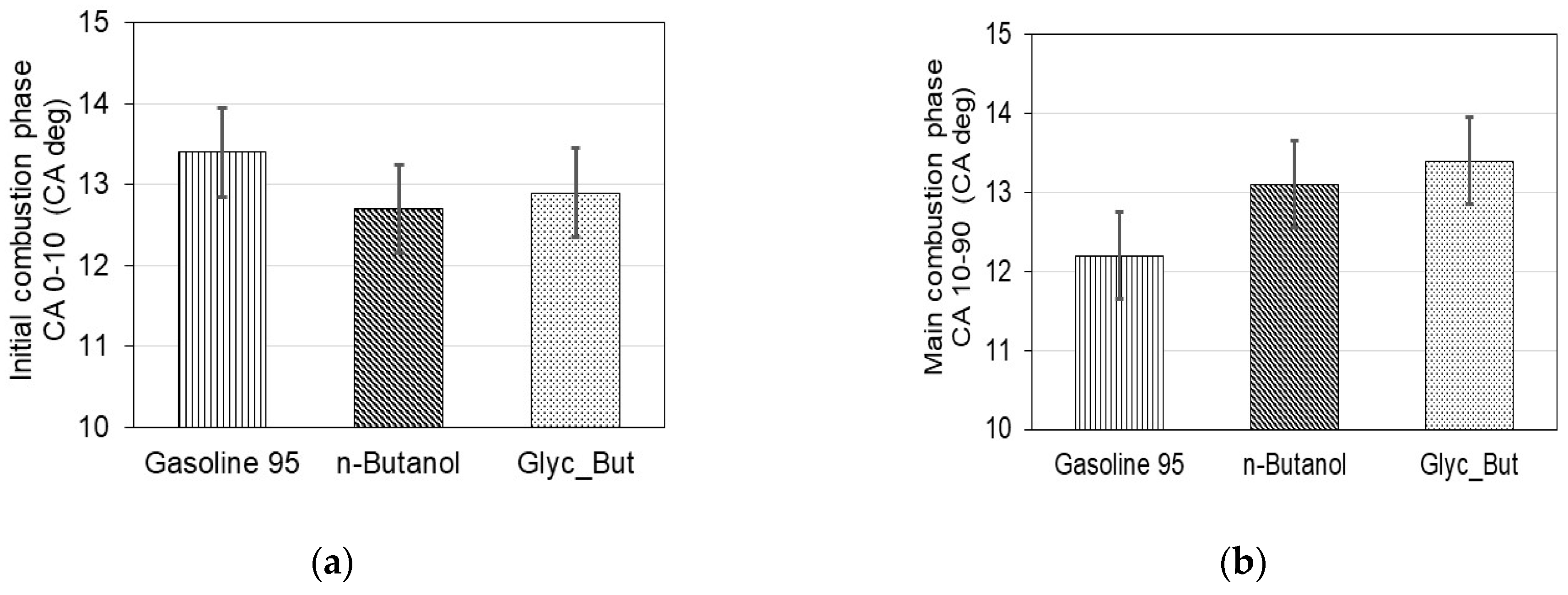

- Combustion duration. Combustion analysis was carried out for the optimal spark timing. Two combustion phases were introduced as follows:

- ○ Initial combustion phase CA0-10

- ○ Main combustion phase CA10-90

- Toxic exhaust gas emission: NOx, CO, and UHC.

