Opportunities in Measuring Multiscale Pore Structure of the Continental Shale of the Yanchang Formation, Ordos Basin, China

Abstract

:1. Introduction

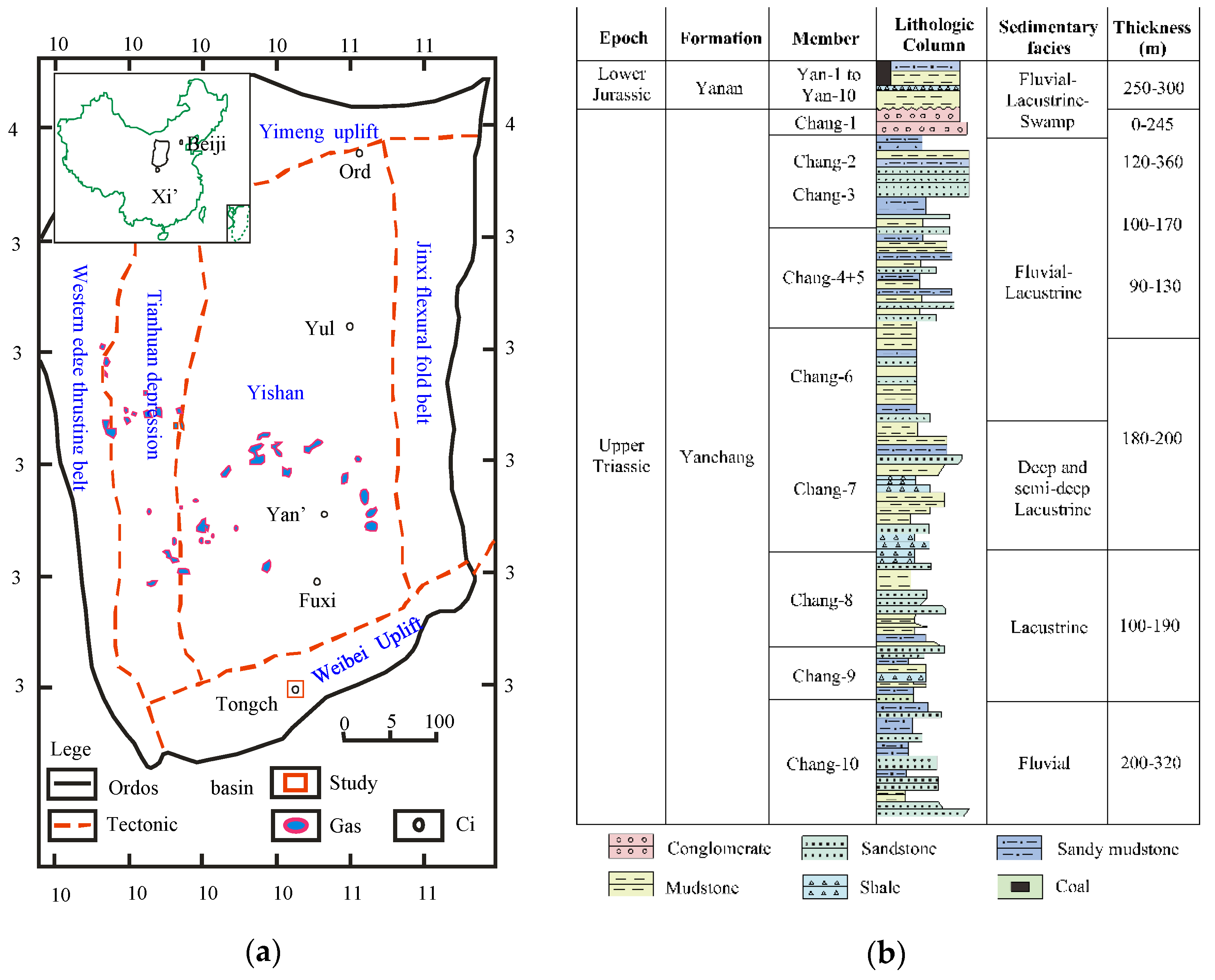

2. Geological Setting

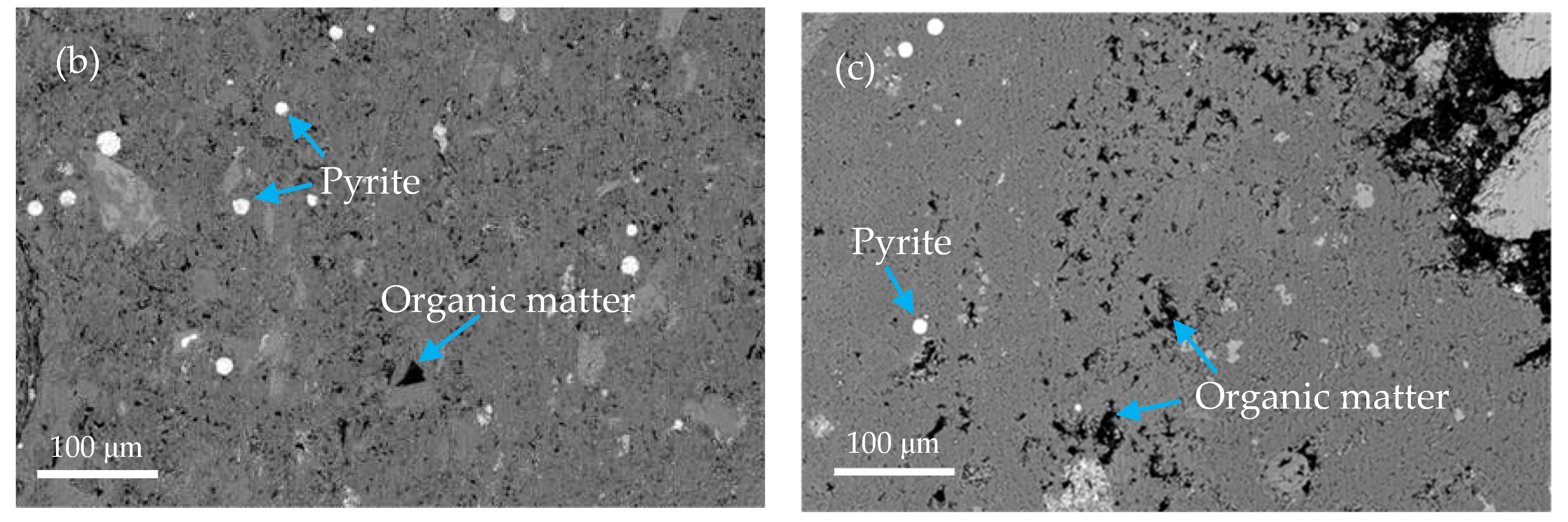

3. Materials and Methods

4. Results and Discussions

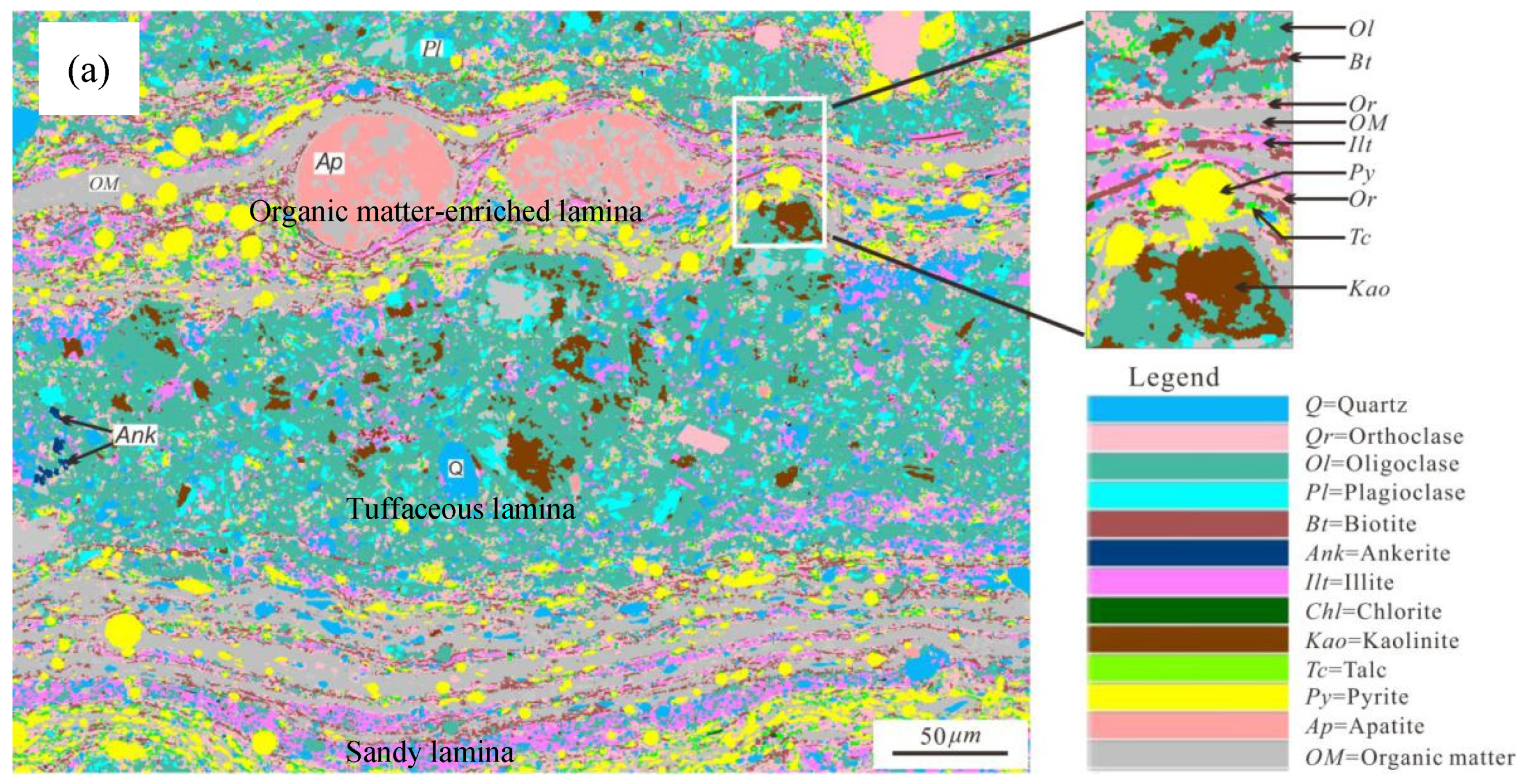

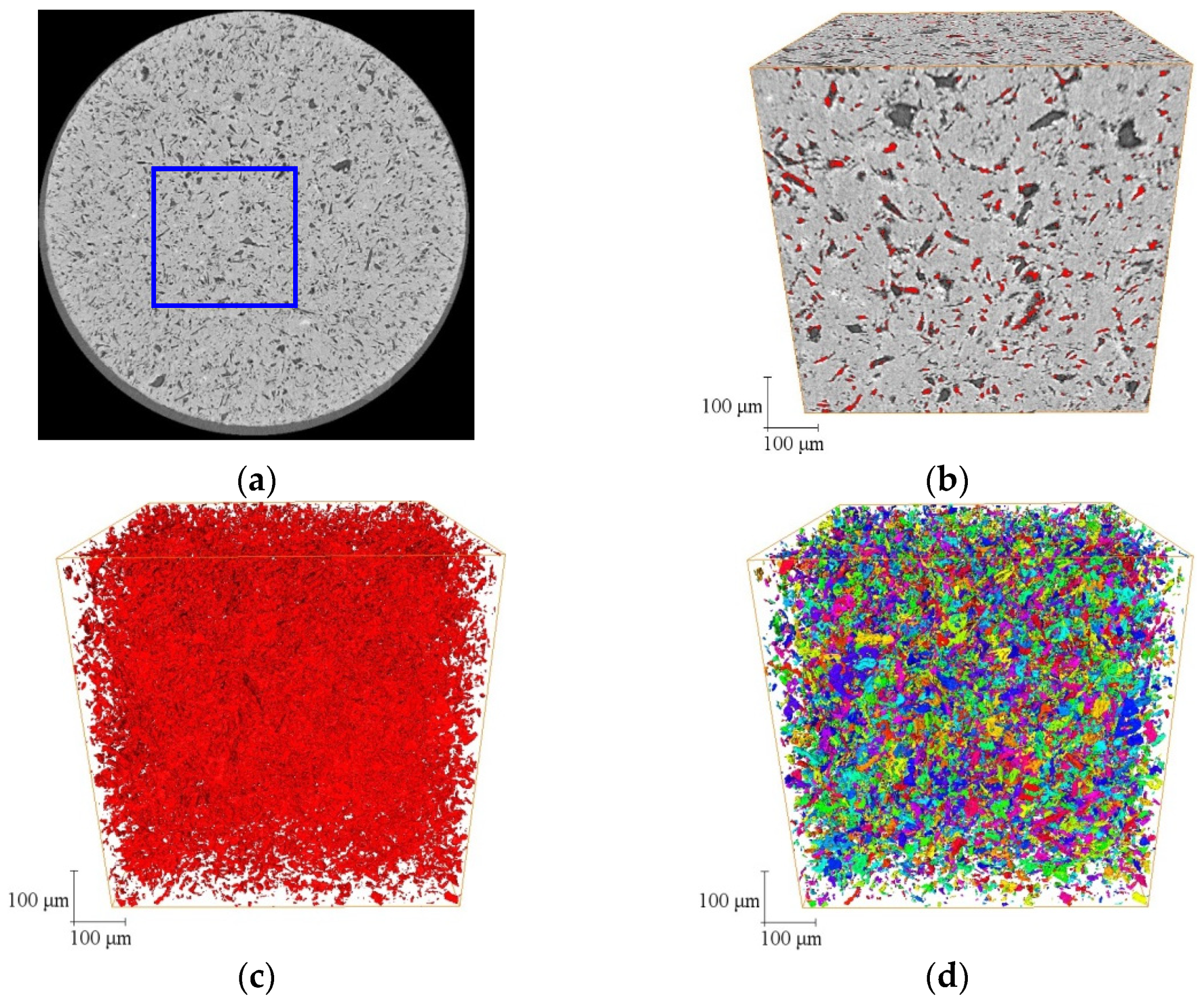

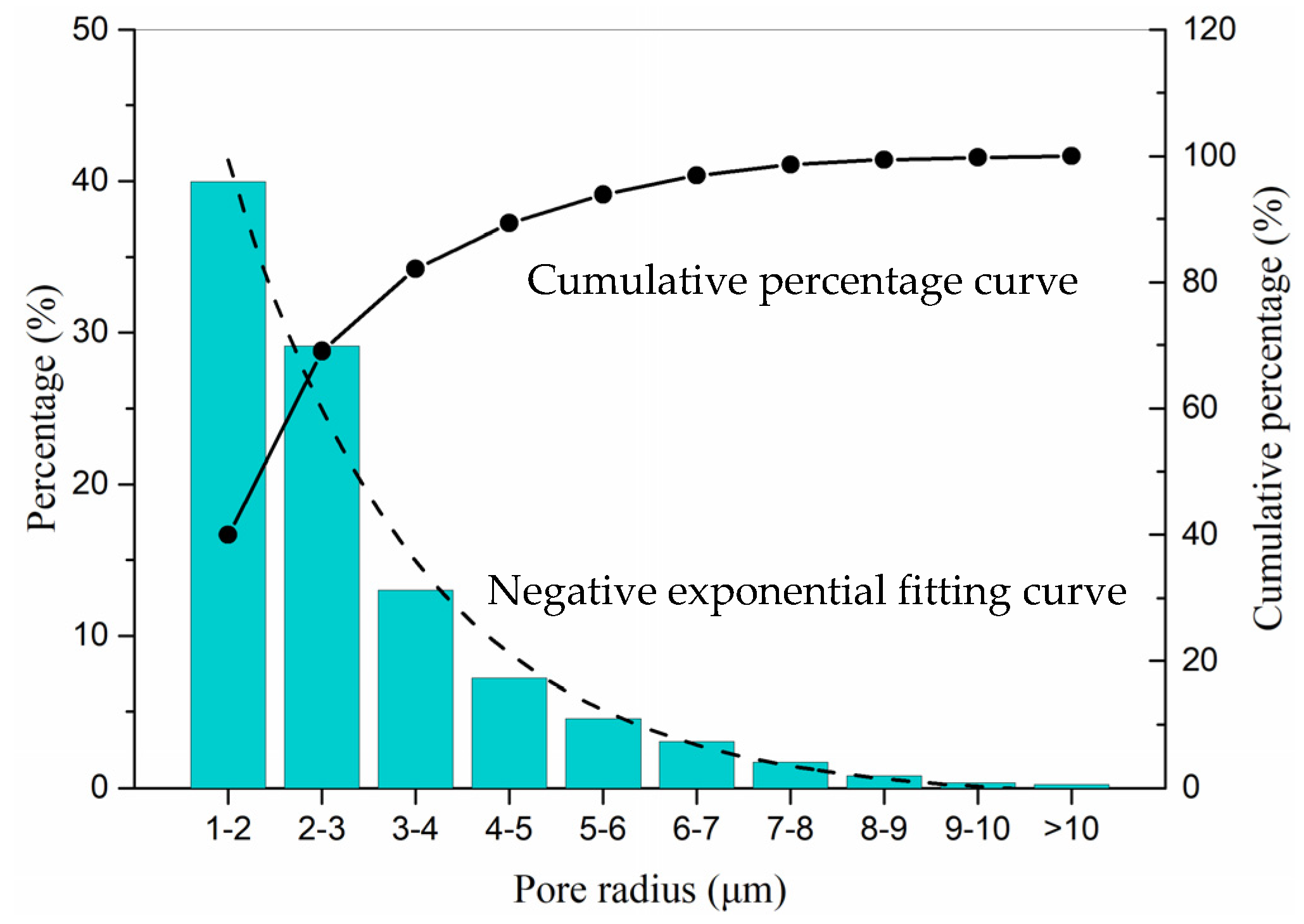

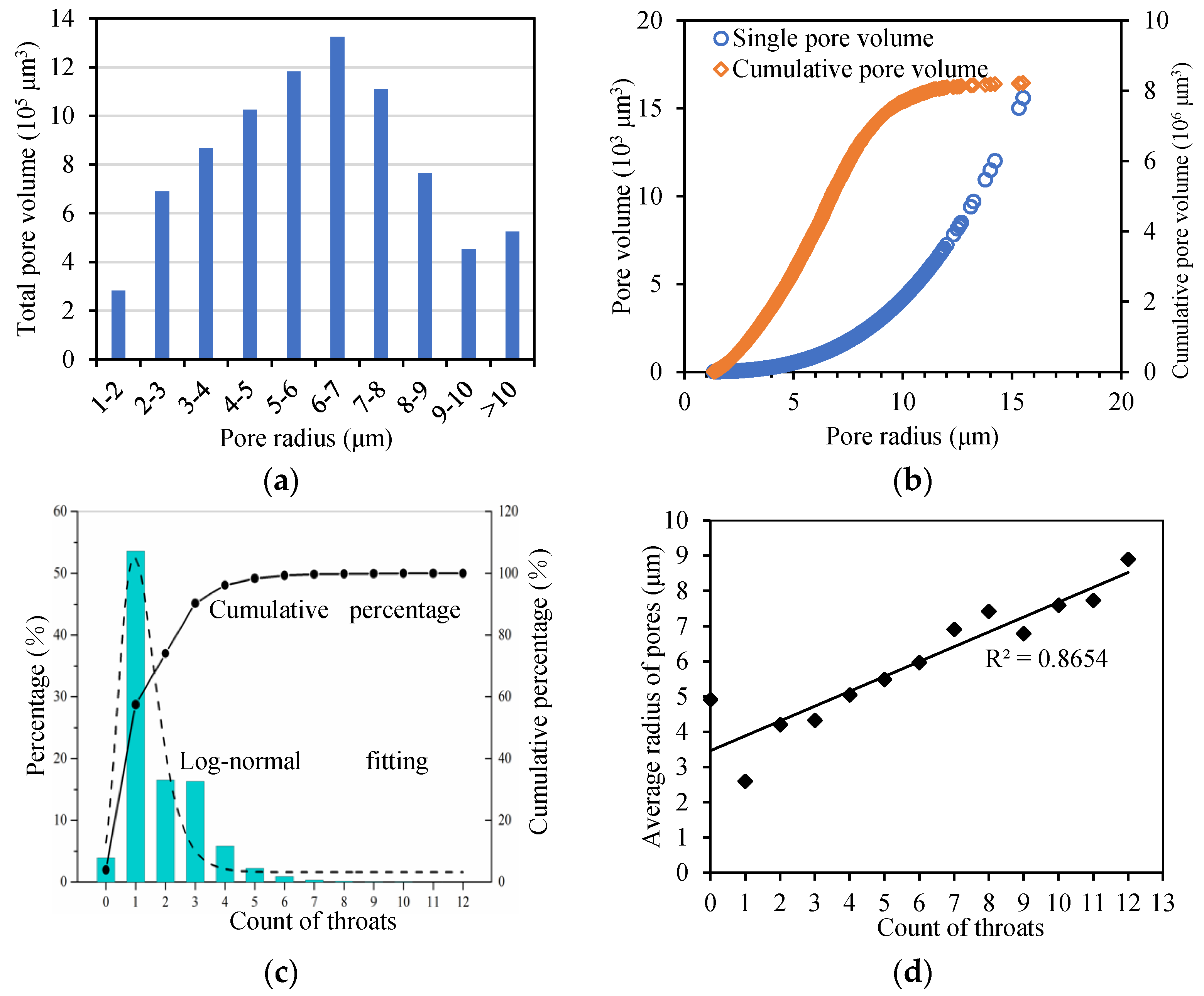

4.1. Micro-Scale Pores

