Multiobjective Scheduling of Hybrid Renewable Energy System Using Equilibrium Optimization

Abstract

:1. Introduction

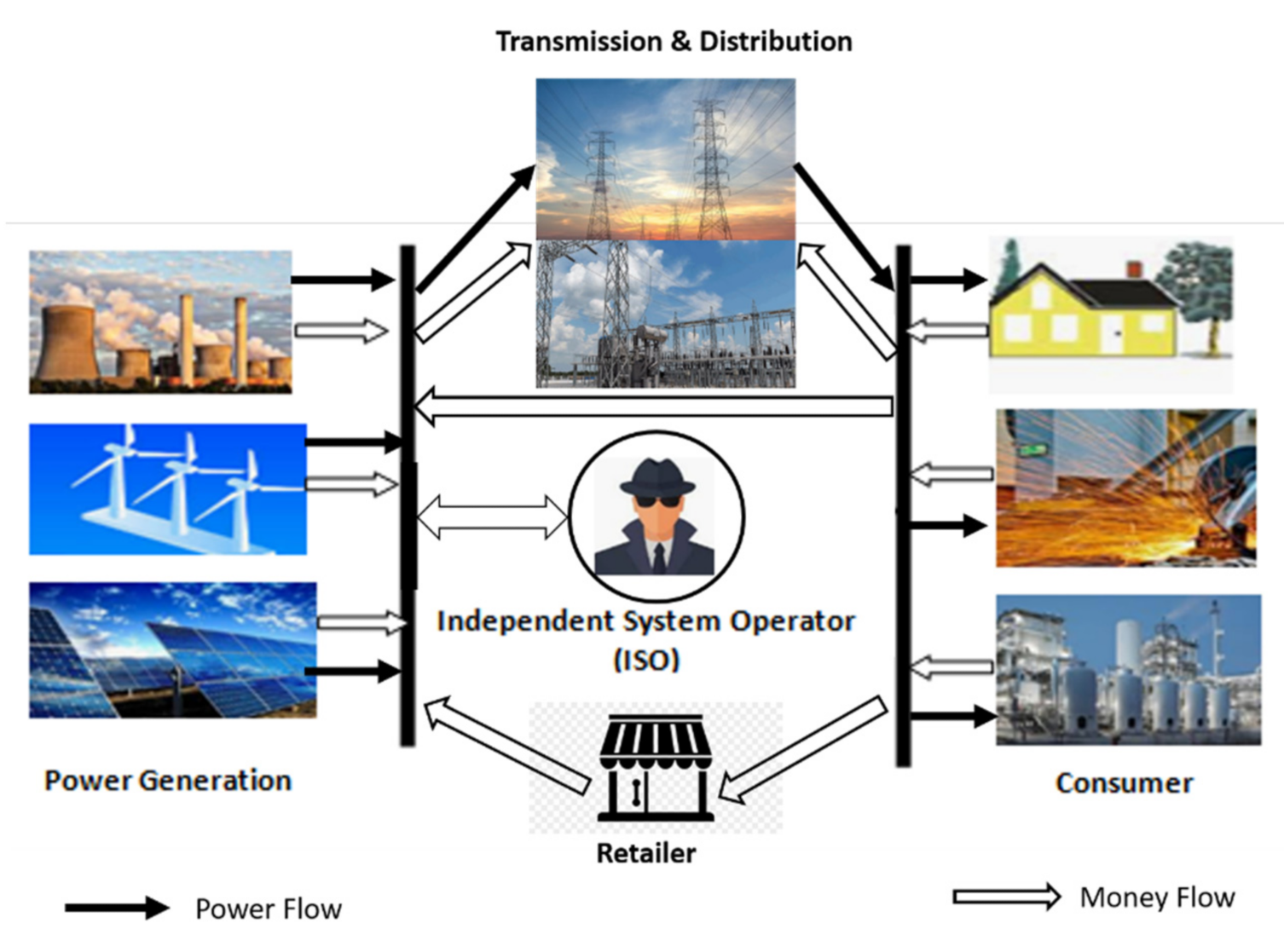

2. Formulation of the Profit-Based Multi-Objective Scheduling Problem

2.1. Objective Function I: Profit Maximization

2.2. Objective Function II: Emission Minimization

2.3. Objective Function III: Simultaneous Optimization of Profit and Emission

2.3.1. Real Power Balance: Power Demand at Any Instant (t) Must Be Equal to the Sum of the Power Output of Associated Generation Units:

2.3.2. Generation Limit: The Power Produced by Each Thermal, Wind and the Solar Unit Must Always Be between Their Respective Specified Bounds, as Given by:

2.3.3. Ramp-Rate Limit Constraints: The Thermal Units Have Limited Ramping (up as Well as Down) Capacity, and Therefore the Output of a Unit between two Consecutive Time-Intervals Must Obey the Inequality Constraint Given by:

2.4. Ranking Approach

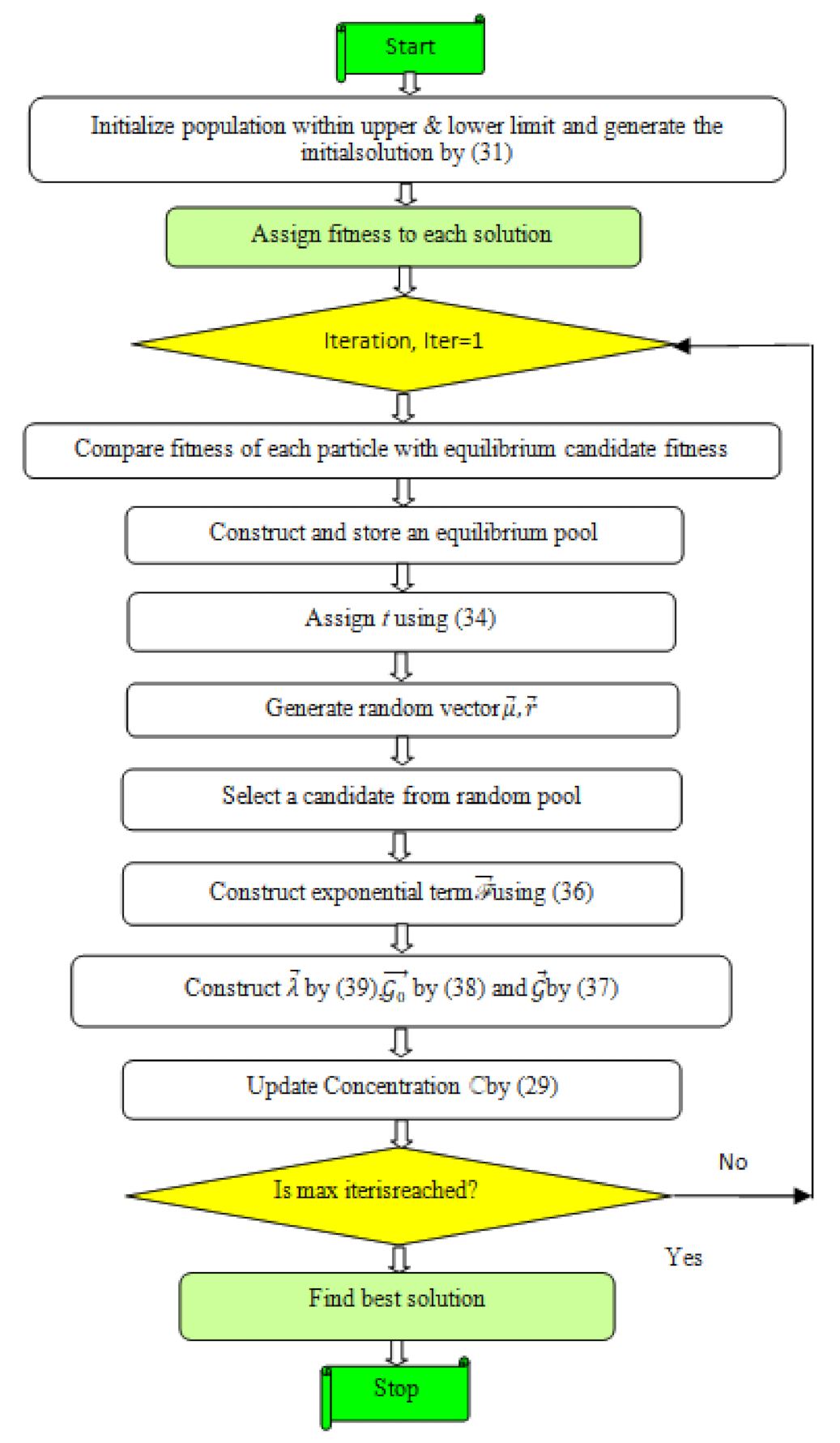

3. Equilibrium Optimization

3.1. Initialization

3.2. Equilibrium Pool and Candidates

3.3. Exponential Term

3.4. Generation Rate

3.5. Particle’s Memory Saving

3.6. Steps for Implementation of EO for Profit Based Generation Scheduling

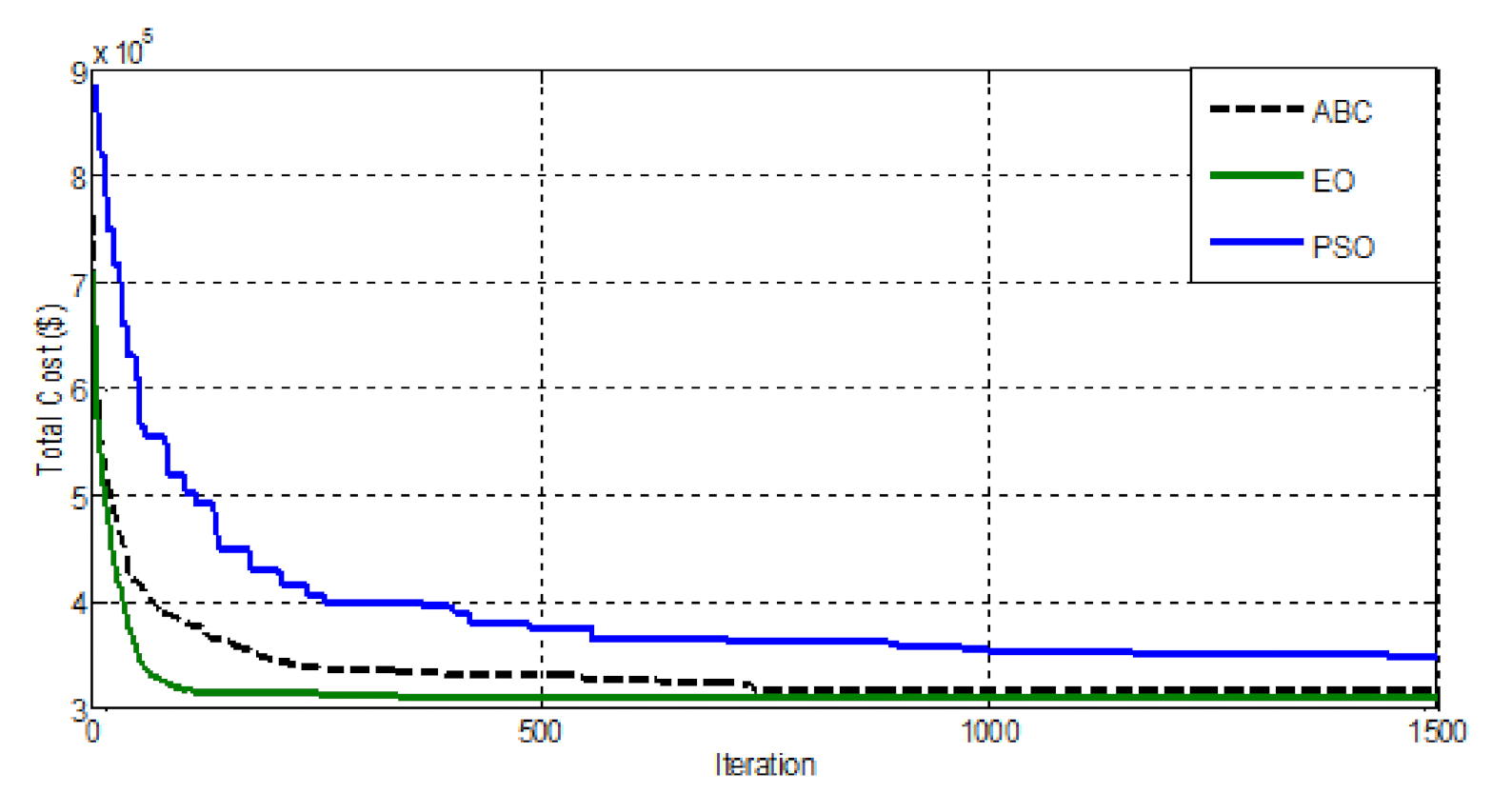

4. Results and Discussion

4.1. Description of Test Cases

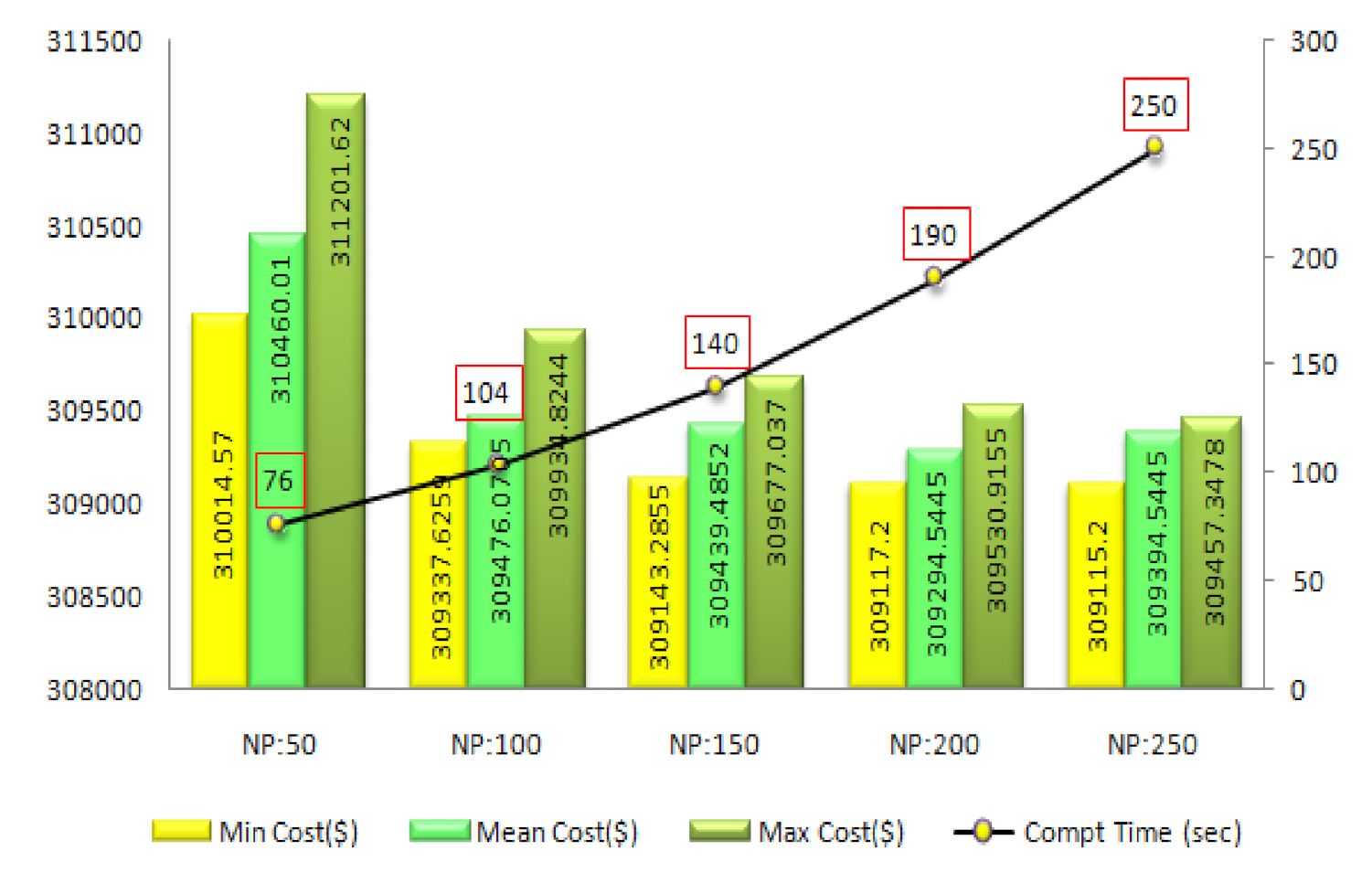

4.2. Effect of Number of Particles

4.3. Effect of Control Parameters on the Performance of EO

- constants and which control the exploration and exploitation, and

- generation probability decides whether exploration or exploitation of search space will occur.