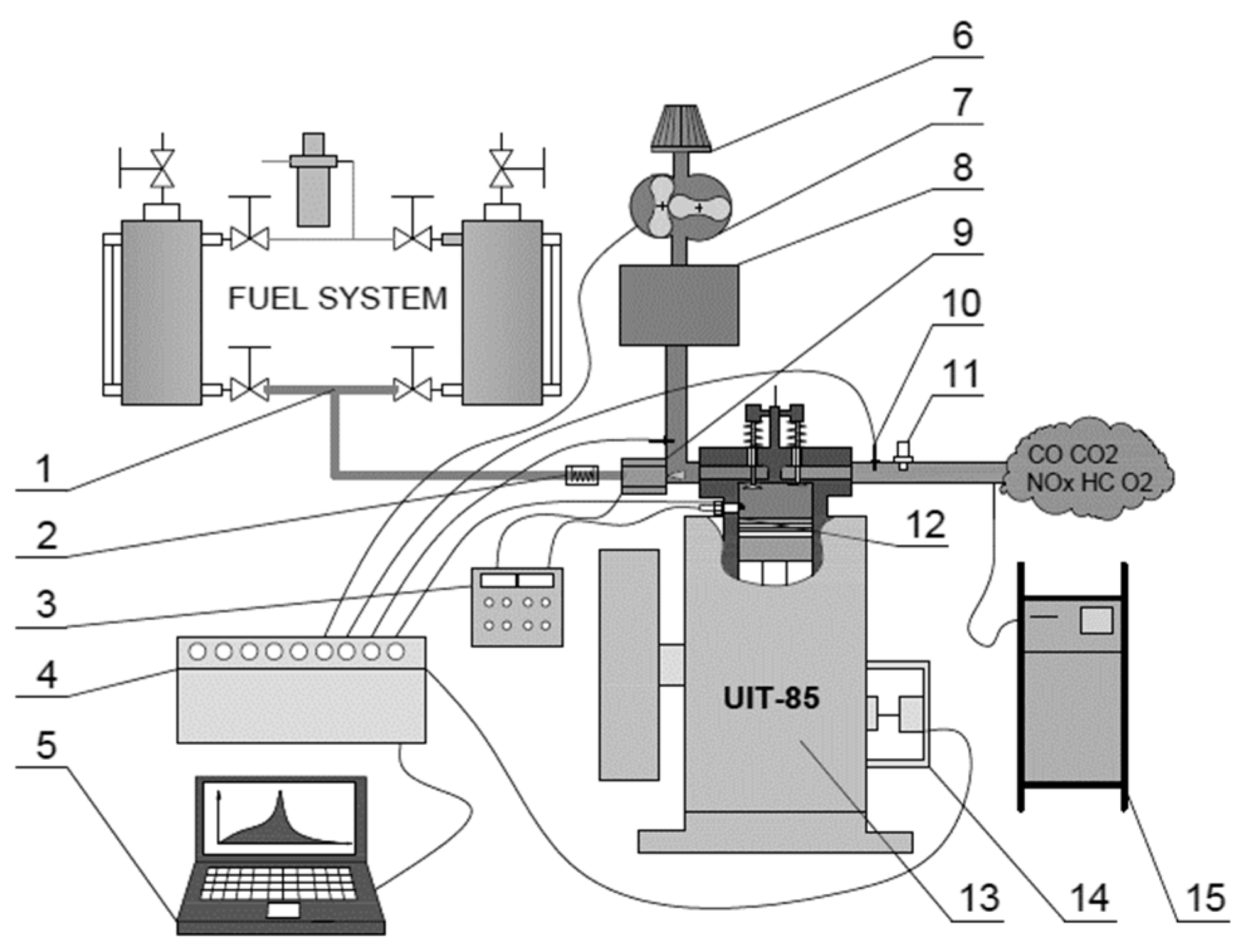

2.2. Test Setup

2.3. Error Analysis

- In-cylinder pressure,

- Temperature of the exhaust gases and ambient intake air,

- Air flow rate to the engine,

- Engine speed,

- Exhaust gas compositions including NOx, UHC, and CO.

- ΔVi—change in cylinder displacement with changing the crank angle from αi to αi + 1,

- pi—change in in-cylinder pressure with changing the crank angle from αi to αi + 1.

- Vs—cylinder displacement,

- Vs—cylinder displacement,

- n—engine crankshaft speed,

- LHVf—the lower heating value of a fuel,

- mf—fuel flow rate.

- std(IMEP)—standard deviation from IMEP population of 100 combustion events,

- mean(IMEP)—mean of this IMEP population.

