Stable Semi-Transparent Dye-Sensitized Solar Modules and Panels for Greenhouse Application

Abstract

:1. Introduction

1.1. The Transparency Relevance for Greenhouse PV Application

1.2. The Role of Filtered Light

1.3. Dye Selection

2. Materials and Methods

Materials and Facilities

3. Results and Discussion

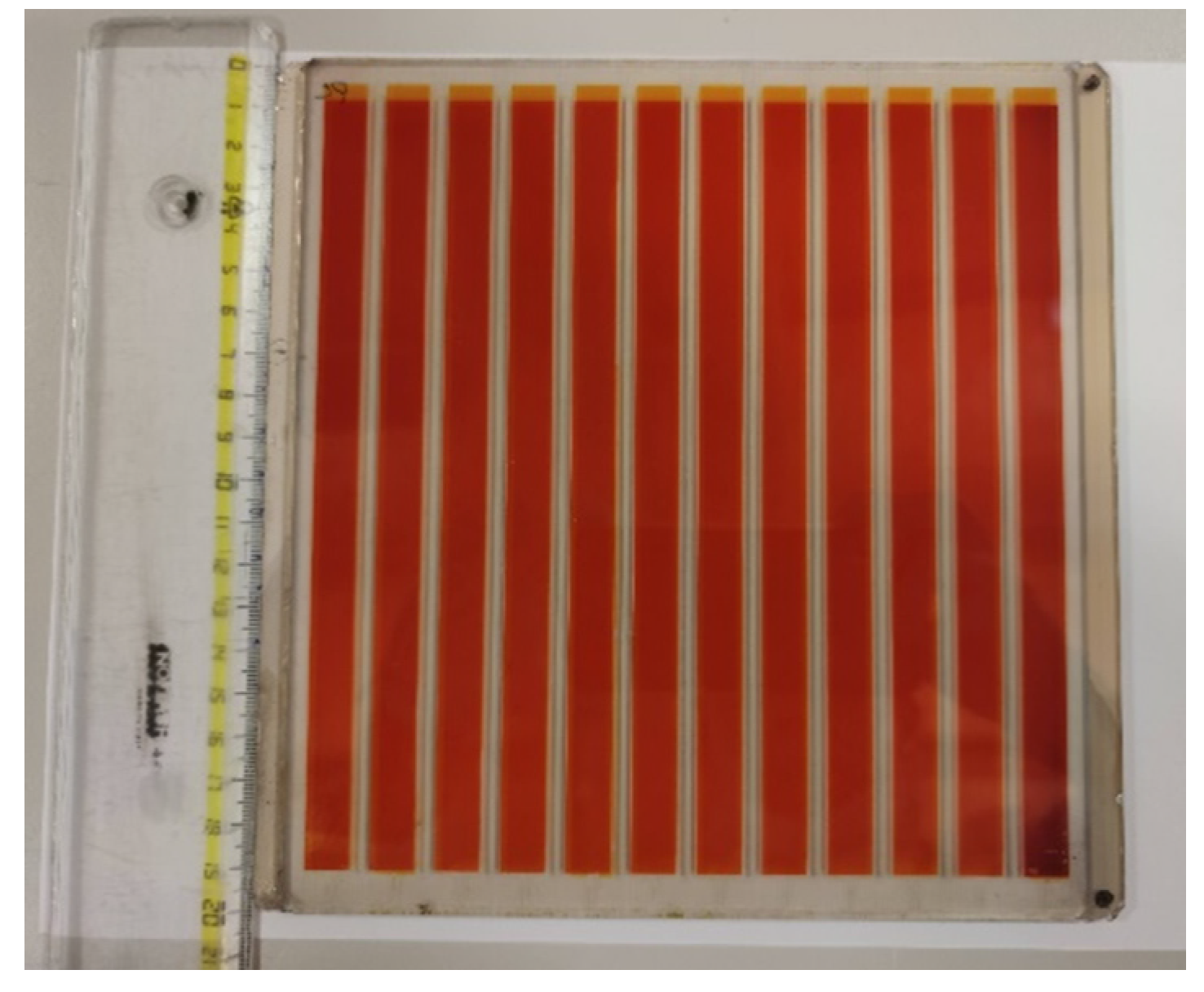

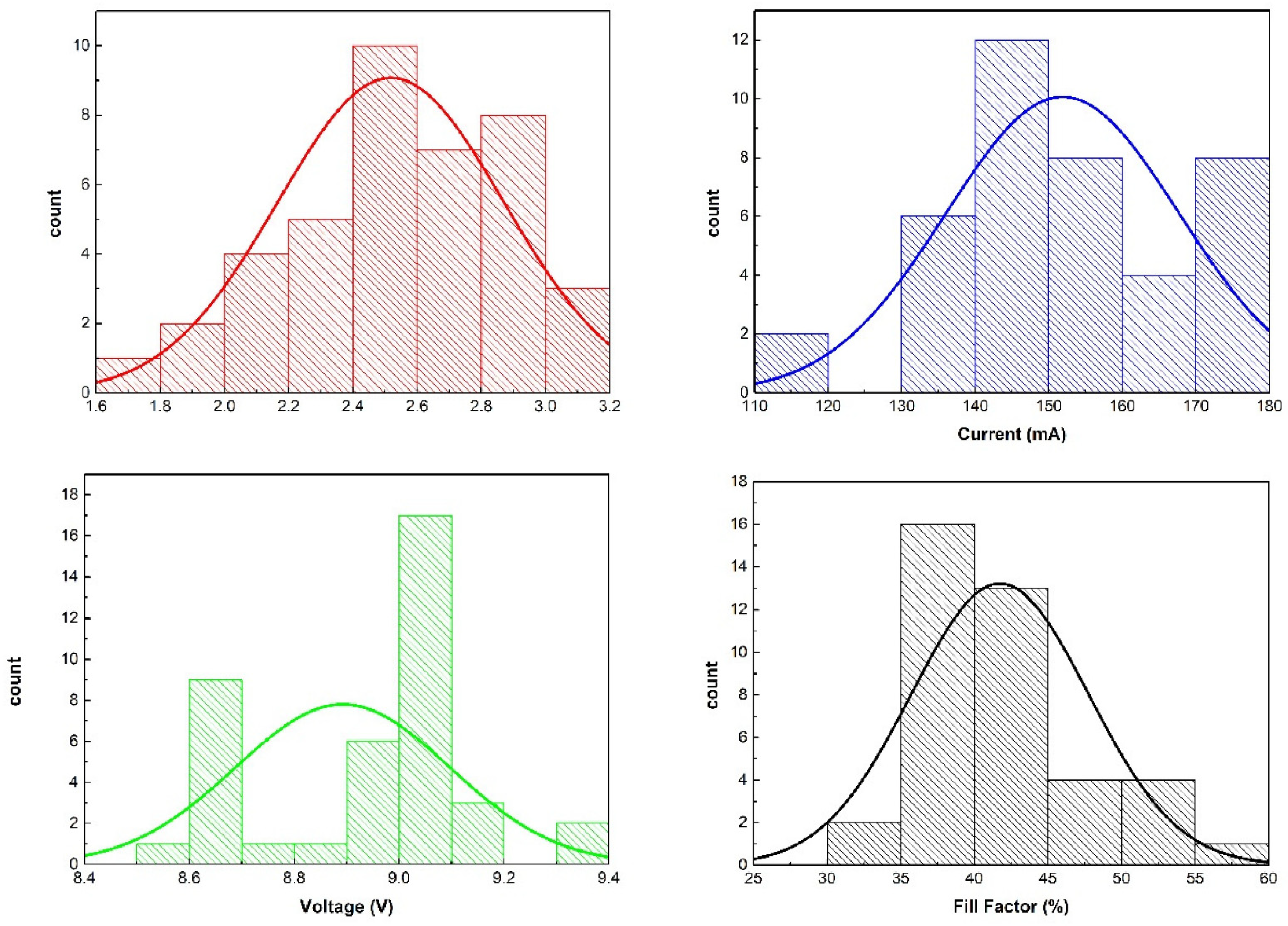

3.1. PV Module Performances

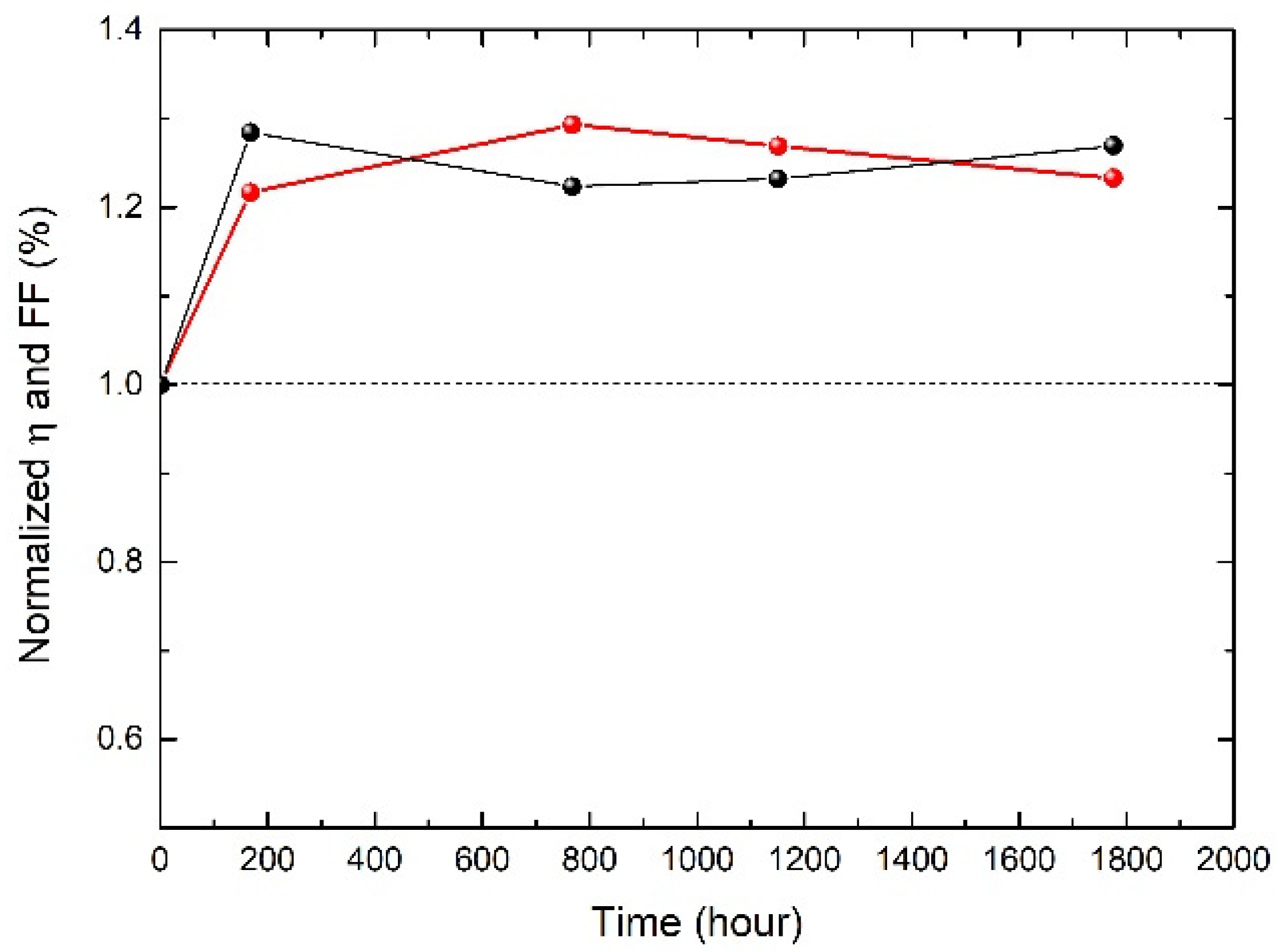

