Healthy and Faulty Experimental Performance of a Typical HVAC System under Italian Climatic Conditions: Artificial Neural Network-Based Model and Fault Impact Assessment

Abstract

1. Introduction

1.1. Automated Fault Detection and Diagnosis Methods for HVAC Systems

1.2. Novelty and Structure of the Paper

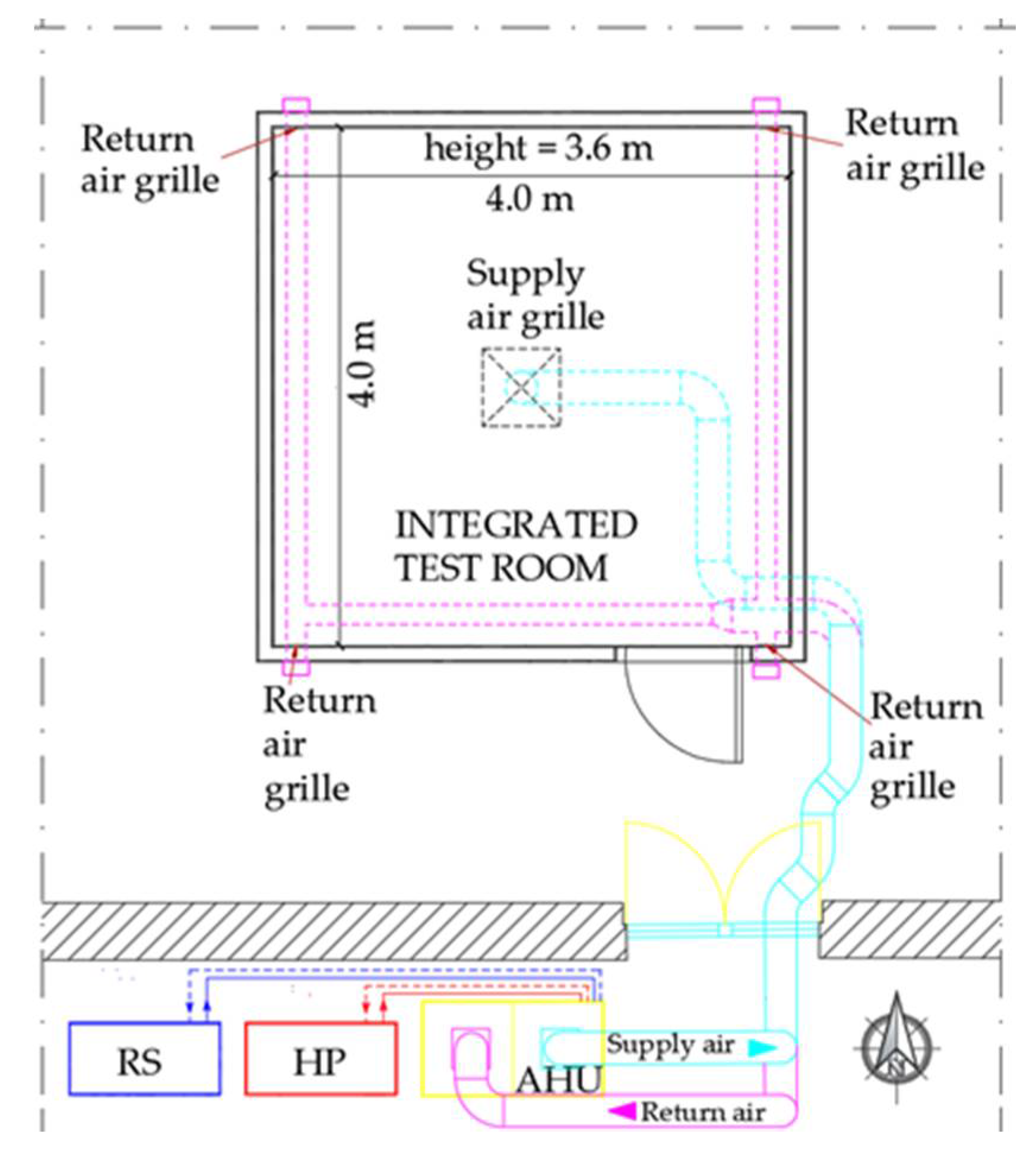

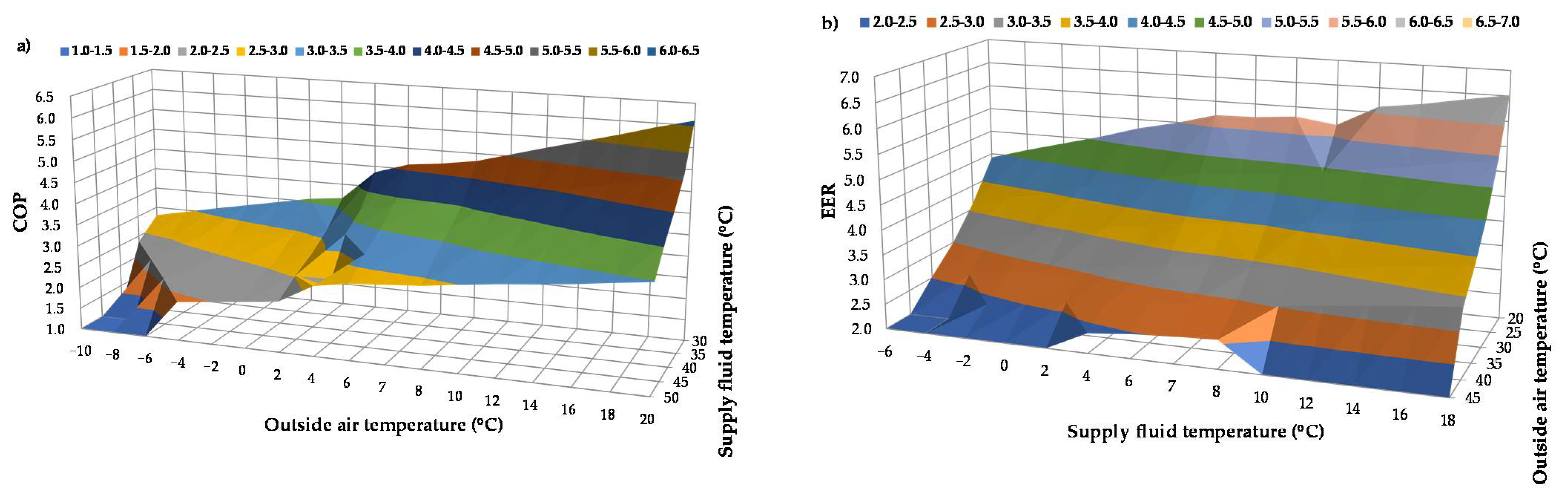

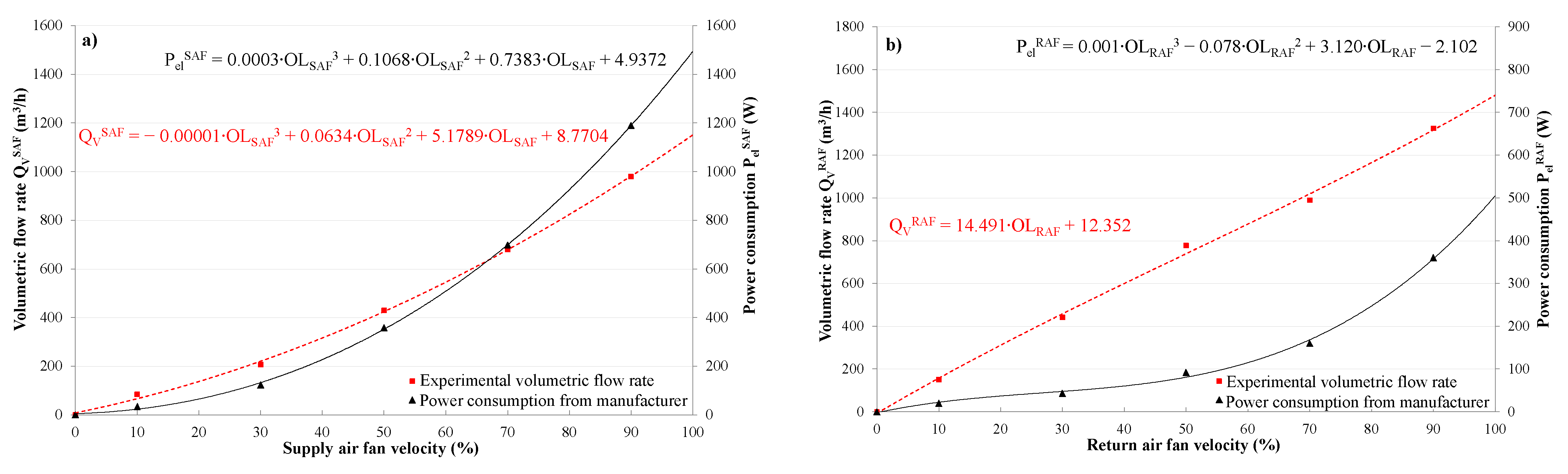

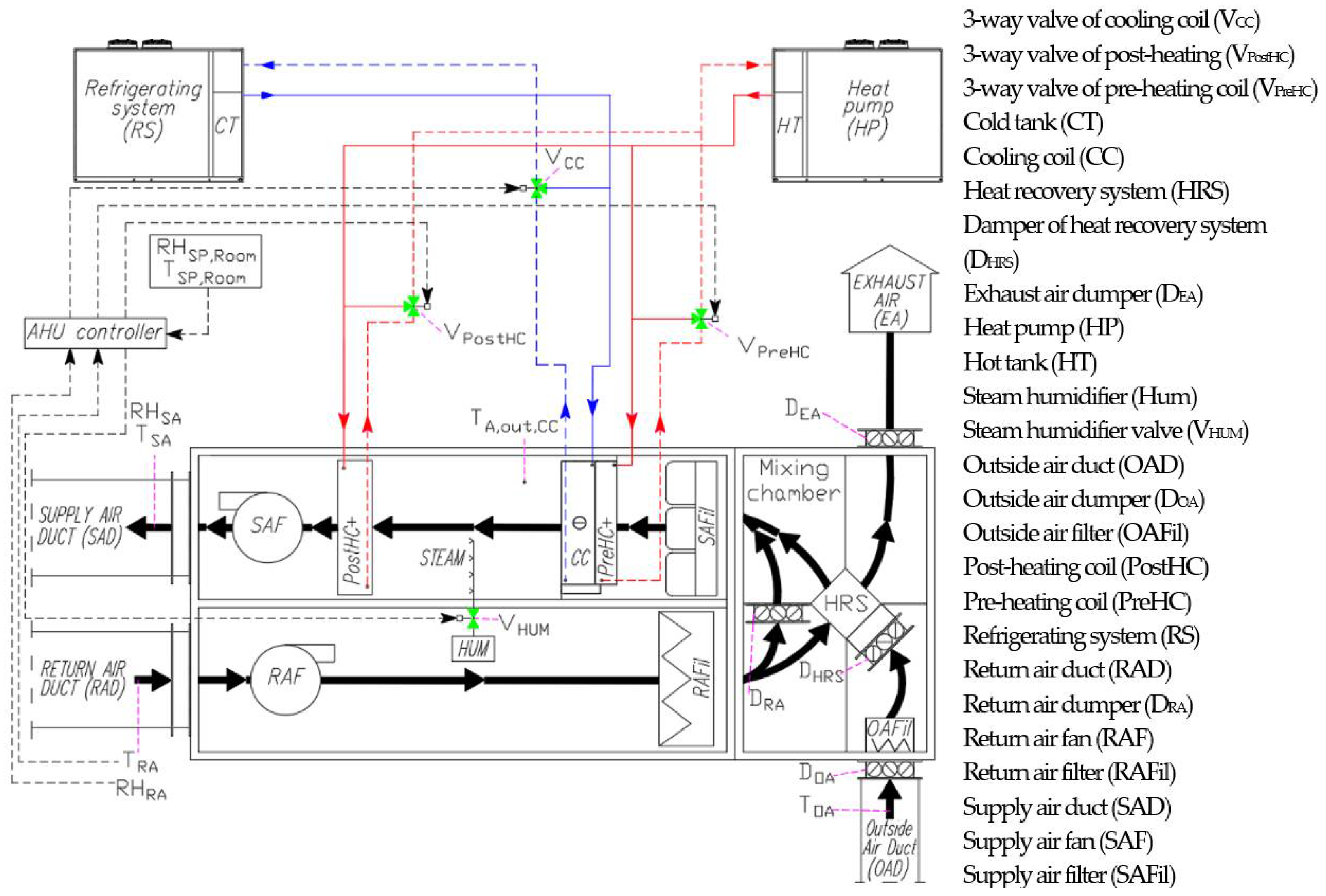

2. Description of the Experimental Setup

3. Experimental Tests

- Fault 1 has been implemented during both the tests n. 5 and n. 14, i.e., the velocity of the supply air fan has been kept at 20% (instead of the nominal value of 50%);

- Fault 2 has been implemented during both the tests n. 6 and n. 15, i.e., the velocity of the return air fan has been kept at 20% (instead of the nominal value of 50%);

- Fault 3 has been implemented during both the tests n. 7 and 16, i.e., the valve managing the flow rate entering the post-heating coil has always been kept closed (instead of allowing its normal operation with an opening percentage in the range 0 ÷ 100% according to the AHU automatic control logic);

- Fault 4 has been implemented during both the tests n. 8 and n. 17, i.e., the valve managing the flow rate entering the cooling coil has always been kept closed (instead of allowing its normal operation with an opening percentage in the range 0 ÷ 100% according to the AHU automatic control logic);

- Fault 5 has been implemented during both the tests n. 9 and n. 18, i.e., opening percentage of the valve managing the flow rate entering the steam humidifier has always been kept closed (instead of allowing its normal operation with an opening percentage in the range 0 ÷ 100% according to the AHU automatic control logic).