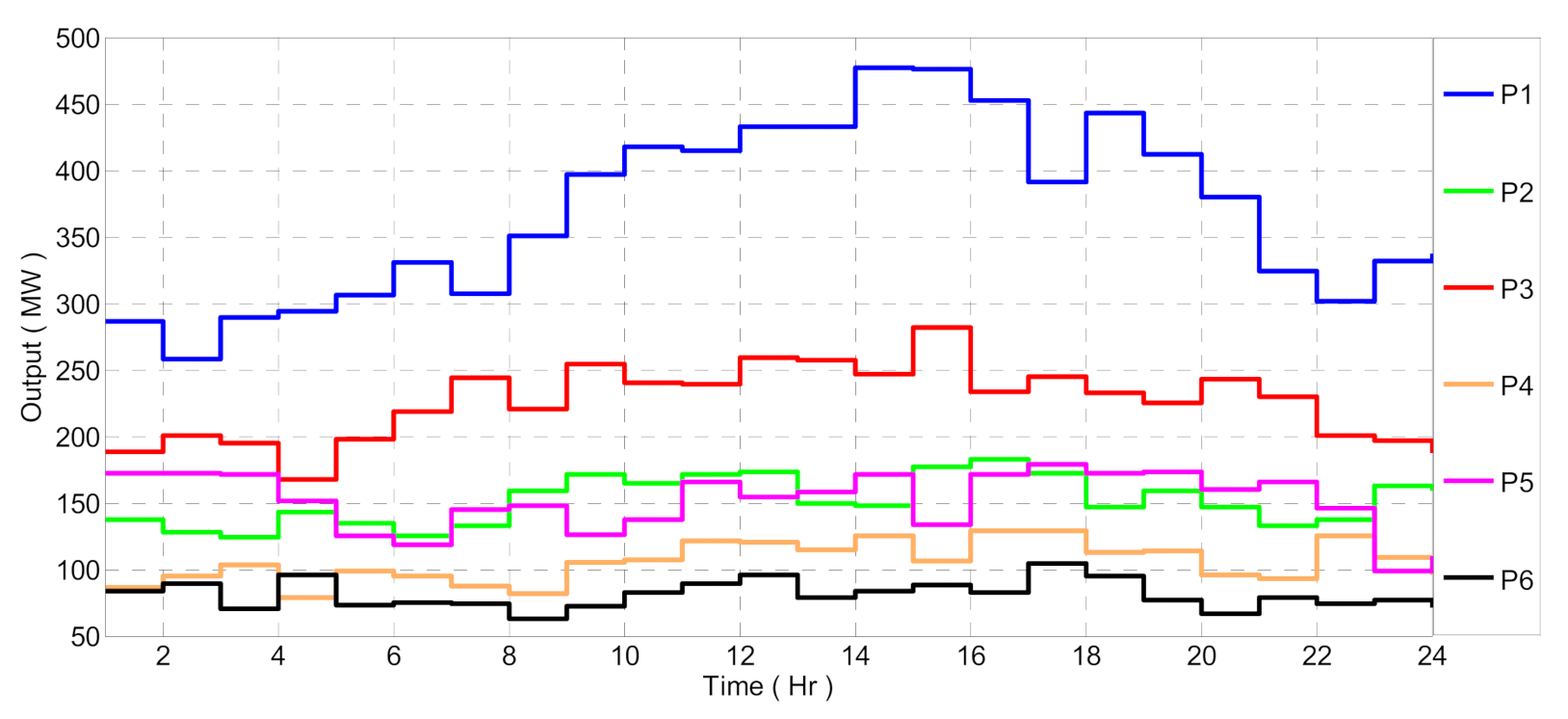

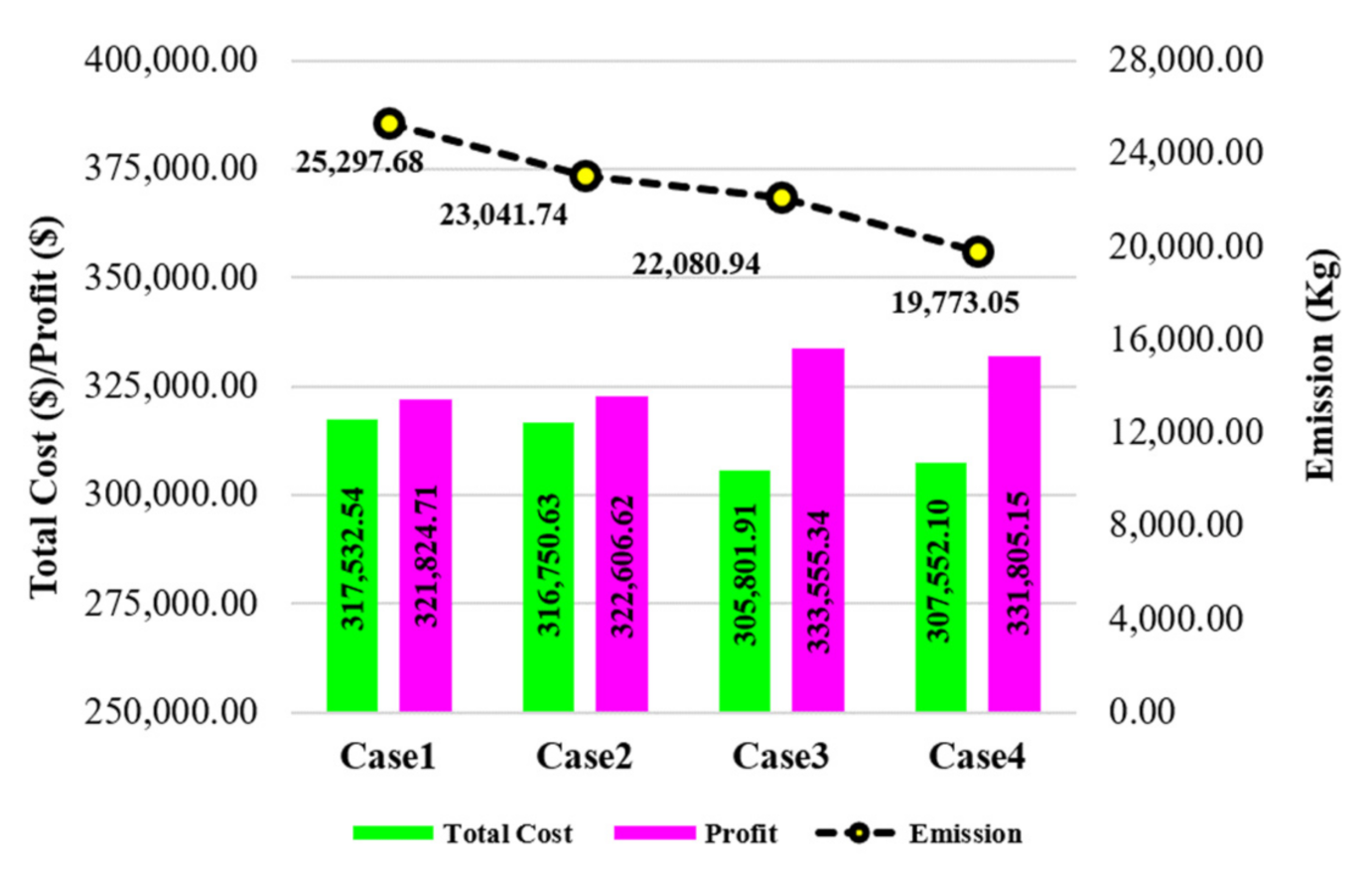

4.4. Effect of RER Integration on Profit Maximization

4.5. Effect of RER Integration on Emission Minimization

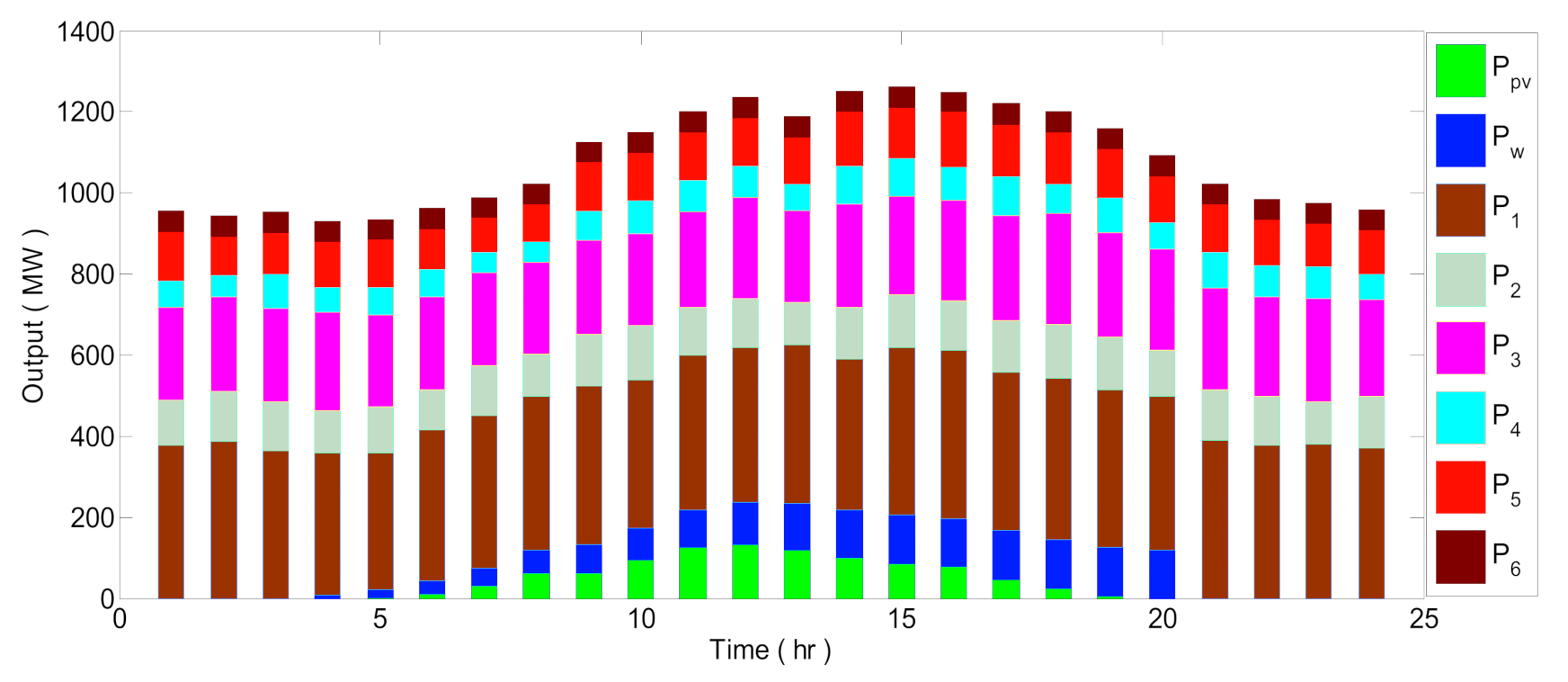

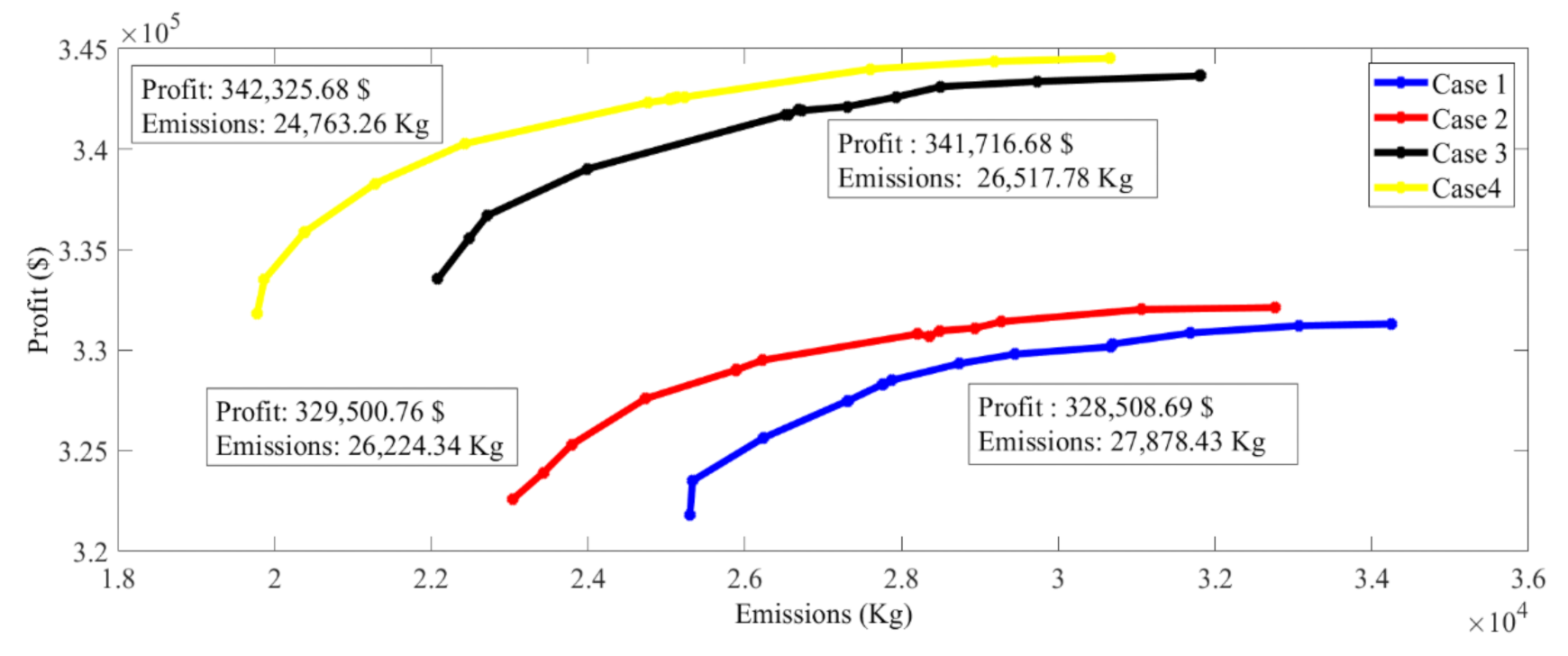