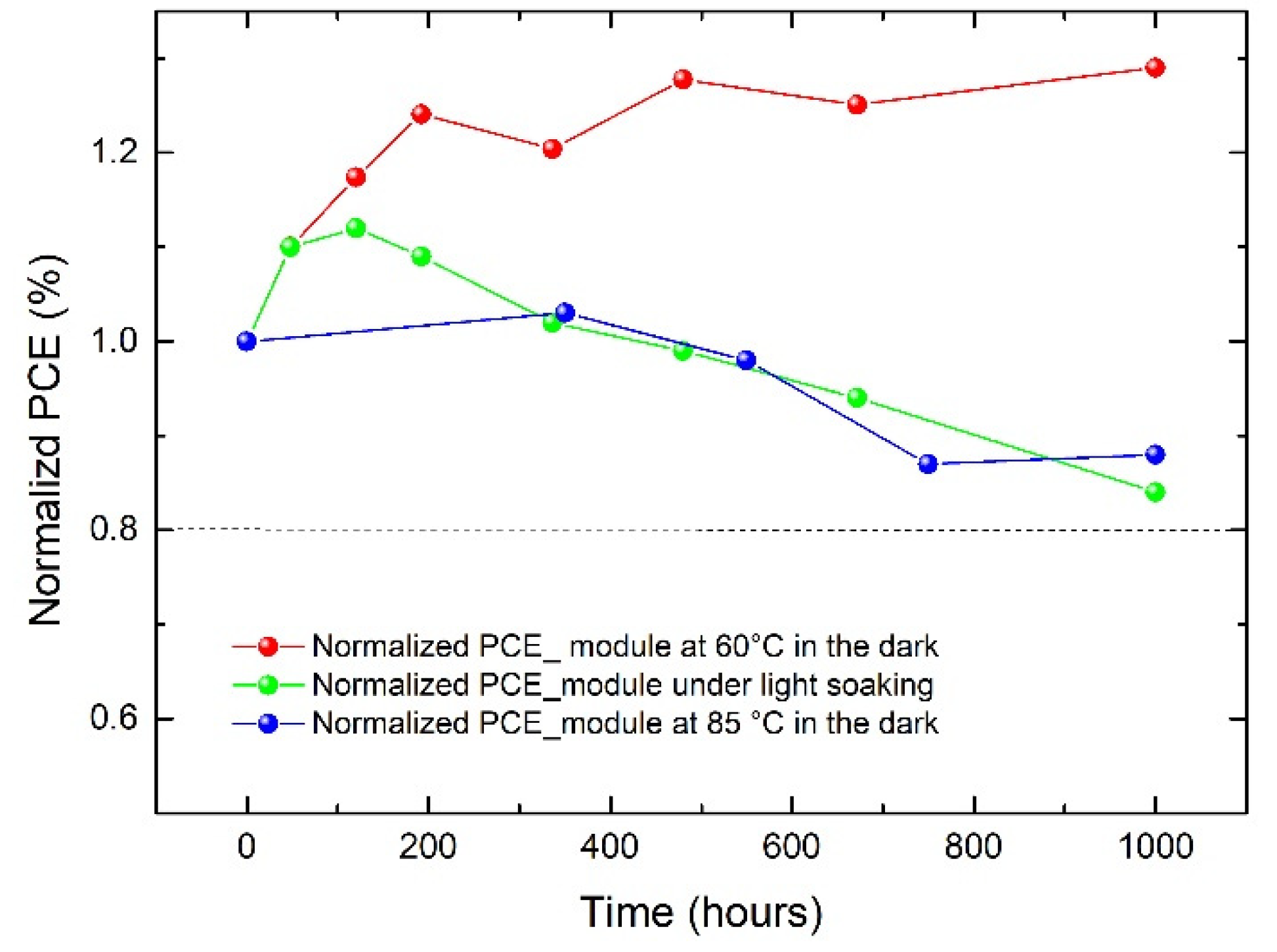

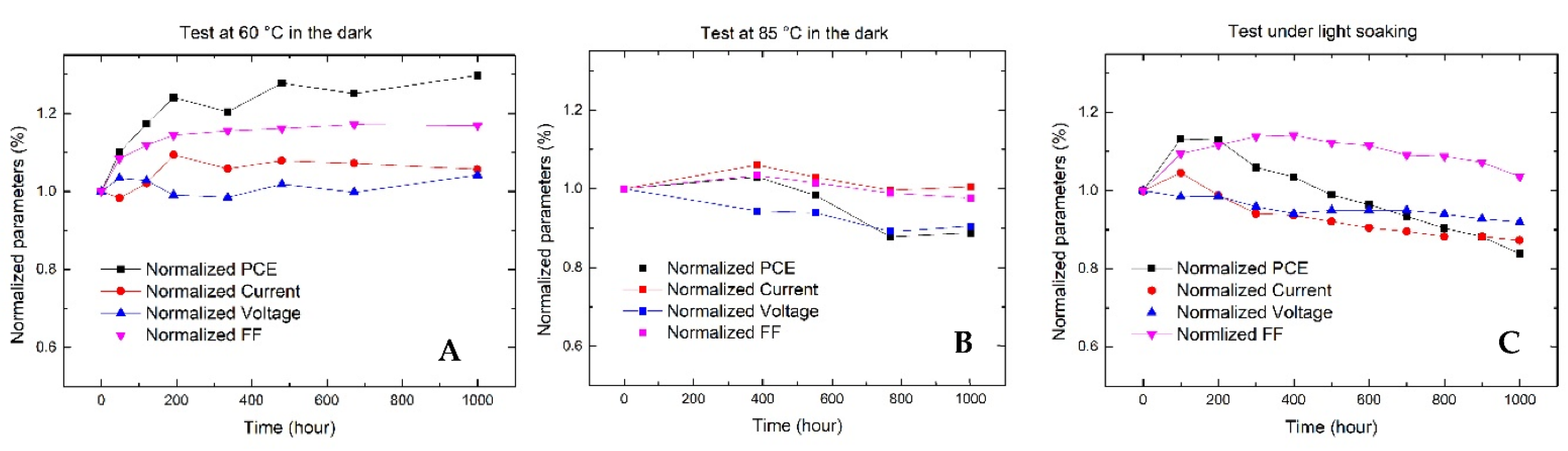

3.2. Stability Test

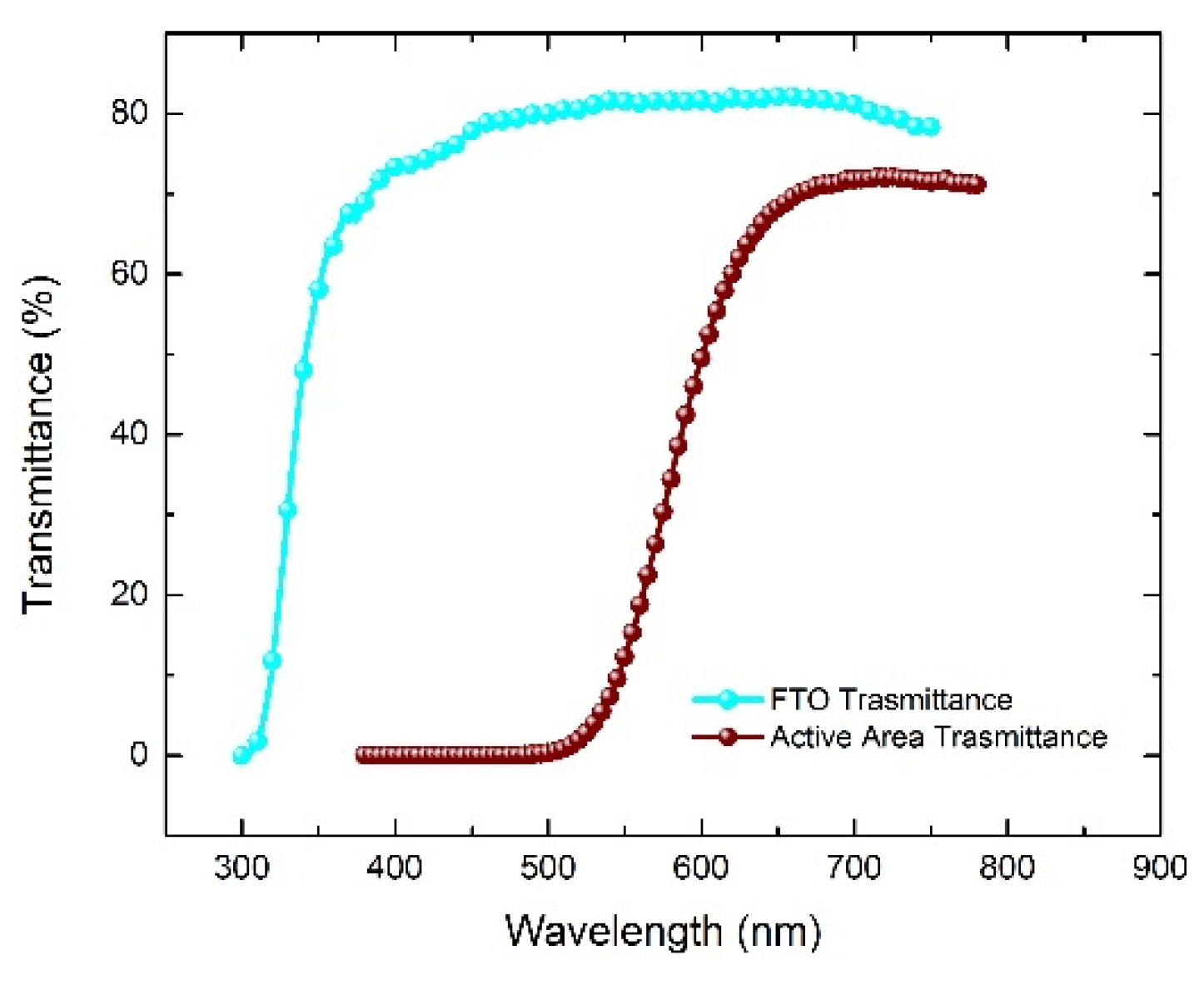

3.3. Transparency

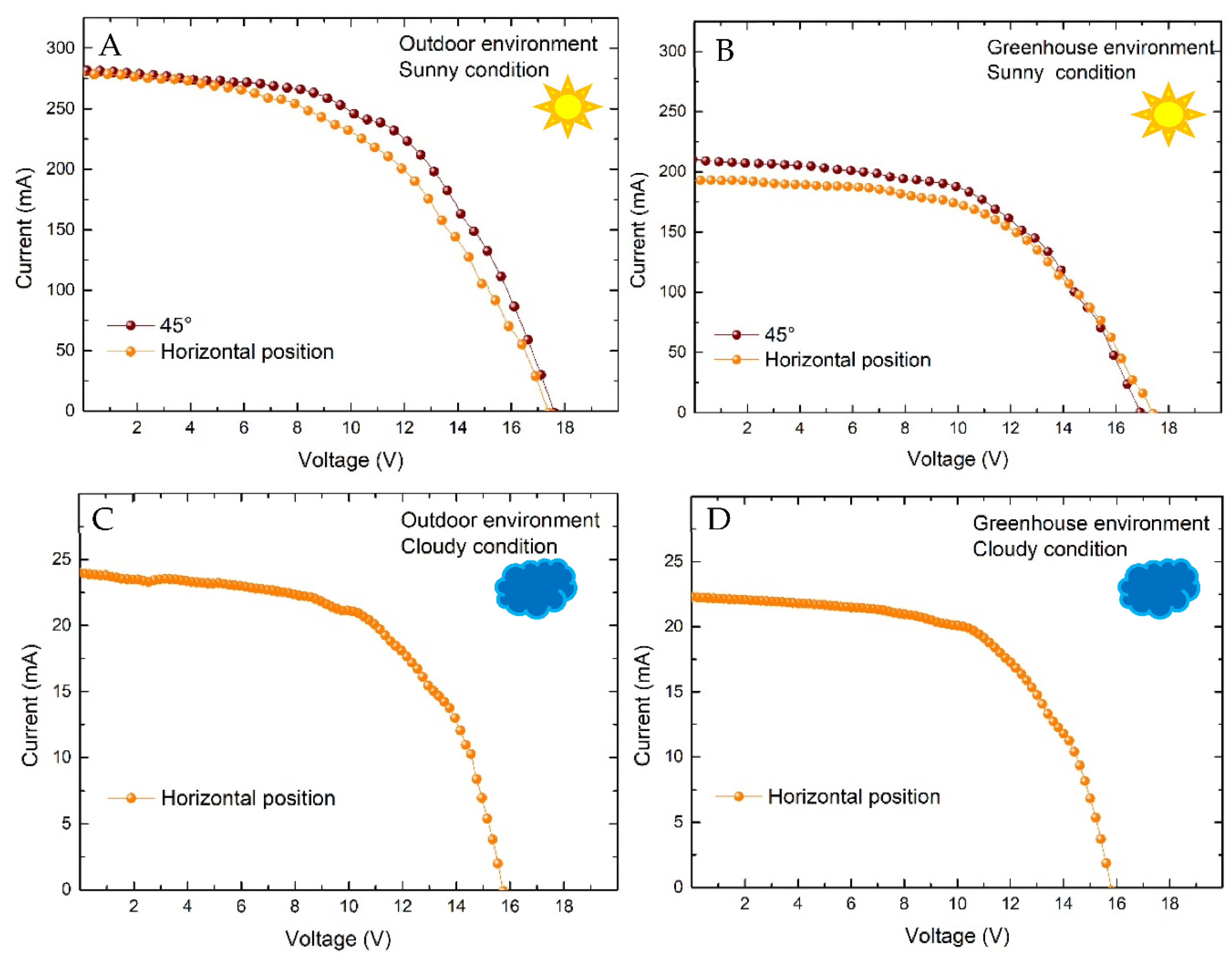

3.4. PV Panel Performances

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- O’Reagan, B.; Grätzel, M. A low-cost, high-efficiency Solar-Cell based on Dye-Sensitized Colloidal TiO2 films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Gong, J.; Sumathy, K.; Qiao, Q.; Zhou, Z. Review on dye-sensitized solar cells (DSSCs): Advanced techniques and research trends. Renew. Sustain. Energy Rev. 2017, 68, 234–246. [Google Scholar] [CrossRef]

- Shakeel Ahmada, M.; Pandeya, A.K.; Abd Rahima, N. Advancements in the development of TiO2 photoanodes and its fabrication methods for dye sensitized solar cell (DSSC) applications. A review. Renew. Sustain. Energy Rev. 2017, 77, 89–108. [Google Scholar] [CrossRef]

- Selvaraj, P.; Roy, A.; Ullah, H.; Devi, P.S.; Tahir, A.A.; Mallick, T.K.; Sundaram, S. Soft-template synthesis of high surface area mesoporous titanium dioxide for dye-sensitized solar cells. Int.J. Energy Res. 2019, 43, 523–524. [Google Scholar] [CrossRef] [Green Version]

- Ullah, H.; Bibi, S.; Tahir, A.; Mallick, T.K. Donor-acceptor polymer for the design of All-Solid-State dye-sensitized solar cells. J. Alloy. Compd. 2017, 696, 914–922. [Google Scholar] [CrossRef]

- NREL Site. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 25 June 2021).