3. Results and Discussion

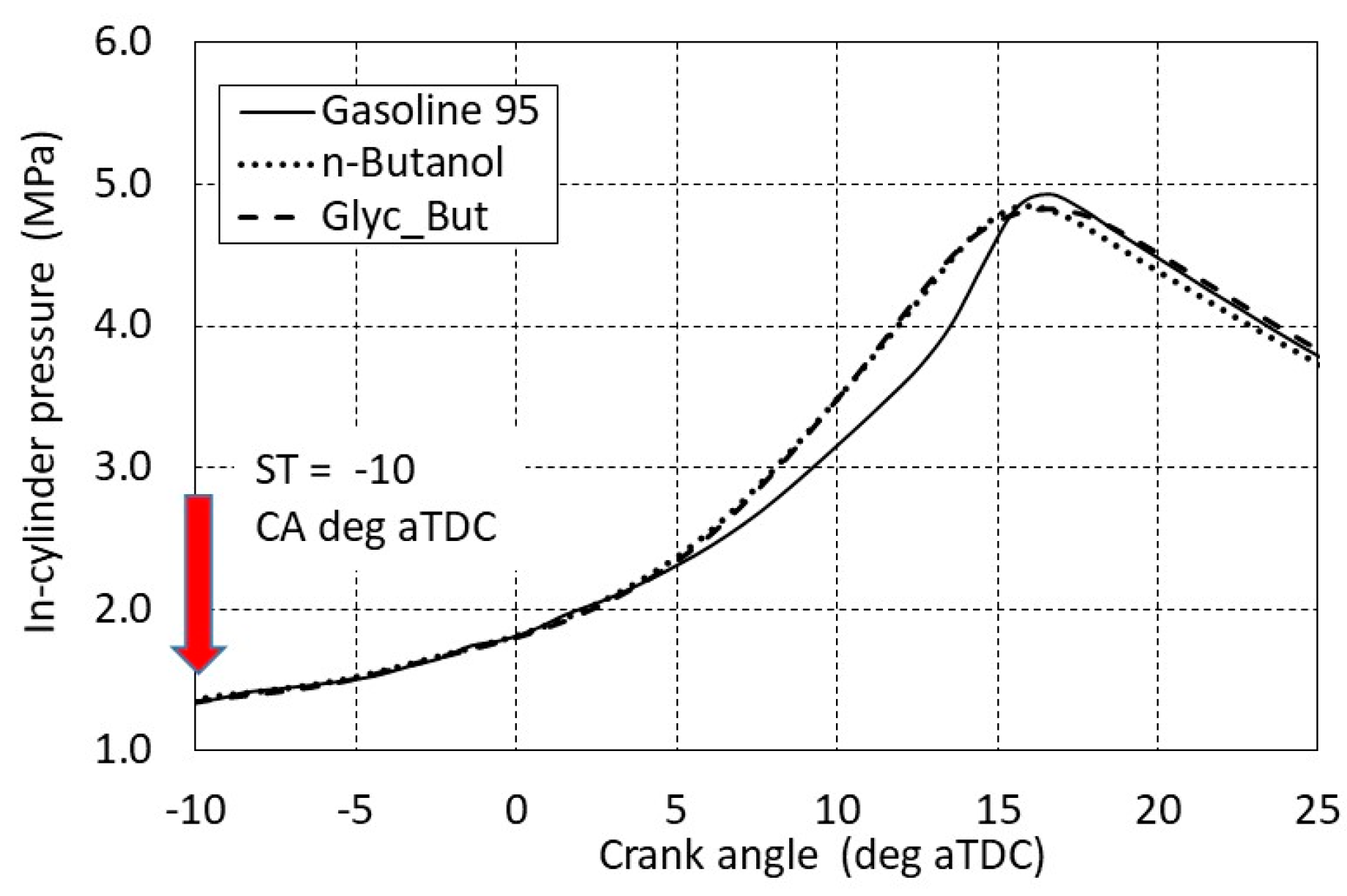

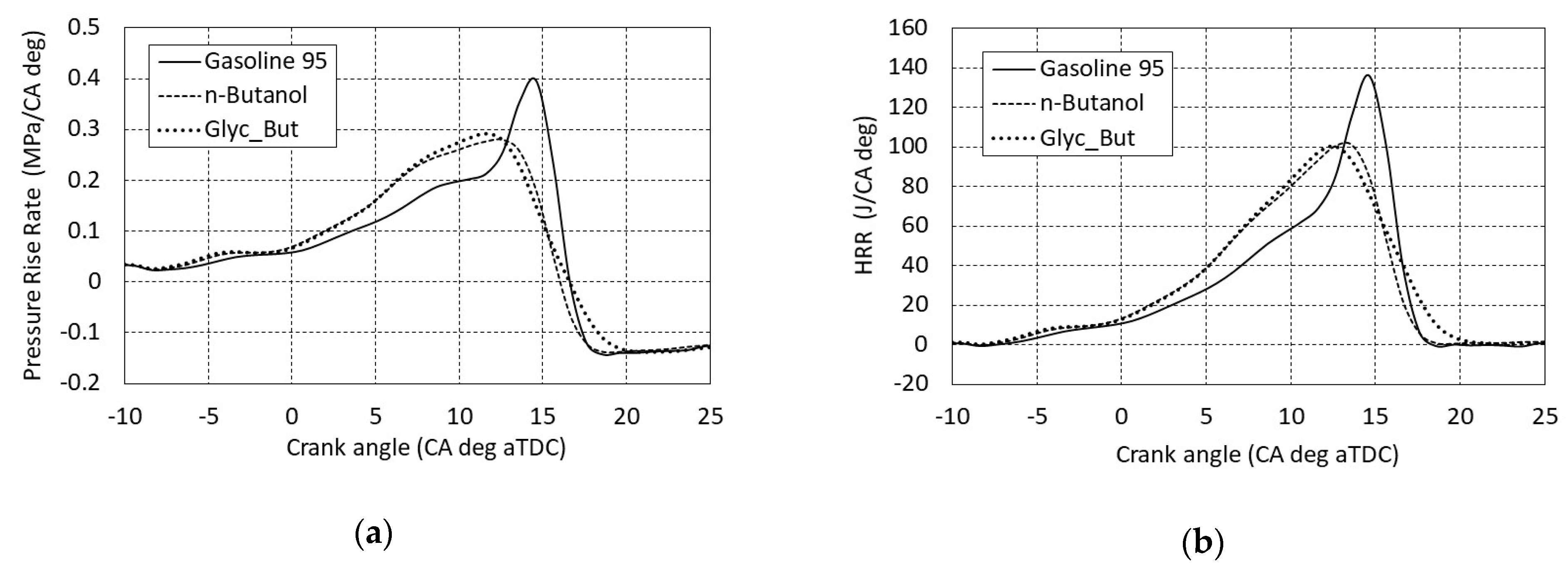

3.1. Combustion Thermodynamic Analysis

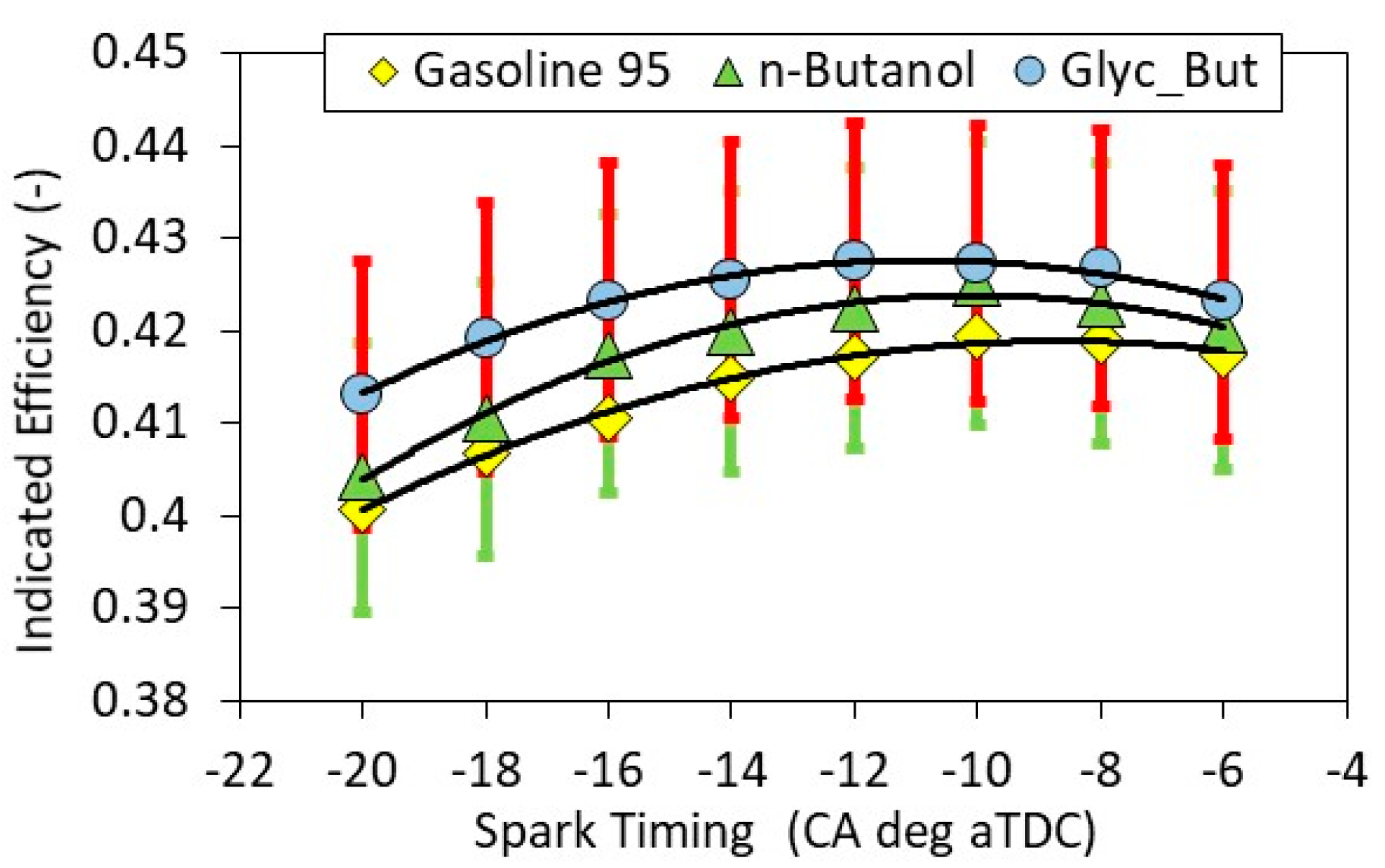

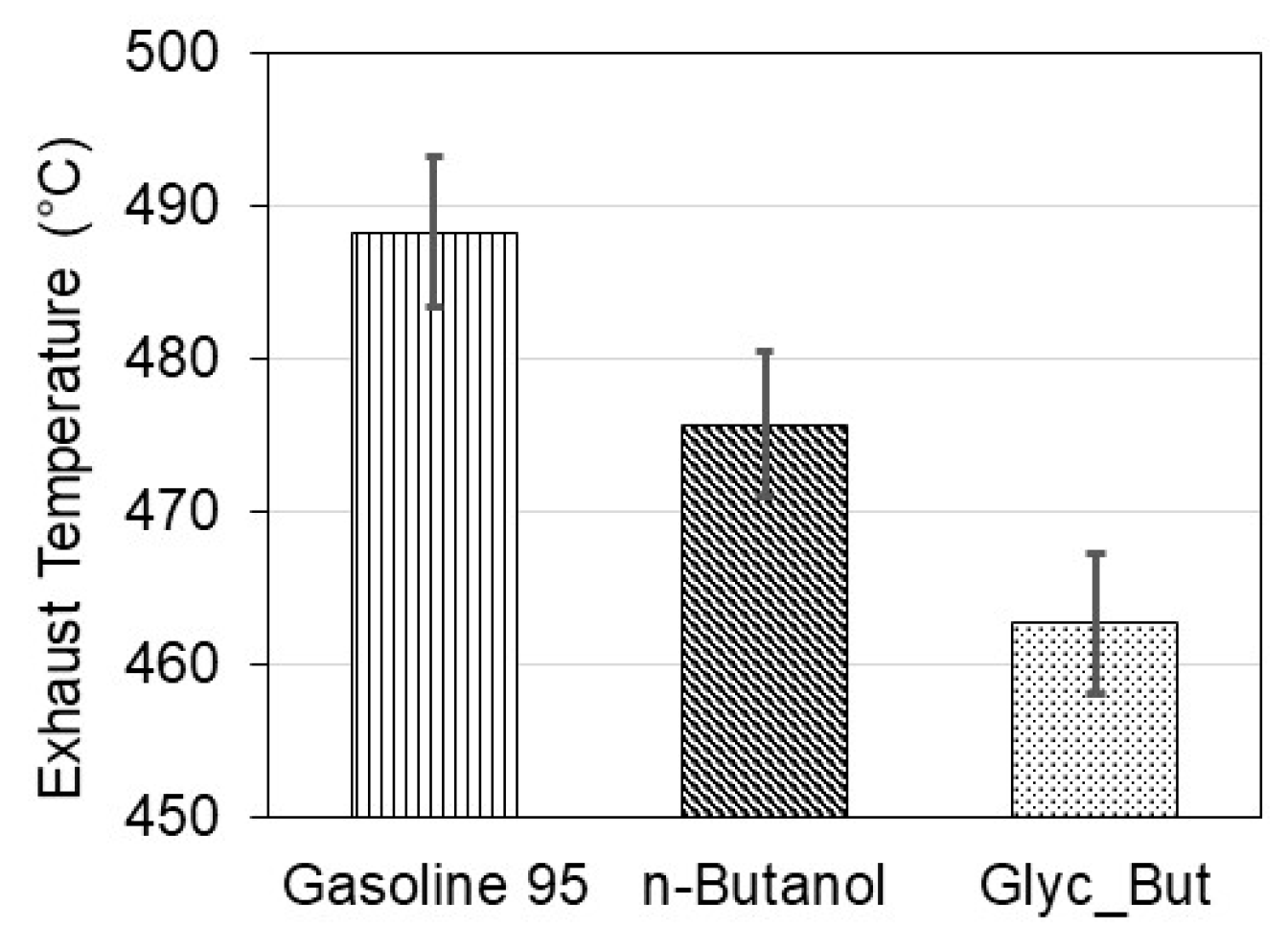

3.2. Engine Performance

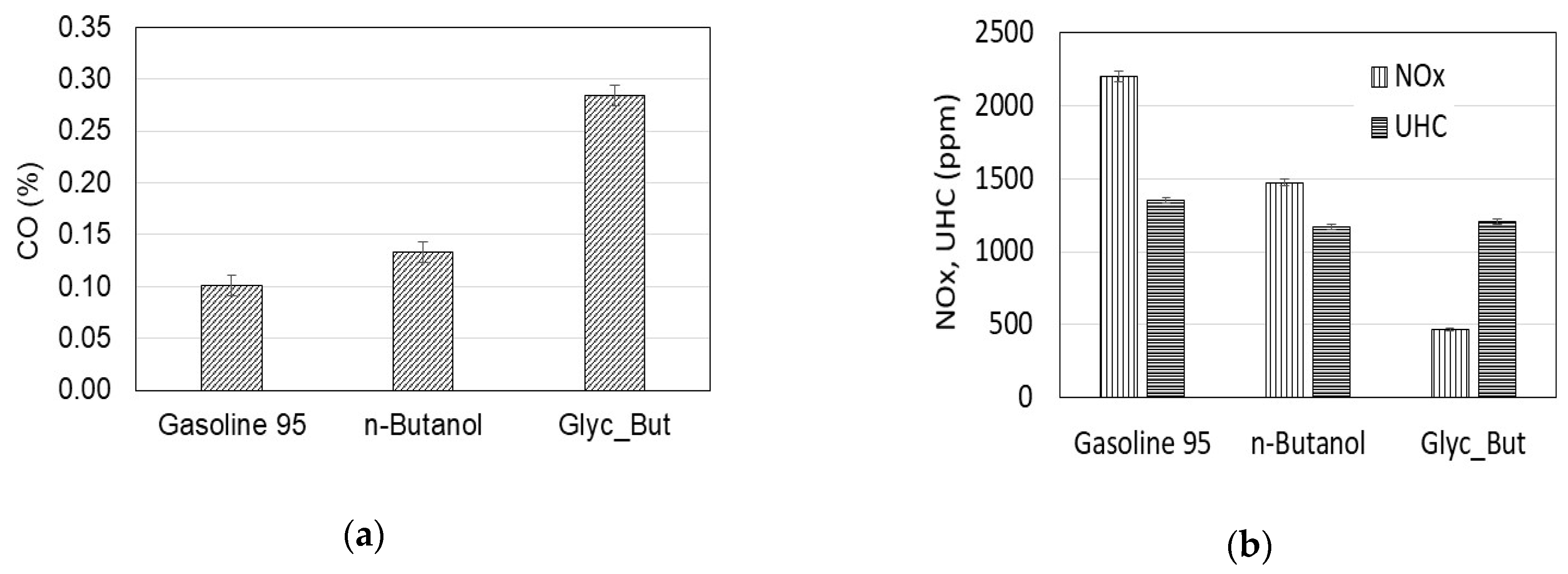

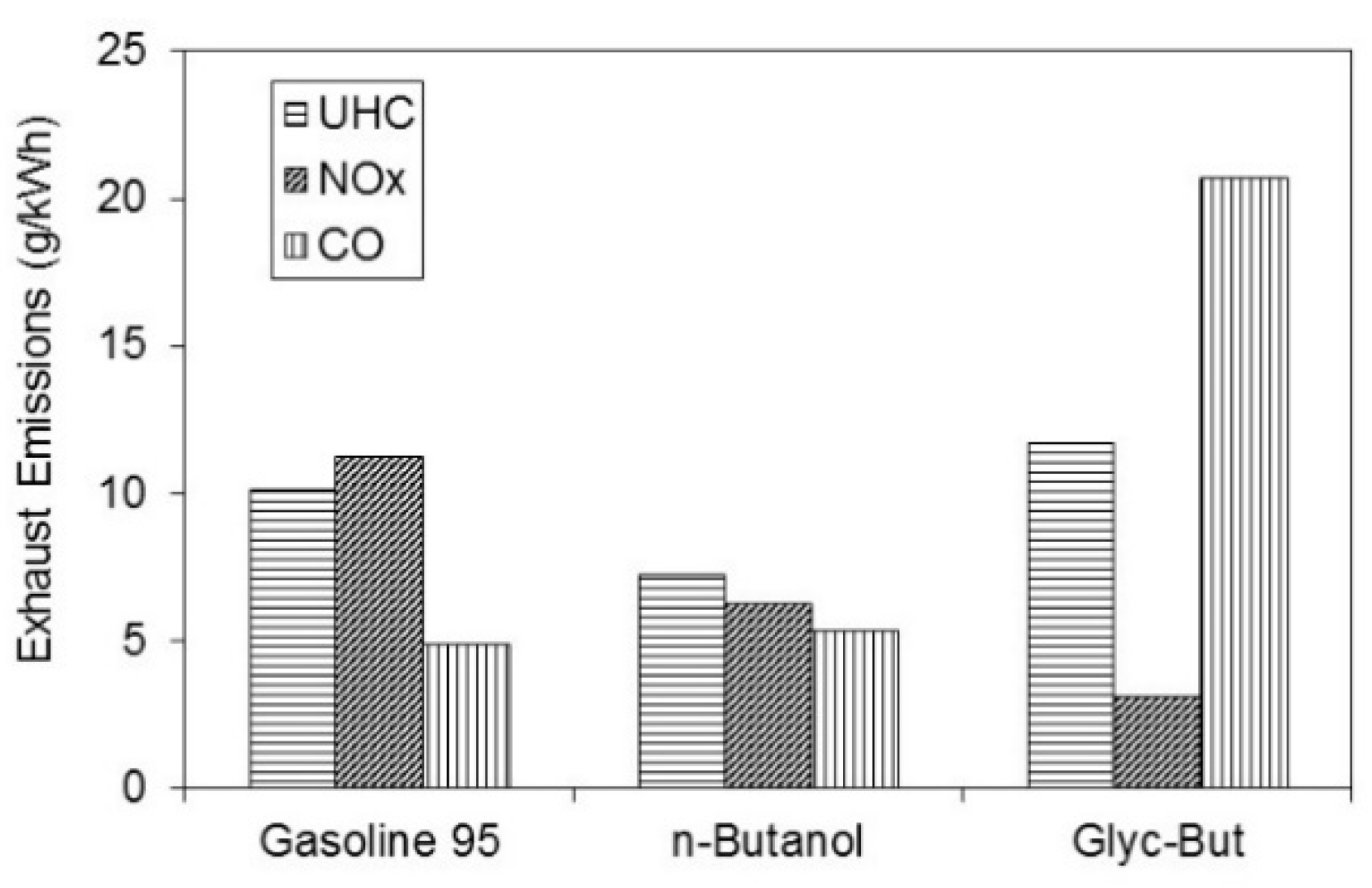

3.3. Exhaust Emissions Tests

4. Conclusions

- comparative analysis of the fuels tested turned out to be a reliable methodology,

- trends in IMEP, efficiency, and combustion phases were proved,

- NOx emission trend was indirectly affected by the heat of vaporization of a fuel tested (Zeldovich mechanism referring to the exhaust gas temperature).

- Engine performance expressed by both the indicated mean effective pressure and the indicated efficiency did not deteriorate. Moreover, these parameters slightly increased, which was caused by lower exhaust gas temperature contributing to the reduction in exhaust heat loss.