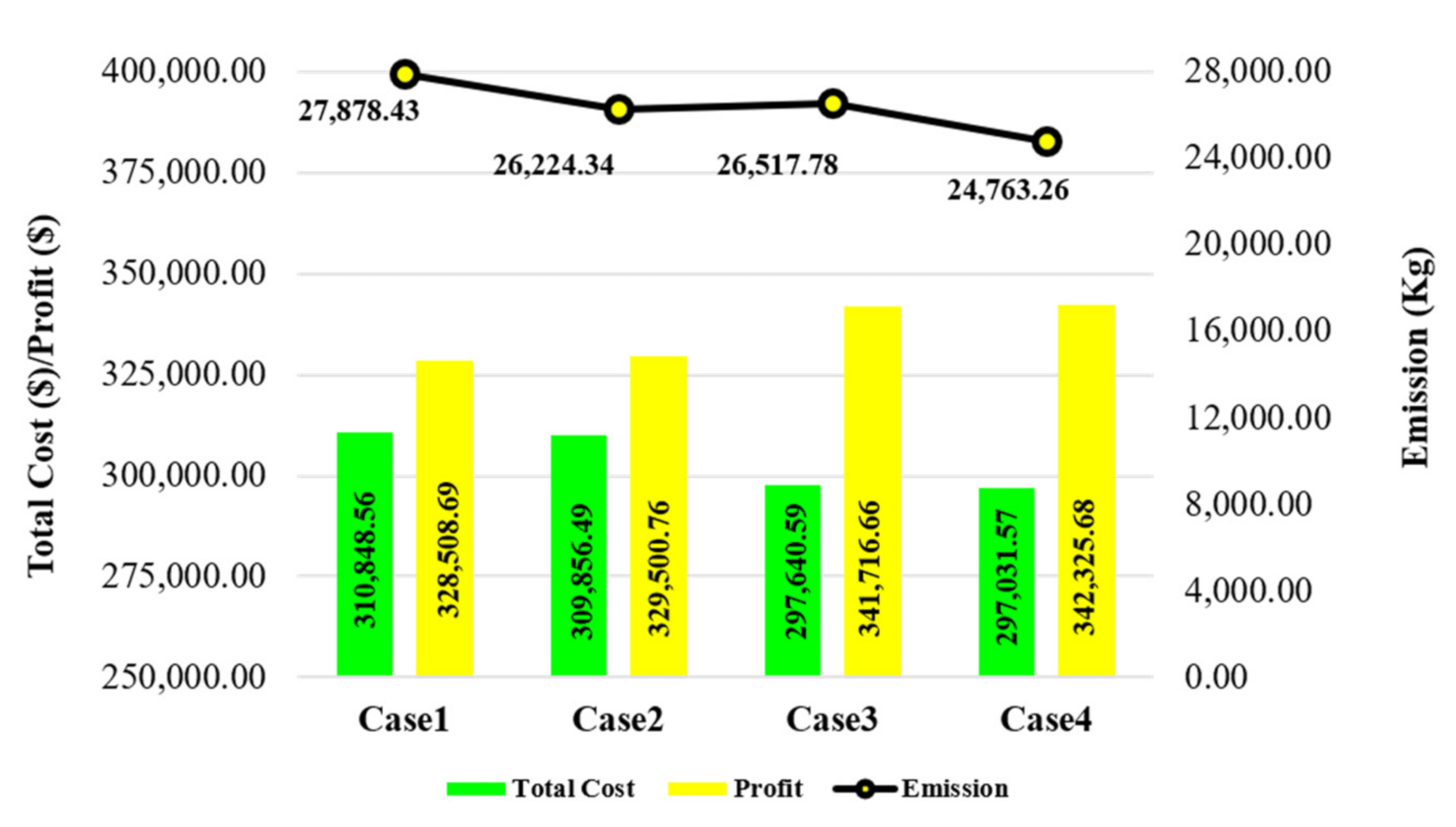

4.6. Effect of RER Integration for the Multiobjective Case

4.7. Analysis and Discussion

5. Conclusions

- The EO is not significantly dependent on algorithm-specific control parameters. The results are found to vary in a very narrow band with variations in control parameters.

