Abstract

In recent years, the use of biodegradable fluids as liquid insulation for distribution and power transformers is spreading. The main biodegradable fluids used are natural and synthetic esters, although biodegradable hydrocarbons have been recently proposed. Biodegradable fluids have a much lower environmental impact than mineral oil, limiting the risk of soil contamination in leaks, which makes them a suitable solution for applications such as offshore transformers or railway transformers. Additionally, these fluids have a higher flash point than conventional mineral oils, which dramatically reduces the risk of fire and collateral damage derived from explosion and fire. Despite these advantageous factors, there are still some aspects that hinder the broadening of their use, such as the difference in thermal properties or the lack of accepted maintenance procedures for transformers that use them as liquid insulation. This paper presents the current status of biodegradable insulating fluids, analyzing some of their properties and discussing the aspects that are still to be investigated in order to make them a real alternative to petroleum-based fluids.

1. Introduction

For more than 100 years, mineral oil (MO) has been used as liquid insulation for power and distribution transformers. Transformer liquid insulation accomplishes a double mission by acting as dielectric material, providing electrical insulation between regions of the transformer at different voltage levels, and by acting as a cooling agent that dissipates the ambient heat losses generated in the transformer windings. Moreover, the insulating fluid impregnates the solid insulation of the transformer, improving the dielectric properties of the cellulose. It is also used for diagnostic purposes, since its periodic sampling and analysis are regarded nowadays as a powerful tool for transformer fault detection.

Despite the excellent performance and low cost of MO, a recent increase in environmental and safety requirements has driven the electricity transmission and distribution industry to look for alternatives to this material [1,2,3]. Polychlorinated biphenyls (PCBs) were used as transformer liquid insulation for some time because of their good dielectric properties and high fire and flash points; however, concerns about their toxicity lead to the total withdrawal of these liquids since the late 1970s [1]. Silicones and fluids of vegetable origin were later explored, but their high price and some physical properties limited their further expansion [1]. In the last few decades, the use of fluids of vegetable origin and other synthetic biodegradable liquids have increased significantly [4,5]. Two types of biodegradable liquids are used nowadays as an alternative to mineral oil: natural esters (NE) obtained from different vegetable seeds, and synthetic esters (SE). Other biodegradable liquids based on hydrocarbons have also recently been launched.

Ester fluids have three main advantages concerning MO [1,2,4]. Firstly, esters are biodegradable materials, therefore the environmental risk and impact as well as the disposal cost of the liquids are minimized. For this reason, these fluids are used in offshore wind power transformers, urban substations, transformers operating on ships, and railway traction transformers. Additionally, the flash point of esters is much higher than that of MO, which means that the fire risk of ester-filled transformers is dramatically lower. This fact makes ester-filled transformers more suitable for areas near to the population or to critical infrastructures. Finally, esters can adsorb more significant amounts of water than MO, allowing the transformer dielectric paper to operate more dryly [1]. It has been proven that this has a positive impact on the transformer loss-of-life curve and, in consequence, on the maximum permissible hottest spot temperature [6,7,8,9].

On the other hand, esters have some properties that slow down their expansion as an alternative to MO. The viscosity of esters is typically higher than that of MO; therefore, their flow through the cooling channels of the transformer is slower, and the temperatures reached at the transformer are higher. It has been estimated that ester-filled transformers operate within 1 and 3 °C hotter than similar MO-based units [1,2,4]. Additionally, the oxidation rate of esters is higher, especially in NE, which makes them more suitable for sealed units. Finally, NE has a high pour point, which means that they are not suitable for outdoor transformers in cool zones unless certain precautions are taken [2,4]. Aiming at improving those drawbacks of ester fluids, techniques like the addition of nanoparticles or the modification of ester’s molecular structure have been proposed [1]. An example of the latter is the Palm Fatty Acid Ester proposed in [3], whose viscosity is even lower than that of MO at the expense of worsening the flash point.

The use of ester fluids as a transformer’s liquid insulation makes it necessary that both the manufacturers and the transformer’s owners redefine the transformer’s life management strategy [9,10,11,12]. This includes introducing changes in the design of the equipment and establishing different guidelines for the operation and the maintenance of these actives.

The objective of this paper is to discuss how the differences between conventional insulating liquids and ester-based fluids impact the management of ester-filled transformers. The paper addresses the problem from a global perspective and revises the effect of using an alternative insulating fluid on the different stages of the transformer life.

Firstly, some numbers are provided that bring out that, although esters are currently an extended solution for small and medium-sized units, their use is still marginal for larger transformers. Given the relevance of the standardization process in the spreading of a new technology, a review of the international standards that has been published on the topic throughout the years is included. Then, the main physic-chemical differences between the different types of liquids and the repercussions of those differences for the design and manufacturing of transformers is considered. Later, the operation of ester-filled transformers is discussed, putting the focus not only on the temperature distribution, but also on the life expectancy and ageing rate of those actives, which are the two factors that define a transformer’s maximum admissible load. Finally, some aspects about the maintenance policies that are currently applied to ester-filled transformers are revised; this is one of the aspects that has been less studied, and in the next few years, important advances will probably be seen on the topic.

2. Field of Application of Ester-Filled Transformers and Standardization

The use of ester fluids as transformer insulation was proposed in the 1990s; the first ester-filled distribution and power transformers were installed in 1996 and 2003, respectively [4]. Since then, the use of esters has increased sharply, although the number of units operating around the world is still limited at present.

In [5], a study performed by one of the leading suppliers of natural esters for electrotechnical purposes is presented, which analyses the number of ester-filled transformers operating around the world, classifying them by their power and voltage levels. Table 1 summarizes the data provided in that survey, distinguishing between new units, which were initially designed to work with an ester as liquid insulation, and retro-filled units. Retro-filled units are transformers initially designed and operated with MO filling their tank and impregnating its solid insulation. The insulating fluid is replaced with an ester. As can be seen in Table 1, the number of ester-immersed transformers with high powers and voltages is still very low.

Table 1.

Number of transformers filled with ester fluids worldwide (2014). Data taken from [3].

The evolution of the standardization of ester-type fluids for application in power transformers has been a long process, as can be seen in Table 2. Two important international institutions have generated reference documents in this field. On the one hand, there are documents published by the International Electrotechnical Commission (IEC). On the other, there are documents generated by the Institute of Electrical and Electronics Engineers (IEEE) of the USA.

Table 2.