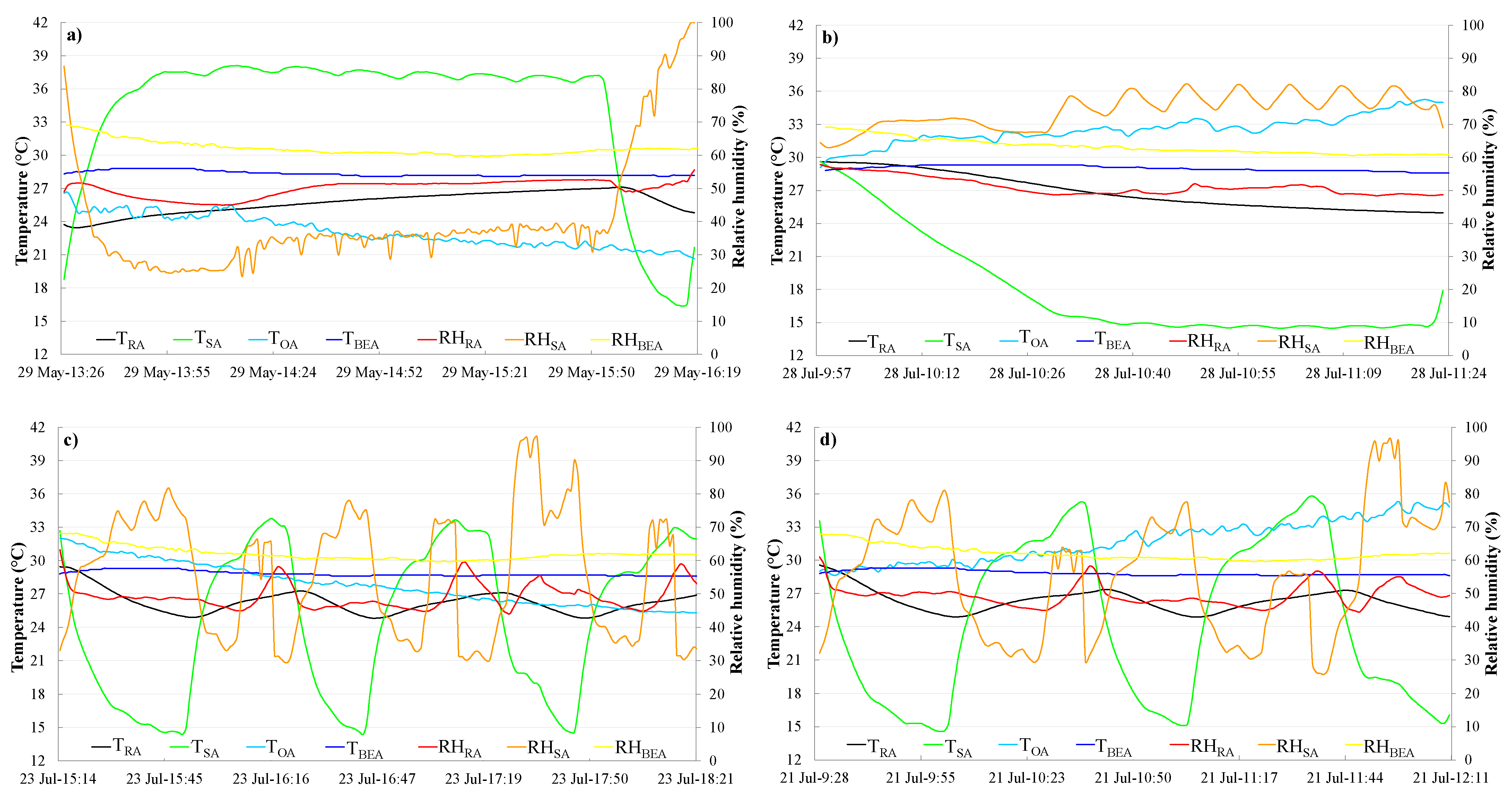

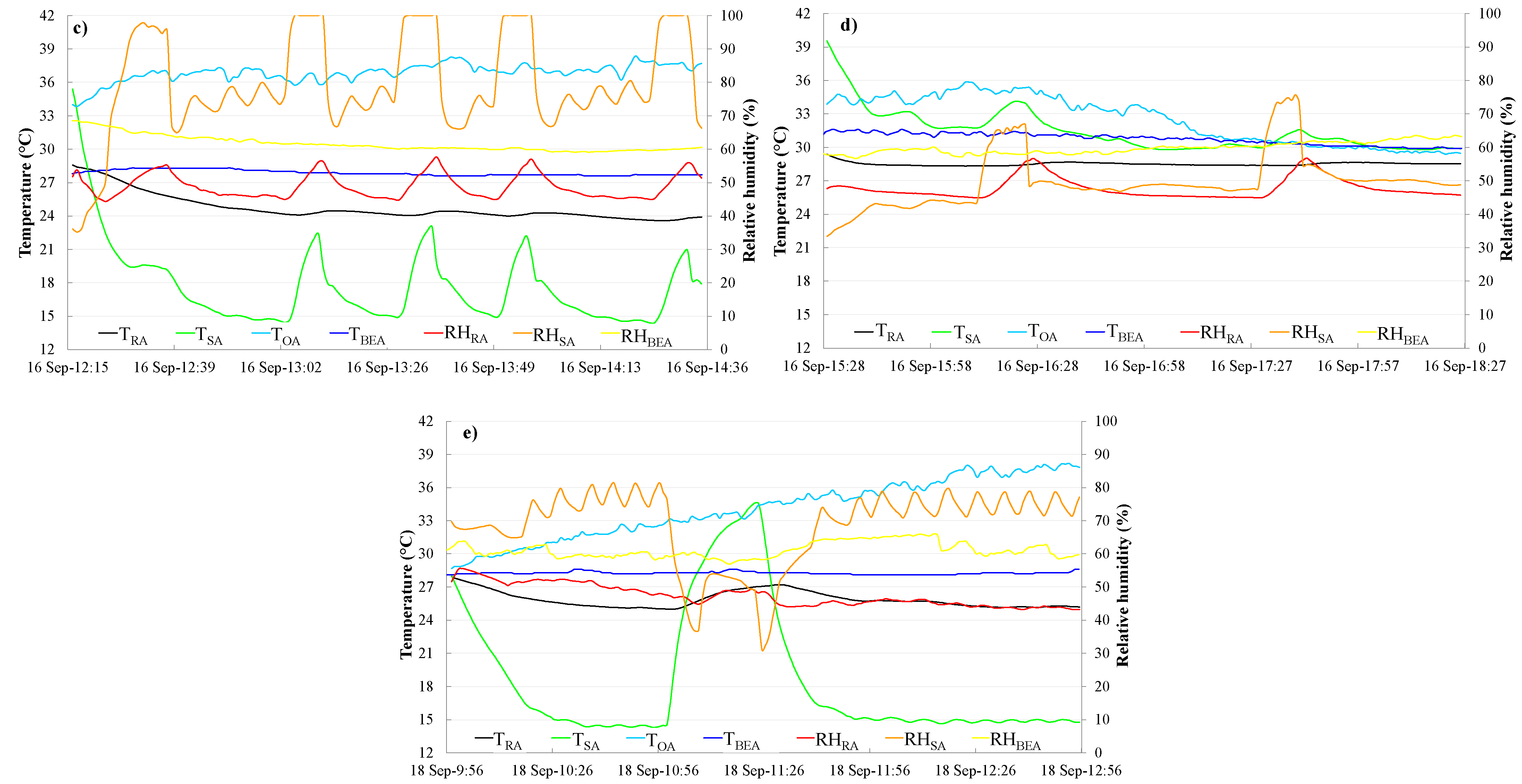

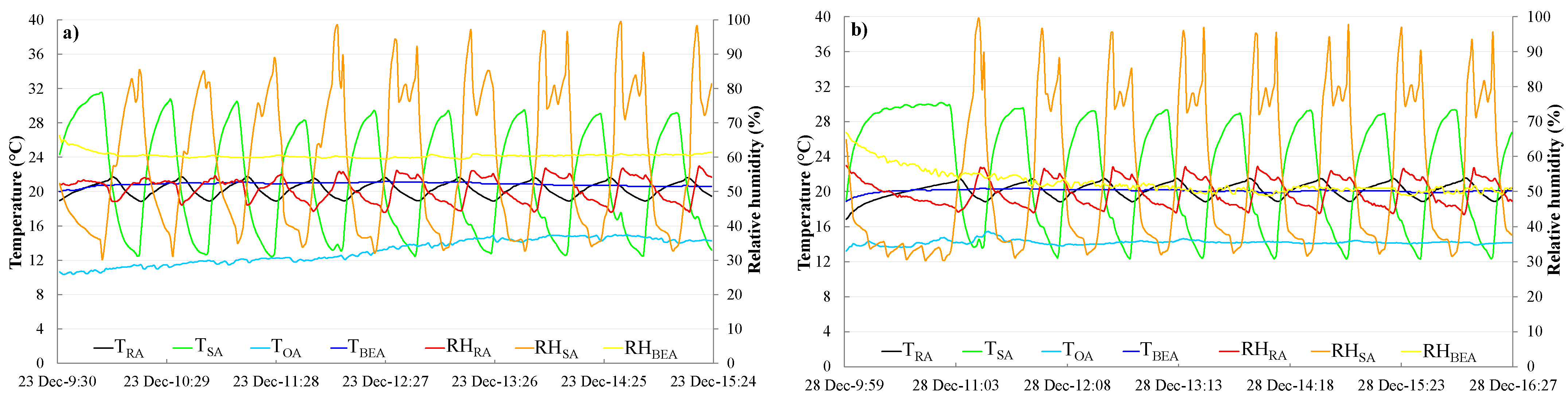

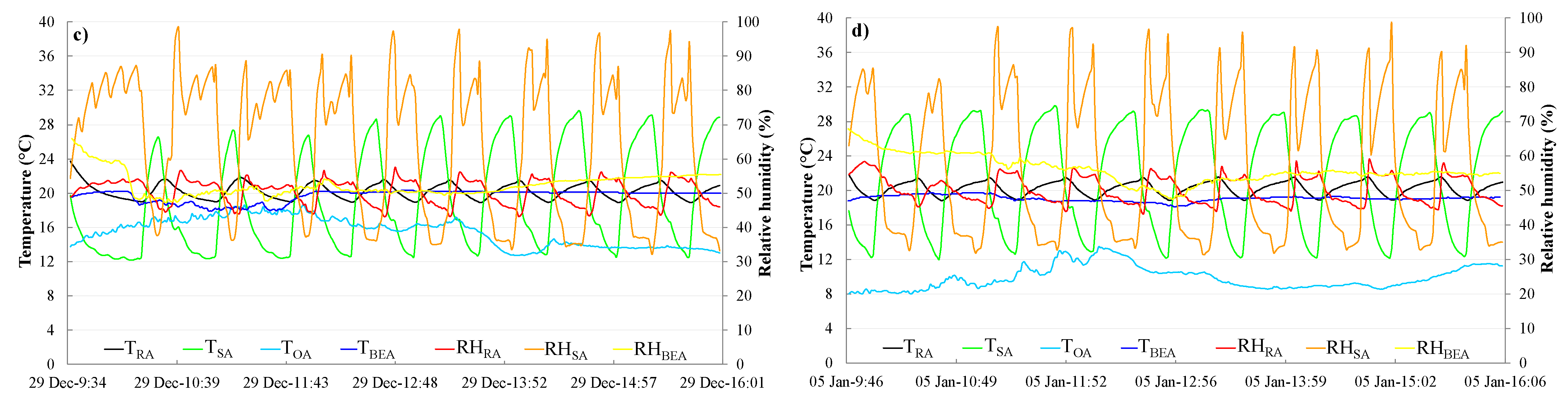

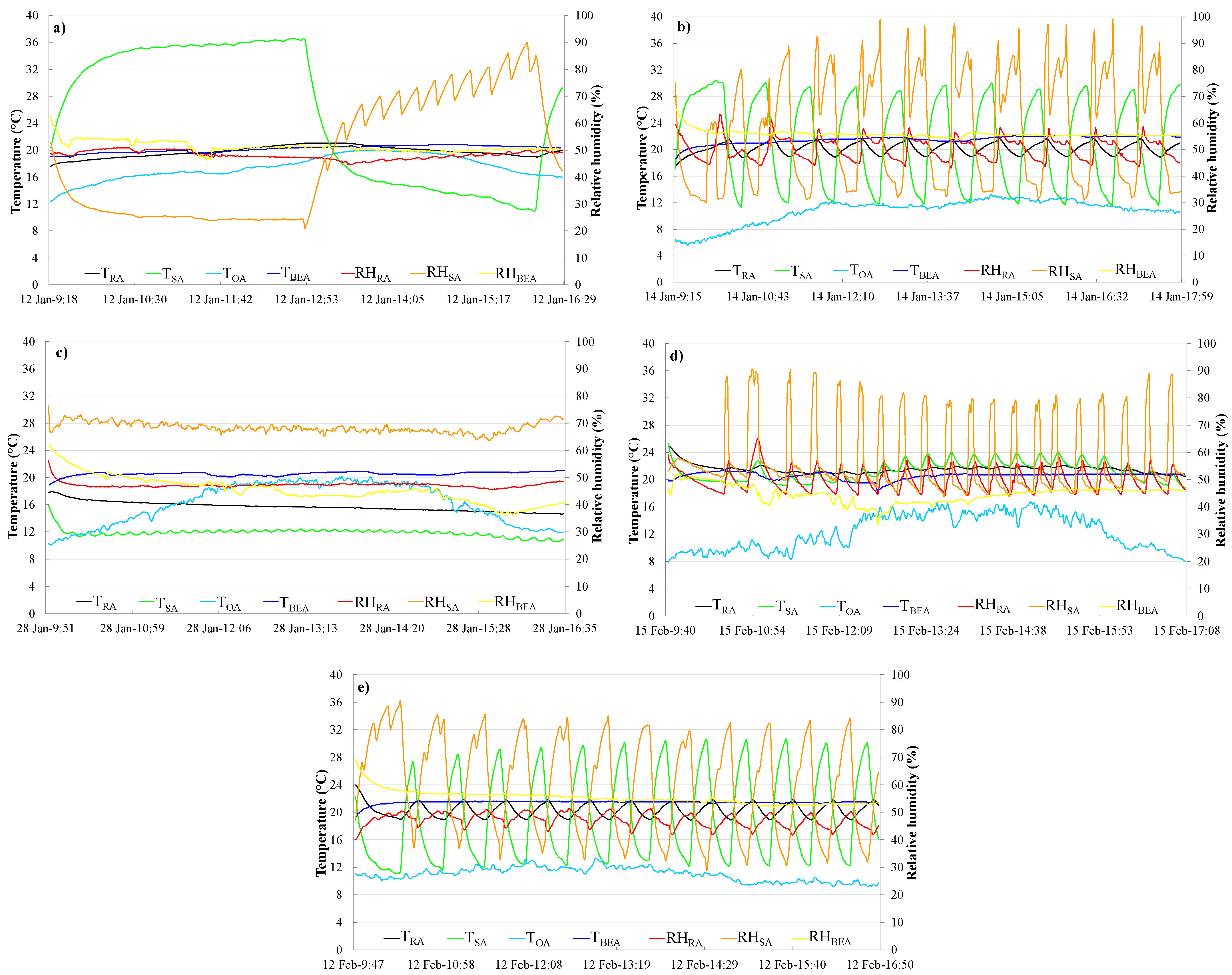

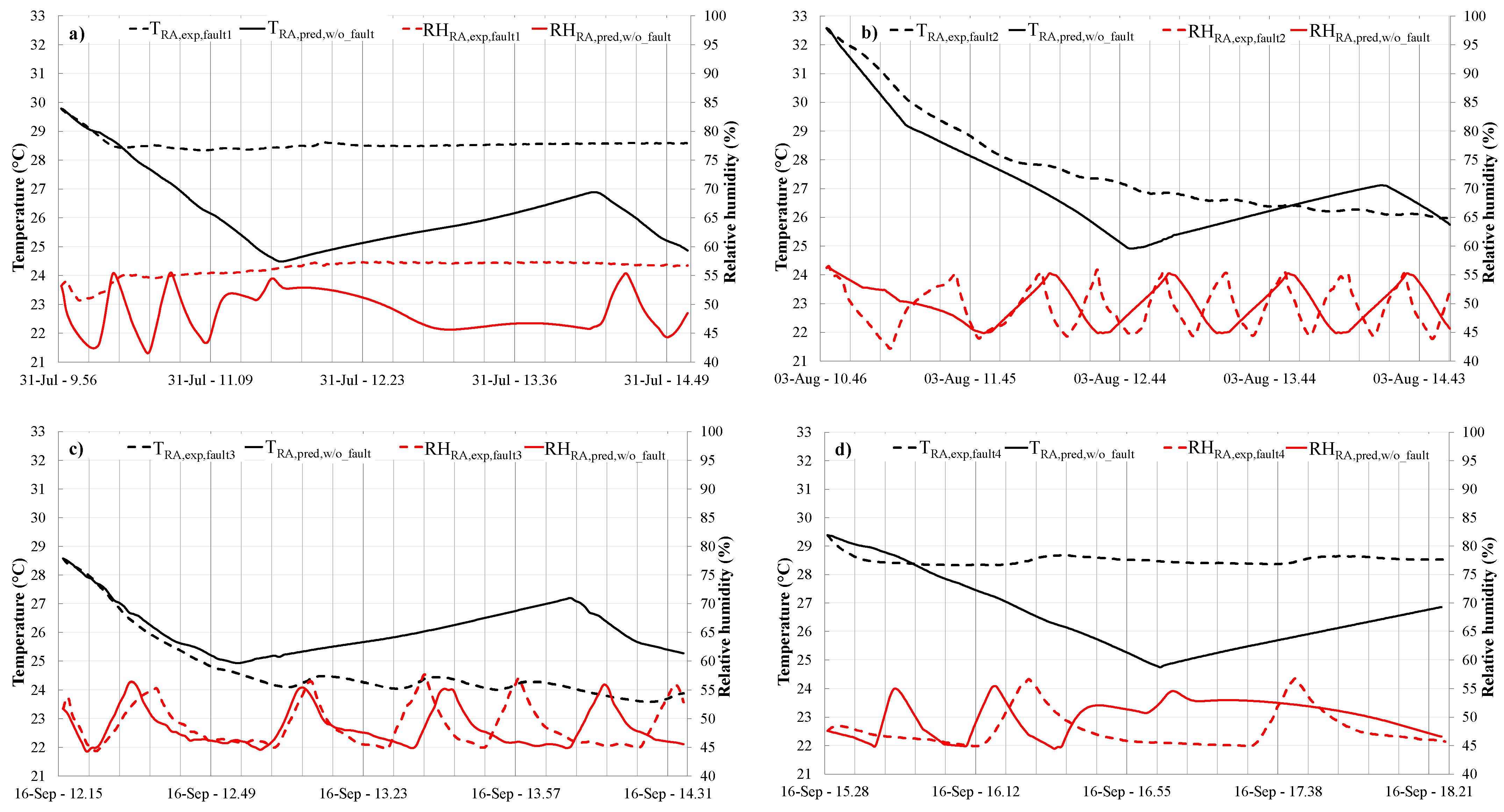

Analysis of Experimental Trends

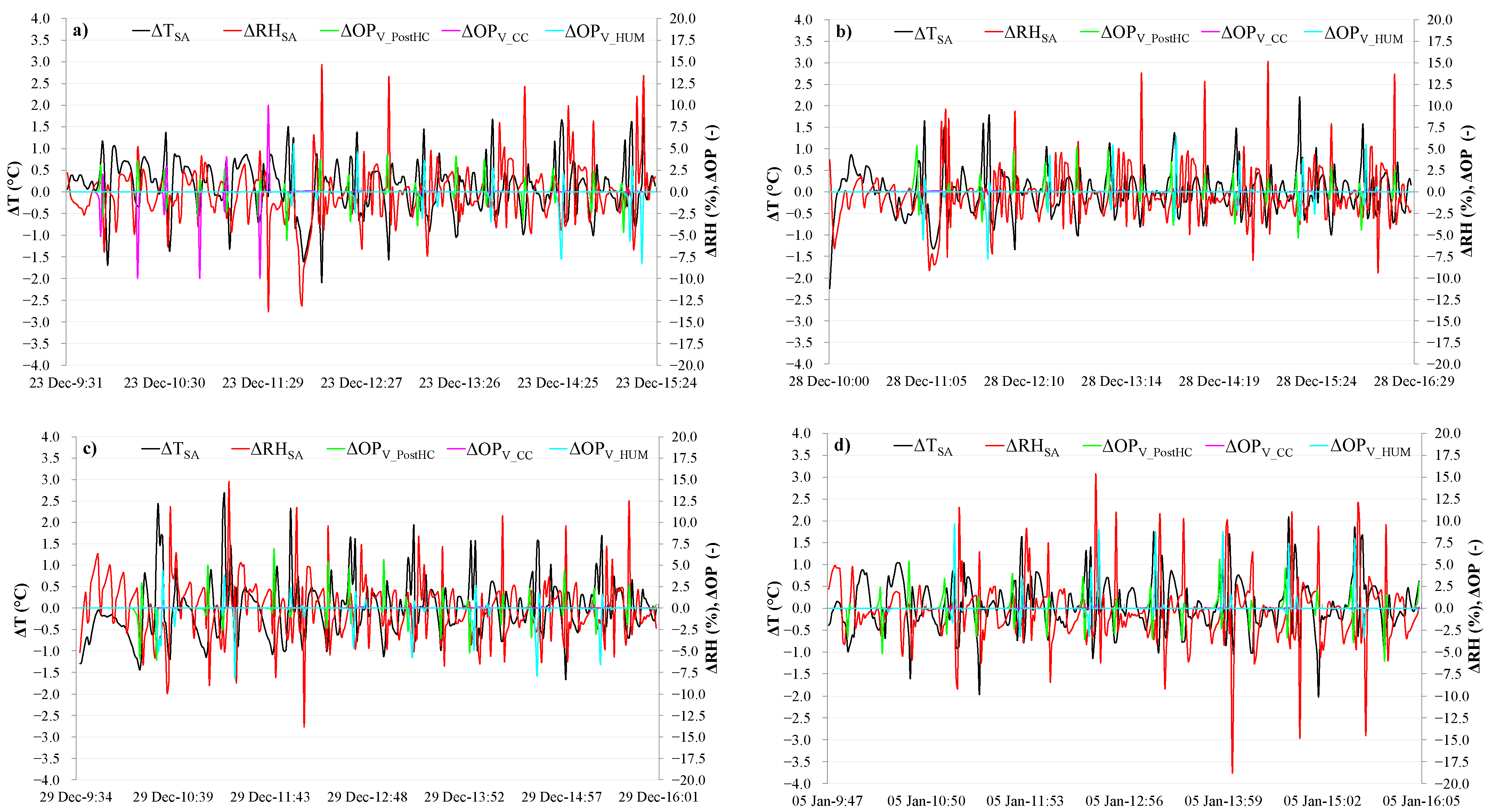

- In Figure 3a (corresponding to the fault 1, i.e., velocity of the supply air fan reduced at 20%), supply air temperature and supply air relative humidity are in a much narrower range as it would expected in the case of reduced supply air flow; in this case, TSA drops to about 18.4 °C and then it remains below 20.5 °C (out of the desired thermal comfort range) during the remaining part of the test, while RHSA is in the range of 51% to 61% with a larger number of oscillations; in addition, it can be noticed that both return air temperature TRA and return air relative humidity RHRA vary much more slowly as a function of time;

