Experimental Investigations of the Ignitability of Several Coal Dust Qualities

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Method

3. Results and Discussion

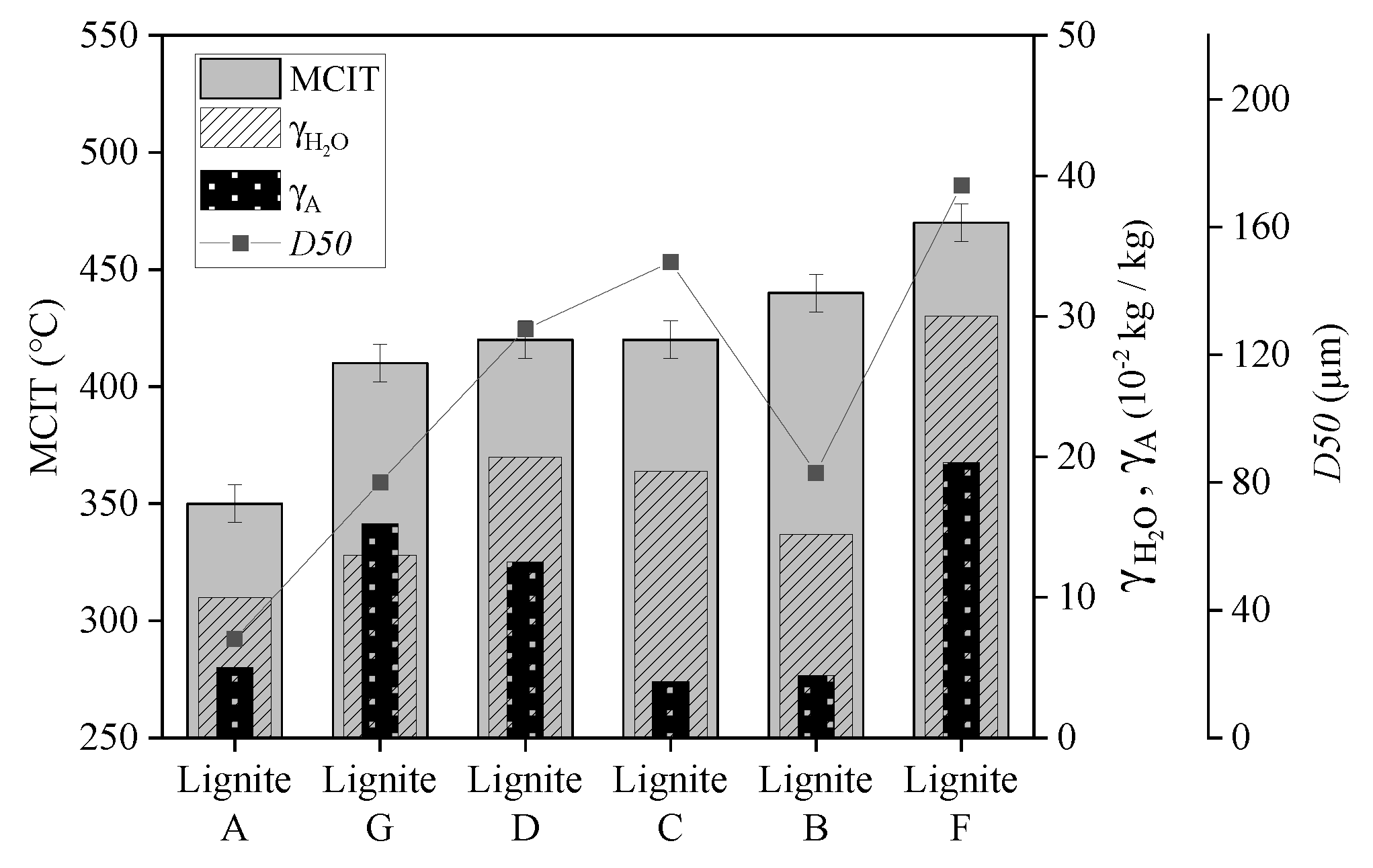

3.1. Minimum Cloud Ignition Temperature (MCIT)

3.2. Explosion Characteristics

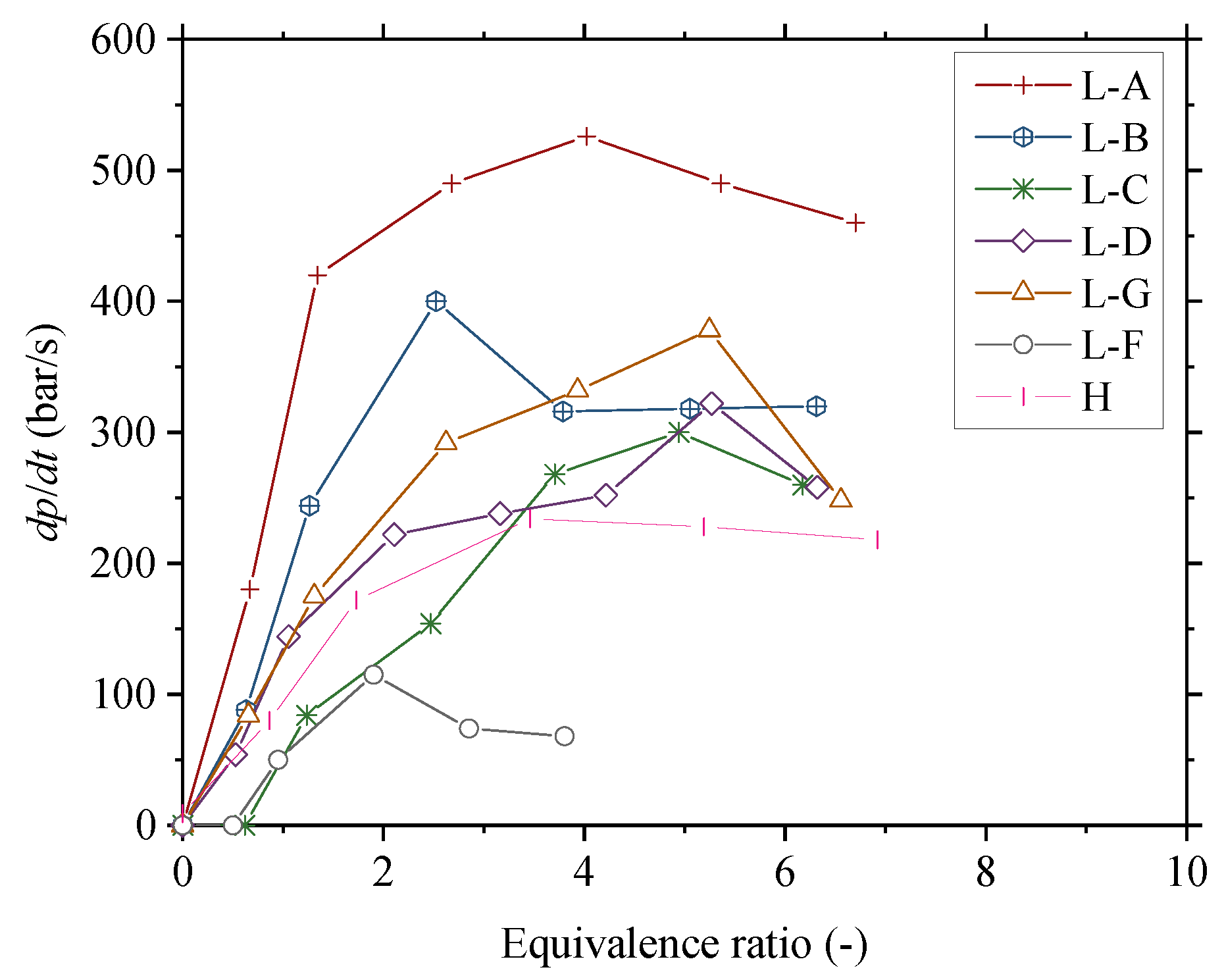

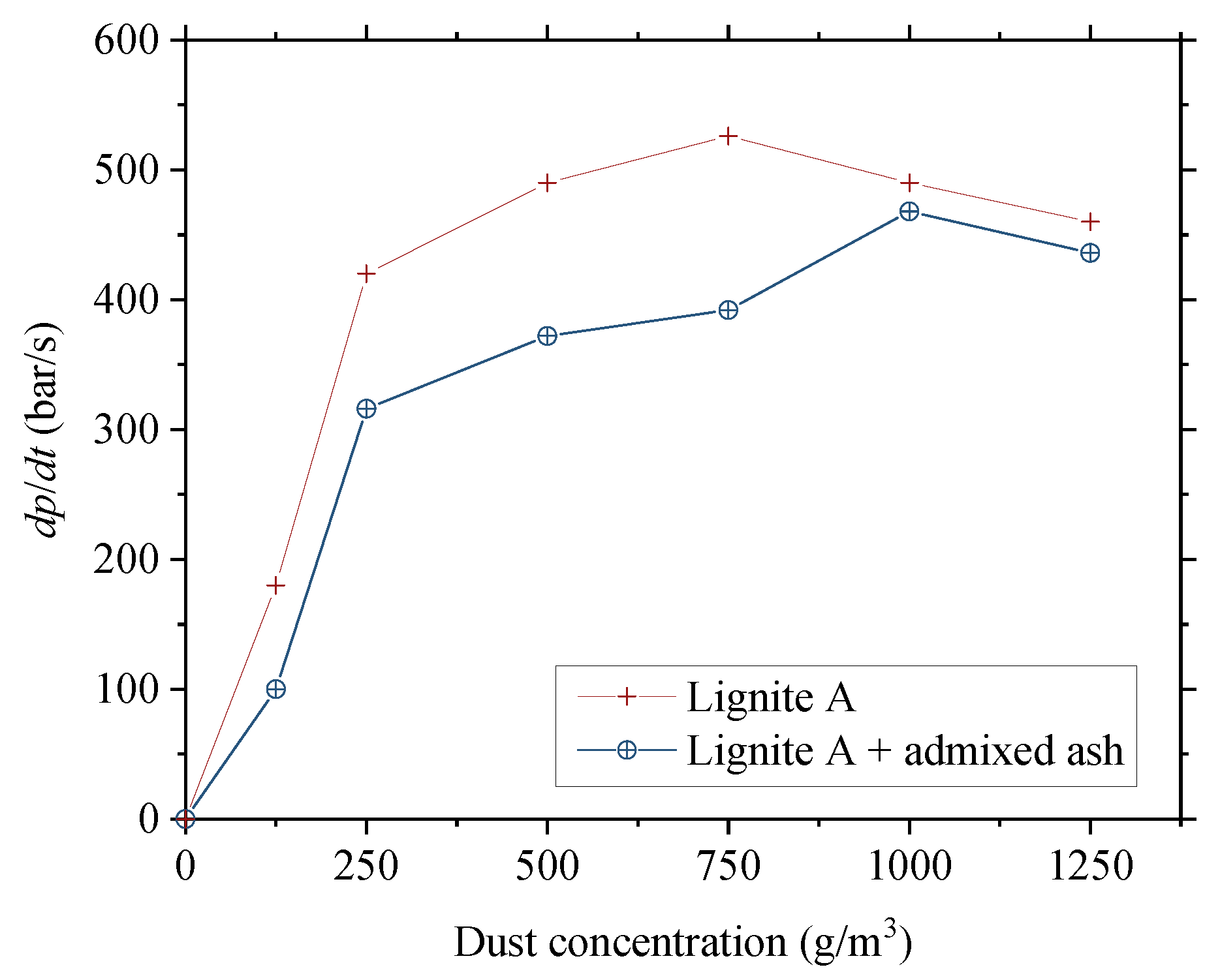

3.2.1. The Rate of Pressure Rise

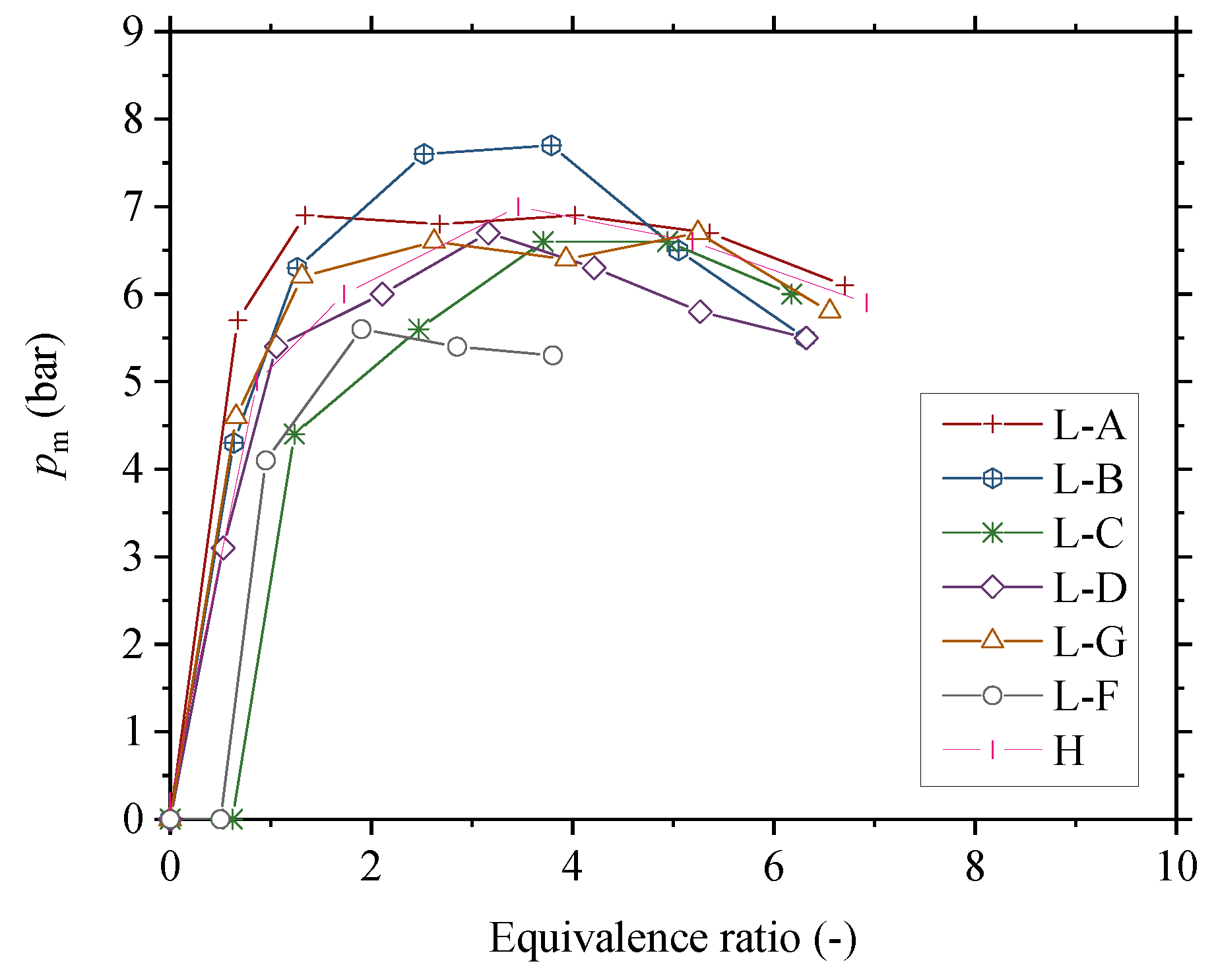

