Techno-Economic Analysis of Fast Pyrolysis of Date Palm Waste for Adoption in Saudi Arabia

Abstract

:1. Introduction

2. Process Description

2.1. Date Palm Waste Analysis

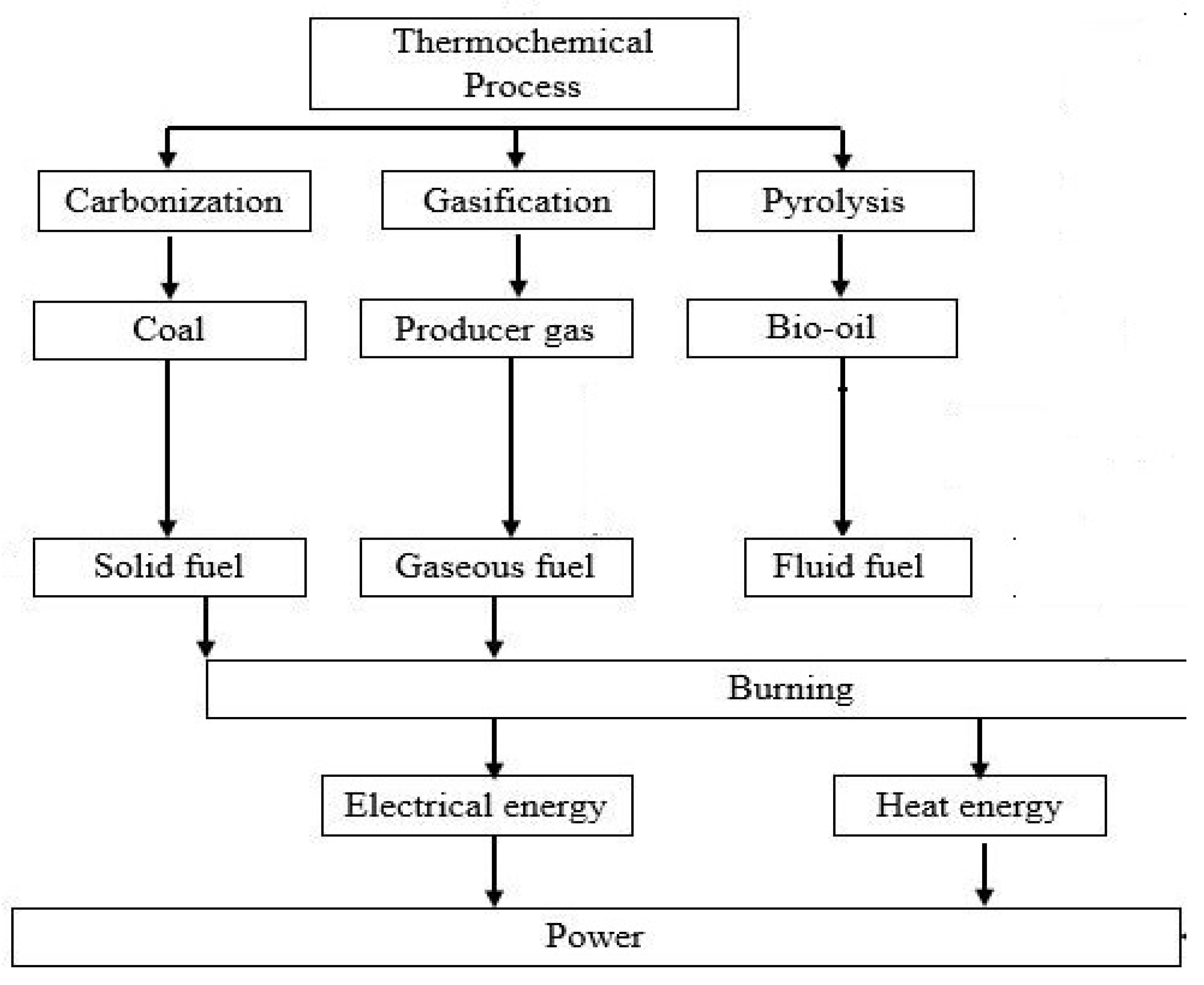

2.2. Thermochemical Conversion Process

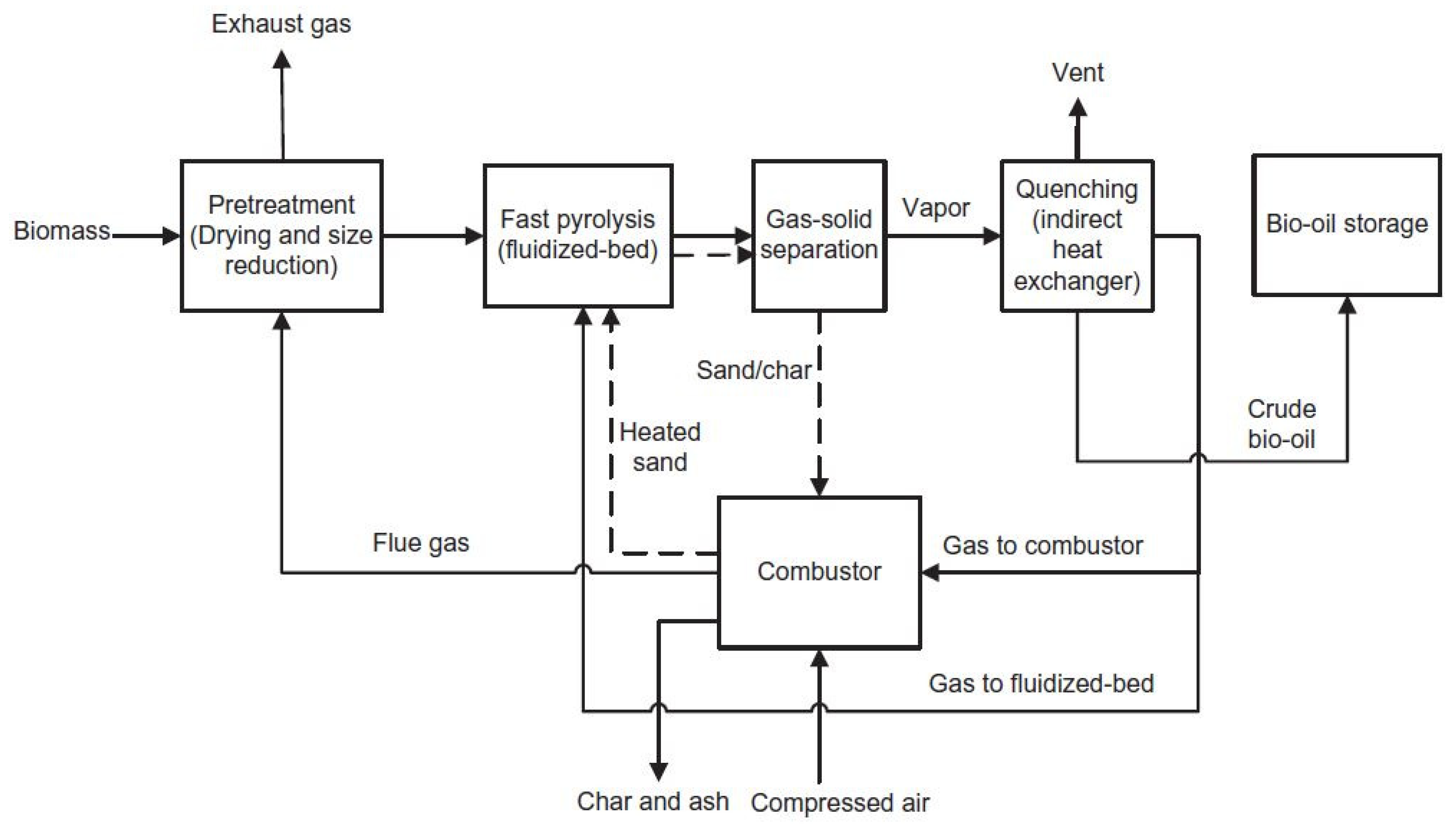

2.3. The Principle of Fast Pyrolysis

2.4. Pyrolysis Unit Description

3. Techno-Economic Analysis

3.1. Technical Analysis

3.1.1. Yield Assessment and Carbon Conversion Efficiency

3.1.2. Energy Balance of Pyrolysis Process

3.1.3. Energy Requirement of Pyrolysis Process

3.2. Economic Analysis

3.2.1. Fixed Cost

3.2.2. Variable Cost

3.2.3. Net Revenue Generation from Pyrolysis of Date Palm Waste

3.2.4. Break-Even Analysis

- X = Operating time in years

- TFC = Total fixed cost invested in the beginning of the project

- V = Total cost (fixed +variable) per annum of pyrolysis unit

- P = Gross revenue generated per year through pyrolysis unit

- X =

- X = 2.57 years

3.2.5. Net Present Value of the Pyrolysis Unit

3.2.6. Internal Rate of Return

3.2.7. Other Performance Indicators

4. Conclusions and Recommendations

- (i)

- Fast pyrolysis is regarded as a promising technology to derive bio-oil, biochar, and non-condensable gas from biomass.

- (ii)