- Figure 3b (corresponding to the fault 2, i.e., velocity of the return air fan reduced at 20%) indicates that, as supposed, supply air temperature varies in a smaller range (in this case between 15.5 °C and 21.0 °C) when return air flow rate is reduced;

- In Figure 3c (corresponding to the fault 3, i.e., post-heating coil valve kept fully closed), supply air temperature TSA assumes lower average values, ranging in a narrower interval (in this case between 14.5 °C and 23.0 °C) due to the fact that post-heating coil is not active; as a consequence, return air temperature, after the initial drop from ~28.5 °C down to ~24.0 °C, remains almost constant during the remaining part of the test (with a value smaller than its lower deadband and, therefore, out of desired thermal comfort range); in addition, it should be underlined that average values of supply air relative humidity are greater;

- In Figure 3d (corresponding to the fault 4, i.e., cooling coil valve kept fully closed), supply air temperature is characterized by much larger average values (as it would be expected due to the missing contribution of the cooling coil), with a narrower variation range (in this case between 30.0 °C and 34.0 °C); return air temperature is substantially constant, assuming a value larger than its upper deadband (in this case equal to ~28.5 °C) and, therefore, out of the desired thermal comfort range;

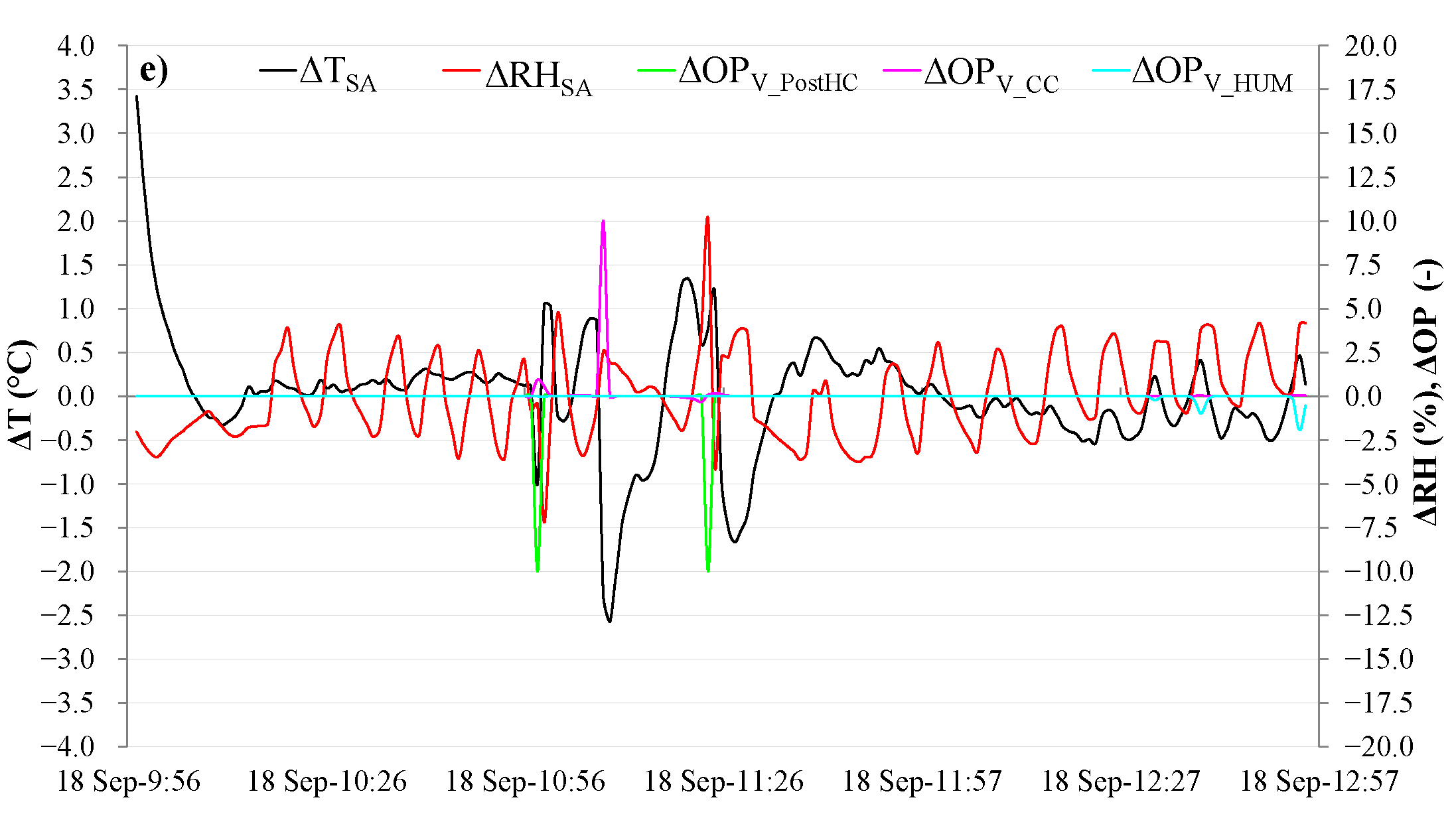

- In Figure 3e (corresponding to the fault 5, i.e., steam humidifier valve kept fully closed), return air relative humidity varies in a narrower range (in this case between 43.0% and 55.5%), highlighting a significantly reduced number of oscillations (as it would be presumed in the case of the humidifier is not active).

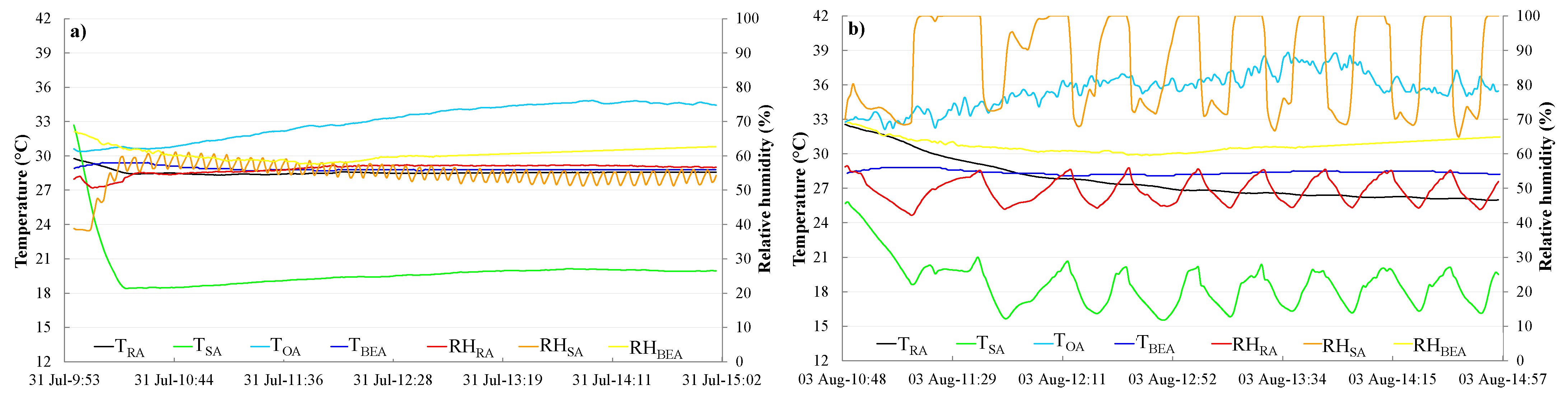

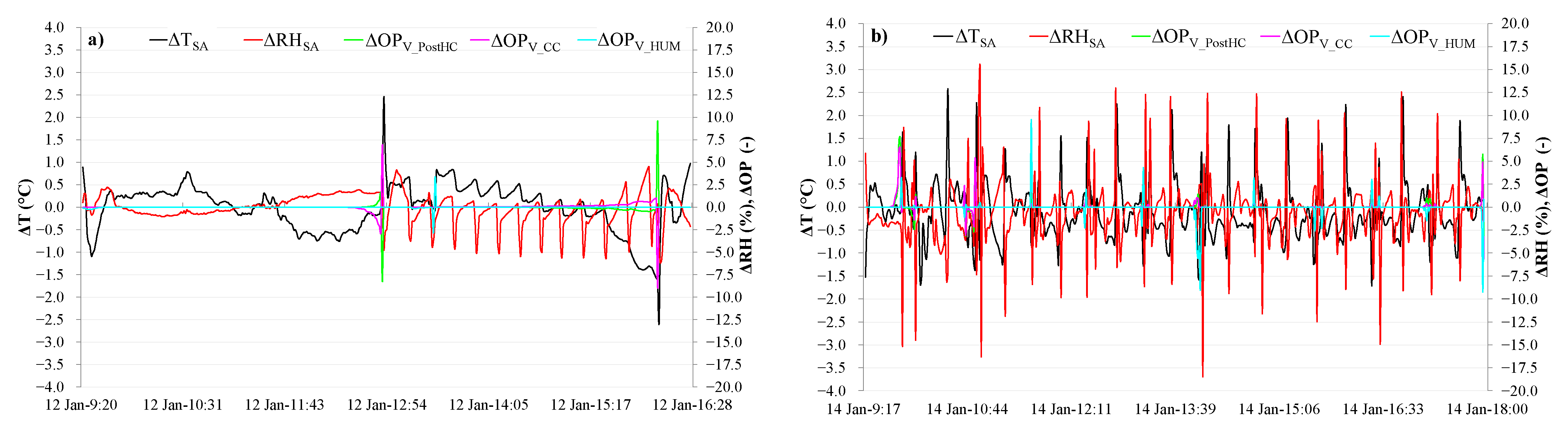

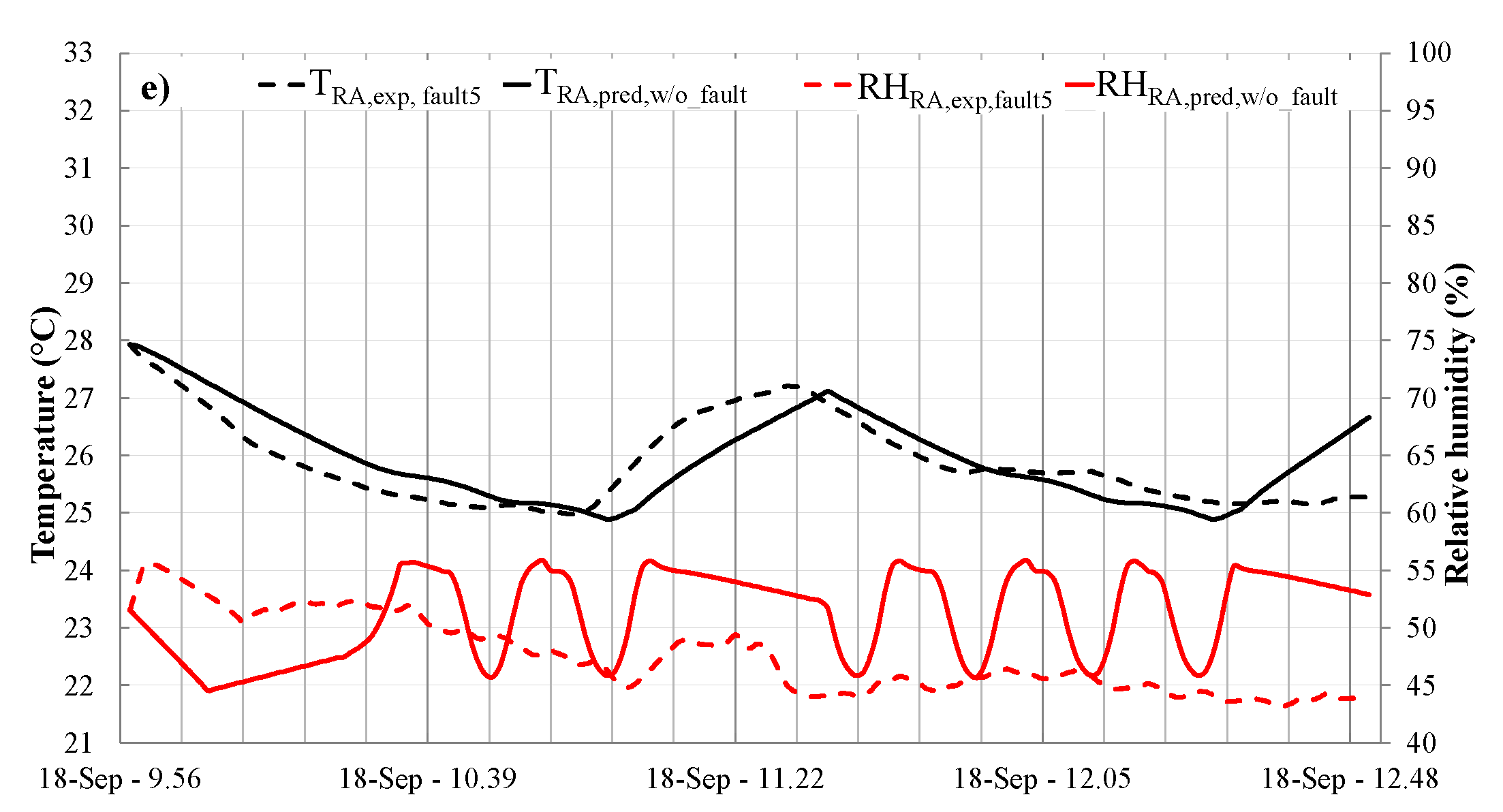

- In Figure 5a (corresponding to the fault 1, i.e., velocity of the supply air fan reduced at 20%), the supply air temperature and supply air relative humidity are in a wider range, with a much lower number of oscillations; similar trends can be recognized for both return air temperature and return air relative humidity;

- Figure 5b (corresponding to the fault 2, i.e., velocity of the return air fan reduced at 20%) indicates that the impact of a reduced return ai flow rate is almost negligible in terms of supply and return air temperature as well as supply and return air relative humidity;