Evolution of standardization on ester-type fluids.

In 1992, the IEC published the first two standards on synthetic organic. The first one focused on the specifications that the unused synthetic organic esters [13] must meet, and the second one was the maintenance guide for transformers cooled with this fluid [14]. Information on properties, safety, storage and disposal, packaging, labeling, and sampling can be found in [13]. The description of tests for the characterization of some aspects of these fluids is also included. Next, [14] detailed the guidelines for maintaining transformers up to 35 kV that are cooled with synthetic organic esters. This standard does not refer to retro-filled transformers that were initially designed for another fluid. The specifications for unused synthetic organic esters were updated in 2010 [15], focusing on their use as dielectric fluids.

The standardization of fluids of natural origin (rapeseed, soybean, sunflower, etc.) as liquid insulation for distribution and power transformers begins later with the publication by the IEEE of [16] in 2008. This document provides useful information for manufacturers and service companies that intend to use these fluids to assess the products’ characteristics on the market. In addition, aspects of handling, maintenance, and environmental management procedures are discussed. This standard provides recommendations for both new machines and machines retro-filled with natural ester after having been in operation with MO. Recently, the IEEE has updated this document by publishing a new version [18].

In 2013, the IEC published its first standard dedicated to NE [19]. It contains specifications and recommended test methods to determine the suitability of a given ester for use in power transformers and similar oil-impregnated electrical equipment.

In the same year, the IEEE published a standard [20] that offers support for the diagnosis of transformers immersed in dielectric fluids. The document considers four types of fluids, one of them being NE. They provide acceptable values for new and in-service NE properties by voltage class: acid number, dielectric breakdown, interfacial tension, dissipation factor, and water. One year later, the IEEE standardization progress on esters continued, and they published a new document [21]. Guidelines are given to interpret the generation of gases in ester-type fluids in operation transformers or other electrical equipment. The document initially focuses on explaining the mechanism of gas formation in transformers containing natural or synthetic esters. Later, it gives guidelines for the correct interpretation of the gases found in these liquids when they have been in transformers in service. Finally, recommended actions related to the results obtained after interpreting the gas content of an ester sample are offered. There is still no IEC standard that addresses the interpretation of gases present in esters that cool transformers.

The latest standard published to date on NE focuses on providing guidelines for the maintenance and use of these liquids in sealed transformers and other electrical equipment [22]. This document represents a second step in the standardization of NE by the IEC, which began with the publication of IEC 62770 [19] for liquids that have not yet been used. IEC 62975 [22] focuses on giving guidelines for the correct diagnosis of the state of NE that are in operation in electrical equipment. From a thorough diagnosis, the most appropriate maintenance strategies for these assets can be implemented, in most cases transformers. Thus, this standard recommends tests and procedures for reconditioning and reclaiming the liquid when its condition is not optimal.

In 2019, the IEC published a new standard dedicated to new liquids manufactured from modified esters or mixtures of esters [23], considering that they would be used in transformers. Liquids within the scope of this document may be based on natural or synthetic bases or a mixture of both. Therefore, fluids that are not covered by either IEC 62770 [19] or IEC 61099 [15] are being considered. The range of the properties of fluids affected by this standard is extensive.

For this reason, the document proposed a classification of liquids according to kinematic viscosity ranges. This characteristic is of great importance in the performance of transformers since it affects the cooling capacity of the fluids. Some commercial fluids of this type have a much lower kinematic viscosity than pure natural or synthetic esters.

Table 3 compares the IEEE [19,21] and IEC [22] maintenance guidelines for transformers using natural esters. As can be seen, the classification that both standards establish according to the voltage level is not the same. Despite this, both documents pose quite similar limits. Although both documents recommend minimum values for dielectric strength, the comparison is difficult as they use different test procedures (ASTM D1816, IEC 60156). Something similar happens in the case of the dissipation factor (ASTM D924, IEC 60247). IEC 62975 [22] presents detailed recommendations for action according to the results obtained in the tests of all the properties. This standard also considers the oxidation inhibitor additive content.

Table 3.

Recommended limits for in-service natural esters in transformers [18,20,22].

Regarding the water content of NE, the IEC standard presents limits that are much more restrictive than those published in the IEEE standards, reducing these by at least half. The references offered for acidity, fire point, and kinematic viscosity at 40 °C are the same in the documents of both standardization institutions. The interfacial tension values presented in the table have been obtained from Annex B of IEEE Std C57.147-2018 [18], which refers to the values of service-aged NE liquids for triggering a prompt additional investigation. For this reason, they are more restrictive limits than the value set by the IEC. Regarding the dissipation factor, the value that can be observed in the table was obtained from IEEE Std C57.152-2013 [20], since IEEE Std C57.147-2018 [18] does not offer a recommended value because it considers that at the time of publishing this document not sufficient information was available.

3. Design and Manufacturing Process

3.1. Properties of Ester Fluids

Although numerous studies have been published about ester fluids’ thermal and dielectric properties [4,10], the determination of them is still an active research field.

Table 4 shows some physic-chemical parameters specified by the dielectric fluids’ manufacturers of four commercial NE and one SE compared with the properties of MO. As can be seen, there are essential significant differences between the properties of NE and SE and those of MO. On the positive side, it must be remarked that the flash point of esters doubles that of the mineral oils. Another key point is that the moisture content of NE is much higher than the moisture contents admissible for mineral oils; as these fluids are more hydrophilic, they may contain higher values of moisture and still keep fair dielectric properties. On the negative side, it can be highlighted that the viscosity of the esters is up to four times higher than the viscosity of MO. This aspect has a negative impact on the cooling system of the transformer. Additionally, the values of the pour point specified by the ester manufacturers (i.e., the temperature below which the liquids lose their flow characteristics) almost halve the value indicated for MO. This implies that the use of ester fluids might be more problematic in locations with very cold weather.

Table 4.

Main properties of different commercial natural and synthetic ester fluids and mineral oil.

An aspect that has not been sufficiently studied is the difference between natural ester fluids of different origins. It must be considered that within the term “natural ester,” fluids with other bases and various properties are included (i.e., soybean oil, sunflower oil, rapeseed oil, soya oil, or hazelnut oil). The four liquids reported in Table 4 are produced from different vegetable seeds, so they constitute an excellent set to compare the properties of other esters. Although the values reported by the manufacturers for some parameters like density, viscosity, or flash point are similar, there are higher differences for others, such as the breakdown voltages, the moisture content, or the pour point of the fluids. The presence of additives to limit the oxidation is another factor that varies between different commercial fluids.