- As the population size increases, EO gives more promising results. However, an increase in population size leads to increased computational time too.

- EO has a unique embedded mechanism for exploration and exploitation which leads to the global best solution.

- The increase in profit and decrease in emission are computed for the integration of solar, wind and wind-solar units in the existing thermal power generation system.

- It is verified that the higher the integration of RER, the greater is the profit, even after including the uncertainty costs of the renewable energy in the model.

- EO is found to produce well-distributed Pareto-optimal solutions for the multiobjective problem. For all the tested cases it is observed that EO is capable of dealing with complex operational constraints under the dynamic environment in an efficient manner.

- The proposed work is beneficial for designing hybrid renewable power systems with optimal capacities for given conditions to achieve desired profit and to reduce emission.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Unit | Pmin (MW) | Pmax (MW) | UR (MW/h) | DR (MW/h) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.007 | 7 | 240 | 100 | 500 | 0.00419 | 0.32767 | 13.8593 | 80 | 120 | |||

| 2 | 0.0095 | 10 | 200 | 50 | 200 | 0.00419 | 0.32767 | 13.8593 | 50 | 90 | |||

| 3 | 0.009 | 8 | 220 | 80 | 300 | 0.00683 | −0.54551 | 40.2669 | 65 | 100 | |||

| 4 | 0.009 | 11 | 200 | 50 | 150 | 0.00683 | −0.54551 | 40.2669 | 50 | 90 | |||

| 5 | 0.008 | 10.5 | 220 | 50 | 200 | 0.00461 | −0.51116 | 42.8955 | 50 | 90 | |||

| 6 | 0.0075 | 12 | 190 | 50 | 120 | 0.00461 | −0.51116 | 42.8955 | 50 | 90 | |||

| Hour | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| PD (MW) | 955 | 942 | 953 | 930 | 935 | 963 | 989 | 1023 | 1126 | 1150 | 1201 | 1235 | |

| SP ($/MW) | 22.65 | 22 | 22.6 | 22.1 | 23 | 23.15 | 24.6 | 25.25 | 24.81 | 26.5 | 27.15 | 30.3 | |

| Hour | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |

| PD (MW) | 1190 | 1251 | 1263 | 1250 | 1221 | 1202 | 1159 | 1092 | 1023 | 984 | 975 | 960 | |

| SP ($/MW) | 29.7 | 28.6 | 25.25 | 24.8 | 23.55 | 22.85 | 23.05 | 23.25 | 23.5 | 23.26 | 22.5 | 22.2 | |

| Type of System | No. of Units | Rated Power (MW/Unit) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Solar PV | 2 | 60 | 12 | 1.5 | 3 | - | - | - | - | - |

| Wind | 2 | 60 | 1.75 | 2 | 10 | 3 | 16 | 25 |

References

- Reddy, S.S.; Bijwe, P.R.; Abhyankar, A.R. Multiobjective market-clearing of electrical energy, spinning reserves and emission for wind-thermal power system. Int. J. Electr. Power Energy Syst. 2013, 53, 782–794. [Google Scholar] [CrossRef]

- Abido, M.A. Multiobjective evolutionary algorithms for electric power dispatch problem. IEEE Trans. Evol. Comput. 2006, 10, 315–329. [Google Scholar] [CrossRef]

- Delshad, M.M.; Rahim, N.A. Multiobjective backtracking search algorithm for economic emission dispatch problem. Appl. Soft Comput. 2016, 40, 479–494. [Google Scholar] [CrossRef]

- Liang, Y.C.; Juarez, J.R.C. A normalization method for solving the combined economic and emission dispatch problem with meta-heuristic algorithms. Int. J. Electr. Power Energy Syst. 2014, 54, 163–186. [Google Scholar] [CrossRef]

- Basu, M. Fuel constrained economic emission dispatch using nondominated sorting genetic algorithm-II. Energy 2014, 78, 649–664. [Google Scholar] [CrossRef]

- Kuk, J.N.; Gonçalves, R.A.; Pavelski, L.M.; Venske, S.M.G.S.; Almeida, C.P.; Pozo, A.T.R. An empirical analysis of constraint handling on evolutionary multiobjective algorithms for the Environmental/Economic Load Dispatch problem. Expert Syst. Appli. 2021, 165, 113774. [Google Scholar] [CrossRef]

- Muthuswamy, R.; Krishnan, M.; Subramanian, K.; Subramanian, B. Environmental and economic power dispatch of thermal generators using modified NSGA-II algorithm. Int. Trans. Electr. Energy Syst. 2014, 25, 1552–1569. [Google Scholar] [CrossRef]

- Wang, L.; Singh, C. Environmental/economic power dispatch using a fuzzified multi-objective particle swarm optimization algorithm. Electr. Power Syst. Res. 2007, 77, 1654–1664. [Google Scholar] [CrossRef]

- Agrawal, S.; Panigrahi, B.K.; Tiwari, M.K. Multiobjective particle swarm algorithm with fuzzy clustering for electrical power dispatch. IEEE Trans. Evol. Comput. 2008, 12, 529–541. [Google Scholar] [CrossRef]

- Goudarzi, A.; Li, Y.; Xiang, J. A hybrid non-linear time-varying double-weighted particle swarm optimization for solving non-convex combined environmental economic dispatch problem. Appl. Soft Comput. 2020, 86, 105894. [Google Scholar] [CrossRef]

- Jeddi, B.; Vahidinasab, V. A modified harmony search method for environ-mental/economic load dispatch of real-world power systems. Energy Convers. Manag. 2014, 78, 661–675. [Google Scholar] [CrossRef]

- Rezaie, H.; Kazemi-Rahbar, M.H.; Vahidi, B.; Rastegar, H. Solution of combined economic and emission dispatch problem using a novel chaotic improved harmony search algorithm. J. Comput. Des. Eng. 2019, 6, 447–467. [Google Scholar] [CrossRef]

- Pandit, M.; Srivastava, L.; Sharma, M. Environmental economic dispatch in multi-area power system employing improved differential evolution with fuzzy selection. Appl. Soft Comp. 2015, 28, 498–510. [Google Scholar] [CrossRef]

- Liang, H.; Liu, Y.; Li, F.; Shen, Y. A multiobjective hybrid bat algorithm for combined economic/emission dispatch. Int. J. Electr. Power Energy Syst. 2018, 101, 103–115. [Google Scholar] [CrossRef]

- Dong, R.; Wang, S. New Optimization Algorithm Inspired by Kernel Tricks for the Economic Emission Dispatch Problem with Valve Point. IEEE Access 2020, 8, 16584–16594. [Google Scholar] [CrossRef]

- Nourianfar, H.; Abdi, H. Solving the multiobjective economic emission dispatch problems using Fast Non-Dominated Sorting TVAC-PSO combined with EMA. Appl. Soft Comp. 2019, 85, 105770. [Google Scholar] [CrossRef]

- Karthik, N.; Parvathy, A.K. Multiobjective economic emission dispatch using interior search algorithm. Int. Trans. Electr. Energy Syst. 2018, 29, e2683. [Google Scholar] [CrossRef] [Green Version]

- Karthikeyan, R. Combined economic emission dispatch using grasshopper optimization algorithm. Mater. Today Proc. 2020, 33, 3378–3382. [Google Scholar] [CrossRef]

- Guesmi, T.; Farah, A.; Marouani, I.; Alshammari, B.; Abdallah, H.H. Chaotic sine–cosine algorithm for chance-constrained economic emission dispatch problem including wind energy. IET Renew. Power Gener. 2020, 14, 1808–1821. [Google Scholar] [CrossRef]