3.2.2. Maximum Explosion Pressure

3.2.3. The Deflagration Index (Kst-Value)

3.3. Modified Ignitability Characteristic Number (ZWZmod.)

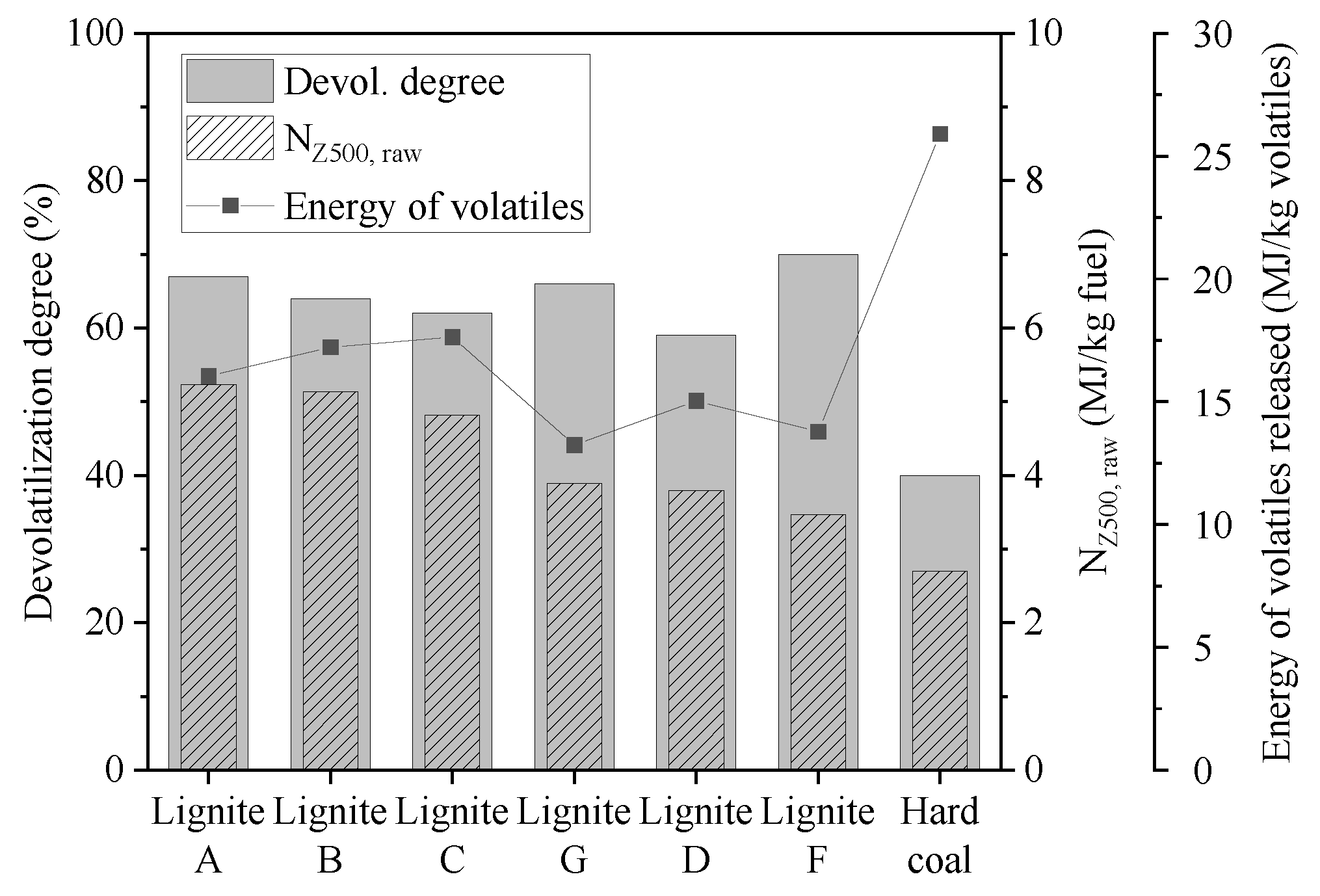

3.4. Comparison of Ignition Characteristic Parameters with the Ignition Performance at Pilot-Scale

4. Conclusions

- The MCIT for four lignite qualities with 10% to 20% moisture content, 5% to 15% ash content and median diameters of 83 to 150 changed in a narrow range of 410 to 440 and did not show a clear correlation to these properties within this range. A 10% increase in the ash content by combustion-derived admixed ash showed a 30 increase in the MCIT. This highlights the importance of the available surface area and different ignition inhibition mechanisms of intrinsic ash and admixed ash when different coal dust types are compared. As the median particle size is considerably reduced to 45 , a high share of fine particles compared to other lignite qualities showed a large reduction in the MCIT to 350 . An increase in the moisture content to 30% and in the ash content to 20% in Lignite F increased the MCIT to 470 .

- The maximum explosion pressure did not represent any clear interdependence to the physical and chemical properties of the investigated dust qualities and, therefore, was not found suitable to be used as an ignition characterization parameter.