3.2. Influence of the Esters’ Properties on the Dielectric Design of the Transformer

Regarding the dielectric design of transformers, two main differences between MO and ester fluids must be taken into account [22,24]:

- The relative permittivity of esters is typically higher than the permittivity of MO. This is also true for solid insulations impregnated with esters. The variations in the permittivity will give rise to differences in the distribution of electric fields within the oil-paper insulation in ester-based transformers. This could be beneficial for ester-based equipment because the field distribution will be more homogeneous, and thus the stress withstood by the dielectric fluid would be softened. On the other hand, the similarity of the permittivity of the esters and solid insulation might increase the probability of creep breakdown. Some works have been presented to better understand creepage under a variety of conditions [25].

- The dielectric strength of esters is, under certain conditions, lower than the dielectric strength of MO. This is particularly important for the case of high volumes of oil subjected to inhomogeneous fields; under these conditions, ester-based transformers are more likely to fail than those filled with MO. Streamer formation and the partial discharges in gas bubbles present in ester fluids have received attention. Analyzing the streamer behavior is crucial because it allows us to understand the pre-breakdown phenomena in liquid dielectrics. The streamer behavior of esters and MO is qualitatively similar, but the streamer propagation process is different for both cases [26], particularly for long gaps subjected to overvoltages of impulse nature ester liquids which are more susceptible to develop fast and high-energy discharges [24].

The balance between the two previous facts must be evaluated for each transformer. Still, the dielectric design of the transformer might need some adjustments if esters are used as liquid insulation. Some authors have carried out experimental work to compare the breakdown voltages of esters and MO for homogeneous and inhomogeneous fields and with different voltage waveforms concluding that, although the pre-breakdown and breakdown behavior of the different liquids might differ, since these are dependent on the chemical composition of the insulation, the performance of esters is generally similar to that of MO under quasi-uniform fields [1,24]. On the other hand, it has been observed that streamer propagation is faster in esters, which might be a weakness in large oil gaps [24,27].

A few works have been published discussing the dielectric design of ester-based transformers [28]. More work is necessary to increase the confidence in ester-filled transformers of high rated powers, as the oil volumes are more significant; therefore, the streamer propagation of those volumes of ester liquids can compromise the dielectric design of the transformers.

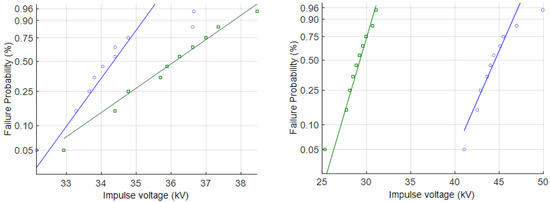

A comparison of the impulse (1.2/50 μs) breakdown voltage of an NE and MO has been carried out by the authors of this work. Both fluids were dried and degasified before the measurement. The electrode configuration was needle-sphere, and the electrode distances were 10 mm for positive impulse and 3 mm for negative impulse. Figure 1 shows the obtained results fitted to a Weibull distribution. As can be seen, the NE behaves slightly better under positive impulse, although the performance is less satisfactory than that of MO for negative impulse. It must be noted that the positive impulse poses a higher risk to the transformer integrity, as the breakdown voltage values are lower.

Figure 1.

Positive (left) and negative (right) impulse breakdown voltage of a natural ester (green) and mineral oil (blue).

3.3. Influence of the Esters’ Properties on the Thermal Design of the Transformer

A suitable thermal design is critical in the power transformer manufacturing process since it is directly related to the aging rate of insulation systems and, consequently, to their useful life. Thus, the correct thermal design will result in efficient use of raw materials, an optimized thermal class, and a more competitive transformer price.

Many thermal designs have been based on extrapolation from known methods. However, the progressive increase in the size of these machines represents a significant technological challenge. This difficulty is being overcome thanks to supercomputers with great computational capacity and the use of powerful software tools for thermal modelling. In addition, mathematical models are being developed that accurately consider the loss distribution in each refrigeration system. The modelling validation is based on measurement with fiber optic sensors of the temperature at the estimated location of hot spots [29].

The use of esters as a cooling fluid in transformers also increases the difficulty of determining the position and temperature of hot spots in windings. In this case, the thermal models must have sufficient information on the variation of specific temperature properties of the fluid. The main thermal properties of different biodegradable liquids have been compared with those of mineral oil by the paper’s authors in [30]. Table 5 summarizes some of the obtained results.

Table 5.

Properties of the fluids [30]. The complete study is reported in [30]. Reprint with permission [30], Copyright 2019, IEEE.

As explained before, the higher viscosity of esters relative to MO is one of the main concerns when carrying out thermal design. High viscosity reduces the ability to transfer heat from the active parts of the transformer to the outside environment and increases the temperature in hot spots. For this reason, it is being proposed that machines with this type of fluids work at high loads to reduce their viscosity and improve the performance of the refrigeration circuit [6].

Another issue that has aroused greater interest is the modelling of the thermal properties of esters at negative ambient temperatures. In these situations, it has been observed that viscosity has a more significant influence compared to the rest of the properties. Undoubtedly, knowing the behavior of the esters at these temperatures is essential if one wants to energize a transformer, since esters begin to gel at temperatures below their pour point (the lowest temperature at which esters could flow) [31].

3.4. Impregnation Process

The use of ester fluids as a transformer’s liquid insulation introduces some challenges related to the impregnation of the solid insulation with oil. During the transformer manufacturing process, the solid insulation must be adequately dried and subsequently impregnated with the dielectric liquid. The impregnation of the solid insulation with dielectric oil is carried out to eliminate the air that might remain inside the solid insulation. The presence of air weakens the insulation level and favors the appearance of partial discharges that degrade the insulation. By removing most of the gas from the transformer and the oil, the hazard of the tiny bubbles of gas is greatly reduced.

The impregnation process involves the phenomenon of pulling up the liquid by capillarity forces and depends on properties such as the viscosity of the fluid and the number and diameter of the pores in the pressboard [32].

Due to their higher viscosity, natural and synthetic esters might require a much longer time to impregnate the cellulosic materials used in insulation systems of power transformers [33]. As an example, [32] points out that a pressboard sample at 100 °C required approximately required time to be impregnated increases by 50% to be impregnated with synthetic esters than with MO. Very few studies have examined the impregnation processes in different solid components of the transformer’s insulation system, even though it is critical to obtain a suitable insulation system.