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (Version 55). Prog. Photovolt. Res. Appl. 2020, 28, 3–15. [Google Scholar] [CrossRef]

- Selvaraj, P.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Investigation of semi-transparent dye-sensitized solar cells for fenestration integration. Renew. Energy 2019, 141, 516–525. [Google Scholar] [CrossRef]

- Pulli, E.; Rozzi, E.; Bella, F. Transparent photovoltaic technologies: Current trends towards upscaling. Energy Convers. Manag. 2020, 219, 112982. [Google Scholar] [CrossRef]

- Ren, Y.; Sun, D.; Cao, Y.; Tsao, H.N.; Yuan, Y.; Zakeeruddin, S.M.; Wang, P.; Grätzel, M. A Stable Blue Photosensitizer for Color Palette of Dye-Sensitized Solar Cells Reaching 12.6% Efficiency. J. Am. Chem. Soc. 2018, 140, 2405–2408. [Google Scholar] [CrossRef]

- Otaka, H.; Kira, M.; Yano, K.; Ito, S.; Mitekura, H.; Kawata, T.; Matsui, F. Multi-colored dye-sensitized solar cells. J. Photochem. Photobiol. A Chem. 2004, 164, 67–73. [Google Scholar] [CrossRef]

- Selvaraj, P.; Baig, H.; Mallick, T.K.; Siviter, J.; Montecucco, A.; Li, W.; Paul, M.; Sweet, T.; Gao, M.; Knox, A.R.; et al. Enhancing the efficiency of transparent dye-sensitized solar cells using concentrated light. Sol. Energy Mater. Sol. Cells 2018, 175, 29–34. [Google Scholar] [CrossRef]

- Zhang, K.; Qin, C.; Yang, X.; Islam, A.; Zhang, S.; Chen, H.; Han, L. High-Performance, transparent, dye-sensitized solar cells for see-through photovoltaic windows. Adv. Energy Mater. 2014, 4, 1301966. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. PV glazing technologies. Renew. Sustain. Energy Rev. 2015, 49, 306–322. [Google Scholar] [CrossRef]

- Parisi, M.L.; Maranghi, S.; Vesce, L.; Sinicropi, A.; di Carlo, A.; Basosi, R. Prospective life cycle assessment of third-generation photovoltaics at the pre-industrial scale: A long-term scenario approach. Renew. Sustain. Energy Rev. 2020, 121, 109703. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Pettersson, H. Dye-Sensitized Solar Cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Chalkias, D.A.; Charalampopoulos, C.; Aivali, S.; Andreopoulou, A.K.; Karavoti, A.; Stathatos, E. A Di-Carbazole-Based Dye as a Potential Sensitizer for Greenhouse-Integrated Dye-Sensitized Solar Cells. Energies 2021, 14, 1159. [Google Scholar] [CrossRef]

- Roslan, N.; Ya’acob, M.E.; Radzi, M.A.M.; Hashimoto, Y.; Jamaludin, D.; Chen, G. Dye Sensitized Solar Cell (DSSC) greenhouse shading: New insights for solar radiation manipulation. Renew. Sustain. Rev. 2018, 92, 171–186. [Google Scholar] [CrossRef]

- Allardyce, C.S.; Fankhauser, C.; Zakeeruddin, S.M.; Grätzel, M.; Dyson, P.J. The influence of greenhouse-integrated photovoltaics on crop production. Sol. Energy 2017, 155, 517–522. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Kadoglidou, K.; Tsivelika, N.; Krommydas, K.; Kalivas, A.; Ralli, P.; Irakli, M. Performance and Hydroponic Tomato Crop Quality Characteristics in a Novel Greenhouse Using Dye-Sensitized Solar Cell Technology for Covering Material. Horticulturae 2019, 5, 42. [Google Scholar] [CrossRef] [Green Version]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Campiotti, C.; Dondi, F.; Genovese, A.; Alonzo, G.; Catanese, V.; Incrocci, L.; Bibbiani, C. Photovoltaic as sustainable Energy for greenhouse and closed plant production system. Acta Hortic. 2008, 797, 373–378. [Google Scholar] [CrossRef]

- Narra, V.K.; Ullah, H.; Singh, V.K.; Giribabu, L.; Senthilarasu, S.; Karazhanov, S.Z.; Tahir, A.A.; Mallick, T.K.; Upadhyay, H.M. D–π–A system based on zinc porphyrin dyes for dye-sensitized solar cells: Combined experimental and DFT–TDDFT study. Polyhedron 2015, 100, 313–320. [Google Scholar] [CrossRef]

- Ureña-Sánchez, R.; Callejón-Ferre, Á.J.; Pérez-Alonso, J.; Carreño-Ortega, Á. Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Sci. Agric. 2012, 69, 233–239. [Google Scholar] [CrossRef]

- Marrou, H.; Wéry, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Babayigit, A.; Ethirajan, A.; Muller, M.; Conings, B. Toxicity of organometal halide perovskite solar cells. Nat. Mater. 2016, 15, 247–251. [Google Scholar] [CrossRef]

- Subhani, W.S.; Wang, K.; Du, M.; Wang, X.; Yuan, N.; Ding, J.; Liu, S. Anti-solvent engineering for efficient semitransparent CH3NH3PbBr 3 perovskite solar cells for greenhouse applications. J. Energy Chem. 2019, 34, 12–19. [Google Scholar] [CrossRef] [Green Version]

- La Notte, L.; Giordano, L.; Calabrò, E.; Bedini, R.; Colla, G.; Puglisi, G.; Reale, A. Hybrid and organic photovoltaics for greenhouse applications. Appl. Energy 2020, 278, 115582. [Google Scholar] [CrossRef]

- Zisis, C.; Pechlivani, E.M.; Tsimikli, S.; Mekeridis, E.; Laskarakis, A.; Logothetidis, S. Organic Photovoltaics on Greenhouse Rooftops: Effects on Plant Growth. Mater. Today Proc. 2019, 19, 65–72. [Google Scholar] [CrossRef]