- Stability of the engine run was found to be the same for the gasoline 95 test.

- Combustion duration phases CA0-10 and CA10-90 did not differ significantly in comparison to combustion of gasoline 95.

- NOx exhaust emission was reduced by four times in comparison to the test with the gasoline fueled engine. UHC emissions were at a similar level. Unfortunately, CO emissions were twice as high.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Almena, A.; Bueno, L.; Díez, M.; Martín, M. Integrated biodiesel facilities: Review of glycerol-based production of fuels and chemicals. Clean Technol. Environ. Policy 2018, 20, 1639–1661. [Google Scholar] [CrossRef]

- Emberson, D.R.; Wyndorps, J.; Ahmed, A.; Bjørgen, K.O.P.; Løvås, T. Detailed examination of the combustion of diesel and glycerol emulsions in a compression ignition engine. Fuel 2021, 291, 120147. [Google Scholar] [CrossRef]

- Presciutti, A.; Asdrubali, F.; Baldinelli, G.; Rotili, A.; Malavasi, M.; Di Salvia, G. Energy and Exergy Analysis of Glycerol Combustion in an Innovative Flameless Power Plant. J. Clean. Prod. 2018, 172, 3817–3824. [Google Scholar] [CrossRef]

- Roberts, W.L.; North Carolina State University; Raleigh NC. Crude Glycerol as Cost-Effective Fuel for Combined Heat and Power to Replace Fossil Fuels, Final Technical Report; Department of Energy: Washington, DC, USA, 2012.

- Quispe, C.A.G.; Coronado, C.J.R.; Carvalho, J.A., Jr. Glycerol: Production, Consumption, Prices, Characterization and New Trends in Combustion. Renew. Sustain. Energy Rev. 2013, 27, 475–493. [Google Scholar] [CrossRef]

- Gupta, M.; Kumar, N. Scope and Opportunities of Using Glycerol as an Energy Source. Renew. Sustain. Energy Rev. 2012, 16, 4551–4556. [Google Scholar] [CrossRef]

- Ferreira, A.G.M.; Egas, A.P.V.; Fonseca, I.M.A.; Costa, A.C.; Abreu, D.C.; Lobo, L.Q. The Viscosity of Glycerol. J. Chem. Thermodyn. 2017, 113, 162–182. [Google Scholar] [CrossRef]

- Sliwinski, K.; Marek, W. The Use of Glycerine as Motor Fuel. Combust. Engines 2019, 178, 166–172. [Google Scholar] [CrossRef]

- Bohon, M.D.; Metzger, B.A.; Linak, W.P.; King, C.J.; Roberts, W.L. Glycerol Combustion and Emissions. Proc. Combust. Inst. 2011, 33, 2717–2724. [Google Scholar] [CrossRef]

- Coronado, C.R.; Carvalho, J.A.; Quispe, C.A.; Sotomonte, C.R. Ecological Efficiency in Glycerol Combustion. Appl. Therm. Eng. 2014, 63, 97–104. [Google Scholar] [CrossRef]