In 1984, researchers from Toshiba Corporation studied the impregnation of transformer boards with mineral oil, carrying out a theoretical study of the equations that govern the phenomenon [34]. These authors included capillarity as a variable that influences the impregnation process. Other researchers have carried out studies of board impregnation with mineral oil, analyzing the effect of temperature on impregnation time or modeling and validating the impregnation process through the measure of breakdown voltage [34,35].

These authors compared the degree of impregnation in mineral oil, a natural ester, and a synthetic ester, finding that the required time to get an adequate impregnation is a function of the viscosity and capillary effect of oil inside cellulose material. It was also found that high temperature can help overcome the higher dynamic viscosity of vegetable insulating oil than mineral oil [34,35,36]. Additionally, it was discovered that the time duration of impregnation significantly affects the dielectric properties of the natural ester impregnated pressboard, such as the capacitance and dielectric dissipation factor [35,36].

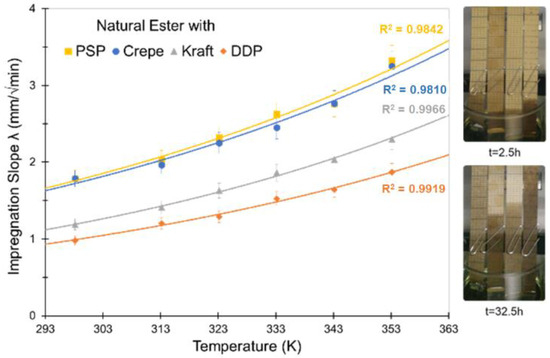

In a recent work [37], the authors of this paper analyzed the impregnation process of a natural ester in different kinds of paper (Figure 2).

Figure 2.

Impregnation slope of a natural ester in different kinds of paper [37]. The complete study is reported in [37]. Reprint with permission [37], Copyright 2019, IEEE.

Four different cellulose-based insulation materials were used in the experiments: crepe, diamond dotted paper (DDP), Kraft paper, and pressboard (PSP 3055), and three different fluids: MO, NE, and SE. The impregnation was carried out in a vacuum oven at 5 mbar and different temperatures to determine its effect, given that both viscosity and surface tension are temperature dependent. For these tests, the papers were cut into 1.5 cm-wide strips and held vertically, with the bottoms immersed in the oil samples. The capillary action occurs when the cohesive intermolecular forces of the liquid are smaller than the interfacial tension between the liquid and surrounding solid surfaces. This physical principle helps us compare the impregnation speed in the previously listed materials. Figure 2 represents the impregnation slope of a natural ester in the different kinds of papers considered. These models allow the prediction the impregnation slope associated with any of these materials for a given temperature. One practical application would be to approximate the temperature at which the esters offer similar impregnation performance to that of mineral oil at room temperature.

4. Operation of Ester-Filled Transformers

The maximum admissible load of a transformer is related to the temperature distribution in the transformer for a certain loading profile and the ageing rate of the insulation under specific working conditions. Using an NE or an SE to fill the transformer tank may impact both of these factors. As was discussed in a previous section, esters have a higher viscosity than mineral oils, which implies that their cooling capacity is lower than that of MO. However, several authors have suggested that the ageing rate of ester-impregnated cellulose insulation is significantly lower than the rate of MO-impregnated insulation under similar operating conditions.

In the case of MO-filled transformers, loading guides [38] are available, which establish the load factors that are admissible for long-term and emergency overloads. For ester-filled transformers, no loading guide is available at this time. Still, it seems clear that specific loading criteria must be established to manage these loading profiles adequately. More work is necessary to develop thermal and ageing models to develop reliable and optimized exploitation programs for ester-filled equipment.

4.1. Temperature Distribution in Ester-Filled Transformers

In order to estimate the maximum overload of a power transformer, it is critical to assess the hot-spot temperature (hottest temperature of winding conductors in contact with solid insulation or insulating liquid) inside power transformers, which is influenced by alternative fluids. The estimation of this temperature is one of the most critical parameters to estimate the remaining lifetime of solid insulation.

Some papers can be found in the literature where authors numerically predict hot spot temperature and temperature distributions in ester-immersed transformers. For instance, in [39], the temperatures measured with fiber-optic sensors are compared using NE and a MO as the coolant in a 50 MVA commercial transformer. In [40], a 2D computational fluid dynamics (CFD) model is used to obtain temperature and velocity profiles of some alternative liquids used in a distribution transformer of 2.3 MVA and a 16.5 MVA power transformer. In [41], a 3D CFD simulation of an ONAN distribution transformer is carried out, comparing an NE, an SE, a high-kinematic-viscosity silicone oil, and a low-kinematic-viscosity silicone oil with MO. These works conclude that alternative liquids produce higher temperatures in transformer windings designed for MO. In [30], a 2D CFD simulation of two NE in the low voltage winding of a power transformer with zigzag cooling was performed, establishing a comparison of thermal capacity with MO.

The numerical models used in CFD studies are based on combining the equations that govern fluid dynamics and heat transfer. In the case of fluid dynamics, the Navier-Stokes equations are used, which are based on the principles of conservation of mass, momentum, and energy:

where ρ is the fluid density, u is the velocity field, p is the pressure field, μ is the fluid viscosity, g is the gravity vector, β is the thermal expansion coefficient, cp is the specific heat of the fluid, k is the thermal conductivity of the liquid and T is the temperature field.

∇u = 0

ρ·∂u/∂t + ρ·(u·∇)u = − ∇p + μ(∇^2 u) + ρref·g·β·(T − Tref)

ρ·cp·∂T/∂t + ρ·cp·∇·(u T) = k·∇^2 T

On the other hand, it is necessary to consider the equation that characterizes heat conduction in solid materials, qs, representing the heat source due to the losses generated in the windings of transformers.

ρ cp ∂T/∂t = k·∇^2 T + qs

For these models to reach a solution, it is necessary to apply boundary conditions to problem-solving. In this sense, it is customary to assume a mass flow and a temperature at the fluid inlet in the winding, while the fluid pressure at the winding outlet is considered to be zero. In addition, the cylinder that surrounds the winding is considered to have low heat conductivity, which allows its surface to be considered adiabatic and non-slip.