- Hooshmand, R.A.; Parastegari, M.; Morshed, M.J. Emission, reserve, and economic load dispatch problem with non-smooth and non-convex cost functions using the hybrid bacterial foraging-Nelder–Mead algorithm. Appl. Energy 2012, 89, 443–453. [Google Scholar] [CrossRef]

- Qu, B.Y.; Zhu, Y.S.; Jiao, Y.C.; Wu, M.Y.; Suganthan, P.N.; Liang, J.J. A survey on multiobjective evolutionary algorithms for the solution of the environmental/economic dispatch problems. Swarm Evol. Comp. 2018, 38, 1–11. [Google Scholar] [CrossRef]

- Dubey, H.M.; Pandit, M.; Panigrahi, B.K. An overview and comparative analysis of recent bio-inspired optimization techniques for wind integrated multiobjective power dispatch. Swarm Evol. Comp. 2018, 38, 12–34. [Google Scholar] [CrossRef]

- Dubey, H.M.; Pandit, M.; Panigrahi, B.K. Hybrid flower pollination algorithm with time-varying fuzzy selection mechanism for wind integrated multiobjective dynamic economic dispatch. Renew Energy 2015, 83, 188–202. [Google Scholar] [CrossRef]

- Hazra, S.; Roy, P.K. Quasi-oppositional chemical reaction optimization for combined economic emission dispatch in power system considering wind power uncertainties. Renew. Energy Focus 2019, 31, 45–62. [Google Scholar] [CrossRef]

- Basu, M. Multi-area dynamic economic emission dispatch of hydro-wind-thermal power system. Renew. Energy Focus 2019, 28, 11–35. [Google Scholar] [CrossRef]

- Dey, B.; Roy, S.K.; Bhattacharyya, B. Solving multiobjective economic emission dispatch of a renewable integrated microgrid using latest bio-inspired algorithms. Int. J. Eng. Sci. Tech. 2019, 22, 55–66. [Google Scholar]

- Reddy, S. Optimal scheduling of thermal-wind-solar power system with storage. Renew. Energy 2017, 101, 1357–1368. [Google Scholar] [CrossRef]

- Zubo, R.H.A.; Mokryani, G.; Abd-Alhameed, R. Optimal operation of distribution networks with high penetration of wind and solar power within a joint active and reactive distribution market environment. Appl. Energy 2018, 220, 713–722. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Wang, F.; Lv, C.; Huang, Q.; Xie, H. Economic-environmental equilibrium based optimal scheduling strategy towards wind-solar-thermal power generation system under limited resources. Appl. Energy 2018, 231, 355–371. [Google Scholar] [CrossRef]

- Panda, A.; Mishra, U.; Tseng, M.L.; Ali, M.H. Hybrid power systems with emission minimization: Multiobjective optimal operation. J. Clean. Prod. 2020, 268, 121418. [Google Scholar] [CrossRef]

- Swain, A.; Salkuti, S.R.; Swain, K. An Optimized and Decentralized Energy Provision System for Smart Cities. Energies 2021, 14, 1451. [Google Scholar] [CrossRef]

- Emad, D.; El-Hameed, M.A.; Yousef, M.T.; El-Fergany, A.A. Computational Methods for Optimal Planning of Hybrid Renewable Microgrids: A Comprehensive Review and Challenges. Arch. Comput. Methods Eng. 2020, 27, 1297–1319. [Google Scholar] [CrossRef]

- Park, H. A Stochastic Planning Model for Battery Energy Storage Systems Coupled with Utility-Scale Solar Photovoltaics. Energies 2021, 14, 1244. [Google Scholar] [CrossRef]

- Faramarzi, A.; Heidarinejad, M.; Stephens, B.; Mirjalili, S. Equilibrium optimizer: A novel optimization algorithm. Knowl.-Based Syst. 2020, 191, 105190. [Google Scholar] [CrossRef]

- Battula, A.R.; Vuddanti, S.; Salkuti, S.R. Review of Energy Management System Approaches in Microgrids. Energies 2021, 14, 5459. [Google Scholar] [CrossRef]

- Lotfi, H.; Dadpour, A.; Samadi, M. Solving economic dispatch in competitive power market using improved particle swarm optimization algorithm. In Proceedings of the Conference on Electrical Power Distribution Networks Conference (EPDC2017), Semnan, Iran, 19–20 April 2017; pp. 188–195. [Google Scholar]

- Joshi, P.M.; Verma, H.K. An improved TLBO based economic dispatch of power generation through distributed energy resources considering environmental constraints. Sustain. Energy Grids Netw. 2019, 18, 1–18. [Google Scholar] [CrossRef]

- Hetzer, J.; Yu, D.C.; Bhattarai, K. An Economic Dispatch Model Incorporating Wind Power. IEEE Trans. Energy Conver. 2008, 23, 603–611. [Google Scholar] [CrossRef]

- Menezes, R.F.A.; Soriano, G.D.; de Aquino, R.R.B. Locational Marginal Pricing and Daily Operation Scheduling of a Hydro-Thermal-Wind-Photovoltaic Power System Using BESS to Reduce Wind Power Curtailment. Energies 2021, 14, 1441. [Google Scholar] [CrossRef]

- Khan, N.A.; Awan, A.B.; Mahmood, A.; Razzaq, S.; Zafar, A.; Sidhu, G.A. Combined emission economic dispatch of power system including solar photovoltaic generation. Energy Conver. Manag. 2015, 92, 82–91. [Google Scholar] [CrossRef]

| Method | Parameters | Min Cost ($) | Mean Cost ($) | Max Cost ($) | SD | CPU Time/Iter. (s) |

|---|---|---|---|---|---|---|

| PSO | 309,125.58 | 309,133.97 | 309,170.86 | 5.3818 | 0.0215 | |

| ABC | Limit=100 | 309,126.34 | 309,154.07 | 309,164.77 | 10.05 | 0.0203 |

| EO | a1=2, a2=1, ρ=0.5 | 309,117.20 | 309,125.54 | 309,139.91 | 0.9103 | 0.0188 |

| Parameters | Total Cost ($) | Profit ($) | Emission (Kg) | |

|---|---|---|---|---|

| a1 | a2 | |||

| 1 | 1 | 301,550.07 | 337,807.18 | 24,412.00 |

| 1 | 2 | 309,167.46 | 330,189.73 | 28,484.83 |

| 2 | 1 | 297,031.57 | 342,325.68 | 24,763.26 |

| 2 | 2 | 297,620.53 | 341,736.72 | 26,759.37 |

| ρ | Total Cost ($) | Profit ($) | Emission (Kg) | |

|---|---|---|---|---|

| a1 = 2, a2 = 1 | 0.1 | 298,680.22 | 340,677.03 | 28,639.24 |

| 0.2 | 298,215.49 | 341,141.76 | 27,678.89 | |

| 0.3 | 298,261.84 | 341,095.41 | 27,217.14 | |

| 0.4 | 298,310.80 | 341,046.45 | 28,180.66 | |

| 0.5 | 297,031.57 | 342,325.68 | 24,763.26 | |

| 0.6 | 297,845.79 | 341,511.46 | 27,399.93 | |

| 0.7 | 297,553.80 | 341,803.45 | 26,343.26 | |

| 0.8 | 297,624.74 | 341,732.51 | 26,728.33 | |

| 0.9 | 298,367.13 | 340,990.12 | 26,233.64 |

| ThC ($) | WC ($) | PVC ($) | TC ($) | SP ($) | Profit ($) | Emission (Kg) | |

|---|---|---|---|---|---|---|---|

| Test Case 1 | 309,117.20 | -- | -- | 309,117.20 | 639,357.25 | 330,240.05 | 31,581.41 |

| Test Case 4 | 276,906.41 | 6290.20 | 11,635.38 | 294,831.99 | 639,357.25 | 344,525.26 | 28,422.29 |

| Test Case 1 | Test Case 2 | ||||||||

| Profit | Emission | µ1 | µ2 | min (µ) | Profit | Emission | µ1 | µ2 | min (µ) |

| 328,508.692 | 27,878.429 | 0.705 | 0.712 | 0.705 | 329,500.761 | 26,224.344 | 0.725 | 0.672 | 0.672 |

| 328,312.919 | 27,759.219 | 0.684 | 0.725 | 0.684 | 329,502.218 | 26,226.754 | 0.725 | 0.672 | 0.672 |

| 328,312.663 | 27,759.160 | 0.684 | 0.725 | 0.684 | 329,503.106 | 26,227.526 | 0.725 | 0.672 | 0.672 |

| 328,311.440 | 27,758.630 | 0.684 | 0.725 | 0.684 | 327,594.083 | 24,734.770 | 0.524 | 0.825 | 0.524 |