- Queirós, P.; Costa, M.; Carvalho, R.H. Co-Combustion of Crude Glycerin with Natural Gas and Hydrogen. Proc. Combust. Inst. 2013, 34, 2759–2767. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, Z.; Zhang, Y.; Setyawan, H.; Liu, P.; Zhang, D. An Experimental Study of the Ignition and Combustion Characteristics of Single Droplets of Biochar-Glycerol-Water Slurry Fuels. Proc. Combust. Inst. 2017, 36, 2475–2482. [Google Scholar] [CrossRef]

- Beatrice, C.; Di Blasio, G.; Guido, C.; Cannilla, C.; Bonura, G.; Frusteri, F. Mixture of Glycerol Ethers as Diesel Bio-Derivable Oxy-Fuel: Impact on Combustion and Emissions of an Automotive Engine Combustion System. Appl. Energy 2014, 132, 236–247. [Google Scholar] [CrossRef]

- Rodrigues, A.; Bordado, J.C.; Santos, R.G.d. Upgrading the Glycerol from Biodiesel Production as a Source of Energy Carriers and Chemicals—A Technological Review for Three Chemical Pathways. Energies 2017, 10, 1817. [Google Scholar] [CrossRef] [Green Version]

- Grab-Rogalinski, K.; Szwaja, S. The Combustion Properties Analysis of Various Liquid Fuels Based on Crude Oil and Renewables. IOP Conf. Ser. Mater. Sci. Eng. 2016, 148. [Google Scholar] [CrossRef] [Green Version]

- Oprescu, E.-E.; Dragomir, R.E.; Radu, E.; Radu, A.; Velea, S.; Bolocan, I.; Stepan, E.; Rosca, P. Performance and Emission Characteristics of Diesel Engine Powered with Diesel–Glycerol Derivatives Blends. Fuel Process. Technol. 2014, 126, 460–468. [Google Scholar] [CrossRef]

- Eaton, S.J.; Harakas, G.N.; Kimball, R.W.; Smith, J.A.; Pilot, K.A.; Kuflik, M.T.; Bullard, J.M. Formulation and Combustion of Glycerol–Diesel Fuel Emulsions. Energy Fuels 2014, 28, 3940–3947. [Google Scholar] [CrossRef]

- Gruca, M.; Pyrc, M.; Szwaja, M.; Szwaja, S. Effective Combustion of Glycerol in a Compression Ignition Engine Equipped with Double Direct Fuel Injection. Energies 2020, 13, 6349. [Google Scholar] [CrossRef]

- Chwist, M.; Pyrc, M.; Gruca, M.; Szwaja, M. By-Products from Thermal Processing of Rubber Waste as Fuel for the Internal Combustion Piston Engine. Combust. Engines 2020, 181, 11–18. [Google Scholar] [CrossRef]

- Merola, S.; Irimescu, A.; Vaglieco, B. Effect of Fuel Injection Strategy on the Carbonaceous Structure Formation and Nanoparticle Emission in a DISI Engine Fuelled with Butanol. Energies 2017, 10, 832. [Google Scholar] [CrossRef] [Green Version]

- Papagiannakis, R.; Rakopoulos, D.; Rakopoulos, C. Theoretical Study of the Effects of Spark Timing on the Performance and Emissions of a Light-Duty Spark Ignited Engine Running under Either Gasoline or Ethanol or Butanol Fuel Operating Modes. Energies 2017, 10, 1198. [Google Scholar] [CrossRef] [Green Version]

- Lapuerta, M.; González-García, I.; Céspedes, I.; Estévez, C.; Bayarri, N. Improvement of Cold Flow Properties of a New Biofuel Derived from Glycerol. Fuel 2019, 242, 794–803. [Google Scholar] [CrossRef]

- Munsin, R.; Laoonual, Y.; Jugjai, S.; Matsuki, M.; Kosaka, H. Effect of Glycerol Ethoxylate as an Ignition Improver on Injection and Combustion Characteristics of Hydrous Ethanol under CI Engine Condition. Energy Convers. Manag. 2015, 98, 282–289. [Google Scholar] [CrossRef]

- Stelmasiak, Z.; Pietras, D. Utilization of Waste Glycerin to Fuelling of Spark Ignition Engines. IOP Conf. Ser. Mater. Sci. Eng. 2016, 148. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Cai, Y.; Li, X.; Jiao, L.; Xia, J.; Deng, X. Effects of the Cellulose, Xylan and Lignin Constituents on Biomass Pyrolysis Characteristics and Bio-Oil Composition Using the Simplex Lattice Mixture Design Method. Energy Convers. Manag. 2017, 138, 106–118. [Google Scholar] [CrossRef]

- Badrawada, I.G.G.; Susastriawan, A.A.P. Influence of Ethanol-Gasoline Blend on Performance and Emission of Four-Stroke Spark Ignition Motorcycle. Clean Technol. Environ. Policy 2019, 21, 1891–1896. [Google Scholar] [CrossRef]

- Larsson, T.; Mahendar, S.K.; Christiansen-Erlandsson, A.; Olofsson, U. The Effect of Pure Oxygenated Biofuels on Efficiency and Emissions in a Gasoline Optimised DISI Engine. Energies 2021, 14, 3908. [Google Scholar] [CrossRef]

- EU: Fuels: Diesel and Gasoline|Transport Policy. Available online: https://www.transportpolicy.net/standard/eu-fuels-diesel-and-gasoline/ (accessed on 3 August 2021).