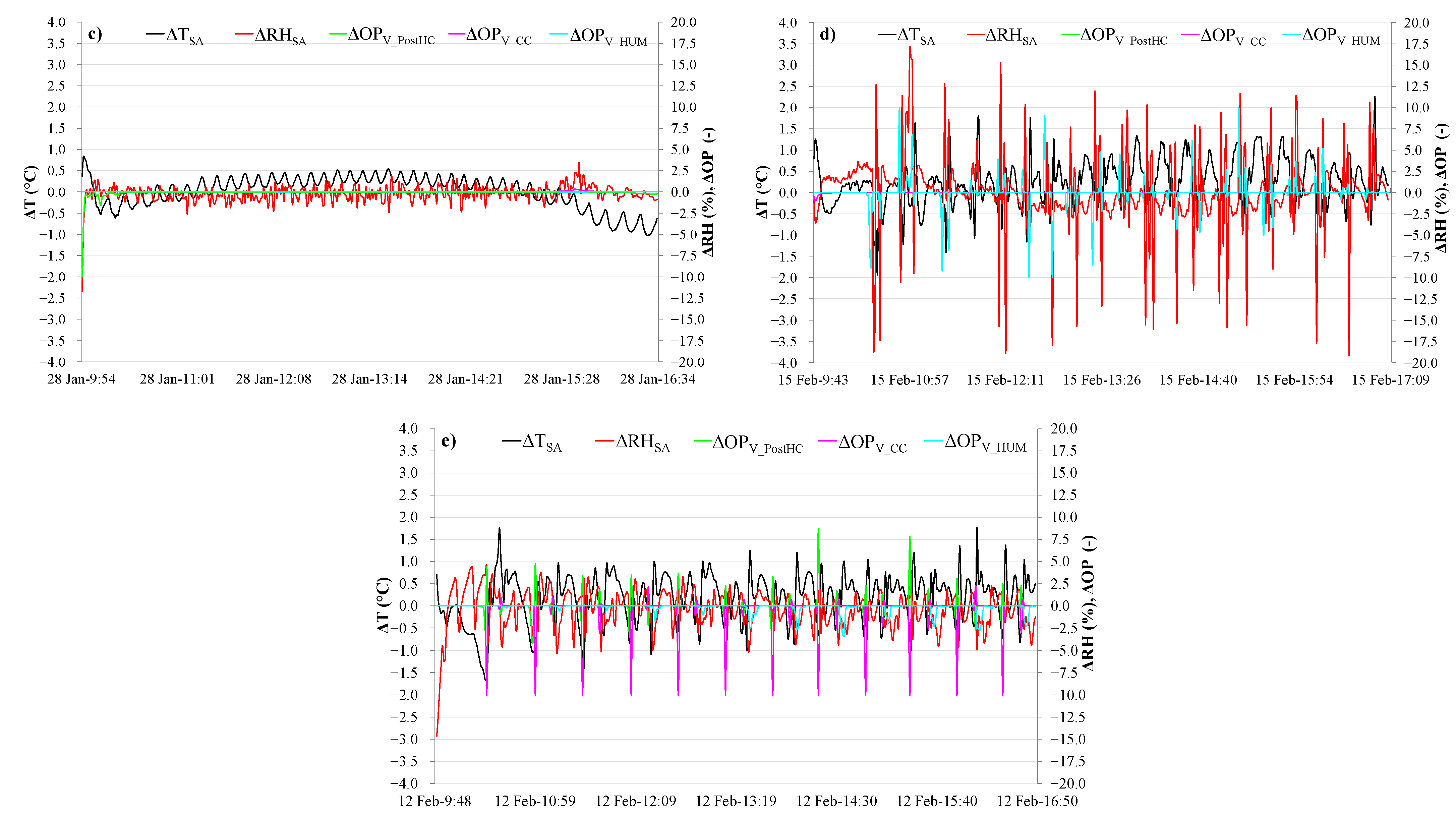

- In Figure 5c (corresponding to the fault 3, i.e., post-heating coil valve kept fully closed), supply air temperature assumes lower average values (as post-heating coil is not active); in particular, TSA is almost constant (and equal to ~12.0 °C in this case). As a consequence, return air temperature remains almost constant during the test, assuming a value much smaller than its lower deadband and, therefore, out of the desired thermal comfort range. In addition, it should be underlined that average values of supply air relative humidity are greater and included in a narrower range (without significant oscillations); return air relative humidity is almost constant (and equal to about 47% in this case);

- In Figure 5d (corresponding to the fault 4, i.e., cooling coil valve kept fully closed), supply air temperature is characterized by lower average values (as it would be presumed due to the missing contribution of the cooling coil), with a narrower variation range (approximately 19.0–24.0 °C in this case); return air temperature is substantially constant, assuming a value out of desired thermal comfort range (slightly larger than its upper deadband and equal to about 22.0 °C in this case);

- In Figure 5e (corresponding to the fault 5, i.e., steam humidifier valve kept fully closed), return air relative humidity varies in a slightly narrower range (as it would be expected in the case of the humidifier is not active).

4. Simulation Model

4.1. Artificial Neural Network-Based Model

4.1.1. Artificial Neural Networks’ Architecture

- all the inputs are multiplied by their weights;

- the weighted values are added to the bias in order to form the net inputs;

- the net inputs are passed by means of the transfer function, which generates the outputs.

4.1.2. Sensitivity Analysis of Artificial Neural Networks

- difference between current return air temperature and related target (ΔT)

- difference between current return air relative humidity and related target (ΔRH)

- supply air temperature at previous minute (TSA-1)

- supply air relative humidity at previous minute (RHSA-1)

- outside air temperature (TOA)

- opening percentage of the valve managing the flow entering the post-heating coil at previous minute (OPV_PostHC-1)

- opening percentage of the valve managing the flow entering the cooling coil at previous minute (OPV_CC-1)

- opening percentage of the valve managing the flow entering the steam humidifier at previous minute (OPV_HUM-1)

- supply air fan velocity (OLSAF)

- return air fan velocity (OLRAF).

- supply air temperature (TSA)

- supply air relative humidity (RHSA)

- opening percentage of the post-heating coil valve (OPV_PostHC)

- opening percentage of the cooling coil valve (OPV_CC)

- opening percentage of the steam humidifier valve (OPV_HUM).

4.1.3. Training, Testing and Validation of ANNs

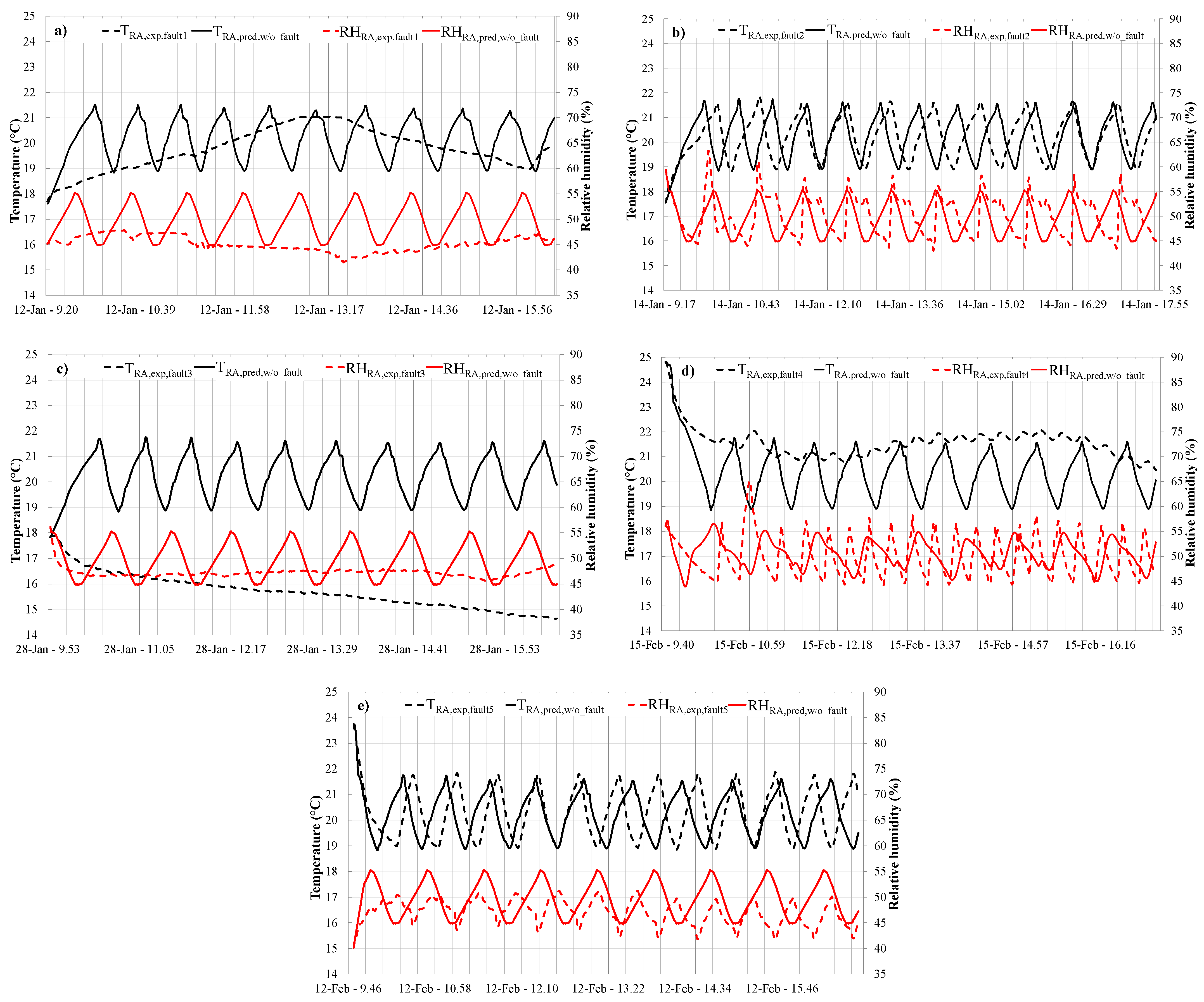

- the overall minimum value of (−2.48%) is obtained in the case of the ANN19 for the parameter OPV_CC; the overall maximum value of (10.71 °C) is obtained in the case of the ANN21 for the parameter TSA;

- the overall minimum value of (0.05%) is achieved by the ANN22 for the parameters OPV_PostHC and OPV_CC as well as in the case of the ANN17 for the parameter OPV_PostHC; the overall worst value of (10.71 °C) is obtained in the case of the ANN21 for the parameter TSA;

- the overall minimum value of MSE (0.14 °C) is obtained in the case of the ANN7 for the parameter TSA; the overall maximum value of MSE (36.62%) is obtained in the case of the ANN21 for the parameter OPV_PostHC;

- the overall minimum value of RMSE (0.38 °C) is achieved by the ANN7 for the parameter TSA; the overall worst value of RMSE (7.17 °C) is obtained by the ANN21 for the parameter TSA;

- with reference to all the ANNs, average values of coefficient of determination R2 in predicting supply air temperature, supply air relative humidity, opening percentage of the post-heating coil valve, opening percentage of the cooling coil valve, and opening percentage of the humidifier valve are very close to 1 and, respectively, equal to 0.95 °C, 0.97%, 0.95%, 0.94%, and 0.97%; the overall worst value of R2 (0.118) is obtained in the case of the ANN21 for the parameter TSA; the overall best value of R2 (0.997) is achieved by the ANN7 for the parameter TSA;

- the ANN22 is characterized by 8 green cells in Table 8, i.e., it works better than the other ANNs with reference to 8 lines of this table; the ANNs 3, 9, and 16 denote 5 green cells, while a lower number of green cells can be recognized for the other ANNs; the ANN4 has no green cells, while the ANN with the largest number of red cells (denoting the worst performance) is the ANN21;

- whatever the metric is, the ANN16 is characterized by greater performance in comparison to the ANN22 with reference to the predictions of both supply air temperature and supply air relative humidity. The percentage difference between the ANN16 and the ANN22 in predicting TSA is 27% in terms of , 40% in terms of MSE, 22% in terms of RMSE, and 0.21% in terms of R2. The percentage difference between the ANN16 and the ANN22 in predicting RHSA is 11% in terms of , 7% in terms of MSE, 4% in terms of RMSE, and 0.21% in terms of R2;

- ANN22 provides better results than ANN16 in predicting the opening percentages of the post-heating coil valve, the cooling coil valve as well as the humidifier valve. The maximum percentage difference in terms of between the ANN22 and the ANN16 in predicting OPV_PostHC, OPV_CC and OPV_HUM is 26%; the maximum percentage difference in terms of MSE between the ANN22 and the ANN16 in predicting OPV_PostHC, OPV_CC, and OPV_HUM is 21%; the maximum percentage difference in terms of RMSE between the ANN22 and the ANN16 in predicting OPV_PostHC, OPV_CC and OPV_HUM is 11%; the maximum difference in terms of R2 between the ANN22 and the ANN16 in predicting OPV_PostHC, OPV_CC, and OPV_HUM is 1.13%.

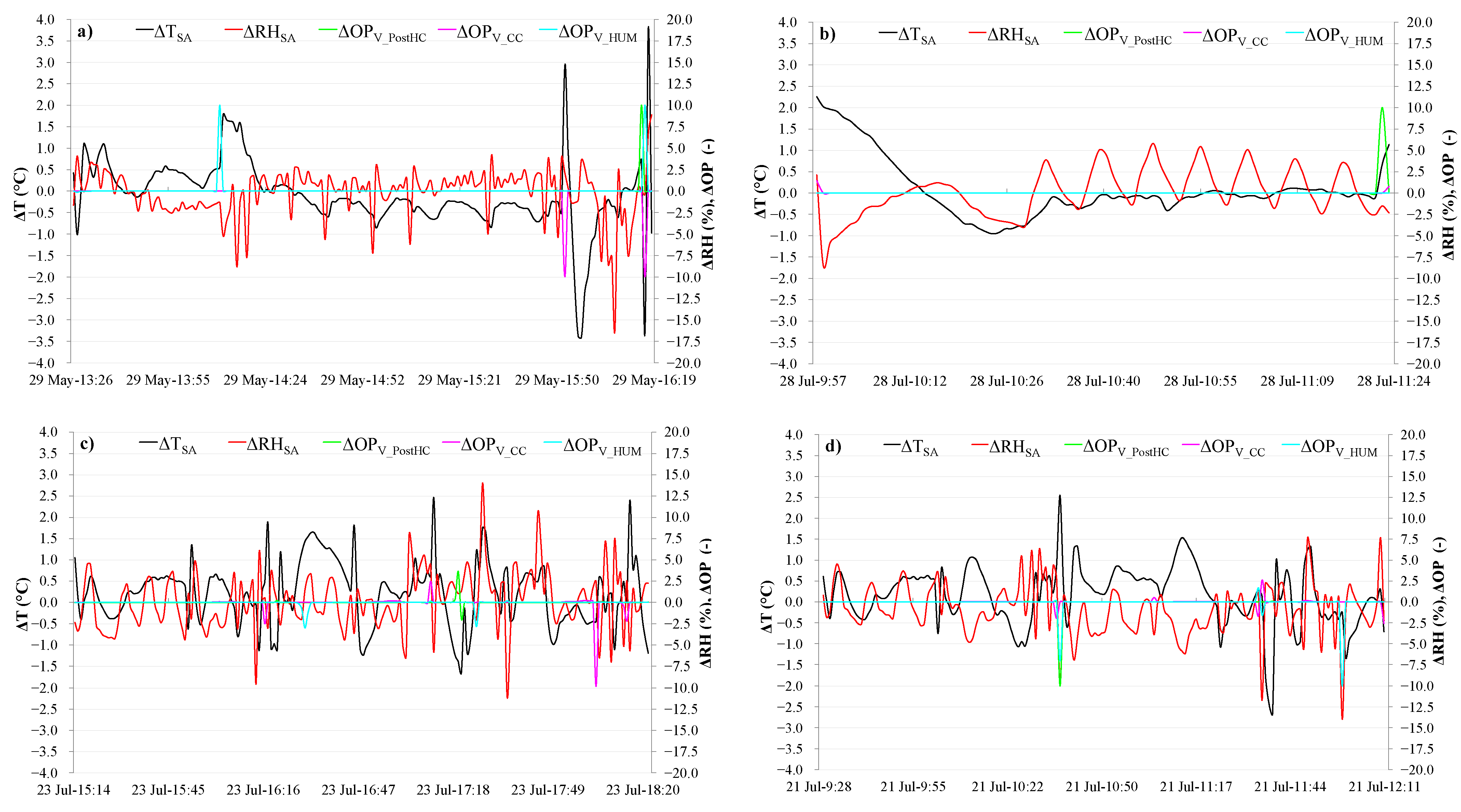

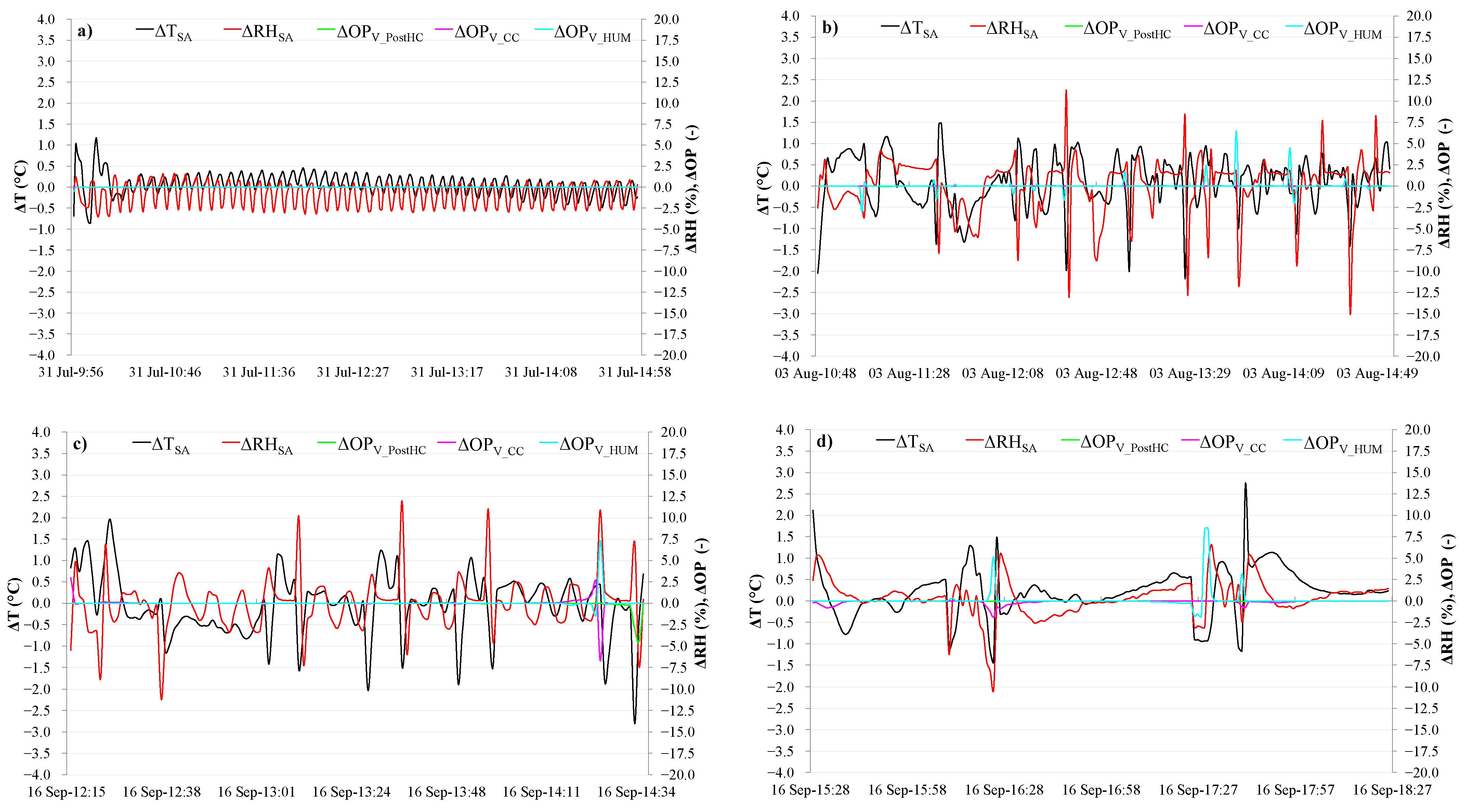

- the minimum value of is −3.41 °C (test n. 1), while its maximum value is 3.80 °C (test n. 1);

- the values of range from −19.20% (test n. 17) up to 17.03% (test n. 17);

- the parameter is in the range −10.05% ÷ 10.12%, where the minimum is achieved during the test n. 4, while the maximum refers to the test n. 2;

- the values of vary from −10.03% (test n. 18) up to 10.09% (test n. 9);

- the values of range between −9.97% (test n. 4) and 10.11% (test n.17).