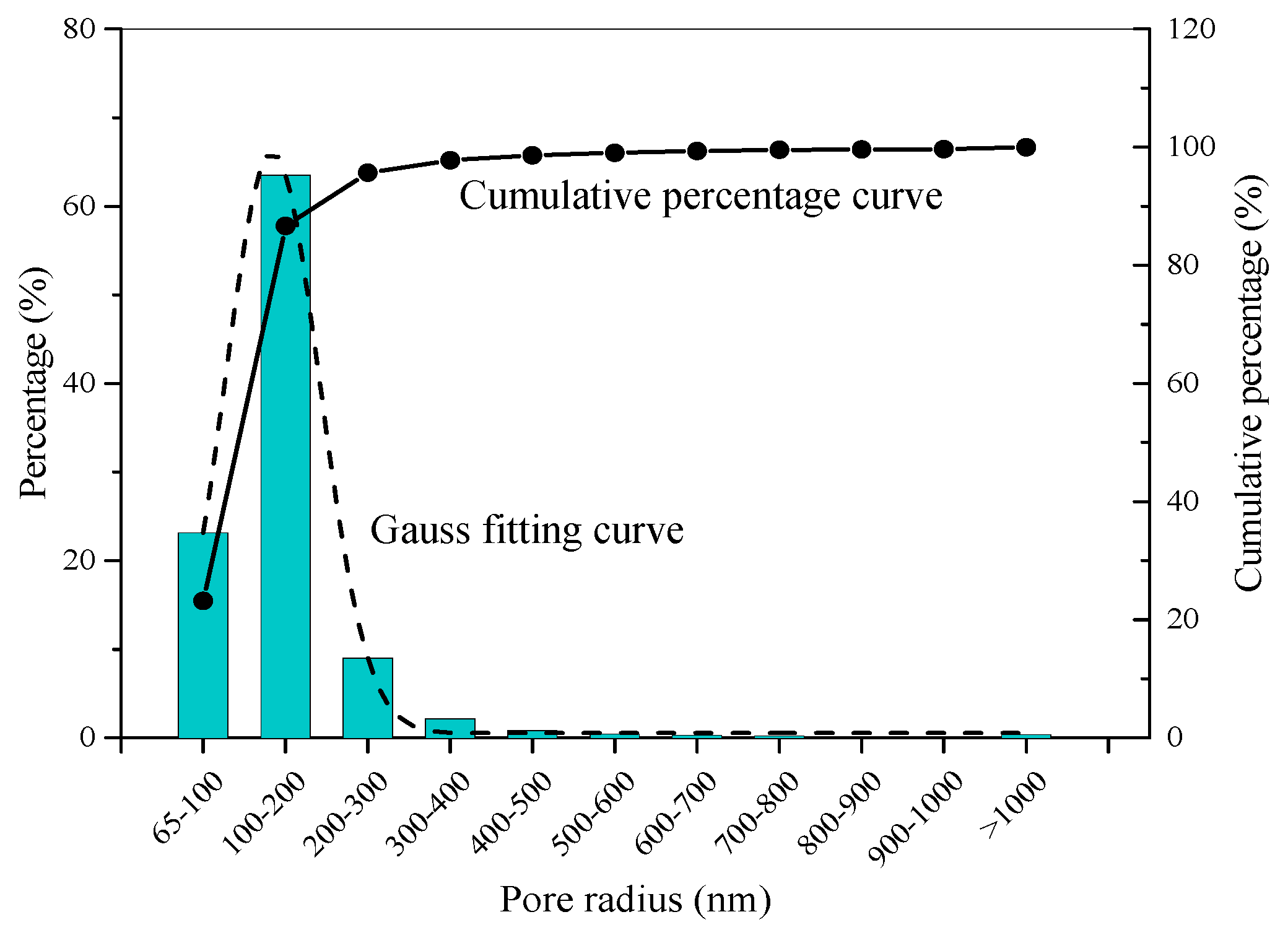

4.2. Nano-Scale Pores

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Zhao, J.; Mountney, N.P.; Liu, C.; Qu, H.; Lin, J. Outcrop architecture of a fluvio-lacustrine succession: Upper Triassic Yanchang Formation, Ordos Basin, China. Mar. Petrol. Geol. 2015, 68, 394–413. [Google Scholar] [CrossRef]

- Xi, K.; Cao, Y.; Liu, K.; Wu, S.; Yuan, G.; Zhu, R.; Kashif, M.; Zhao, Y. Diagenesis of tight sandstone reservoirs in the Upper Triassic Yanchang