- This techno-economic analysis affirmed the feasibility of fast pyrolysis of date palm waste, based on the experimental data. However, it is necessary to operate pilot plant for a reasonably long period to collect more reliable first-hand data for determining optimal operational conditions and for making this analysis more reliable.

- (iii)

- The economic analysis revealed that a date grower can secure net saving of USD 556.8 by converting one ton of date palm waste into biofuel through fast pyrolysis.

- (iv)

- If 50% of date palm waste produced in Saudi Arabia is converted into biofuel through fast pyrolysis, a net amount of USD 44.77 million per annum can be earned.

- (v)

- The payback period of a fast pyrolysis unit having 10 tons/day capacity was worked out to be 2.57 years. The net present value of this project was positive, and internal rate of return was calculated as 36.45%.

- (vi)

- It was observed that the most sensitive parameter for the economic analysis was the selling price of the byproducts (bio-oil, biochar, syn gas) of fast pyrolysis unit, particularly, the price variation of biochar is very high. In this analysis, the average selling price of biochar was considered.

- (vii)

- Based on the findings of this techno-economic analysis, it is recommended to frame a research and commercialization project of biomass energy generation in Saudi Arabia. This will help in exploring the potential of biomass energy resources and suggest adoption of appropriate technologies in the Kingdom based on scientific research.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations or Acronyms

| Atm | Atmosphere |

| MENA | Middle East and North Africa |

| HHV | Higher Heating Value |

| m × HHV | Higher Heating Value of the products based on mass |

| MJ | Mega Joules |

| wt % | Weight percent |

| Gj | Gega Joules |

| Ms | Milliseconds |

| kWh | Kilo Watt hour |

| GWh | Giga Watt hour |

| TEA | Techno-economic Analysis |

| CV | Calorific Values |

| Tpd | Tons per day |

| BEP | Break Even Point |

| TFC | Total Fixed Cost |

| X | Operating time in years |

| V | Total cost (fixed +variable) per annum |

| P | Gross revenue generated per year |

| NPV | Net Present Value |

| IRR | Internal Rate of Return |

| GHG | Green House Gas |

References

- Al-Farsi, M.A.; Lee, C.Y. Optimization of phenolics and dietary fibre extraction from date seeds. Food Chem. 2008, 108, 977–985. [Google Scholar] [CrossRef]

- Hussain, A.; Farooq, A.; Bassyouni, M.I.; Sait, H.H.; El-Wafa, M.A.; Hasan, S.W.; Ani, F.N. Pyrolysis of Saudi Arabian date palm waste: A viable option for converting waste into wealth. Life Sci. J. 2014, 11, 12. [Google Scholar]

