A Review on Failure Modes of Wind Turbine Components

Abstract

1. Introduction

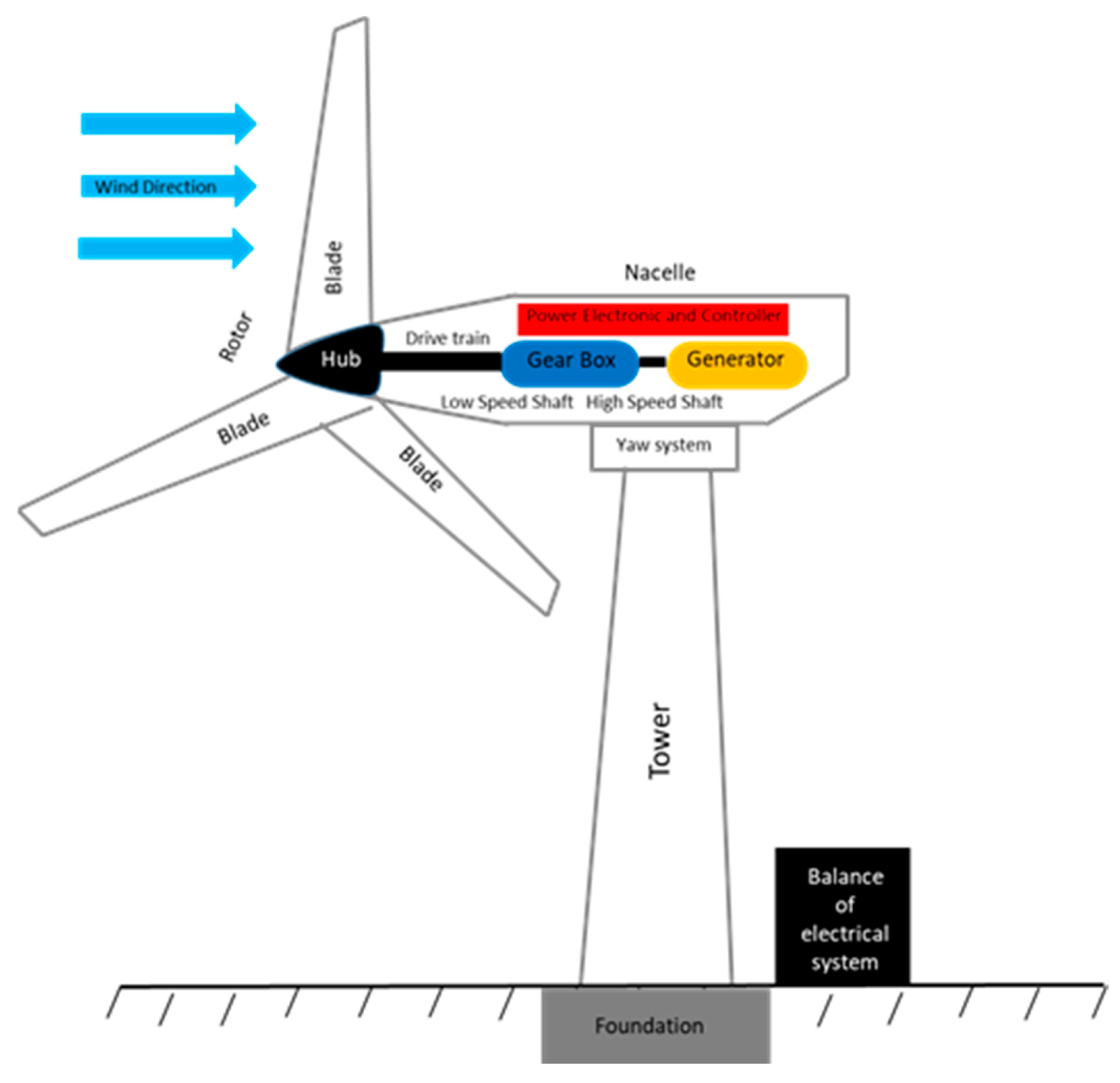

2. Wind Turbine Components

3. Wind Turbine Blades

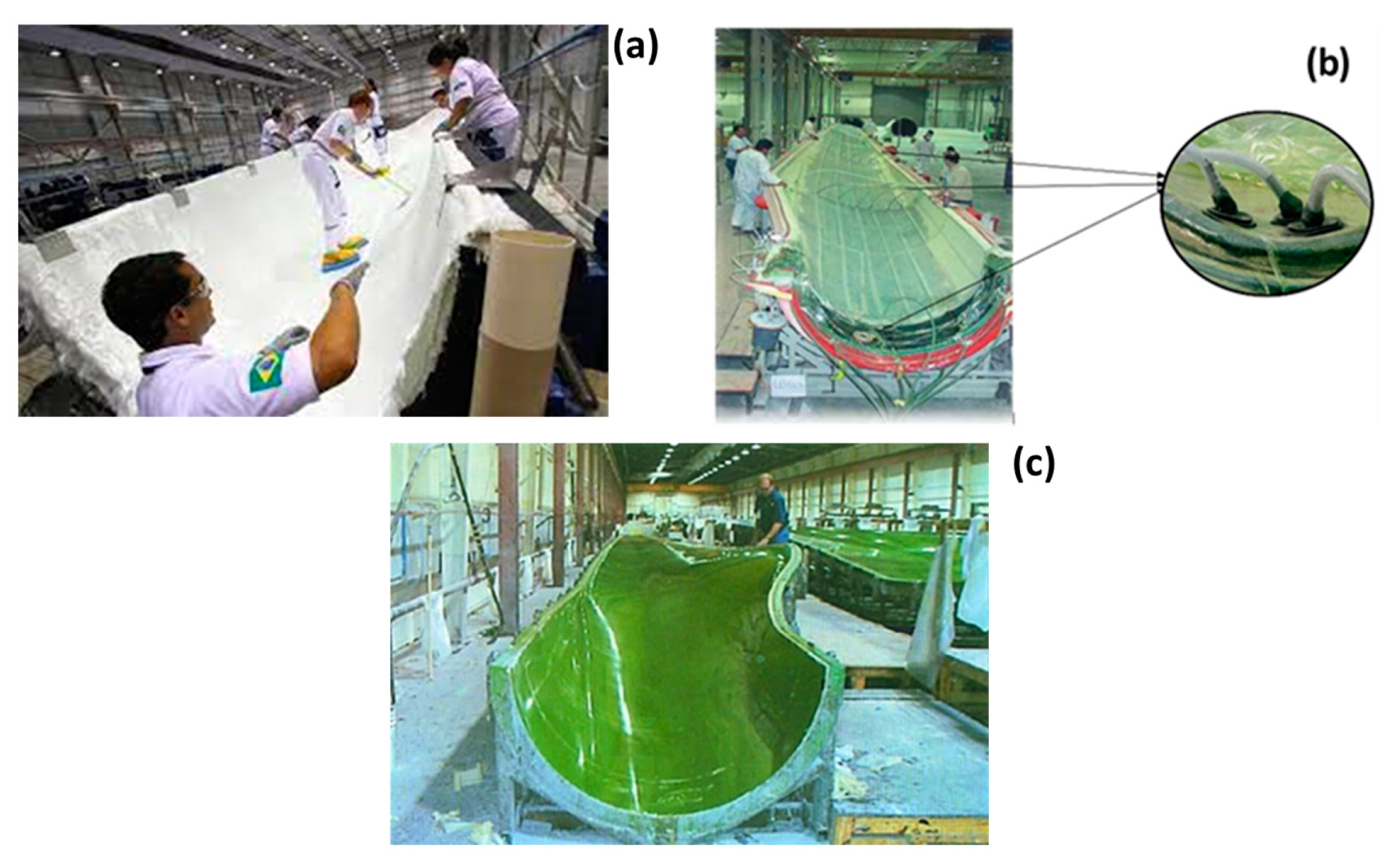

3.1. Wind Turbines Production

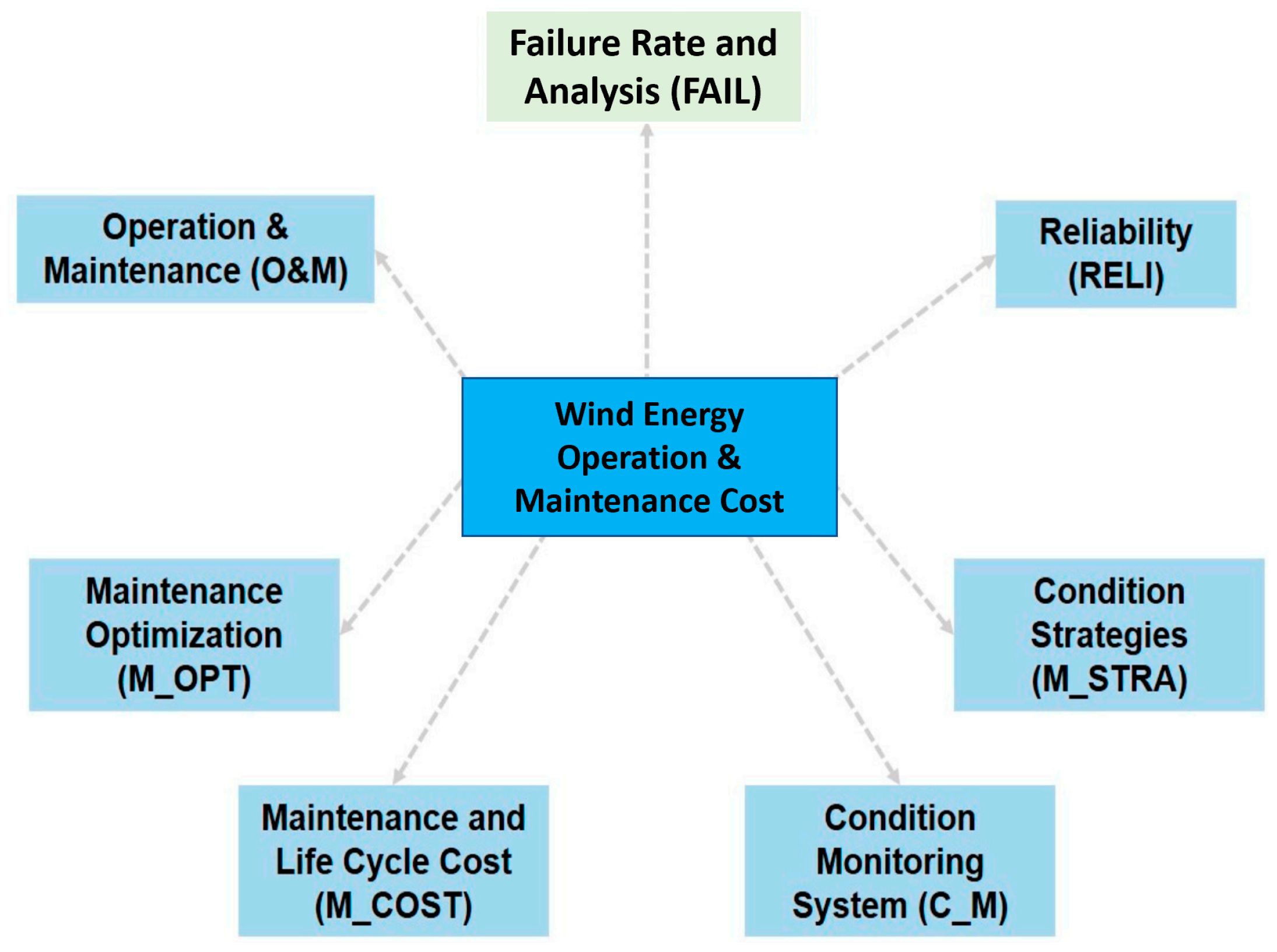