- Zeldovich, Y.B. The oxidation of nitrogen in combustion explosions. Acta Phys. Ussr 1946, 21, 577–628. [Google Scholar]

| Property | Unit | Number |

|---|---|---|

| Water content | % | 14–17 |

| Mineral content (mainly alkaline) | % | 6–8 |

| Other organic compounds | % | <5 |

| Methanol content | % | <1 |

| Kinematic viscosity at 25 °C | m2/s | (450–750) × 10−6 |

| Characteristics of the combustion reaction at stoic. ratio in air | ||

| Heat of combustion | MJ/kg | 18 |

| kJ/mol | 1662 | |

| Lower heating value (LHV) | MJ/kg | 16 |

| Gibbs free energy | kJ/mol | −2211 1 |

| Parameter | Unit | Gasoline 95 [28] | n-Butanol [21,27] | Glycerol [7,8] | Glyc_But 1 |

|---|---|---|---|---|---|

| LHV | MJ/kg | 43.4 | 33.1 | 16.9 | 29.2 |

| Density at NTP | kg/dm3 | 0.735 | 0.810 | 1.252 | 0.923 |

| Purity (Composition) | - | 100% | 99.9% wt | 99.5% wt | 25/75% vol |

| Air to fuel (A/F) stoichiometric ratio | - | 14.97 | 11.15 | 5.20 | 9.13 |

| Latent heat of evaporation | kJ/kg | 350 | 582 | 974 | 715 |

| Test No. | Fuels | Parameters | Value |

|---|---|---|---|

| Test 1 Preliminary investigation | Glyc_But n-Butanol Gasoline 95 | Spark advance angle | (−2)–(−20) |

| Relative equivalence ratio “lambda” | 1.00–1.05 | ||

| Engine load | Maximum at WOT | ||

| Test 2 Combustion progress CA0-10 CA10-90 | Glyc_But n-Butanol Gasoline 95 | Spark advance angle | Optimal to obtain max. IMEP |

| Relative equivalence ratio “lambda” | 1.00–1.05 | ||

| Engine load | Max. IMEP | ||

| Test 3 Exhaust emissions at max. IMEP | Glyc_But n-Butanol Gasoline 95 | Spark advance angle | (a) Varying (b) Optimal for max. IMEP |

| Relative equivalence ratio “lambda” | 1.00–1.05 | ||

| Engine load | Maximum at WOT |

| Type of Engine | Single Cylinder, Four-Stroke, Freely Aspirated |

|---|---|

| Ignition system | Spark ignited |

| Cylinder bore | 85 mm |

| Piston stroke | 115 mm |

| Connecting rod length | 266 mm |

| Swept volume | 652 cm3 |

| Compression ratio | 9.5:1 |

| Crank shaft speed | 600 rpm |

| Instrument | Range | Uncertainty |

|---|---|---|

| Exhaust gas analyzer Bosch BEA 350 | CO: 0.000–10.00% | 0.1% (FS) |

| UHC: 0–9.999% | 12 ppm | |

| CO2: 0.00–18.00% | 0.1% (FS) | |

| O2: 0.00–22.00% | 0.1% (FS) | |

| NO: 0–5000 ppm | 25 ppm | |

| Flowmeter CGR-01 | 0.25–25.00 m3/h | 0.1% |

| Charge amplifier Kistler 5018A | 2–10 pC | ±2% |

| 10–100 pC | ±0.6% | |

| 100–2,200,000 pC | ±0.3% | |

| Pressure sensor: Kistler 6118C | 0–200 bar | ±1% (FS) |

| Pressure sensor: MPX 5100AP | 0–1.1 bar | ±2.5% (FS) |

| Data acq. system: USB-1608HS | ±10 V | 16 bits ±1 |

| Thermocouple NiCR-NiAl (K) | (−40)–1140 °C | ±1% (FS) |

| Encoder PR90 | max 6000 rpm | 0.3 deg/rev. |

| Scale and timer for fuel flow rate | 80–650 × 10−6 kg/s | ±1% |

| Quantity | Uncertainty | Relative Uncertainty (%) |

|---|---|---|

| IMEP | 18 kPa | 2.2 |

| Indicated efficiency | 0.015 | 3.7 |

| CA0-10 | 0.55 CA deg | 3.5 |

| CA10-90 | 0.55 CA deg | 3.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szwaja, S.; Gruca, M.; Pyrc, M.; Juknelevičius, R. Performance and Exhaust Emissions of a Spark Ignition Internal Combustion Engine Fed with Butanol–Glycerol Blend. Energies 2021, 14, 6473. https://doi.org/10.3390/en14206473

Szwaja S, Gruca M, Pyrc M, Juknelevičius R. Performance and Exhaust Emissions of a Spark Ignition Internal Combustion Engine Fed with Butanol–Glycerol Blend. Energies. 2021; 14(20):6473. https://doi.org/10.3390/en14206473

Chicago/Turabian StyleSzwaja, Stanislaw, Michal Gruca, Michal Pyrc, and Romualdas Juknelevičius. 2021. "Performance and Exhaust Emissions of a Spark Ignition Internal Combustion Engine Fed with Butanol–Glycerol Blend" Energies 14, no. 20: 6473. https://doi.org/10.3390/en14206473

APA StyleSzwaja, S., Gruca, M., Pyrc, M., & Juknelevičius, R. (2021). Performance and Exhaust Emissions of a Spark Ignition Internal Combustion Engine Fed with Butanol–Glycerol Blend. Energies, 14(20), 6473. https://doi.org/10.3390/en14206473