- Elmay, Y.; Jeguirim, M.; Trouvé, G.; Said, R. Kinetic analysis of thermal decomposition of date palm residues using Coats–Redfern method. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 1117–1124. [Google Scholar] [CrossRef]

- Sait, H.H.; Hussain, A.; Salema, A.; Ani, F.N. Pyrolysis and combustion kinetics of date palm biomass using thermogravimetric analysis. Bioresour. Technol. 2012, 118, 382–389. [Google Scholar] [CrossRef]

- Zaman, C.Z.; Pal, K.; Yehye, W.A.; Sagadevan, S.; Shah, S.T.; Adebisi, G.A.; Marliana, E.; Rafique, R.F.; Bin Johan, R. Pyrolysis: A sustainable way to generate energy from waste. In Pyrolysis; IntechOpen: Rijeka, Croatia, 2017; Volume 1, p. 316806. [Google Scholar]

- Elliott, D.; Beckman, D.; Bridgwater, A.V.; Diebold, J.P.; Gevert, S.B.; Solantausta, Y. Developments in direct thermochemical liquefaction of biomass: 1983–1990. Energy Fuels 1991, 5, 399–410. [Google Scholar] [CrossRef]

- Jung, S.-H.; Kang, B.-S.; Kim, J.-S. Production of bio-oil from rice straw and bamboo sawdust under various reaction conditions in a fast pyrolysis plant equipped with a fluidized bed and a char separation system. J. Anal. Appl. Pyrolysis 2008, 82, 240–247. [Google Scholar] [CrossRef]

- Gust, S. Combustion experiences of flash pyrolysis fuel in intermediate size boilers. In Developments in Thermochemical Biomass Conversion: Volume 1/Volume 2; Bridgwater, A.V., Boocock, D.G.B., Eds.; Springer: Dordrecht, The Netherlands, 1997; pp. 481–488. [Google Scholar]

- Joardder, M.U.H.; Uddin, S.; Islam, M.N. The Utilization of Waste Date Seed as Bio-Oil and Activated Carbon by Pyrolysis Process. Adv. Mech. Eng. 2012, 4, 316806. [Google Scholar] [CrossRef]

- Mahdi, Z.; El Hanandeh, A.; Yu, Q.J. Date Palm (Phoenix dactylifera L.) Seed Characterization for Biochar Preparation. In Proceedings of the 6th International Conference on Engineering, Project, and Production Management (EPPM), Gold Coast, Australia, 2–4 September 2015; Volume 7, pp. 130–138. [Google Scholar]

- Makkawi, Y.; El Sayed, Y.; Salih, M.; Nancarrow, P.; Banks, S.; Bridgwater, T. Fast pyrolysis of date palm (Phoenix dactylifera) waste in a bubbling fluidized bed reactor. Renew. Energy 2019, 143, 719–730. [Google Scholar] [CrossRef]

- Bensidhom, G.; Trabelsi, A.B.H.; Alper, K.; Sghairoun, M.; Zaafouri, K.; Trabelsi, I. Pyrolysis of Date palm waste in a fixed-bed reactor: Characterization of pyrolytic products. Bioresour. Technol. 2018, 247, 363–369. [Google Scholar] [CrossRef]

- Jirka, S.; Tomlinson, T. State of the Biochar Industry 2013—A Survey of Commercial Activity in the Biochar Field; International Biochar Initiative: Philadeplhia, PA, USA, 2014. [Google Scholar]

- Badger, P.; Badger, S.; Puettmann, M.; Steele, P.; Cooper, J. Techno-economic analysis: Preliminary assessment of pyrolysis oil production costs and material energy balance associated with a transportable fast pyrolysis system. Bioresources 2010, 6, 1. [Google Scholar] [CrossRef]