- with reference to all the tests, the average values of R2 in predicting TSA, RHSA, OPV_PostHC, OPV_CC and OPV_HUM are, respectively, 0.95 °C, 0.93%, 0.95%, 0.97%, and 0.96%;

- with reference to the tests n. 1–4 (performed without faults during summer), the values of R2 are always larger than 0.9 for all the parameters, except the cases of ∆RHSA and ∆OPV_PostHC for the test n. 2;

- with reference to the tests n. 5–9 (performed with faults during summer), the coefficient of determination is always greater than 0.9 for all the parameters, except the cases of ∆RHSA for the test n. 5 (with fault 1) and ∆TSA for the test n. 6 (with fault 2);

- with reference to the tests n. 10–13 (performed without faults during winter), the values of R2 are always larger than 0.9 for all the parameters, except the case of ∆OPV_HUM for the test n. 13;

- with reference to the tests n. 14–18 (performed with faults during winter), the coefficient of determination is always greater than 0.9 for all the parameters, except (i) the cases of both ∆TSA and ∆RHSA for both the tests n. 16 (fault 3) and n. 17 (fault 4), (ii) the cases of both ∆OPV_PostHC and ∆OPV_CC for the test n. 15 (fault 2), (iii) the case of ∆OPV_CC for the test n. 18 (fault 5) as well as (iv) the case of ∆OPHUM for the test n. 17 (fault 4);

- whatever the test is, the values of for the parameter ∆TSA are always lower than 0.8 °C (that is the accuracy of the sensor used for measuring TSA), with a minimum of 0.19 °C (test n. 5) up to a maximum of 0.60 °C (test. n. 3);

- the values of for the parameter ∆RHSA range between a minimum of 0.7% up to a maximum of 11.1% and, therefore, they are always smaller than 3% (that is the accuracy of the sensor used for measuring RHSA), except the only case of the test n. 6 (performed with fault 2 during summer);

- the maximum values of MSE and RMSE with reference to the parameter ∆TSA are, respectively, not larger than 0.71 °C and 0.84 °C (obtained for the test n. 1 performed without faults during summer);

- the maximum values of MSE and RMSE with reference to the parameter ∆RHSA are, respectively, not larger than 22.4% and 4.74% (achieved for the test n. 17 performed with fault 4 during winter);

- the maximum value of MSE with reference to the parameters ∆OPV_PostHC, ∆OPV_CC and ∆OPV_HUM is 3.0%, obtained in the case of the test n. 18 performed with fault 5 during winter;

- the maximum value of RMSE with reference to the parameters ∆OPV_PostHC, ∆OPV_CC and ∆OPV_HUM is 1.7%, achieved in the case of the test n. 18 performed with fault 5 during winter.

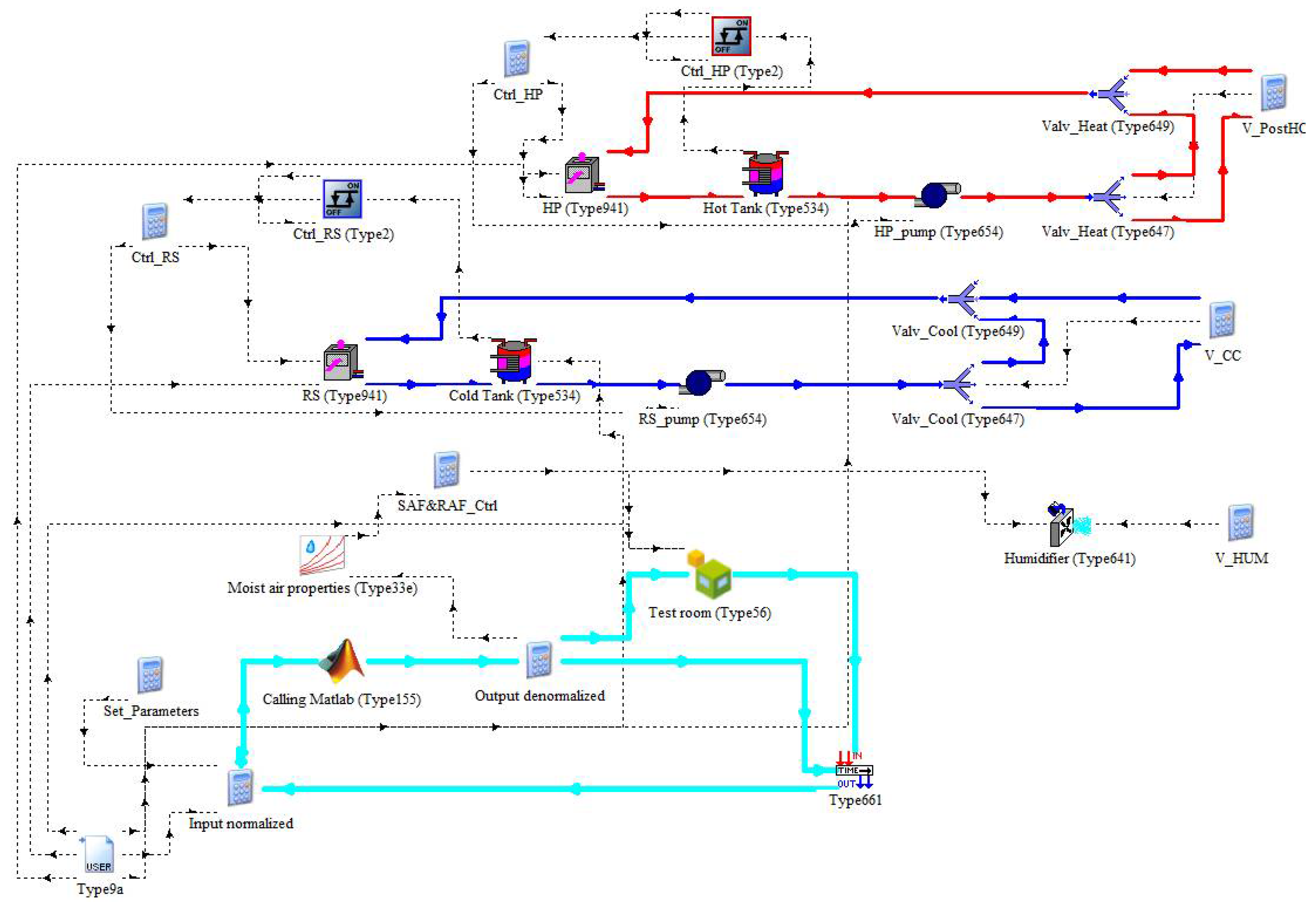

4.2. TRNSYS Model

5. Assessment of Faults’ Impact

- The experimental tests n. 5 and n. 14 (with the fault 1, i.e., with the velocity of the supply air fan kept at 20%) have been compared with the simulation cases where the velocity of supply air fan has been kept at the nominal value of 50%;

- The experimental tests n. 6 and n. 15 (with the fault 2, i.e., the velocity of the return air fan kept at 20%) have been compared with the simulation cases where the velocity of return air fan has been kept at the nominal value of 50%;

- The experimental tests n. 7 and n. 16 (with the fault 3, i.e., the post-heating coil valve kept always closed) have been compared with the simulation cases where the values of OPV_PostHC can vary according to the automatic control logic in the range of 0 to 100;

- The experimental tests n. 8 and n. 17 (with the fault 4, i.e., the cooling coil valve kept always closed) have been compared with the simulation cases where the values of OPV_CC can vary according to the automatic control logic in the range of 0 to 100;

- The experimental tests n. 9 and n. 18 (with the fault 5, i.e., the opening percentage of the steam humidifier valve kept always closed) have been compared with the simulation cases where the values of OPV_HUM can vary according to the automatic control logic in the range of 0 to 100.

5.1. Results: Faults’ Impact on Thermo-Hygrometric Comfort

5.2. Results: Faults’ Impact on Key Operating Parameters

5.3. Results: Faults’ Impact on Electric Energy Consumption

5.4. Discussion

- During summer (test n. 5) it strongly reduces both the thermal comfort time (66%) and the hygrometric comfort time (71%), while significantly lowering the overall electric energy consumption (42%) thanks to reduced consumption of the heat pump (97%), the steam humidifier (100%), and the supply air fan (87%);

- During winter (test n. 14) it decreases the hygrometric comfort time (38%), without significant variation of the hygrometric comfort time (1%), while considerably lowering the total electric energy consumption (31%) thanks to reduced consumption of the refrigerating system (37%), the heat pump (19%), the steam humidifier (32%), and the supply air fan (91%).

- During summer (test n. 6) slightly decreases both the thermal comfort time (8%) and the hygrometric comfort time (7%), while slightly reducing the overall electric energy consumption (2%) because of the lower consumption of both the heat pump (95%) and return air fan (66%);

- During winter (test n. 15) slightly decreases the hygrometric comfort time (4%), without relevant variation of the hygrometric comfort time (1%), while increasing the overall electric energy consumption (8%) due to greater consumption of heat pump (39%).

- During summer (test n. 7) strongly reduces the thermal comfort time (69%), without significant variation of the hygrometric comfort time (1%), while lowering the overall electric energy consumption (25%) because of the reduced consumption of the heat pump (95%);

- During winter (test n. 16) strongly reduces the thermal comfort time (70%) and slightly decreases the hygrometric comfort time (14%), while significantly lowering the overall electric energy consumption (57%) because of the reduced consumption of both the heat pump (96%), and the steam humidifier (100%).

- During summer (test 8) significantly decreases the thermal comfort time (63%) and slightly reduces the hygrometric comfort time (4%), while greatly lowering the overall electric energy demand (81%) because of the reduced consumption of the heat pump (96%), the refrigerating system (90%), and the steam humidifier (50%);

- During winter (test n. 17) significantly decreases the thermal comfort time (52%) and slightly reduces the hygrometric comfort time (15%), while considerably lowering the overall electric energy demand (75%) because of the reduced consumption of the heat pump (96%), the refrigerating system (98%), and the steam humidifier (18%).

- During summer (test n. 9) reduces the thermal comfort time by a slight amount (3%) and decreases the hygrometric comfort time (16%), while decreasing the overall electric energy demand (37%) because of the lower consumption of the heat pump (32%), the refrigerating system (20%), and the humidifier (100%);

- During winter (test n. 18) reduces the thermal comfort time by a slight amount (6%) and significantly decreases the hygrometric comfort time (28%), while decreasing the overall electric energy demand (56%) because of the lower consumption of the heat pump (44%), the refrigerating system (34%), and the humidifier (100%).

- The fault 1 significantly affects the values of σ for both TRA and RHRA under summer conditions as well as the values of σ for RHRA only under winter conditions;

- The effects of the fault 2 are negligible with reference to the values of both σ and μ for both TRA and RHRA under both summer and winter conditions;

- The fault 3 greatly affects the values of σ for TRA under summer conditions, the values of both σ and μ for TRA under winter conditions, as well as the values of σ for RHRA under winter conditions;

- The impact of the fault 4 is significant with reference to the values of σ for TRA under summer conditions as well as the values of σ for both TRA and RHRA under winter conditions;

- The fault 5 significantly affects only the values of σ associated to RHRA under winter conditions.

6. Conclusions

- Fault 3 is associated with the valve supplying the post-heating coil (always kept closed) is the one significantly affecting indoor thermal comfort, with a reduction of about 68% (during summer) and 70% (during winter) with respect to the fault free conditions;

- Fault 1 is associated with the supply air fan (kept at a reduced velocity of 20% instead of the nominal value of 50%) is the one considerably influencing indoor hygrometric comfort, with a reduction of about 71% (during summer) and 38% (during winter) in comparison to the fault free tests;

- Fault 4 is associated with the valve supplying the cooling coil (always kept closed) is the one causing important variation in terms of overall electric energy consumption (81% during summer and 75% during winter) with reference to the fault free scenarios.

- The fault 1 significantly affects the values of σ for both TRA and RHRA under summer conditions as well as the values of σ for RHRA only under winter conditions;

- The fault 3 greatly affects the values of σ for TRA under summer conditions, the values of both σ and μ for TRA under winter conditions, as well as the values of σ for RHRA under winter conditions;

- The impact of the fault 4 is significant with reference to the values of σ for TRA under summer conditions as well as the values of σ for both TRA and RHRA under winter conditions;

- The fault 5 significantly affects only the values of σ associated to RHRA under winter conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AFDD | Automatic fault detection and diagnosis |

| AHU | Air handling unit |

| ANN | Artificial neural network |

| CAV | Constant air volume |

| CC | Cooling coil |

| COP | Coefficient of performance (-) |

| CT | Cold tank |

| DBRH | Deadband of RHSP,Room (%) |

| DBT | Deadband of TSP,Room (°C) |

| DEA | Exhaust air damper |

| DHRS | Damper of heat recovery system |

| di | Value at time step i |

| DOA | Outside air damper |

| DRA | Return air damper |

| EEfault,i | Electric energy consumption of AHU component with fault (kWh) |

| EEHP | Electric energy consumption of the HP (kWh) |

| EEHUM | Electric energy consumption of the HUM (kWh) |

| EER | Energy efficiency ratio (kWh) |

| EERAF | Electric energy consumption of the RAF (kWh) |

| EERS | Electric energy consumption of the RS (kWh) |

| EESAF | Electric energy consumption of the SAF (kWh) |

| EETOT | Overall electric energy consumption (kWh) |

| EEw/o_fault,i | Electric energy consumption of AHU component without faults (kWh) |

| EPD | Energy percentage difference (%) |

| gpred,i | Predicted value at time step i |

| gexp,i | Measured value at time step i |

| pred | Arithmetic mean of predicted values |

| HP | Heat pump |

| HRS | Static cross-flow heat recovery system |

| HT | Hot tank |

| HUM | Humidifier |

| HVAC | Heating, ventilation and air-conditioning |

| MSE | Mean square error |

| N | Number of points |

| OAD | Outside air duct |

| OAFil | Outside air filter |

| OLRAF | Velocity of RAF (%) |

| OLSAF | Velocity of SAF (%) |

| OPDEA | Opening percentage of DEA (%) |

| OPDHRS | Opening percentage of DHRS (%) |

| OPDOA | Opening percentage of DOA (%) |

| OPDRA | Opening percentage of DRA (%) |

| OPV_CC | Opening percentage of valve regulating the flow entering CC (%) |

| OPV_CC−1 | Opening percentage of valve regulating the flow entering CC at previous minute (%) |

| OPV_CC,pred | Predicted opening percentage of valve regulating the flow entering CC (%) |

| OPV_CC,exp | Experimental opening percentage of valve regulating the flow entering CC (%) |

| OPV_HUM | Opening percentage of valve regulating the flow entering HUM (%) |

| OPV_HUM-1 | Opening percentage of valve regulating the flow entering HUM at previous minute (%) |

| OPV_HUM,pred | Predicted opening percentage of valve regulating the flow entering HUM (%) |

| OPV_HUM,exp | Experimental opening percentage of valve regulating the flow entering HUM (%) |

| OPV_PostHC | Opening percentage of valve regulating the flow entering PostHC (%) |

| OPV_PostHC-1 | Opening percentage of valve regulating the flow entering the PostHC at previous minute (%) |

| OPV_PostHC,pred | Predicted opening percentage of valve regulating the flow entering PostHC (%) |

| OPV_PostHC,exp | Experimental opening percentage of valve regulating the flow entering PostHC (%) |

| OPV_PreHC | Opening percentage of valve regulating the flow entering PreHC (%) |

