Parametric Study for Thermal and Catalytic Methane Pyrolysis for Hydrogen Production: Techno-Economic and Scenario Analysis

Abstract

:1. Introduction

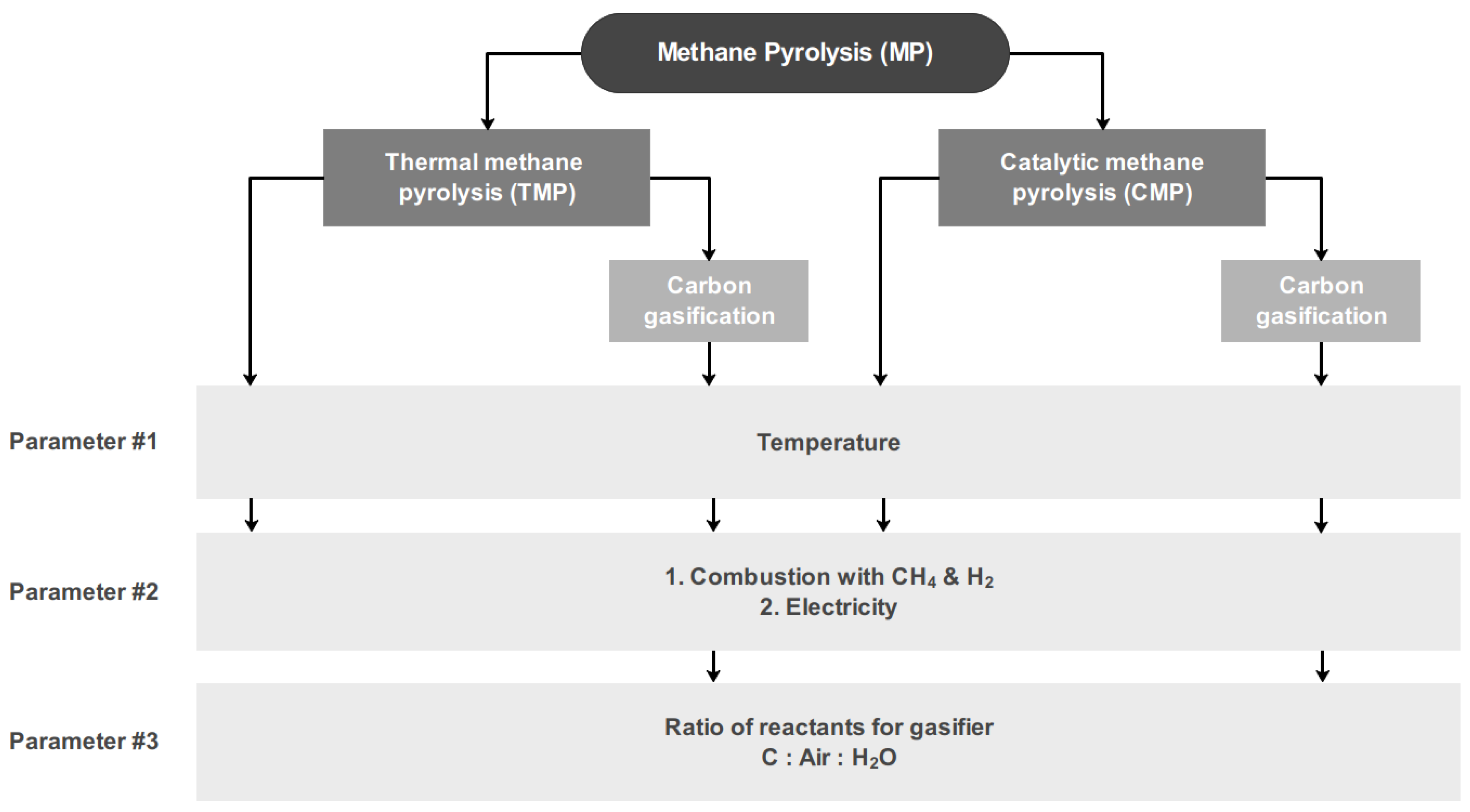

2. Methods

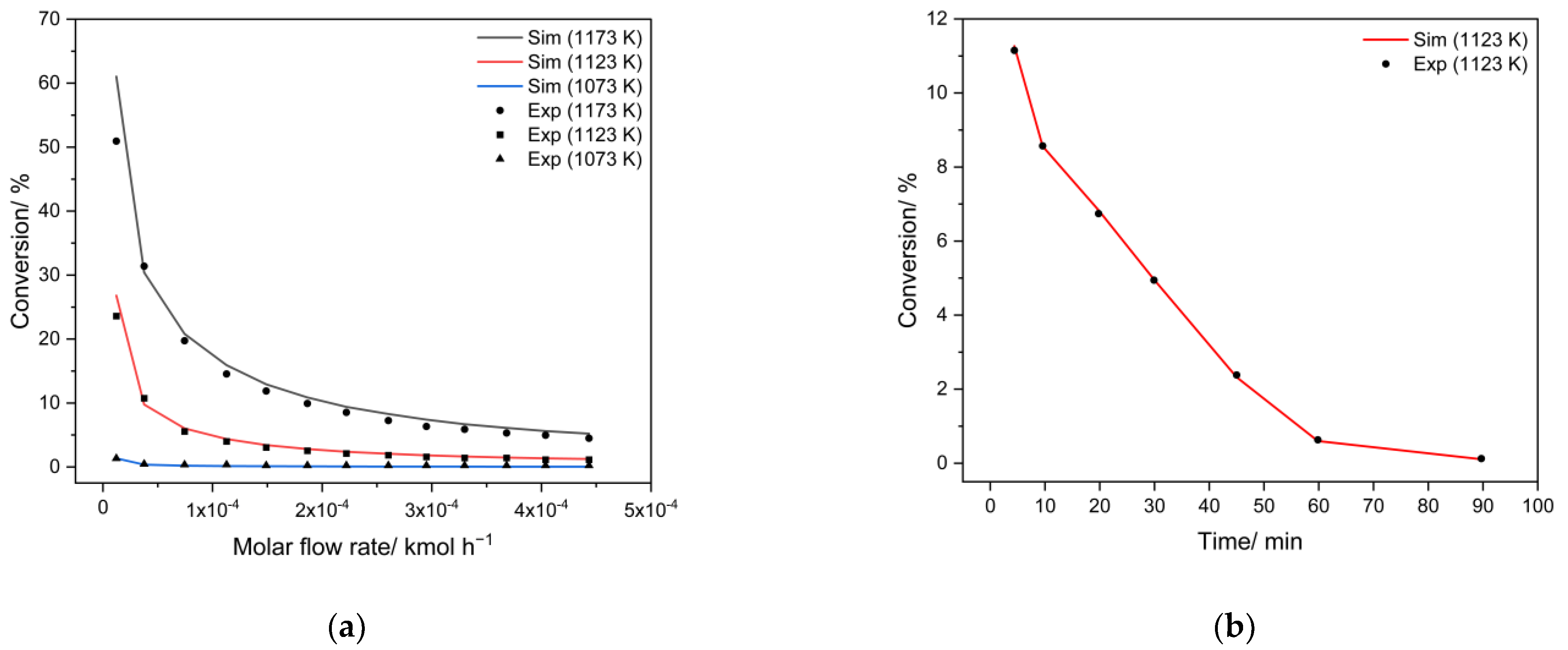

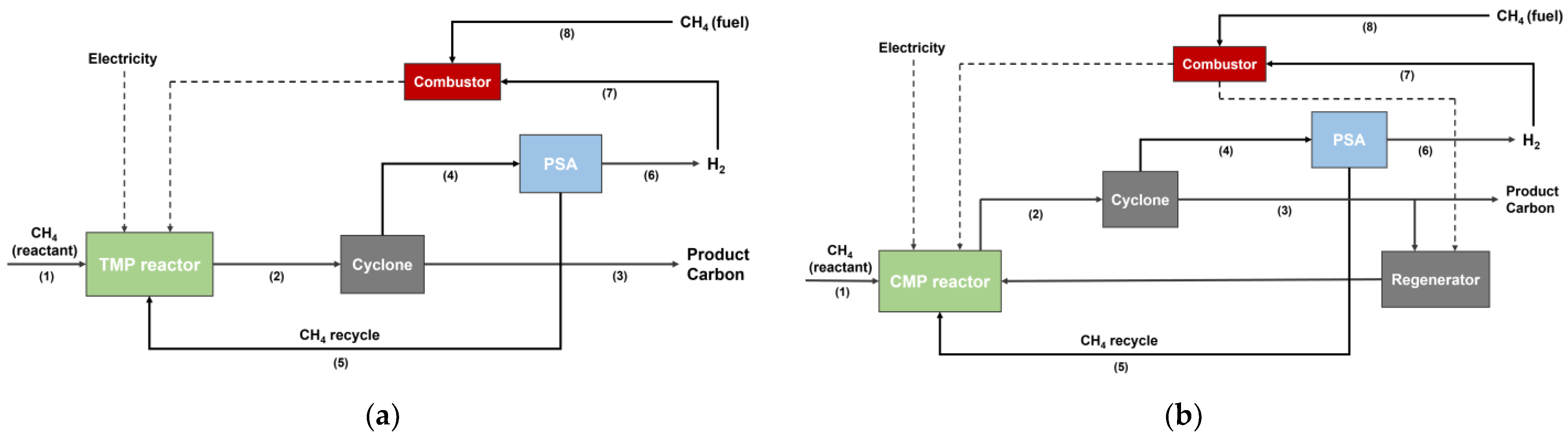

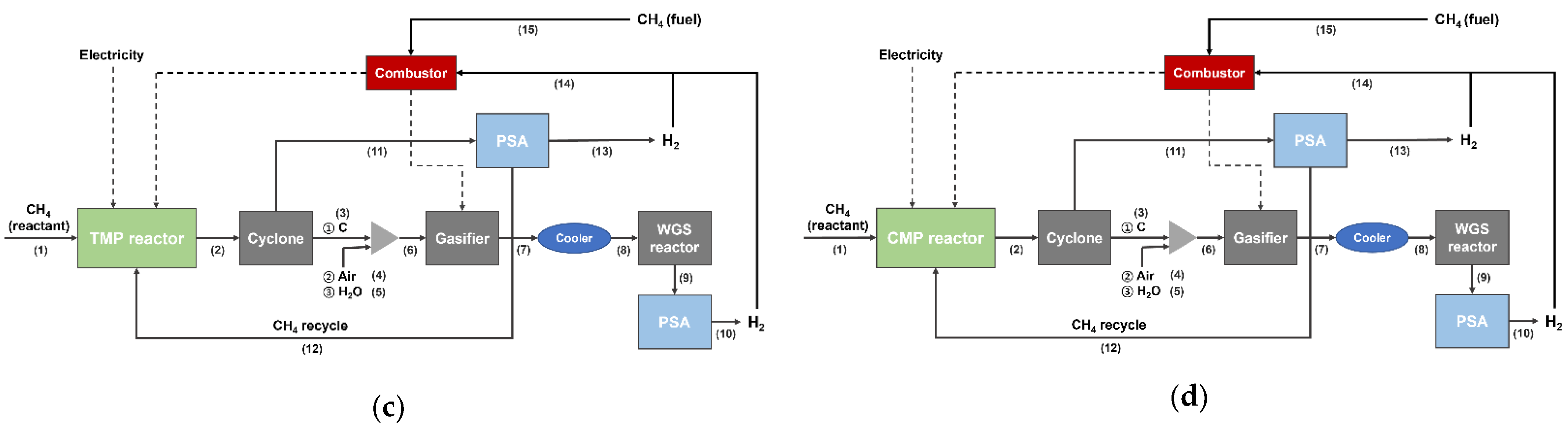

2.1. Process Simulation

2.2. Itemized Cost Estimation

| Economic Parameters | |

| Capital Cost | |

| MP reactor [56] | EUR 2740 k |

| WGS reactor [56] | EUR 59 k |

| Regenerator [57] | USD 12,112,138 |

| Catalyst [58] | USD 1.138 kg−1 |

| Gasifier [56] | EUR 211 k |

| PSA [59] | (USD) |

| Cyclone [58] | USD 31,400 |

| Supplement | 20% of (Capital cost-Supplement) (USD) |

| Operating Cost | |

| CH4 [60] | USD 0.005 MJLHV−1 |

| Catalyst operating cost | Assumed as 10% loss per month |

| Water [61] | USD 12 ton−1 |

| Electricity [32] | USD 56 MWh−1 |

| Labor [62] | USD 11 hr−1 |

| PSA operating cost [59] | ) (USD) |

| C selling price [63] | EUR 500 ton−1 |

| Maintenance [64] | 1% of (Capital cost-Supplement) (USD y−1) |

| Other cost [64] | 2% of (Capital cost-Supplement) (USD y−1) |

| Economic Assumptions | |

| CEPCI (2021) | 655.9 |

| i | 0.045 |

| Exchange rate | USD 1 = EUR 0.85 |

| N | 20 years for MP reactor 10 years for WGS reactor, regenerator, PSA, PSA operating cost, cyclone, and supplement 1 year for catalyst |