3.2. Wind Turbines Blade Damages

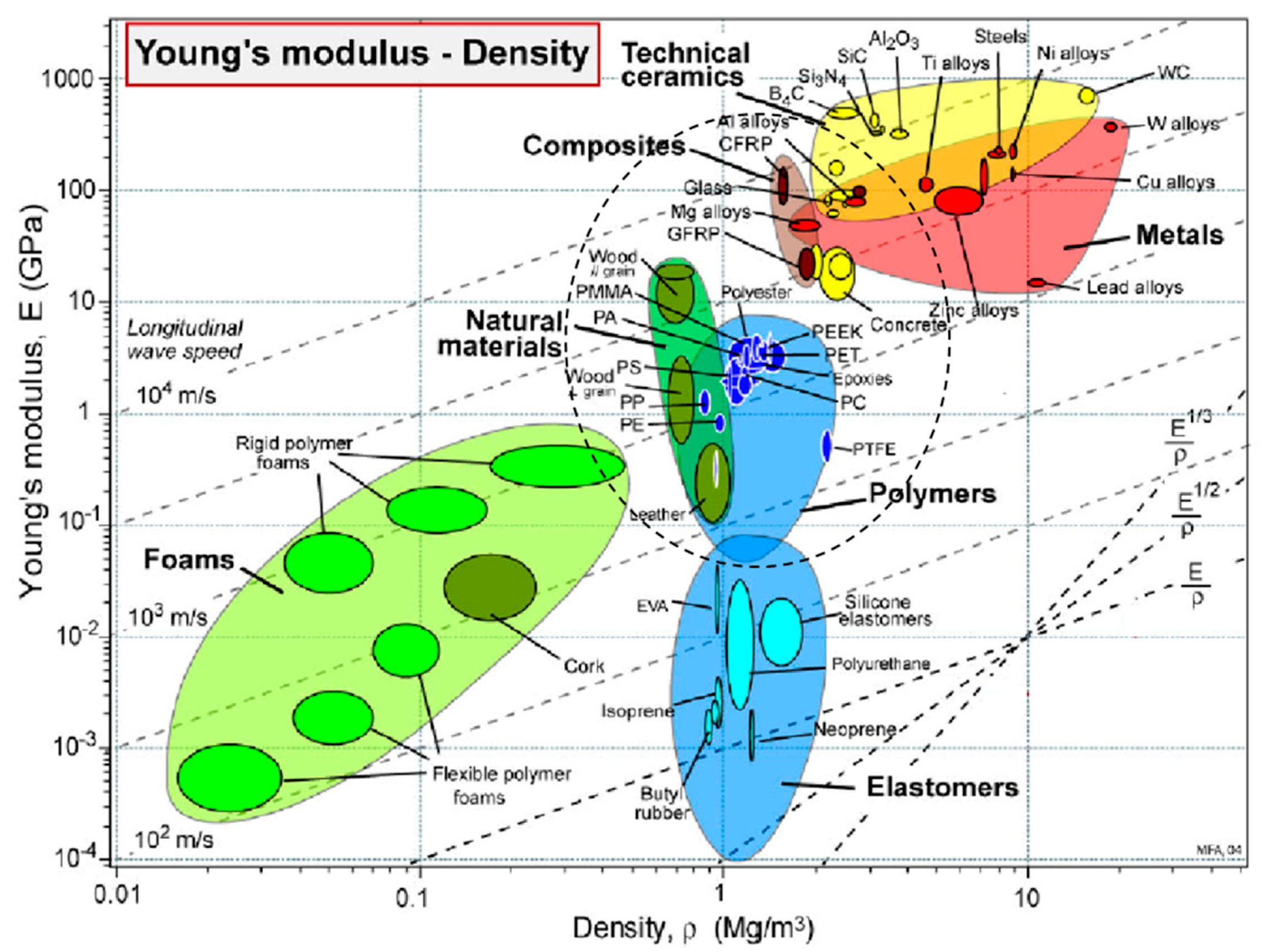

4. Materials for Wind Turbine Blades

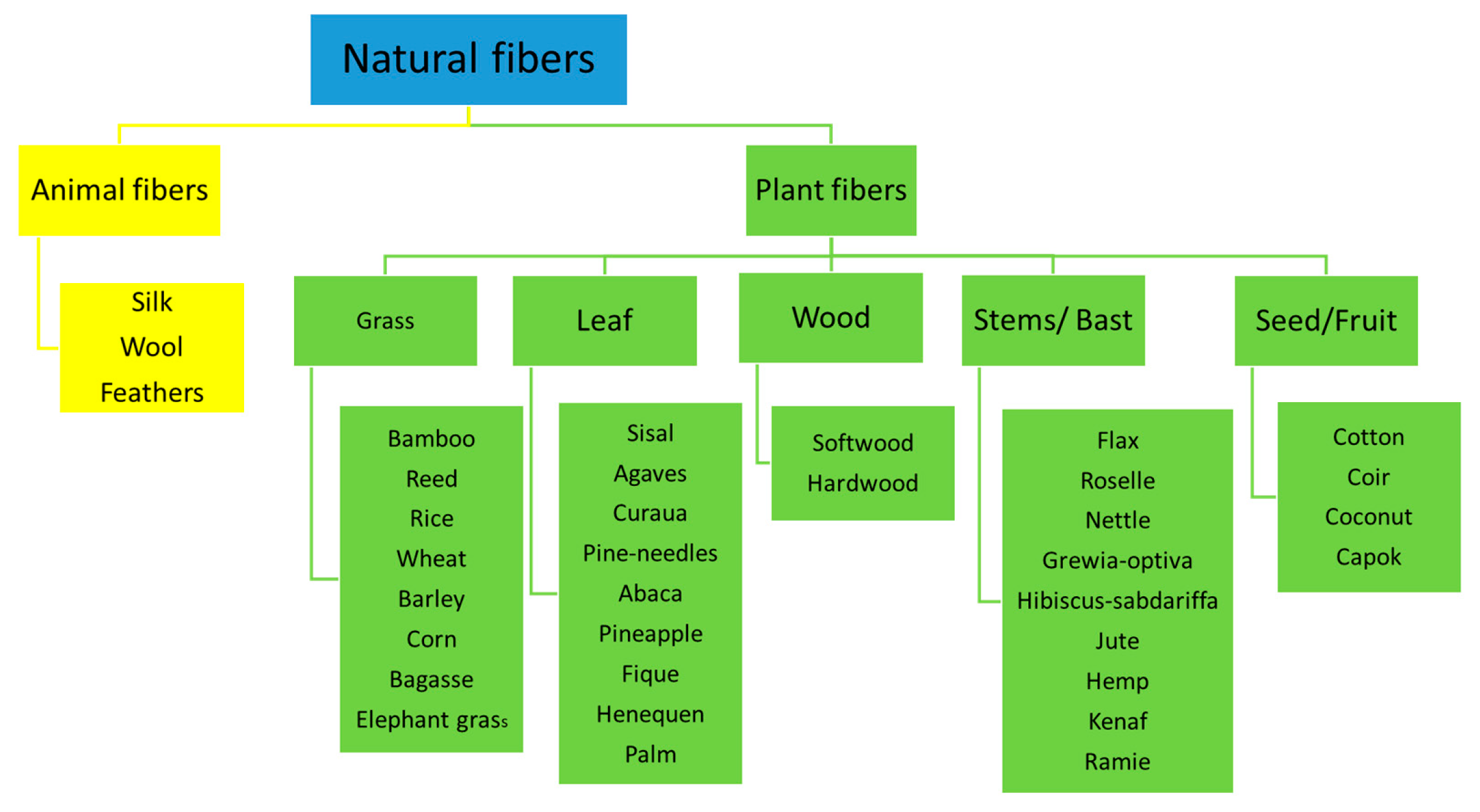

4.1. Natural Fiber

4.2. Carbon and Glass Fibers

4.3. Basalt Fibers

4.4. Hybrid Composite

4.5. Matrix

4.5.1. Thermosets

4.5.2. Thermoplastics