- Bu, Q.; Lei, H.; Zacher, A.H.; Wang, L.; Ren, S.; Liang, J.; Wei, Y.; Liu, Y.; Tang, J.; Zhang, Q.; et al. A review of catalytic hydrodeoxygenation of lignin-derived phenols from biomass pyrolysis. Bioresour. Technol. 2012, 124, 470–477. [Google Scholar] [CrossRef]

- Brown, T.R.; Thilakaratne, R.; Brown, R.C.; Hu, G. Techno-economic analysis of biomass to transportation fuels and electricity via fast pyrolysis and hydroprocessing. Fuel 2013, 106, 463–469. [Google Scholar] [CrossRef] [Green Version]

- Taufiq-Yap, Y.H.; Teo, S.; Rashid, U.; Islam, A.; Hussien, M.Z.; Lee, K.T. Transesterification of Jatropha curcas crude oil to biodiesel on calcium lanthanum mixed oxide catalyst: Effect of stoichiometric composition. Energy Convers. Manag. 2014, 88, 1290–1296. [Google Scholar] [CrossRef]

- Go, A.; Sutanto, S.; Ong, L.K.; Tran-Nguyen, P.L.; Ismadji, S.; Ju, Y.-H. Developments in in-situ (trans) esterification for biodiesel production: A critical review. Renew. Sustain. Energy Rev. 2016, 60, 284–305. [Google Scholar] [CrossRef] [Green Version]

- Czernik, S.; Bridgwater, A.V. Overview of Applications of Biomass Fast Pyrolysis Oil. Energy Fuels 2004, 18, 590–598. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Meier, D.; Radlein, D. An overview of fast pyrolysis of biomass. Org. Geochem. 1999, 30, 1479–1493. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Abdullah, N.; Gerhauser, H. Bio-oil derived from empty fruit bunches. Fuel 2008, 87, 2606–2613. [Google Scholar] [CrossRef] [Green Version]

- Do, T.X.; Lim, Y.-I.; Yeo, H. Techno-economic analysis of biooil production process from palm empty fruit bunches. Energy Convers. Manag. 2014, 80, 525–534. [Google Scholar] [CrossRef]

- Swanson, R.M.; Satrio, J.A.; Brown, R.C.; Hsu, D.D. Techno-Economic Analysis of Biofuels Production Based on Gasification Techno-Economic Analysis of Biofuels Production Based on Gasification Alexandru Platon. Energy 2010, 89. Available online: https://www.osti.gov/biblio/994017 (accessed on 1 August 2021).

- Kole, C.; Joshi, C.P.; Shonnard, D.R. Handbook of Bioenergy Crop Plants; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Shemfe, M.B.; Gu, S.; Ranganathan, P. Techno-economic performance analysis of biofuel production and miniature electric power generation from biomass fast pyrolysis and bio-oil upgrading. Fuel 2015, 143, 361–372. [Google Scholar] [CrossRef] [Green Version]

- Bridgwater, A. Principles and practice of biomass fast pyrolysis processes for liquids. J. Anal. Appl. Pyrolysis 1999, 51, 3–22. [Google Scholar] [CrossRef]

- Lyu, G.; Wu, S.; Zhang, H. Estimation and Comparison of Bio-Oil Components from Different Pyrolysis Conditions. Front. Energy Res. 2015, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Rogers, J.; Brammer, J. Estimation of the production cost of fast pyrolysis bio-oil. Biomass Bioenergy 2012, 36, 208–217. [Google Scholar] [CrossRef]

- Whittaker, J.D.; Smith, G.W. Engineering Economy, Analysis of Capital Expenditures. Oper. Res. Q. 1975, 26, 773. [Google Scholar] [CrossRef]

- IPCC. App 4. Method for estimating the change in mineral soil organic carbon stocks from biochar amendments: Basis for future methodological development, 2019 Refinement to 2006 IPCC Guidel. Natl. Greenh. Gas Invent. 2019. Available online: https://www.ipcc-tfi.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch02_Ap4_Biochar.pdf (accessed on 1 August 2021).