- Dessì, A.; Calamante, M.; Sinicropi, A.; Parisi, M.L.; Vesce, L.; Mariani, P.; Taheri, B.; Ciocca, M.; Di Carlo, A.; Zani, L.; et al. Thiazolo [5,4-d] thiazole-based organic sensitizers with improved spectral properties for application in greenhouse-integrated dye-sensitized solar cells. Sustain. Energy Fuels 2020, 4, 2309–2321. [Google Scholar] [CrossRef]

- Yorio, N.C.; Goins, G.D.; Kagie, H.R.; Wheeler, R.M.; Sager, J.C. Improving Spinach, Radish, and Lettuce Growth under Red Light Emitting Diodes (LEDs) with Blue Light Supplementation. HortScience 2001, 36, 380–383. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Kang, M.; Kwak, O.K.; Yoon, Y.; Min, K.S.; Chu, M. Fabrication and Characterization of Dye-Sensitized Solar Cells for Greenhouse Application. Int. J. Photoenergy 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- McNellis, T.W.; Deng, X.W. Light control of seedling morphogenetic pattern. Plant Cell 1995, 7, 1749–1761. [Google Scholar]

- Kim, H.H.; Goins, G.D.; Wheeler, R.M.; Sager, J.C. Stomatal conductance of lettuce grown under or exposed to different light quality. Ann. Bot. 2004, 94, 691–697. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Ya’acob, M.E.; Anuar, M.S.; Chen, G.; Othman, M.H.; Iskandar, A.N.; Roslan, N. Thermal analysis of a portable DSSC mini greenhouse for botanical drugs cultivation. Energy Rep. 2020, 6, 238–253. [Google Scholar] [CrossRef]

- Dominguez, A.; Kleiss, J.; Luvall, J.C. Effect of solar photovoltaic panels on roof heat transfer. Sol. Energy 2011, 85, 2244–2255. [Google Scholar] [CrossRef] [Green Version]

- Garcıa, M.L.; Medrano, E.; Sanchez-Guerrero, M.C.; Lorenzo, P. Climatic effects of two cooling systems in greenhouses in the Mediterranean area: External mobile shading and fog system. Biosyst. Eng. 2011, 108, 133–143. [Google Scholar] [CrossRef]

- Leandri, V.; Ellis, H.; Gabrielsson, E.; Sun, L.; Boschloo, G.; Hagfeldtb, A. Organic hydrophilic dye for water-based dyesensitized solar cells. Phys. Chem. Chem. Phys. 2014, 16, 19964–19971. [Google Scholar] [CrossRef] [PubMed]

- Vamvounis, G.; Glasson, C.R.; Bieskeb, E.J.; Dryza, V. Modulating electron injection from an organic dye to a titania nanoparticle with a photochromic energy transfer acceptor. J. Mater. Chem. C 2016, 4, 6215. [Google Scholar] [CrossRef] [Green Version]

- Hagberg, D.P.; Jiang, X.; Gabrielsson, E.; Linder, M.; Marinado, T.; Brinck, T.; Hagfeldtbd, A.; Sun, L. Symmetric and unsymmetric donor functionalization. comparing structural and spectral benefits of chromophores for dye-sensitized solar cells. J. Mater. Chem. 2009, 19, 7232–7238. [Google Scholar] [CrossRef]

- Jiang, X.; Marinado, T.; Gabrielsson, E.; Hagberg, D.P.; Sun, L.; Hagfeldt, A. Hagfeldt. Structural Modification of Organic Dyes for Efficient Coadsorbent-Free Dye-Sensitized Solar Cells. J. Phys. Chem. C 2010, 114, 2799–2805. [Google Scholar] [CrossRef]

- Perganti, D.; Giannouri, M.; Kontos, A.G.; Falaras, P. Cost-efficient platinum-free DSCs using colloidal graphite counter electrodes combined with D35 organic dye and cobalt (II/III) redox couple. Electrochim. Acta 2017, 232, 517–527. [Google Scholar] [CrossRef]

- Vesce, L.; Guidobaldi, A.; Mariani, P.; di Carlo, A.; Parisi, M.L.; Maranghi, S.; Baso, R. Scaling-up of Dye Sensitized Solar Modules. In World Scientific Reference of Hybrid Materials; World Scientific: Singapore, 2019; pp. 423–485. [Google Scholar]

- Ramasamy, E.; Lee, W.J.; Lee, D.Y.; Song, J.S. Portable, parallel grid dye-sensitized solar cell module prepared by screen printing. J. Power Sources 2007, 165, 446–449. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, H.; Li, J.B.; Li, X.; Zhao, X.C. DSCs Modules Fabricated by Screen Printing. Key Eng. Mater. 2010, 434-435, 638–641. [Google Scholar] [CrossRef]

- Mariani, P.; Vesce, L.; di Carlo, A. The role of printing techniques for large-area dye sensitized solar cells. Semicond. Sci. Technol. 2015, 30, 104003. [Google Scholar] [CrossRef]

- Dai, S.; Wang, K.; Weng, J.; Sui, Y.; Huang, Y.; Xiao, S.; Chen, S.; Hu, L.; Kong, F.; Pan, X.; et al. Design of DSC panel with efficiency more than 6%. Sol. Energy Mater. Sol. Cells 2005, 85, 447–455. [Google Scholar] [CrossRef]

- Takeda, Y.; Kato, N.; Higuchi, K.; Takeichi, A.; Motohiro, T.; Fukumoto, S.; Sano, T.; Toyoda, T. Monolithically series-interconnected transparent modules of dye-sensitized solar cells. Sol. Energy Mater. Sol. Cells 2009, 93, 808–811. [Google Scholar] [CrossRef]

- Fukui, A.; Fuke, N.; Komiya, R.; Koide, N.; Yamanaka, R.; Katayama, H.; Han, L. Dye-Sensitized Photovoltaic Module with Conversion Efficiency of 8.4%. Appl. Phys. Express 2009, 2, 082202. [Google Scholar] [CrossRef]

- Giordano, F.; Guidobaldi, A.; Petrolati, E.; Vesce, L.; Riccitelli, R.; Reale, A.; Brown, T.M.; di Carlo, A. Realization of high performance large area Z-series-interconnected opaque dye solar cell modules. Prog. Photovoltaics Res. Appl. 2013, 21, 1653–1658. [Google Scholar] [CrossRef]

- Iftikhar, H.; Sonai, G.G.; Hashmi, S.G.; Nogueira, A.F.; Lund, P.D. Progress on Electrolytes Development in Dye-Sensitized Solar Cells. Materials 2019, 12, 1998. [Google Scholar] [CrossRef] [PubMed] [Green Version]