4.5.3. Nano-Engineered Composites

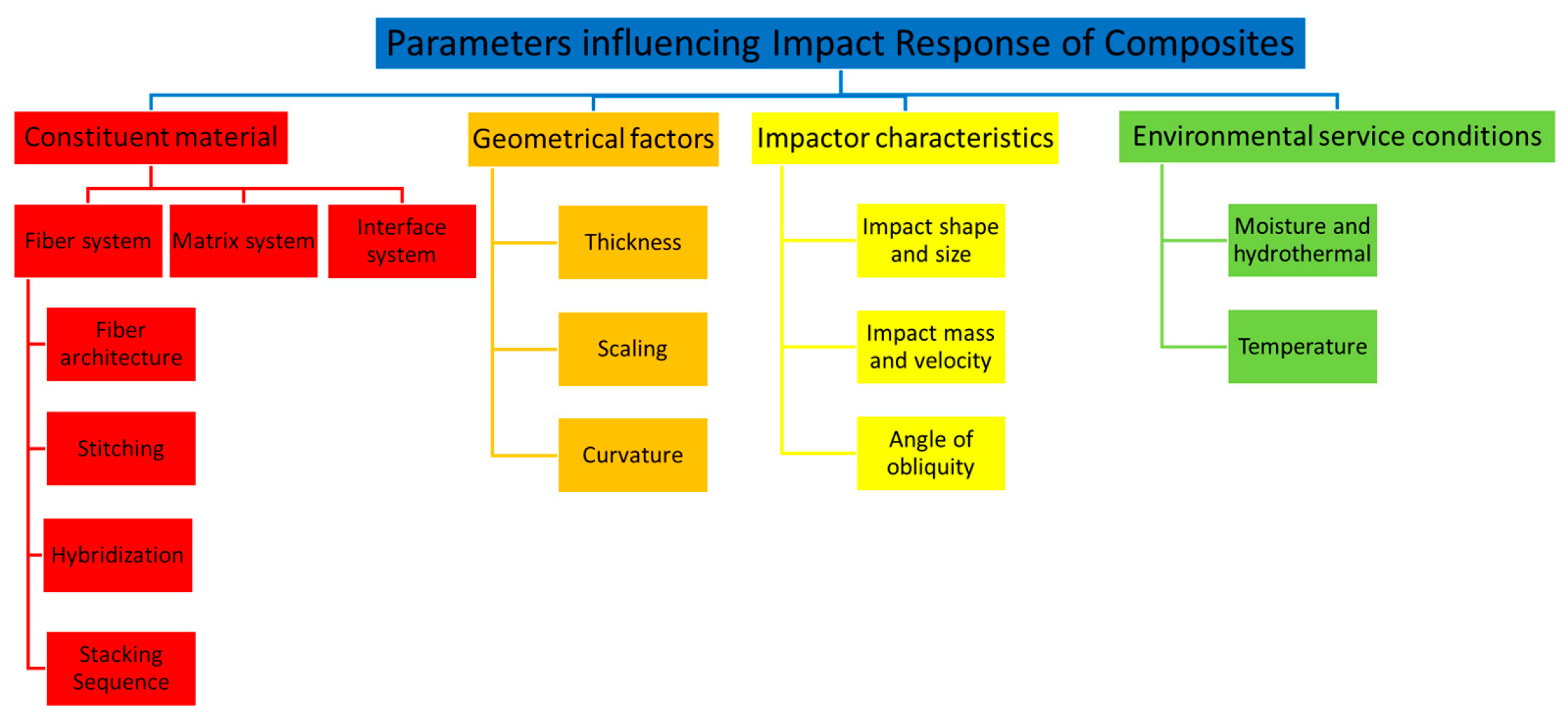

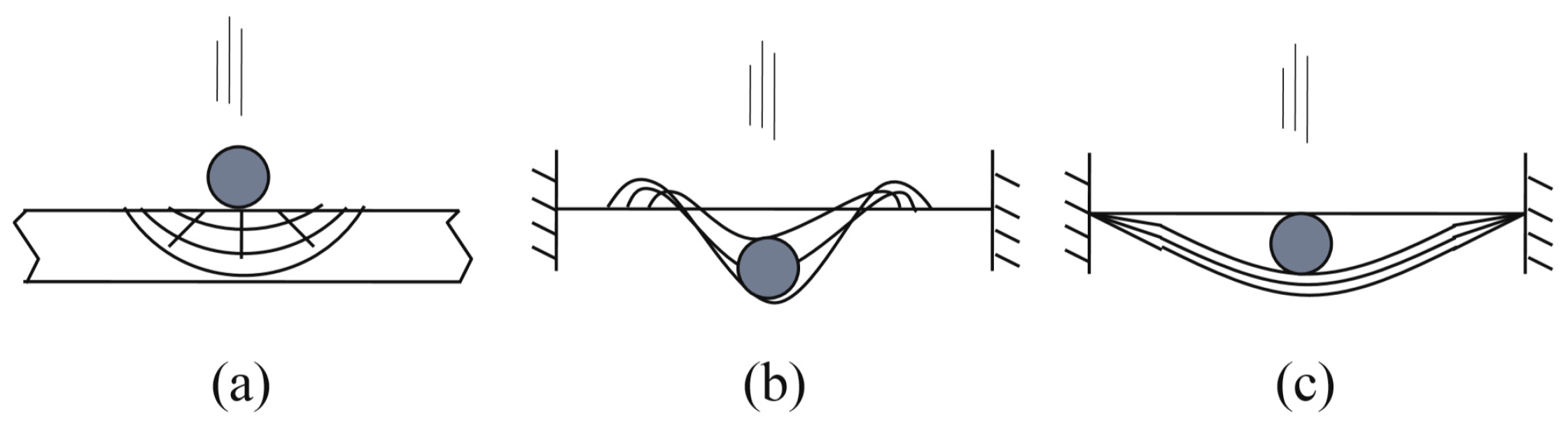

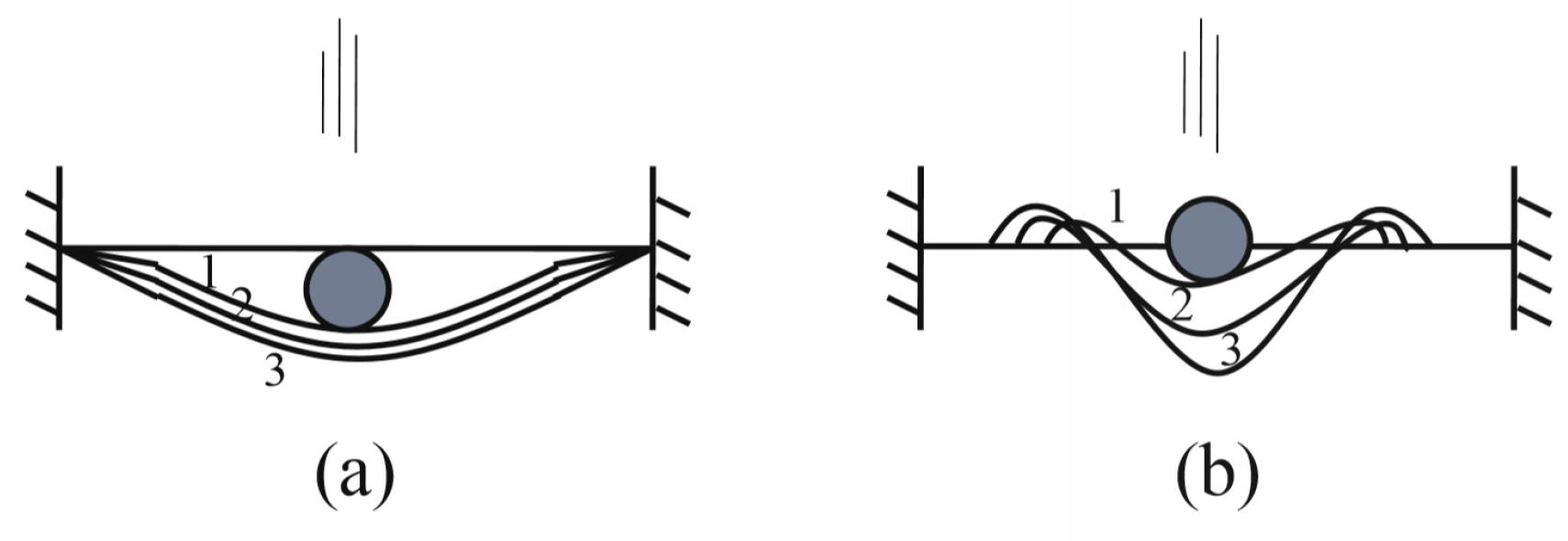

4.6. Factors That Influence Damage of Fiber-Reinforced Composites

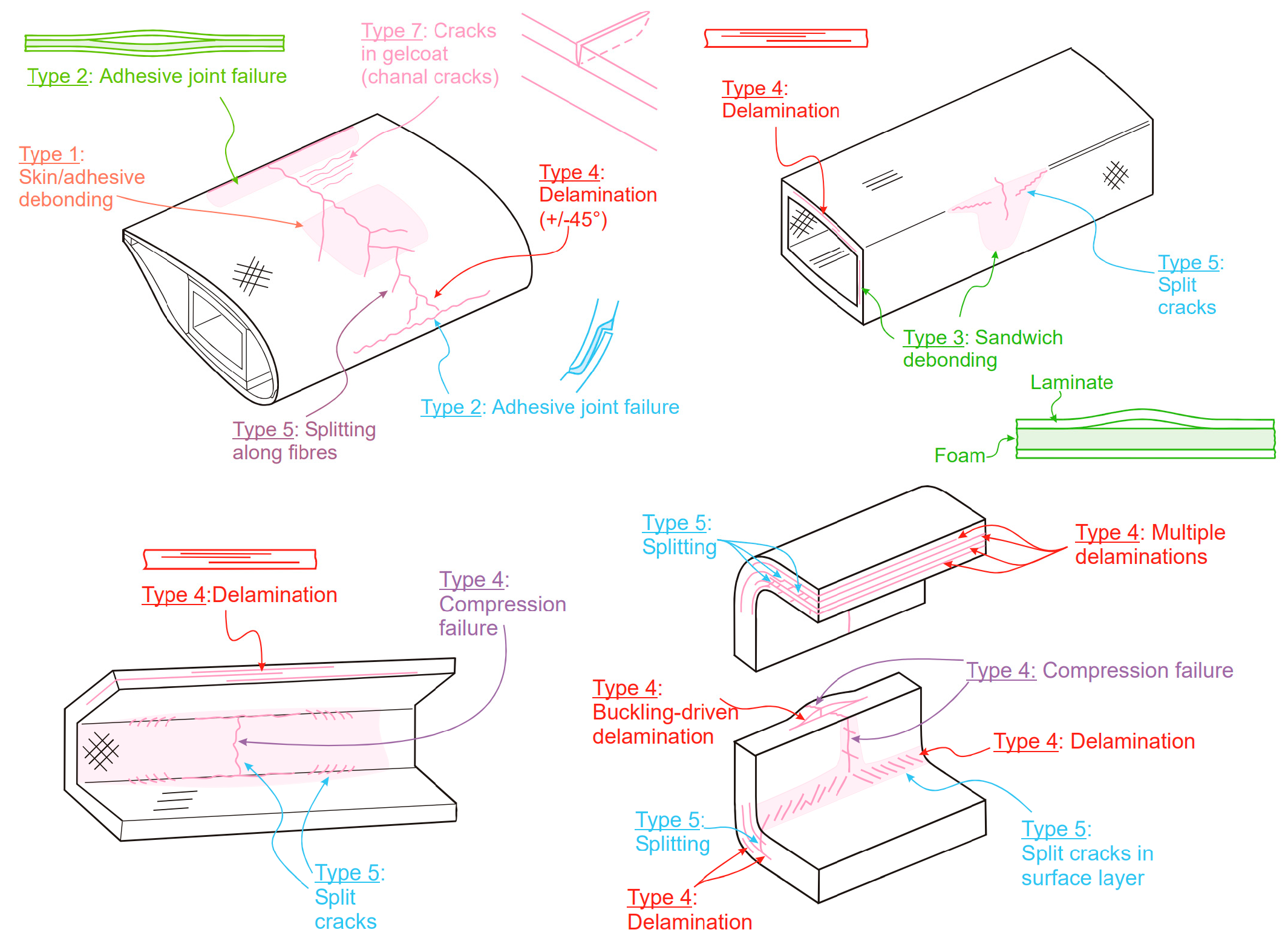

5. Failure Modes of Wind Turbine

5.1. Extension of Wind Turbine Blades

Pitch Control System

5.2. Gear Box Failures

5.3. Generator

5.4. Power Electronics and Electric Controls

5.5. Towers and Foundation

5.6. Summary of Wind Turbine Blade Failure Modes

- Buckling, massive deflection, crushing and folding are all caused by geometrical influences.

- Plasticity, ductile/brittle breakdown, rupture and splitting damage are also material considerations to consider.

- Original fabrication flaws, such as initial distortion, residual stresses or manufacturing flaws.

- Low temperatures are correlated with activity in cold climates, and high temperatures are associated with fire and fires.

- Dynamic factors (strain rate sensitivity, inertia influence, damage) linked to impact pressure caused by explosions, dropped artefacts or related events.

- Fatigue cracking is an example of age-related degradation.