| Stream factor | 0.95 |

2.3. Sensitivity and Scenario Analysis

3. Results and Discussion

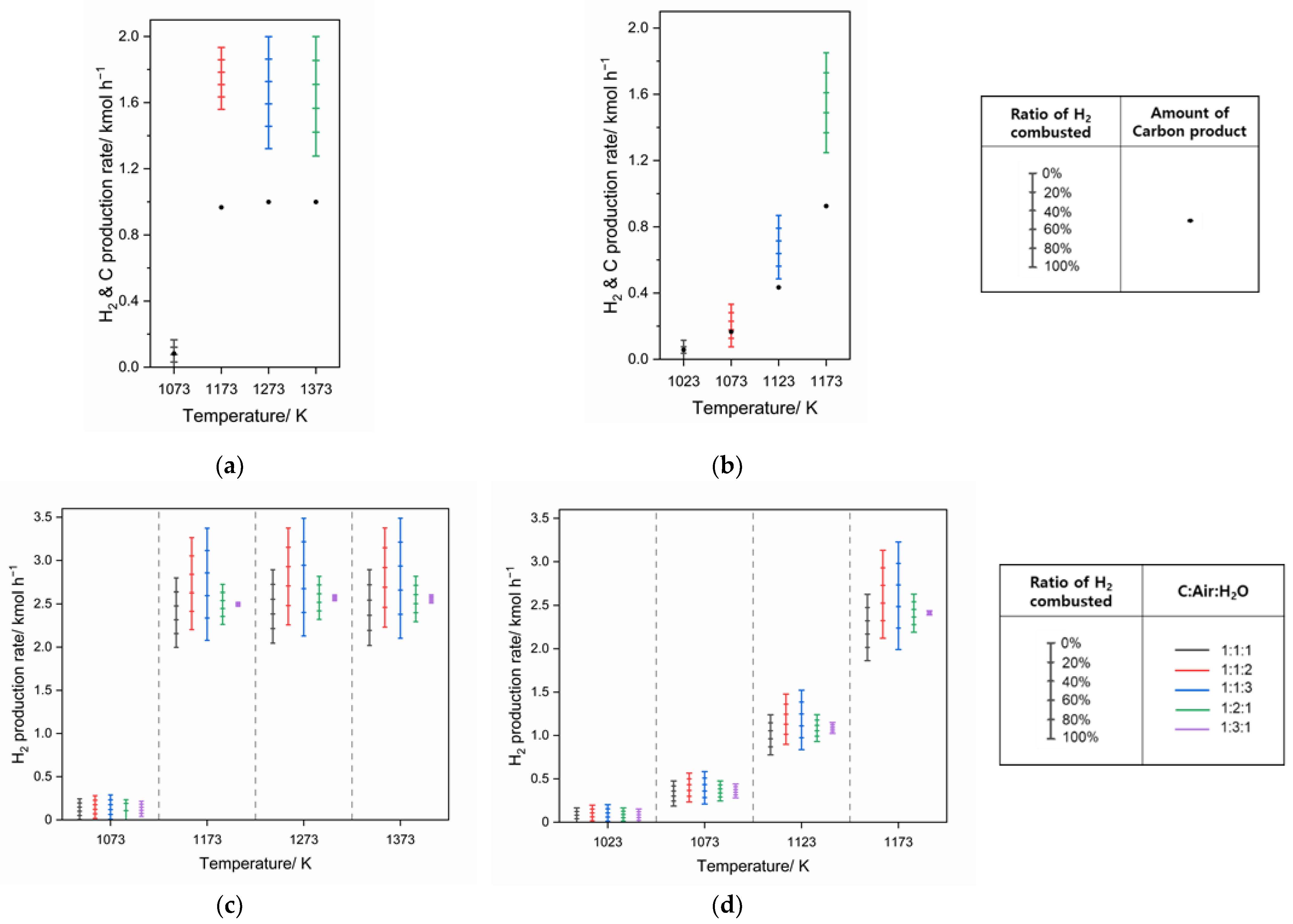

3.1. H2 and C Production Rates

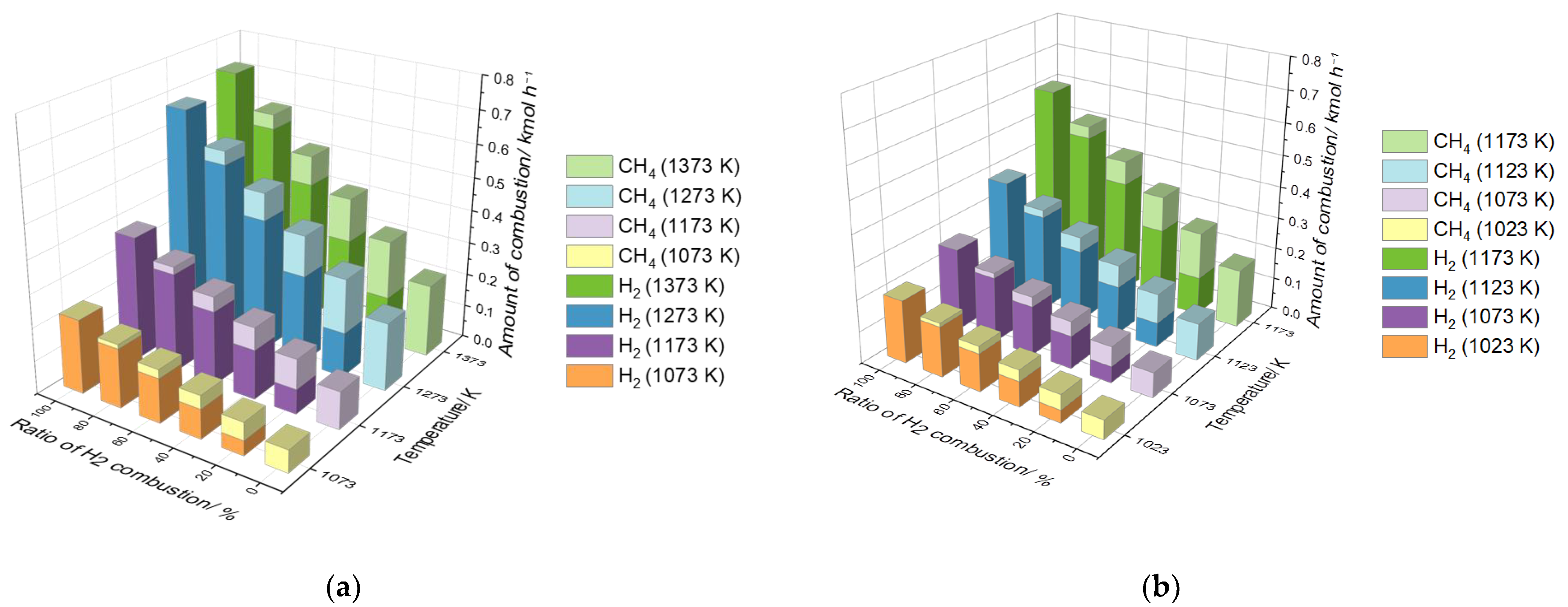

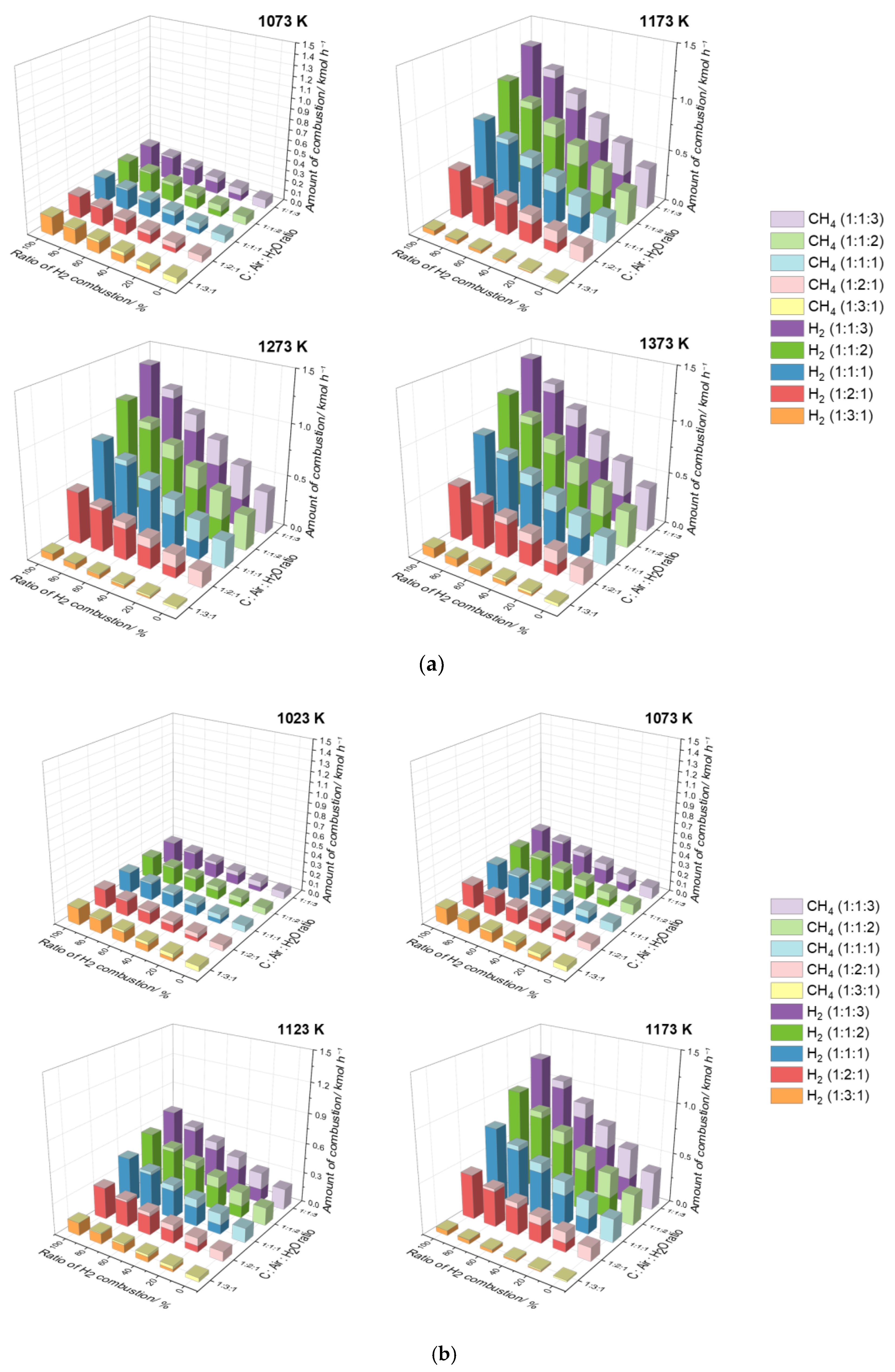

3.2. Parametric Study—Fuel Consumption

3.3. Itemized Cost Estimation

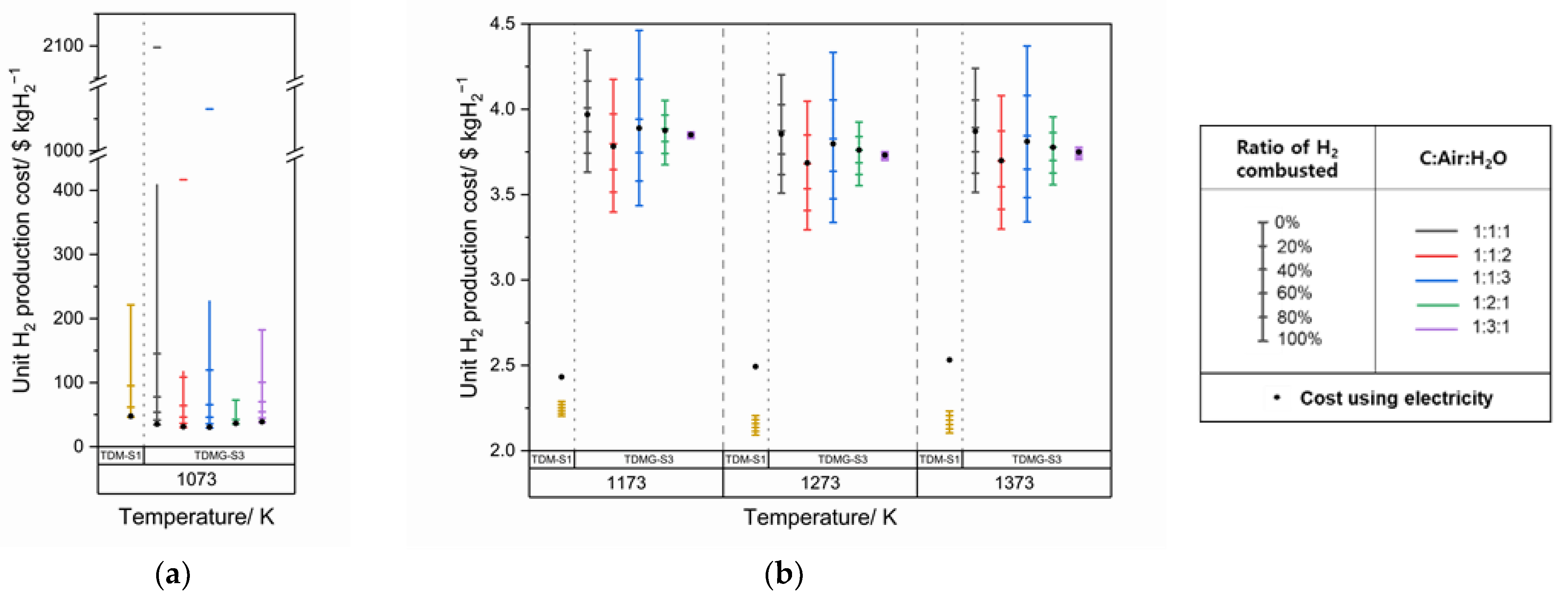

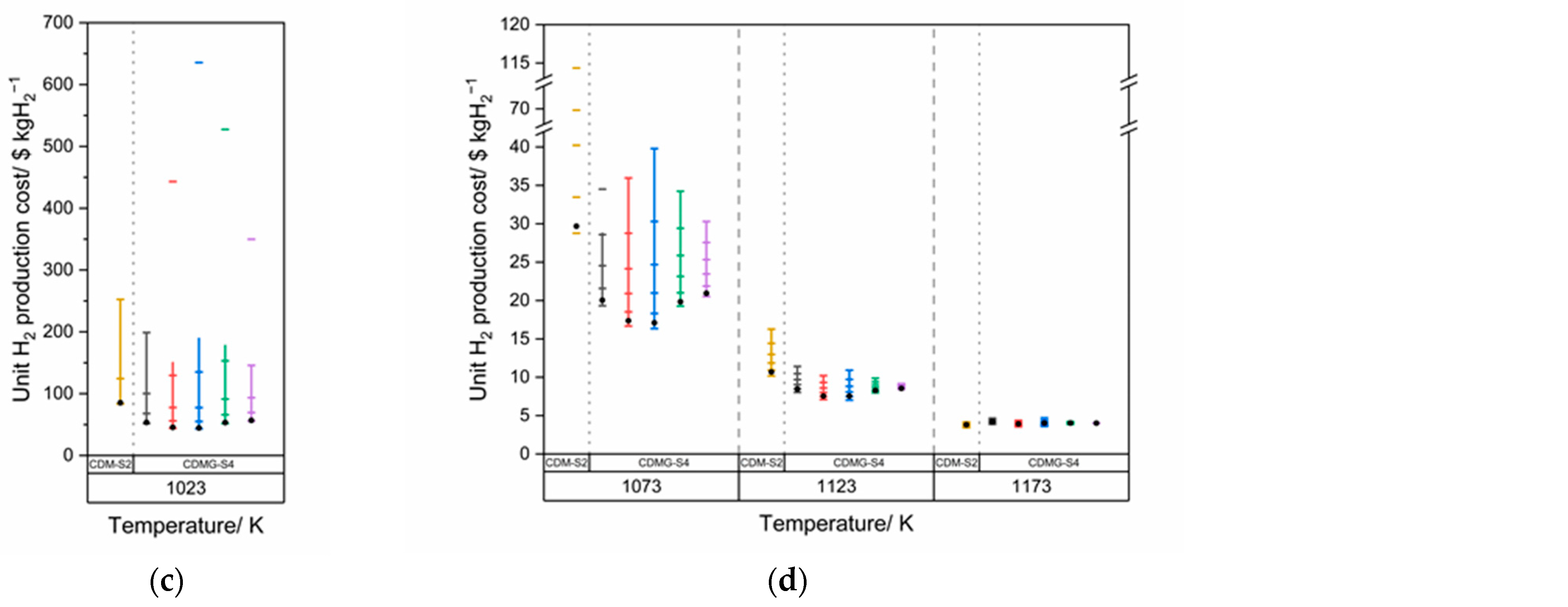

3.4. Parametric Study—Economic Aspects

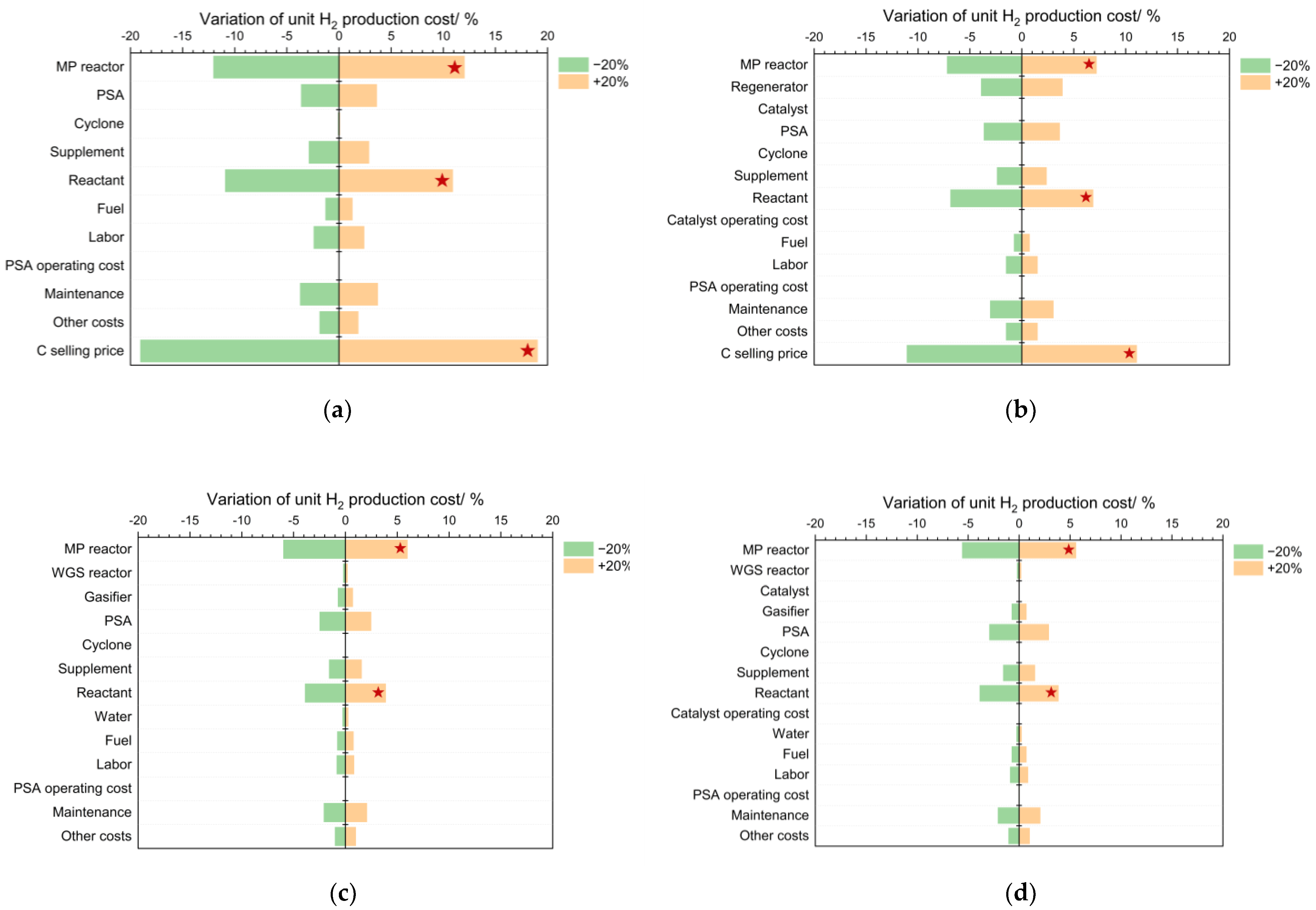

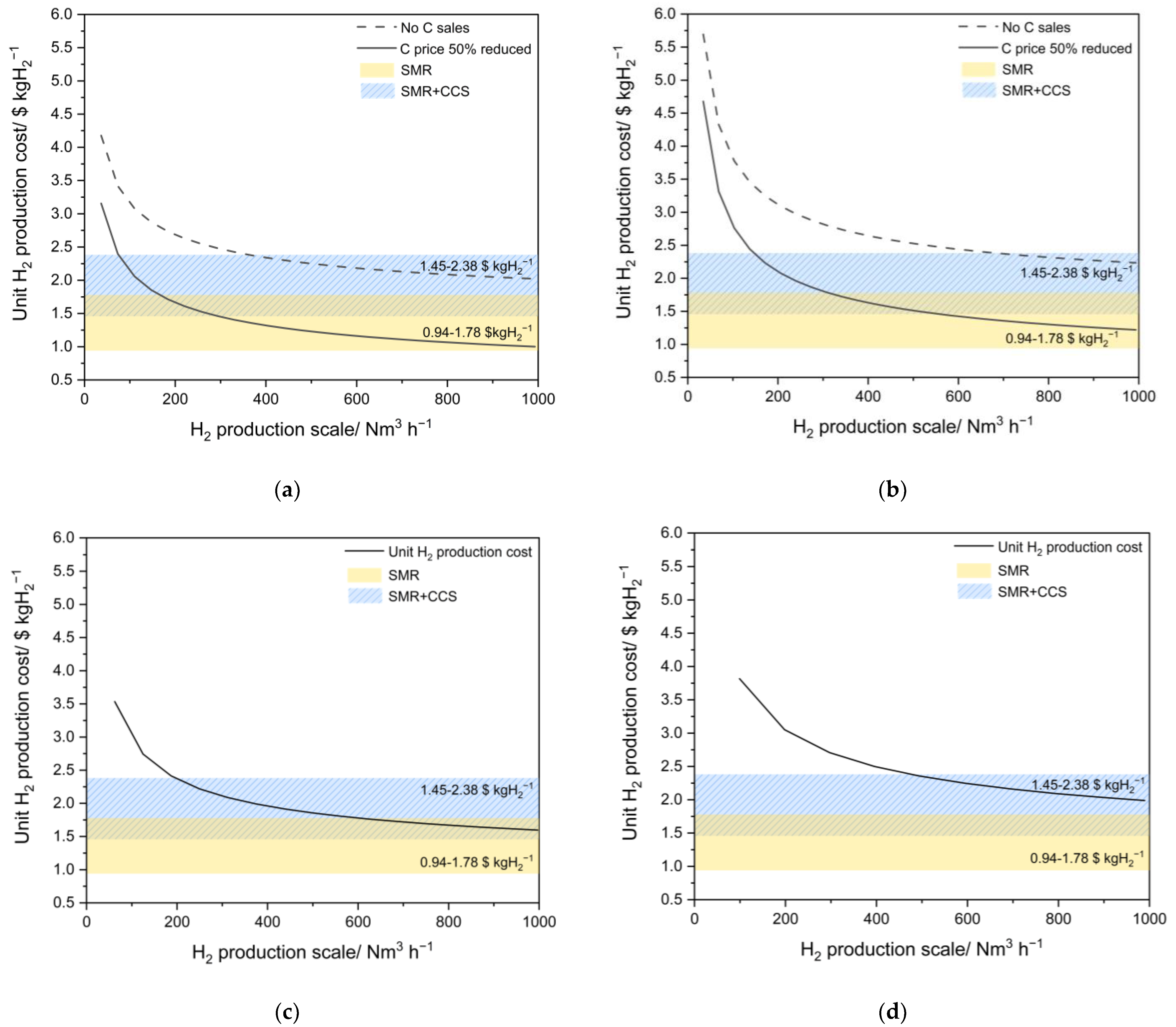

3.5. Sensitivity and Scenario Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CO2 | Carbon dioxide |

| CO | Carbon monoxide |

| CCS | Carbon capture and storage |

| CMP | Catalytic methane pyrolysis |

| CMPG | Catalytic methane pyrolysis with carbon gasification |

| CRF | Capital recovery factor |

| CEPCI | Chemical engineering plant cost index |

| MP | Methane pyrolysis |