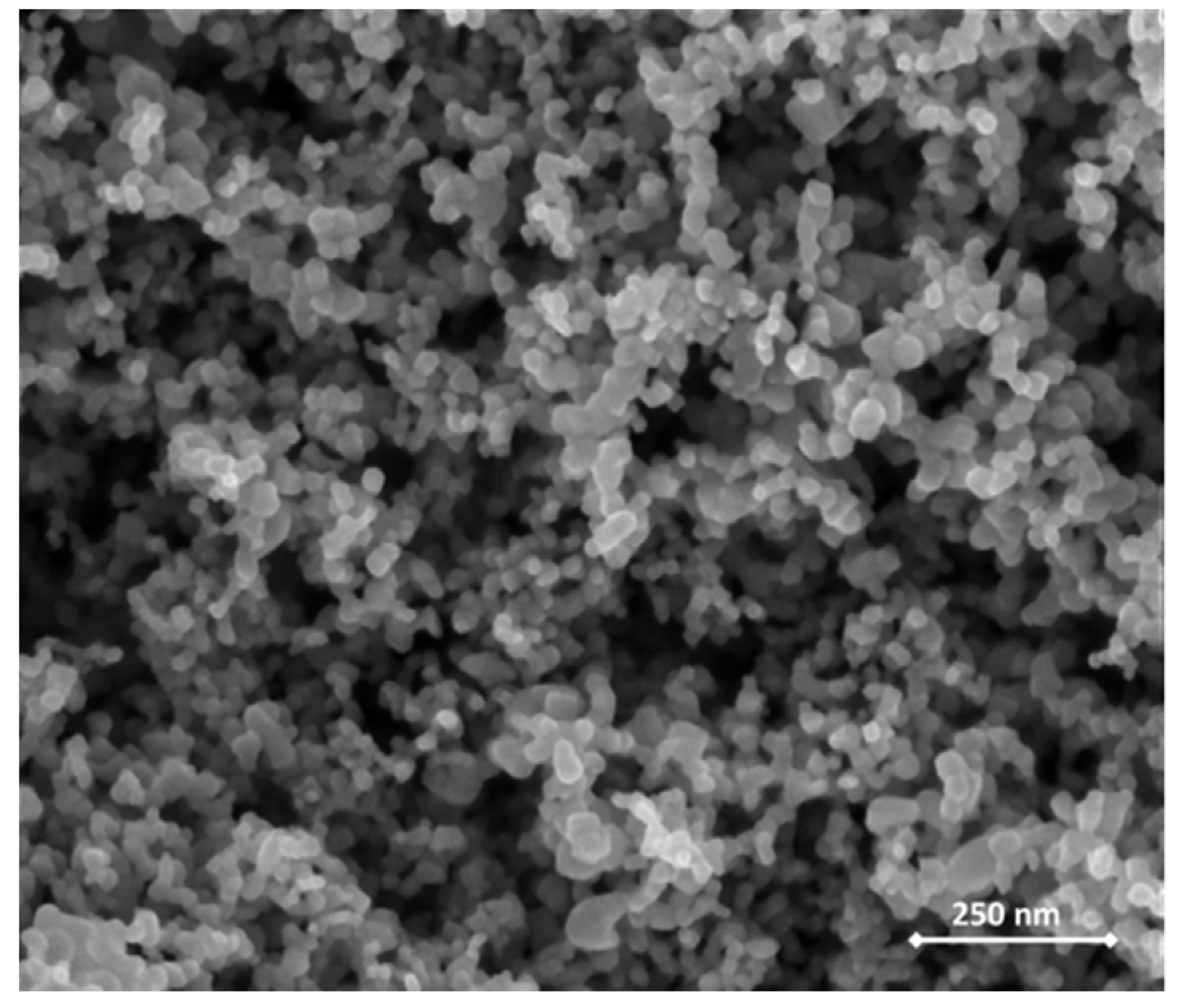

- Vesce, L.; Riccitelli, R.; Soscia, G.; Brown, T.M.; di Carlo, A.; Reale, A. Optimization of nanostructured titania photoanodes for dye-sensitized solar cells: Study and experimentation of TiCl4 treatment. J. Non-Cryst. Solids 2010, 356, 1958–1961. [Google Scholar] [CrossRef] [Green Version]

- Reale, A.; Cinà, L.; Malatesta, A.; de Marco, R.; Brown, T.M.; di Carlo, A. Estimation of Energy Production of Dye-Sensitized Solar Cell Modules for Building-Integrated Photovoltaic Applications. Energy Technol. 2014, 2, 531–541. [Google Scholar] [CrossRef]

- Sastrawana, R.; Beierb, J.; Belledina, U.; Hemmingc, S.; Hinschd, A.; Kernd, R.; Vetterb, C.; Petrate, F.M.; Prodi-Schwabe, A.; Lechnerf, P.; et al. A glass frit-sealed dye solar cell module with integrated series connections. Sol. Energy Mater. Sol. Cells 2006, 90, 1680–1691. [Google Scholar] [CrossRef]

- Giordano, F.; Petrolati, E.; Brown, T.M.; Reale, A.; di Carlo, A. Series-connection designs for dye solar cell modules. IEEE Trans. Electron Devices 2011, 58, 2759–2764. [Google Scholar] [CrossRef]

- Han, C.; Park, S.; Oh, W. Reliability-based structural optimization of 300 × 300 mm 2 dye-sensitized solar cell module. Sol. Energy 2017, 150, 128–135. [Google Scholar] [CrossRef]

- Mariani, P.; Agresti, A.; Vesce, L.; Pescetelli, S.; Palma, A.L.; Tomarchio, F.; Karagiannidis, P.; Ferrari, A.C.; di Carlo, A. Graphene-Based Interconnects for Stable Dye-Sensitized Solar Modules. ACS Appl. Energy Mater. 2021, 4, 98–110. [Google Scholar] [CrossRef]

- Desilvestro, H.; Bertoz, M.; Tulloch, S.; Tulloch, G.E. Packaging, Scale-up, and Commercialization of Dye Solar Cells. In Dye Sensitized Solar Cells; Kalianasundaram, K., Ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 207–230. [Google Scholar]

- Toyoda, T.S.; Nakajima, J.; Doi, S.; Fukumoto, S.; Ito, A.; Tohyama, T.; Yoshida, M.; Kanagawa, T.; Motohiro, T.; Shiga, T.; et al. Outdoor performance of large scale DSC modules. J. Photochem. Photobiol. 2004, 164, 203–207. [Google Scholar] [CrossRef]

- Dai, S.; Weng, J.; Sui, Y.; Chen, S.; Xiao, S.; Huang, Y.; Kong, F.; Pan, X.; Hu, L.; Zhang, C.; et al. The design and outdoor application of dye-sensitized solar cells. Inorg. Chim. Acta 2008, 361, 786–791. [Google Scholar]