| 329,335.245 | 28,738.401 | 0.792 | 0.616 | 0.616 | 327,593.259 | 24,733.423 | 0.524 | 0.825 | 0.524 |

| 329,336.053 | 28,739.487 | 0.792 | 0.616 | 0.616 | 327,591.770 | 24,732.427 | 0.524 | 0.826 | 0.524 |

| 329,336.009 | 28,739.710 | 0.792 | 0.616 | 0.616 | 330,805.950 | 28,204.049 | 0.862 | 0.468 | 0.468 |

| 327,479.749 | 27,313.518 | 0.596 | 0.775 | 0.596 | 330,805.924 | 28,204.710 | 0.862 | 0.468 | 0.468 |

| 327,478.885 | 27,312.756 | 0.596 | 0.775 | 0.596 | 330,805.931 | 28,205.116 | 0.862 | 0.468 | 0.468 |

| 327,478.002 | 27,312.382 | 0.596 | 0.775 | 0.596 | 330,689.142 | 28,348.341 | 0.849 | 0.454 | 0.454 |

| Test Case 3 | Test Case 4 | ||||||||

| Profit | Emission | µ1 | µ2 | min (µ) | Profit | Emission | µ1 | µ2 | min (µ) |

| 341,716.684 | 26,517.776 | 0.760 | 0.567 | 0.567 | 342,325.682 | 24,763.258 | 0.827 | 0.542 | 0.542 |

| 341,716.956 | 26,518.660 | 0.760 | 0.567 | 0.567 | 342,325.842 | 24,763.330 | 0.827 | 0.542 | 0.542 |

| 341,717.139 | 26,518.991 | 0.760 | 0.567 | 0.567 | 342,477.714 | 25,040.173 | 0.839 | 0.516 | 0.516 |

| 341,708.322 | 26,549.079 | 0.759 | 0.564 | 0.564 | 342,478.170 | 25,040.791 | 0.839 | 0.516 | 0.516 |

| 341,708.646 | 26,549.144 | 0.759 | 0.564 | 0.564 | 342,532.703 | 25,090.462 | 0.843 | 0.512 | 0.512 |

| 341,708.329 | 26,549.322 | 0.759 | 0.564 | 0.564 | 342,533.058 | 25,090.864 | 0.843 | 0.512 | 0.512 |

| 341,960.680 | 26,683.972 | 0.791 | 0.550 | 0.550 | 338,289.653 | 21,279.033 | 0.510 | 0.862 | 0.510 |

| 341,960.976 | 26,684.062 | 0.791 | 0.549 | 0.549 | 338,288.413 | 21,278.272 | 0.510 | 0.862 | 0.510 |

| 341,961.230 | 26,684.330 | 0.791 | 0.549 | 0.549 | 342,585.154 | 25,130.773 | 0.847 | 0.508 | 0.508 |

| 341,924.268 | 26,723.629 | 0.786 | 0.545 | 0.545 | 342,584.919 | 25,130.786 | 0.847 | 0.508 | 0.508 |

| Hour | P1 (MW) | P2 (MW) | P3 (MW) | P4 (MW) | P5 (MW) | P6 (MW) | TC ($) | SP ($) | Profit ($) | Emission (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 267.18 | 116.94 | 189.30 | 137.60 | 125.15 | 118.82 | 11,431.4097 | 21,630.75 | 10,199.34 | 884.64 |

| 2 | 290.12 | 120.26 | 180.63 | 108.07 | 135.22 | 107.69 | 11,208.0562 | 20,724.00 | 9515.94 | 900.50 |

| 3 | 273.65 | 147.61 | 201.12 | 89.01 | 122.96 | 118.66 | 11,357.6823 | 21,537.80 | 10,180.12 | 920.34 |

| 4 | 258.12 | 147.41 | 159.08 | 113.96 | 146.97 | 104.46 | 11,145.9213 | 20,553.00 | 9407.08 | 831.10 |

| 5 | 282.57 | 118.86 | 190.11 | 87.82 | 156.66 | 98.97 | 11,113.801 | 21,505.00 | 10,391.20 | 894.89 |

| 6 | 268.65 | 134.94 | 188.96 | 131.20 | 133.12 | 106.13 | 11,506.8602 | 22,293.45 | 10,786.59 | 903.10 |

| 7 | 282.25 | 110.86 | 200.46 | 116.44 | 161.67 | 117.31 | 11,814.661 | 24,329.40 | 12,514.74 | 943.67 |

| 8 | 318.19 | 126.99 | 194.56 | 113.38 | 162.78 | 107.09 | 12,181.5529 | 25,830.73 | 13,649.18 | 1047.15 |

| 9 | 324.15 | 164.39 | 226.84 | 118.69 | 198.86 | 93.06 | 13,471.5765 | 27,936.05 | 14,464.47 | 1239.81 |

| 10 | 344.50 | 155.59 | 211.73 | 122.96 | 196.45 | 118.77 | 13,786.5861 | 30,475.00 | 16,688.41 | 1265.30 |

| 11 | 350.92 | 183.98 | 240.31 | 139.40 | 167.58 | 118.81 | 14,416.1753 | 32,607.14 | 18,190.97 | 1395.27 |

| 12 | 386.77 | 178.95 | 231.68 | 148.91 | 169.39 | 119.30 | 14,838.8277 | 37,420.49 | 22,581.67 | 1501.13 |

| 13 | 358.79 | 159.28 | 228.62 | 149.05 | 174.61 | 119.65 | 14,275.8021 | 35,342.99 | 21,067.19 | 1368.31 |

| 14 | 379.97 | 165.36 | 249.43 | 146.40 | 190.98 | 118.86 | 15,041.8218 | 35,778.61 | 20,736.78 | 1522.54 |

| 15 | 387.37 | 178.49 | 247.30 | 148.43 | 182.26 | 119.15 | 15,195.1235 | 31,890.75 | 16,695.63 | 1558.50 |

| 16 | 364.96 | 197.62 | 245.53 | 132.81 | 189.51 | 119.58 | 15,050.0093 | 31,000.00 | 15,949.99 | 1499.40 |

| 17 | 358.21 | 169.93 | 256.18 | 129.27 | 189.03 | 118.39 | 14,658.0997 | 28,754.55 | 14,096.45 | 1450.01 |

| 18 | 360.92 | 172.60 | 225.78 | 148.92 | 174.26 | 119.51 | 14,434.0764 | 27,465.70 | 13,031.62 | 1390.41 |

| 19 | 322.15 | 154.47 | 229.83 | 133.87 | 199.14 | 119.54 | 13,920.6668 | 26,714.95 | 12,794.28 | 1255.61 |

| 20 | 335.55 | 147.30 | 209.25 | 108.47 | 172.87 | 118.56 | 13,035.613 | 25,389.00 | 12,353.38 | 1174.63 |

| 21 | 296.40 | 167.11 | 206.24 | 121.43 | 142.45 | 89.38 | 12,187.7462 | 24,040.49 | 11,852.75 | 1055.36 |

| 22 | 275.73 | 153.09 | 199.98 | 95.28 | 164.90 | 95.01 | 11,732.3309 | 22,887.84 | 11,155.51 | 959.52 |

| 23 | 267.59 | 160.44 | 225.76 | 94.03 | 156.50 | 70.68 | 11,596.8066 | 21,937.49 | 10,340.69 | 996.03 |

| 24 | 295.98 | 99.08 | 185.82 | 115.74 | 144.14 | 119.23 | 11,447.352 | 21,312.00 | 9864.65 | 921.21 |

| Total | 7650.70 | 3631.54 | 5124.51 | 2951.15 | 3957.45 | 2656.65 | 310,848.56 | 639,357.25 | 328,508.69 | 27,878.43 |

| A. Optimal Generation Schedule for Test Case 4 (Best Compromise Solution) | ||||||||||||||||

| Hour | P1 (MW) | P2 (MW) | P3 (MW) | P4 (MW) | P5 (MW) | P6 (MW) | TS (MW) | Emission (Kg) | WS (MW) | PV Share (MW) | ||||||

| 1 | 326.45 | 101.35 | 186.46 | 98.17 | 150.86 | 91.71 | 955.00 | 991.51 | 0.00 | 0.00 | ||||||

| 2 | 303.95 | 107.68 | 198.92 | 101.68 | 128.74 | 101.03 | 942.00 | 947.51 | 0.00 | 0.00 | ||||||

| 3 | 281.69 | 119.22 | 232.89 | 81.07 | 143.44 | 94.68 | 953.00 | 975.98 | 0.00 | 0.00 | ||||||

| 4 | 258.20 | 135.39 | 186.99 | 102.72 | 149.44 | 88.95 | 921.69 | 849.56 | 8.31 | 0.00 | ||||||