| FLBR | Fluidized bed reactor |

| GHG | Greenhouse gas |

| H2 | Hydrogen |

| CH4 | Methane |

| PSA | Pressure swing adsorption |

| SMR | Steam methane reforming |

| SMR with CCS | Steam methane reforming with carbon capture and storage |

| TMP | Thermal methane pyrolysis |

| TMPG | Thermal methane pyrolysis with carbon gasification |

| VPMDCS | Vacuum promote methane decomposition with carbon separation |

| H2O | Water |

| WE | Water electrolysis |

| WGS | Water-gas shift |

References

- Federal Ministry for Economic Affairs and Energy. Available online: https://www.bmwi.de/Redaktion/EN/Publikationen/Energie/the-national-hydrogen-strategy.html (accessed on 20 July 2021).

- European Commission. Available online: https://ec.europa.eu/energy/topics/energy-system-integration/hydrogen_en#eu-hydrogen-strategy (accessed on 20 July 2021).

- Ministry of Economy, Trade and Industry. 2017. Available online: https://www.meti.go.jp/english/press/2017/1226_003.html (accessed on 20 July 2021).

- Ministry of Economy, Trade and Industry. 2018. Available online: https://www.meti.go.jp/english/press/2018/0703_002.html (accessed on 20 July 2021).

- Ministry of Economy, Trade and Industry. 2019. Available online: https://www.meti.go.jp/english/press/2019/0312_002.html (accessed on 20 July 2021).

- Climate Change Committee. Available online: https://www.theccc.org.uk/publication/hydrogen-in-a-low-carbon-economy/ (accessed on 20 July 2021).

- U.S. Department of Energy. Available online: https://www.energy.gov/eere/fuelcells/h2scale (accessed on 20 July 2021).

- The Commonwealth Scientific and Industrial Research Organisation (CSIRO). Available online: https://www.csiro.au/en/work-with-us/services/consultancy-strategic-advice-services/csiro-futures/futures-reports/hydrogen-roadmap (accessed on 20 July 2021).