- Fakharuddin, A.; Jose, R.; Brown, T.M.; Fabregat-Santiago, F.; Bisquert, J. A perspective on the production of dye-sensitized solar modules. Energy Environ. Sci. 2014, 7, 3952–3981. [Google Scholar] [CrossRef]

- Mincuzzi, G.; Vesce, L.; Liberatore, M.; Reale, A.; di Carlo, A.; Brown, T.M. Laser-Sintered TiO2 Films for Dye Solar Cell Fabrication: An Electrical, Morphological, and Electron Lifetime Investigation. IEEE Trans. Electron Devices 2011, 58, 3179–3188. [Google Scholar] [CrossRef]

- Vesce, L.; Riccitelli, R. Processing and characterization of a TiO2 paste based on small particle size powders for dye-sensitized solar cell semi-transparent photo-electrodes. Prog. Photovoltaics Res. Appl. 2011, 20, 960–966. [Google Scholar] [CrossRef]

- Tagliaferro, R.; Colonna, D.; Brown, T.M.; Reale, A.; di Carlo, A. Interplay between transparency and efficiency in dye sensitized solar cells. Opt. Express 2013, 21, 3. [Google Scholar] [CrossRef] [PubMed]

- Khenkin, M.V.; Katz, E.A.; Abate, A.; Bardizza, G.; Berry, J.J.; Brabec, C.; Brunetti, F.; Bulović, V.; Burlingame, Q.; Di Carlo, A.; et al. Consensus statementfor stability assessment and reporting for perovskite photovoltaics based on ISOS procedures. Nat. Energy 2020, 5, 35–49. [Google Scholar] [CrossRef]

- Calogero, G.; Barichello, J.; Citro, I.; Mariani, P.; Vesce, L.; Bartolotta, A.; di Carlo, A.; di Marco, G. Photoelectrochemical and spectrophotometric studies on dye-sensitized solar cells (DSCs) and stable modules (DSCMs) based on natural apocarotenoids pigments. Dye. Pigment. 2018, 155, 75–83. [Google Scholar] [CrossRef]

- Castro-Hermosa, S.A.; Yadav, S.K.; Vesce, L.; Guidobaldi, A.; Reale, A.; Di Carlo, A.; Brown, T.M. Stability issues pertaining large area perovskite and dye-sensitized solar cells and modules. J. Phys. D Appl. Phys. 2016, 50, 3. [Google Scholar] [CrossRef]

- Hinsh, A.; Kroon, J.M.; Kern, R.; Uhlendorf, I.; Holzbock, J.; Meyer, A.; Ferber, J. Long term stability of Dye Sensitized Solar Cells. Prog. Photovolt. Res. App. 2001, 9, 425–438. [Google Scholar] [CrossRef]

- Djurišić, A.B.; Liu, F.; Ng, A.M.; Dong, Q.; Wong, M.K.; Ng, A.; Surya, C. Stability issues of the next generation solar cells. Phys. Status Solidi (RRL) 2016, 10, 281–299. [Google Scholar] [CrossRef]

- Bari, D.; Wrachien, N.; Tagliaferro, R.; Penna, S.; Brown, T.M.; Reale, A.; di Carlo, A.; Meneghesso, G. Thermal stress effects on Dye-Sensitized Solar Cells (DSSCs). Microelectron. Reliab. 2011, 51, 1762–1766. [Google Scholar] [CrossRef]

- Sauvage, F. A Review on Current Status of Stability and Knowledge on Liquid Electrolyte-Based Dye-Sensitized Solar Cells. Adv. Chem. 2014, 2014, 1–23. [Google Scholar] [CrossRef]

- Kwak, C.H.; Baeg, J.H.; Yang, I.M.; Giribabu, K.; Lee, S.; Huh, Y.S. Degradation analysis of dye-sensitized solar cell module consisting of 22 unit cells for thermal stability: Raman spectroscopy study. Sol. Energy 2016, 130, 244–249. [Google Scholar] [CrossRef]

| PCE Average (%) | Current Average (mA) | Voltage Average (V) | FF Average (%) |

|---|---|---|---|

| 2.5 ± 0.4 | 152 ± 16 | 8.9 ± 0.2 | 41.7 ± 1.1 |

| Module Section | Trasmittance | Area (cm2) |

|---|---|---|

| Active Area | 24% | 221.52 |

| Glass | 78% | 71.36 |

| Silver grids | 0% | 20.02 |

| SUNNY CONDITION, Outdoor | P max (W) | Isc (mA) | Voc (V) | FF (%) | PCE (%) |

|---|---|---|---|---|---|

| 45° | 2.7 | 281.26 | 17.6 | 54.7 | 3.05 |

| Horizontal | 2.4 | 278.98 | 17.4 | 49.6 | 3.83 |

| SUNNY CONDITION, Greenhouse | |||||

| 45° | 1.94 | 210.28 | 16.9 | 54.5 | 2.18 |

| Horizontal | 1.8 | 192.44 | 16.9 | 54.8 | 2.94 |

| CLOUDY CONDITION, Outdoor | |||||

| Horizontal | 0.22 | 23.98 | 15.7 | 58.4 | 4.62 |

| CLOUDY CONDITION, Greenhouse | |||||

| Horizontal | 0.2 | 22.3 | 15.8 | 59.8 | 4.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barichello, J.; Vesce, L.; Mariani, P.; Leonardi, E.; Braglia, R.; Di Carlo, A.; Canini, A.; Reale, A. Stable Semi-Transparent Dye-Sensitized Solar Modules and Panels for Greenhouse Application. Energies 2021, 14, 6393. https://doi.org/10.3390/en14196393

Barichello J, Vesce L, Mariani P, Leonardi E, Braglia R, Di Carlo A, Canini A, Reale A. Stable Semi-Transparent Dye-Sensitized Solar Modules and Panels for Greenhouse Application. Energies. 2021; 14(19):6393. https://doi.org/10.3390/en14196393

Chicago/Turabian StyleBarichello, Jessica, Luigi Vesce, Paolo Mariani, Enrico Leonardi, Roberto Braglia, Aldo Di Carlo, Antonella Canini, and Andrea Reale. 2021. "Stable Semi-Transparent Dye-Sensitized Solar Modules and Panels for Greenhouse Application" Energies 14, no. 19: 6393. https://doi.org/10.3390/en14196393

APA StyleBarichello, J., Vesce, L., Mariani, P., Leonardi, E., Braglia, R., Di Carlo, A., Canini, A., & Reale, A. (2021). Stable Semi-Transparent Dye-Sensitized Solar Modules and Panels for Greenhouse Application. Energies, 14(19), 6393. https://doi.org/10.3390/en14196393