| PelRAF | Power consumption of RAF (W) |

| PelSAF | Power consumption of SAF (W) |

| PID | Proportional-integral-derivative |

| PostHC | Post-heating coil |

| PreHC | Pre-heating coil |

| QVRAF | Air volumetric flow rate of RAF (m3/h) |

| QVSAF | Air volumetric flow rate of SAF (m3/h) |

| R2 | Coefficient of determination (-) |

| RAD | Return air duct |

| RAF | Return air fan |

| RAFil | Return air filter |

| RHBEA | Air relative humidity outside the room (%) |

| RHRA | Return air relative humidity (%) |

| RHRA,exp,fault | Measured return air relative humidity under faulty conditions (%) |

| RHRA,pred,w/o_fault | Predicted return air relative humidity without faults (%) |

| RHSA | Supply air relative humidity (%) |

| RHSA-1 | Supply air relative humidity at previous minute (%) |

| RHSP,Room | Target of indoor air relative humidity (%) |

| RMSE | Root mean square error |

| RS | Refrigerating unit |

| SAD | Supply air duct |

| SAF | Supply air fan |

| SAFil | Supply air filter |

| TA,out,CC | Air temperature at CC outlet (°C) |

| TBEA | Air temperature outside the room (°C) |

| TOA | External air temperature (°C) |

| TRA | Return air temperature (°C) |

| TRA,exp,fault | Measured return air temperature under faulty conditions (°C) |

| TRA,pred,w/o_fault | Predicted return air temperature without faults (°C) |

| TSA | Supply air temperature (°C) |

| TSA-1 | Supply air temperature at previous minute (°C) |

| TSP,Room | Target of indoor air temperature (°C) |

| VAV | Variable air volume |

| VCC | 3-way valve of CC |

| VHUM | Valve of HUM |

| VPostHC | 3-way valve of PostHC |

| VPreHC | 3-way valve of PreHC |

| Xfault,i | Arithmetic mean or standard deviation with fault |

| Xw/o_fault,i | Arithmetic mean or standard deviation without faults |

| %D | Percentage difference (%) |

| ΔRH | Difference between current return air relative humidity and related target (%) |

| ΔT | Difference between current return air temperature and related target (°C) |

| ΔOPV_CC | Instantaneous errors between the values predicted by the ANN16 and the measured data in terms of OPV_CC (%) |

| ΔOPV_HUM | Instantaneous errors between the values predicted by the ANN16 and the measured data in terms of OPV_HUM (%) |

| ΔOPV_PostHC | Instantaneous errors between the values predicted by the ANN16 and the measured data in terms of OPV_PostHC (%) |

| ΔRHSA | Instantaneous errors between the values predicted by the ANN16 and the measured data in terms of RHSA (%) |

| ΔTSA | Instantaneous errors between the values predicted by the ANN16 and the measured data in terms of TSA (°C) |

| εi | Instantaneous error |

| Instantaneous absolute error | |

| Average error | |

| Average absolute error | |

| μ | Arithmetic mean |

| σ | Standard deviation |

Appendix A

| Material (from Outside to Inside) | Thickness (m) | Thermal Conductivity (W/mK) | Thermal Resistance (m2K/W) | Heat Transfer Area (m2) | ||

|---|---|---|---|---|---|---|

| Ceiling | Plasterboard | 0.0125 | 0.250 | 0.050 | 2.023 | 16.00 |

| Rock wool | 0.0800 | 0.042 | 1.905 | |||

| Polyurethane panel | 0.0150 | 0.220 | 0.068 | |||

| Floor | Subfloor | 0.1000 | 1.350 | 0.074 | 3.107 | 16.00 |

| Tiles | 0.0500 | 2.100 | 0.024 | |||

| Polystyrene panel | 0.0800 | 0.035 | 2.286 | |||

| Galvanized steel slab | 0.0020 | 52.000 | 0.000 | |||

| Tiles | 0.0100 | 1.050 | 0.010 | |||

| West and East oriented vertical walls | Plasterboard | 0.0125 | 0.250 | 0.050 | 2.005 | 14.40 |

| Rock wool | 0.0800 | 0.042 | 1.905 | |||

| Radiant panel | 0.0150 | 0.300 | 0.050 | |||

| South and North oriented vertical walls | Plasterboard | 0.0125 | 0.250 | 0.050 | 1.998 | 14.40 |

| Rock wool | 0.0800 | 0.042 | 1.905 | |||

| Fiber-cement panel | 0.0150 | 0.350 | 0.043 | |||

| Door | Soft wood | 0.0500 | 0.140 | 0.357 | 0.357 | 1.68 |

References

- Wang, H.; Chen, Y. A robust fault detection and diagnosis strategy for multiple faults of VAV air handling units. Energy Build. 2016, 127, 442–451. [Google Scholar] [CrossRef]

- Lee, K.P.; Wu, B.H.; Peng, S.L. Deep-learning-based fault detection and diagnosis of air-handling units. Build. Environ. 2019, 157, 24–33. [Google Scholar] [CrossRef]

- Schibuola, L.; Scarpa, M.; Tambani, C. Variable speed drive (VSD) technology applied to HVAC systems for energy saving: An experimental investigation. Energy Procedia 2018, 148, 806–813. [Google Scholar] [CrossRef]

- Tang, R.; Wang, S.; Shan, K. Optimal and near-optimal indoor temperature and humidity controls for direct load control and proactive building demand response towards smart grids. Autom. Construct. 2018, 96, 250–261. [Google Scholar] [CrossRef]

- Piscitelli, M.S.; Mazzarelli, D.M.; Capozzoli, A. Enhancing operational performance of AHUs through an advanced fault detection and diagnosis process based on temporal association and decision rules. Energy Build. 2020, 226, 110369. [Google Scholar] [CrossRef]

- Yan, K.; Zhong, C.; Ji, Z.; Huang, J. Semi-supervised learning for early detection and diagnosis of various air handling unit faults. Energy Build. 2018, 181, 75–83. [Google Scholar] [CrossRef]

- Lin, G.; Kramer, H.; Granderson, J. Building fault detection and diagnostics: Achieved savings, and methods to evaluate algorithm performance. Build. Environ. 2020, 168, 106505. [Google Scholar] [CrossRef]

- Au-Yong, C.P.; Ali, A.S.; Ahmad, F. Improving occupants’ satisfaction with effective maintenance management of HVAC system in office buildings. Autom. Constr. 2014, 43, 31–37. [Google Scholar] [CrossRef][Green Version]

- Rosato, A.; Guarino, F.; Filomena, V.; Sibilio, S.; Maffei, L. Experimental calibration and validation of a simulation model for fault detection of HVAC systems and application to a case study. Energies 2020, 13, 3948. [Google Scholar] [CrossRef]

- Granderson, J.; Lin, G.; Singla, R.; Mayhorn, E.; Ehrlich, P.; Vrabie, D.; Franck, S. Commercial Fault Detection and Diagnostics Tools: What They Offer, How They Differ, and What’s Still Needed; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2018. Available online: https://escholarship.org/uc/item/4j72k57p (accessed on 26 August 2021). [CrossRef]

- Entchev, E.; Yang, L.; Ghorab, M.; Rosato, A.; Sibilio, S. Energy, economic and environmental performance simulation of a hybrid renewable microgeneration system with neural network predictive control. Alex. Eng. J. 2018, 57, 455–473. [Google Scholar] [CrossRef]

- Kim, W.; Katipamula, S. A review of fault detection and diagnostics methods for building systems. Sci. Technol. Built Environ. 2018, 24, 3–21. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, T.; Zhang, X.; Zhang, C. Artificial intelligence-based fault detection and diagnosis methods for building energy systems: Advantages, challenges and the future. Renew. Sustain. Energy Rev. 2019, 109, 85–101. [Google Scholar] [CrossRef]

- Yu, Y.; Woradechjumroen, D.; Yu, D. A review of fault detection and diagnosis methodologies on air-handling units. Energy Build. 2014, 82, 550–562. [Google Scholar] [CrossRef]

- Beghi, A.; Brignoli, R.; Cecchinato, L.; Menegazzo, G.; Rampazzo, M.; Simmini, F. Data-driven Fault Detection and Diagnosis for HVAC water chillers. Control Eng. Pract. 2016, 53, 79–91. [Google Scholar] [CrossRef]

- Dehestani, D.; Eftekhari, F.; Guo, Y.; Ling, S.; Su, S.; Nguyen, H. Online Support Vector Machine Application for Model Based Fault Detection and Isolation of HVAC System. Int. J. Mach. Learn. Comput. 2011, 1, 66–72. [Google Scholar] [CrossRef][Green Version]

- Zhao, Y.; Wen, J.; Xiao, F.; Yang, X.; Wang, S. Diagnostic Bayesian networks for diagnosing air handling units faults—part I: Faults in dampers, fans, filters and sensors. Appl. Therm. Eng. 2017, 111, 1272–1286. [Google Scholar] [CrossRef]

- Zhao, Y.; Wen, J.; Wang, S. Diagnostic Bayesian networks for diagnosing air handling units faults-Part II: Faults in coils and sensors. Appl. Therm. Eng. 2015, 90, 145–157. [Google Scholar] [CrossRef]

- Mulumba, T.; Afshari, A.; Yan, K.; Shen, W.; Norford, L.K. Robust model-based fault diagnosis for air handling units. Energy Build. 2015, 86, 698–707. [Google Scholar] [CrossRef]

- Yan, R.; Ma, Z.; Zhao, Y.; Kokogiannakis, G. A decision tree based data-driven diagnostic strategy for air handling units. Energy Build. 2016, 133, 37–45. [Google Scholar] [CrossRef]

- Mchugh, M.K. Data-Driven Leakage Detection in Air-Handling Units on a University Campus. In Proceedings of the ASHRAE Annual Conference, Kansas City, MO, USA, 5 March 2019. [Google Scholar]

- Du, Z.M.; Jin, X.Q. Detection and diagnosis for multiple faults in VAV systems. Energy Build. 2007, 39, 923–934. [Google Scholar] [CrossRef]

- Hu, R.I.; Granderson, J.; Auslader, D.M.; Agogino, A. Design of machine learning models with domain experts for automated sensor selection for energy fault detection. Appl. Energy 2019, 235, 117–128. [Google Scholar] [CrossRef]

- Wen, J.; Li, S. ASHRAE RP-1312—Tools for Evaluating Fault Detection and Diagnostic Methods for Air-Handling Units; American Society of Heating, Refrigeration and Air-Conditioning Engineers: Atlanta, GA, USA, 2012; Available online: https://www.techstreet.com/ashrae/standards/rp-1312-tools-for-evaluating-fault-detection-and-diagnostic-methods-for-air-handling-units?gateway_code=ashrae&product_id=1833299 (accessed on 26 August 2021).

- Granderson, J.; Lin, G.; Harding, A.; Im, P.; Chen, Y. Building Fault Detection Data to Aid Diagnostic Algorithm Creation and Performance Testing. Sci. Data 2020, 7, 65. Available online: https://www.nature.com/articles/s41597-020-0398-6.pdf (accessed on 14 August 2021). [CrossRef]

- Casillas, A.; Lin, G.; Granderson, J. Curation of Ground-Truth Validated Benchmarking Datasets for Fault Detection & Diagnostics Tools; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2021. Available online: https://eta-publications.lbl.gov/sites/default/files/curation_of_ground-truth_validated_benchmarking_datasets_for_fault_detection_acasillas_0.pdf (accessed on 14 August 2021).

- Yun, W.S.; Hong, W.H.; Seo, H. A data-driven fault detection and diagnosis scheme for air handling units in building HVAC systems considering undefined states. J. Build. Eng. 2021, 35, 102111. [Google Scholar] [CrossRef]

- Fan, C.; Liu, X.; Xue, P.; Wang, J. Statistical characterization of semi-supervised neural networks for fault detection and diagnosis of air handling units. Energy Build. 2021, 234, 110733. [Google Scholar] [CrossRef]

- Wang, L.; Greenberg, S.; Fiegel, J.; Rubalcava, A.; Earni, S.; Pang, X.; Yin, R.; Woodworth, S.; Hernandez-Maldonado, J. Monitoring-based HVAC commissioning of an existing office building for energy efficiency. Appl. Energy 2013, 102, 1382–1390. [Google Scholar] [CrossRef]

- Basarkar, M. Modeling and Simulation of Hvac Faults in Energyplus; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2011. Available online: https://escholarship.org/uc/item/9ps43482 (accessed on 14 August 2021).

- Zhang, R.; Hong, T. Modeling of HVAC operational faults in building performance simulation. Appl. Energy 2017, 202, 178–188. [Google Scholar] [CrossRef]

- MathWorks. Available online: https://it.mathworks.com/products/matlab.html (accessed on 21 July 2021).

- TRNSYS—Transient System Simulation Tool. Available online: http://www.trnsys.com (accessed on 21 July 2021).

- COMMISSION REGULATION (EU) No 1253/2014 of 7 July 2014 Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Ventilation Units. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014R1253&from=FR (accessed on 14 August 2021).

- CAREL Humidifiers Datasheet. Available online: https://www.carel.com/documents/10191/0/%2B030220621/92fca658-a251-49ee-9979-b8829fcba49f?version=1.0 (accessed on 21 July 2021).

- AERMEC Reversible Air/Water Heat Pump Datasheet. Available online: https://download.aermec.com/docs/schede/ANL-021-203-HP_Y_UN50_03.pdf?r=14395 (accessed on 21 July 2021).

- SIEMENS Duct Sensors Datasheet. Available online: https://www.downloads.siemens.com/download-center/Download.aspx?pos=download&fct=getasset&id1=24897 (accessed on 21 July 2021).

- SIEMENS Duct Temperature Sensors Datasheet. Available online: https://www.downloads.siemens.com/download-center/Download.aspx?pos=download&fct=getasset&id1=10859 (accessed on 21 July 2021).

- TSI Q-TRAK Datasheet. Available online: https://tsi.com/getmedia/d2a8d1d1-7551-47fe-8a0f-3c14b09b494b/7575_QTrak_A4_UK_5001356-web?ext=.pdf (accessed on 21 July 2021).

- Cheng, F.; Cai, W.; Zhang, X.; Liao, H.; Cui, C. Fault detection and diagnosis for Air Handling Unit based on multiscale convolutional neural networks. Energy Build. 2021, 236, 110795. [Google Scholar] [CrossRef]

- Lee, J.M.; Hong, S.H.; Seob, B.M.; Leec, K.H. Application of artificial neural networks for optimized AHU discharge air temperature set-point and minimized cooling energy in VAV system. Appl. Therm. Eng. 2019, 153, 726–738. [Google Scholar] [CrossRef]

- Jang, J.; Baek, J.; Leigh, S.B. Prediction of optimum heating timing based on artificial neural network by utilizing BEMS data. J. Build. Eng. 2019, 22, 66–74. [Google Scholar] [CrossRef]

- Elnour, M.; Meskin, N.; Al-Naemi, M. Sensor data validation and fault diagnosis using Auto-Associative Neural Network for HVAC systems. J. Build. Eng. 2020, 27, 100935. [Google Scholar] [CrossRef]

- Shibata, K.; Ikeda, Y. Effect of number of hidden neurons on learning in large-scale layered neural networks. In Proceedings of the ICROS-SICE International Joint Conference, Fukuoka, Japan, 18–21 August 2009; pp. 5008–5013. [Google Scholar]

- Jinchuan, K.; Xinzhe, L. Empirical analysis of optimal hidden neurons in neural network modeling for stock prediction. In Proceedings of the Pacific-Asia Workshop on Computational Intelligence and Industrial Application, Wuhan, China, 19–20 December 2008; pp. 828–832. [Google Scholar]