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Mazloomi, K.; Gomes, C. Hydrogen as an energy carrier: Prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 3024–3033. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G. Hydrogen production for energy: An overview. Int. J. Hydrog. Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef] [Green Version]

- Acar, C.; Dincer, I. Review and evaluation of hydrogen production options for better environment. J. Clean. Prod. 2019, 218, 835–849. [Google Scholar] [CrossRef]

- Reuß, M.; Grube, T.; Robinius, M.; Preuster, P.; Wasserscheid, P.; Stolten, D. Seasonal storage and alternative carriers: A flexible hydrogen supply chain model. Appl. Energy 2017, 200, 290–302. [Google Scholar] [CrossRef]

- Tuomi, S.; Santasalo-Aarnio, A.; Kanninen, P.; Kallio, T. Hydrogen production by methanol–Water solution electrolysis with an alkaline membrane cell. J. Power Sources 2013, 229, 32–35. [Google Scholar] [CrossRef]

- Lee, B.; Heo, J.; Kim, S.; Sung, C.; Moon, C.; Moon, S.; Lim, H. Economic feasibility studies of high pressure PEM water electrolysis for distributed H2 refueling stations. Energy Convers. Manag. 2018, 162, 139–144. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I. Comparative assessment of renewable energy-based hydrogen production methods. Renew. Sustain. Energy Rev. 2020, 135, 110192. [Google Scholar] [CrossRef]

- Parkinson, B.; Balcombe, P.; Speirs, J.F.; Hawkes, A.D.; Hellgardt, K. Levelized cost of CO2 mitigation from hydrogen production routes. Energy Environ. Sci. 2018, 12, 19–40. [Google Scholar] [CrossRef]

- Navarro, R.M.; Sánchez-Sánchez, M.C.; Alvarez-Galvan, M.C.; Del Valle, F.; Fierro, J.L.G. Hydrogen production from renewable sources: Biomass and photocatalytic opportunities. Energy Environ. Sci. 2008, 2, 35–54. [Google Scholar] [CrossRef]

- Nguyen, T.; Abdin, Z.; Holm, T.; Mérida, W. Grid-connected hydrogen production via large-scale water electrolysis. Energy Convers. Manag. 2019, 200, 112108. [Google Scholar] [CrossRef]

- Zhang, C.; Greenblatt, J.B.; Wei, M.; Eichman, J.; Saxena, S.; Muratori, M.; Guerra, O.J. Flexible grid-based electrolysis hydrogen production for fuel cell vehicles reduces costs and greenhouse gas emissions. Appl. Energy 2020, 278, 115651. [Google Scholar] [CrossRef]

- Christopher, K.; Dimitrios, R. A review on exergy comparison of hydrogen production methods from renewable energy sources. Energy Environ. Sci. 2012, 5, 6640–6651. [Google Scholar] [CrossRef]

- Vincent, I.; Bessarabov, D. Low cost hydrogen production by anion exchange membrane electrolysis: A review. Renew. Sustain. Energy Rev. 2018, 81, 1690–1704. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development. Renew. Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

- Stojić, D.L.; Marčeta, M.P.; Sovilj, S.P.; Miljanić, S. Hydrogen generation from water electrolysis—Possibilities of energy saving. J. Power Sources 2003, 118, 315–319. [Google Scholar] [CrossRef]

- Boot-Handford, M.E.; Abanades, J.C.; Anthony, E.J.; Blunt, M.; Brandani, S.; Mac Dowell, N.; Fernández, J.R.; Ferrari, M.-C.; Gross, R.; Hallett, J.; et al. Carbon capture and storage update. Energy Environ. Sci. 2013, 7, 130–189. [Google Scholar] [CrossRef]

- Wilberforce, T.; Baroutaji, A.; Soudan, B.; Al-Alami, A.H.; Olabi, A.G. Outlook of carbon capture technology and challenges. Sci. Total. Environ. 2018, 657, 56–72. [Google Scholar] [CrossRef] [Green Version]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef] [Green Version]

- Younessi-Sinaki, M.; Matida, E.A.; Hamdullahpur, F. Kinetic model of homogeneous thermal decomposition of methane and ethane. Int. J. Hydrog. Energy 2009, 34, 3710–3716. [Google Scholar] [CrossRef]

- Kang, D.; Rahimi, N.; Gordon, M.J.; Metiu, H.; McFarland, E.W. Catalytic methane pyrolysis in molten MnCl2-KCl. Appl. Catal. B Environ. 2019, 254, 659–666. [Google Scholar] [CrossRef]

- Parfenov, V.E.; Nikitchenko, N.V.; Pimenov, A.A.; Kuz’Min, A.E.; Kulikova, M.V.; Chupichev, O.B.; Maksimov, A.L. Methane Pyrolysis for Hydrogen Production: Specific Features of Using Molten Metals. Russ. J. Appl. Chem. 2020, 93, 625–632. [Google Scholar] [CrossRef]

- Bhaskar, A.; Assadi, M.; Somehsaraei, H.N. Can methane pyrolysis based hydrogen production lead to the decarbonisation of iron and steel industry? Energy Convers. Manag. X 2021, 10, 100079. [Google Scholar] [CrossRef]

- Fincke, J.R.; Anderson, R.P.; Hyde, T.A.; Detering, B.A. Plasma Pyrolysis of Methane to Hydrogen and Carbon Black. Ind. Eng. Chem. Res. 2002, 41, 1425–1435. [Google Scholar] [CrossRef]

- Wang, I.-W.; Kutteri, D.A.; Gao, B.; Tian, H.; Hu, J. Methane Pyrolysis for Carbon Nanotubes and COx-Free H2 over Transition-Metal Catalysts. Energy Fuels 2018, 33, 197–205. [Google Scholar] [CrossRef]

- Rahimi, N.; Kang, D.; Gelinas, J.; Menon, A.; Gordon, M.J.; Metiu, H.; McFarland, E.W. Solid carbon production and recovery from high temperature methane pyrolysis in bubble columns containing molten metals and molten salts. Carbon 2019, 151, 181–191. [Google Scholar] [CrossRef]

- Farmer, T.C.; McFarland, E.W.; Doherty, M.F. Membrane bubble column reactor model for the production of hydrogen by methane pyrolysis. Int. J. Hydrog. Energy 2019, 44, 14721–14731. [Google Scholar] [CrossRef]

- Abbas, H.F.; Daud, W.W. Hydrogen production by methane decomposition: A review. Int. J. Hydrog. Energy 2010, 35, 1160–1190. [Google Scholar] [CrossRef]

- Muradov, N. Low to near-zero CO2 production of hydrogen from fossil fuels: Status and perspectives. Int. J. Hydrog. Energy 2017, 42, 14058–14088. [Google Scholar] [CrossRef]

- Hu, C.; Shen, H.; Zhang, S.; Li, H. Methane pyrolysis in preparation of pyrolytic carbon: Thermodynamic and kinetic analysis by density functional theory. Chin. J. Aeronaut. 2019, 33, 1064–1073. [Google Scholar] [CrossRef]

- Guéret, C.; Daroux, M.; Billaud, F. Methane pyrolysis: Thermodynamics. Chem. Eng. Sci. 1997, 52, 815–827. [Google Scholar] [CrossRef]

- Sánchez-Bastardo, N.; Schlögl, R.; Ruland, H. Methane Pyrolysis for CO2-Free H2 Production: A Green Process to Overcome Renewable Energies Unsteadiness. Chem. Ing. Tech. 2020, 92, 1596–1609. [Google Scholar] [CrossRef]

- Nishii, H.; Miyamoto, D.; Umeda, Y.; Hamaguchi, H.; Suzuki, M.; Tanimoto, T.; Harigai, T.; Takikawa, H.; Suda, Y. Catalytic activity of several carbons with different structures for methane decomposition and by-produced carbons. Appl. Surf. Sci. 2018, 473, 291–297. [Google Scholar] [CrossRef]

- Tezel, E.; Figen, H.E.; Baykara, S.Z. Hydrogen production by methane decomposition using bimetallic Ni–Fe catalysts. Int. J. Hydrog. Energy 2019, 44, 9930–9940. [Google Scholar] [CrossRef]

- Qian, J.X.; Enakonda, L.R.; Wang, W.J.; Gary, D.; Del-Gallo, P.; Basset, J.-M.; Bin Liu, D.; Zhou, L. Optimization of a fluidized bed reactor for methane decomposition over Fe/Al2O3 catalysts: Activity and regeneration studies. Int. J. Hydrog. Energy 2019, 44, 31700–31711. [Google Scholar] [CrossRef]

- Patzschke, C.F.; Parkinson, B.; Willis, J.J.; Nandi, P.; Love, A.M.; Raman, S.; Hellgardt, K. Co-Mn catalysts for H2 production via methane pyrolysis in molten salts. Chem. Eng. J. 2021, 414, 128730. [Google Scholar] [CrossRef]