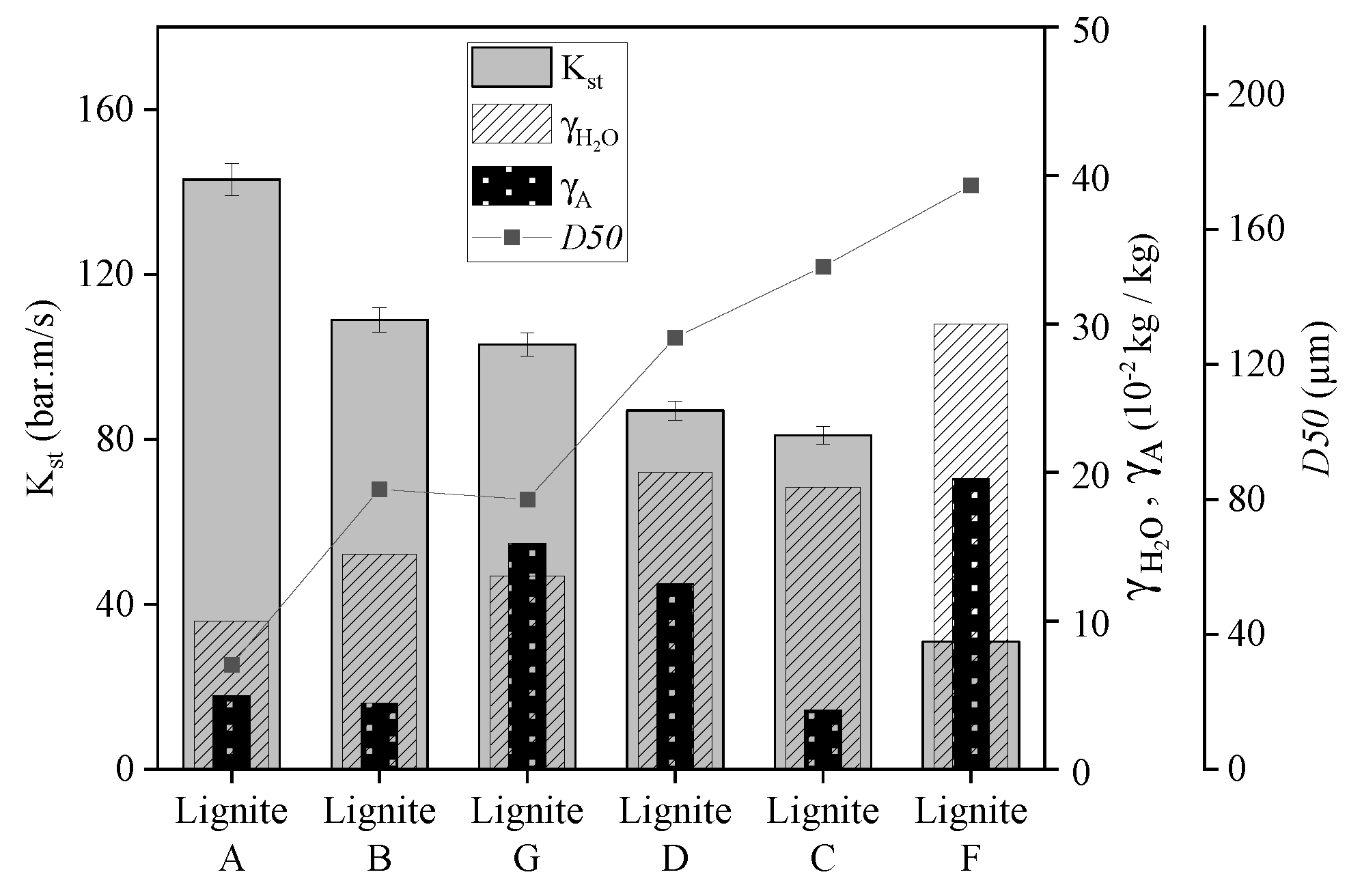

- The deflagration index showed a strong dependency on the moisture content and was more susceptible to changes as the dust properties varied. Lignite A and Lignite F had the largest and the smallest Kst-value among the tested dust qualities. Lignite B and Lignite G with 10% moisture had higher Kst-values than Lignite C and Lignite D with a moisture content of 20%. Similar to MCIT, the admixed ash reduced the Kst-value, but no clear correlation between the ash content of different lignite dusts and the Kst-value was found.