- Xu, S.; Chen, L. A novel approach for determining the optimal number of hidden layer neurons for FNN’s and its application in data mining. In Proceedings of the 5th International Conference on Information Technology and Applications, Cairns, Australia, 23–26 June 2008; pp. 683–686. [Google Scholar]

| Supply air fan (SAF) | Maximum number of revolutions per minute (rpm) | 3640 |

| Nominal velocity of supply air fan (%) | 50 | |

| Return air fan (RAF) | Maximum number of revolutions per minute (rpm) | 3080 |

| Nominal velocity of return air fan (%) | 50 | |

| Cross flow heat recovery system (HRS) | Nominal recovery capacity (kW) | 3.1 |

| Nominal efficiency (%) | 74.7 | |

| Nominal pressure drops on external/exhaust air side (kPa) | 0.047/0.048 | |

| Return air filter (RAFil) and outside air filter (OAFil) | Type/Efficiency class | Fluted/G4 |

| Supply air filter (SAFil) | Type/Efficiency class | Rigid pocket/G4 |

| Return air duct (RAD) and supply air duct (SAD) | Diameter (m) | 0.25 |

| Supply/Return length (m) | 9.8/16.8 | |

| Thermal resistance of insulating material (m2K/W) | 0.25 | |

| Pre-heating coil (PreHC) | Nominal heating capacity (kW) | 4.1 |

| Nominal air/fluid volumetric flow rate (m3/h) | 600/0.710 | |

| Nominal air/fluid pressure drops (kPa) | 0.00321/12.43 | |

| Colling coil (CC) | Nominal cooling capacity (kW) | 5.0 |

| Nominal air/fluid volumetric flow rate (m3/h) | 600/0.860 | |

| Nominal air/fluid pressure drops (kPa) | 0.0178/13.56 | |

| Steam humidifier (HUM) [35] | Nominal steam capacity (kg/h) | 5.0 |

| Nominal power (kW) | 3.7 | |

| Post-heating coil (PostHC) | Nominal heating capacity (kW) | 5.0 |

| Nominal air/fluid volumetric flow rate (m3/h) | 600/0.860 | |

| Nominal air/fluid pressure drops (kPa) | 0.0497/20.35 | |

| Heat Pump (HP) [36] | Nominal capacity (kW) | 14.0 |

| Nominal input power (kW) | 4.75 | |

| Nominal heat carrier fluid volumetric flow rate (m3/h) | 2.41 | |

| Refrigerating System (RS) [36] | Nominal capacity (kW) | 13.4 |

| Nominal input power (kW) | 4.48 | |

| Nominal heat carrier fluid volumetric flow rate (m3/h) | 2.31 |

| Test n. | TSP,Room (°C) | RHSP,Room (%) | TOA (°C) | OLRAF (%) | OLSAF (%) | OPV_PostHC (%) | OPV_CC (%) | OPV_HUM (%) | Date (dd/mm/yyyy) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 26 | 50 | 20.6 ÷ 26.7 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 29/06/2020 |

| 2 | 26 | 50 | 29.1 ÷ 35.2 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 28/07/2020 |

| 3 | 26 | 50 | 25.3 ÷ 32.0 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 23/07/2020 |

| 4 | 26 | 50 | 28.6 ÷ 35.3 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 21/07/2020 |

| 5 (fault1) | 26 | 50 | 30.4 ÷ 34.9 | 50 | 20 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 31/07/2020 |

| 6 (fault2) | 26 | 50 | 32.1 ÷ 38.8 | 20 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 03/08/2020 |

| 7 (fault3) | 26 | 50 | 33.8 ÷ 38.4 | 50 | 50 | 0 | 0 ÷ 100 | 0 ÷ 100 | 16/09/2020 |

| 8 (fault4) | 26 | 50 | 29.4 ÷ 35.8 | 50 | 50 | 0 ÷ 100 | 0 | 0 ÷ 100 | 16/09/2020 |

| 9 (fault5) | 26 | 50 | 28.7 ÷ 38.2 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 | 18/09/2020 |

| Test n. | TSP,Room (°C) | RHSP,Room (%) | TOA (°C) | OLRAF (%) | OLSAF (%) | OPV_PostHC (%) | OPV_CC (%) | OPV_HUM (%) | Date (dd/mm/yyyy) |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 50 | 10.3 ÷ 15.0 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 23/12/2020 |

| 11 | 20 | 50 | 13.2 ÷ 15.4 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 28/12/2020 |

| 12 | 20 | 50 | 12.7 ÷ 18.6 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 29/12/2020 |

| 13 | 20 | 50 | 8.0 ÷ 13.5 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 05/01/2021 |

| 14 (fault1) | 20 | 50 | 12.3 ÷ 20.0 | 50 | 20 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 12/01/2021 |

| 15 (fault2) | 20 | 50 | 5.6 ÷ 12.2 | 20 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 ÷ 100 | 14/01/2021 |

| 16 (fault3) | 20 | 50 | 10.5 ÷ 15.9 | 50 | 50 | 0 | 0 ÷ 100 | 0 ÷ 100 | 28/01/2021 |

| 17 (fault4) | 20 | 50 | 7.8 ÷ 16.8 | 50 | 50 | 0 ÷ 100 | 0 | 0 ÷ 100 | 15/02/2021 |

| 18 (fault5) | 20 | 50 | 9.2 ÷ 13.3 | 50 | 50 | 0 ÷ 100 | 0 ÷ 100 | 0 | 12/02/2021 |

| ANN ID | Number of Hidden Layers | Number of Neurons in Each Hidden Layer |

|---|---|---|

| ANN1 | 1 | 10 |

| ANN2 | 1 | 20 |

| ANN3 | 1 | 30 |

| ANN4 | 1 | 40 |

| ANN5 | 1 | 50 |

| ANN6 | 1 | 60 |

| ANN7 | 1 | 70 |

| ANN8 | 2 | 10 |

| ANN9 | 2 | 20 |

| ANN10 | 2 | 30 |

| ANN11 | 2 | 40 |

| ANN12 | 2 | 50 |

| ANN13 | 3 | 10 |

| ANN14 | 3 | 20 |

| ANN15 | 3 | 30 |

| ANN16 | 3 | 40 |

| ANN17 | 4 | 10 |

| ANN18 | 4 | 20 |

| ANN19 | 4 | 30 |

| ANN20 | 5 | 10 |

| ANN21 | 5 | 20 |

| ANN22 | 5 | 30 |

| Number of Inputs | Input ID | Number of Outputs | Outputs ID |

|---|---|---|---|

| 1 | ΔT | 1 | TSA |

| 2 | ΔRH | ||

| 3 | TSA-1 | 2 | RHSA |

| 4 | RHSA-1 | ||

| 5 | TOA | 3 | OPV_PostHC |

| 6 | OPV_PostHC-1 | ||

| 7 | OPV_CC-1 | 4 | OPV_CC |

| 8 | OPV_HUM-1 | ||

| 9 | OLSAF | 5 | OPV_HUM |

| 10 | OLRAF |

| Errors | ANN Outputs | ANN1 | ANN2 | ANN3 | ANN4 | ANN5 | ANN6 | ANN7 | ANN8 | ANN9 | ANN10 | ANN11 | ANN12 | ANN13 | ANN14 | ANN15 | ANN16 | ANN17 | ANN18 | ANN19 | ANN20 | ANN21 | ANN22 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TSA (°C) | −0.11 | −0.03 | 0.00 | −0.01 | −0.01 | −0.01 | −0.01 | 0.00 | −0.01 | 0.00 | 0.05 | −0.01 | −0.09 | 0.00 | 0.01 | 0.00 | 0.00 | 0.04 | −0.02 | 0.02 | 10.71 | −0.01 | |

| RHSA (%) | 0.22 | −0.02 | 0.10 | 0.08 | 0.04 | −0.06 | 0.04 | −0.03 | 0.06 | −0.02 | −0.24 | 0.06 | 0.18 | 0.05 | 0.00 | −0.01 | −0.04 | 0.02 | −0.05 | −0.02 | 0.01 | 0.01 | |

| OPV_PostHC (%) | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | −0.01 | −0.01 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | −0.01 | −0.01 | 0.02 | 0.00 | 0.01 | −0.01 | 0.00 | 3.66 | −0.01 | |

| OPV_CC (%) | 0.00 | −0.02 | 0.00 | 0.06 | 0.01 | 0.04 | 0.01 | −0.02 | 0.01 | 0.02 | −0.02 | −0.01 | −0.03 | 0.00 | 0.02 | 0.01 | −0.03 | 0.01 | −2.48 | 0.00 | 0.02 | 0.01 | |

| OPV_HUM (%) | 0.01 | 0.00 | −0.03 | 0.04 | −0.01 | −0.02 | −0.02 | 0.01 | −0.01 | −0.02 | −0.02 | −0.02 | 0.03 | −0.03 | 0.01 | 0.01 | 0.07 | 0.00 | 0.03 | 0.03 | −0.02 | 0.01 | |

| TSA (°C) | 0.72 | 0.36 | 0.36 | 0.36 | 0.31 | 0.26 | 0.25 | 0.62 | 0.41 | 0.42 | 0.44 | 0.34 | 0.70 | 0.47 | 0.43 | 0.27 | 0.72 | 0.46 | 0.45 | 0.69 | 10.71 | 0.36 | |

| RHSA (%) | 2.80 | 2.00 | 2.00 | 1.95 | 1.80 | 1.67 | 1.75 | 2.32 | 2.02 | 1.98 | 1.99 | 1.77 | 2.46 | 2.13 | 1.94 | 1.62 | 2.26 | 2.00 | 1.88 | 2.57 | 2.00 | 1.83 | |

| OPV_PostHC (%) | 0.08 | 0.06 | 0.08 | 0.19 | 0.12 | 0.10 | 0.12 | 0.06 | 0.06 | 0.20 | 0.13 | 0.11 | 0.07 | 0.10 | 0.13 | 0.06 | 0.05 | 0.11 | 0.07 | 0.10 | 3.66 | 0.05 | |

| OPV_CC (%) | 0.07 | 0.07 | 0.06 | 0.15 | 0.08 | 0.09 | 0.08 | 0.07 | 0.07 | 0.14 | 0.09 | 0.10 | 0.07 | 0.08 | 0.11 | 0.07 | 0.09 | 0.08 | 2.48 | 0.09 | 0.12 | 0.05 | |

| OPV_HUM (%) | 0.19 | 0.13 | 0.15 | 0.20 | 0.15 | 0.13 | 0.17 | 0.13 | 0.12 | 0.23 | 0.15 | 0.18 | 0.16 | 0.17 | 0.18 | 0.11 | 0.16 | 0.15 | 0.13 | 0.16 | 0.16 | 0.11 | |

| MSE | TSA (°C) | 0.81 | 0.26 | 0.26 | 0.28 | 0.21 | 0.16 | 0.14 | 0.77 | 0.35 | 0.38 | 0.36 | 0.24 | 0.94 | 0.50 | 0.40 | 0.16 | 1.15 | 0.50 | 0.44 | 1.04 | 6.01 | 0.27 |

| RHSA (%) | 16.59 | 10.00 | 9.86 | 10.14 | 9.18 | 8.05 | 8.60 | 13.07 | 10.13 | 10.48 | 9.74 | 8.73 | 13.77 | 11.16 | 10.17 | 7.69 | 13.30 | 10.17 | 8.93 | 15.38 | 9.48 | 8.31 | |

| OPV_PostHC (%) | 0.49 | 0.35 | 0.43 | 0.82 | 0.50 | 0.38 | 0.51 | 0.37 | 0.32 | 0.81 | 0.51 | 0.51 | 0.42 | 0.43 | 0.49 | 0.36 | 0.32 | 0.52 | 0.38 | 0.47 | 36.62 | 0.28 | |

| OPV_CC (%) | 0.41 | 0.48 | 0.28 | 0.75 | 0.40 | 0.65 | 0.39 | 0.57 | 0.28 | 0.57 | 0.49 | 0.46 | 0.59 | 0.39 | 0.37 | 0.41 | 0.61 | 0.41 | 24.83 | 0.47 | 0.80 | 0.33 | |

| OPV_HUM (%) | 1.10 | 0.79 | 0.82 | 1.12 | 0.71 | 0.72 | 1.17 | 0.94 | 0.68 | 1.03 | 0.74 | 0.75 | 1.12 | 0.88 | 0.94 | 0.77 | 1.21 | 0.75 | 0.72 | 1.11 | 0.78 | 0.68 | |

| RMSE | TSA (°C) | 0.89 | 0.51 | 0.51 | 0.53 | 0.46 | 0.40 | 0.38 | 0.88 | 0.59 | 0.61 | 0.60 | 0.49 | 0.97 | 0.71 | 0.63 | 0.40 | 1.07 | 0.71 | 0.66 | 1.02 | 7.17 | 0.52 |

| RHSA | 4.07 | 3.16 | 3.14 | 3.18 | 3.03 | 2.84 | 2.93 | 3.62 | 3.18 | 3.24 | 3.11 | 2.95 | 3.71 | 3.34 | 3.19 | 2.77 | 3.65 | 3.19 | 2.99 | 3.92 | 3.08 | 2.88 | |

| OPV_PostHC (%) | 0.70 | 0.59 | 0.66 | 0.90 | 0.71 | 0.62 | 0.71 | 0.60 | 0.57 | 0.90 | 0.71 | 0.72 | 0.65 | 0.66 | 0.70 | 0.60 | 0.56 | 0.72 | 0.62 | 0.69 | 4.82 | 0.53 | |

| OPV_CC (%) | 0.64 | 0.69 | 0.53 | 0.86 | 0.63 | 0.80 | 0.63 | 0.75 | 0.53 | 0.75 | 0.70 | 0.68 | 0.76 | 0.62 | 0.61 | 0.64 | 0.78 | 0.64 | 4.32 | 0.68 | 0.89 | 0.57 | |

| OPV_HUM (%) | 1.05 | 0.89 | 0.90 | 1.06 | 0.84 | 0.85 | 1.08 | 0.97 | 0.83 | 1.01 | 0.86 | 0.86 | 1.06 | 0.94 | 0.97 | 0.88 | 1.10 | 0.87 | 0.85 | 1.06 | 0.88 | 0.83 | |

| R2 | TSA (°C) | 0.985 | 0.995 | 0.994 | 0.994 | 0.996 | 0.996 | 0.997 | 0.980 | 0.991 | 0.990 | 0.991 | 0.996 | 0.976 | 0.987 | 0.990 | 0.996 | 0.967 | 0.988 | 0.989 | 0.978 | 0.118 | 0.994 |

| RHSA (%) | 0.955 | 0.975 | 0.976 | 0.975 | 0.978 | 0.981 | 0.979 | 0.957 | 0.972 | 0.974 | 0.977 | 0.977 | 0.963 | 0.967 | 0.974 | 0.982 | 0.964 | 0.973 | 0.976 | 0.956 | 0.976 | 0.980 | |

| OPV_PostHC (%) | 0.979 | 0.989 | 0.982 | 0.981 | 0.982 | 0.988 | 0.990 | 0.987 | 0.987 | 0.985 | 0.980 | 0.978 | 0.982 | 0.981 | 0.987 | 0.982 | 0.987 | 0.984 | 0.978 | 0.984 | 0.140 | 0.993 | |

| OPV_CC (%) | 0.981 | 0.986 | 0.985 | 0.976 | 0.975 | 0.980 | 0.983 | 0.979 | 0.983 | 0.969 | 0.984 | 0.968 | 0.974 | 0.977 | 0.986 | 0.973 | 0.962 | 0.981 | 0.131 | 0.971 | 0.974 | 0.983 | |

| OPV_HUM (%) | 0.965 | 0.975 | 0.978 | 0.972 | 0.982 | 0.973 | 0.977 | 0.970 | 0.977 | 0.957 | 0.977 | 0.981 | 0.961 | 0.965 | 0.969 | 0.970 | 0.975 | 0.975 | 0.966 | 0.969 | 0.990 | 0.981 |

| Fault Free Tests during Summer | Faulty Tests during Summer | Fault Free Tests during Winter | Faulty Tests during Winter | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Errors | Parameters | Test n. 1 | Test n. 2 | Test n. 3 | Test n. 4 | Test n. 5 | Test n. 6 | Test n. 7 | Test n. 8 | Test n. 9 | Test n. 10 | Test n. 11 | Test n. 12 | Test n. 13 | Test n. 14 | Test n. 15 | Test n. 16 | Test n. 17 | Test n. 18 |

| ∆TSA (°C) | −0.10 | 0.09 | 0.22 | 0.17 | 0.06 | 0.09 | −0.04 | 0.21 | 0.01 | 0.11 | −0.01 | −0.02 | 0.07 | −0.02 | −0.11 | 0.01 | 0.22 | 0.16 | |

| ∆RHSA (%) | −0.18 | 0.04 | 0.28 | −0.88 | −0.87 | 0.11 | 0.01 | 0.33 | −0.05 | −0.24 | −0.43 | −0.03 | −0.36 | −0.08 | −0.61 | −0.22 | −0.02 | −0.39 | |

| ∆OPV_PostHC (%) | 0.06 | 0.11 | 0.02 | −0.06 | 0.00 | −0.01 | −0.07 | 0.00 | −0.11 | 0.01 | 0.06 | 0.00 | 0.02 | −0.03 | 0.05 | −0.10 | 0.00 | 0.05 | |

| ∆OPV_CC (%) | −0.12 | 0.03 | −0.05 | −0.01 | 0.00 | 0.01 | 0.03 | −0.10 | 0.06 | −0.06 | 0.02 | 0.01 | 0.01 | 0.02 | 0.06 | 0.02 | −0.01 | −0.31 | |

| ∆OPV_HUM (%) | 0.12 | 0.00 | −0.04 | −0.10 | 0.00 | 0.03 | 0.04 | 0.12 | −0.03 | −0.07 | −0.03 | −0.16 | 0.11 | −0.01 | −0.04 | 0.00 | −0.01 | −0.16 | |

| ∆TSA (°C) | 0.55 | 0.46 | 0.60 | 0.56 | 0.19 | 0.38 | 0.53 | 0.44 | 0.43 | 0.47 | 0.38 | 0.48 | 0.43 | 0.41 | 0.47 | 0.30 | 0.45 | 0.46 | |

| ∆RHSA (%) | 1.97 | 2.19 | 2.57 | 2.40 | 1.21 | 11.09 | 2.12 | 1.47 | 1.99 | 2.24 | 2.04 | 2.49 | 2.32 | 1.18 | 2.26 | 0.70 | 2.84 | 1.69 | |

| ∆OPV_PostHC (%) | 0.06 | 0.11 | 0.04 | 0.06 | 0.00 | 0.00 | 0.07 | 0.00 | 0.11 | 0.24 | 0.23 | 0.26 | 0.30 | 0.09 | 0.12 | 0.10 | 0.00 | 0.25 | |

| ∆OPV_CC (%) | 0.12 | 0.03 | 0.11 | 0.07 | 0.00 | 0.00 | 0.13 | 0.10 | 0.07 | 0.18 | 0.02 | 0.01 | 0.01 | 0.13 | 0.12 | 0.02 | 0.01 | 0.36 | |

| ∆OPV_HUM (%) | 0.12 | 0.00 | 0.05 | 0.13 | 0.00 | 0.37 | 0.07 | 0.21 | 0.03 | 0.19 | 0.20 | 0.26 | 0.22 | 0.02 | 0.15 | 0.00 | 0.45 | 0.16 | |

| MSE | ∆TSA (°C) | 0.71 | 0.51 | 0.58 | 0.51 | 0.07 | 0.38 | 0.52 | 0.36 | 0.47 | 0.36 | 0.27 | 0.42 | 0.32 | 0.28 | 0.38 | 0.14 | 0.34 | 0.32 |