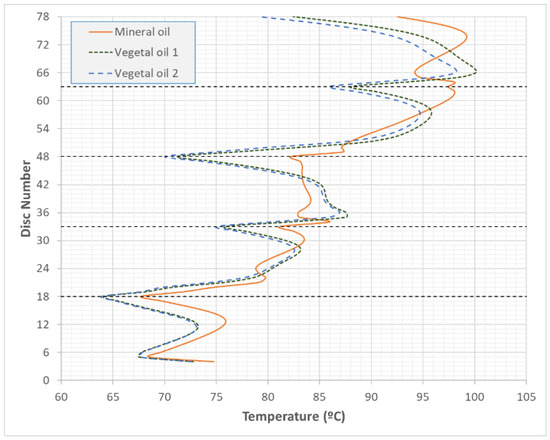

Figure 3 shows the average temperature of each disc in the low voltage winding of a 66 MVA 225/26.4 kV ONAN/ONAF transmission transformer. The whole winding consists of 78 discs divided in five passes separated by oil washers with 15 discs in each one with the exception the first section which has an additional inlet section with three discs. The winding geometry is described in [30]. The analysis was performed for three liquids, one mineral oil and two vegetal esters. In the figure it is observed that both vegetal liquids show a similar behavior to each other and different from mineral oil, due to their higher density and viscosity.

Figure 3.

Average temperature of discs with 5 pass geometry [30]. The complete study is reported in [30]. Reprint with permission [30], Copyright 2019, IEEE.

4.2. Ageing Process of Ester-Impregnated Solid Insulation Using Oil Analysis

The temperature reached by the solid insulation of a transformer under certain operating conditions is a key factor to evaluating whether a specific overload is admissible or not. However, it is even more important to assess the loss of life associated with these operating conditions.

Two main factors determine the expected life of transformer cellulose insulation: its operation temperature and its moisture content. For MO-filled transformers, there are well-established rules that allow the transformer owner to calculate the loss of life associated with specific operating conditions. In the case of esters, some works suggest that the expectancy is higher for similar values of both parameters.

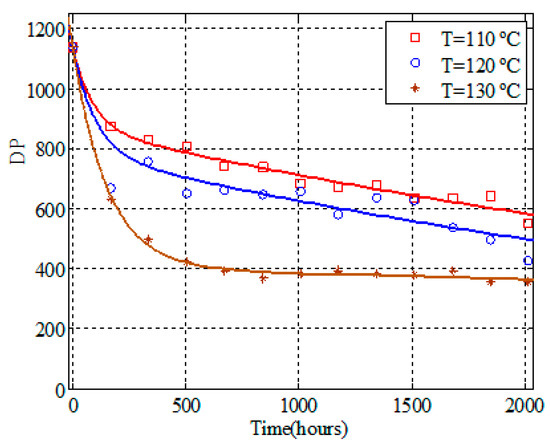

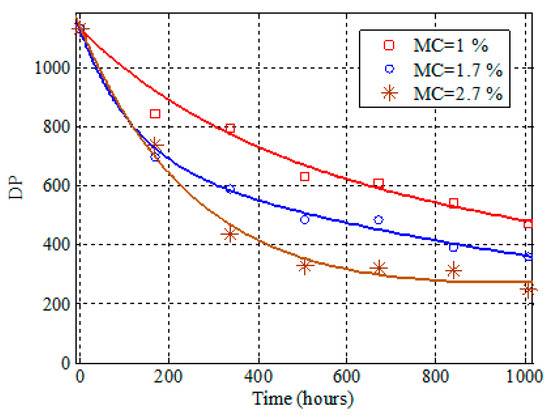

The authors of this work carried out a comprehensive experimental study [7] to analyze the impact of the temperature and moisture content of paper on the ageing rate of transformers insulated with NE. Figure 4 shows the results of accelerated ageing tests performed on NE paper insulation at different temperatures. As is typical for MO-based insulation, the ageing rate depends significantly on temperature.

Figure 4.

Ageing process of natural-ester immersed paper as a function of temperature. The complete study is reported in [7]. Reprint with permission [7], Copyright 2017, IEEE.

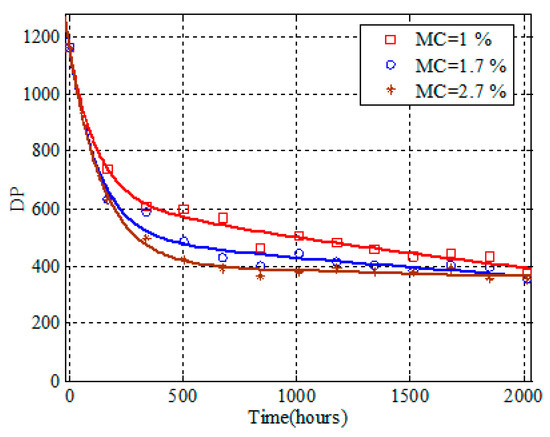

A significant difference was observed in the impact of moisture on the ageing rate of MO and NE-impregnated insulation. Figure 5 and Figure 6 compare the ageing rate of several cellulose samples prepared with different moisture contents and subjected to accelerated ageing at 130 °C while immersed in MO (Figure 5) and NE (Figure 6). As it can be seen, the initial moisture of the samples has a certain impact on the ageing process for all of the specimens, but the effect is much more important for the MO-impregnated samples. It can be seen that the ageing rate of MO is higher than of NE for all the moisture levels, but especially for the samples with higher moisture contents.

Figure 5.

Ageing process at a temperature of 130 °C of MO-immersed paper samples as a function of moisture. Fully described in [7]. Reprint with permission, Copyright 2017, IEEE.

Figure 6.

Ageing process at a temperature of 130 °C of NE-immersed paper samples for different initial moisture contents. Fully described in [7]. Reprint with permission [7], Copyright 2017, IEEE.

The observed behavior is justified because the chemical reactions involved in the ageing processes of both systems are different. The main reactions in MO-paper systems are the oxidation of the oil and the cleavage of the cellulose chains by hydrolysis. These reactions do not involve a global consumption of water. In the case of the NE-paper systems, the hydrolysis of ester and the transesterification of the paper have a key role in the ageing process; both reactions involve the consumption of several molecules of water, and the consumption of water involved in both reactions provokes a reduction of the water content of the cellulose during the experiment and a reduction of the ageing rate.