- Cheng, F.; Luo, H.; Colosi, L.M. Slow pyrolysis as a platform for negative emissions technology: An integration of machine learning models, life cycle assessment, and economic analysis. Energy Convers. Manag. 2020, 223, 113258. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 1. [Google Scholar] [CrossRef] [Green Version]

| Ultimate Analysis | |||||

| Biomass | C | H | N | S | O |

| Seed | 44.1 | 6.1 | 0.9 | 0.6 | 48.3 |

| Leaf | 50.4 | 6.3 | 1.1 | 0.4 | 41.8 |

| Stem | 38.1 | 5.2 | 0.8 | 0.3 | 55.6 |

| Proximate Analysis | |||||

| Biomass | Moisture | Volatile Matter | Ash contents | Fixed Carbon | |

| Seed | 5.1 | 75.1 | 9.8 | 8.1 | |

| Leaf | 5.3 | 77.5 | 12.1 | 6.1 | |

| Stem | 18.1 | 52.1 | 20.2 | 8.1 | |

| Material | Input Energy (kWh) | Pyrolysis Products from One Ton of Waste (Tons) | Output Energy (kWh) |

|---|---|---|---|

| Date palm waste, 8% MC (wet basis) | 5230.5 | ||

| Bio-oil | 0.388 | 2250.4 | |

| Char | 0.372 | 2041.8 | |

| Syngas | 0.240 | 593.3 | |

| Ash and heat loss from pyrolysis unit | 345.0 | ||

| Total | 5230.5 |

| S # | Steps in Pyrolysis Process | Energy Consumed (MJ/kg) | Energy Consumed (kWh/ton) |

|---|---|---|---|

| A. Electrical Energy | |||

| (i) | Electricity consumption by fluidized bed pyrolysis unit | - | 200.0 [30] |

| (ii) | Electricity consumed for biomass handling and pre-processing (chopping and grinding) | - | 40 [30] |

| Total electric energy consumed per ton | 240.00 | ||

| B. Thermal energy | |||

| (i) | Drying (removal of residual moisture from 8% to zero%), about 80 kg/ton | 0.3 | 6.66 |

| (ii) | Heat required to raise the biomass to 500 °C and decompose it (920 kg/ton) | 1.5 | 383.3 |

| (iii) | Heat required to raise fluidizing gas up to 500 °C from 50 °C quenching temperature (2.75 kg of fluidizing gas per kg of biomass (Wright et al., 2010)) [31] | 0.60 [30] | 458.33 |

| (iv) | Radiation, convection, and conduction losses (3% of heat input to pyrolysis reactor) | - | 25.45 |

| Total thermal energy required per ton of date palm waste, kWh | 872.74 |

| Parameters | Assumptions |

|---|---|

| Financing | 100% owned capital |

| Pyrolysis unit availability | 300 days/year |

| Pyrolysis unit depreciation period | 8 years |

| Interest on investment | 10% |

| Housing and insurance cost | 2% of the initial cost of pyrolysis unit |

| Capacity of pyrolysis unit selected | 10 tons per day |

| Annual capacity of pyrolysis unit for processing date palm waste | 3000 tons |

| Total annual operating hours | 7200 h |

| Item Description | Quantity | Price (USD Million) |

|---|---|---|

| Pyrolysis unit (10 tons/day capacity) | 1 | 1.70 |

| Shredder | 1 | 0.05 |

| Storage tanks | 2 | 0.05 |

| Civil work | 0.05 | |

| Miscellaneous equipment | 0.15 | |

| Total cost | 2.00 |

| Sr # | Parameters | Assumptions |

|---|---|---|

| (i) | Repair and maintenance cost | 2.0% of the initial cost per annum [24] |

| (ii) | Labor cost (3 shifts and 3 workers in each shift) | USD 30,000/worker/annum |

| (iii) | Date palm waste purchasing and transportation cost per ton | USD 50.00 |