- Karaismailoglu, M.; Figen, H.E.; Baykara, S.Z. Hydrogen production by catalytic methane decomposition over yttria doped nickel based catalysts. Int. J. Hydrog. Energy 2019, 44, 9922–9929. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, R.; Xia, G.; Wu, Y.; Li, H.; Sun, Z.; Sun, Z. Vacuum promoted methane decomposition for hydrogen production with carbon separation: Parameter optimization and economic assessment. Energy 2021, 222, 119953. [Google Scholar] [CrossRef]

- Riley, J.; Atallah, C.; Siriwardane, R.; Stevens, R. Technoeconomic analysis for hydrogen and carbon Co-Production via catalytic pyrolysis of methane. Int. J. Hydrog. Energy 2021, 46, 20338–20358. [Google Scholar] [CrossRef]

- Pérez, B.J.L.; Jiménez, J.A.M.; Bhardwaj, R.; Goetheer, E.; Annaland, M.V.S.; Gallucci, F. Methane pyrolysis in a molten gallium bubble column reactor for sustainable hydrogen production: Proof of concept & techno-economic assessment. Int. J. Hydrog. Energy 2020, 46, 4917–4935. [Google Scholar] [CrossRef]

- Kerscher, F.; Stary, A.; Gleis, S.; Ulrich, A.; Klein, H.; Spliethoff, H. Low-carbon hydrogen production via electron beam plasma methane pyrolysis: Techno-economic analysis and carbon footprint assessment. Int. J. Hydrog. Energy 2021, 46, 19897–19912. [Google Scholar] [CrossRef]

- Zhang, X.; Kätelhön, A.; Sorda, G.; Helmin, M.; Rose, M.; Bardow, A.; Madlener, R.; Palkovits, R.; Mitsos, A. CO2 mitigation costs of catalytic methane decomposition. Energy 2018, 151, 826–838. [Google Scholar] [CrossRef]

- Timmerberg, S.; Kaltschmitt, M.; Finkbeiner, M. Hydrogen and hydrogen-derived fuels through methane decomposition of natural gas—GHG emissions and costs. Energy Convers. Manag. X 2020, 7, 100043. [Google Scholar] [CrossRef]

- Keipi, T.; Li, T.; Løvås, T.; Tolvanen, H.; Konttinen, J. Methane thermal decomposition in regenerative heat exchanger reactor: Experimental and modeling study. Energy 2017, 135, 823–832. [Google Scholar] [CrossRef]

- Kim, M.H.; Lee, E.K.; Jun, J.H.; Kong, S.J.; Han, G.Y.; Lee, B.K.; Lee, T.-J.; Yoon, K.J. Hydrogen production by catalytic decomposition of methane over activated carbons: Kinetic study. Int. J. Hydrog. Energy 2003, 29, 187–193. [Google Scholar] [CrossRef]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A.; Bhattacharyya, D. Analysis, Synthesis, and Design of Chemical Processes, 4th ed.; Pearson Education: Upper Saddle River, NJ, UAS, 2013; pp. 157–226. [Google Scholar]

- Keipi, T.; Tolvanen, H.; Konttinen, J. Economic analysis of hydrogen production by methane thermal decomposition: Comparison to competing technologies. Energy Convers. Manag. 2018, 159, 264–273. [Google Scholar] [CrossRef]

- Vasalos, I.A.; Lappas, A.A.; Kopalidou, E.P.; Kalogiannis, K.G. Biomass catalytic pyrolysis: Process design and economic analysis. Wiley Interdiscip. Rev. Energy Environ. 2016, 5, 370–383. [Google Scholar] [CrossRef]

- Liu, L.; Qian, H.; Mu, L.; Wu, J.; Feng, X.; Lu, X.; Zhu, J. Techno-economic analysis of biomass processing with dual outputs of energy and activated carbon. Bioresour. Technol. 2020, 319, 124108. [Google Scholar] [CrossRef]

- Hoffman, Z. Simulation and Economic Evaluation of Coal Gasification with SETS Reforming Process for Power Production. Master’s Thesis, Louisiana State University (LSU), Baton Rouge, LA, USA, 2005. Available online: https://digitalcommons.lsu.edu/gradschool_theses/2269 (accessed on 21 July 2021).

- Cruellas, A.; Bakker, J.; Annaland, M.V.S.; Medrano, J.; Gallucci, F. Techno-economic analysis of oxidative coupling of methane: Current state of the art and future perspectives. Energy Convers. Manag. 2019, 198, 111789. [Google Scholar] [CrossRef]

- Parkinson, B.; Tabatabaei, M.; Upham, D.C.; Ballinger, B.; Greig, C.; Smart, S.; McFarland, E. Hydrogen production using methane: Techno-economics of decarbonizing fuels and chemicals. Int. J. Hydrog. Energy 2018, 43, 2540–2555. [Google Scholar] [CrossRef]

- Chen, J.; Tyagi, R.D.; Li, J.; Zhang, X.; Drogui, P.; Sun, F. Economic assessment of biodiesel production from wastewater sludge. Bioresour. Technol. 2018, 253, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Keipi, T.I.-M.; Hankalin, V.; Nummelin, J.; Raiko, R. Techno-economic analysis of four concepts for thermal decomposition of methane: Reduction of CO2 emissions in natural gas combustion. Energy Convers. Manag. 2016, 110, 1–12. [Google Scholar] [CrossRef]

- Gim, B.-J.; Kim, J.-W.; Ko, H.-M. Economic evaluation of domestic low-temperature water electrolysis hydrogen production. Trans. Korean Hydrog. New Energy Soc. 2011, 22, 559–567. [Google Scholar] [CrossRef]

- Dolan, M.; Beath, A.; Hla, S.; Way, J.; Abu El Hawa, H. An experimental and techno-economic assessment of solar reforming for H2 production. Int. J. Hydrog. Energy 2016, 41, 14583–14595. [Google Scholar] [CrossRef]

- Gim, B.; Yoon, W.L. Analysis of the economy of scale and estimation of the future hydrogen production costs at on-site hydrogen refueling stations in Korea. Int. J. Hydrog. Energy 2012, 37, 19138–19145. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Available online: https://www.iea.org/data-and-statistics/charts/hydrogen-production-costs-using-natural-gas-in-selected-regions-2018-2 (accessed on 25 July 2021).

| (a) TMP-S1 | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

| Temperature/K | 298 | 1273 | 1273 | 1273 | 1273 | 1273 | 1273 | 298 |

| Pressure/bar | 1.00 | 1.00 | 1.00 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 |

| Molar flow/kmol h−1 | 1.00 | 3.02 | 1.00 | 2.02 | 0.02 | 2.00 | 0.27 | 0.12 |

| Mole fraction | ||||||||

| CH4 | 1.00 | 0.01 | 0 | 0.01 | 1.00 | 0 | 0 | 1.00 |

| C | 0 | 0.33 | 1.00 | 0 | 0 | 0 | 0 | 0 |

| H2 | 0 | 0.66 | 0 | 0.99 | 0 | 1.00 | 1.00 | 0 |

| (b) CMP-S2 | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

| Temperature/K | 298 | 1173 | 1173 | 1173 | 1173 | 1173 | 1173 | 298 |

| Pressure/bar | 1.00 | 1.00 | 1.00 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 |

| Molar flow/kmol h−1 | 1.00 | 5.27 | 0.93 | 4.34 | 2.42 | 1.85 | 0.24 | 0.11 |

| Mole fraction | ||||||||

| CH4 | 1.00 | 0.48 | 0 | 0.57 | 1.00 | 0 | 0 | 1.00 |

| C | 0 | 0.18 | 1.00 | 0 | 0 | 0 | 0 | 0 |

| H2 | 0 | 0.35 | 0 | 0.43 | 0 | 1.00 | 1.00 | 0 |

| (c) TMPG-S3 | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

| Temperature/K | 298 | 1273 | 1273 | 298 | 298 | 341 | 973 | 623 |

| Pressure/bar | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Molar flow/kmol h−1 | 1.00 | 3.02 | 1.00 | 1.00 | 2.00 | 4.00 | 3.78 | 3.78 |