The ageing rate of both types of samples was adjusted to a kinetic model which estimates the life expectancy of the MO-paper and NE-paper specimens, concluding that, although the life expectancies estimated for samples with low moisture contents were similar for samples with both impregnating fluids, the loss of life associated to MO-impregnated samples with high and medium levels of moisture was much higher under similar operating temperatures. This could be a key factor for the load management of transformers operating for a long time with MO (which typically have medium and high moisture contents) and are retro-filled with an ester fluid.

5. Maintenance of Ester Filled Transformers

Dielectric liquids, including NE and SE, are characterized by their different electrical, physical, and chemical properties, all of which are interrelated. As esters, especially natural ones, have a shorter history of use in transformers than MO, there is still significant uncertainty about the ranges of variation or the limits of the physic-chemical parameters to determine the oil and the condition of the transformer insulation system.

As explained before, IEEE and IEC standards provide some specifications and serve as a guide to determine the different properties of esters and reference limit values. In the case of NE, IEEE C57.147 [18] recommends measuring the AC breakdown voltage, dissipation factor, water content, kinematic viscosity, and optionally the fire point of the fluid as key parameters for transformers’ maintenance. However, regarding those parameters, the suggested limits are conditioned by the manufacturers’ recommendations.

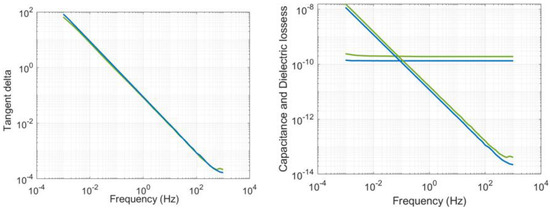

As an example of esters’ performance, Figure 7 shows the results of frequency domain spectroscopy measurements (FDS) carried out by the authors of this paper on samples of MO and an NE. The figure on the left shows the variation of the dissipation factor (tangent delta) with frequency, whereas the figure on the right shows the two factors that influence the dissipation factor: the capacitance and the dielectric losses. As can be seen both, the capacitance and the dielectric losses of the NE are higher than those of the MO. Nevertheless, the tangent delta of the two liquids is almost identical (note that tangent delta is the ratio between dielectric losses and the capacitance of the liquid).

Figure 7.

Tangent delta and complex capacitance in the frequency domain of a natural ester (green) and a mineral oil (blue).

Oil contamination and oxidation increase the viscosity of esters. Higher viscosity is generally a product of the interaction of esters with atmospheric air. On the other hand, the oil density and pour point is less related to the degradation and may not be helpful for the ester aging assessment purposes [42]. The oxidation stability can potentially be another parameter to evaluate the performance of the ester; however, experience shows that even using standardized methods, there is no agreement between the laboratory evaluation and the field performance of these fluids.

Regarding the maintenance of the ester itself, two processes may be used to recover its properties: oil reconditioning and reclaiming. Reconditioning refers to removing solid materials and water (free and dissolved) using mechanical techniques, filtering, and applying vacuum. On the other hand, reclaiming consists of eliminating contaminants, acids, and oxidized matter through chemical and adsorbent mean like Fuller’s earth.

Another important aspect is related to the detection of incipient faults through the dissolved gas analysis (DGA) method. Gas formation is caused by thermal and electrical stresses within an operating transformer as the gases are by-products of the thermal decomposition of the liquid and the solid insulation. DGA in MO-filled transformers has been used for years and, in addition to widely accepted international standards [43], research works that propose new assessment approaches and practical cases are often published [44,45] and contribute to improving the reliability of the technique. In the case of NE, the available information is still scarce, and it is expectable that more experience will be gained in the coming years. IEEE Std C57.155 [21] can serve as a guide to evaluate DGA data obtained from NE- and SE-filled transformers. The recommendations of IEEE Std C57.155 [21] “are based on a limited amount of in-service esters’ DGA results and several laboratory-based experimental data sets.” The guide clearly explains that experimental laboratory data does not replicate in-service conditions and fault conditions in an operating transformer. The proposed approach for the interpretation of DGA is similar for MO and ester liquids. However, as there are differences in the production rate, the proportions between the different gases, and the solubility of these gases in MO and esters, the recommended reference values and ratios differ fi11,21,46]. Modifications of Duval’s Triangle for different alternative fluids have been proposed, since the application of the conventional version of the method leads to unreliable diagnosis [1]. Recent experimental works [1,11,32] have suggested that the gas generation rate in esters is significantly high and have suggested propane and propylene might be useful markers for the DGA in ester-filled transformers. Another aspect to take into account is that there are a wide variety of natural ester sources, and the performance of these esters can be different. Therefore, the interpretation of DGA is a field that requires more research.

Finally, in terms of the possibility of using chemical markers, as furanic compounds, to estimate the ageing condition of solid insulation in ester-based systems, some studies suggest that since the ageing process of paper is different in the presence of esters, the interpretation of these types of markers should be revisited [27,46].

6. Conclusions

The use of biodegradable liquids as liquid insulation in transformers has become more common in recent years. Some properties of these liquids are better than those of MO, such as their fire point and biodegradability. Other aspects hinder their spread.

In this paper, a revision of the main aspects of ester fluids and their use in transformers presents some experimental data to compare their performance with that of MO. The main conclusions and future scope of the study are highlighted next:

- -

- The use of esters in large transformers is still very marginal, although an increasing number of experiences have been reported in recent years. The publication of international standards to assess the operation and maintenance of these actives will be important for the spread of the technology.

- -

- The physic-chemical properties of esters are diverse and differ from those of MO. This has an impact on the thermal and dielectric design of the equipment and also on the manufacturing process of the transformers that use those liquids as insulation.

- -

- No loading guide for ester-filled transformers has been published yet. Two main factors impact the maximum load that may be safely applied to an ester-filled transformer: the hottest spot temperature and the ageing rate of the insulation. Both aspects change in ester-filled transformers in opposite senses: while higher hottest spot temperatures are expected in ester-filled transformers, a lower ageing rate has been suggested for the solid insulation. More research is needed to optimize the load capability of the equipment.

- -

- Maintenance policies must be revisited. The chemical reactions that take place in ester-paper insulation differ from those of MO–paper insulation, thus the reference values for the markers used in predictive maintenance might change or new meaningful markers may be identified in the future that allow a better assessment of the transformer condition.