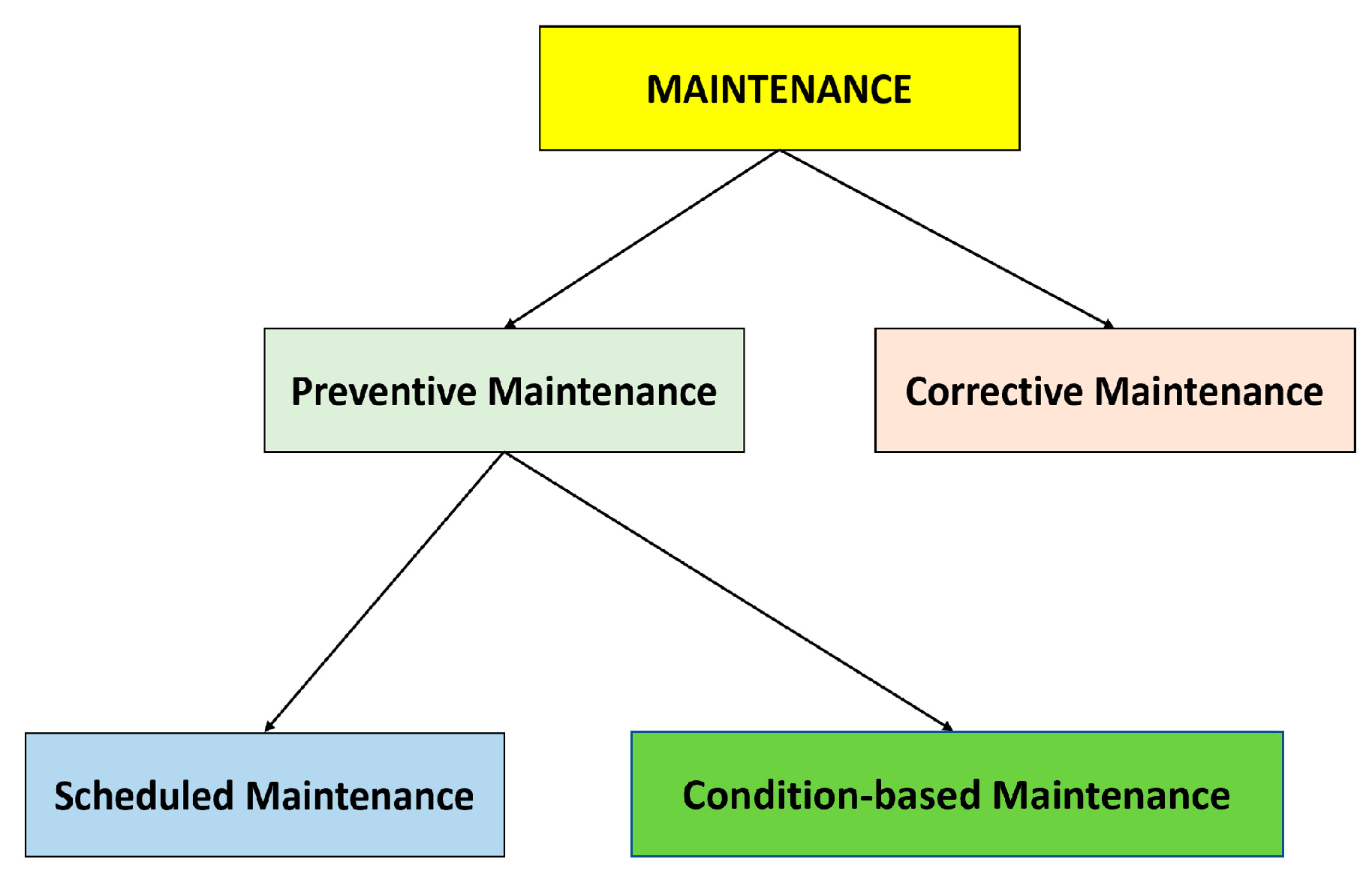

5.7. Maintenance for Wind Turbines

- Oil Analysis (OA) is used to assess the consistency of oil within a wind turbine gearbox and whether debris contaminant is present due to harm to bearings and gearings [167].

- In a wind turbine, electrical results are added to electrical devices such as turbines, pumps and accumulators [167].

- The shock pulse system (SPM) is a technique for detecting bearing harm utilising transducers and signal reading [168].

- The below are the major NDT for wind turbine modules and subsystems:

- Ultrasonic monitoring techniques (UTTs), which are used to assess surface and subsurface structural deterioration on wind turbine towers and rotor blades [168].

- Visual inspection (VI) is an ancient condition monitoring method that is used to detect problems that other condition monitoring techniques fail to detect, such as loose bits, contacts, oil leaks, rust and chattering gears [167].

- Vibration analysis (VA) on WT parts such as shafts, bearings and rotor blades, as well as subsystems such as the gearbox [168]. Vibration sensors are applied to the surface of the inspected object, and data for the frequency of the component’s vibration is investigated.

- Strain measurement (SM), which uses strain gauges to calculate stress levels in situ and predict lifetime in a laboratory [168]. It is primarily used on wind turbine blades.

- To locate defects in gearboxes, bearings, shafts and blades, acoustic emission uses transducers and optic fiber displacement sensors [167].

- Infrared cameras are used to identify hot spots in electrical and mechanical devices, as well as rotor blades, in thermography [168].

- Using data such as strength, wind direction, rotor blade angle and rotor speed, performance analysis may be used as a wind turbine condition monitoring technique [168].

- X-ray imaging is used to expose close delaminations or cracks in a wind turbine part during radiographic inspection [168].