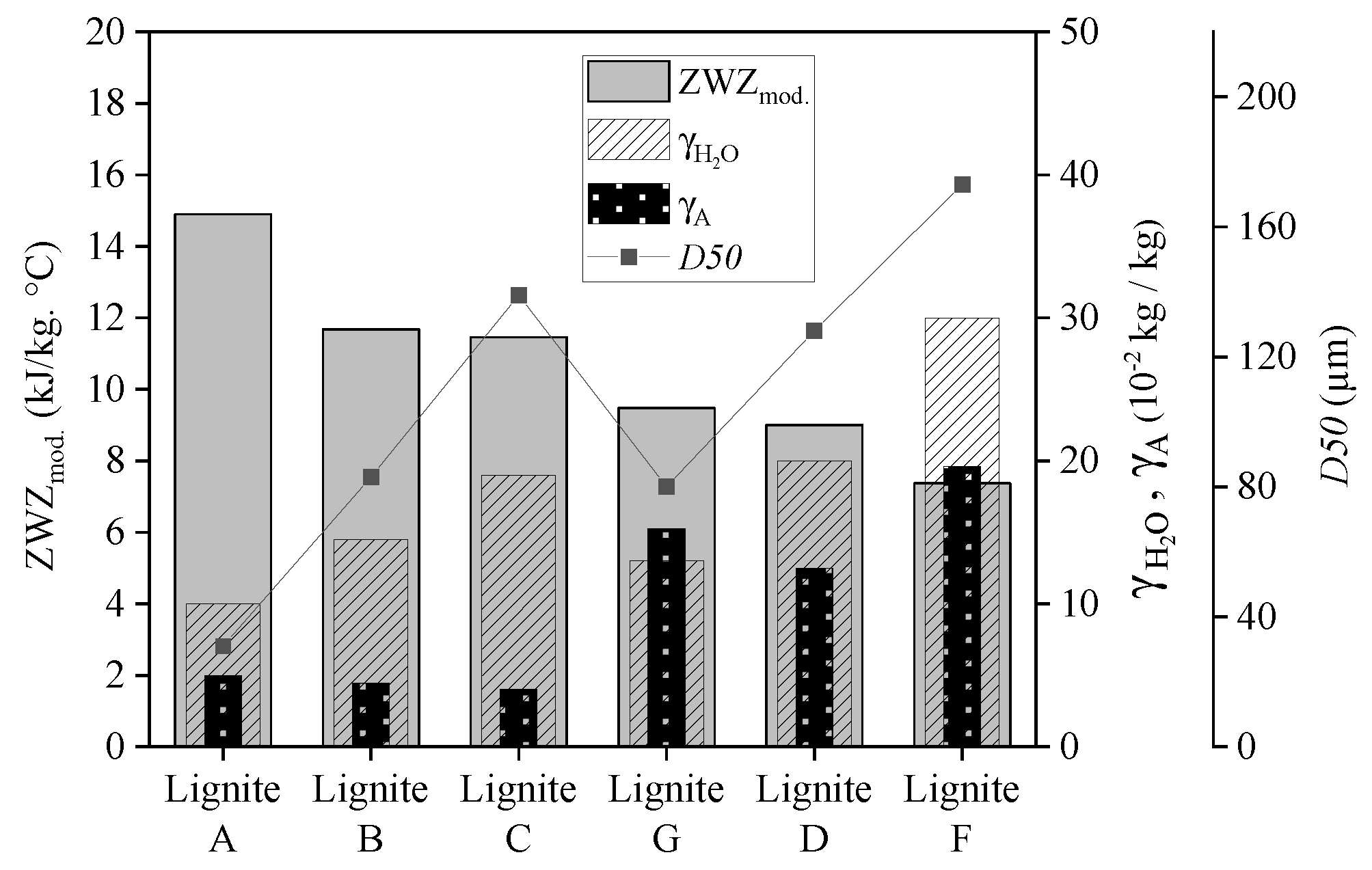

- The modified ignitability characteristic number correlated the released energy during the devolatilization to the ignition temperature. This parameter considers the devolatilization degree and the calorific value of the released volatiles. The results showed that Lignite A, Lignite B and Lignite C produce volatile materials with higher calorific values than Lignite D, Lignite G and Lignite F as well as correspondingly higher ZWZmod. values. The latter group has also higher ash content compared to the former one. The ignition potential is slightly reduced as the moisture is increased from Lignite A to Lignite C. However, ZWZmod. drops significantly as the median particle size increases from Lignite A to Lignite B and Lignite C, related to an increase in the ignition temperature. Overall, ZWZmod. did not show an evident correlation to the median particle size.