Author Contributions

Conceptualization, B.G., A.O., C.R. and D.F.G.; investigation, B.G., A.O., C.R., D.F.G. and A.M.; data curation, B.G., A.O., C.R. and D.F.G.; writing—original draft preparation, B.G., A.O., C.R., D.F.G. and A.M.; writing—review and editing, B.G., A.O., C.R., D.F.G. and A.M.; project administration, resources, B.G., A.O. and C.R.; funding acquisition, resources, B.G., A.O. and C.R. All authors have read and agreed to the published version of the manuscript.

Funding

Part of the work was performed during secondments and short visits between University of Valle, University Carlos III of Madrid and University of Cantabria executed in the framework of the BIOTRAFO project “Raising knowledge and developing technology for the design and deployment of high-performance power transformers immersed in biodegradable fluids”, H2020-MSCA-RISE-2018- 823969, 2019-21. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 823969. Also, we acknowledge the support of the Spanish Ministry of Science and Innovation by means of the National Research Project Asset management of biodegradable-fluid-based transformers (PID2019-107126RB-C21/AEI/10.13039/501100011033 and PID2019-107126RB-C22/AEI/ 10.13039/501100011033).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shen, Z.; Wang, F.; Wang, Z.; Li, J. A critical review of plant-based insulating fluids for transformer: 30-year development. Renew. Sustain. Energy Rev. 2021, 141, 110783. [Google Scholar] [CrossRef]

- Rao, U.M.; Fofana, I.; Jaya, T.; Rodriguez-Celis, E.M.; Jalbert, J.; Picher, P. Alternative dielectric fluids for transformer insulation system: Progress, challenges, and future prospects. IEEE Access 2019, 7, 184552–184571. [Google Scholar] [CrossRef]

- Tokunaga, J.; Nikaido, M.; Koide, H.; Hikosaka, T. Palm fatty acid ester as biodegradable dielectric fluid in transformers: A review. IEEE Electr. Insul. Mag. 2019, 35, 34–46. [Google Scholar] [CrossRef]

- Martin, R.; Athanassatou, H.; Duart, J.C.; Perrier, C.; Sitar, I.; Walker, J.; Claiborne, C.; Boche, T.; Cherry, D.; Darwin, A. Experiences in Service with New Insulating Liquids; E-Cigre: Paris, France, 2010. [Google Scholar]

- Rapp, K.J.; Luksich, J.; Sbravati, A. Application of natural ester insulating liquids in power transformers. In Proceedings of the My Transfo, Sao Paolo, Brazil, 18–19 November 2014. [Google Scholar]

- Vasconcellos, V.; Sbravati, A.; Zanetta, L.C.; Rapp, K.; Lombini, L.; Nazzari, S.; Scatiggio, F.; Valant, A. Increased loadability of transformers using natural ester and cellulosic materials as high temperature insulation systems. IEEE Electr. Insul. Mag. 2018, 34, 8–17. [Google Scholar] [CrossRef]

- Garcia, B.; Garcia, T.; Primo, V.; Burgos, J.C.; Urquiza, D. Studying the loss of life of natural-ester-filled transformer insulation: Impact of moisture on the aging rate of paper. IEEE Electr. Insul. Mag. 2017, 33, 15–23. [Google Scholar] [CrossRef]

- Malde, J.; Martin, R.; Prevost, T.; Greaves, B. Influence of pressure in sealed tube ageing test. In Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019. [Google Scholar]

- Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Thermally accelerated aging of insulation paper for transformers with different insulating liquids. Energies 2021, 14, 3036. [Google Scholar] [CrossRef]

- García, B.; Ortíz, A.; Renedo, C.; Burgos, J.C.; Gómez, D.G.; Rosa, D.P. Application of Biodegradable fluids as liquid insualtion for distribution and power transformers. In Proceedings of the IEEE International Conference of Environment and Electrical Engineering, Madrid, Spain, 9–12 June 2020; pp. 1–5. [Google Scholar]

- Przybylek, P.; Gielniak, J. Analysis of gas generated in mineral oil, synthetic ester, and natural ester as a consequence of thermal faults. IEEE Access 2019, 7, 65040–65051. [Google Scholar] [CrossRef]

- Loiselle, L.; Rao, U.M.; Fofana, I. Influence of aging on oil degradation and gassing tendency for mineral oil and synthetic ester under low energy discharge electrical faults. Energies 2020, 13, 595. [Google Scholar] [CrossRef]

- IEC 61099: 1992. Insulating Liquids—Specifications for Unused Synthetic Organic Esters for Electrical Purposes, 61099 1992; IEC: Geneva, Switzerland, 1992.

- IEC 61203: 1992, Synthetic Organic Esters for Electrical Purposes—Guide for Maintenance of Transformer Esters in Equipment; 612031992; IEC: Geneva, Switzerland, 1992; pp. 1–15.

- IEC 61099: 2010, Insulating Liquids—Specifications for Unused Synthetic Organic Esters for Electrical Purposes; 61099 2010; IEC: Geneva, Switzerland, 2010; pp. 1–28.

- IEEE Guide for Acceptance and Maintenance of Natural Ester Fluids in Transformers; IEEE Std C57.147-2008; IEC: Geneva, Switzerland, 2008; pp. 1–31.

- ASTM International. D6871—17 Standard Specification for Natural (Vegetable Oil) Ester Fluids Used in Electrical Apparatus; ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–4. [Google Scholar]

- IEEE Std C57. 147: Guide for Acceptance and Maintenance of Natural Ester Insulating Liquid in Transformers IEEE Power and Energy Society Sponsored by the Transformers Committee; IEEE Std C57.147; IEC: Geneva, Switzerland, 2018.

- IEC 62770: 2013, Fluids for Electrotechnical Applications—Unused Natural Esters for Transformers and Similar Electrical Equipment; IEC: Geneva, Switzerland, 2013; pp. 1–34.

- IEEE Std C57. 152: Guide for Diagnostic Field Testing of Fluid-Filled Power Transformers, Regulators, and Reactors; IEEE Std C57.152-2013; IEC: Geneva, Switzerland, 2013; pp. 1–121.

- IEEE Std C57.155: Guide for Interpretation of Gases Generated in Natural Ester and Synthetic Ester-Immersed Transformers IEEE Power and Energy Society, IEEE Std C57.155; IEC: Geneva, Switzerland, 2014.

- IEC 62975: 2021 Natural Esters—Guidelines for Maintenance and Use in Electrical Equipment; IEC 62975 2021; IEC: Geneva, Switzerland, 2021; pp. 1–73.

- IEC 63012:2019 Insulating Liquids—Unused Modified or Blended Esters for Electrotechnical Applications; 630122019; IEC: Geneva, Switzerland, 2019; pp. 1–41.