Formation, southwestern Ordos Basin, China. Mar. Petrol. Geol. 2019, 99, 548–562. [Google Scholar] [CrossRef]

- Slatt, R.M.; O’Brien, N.R. Pore types in the barnett and woodford gas shales: Contribution to understanding gas storage and migration pathways in finegrained rocks. AAPG Bull. 2011, 95, 2017–2030. [Google Scholar] [CrossRef]

- Tiwari, P.; Deo, M.; Lin, C.L.; Miller, J.D. Characterization of oil shale pore structure before and after pyrolysis by using X-ray micro CT. Fuel 2013, 107, 547–554. [Google Scholar] [CrossRef]

- Zhou, S.; Yan, G.; Xue, H.; Guo, W.; Li, X. 2D and 3D nanopore characterization of gas shale in Longmaxi formation based on FIB-SEM. Mar. Petrol. Geol. 2016, 73, 174–180. [Google Scholar] [CrossRef]

- Kim, C.; Jang, H.; Lee, Y.; Lee, J. Diffusion characteristics of nanoscale gas flow in shale matrix from Haenam basin, Korea. Environ. Earth Sci. 2016, 75, 350. [Google Scholar] [CrossRef]

- Basu, S.; Verchovsky, A.B.; Bogush, A.; Jones, A.P.; Jourdan, A.L. Stability of Organic Carbon Components in Shale: Implications for Carbon Cycle. Front. Earth Sci. 2019, 7, 297. [Google Scholar] [CrossRef] [Green Version]

- Gundogar, A.S.; Ross, C.M.; Akin, S.; Kovscek, A.R. Multiscale pore structure characterization of middle east carbonates. J. Petrol. Sci Eng. 2016, 146, 570–583. [Google Scholar] [CrossRef]

- Dong, T.; Harris, N.B.; Ayranci, K.; Twemlow, C.E.; Nassichuk, B.R. The impact of composition on pore throat size and permeability in high maturity shales: Middle and Upper Devonian Horn River Group, northeastern British Columbia, Canada. Mar. Petrol. Geol. 2017, 81, 220–236. [Google Scholar] [CrossRef]

- Guo, X.; Shen, Y.; He, S. Quantitative pore characterization and the relationship between pore distributions and organic matter in shale based on Nano-CT image analysis: A case study for a lacustrine shale reservoir in the Triassic Chang 7 member, Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 27, 1630–1640. [Google Scholar] [CrossRef]