| ∆RHSA (%) | 8.59 | 7.44 | 11.13 | 10.23 | 2.48 | 11.09 | 10.08 | 4.85 | 6.15 | 10.50 | 9.12 | 11.06 | 12.27 | 2.73 | 13.25 | 1.08 | 22.41 | 5.19 | |

| ∆OPV_PostHC (%) | 0.58 | 1.15 | 0.09 | 0.62 | 0.00 | 0.00 | 0.22 | 0.00 | 1.18 | 0.74 | 0.73 | 0.99 | 0.95 | 0.40 | 0.43 | 0.31 | 0.00 | 0.87 | |

| ∆OPV_CC (%) | 1.16 | 0.03 | 0.60 | 0.13 | 0.00 | 0.00 | 0.47 | 0.07 | 0.60 | 1.33 | 0.00 | 0.00 | 0.00 | 0.38 | 0.40 | 0.00 | 0.00 | 3.00 | |

| ∆OPV_HUM (%) | 1.16 | 0.00 | 0.10 | 0.95 | 0.00 | 0.37 | 0.42 | 1.12 | 0.03 | 0.85 | 0.79 | 1.10 | 1.38 | 0.05 | 0.78 | 0.00 | 2.63 | 0.29 | |

| RMSE | ∆TSA (°C) | 0.84 | 0.71 | 0.73 | 0.70 | 0.25 | 0.61 | 0.72 | 0.57 | 0.67 | 0.59 | 0.52 | 0.65 | 0.56 | 0.53 | 0.61 | 0.37 | 0.54 | 0.54 |

| ∆RHSA (%) | 2.93 | 2.74 | 3.34 | 3.09 | 1.32 | 3.34 | 3.19 | 2.18 | 2.42 | 3.24 | 2.99 | 3.33 | 3.49 | 1.65 | 3.59 | 1.02 | 4.74 | 2.25 | |

| ∆OPV_PostHC (%) | 0.76 | 1.07 | 0.30 | 0.79 | 0.00 | 0.01 | 0.46 | 0.01 | 1.05 | 0.86 | 0.85 | 1.00 | 0.98 | 0.63 | 0.65 | 0.55 | 0.01 | 0.93 | |

| ∆OPV_CC (%) | 1.08 | 0.17 | 0.78 | 0.35 | 0.00 | 0.01 | 0.68 | 0.25 | 0.75 | 1.15 | 0.03 | 0.02 | 0.02 | 0.61 | 0.63 | 0.04 | 0.07 | 1.71 | |

| ∆OPV_HUM (%) | 1.07 | 0.00 | 0.32 | 0.97 | 0.03 | 0.61 | 0.65 | 1.05 | 0.17 | 0.92 | 0.89 | 1.04 | 1.17 | 0.21 | 0.89 | 0.01 | 1.62 | 0.51 | |

| R2 | ∆TSA (°C) | 0.98 | 0.99 | 0.99 | 0.99 | 0.98 | 0.85 | 0.96 | 0.92 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 | 0.99 | 0.60 | 0.85 | 0.99 |

| ∆RHSA (%) | 0.97 | 0.76 | 0.97 | 0.96 | 0.89 | 0.92 | 0.93 | 0.94 | 0.96 | 0.97 | 0.98 | 0.97 | 0.97 | 1.00 | 0.97 | 0.77 | 0.87 | 0.98 | |

| ∆OPV_PostHC (%) | 0.95 | 0.49 | 1.00 | 0.98 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.97 | 0.97 | 0.96 | 0.96 | 0.98 | 0.89 | 1.00 | 1.00 | 0.96 | |

| ∆OPV_CC (%) | 0.91 | 1.00 | 0.95 | 0.99 | 1.00 | 1.00 | 0.97 | 1.00 | 1.00 | 0.91 | 1.00 | 1.00 | 1.00 | 0.98 | 0.90 | 1.00 | 1.00 | 0.88 | |

| ∆OPV_HUM (%) | 0.94 | 1.00 | 0.99 | 0.94 | 1.00 | 0.98 | 0.98 | 0.92 | 1.00 | 0.93 | 0.95 | 0.92 | 0.86 | 1.00 | 0.94 | 1.00 | 0.87 | 1.00 | |

| Simulated Component | TRNSYS Type/Model |

|---|---|

| Test room | 56 |

| Heat pump/Refrigerating system | 941 |

| Hot and cold tanks | 534 |

| Humidifier | 641 |

| HP/RS pump | 654 |

| Diverting/mixing valves | 647/649 |

| On/Off differential controllers | 2 |

| Moist air properties | 33e |

| Integrated test room | 56 |

| ID Test | Thermal Comfort Time (%) | Hygrometric Comfort Time (%) | ||

|---|---|---|---|---|

| Summer tests | Test 5 | With fault 1 (experimental) | 0.00 | 16.17 |

| Without fault (predicted) | 65.79 | 86.84 | ||

| Difference between faulty and healthy operation | −65.79 | −70.67 | ||

| Test 6 | With fault 2 (experimental) | 50.61 | 81.38 | |

| Without fault (predicted) | 58.70 | 88.26 | ||

| Difference between faulty and healthy operation | −8.09 | −6.88 | ||

| Test 7 | With fault 3 (experimental) | 13.43 | 88.06 | |

| Without fault (predicted) | 81.95 | 88.72 | ||

| Difference between faulty and healthy operation | −68.52 | −0.66 | ||

| Test 8 | With fault 4 (experimental) | 0.00 | 90.59 | |

| Without fault (predicted) | 63.31 | 94.67 | ||

| Difference between faulty and healthy operation | −63.31 | −4.08 | ||

| Test 9 | With fault 5 (experimental) | 86.59 | 65.36 | |

| Without fault (predicted) | 84.00 | 81.14 | ||

| Difference between faulty and healthy operation | 2.59 | −15.78 | ||

| Winter tests | Test 14 | With fault 1 (experimental) | 75.41 | 49.41 |

| Without fault (predicted) | 76.11 | 87.35 | ||

| Difference between faulty and healthy operation | −0.70 | −37.94 | ||

| Test 15 | With fault 2 (experimental) | 68.71 | 82.34 | |

| Without fault (predicted) | 69.23 | 86.23 | ||

| Difference between faulty and healthy operation | −0.52 | −3.89 | ||

| Test 16 | With fault 3 (experimental) | 0.00 | 99.75 | |

| Without fault (predicted) | 69.75 | 86.25 | ||

| Difference between faulty and healthy operation | −69.75 | 13.50 | ||

| Test 17 | With fault 4 (experimental) | 15.73 | 80.45 | |

| Without fault (predicted) | 67.79 | 95.72 | ||

| Difference between faulty and healthy operation | −52.06 | −15.27 | ||

| Test 18 | With fault 5 (experimental) | 64.85 | 22.67 | |

| Without fault (predicted) | 70.48 | 51.03 | ||

| Difference between faulty and healthy operation | −5.63 | −28.36 | ||

| ID Test | TRA (°C) | RHRA (%) | ||||

|---|---|---|---|---|---|---|

| μ | σ | μ | σ | |||

| Summer tests | Test 5 | With fault 1 (experimental) | 28.55 | 0.22 | 56.17 | 1.54 |

| Without fault (predicted) | 26.20 | 1.28 | 48.58 | 3.36 | ||

| %D | 8.98% | −82.73% | 15.64% | −54.25% | ||

| Test 6 | With fault 2 (experimental) | 27.72 | 1.78 | 49.32 | 3.59 | |

| Without fault (predicted) | 27.16 | 1.79 | 49.97 | 3.30 | ||

| %D | 2.07% | −0.17% | −1.30% | 8.75% | ||

| Test 7 | With fault 3 (experimental) | 24.72 | 1.20 | 48.88 | 3.56 | |

| Without fault (predicted) | 26.12 | 0.84 | 48.42 | 3.22 | ||

| %D | −5.34% | 42.68% | 0.96% | 10.46% | ||

| Test 8 | With fault 4 (experimental) | 28.50 | 0.14 | 47.77 | 3.06 | |

| Without fault (predicted) | 26.57 | 1.28 | 50.13 | 2.92 | ||

| %D | 7.24% | −89.05% | −4.69% | 4.93% | ||

| Test 9 | With fault 5 (experimental) | 25.88 | 0.74 | 47.50 | 3.31 | |

| Without fault (predicted) | 25.95 | 0.77 | 51.15 | 3.71 | ||

| %D | −0.27% | −3.48% | −7.14% | −10.79% | ||

| Winter tests | Test 14 | With fault 1 (experimental) | 19.77 | 0.80 | 45.18 | 1.48 |

| Without fault (predicted) | 20.14 | 0.84 | 49.61 | 3.38 | ||

| %D | −1.85% | −4.26% | −8.93% | −56.06% | ||

| Test 15 | With fault 2 (experimental) | 20.18 | 0.86 | 50.12 | 4.01 | |

| Without fault (predicted) | 20.21 | 0.88 | 49.70 | 3.42 | ||

| %D | −0.13% | −1.35% | 0.85% | 17.23% | ||

| Test 16 | With fault 3 (experimental) | 15.71 | 0.69 | 47.22 | 0.91 | |

| Without fault (predicted) | 20.21 | 0.87 | 49.67 | 3.41 | ||

| %D | −22.25% | −20.88% | −4.94% | −73.38% | ||

| Test 17 | With fault 4 (experimental) | 21.55 | 0.59 | 49.99 | 3.95 | |

| Without fault (predicted) | 20.38 | 1.06 | 50.48 | 2.76 | ||

| %D | 5.77% | −44.25% | −0.98% | 43.17% | ||

| Test 18 | With fault 5 (experimental) | 20.30 | 0.97 | 47.05 | 2.41 | |

| Without fault (predicted) | 20.25 | 0.89 | 49.56 | 3.46 | ||

| %D | 0.25% | 9.53% | −5.07% | −30.29% | ||

| ID Fault | TRA | RHRA | |||

|---|---|---|---|---|---|

| μ | σ | μ | σ | ||

| Summer tests | Fault 1 (related to velocity of the supply air fan) | 0 | - | 0 | - |

| Fault 2 (related to velocity of the return air fan) | 0 | 0 | 0 | 0 | |

| Fault 3 (related to the post-heating coil valve) | 0 | + | 0 | 0 | |

| Fault 4 (related to the cooling coil valve) | 0 | - | 0 | 0 | |

| Fault 5 (related to the humidifier valve) | 0 | 0 | 0 | 0 | |

| Winter tests | Fault 1 (related to velocity of the supply air fan) | 0 | 0 | 0 | - |

| Fault 2 (related to velocity of the return air fan) | 0 | 0 | 0 | 0 | |

| Fault 3 (related to the post-heating coil valve) | - | - | 0 | - | |

| Fault 4 (related to the cooling coil valve) | 0 | - | 0 | + | |

| Fault 5 (related to the humidifier valve) | 0 | 0 | 0 | - | |

| ID Test | Electric Energy Consumption | |||||||

|---|---|---|---|---|---|---|---|---|

| EEHP (kWh) | EERS (kWh) | EEHUM (kWh) | EESAF (kWh) | EERAF (kWh) | EETOT (kWh) | |||

| Summer tests | Test 5 | With fault 1 (experimental) | 0.28 | 19.37 | 0.00 | 0.17 | 0.43 | 20.25 |

| Without fault (predicted) | 9.43 | 18.99 | 4.75 | 1.29 | 0.43 | 34.89 | ||

| EPD | +97% | −2% | +100% | +87% | 0% | +42% | ||

| Test 6 | With fault 2 (experimental) | 0.29 | 16.68 | 9.00 | 1.04 | 0.12 | 27.13 | |

| Without fault (predicted) | 5.45 | 13.88 | 7.09 | 1.04 | 0.35 | 27.81 | ||

| EPD | +95% | −20% | −27% | 0% | +66% | +2% | ||

| Test 7 | With fault 3 (experimental) | 0.22 | 7.19 | 2.65 | 0.56 | 0.19 | 10.81 | |

| Without fault (predicted) | 4.35 | 6.91 | 2.34 | 0.56 | 0.19 | 14.35 | ||

| EPD | +95% | −4% | −13% | 0% | 0% | +25% | ||

| Test 8 | With fault 4 (experimental) | 0.22 | 0.99 | 1.48 | 0.72 | 0.24 | 3.65 | |

| Without fault (predicted) | 4.94 | 10.13 | 2.96 | 0.72 | 0.24 | 18.99 | ||

| EPD | +96% | +90% | +50% | 0% | 0% | +81% | ||

| Test 9 | With fault 5 (experimental) | 2.65 | 8.76 | 0.00 | 0.74 | 0.25 | 12.40 | |

| Without fault (predicted) | 3.90 | 10.94 | 3.88 | 0.74 | 0.25 | 19.71 | ||

| EPD | +32% | +20% | +100% | 0% | 0% | +37% | ||

| Winter tests | Test 14 | With fault 1 (experimental) | 13.13 | 8.49 | 11.04 | 0.17 | 0.61 | 33.44 |

| Without fault (predicted) | 16.30 | 13.56 | 16.16 | 1.81 | 0.61 | 48.44 | ||

| EPD | +19% | +37% | +32% | +91% | 0% | +31% | ||

| Test 15 | With fault 2 (experimental) | 28.95 | 20.23 | 17.70 | 2.21 | 0.25 | 69.34 | |

| Without fault (predicted) | 20.90 | 21.01 | 19.36 | 2.21 | 0.74 | 64.22 | ||

| EPD | −39% | +4% | +9% | 0% | +66% | −8% | ||

| Test 16 | With fault 3 (experimental) | 0.61 | 16.27 | 0.00 | 1.70 | 0.57 | 19.15 | |

| Without fault (predicted) | 16.37 | 12.26 | 14.00 | 1.70 | 0.57 | 44.90 | ||

| EPD | +96% | −33% | +100% | 0% | 0% | +57% | ||

| Test 17 | With fault 4 (experimental) | 0.61 | 0.37 | 7.65 | 1.89 | 0.63 | 11.15 | |

| Without fault (predicted) | 14.85 | 18.06 | 9.31 | 1.89 | 0.63 | 44.74 | ||

| EPD | +96% | +98% | +18% | 0% | 0% | +75% | ||

| Test 18 | With fault 5 (experimental) | 9.05 | 11.24 | 0.00 | 1.78 | 0.60 | 22.67 | |

| Without fault (predicted) | 16.20 | 17.10 | 15.35 | 1.78 | 0.60 | 51.03 | ||

| EPD | +44% | +34% | +100% | 0% | 0% | +56% | ||

| Sensor Model | Monitored Parameter | Measuring Range | Accuracy |

|---|---|---|---|

| Siemens QFM2160 [37] | Return air temperature (TRA) | 0 ÷ 50 °C | ±0.8 °C |

| Return air relative humidity (RHRA) | 0 ÷ 100% | ±3% | |

| Siemens QFM2160 [37] | Supply air temperature (TSA) | 0 ÷ 50 °C | ±0.8 °C |

| Supply air relative humidity (RHSA) | 0 ÷ 100% | ±3% | |

| Siemens QAM2161.040 [38] | Outside air temperature (TOA) | −50 ÷ 50 °C | ±0.75 °C |

| Siemens QAM2161.040 [38] | Cooling coil outlet air temperature (TA,out,CC) | −50 ÷ 50 °C | ±0.75 °C |

| TSI 7575, 982 IAQ [39] | Temperature of air around the test room (TBEA) | −10 ÷ 60 °C | ±0.50 °C |

| Relative humidity of air around the test room (RHBEA) | 5 ÷ 95% | ±3% |

| Component of AHU | ON | OFF |

|---|---|---|

| Steam humidifier (HUM) | RHRA ≤ (RHSP,Room − DBRH) | RHRA ≥ (RHSP,Room + DBRH) |

| Cooling coil (CC) | TRA ≥ (TSP,Room + DBT) OR RHRA ≥ (RHSP,Room + DBRH) | TRA ≤ (TSP,Room − DBT) AND RHRA ≤ (RHSP,Room − DBRH) |

| Post-heating coil (PostHC) | TRA ≤ (TSP,Room − DBT) | TRA ≥ (TSP,Room + DBT) |

| Heat Pump (HP) [36] | THT < 44 °C | THT ≥ 46 °C |

| Refrigerating System (RS) [36] | TCT > 8 °C | TCT ≤ 6 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosato, A.; Guarino, F.; Sibilio, S.; Entchev, E.; Masullo, M.; Maffei, L. Healthy and Faulty Experimental Performance of a Typical HVAC System under Italian Climatic Conditions: Artificial Neural Network-Based Model and Fault Impact Assessment. Energies 2021, 14, 5362. https://doi.org/10.3390/en14175362

Rosato A, Guarino F, Sibilio S, Entchev E, Masullo M, Maffei L. Healthy and Faulty Experimental Performance of a Typical HVAC System under Italian Climatic Conditions: Artificial Neural Network-Based Model and Fault Impact Assessment. Energies. 2021; 14(17):5362. https://doi.org/10.3390/en14175362

Chicago/Turabian StyleRosato, Antonio, Francesco Guarino, Sergio Sibilio, Evgueniy Entchev, Massimiliano Masullo, and Luigi Maffei. 2021. "Healthy and Faulty Experimental Performance of a Typical HVAC System under Italian Climatic Conditions: Artificial Neural Network-Based Model and Fault Impact Assessment" Energies 14, no. 17: 5362. https://doi.org/10.3390/en14175362

APA StyleRosato, A., Guarino, F., Sibilio, S., Entchev, E., Masullo, M., & Maffei, L. (2021). Healthy and Faulty Experimental Performance of a Typical HVAC System under Italian Climatic Conditions: Artificial Neural Network-Based Model and Fault Impact Assessment. Energies, 14(17), 5362. https://doi.org/10.3390/en14175362