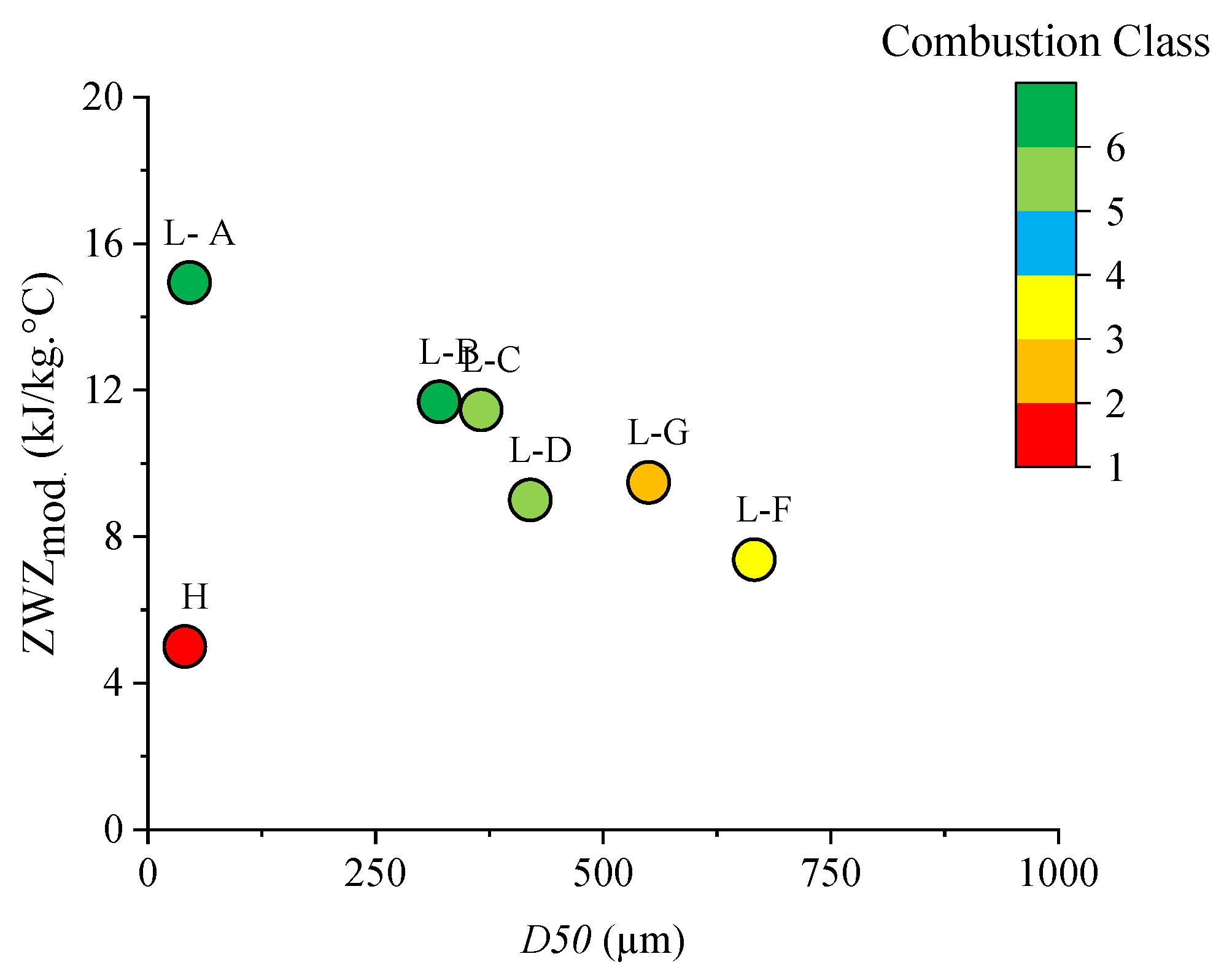

- Kst-value and ZWZmod. were observed to have a higher sensitivity to the changes in fuel properties and, therefore, were correlated to the ignition performance in the pilot-scale experiments. Both parameters showed satisfactory correlation to the ignition performance in the pilot-scale testing and can potentially be used as indicators to predict dedicated dust quality ignition performance for the investigated application. For each parameter, an approximate range can be determined based on the ignition performance defined by different Combustion Classes. However, this argument is only valid when the dust quality has a sufficient share of fine particles. The share of fine particles is a critical parameter necessary for the ignition initiation.This study should be further expanded within a larger case study in which different ranks of solid fuels, such as high- and low-volatile hard coal and biomass qualities, are investigated. The critical parameters that represent the ignition characteristics and also the relevance of the parameters to the ignition performance at an industrially-relevant environment need to be identified for this extended case study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Symbol | Unit | Quantity |

| a | Specific surface area based on BET method | |

| D10 | The particle diameter where 10% of the distribution has a smaller particle size | |

| D50 | Median particle size | |

| D90 | The particle diameter where 90% of the distribution has a smaller particle size | |

| dp/dt | The rate of pressure rise | |

| (dp/dt)max | The maximum rate of pressure rise | |

| kg/kg | Mass fraction of the material i in the fuel | |

| Kst | Deflagration index | |

| MCIT | Minimum cloud ignition temperature | |

| NCV | MJ/kg | Net calorific value |

| NZ500 | Ignition potential | |

| pm | Explosion pressure | |

| pmax | bar | Maximum explosion pressure |

| % | Cumulative particle size distribution at the particle size of 63 | |

| ZWZmod. | modified ignitability characteristics number |

References

- Messerle, V.E.; Karpenko, E.I.; Ustimenko, A.B.; Lavrichshev, O.A. Plasma preparation of coal to combustion in power boilers. Fuel Process. Technol. 2013, 107, 93–98. [Google Scholar] [CrossRef]

- Heimann, G. Erfolgreiche Installation und Inbetriebnahme einer Zünd- und Stützfeuerung mittels Trockenbraunkohlebrenner mit Plasmazündung. VGB PowerTech 2016, 7, 40–44. [Google Scholar]

- Zelkowski, J.B. Kohlecharakterisierung und Kohleverbrennung, 2nd ed.; VGB PowerTech Service GmbH: Essen, Germany, 2004. [Google Scholar]

- Torrent, J.G.; Armada, I.S.; Pedreira, R. A correlation between composition and explosibility index for coal dust. Fuel 1988, 67, 1629–1632. [Google Scholar] [CrossRef]

- García-Torrent, G.; Cantalapiedra-Fuchs, J.; Montes-Villalón, R.; Alcántara-Pedreira, R. Improvement in the correlation between the composition index and the explosibility index for coal dust. Fuel 1991, 70, 1099–1101. [Google Scholar] [CrossRef]

- Cashdollar, K.L. Overview of dust explosibility characteristics. J. Loss Prev. Process Ind. 2000, 13, 183–199. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Dust explosions-cases, causes, consequences, and control. J. Hazard. Mater. 2007, 140, 7–44. [Google Scholar] [CrossRef] [PubMed]

- Amyotte, P.R. Solid inertants and their use in dust explosion prevention and mitigation. J. Loss Prev. Process Ind. 2006, 19, 161–173. [Google Scholar] [CrossRef]

- Fernandez-Anez, N.; Slatter, D.J.F.; Saeed, M.A.; Phylaktou, H.N.; Andrews, G.E.; Garcia-Torrent, J. Ignition sensitivity of solid fuel mixtures. Fuel 2018, 223, 451–461. [Google Scholar] [CrossRef]

- Yuan, J.; Wei, W.; Huang, W.; Du, B.; Liu, L.; Zhu, J. Experimental investigations on the roles of moisture in coal dust explosion. J. Taiwan Inst. Chem. Eng. 2014, 45, 2325–2333. [Google Scholar] [CrossRef]

- Kurose, R.; Tsuji, H.; Makino, H. Effects of moisture in coal on pulverized coal combustion characteristics. Fuel 2001, 80, 1457–1465. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Influence of dispersibility and coagulation on the dust explosion risk presented by powders consisting of nm-particles. Powder Technol. 2013, 239, 223–230. [Google Scholar] [CrossRef]

- Traoré, M.; Dufaud, O.; Perrin, L.; Chazelet, S.; Thomas, D. Dust explosions: How should the influence of humidity be taken into account? Process Saf. Environ. Prot. 2009, 87, 14–20. [Google Scholar] [CrossRef]

- Youssefi, R.; Maier, J.; Scheffknecht, G. Pilot-Scale Experiences on a Plasma Ignition System for Pulverized Fuels. Energies 2021, 14, 4726. [Google Scholar] [CrossRef]

- VDI Verein Deutscher Ingenieure e.V. VDI 2263:2003-05—Dust Fires and Dust Explosions Hazards-Assessment-Protective Measures—Part 1: Test Methods for the Determination of the Safety Characteristic of Dusts; VDI: Düsseldorf, Germany, 1990. [Google Scholar]