- Liu, S.; Sang, S.; Wang, G.; Ma, J.; Wang, X.; Wang, W.; Du, Y.; Wang, T. FIB-SEM and X-ray CT characterization of interconnected pores in high-rank coal formed from regional metamorphism. J. Petrol. Sci. Eng. 2017, 148, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Tang, X.; Jiang, Z.; Jiang, S.; Li, Z. Heterogeneous nanoporosity of the Silurian Longmaxi Formation shale gas reservoir in the Sichuan Basin using the QEMSCAN, FIB-SEM, and nano-CT methods. Mar. Petrol. Geol. 2016, 78, 99–109. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Wei, Q.; Gao, W.; Liang, W.; Wang, Z.; Wang, F. Quantitative characterization of pore-fracture system of organic-rich marine-continental shale reservoirs: A case study of the Upper Permian Longtan Formation, Southern Sichuan Basin, China. Fuel 2017, 200, 272–281. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, Z.; Zhong, N.; Connell, L.D.; Down, D.I.; Lin, W.; Zhang, Y. Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China. Fuel 2016, 180, 106–115. [Google Scholar] [CrossRef]

- Wang, Y.; Pu, J.; Wang, L.; Wang, J.; Jiang, Z.; Song, Y.F.; Wang, C.C.; Wang, Y.; Jin, C. Characterization of typical 3D pore networks of Jiulaodong formation shale using nano-transmission X-ray microscopy. Fuel 2016, 170, 84–91. [Google Scholar] [CrossRef]

- Gaboreau, S.; Robinet, J.C.; Prêt, D. Optimization of pore-network characterization of a compacted clay material by TEM and FIB/SEM imaging. Microporous Mesoporous Mater. 2016, 224, 116–128. [Google Scholar] [CrossRef]

- Gou, Q.; Xu, S.; Hao, F.; Yang, F.; Zhang, B.; Shu, Z.; Zhang, A.; Wang, Y.; Lu, Y.; Cheng, X.; et al. Full-scale pores and micro-fractures characterization using FE-SEM, gas adsorption, nano-CT and micro-CT: A case study of the Silurian Longmaxi Formation shale in the Fuling area, Sichuan Basin, China. Fuel 2019, 253, 167–179. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, J.; Liu, J. Status of Chinese shale gas revolution and development proposal. Drill. Eng. 2019, 46, 1–9. [Google Scholar]

- Pan, S.; Horsfield, B.; Zou, C.; Yang, Z.; Gao, D. Statistical analysis as a tool for assisting geochemical interpretation of the Upper Triassic Yanchang Formation, Ordos Basin, Central China. Int. J. Coal Geol. 2017, 173, 51–64. [Google Scholar] [CrossRef] [Green Version]

- Jiang, F.; Chen, D.; Wang, Z.; Xu, Z.; Chen, J.; Liu, L.; Huyan, Y.; Liu, Y. Pore characteristic analysis of a lacustrine shale: A case study in the Ordos Basin, NW China. Mar. Petrol. Geol. 2016, 73, 554–571. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore throat structure and fractal characteristics of tight oil sandstone: A case study in the Ordos Basin, China. J. Petrol. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Ma, L.; Slater, T.; Dowey, P.J.; Yue, S.; Rutter, E.H.; Taylor, K.G.; Lee, P.D. Hierarchical integration of porosity in shales. Sci. Rep. 2018, 8, 11683. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Dong, X.; Chen, Z.; Hou, Y.; Luo, Q.; Chen, Y. A novel experimental investigation on the occurrence state of fluids in microscale pores of tight reservoirs. J. Petrol. Sci. Eng. 2021, 196, 107656. [Google Scholar] [CrossRef]

- Ji, L.; He, C.; Zhang, M.; Wu, Y.; Li, X. Bicyclic alkanes in source rocks of the Triassic Yanchang Formation in the Ordos Basin and their inconsistency in oil-source correlation. Mar. Petrol. Geol. 2016, 72, 359–373. [Google Scholar] [CrossRef]

- Yang, W.; Liu, G.; Feng, Y. Geochemical significance of 17α(H)-diahopane and its application in oil-source correlation of Yanchang formation in Longdong area, Ordos basin, China. Mar. Petrol. Geol. 2016, 71, 238–249. [Google Scholar] [CrossRef]

- Li, L.; Huang, B.; Tan, Y.; Deng, X.; Li, Y.Y.; Zheng, H. Geometric Heterogeneity of Continental Shale in the Yanchang Formation, Southern Ordos Basin, China. Sci. Rep. 2017, 7, 6006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.Y.; Shang, Y.J.; Yang, P. Modeling fracture connectivity in naturally fractured reservoirs: A case study in the Yanchang Formation, Ordos Basin, China. Fuel 2018, 211, 789–796. [Google Scholar] [CrossRef]

- Liu, G.; Huang, Z.; Chen, F.; Jiang, Z.; Gao, X.; Li, T.; Chen, L.; Xia, L.; Han, W. Reservoir characterization of Chang 7 member shale: A case study of lacustrine shale in the Yanchang Formation, Ordos Basin, China. J. Nat. Gas Sci. Eng. 2016, 34, 458–471. [Google Scholar] [CrossRef]