| Mole fraction | ||||||||

| CH4 | 1.00 | 0.01 | 0 | 0 | 0 | 0 | 0 | 0 |

| C | 0 | 0.33 | 1.00 | 0 | 0 | 0.25 | 0 | 0 |

| H2 | 0 | 0.66 | 0 | 0 | 0 | 0 | 0.30 | 0.30 |

| O2 | 0 | 0 | 0 | 0.21 | 0 | 0.05 | 0 | 0 |

| H2O | 0 | 0 | 0 | 0 | 1.00 | 0.50 | 0.23 | 0.23 |

| N2 | 0 | 0 | 0 | 0.79 | 0 | 0.20 | 0.21 | 0.21 |

| CO2 | 0 | 0 | 0 | 0 | 0 | 0 | 0.15 | 0.15 |

| CO | 0 | 0 | 0 | 0 | 0 | 0 | 0.12 | 0.12 |

| (c) TMPG-S3 | (9) | (10) | (11) | (12) | (13) | (14) | (15) | |

| Temperature/K | 623 | 623 | 1273 | 1273 | 1273 | 1273 | 298 | |

| Pressure/bar | 1.00 | 1.00 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 | |

| Molar flow/kmol h−1 | 3.78 | 1.38 | 2.02 | 0.02 | 2.00 | 0.45 | 0.20 | |

| Mole fraction | ||||||||

| CH4 | 0 | 0 | 0.01 | 1.00 | 0 | 0 | 1.00 | |

| C | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| H2 | 0.36 | 1.00 | 0.99 | 0 | 1.00 | 1.00 | 0 | |

| O2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| H2O | 0.16 | 0 | 0 | 0 | 0 | 0 | 0 | |

| N2 | 0.21 | 0 | 0 | 0 | 0 | 0 | 0 | |

| CO2 | 0.21 | 0 | 0 | 0 | 0 | 0 | 0 | |

| CO | 0.05 | 0 | 0 | 0 | 0 | 0 | 0 | |

| (d) CMPG-S4 | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) |

| Temperature/K | 298 | 1173 | 1173 | 298 | 298 | 337 | 923 | 623 |

| Pressure/bar | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Molar flow/kmol h−1 | 1.00 | 5.08 | 0.92 | 0.92 | 1.84 | 3.68 | 3.45 | 3.45 |

| Mole fraction | ||||||||

| CH4 | 1.00 | 0.46 | 0 | 0 | 0 | 0 | 0 | 0 |

| C | 0 | 0.18 | 1.00 | 0 | 0 | 0.25 | 0 | 0 |

| H2 | 0 | 0.36 | 0 | 0 | 0 | 0 | 0.30 | 0.30 |

| O2 | 0 | 0 | 0 | 0.21 | 0 | 0.05 | 0 | 0 |

| H2O | 0 | 0 | 0 | 0 | 1.00 | 0.50 | 0.22 | 0.22 |

| N2 | 0 | 0 | 0 | 0.79 | 0 | 0.20 | 0.21 | 0.21 |

| CO2 | 0 | 0 | 0 | 0 | 0 | 0 | 0.16 | 0.16 |

| CO | 0 | 0 | 0 | 0 | 0 | 0 | 0.10 | 0.10 |

| (d) CMPG-S4 | (9) | (10) | (11) | (12) | (13) | (14) | (15) | |

| Temperature/K | 623 | 623 | 1173 | 1173 | 1173 | 1173 | 298 | |

| Pressure/bar | 1.00 | 1.00 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 | |

| Molar flow/kmol h−1 | 3.45 | 1.29 | 4.16 | 2.24 | 1.84 | 0.40 | 0.18 | |

| Mole fraction | ||||||||

| CH4 | 0 | 0 | 0.56 | 1.00 | 0 | 0 | 1.00 | |

| C | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| H2 | 0.37 | 1.00 | 0.44 | 0 | 1.00 | 1.00 | 0 | |

| O2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| H2O | 0.15 | 0 | 0 | 0 | 0 | 0 | 0 | |

| N2 | 0.21 | 0 | 0 | 0 | 0 | 0 | 0 | |

| CO2 | 0.23 | 0 | 0 | 0 | 0 | 0 | 0 | |

| CO | 0.03 | 0 | 0 | 0 | 0 | 0 | 0 |

| (a) TMP-S1 | (b) CMP-S2 | (c) TMPG-S3 | (d) CMPG-S4 | |||||

|---|---|---|---|---|---|---|---|---|

| Items | Annualized Cost/USD y−1 | Unit H2 Production Cost/USD kgH2−1 | Annualized Cost/USD y−1 | Unit H2 Production Cost/USD kgH2−1 | Annualized Cost/USD y−1 | Unit H2 Production Cost/USD kgH2−1 | Annualized Cost/USD y−1 | Unit H2 Production Cost/ USD kgH2−1 |

| 1. Capital cost | ||||||||

| MP reactor | 37,139 | 1.29 | 35,590 | 1.33 | 50,967 | 1.05 | 48,840 | 1.08 |

| WGS reactor | - | - | - | - | 1804 | 0.04 | 1729 | 0.04 |

| Regenerator | - | - | 19,233 | 0.72 | - | - | - | - |

| Catalyst | - | - | 6 | 0.00 | - | - | 6 | 0.00 |

| Gasifier | - | - | - | - | 6452 | 0.13 | 6183 | 0.14 |

| PSA | 11,323 | 0.39 | 17,924 | 0.67 | 21,320 | 0.44 | 25,460 | 0.56 |

| Cyclone | 224 | 0.01 | 214 | 0.01 | 224 | 0.00 | 213 | 0.00 |

| Supplement | 8833 | 0.31 | 11,665 | 0.44 | 13,819 | 0.28 | 13,854 | 0.31 |

| 2. Operating cost | ||||||||

| Reactant | 33,704 | 1.17 | 33,704 | 1.26 | 33,704 | 0.69 | 33,704 | 0.74 |

| Catalyst operating cost | - | - | 6 | 0.00 | - | - | 6 | 0.00 |

| Water | - | - | - | - | 2448 | 0.05 | 2251 | 0.05 |

| Fuel | 4150 | 0.14 | 3696 | 0.14 | 6848 | 0.14 | 6189 | 0.14 |

| Labor | 7524 | 0.26 | 7524 | 0.28 | 7524 | 0.15 | 7524 | 0.17 |

| PSA operating cost | 2 | 0.00 | 183 | 0.01 | 178 | 0.00 | 341 | 0.01 |

| Maintenance | 11,489 | 0.40 | 15,173 | 0.57 | 17,975 | 0.37 | 18,021 | 0.40 |

| Other costs | 5745 | 0.20 | 7587 | 0.28 | 8988 | 0.18 | 9011 | 0.20 |

| 3. C selling price | −58,700 | −2.04 | −54,352 | −2.03 | - | - | - | - |

| 4. Total cost | 61,431 | 2.14 | 98,152 | 3.66 | 172,250 | 3.53 | 173,332 | 3.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheon, S.; Byun, M.; Lim, D.; Lee, H.; Lim, H. Parametric Study for Thermal and Catalytic Methane Pyrolysis for Hydrogen Production: Techno-Economic and Scenario Analysis. Energies 2021, 14, 6102. https://doi.org/10.3390/en14196102

Cheon S, Byun M, Lim D, Lee H, Lim H. Parametric Study for Thermal and Catalytic Methane Pyrolysis for Hydrogen Production: Techno-Economic and Scenario Analysis. Energies. 2021; 14(19):6102. https://doi.org/10.3390/en14196102

Chicago/Turabian StyleCheon, Seunghyun, Manhee Byun, Dongjun Lim, Hyunjun Lee, and Hankwon Lim. 2021. "Parametric Study for Thermal and Catalytic Methane Pyrolysis for Hydrogen Production: Techno-Economic and Scenario Analysis" Energies 14, no. 19: 6102. https://doi.org/10.3390/en14196102

APA StyleCheon, S., Byun, M., Lim, D., Lee, H., & Lim, H. (2021). Parametric Study for Thermal and Catalytic Methane Pyrolysis for Hydrogen Production: Techno-Economic and Scenario Analysis. Energies, 14(19), 6102. https://doi.org/10.3390/en14196102