- DIN Deutsches Institute für Normung e.V. DIN EN ISO/IEC 80079-20-2:2016-12—Explosive Atmospheres-Part 20-2: Material Characteristics-Combustible Dusts Test Methods; DIN: Berlin, Germany, 2016. [Google Scholar]

- DIN Deutsches Institute für Normung e.V. DIN EN 14034-1:2011-04—Determination of Explosion Characteristics of Dust Clouds—Part 1: Determination of the Maximum Explosion Pressure Pmax of Dust Clouds; DIN: Berlin, Germany, 2011. [Google Scholar]

- DIN Deutsches Institute für Normung e.V. DIN EN 14034-2:2011-04—Determination of Explosion Characteristics of Dust Clouds—Part 2: Determination of the Maximum Rate of Explosion Pressure Rise (dp/dt)max of Dust Clouds; DIN: Berlin, Germany, 2011. [Google Scholar]

- Ajrash, M.J.; Zanganeh, J.; Moghtaderi, B. The effects of coal dust concentrations and particle sizes on the minimum auto-ignition temperature of a coal dust cloud. Fire Mater. 2017, 41, 908–915. [Google Scholar] [CrossRef]

- Du, B.; Huang, W.; Kuai, N.; Yuan, J.; Li, Z.; Gan, Y. Experimental Investigation on Inerting Mechanism of Dust Explosion. Procedia Eng. 2012, 43, 338–342. [Google Scholar] [CrossRef]

- Dastidar, A.G.; Amyotte, P.R.; Pegg, M.J. Factors influencing the suppression of coal dust explosions. Fuel 1997, 76, 663–670. [Google Scholar] [CrossRef]

- Yu, H.; Wang, C.; Pang, L.; Cui, Y.; Chen, D. Inhibiting effect of coal fly ash on minimum ignition temperature of coal dust clouds. J. Loss Prev. Process Ind. 2019, 61, 24–29. [Google Scholar] [CrossRef]

- Garcia-Torrent, J.; Fernandez-Anez, N.; Medic-Pejic, L.; Blandon-Montes, A.; Molina-Escobar, J.M. Ignition and explosion parameters of Colombian coals. J. Loss Prev. Process Ind. 2016, 43, 706–713. [Google Scholar] [CrossRef]

- Segers, T.; Norman, F.; Youssefi, R.; Maier, J.; Verplaetsen, F. The Influence of Sieving on the Dust Explosion Characteristics of a Lignite Coal. Chem. Eng. Trans. 2019, 77, 475–480. [Google Scholar]

- Cashdollar, K.L. Coal dust explosibility. J. Loss Prev. Process Ind. 1996, 9, 65–76. [Google Scholar] [CrossRef]

| NCV | ||||

|---|---|---|---|---|

| Fuel | Raw | |||

| 10 kg/kg (%) | ||||

| Lignite A | 20.8 | 10.5 | 5.0 | 48.5 |

| Lignite B | 20.2 | 14.5 | 4.7 | 46.4 |

| Lignite C | 18.8 | 19.4 | 4.0 | 43.8 |

| Lignite D | 15.8 | 20.2 | 12.5 | 42.6 |

| Lignite F | 12.2 | 29.3 | 19.6 | 32.5 |

| Lignite G | 19.6 | 12.6 | 15.5 | 44.7 |

| Hard coal | 25.9 | 2.6 | 15.2 | 26.2 |

| D10 | D50 | D90 | D10 | D50 | D90 | a | |

|---|---|---|---|---|---|---|---|

| Fuel | 0.5 mm Sieved | 2 mm Sieved | |||||

| m | m/g | ||||||

| Lignite A | 5 | 46 | 184 | 0.56 | |||

| Lignite B | 19 | 83 | 225 | 42 | 320 | 1500 | |

| Lignite C | 22 | 149 | 402 | 31 | 366 | 1600 | 1.79 |

| Lignite D | 15 | 128 | 503 | 34 | 420 | 1726 | 19.8 |

| Lignite F | 18 | 173 | 520 | 73 | 667 | 1935 | 5.0 |

| Lignite G | 8 | 80 | 337 | 31 | 551 | 1143 | 15.5 |

| Hard coal | 5 | 40 | 158 | ||||

| Fuel | Lignite A+ash | Hard Coal |

|---|---|---|

| MCIT () | 380 | 540 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Youssefi, R.; Segers, T.; Norman, F.; Maier, J.; Scheffknecht, G. Experimental Investigations of the Ignitability of Several Coal Dust Qualities. Energies 2021, 14, 6323. https://doi.org/10.3390/en14196323

Youssefi R, Segers T, Norman F, Maier J, Scheffknecht G. Experimental Investigations of the Ignitability of Several Coal Dust Qualities. Energies. 2021; 14(19):6323. https://doi.org/10.3390/en14196323

Chicago/Turabian StyleYoussefi, Reyhane, Tom Segers, Frederik Norman, Jörg Maier, and Günter Scheffknecht. 2021. "Experimental Investigations of the Ignitability of Several Coal Dust Qualities" Energies 14, no. 19: 6323. https://doi.org/10.3390/en14196323

APA StyleYoussefi, R., Segers, T., Norman, F., Maier, J., & Scheffknecht, G. (2021). Experimental Investigations of the Ignitability of Several Coal Dust Qualities. Energies, 14(19), 6323. https://doi.org/10.3390/en14196323