- Zhang, W.Z.; Hua, Y.; Yang, Y.H. Petrology and element geochemistry and development environment of Yanchang Formation Chang-7 high quality source rocks in Ordos Basin. Geochimica 2008, 37, 59–64. [Google Scholar]

- Zhang, T.W.; Ellis, G.S.; Rupple, S.C.; Milliken, K.; Yang, R. Effect of organic matter type and thermal maturity on methane adsorption in shale-gas systems. Org. Geochem. 2012, 47, 120–131. [Google Scholar] [CrossRef]

- Li, Y.; Li, G.; Luo, H.; Zhang, W. Study on the technology of improving the mechanical drilling speed of horizontal wells for terrestrial shale gas. Drill. Eng. 2020, 47, 9–15. [Google Scholar]

- Basu, S.; Jones, A.; Mahzari, P. Best Practices for Shale Core Handling: Transportation, Sampling and Storage for Conduction of Analyses. J. Mar. Sci. Eng. 2020, 8, 136. [Google Scholar] [CrossRef] [Green Version]

- Bai, B.; Zhu, R.; Wu, S.; Yang, W.; Gelb, J.; Gu, A.; Zhang, X.; Su, L. Multi-scale method of Nano(Micro)-CT study on microscopic pore structure of tight sandstone of Yanchang Formation, Ordos Basin. Petrol. Explor. Dev. 2013, 40, 354–358. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

| Sample ID | Depth (m) | Toc (wt. %) | Mineral Composition (wt. %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ill. | Kln. | Chl. | Qtz. | Fel. | Cal. | Dol. | Py. | Sd. | |||

| 1 | 1270.6 | 1.0 | 22 | 0 | 30 | 37 | 24 | 0 | 0 | 0 | 0 |

| 2 | 1271.0 | 0.5 | 21 | 0 | 13 | 33 | 13 | 2 | 11 | 2 | |

| 3 | 1378.5 | 2.1 | 24 | 0 | 7 | 34 | 12 | 2 | 0 | 4 | |

| 4 | 1450.2 | 5.5 | 29 | 0 | 17 | 35 | 15 | 0 | 0 | 2 | |

| 5 | 1450.6 | 3.9 | 33 | 5 | 10 | 31 | 19 | 0 | 16 | 0 | 0 |

| 6 | 1451.1 | 4.8 | 25 | 10 | 16 | 27 | 11 | 5 | |||

| 7 | 1453.4 | 4.3 | 25 | 9 | 13 | 32 | 12 | 5 | |||

| 8 | 1443.8 | 2.1 | 26 | 17 | 26 | 7 | 16 | ||||

| 9 | 1445.5 | 4.1 | 32 | 9 | 11 | 27 | 20 | ||||

| 10 | 1446.7 | 7.2 | 25 | 24 | 26 | 15 | 5 | ||||

| 11 | 1449.5 | 4.8 | 26 | 12 | 31 | 16 | 16 | ||||

| 12 | 1451.0 | 5.2 | 29 | 10 | 9 | 22 | 12 | 5 | 5 | 11 | 1 |

| 13 | 1518.6 | 4.6 | 25 | 25 | 29 | 16 | |||||

| 14 | 1625.2 | 11.4 | 32 | 16 | 26 | 16 | 5 | 7 | |||

| 15 | 1212.5 | 4.8 | 29 | 13 | 28 | 27 | 2 | 3 | |||

| 16 | 1621.5 | 3.7 | 21 | 2 | 4 | 28 | 20 | 3 | 2 | 8 | |

| 17 | 1392.5 | 9.7 | 24 | 6 | 27 | 13 | 3 | 2 | 7 | ||

| 18 | 1399.4 | 4.7 | 22 | 7 | 25 | 17 | 2 | 13 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhang, Z.; Wei, S.; Yang, P.; Shang, Y. Opportunities in Measuring Multiscale Pore Structure of the Continental Shale of the Yanchang Formation, Ordos Basin, China. Energies 2021, 14, 5282. https://doi.org/10.3390/en14175282

Li Y, Zhang Z, Wei S, Yang P, Shang Y. Opportunities in Measuring Multiscale Pore Structure of the Continental Shale of the Yanchang Formation, Ordos Basin, China. Energies. 2021; 14(17):5282. https://doi.org/10.3390/en14175282

Chicago/Turabian StyleLi, Yanyan, Zhihong Zhang, Siyu Wei, Peng Yang, and Yanjun Shang. 2021. "Opportunities in Measuring Multiscale Pore Structure of the Continental Shale of the Yanchang Formation, Ordos Basin, China" Energies 14, no. 17: 5282. https://doi.org/10.3390/en14175282

APA StyleLi, Y., Zhang, Z., Wei, S., Yang, P., & Shang, Y. (2021). Opportunities in Measuring Multiscale Pore Structure of the Continental Shale of the Yanchang Formation, Ordos Basin, China. Energies, 14(17), 5282. https://doi.org/10.3390/en14175282