- Rao, U.M.; Fofana, I.; Beroual, A.; Rozga, P.; Pompili, M.; Calcara, L.; Rapp, K.J. A review on pre-breakdown phenomena in ester fluids: Prepared by the international study group of IEEE DEIS liquid dielectrics technical committee. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1546–1560. [Google Scholar] [CrossRef]

- Haegele, S.; Vahidi, F.; Tenbohlen, S.; Rapp, K.; Sbravati, A. Investigation of interfacial surface creep breakdown at oil-pressboard interfaces in natural ester liquid and mineral oil. In Proceedings of the 2017 IEEE 19th International Conference on Dielectric Liquids (ICDL), Manchester, UK, 25–29 June 2017; pp. 1–5. [Google Scholar]

- Eriksson, A.B.; Liu, R.; Tornkvist, C. Differences in streamer initiation and propagation in ester fluids and mineral oil. In Proceedings of the 2011 IEEE International Conference on Dielectric Liquids, Trondheim, Norway, 26–30 June 2011; pp. 1–4. [Google Scholar]

- Matharage, B.S.H.M.S.Y.; Liu, Q.; Wang, Z.; Wilson, G.; Krause, C. Aging assessment of synthetic ester impregnated thermally non-upgraded kraft paper through chemical markers in oil. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 507–515. [Google Scholar] [CrossRef]

- Lashbrook, M.; Gyore, A.; Martin, R.; Cselko, R.; Nemeth, B. Design considerations for the use of ester-based dielectric liquids in transmission equipment. In Proceedings of the 2017 IEEE 19th International Conference on Dielectric Liquids (ICDL), Manchester, UK, 25–29 June 2017; pp. 1–6. [Google Scholar]

- WG A2. 38, Transformer Thermal Modelling; e-Cigre: Paris, France, 2016.

- Santisteban, A.; Piquero, A.; Ortiz, F.; Delgado, F.; Ortiz, A. Thermal modelling of a power transformer disc type winding immersed in mineral and ester-based oils using network models and CFD. IEEE Access 2019, 7, 174651–174661. [Google Scholar] [CrossRef]

- Moore, S.P.; Wangard, W.; Rapp, K.J.; Woods, D.L.; Del Vecchio, R.M. Cold start of a 240-MVA generator step-up transformer filled with natural ester fluid. IEEE Trans. Power Deliv. 2015, 30, 256–263. [Google Scholar] [CrossRef]

- Rozga, P.; Beroual, A.; Przybylek, P.; Jaroszewski, M.; Strzelecki, K. A review on synthetic ester liquids for transformer applications. Energies 2020, 13, 6429. [Google Scholar] [CrossRef]

- Krause, C.; Goetz, W.; Heinrich, B. The impact of drying and oil impregnation conditions and of temperature cycles on the clamping force of power transformer windings. In Proceedings of the 2002 IEEE International Symposium on Electrical Insulation, Boston, MA, USA, 7–10 April 2003; pp. 350–353. [Google Scholar]

- Suzuki, T.; Takagi, M. Oil impregnation in transformer boards (2) theoretical analysis of changes in impregnation depth. IEEE Trans. Electr. Insul. 1984, EI-19, 344–349. [Google Scholar] [CrossRef]

- Lu, G.; Huang, Q.; Song, H.; Wu, P. Impregnation model and experimental investigation of vegetable insulating oil-paper insulation. In Proceedings of the 2014 ICHVE International Conference on High Voltage Engineering and Application, Poznan, Poland, 8–11 September 2014; pp. 1–4. [Google Scholar]

- Jariyanurat, K.; Maneerot, S.; Pattanadech, N.; Potivejkul, S. Electrical characteristics of natural ester impregnated pressboards under different periods of impregnation. In Proceedings of the 2016 International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 262–265. [Google Scholar]

- Sancibrian, O.; Vila, C.; Fernandez, I.; Olmo, C.; Ortiz, A. Analysis of the impregnation process of cellulosic materials by ester-based insulating liquids. In Proceedings of the 2019 6th International Advanced Research Workshop on Transformers (ARWtr), Cordoba, Spain, 6–9 October 2019; IEEE: New York, NY, USA, 2019; pp. 59–63. [Google Scholar] [CrossRef]

- IEC 60076-7:2018. In Power Transformers—Part 7: Loading Guide for Mineral-Oil-Immersed Power Transformers; IEC: Geneva, Switzerland, 60076-72018; 2018; pp. 1–89.

- Girgis, R.; Bernesjö, M.; Frimpong, G.K. Detailed performance of a 50 MVA transformer filled with a Natural Ester fluid versus Mineral oil. 43rd Int. Conf. Large High Volt. Electr. Syst. 2010, CIGRE 2010, 2010. [Google Scholar]

- Park, T.-W.; Han, S.H. Numerical analysis of local hot-spot temperatures in transformer windings by using alternative dielectric fluids. Electr. Eng. 2015, 97, 261–268. [Google Scholar] [CrossRef]

- Lecuna, R.; Delgado, F.; Ortiz, A.; Castro, P.; Fernández, A.O.; Renedo, C.J. Thermal-fluid characterization of alternative liquids of power transformers: A numerical approach. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2522–2529. [Google Scholar] [CrossRef][Green Version]

- Rao, U.M.; Fofana, I.; N’Cho, J.S. On some imperative IEEE standards for usage of natural ester liquids in transformers. IEEE Access 2020, 8, 145446–145456. [Google Scholar] [CrossRef]

- IEEE. Guide for the Interpretation of Gases Generated in Mineral Oil-Immersed Transformers; IEEE: New York, NY, USA, 2019; pp. 1–98. [Google Scholar]

- Zope, N.; Ali, S.I.; Padmanaban, S.; Bhaskar, M.S.; Mihet-Popa, L. Analysis of 132 kV/33 kV 15 MVA power transformer dissolved gas using transport-X Kelman Kit through Duval’s triangle and Roger’s ratio prediction. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018; pp. 1160–1164. [Google Scholar]

- Wang, M.-H. A novel extension method for transformer fault diagnosis. IEEE Trans. Power Deliv. 2003, 18, 164–169. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Yi, X.; Li, S.; Hinshaw, J.V. Gas generation in natural ester and mineral oil under partial discharge and sparking faults. IEEE Electr. Insul. Mag. 2013, 29, 62–70. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).