| 5 | 268.76 | 145.56 | 193.86 | 86.33 | 139.38 | 80.16 | 914.06 | 882.95 | 20.31 | 2.63 | ||||||

| 6 | 292.74 | 121.33 | 177.03 | 93.73 | 132.47 | 101.55 | 918.84 | 885.64 | 32.31 | 13.85 | ||||||

| 7 | 291.77 | 131.62 | 183.65 | 96.06 | 121.16 | 90.69 | 914.93 | 900.13 | 44.31 | 30.76 | ||||||

| 8 | 298.97 | 120.68 | 193.18 | 90.61 | 119.46 | 80.31 | 903.21 | 916.65 | 56.31 | 63.48 | ||||||

| 9 | 324.98 | 125.01 | 202.09 | 118.72 | 136.55 | 88.13 | 995.48 | 1056.59 | 68.31 | 62.22 | ||||||

| 10 | 327.58 | 135.25 | 204.20 | 106.08 | 142.04 | 61.42 | 976.57 | 1070.75 | 80.31 | 93.12 | ||||||

| 11 | 352.28 | 112.17 | 217.72 | 103.03 | 122.32 | 74.72 | 982.24 | 1134.22 | 92.31 | 120.00 | ||||||

| 12 | 347.07 | 122.85 | 186.34 | 108.57 | 144.80 | 89.03 | 998.66 | 1086.44 | 104.31 | 120.00 | ||||||

| 13 | 314.33 | 127.82 | 176.08 | 116.53 | 143.55 | 76.50 | 954.81 | 975.73 | 116.31 | 118.88 | ||||||

| 14 | 335.61 | 146.32 | 213.07 | 112.85 | 143.72 | 79.95 | 1031.51 | 1143.19 | 120.00 | 99.49 | ||||||

| 15 | 322.65 | 155.12 | 241.44 | 96.25 | 142.49 | 99.82 | 1057.76 | 1180.47 | 120.00 | 85.24 | ||||||

| 16 | 334.44 | 157.54 | 226.78 | 108.63 | 139.08 | 86.81 | 1053.29 | 1185.25 | 120.00 | 76.71 | ||||||

| 17 | 342.95 | 162.21 | 186.79 | 125.49 | 159.30 | 78.16 | 1054.91 | 1161.91 | 120.00 | 56.09 | ||||||

| 18 | 351.52 | 163.81 | 180.67 | 101.87 | 156.07 | 102.82 | 1056.77 | 1161.48 | 120.00 | 26.23 | ||||||

| 19 | 306.51 | 160.14 | 194.76 | 120.31 | 150.81 | 101.95 | 1034.48 | 1057.68 | 120.00 | 6.52 | ||||||

| 20 | 331.46 | 140.31 | 196.15 | 92.82 | 129.68 | 81.58 | 972.00 | 1055.65 | 120.00 | 0.00 | ||||||

| 21 | 351.75 | 122.82 | 222.79 | 98.26 | 135.87 | 91.50 | 1023.00 | 1168.49 | 0.00 | 0.00 | ||||||

| 22 | 327.44 | 136.26 | 204.65 | 92.46 | 144.33 | 78.86 | 984.00 | 1066.00 | 0.00 | 0.00 | ||||||

| 23 | 302.88 | 129.99 | 188.70 | 97.67 | 170.58 | 85.18 | 975.00 | 980.05 | 0.00 | 0.00 | ||||||

| 24 | 265.65 | 140.16 | 211.95 | 95.83 | 154.01 | 92.41 | 960.00 | 929.40 | 0.00 | 0.00 | ||||||

| Total | 7561.66 | 3220.61 | 4807.17 | 2445.70 | 3400.14 | 2097.93 | 23,533.20 | 24,763.26 | 1463.08 | 975.72 | ||||||

| B. Cost, Selling Price and Profit for Test Case 4 (Best Compromise Solution) | ||||||||||||||||

| Hour | Th Cost ($) | WC ($) | PV Cost ($) | TC ($) | SP ($) | Profit ($) | ||||||||||

| 1 | 11,313.10 | 26.59 | 0.00 | 11,339.69 | 21,630.75 | 10,291.06 | ||||||||||

| 2 | 11,163.59 | 26.59 | 0.00 | 11,190.18 | 20,724.00 | 9533.82 | ||||||||||

| 3 | 11,300.92 | 26.59 | 0.00 | 11,327.51 | 21,537.80 | 10,210.30 | ||||||||||

| 4 | 10,982.15 | 30.71 | 0.00 | 11,012.86 | 20,553.00 | 9540.14 | ||||||||||

| 5 | 10,848.76 | 55.33 | 7.55 | 10,911.64 | 21,504.92 | 10,593.28 | ||||||||||

| 6 | 10,907.79 | 102.07 | 141.28 | 11,151.14 | 22,293.51 | 11,142.37 | ||||||||||

| 7 | 10,840.90 | 157.43 | 354.88 | 11,353.21 | 24,329.42 | 12,976.21 | ||||||||||

| 8 | 10,666.11 | 214.29 | 757.03 | 11,637.43 | 25,830.68 | 14,193.25 | ||||||||||

| 9 | 11,798.47 | 271.29 | 741.92 | 12,811.68 | 27,936.16 | 15,124.48 | ||||||||||

| 10 | 11,535.66 | 328.29 | 1110.51 | 12,974.46 | 30,474.88 | 17,500.42 | ||||||||||

| 11 | 11,585.74 | 385.29 | 1507.91 | 13,478.94 | 32,607.17 | 19,128.22 | ||||||||||

| 12 | 11,834.05 | 442.29 | 1574.49 | 13,850.83 | 37,420.41 | 23,569.58 | ||||||||||

| 13 | 11,321.05 | 499.29 | 1417.69 | 13,238.03 | 35,342.89 | 22,104.87 | ||||||||||

| 14 | 12,224.89 | 516.83 | 1186.46 | 13,928.18 | 35,778.49 | 21,850.31 | ||||||||||

| 15 | 12,566.34 | 516.83 | 1016.51 | 14,099.68 | 31,890.71 | 17,791.02 | ||||||||||

| 16 | 12,496.84 | 516.83 | 914.82 | 13,928.49 | 30,999.90 | 17,071.41 | ||||||||||

| 17 | 12,556.04 | 516.83 | 549.59 | 13,622.46 | 28,754.62 | 15,132.16 | ||||||||||

| 18 | 12,588.57 | 516.83 | 300.88 | 13,406.28 | 27,465.67 | 14,059.40 | ||||||||||

| 19 | 12,338.22 | 516.83 | 53.85 | 12,908.90 | 26,715.04 | 13,806.14 | ||||||||||

| 20 | 11,488.50 | 516.83 | 0.00 | 12,005.33 | 25,389.00 | 13,383.67 | ||||||||||

| 21 | 12,101.88 | 26.59 | 0.00 | 12,128.47 | 24,040.50 | 11,912.03 | ||||||||||

| 22 | 11,634.79 | 26.59 | 0.00 | 11,661.38 | 22,887.84 | 11,226.46 | ||||||||||

| 23 | 11,583.47 | 26.59 | 0.00 | 11,610.06 | 21,937.50 | 10,327.44 | ||||||||||

| 24 | 11,428.16 | 26.59 | 0.00 | 11,454.75 | 21,312.00 | 9857.25 | ||||||||||

| Total | 279,105.98 | 6290.22 | 11,635.37 | 297,031.57 | 639,357.25 | 342,325.68 | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubey, S.M.; Dubey, H.M.; Pandit, M.; Salkuti, S.R. Multiobjective Scheduling of Hybrid Renewable Energy System Using Equilibrium Optimization. Energies 2021, 14, 6376. https://doi.org/10.3390/en14196376

Dubey SM, Dubey HM, Pandit M, Salkuti SR. Multiobjective Scheduling of Hybrid Renewable Energy System Using Equilibrium Optimization. Energies. 2021; 14(19):6376. https://doi.org/10.3390/en14196376

Chicago/Turabian StyleDubey, Salil Madhav, Hari Mohan Dubey, Manjaree Pandit, and Surender Reddy Salkuti. 2021. "Multiobjective Scheduling of Hybrid Renewable Energy System Using Equilibrium Optimization" Energies 14, no. 19: 6376. https://doi.org/10.3390/en14196376

APA StyleDubey, S. M., Dubey, H. M., Pandit, M., & Salkuti, S. R. (2021). Multiobjective Scheduling of Hybrid Renewable Energy System Using Equilibrium Optimization. Energies, 14(19), 6376. https://doi.org/10.3390/en14196376