| (iv) | Electricity cost (5.4 cents/kWh in US) | 0.054 USD/kWh |

| (v) | Nitrogen cost per ton of biomass [32] | USD 2.66 |

| (vi) | Miscellaneous chemical cost per ton of biomass [32] | USD 4.00 |

| Sr # | Item | Cost USD/Annum | Cost USD/Ton of Date Palm Waste Processed | Cost USD/h of Date Palm Waste Processed |

|---|---|---|---|---|

| A Fixed cost estimates | ||||

| (i) | Depreciation cost | 225,000 | 75.0 | 31.25 |

| (ii) | Interest on investment | 110,000 | 36.0 | 15.2 |

| (iii) | Housing and insurance cost | 40,000 | 13.3 | 5.5 |

| Sum of fixed cost | 375,000 | 124.3 | 51.95 | |

| B Variable cost estimates | ||||

| (i) | Repair and maintenance cost | 40,000 | 13.3 | 5.5 |

| (ii) | Labor cost | 270,000 | 90.00 | 37.5 |

| (iii) | Date palm waste purchasing and transportation cost | 150,000 | 50.00 | 20.83 |

| (iv) | Electricity cost for biomass pyrolysis and pre-processing (240 kWh/ton @ 0.054 USD/kWh) | 38,880 | 12.96 | 5.4 |

| (v) | Nitrogen induction in the reactor cost | 7980 | 2.66 | 1.11 |

| (vi) | Miscellaneous chemical cost | 12,000 | 4.00 | 1.67 |

| Sum of Variable Cost | 518,860 | 172.92 | 72.01 | |

| Total Cost (Fixed + Variable) | 893,860 | 297.22 | 123.96 |

| Item | Quantity Produced (Tons) | Quantity Consumed in the Process (Tons) | Net Quantity for Selling (Tons) | $/Ton | Income from the Sale of Pyrolysis Products ($) |

|---|---|---|---|---|---|

| Bio-oil | 0.388 | 0.180 | 0.208 | 300 | 62.4 |

| Biochar [33] | 0.372 | - | 0.372 | 1200 | 446.4 |

| Non-condensable gas | 0.240 | - | 0.240 | 200 | 48.0 |

| Total revenue generated/ton | 556.8 | ||||

| Total revenue generated/h | 232.0 |

| Sr # | Performance Indicator | Amount |

|---|---|---|

| 1 | Annual Bio-oil production | 624 tons (Excluding the bio-oil consumed during the process) |

| 2 | Annual Char production | 1116 tons |

| 3 | Annual syngas production | 720 tons |

| 4 | Annual energy yield | 12.12 GWh |

| 5 | Total energy yield during the life of the pyrolysis unit | 96.96 GWh |

| 6 | Levelized cost of energy | 0.048 $/kWh |

| 7 | Simple payback time | 2.57 years |

| 8 | Annual GHG emission reduction | 2029 tons of CO2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahya, S.A.; Iqbal, T.; Omar, M.M.; Ahmad, M. Techno-Economic Analysis of Fast Pyrolysis of Date Palm Waste for Adoption in Saudi Arabia. Energies 2021, 14, 6048. https://doi.org/10.3390/en14196048

Yahya SA, Iqbal T, Omar MM, Ahmad M. Techno-Economic Analysis of Fast Pyrolysis of Date Palm Waste for Adoption in Saudi Arabia. Energies. 2021; 14(19):6048. https://doi.org/10.3390/en14196048

Chicago/Turabian StyleYahya, Sulaiman Al, Tahir Iqbal, Muhammad Mubashar Omar, and Munir Ahmad. 2021. "Techno-Economic Analysis of Fast Pyrolysis of Date Palm Waste for Adoption in Saudi Arabia" Energies 14, no. 19: 6048. https://doi.org/10.3390/en14196048

APA StyleYahya, S. A., Iqbal, T., Omar, M. M., & Ahmad, M. (2021). Techno-Economic Analysis of Fast Pyrolysis of Date Palm Waste for Adoption in Saudi Arabia. Energies, 14(19), 6048. https://doi.org/10.3390/en14196048