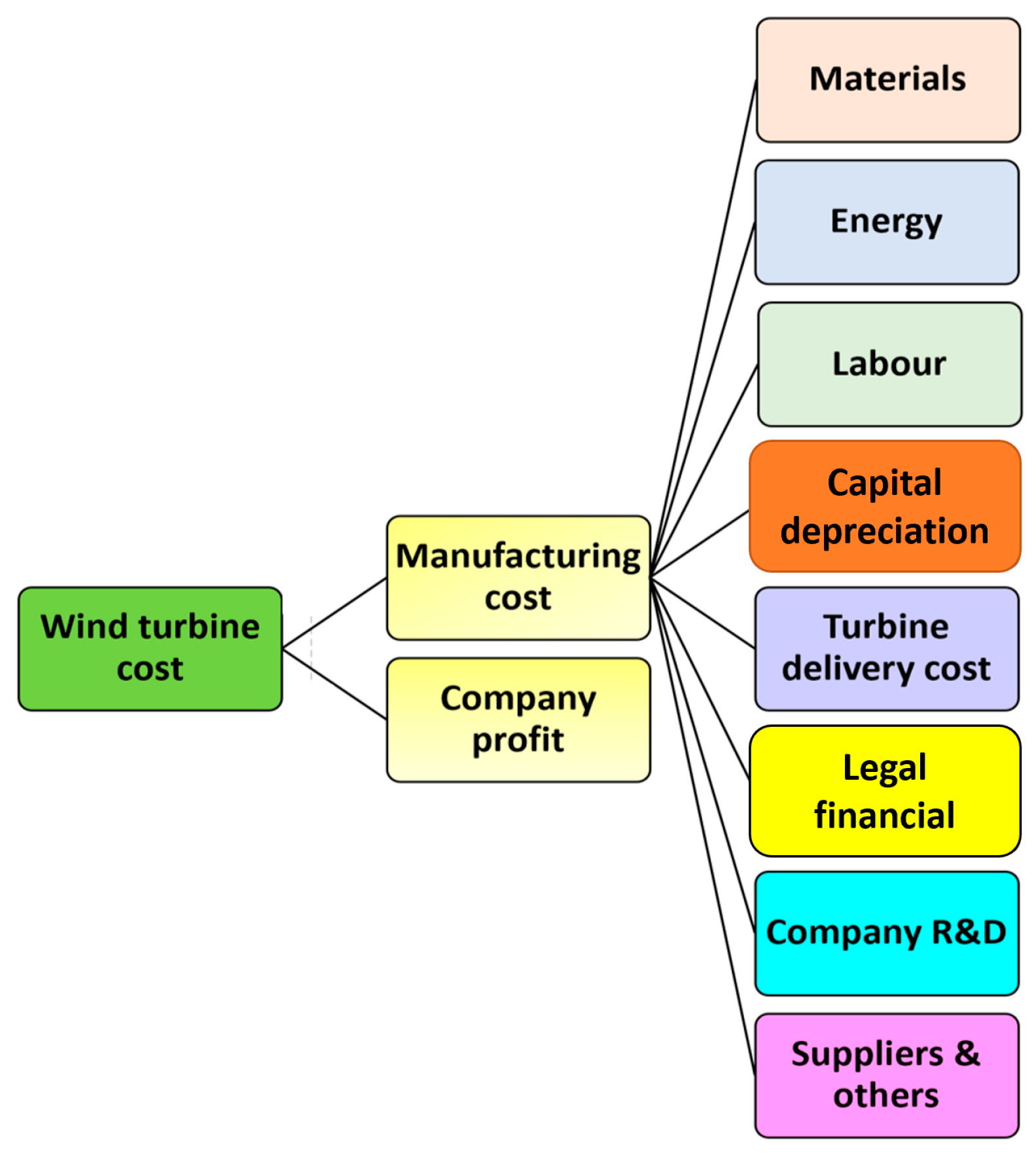

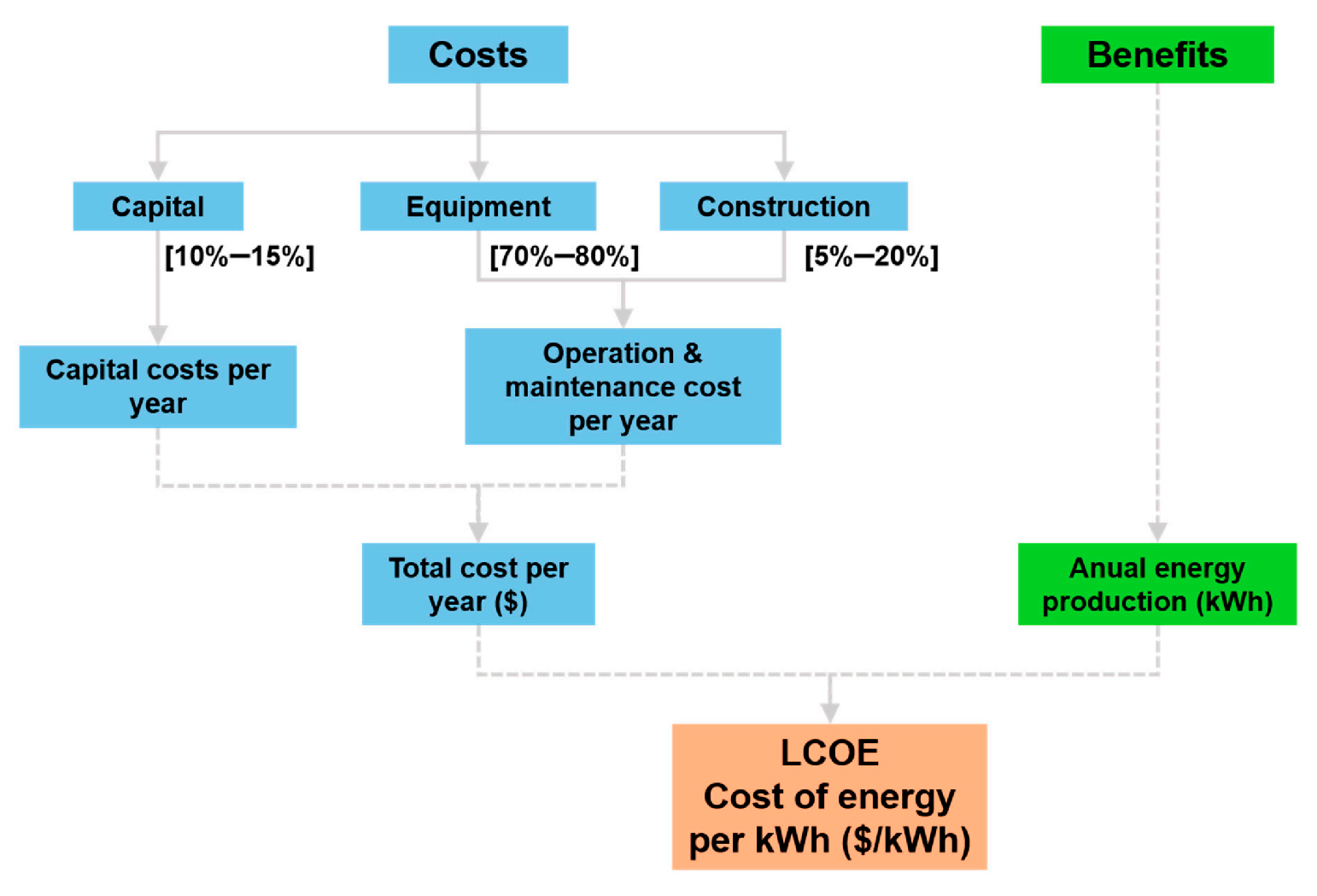

6. Overview on Cost of Wind Turbine

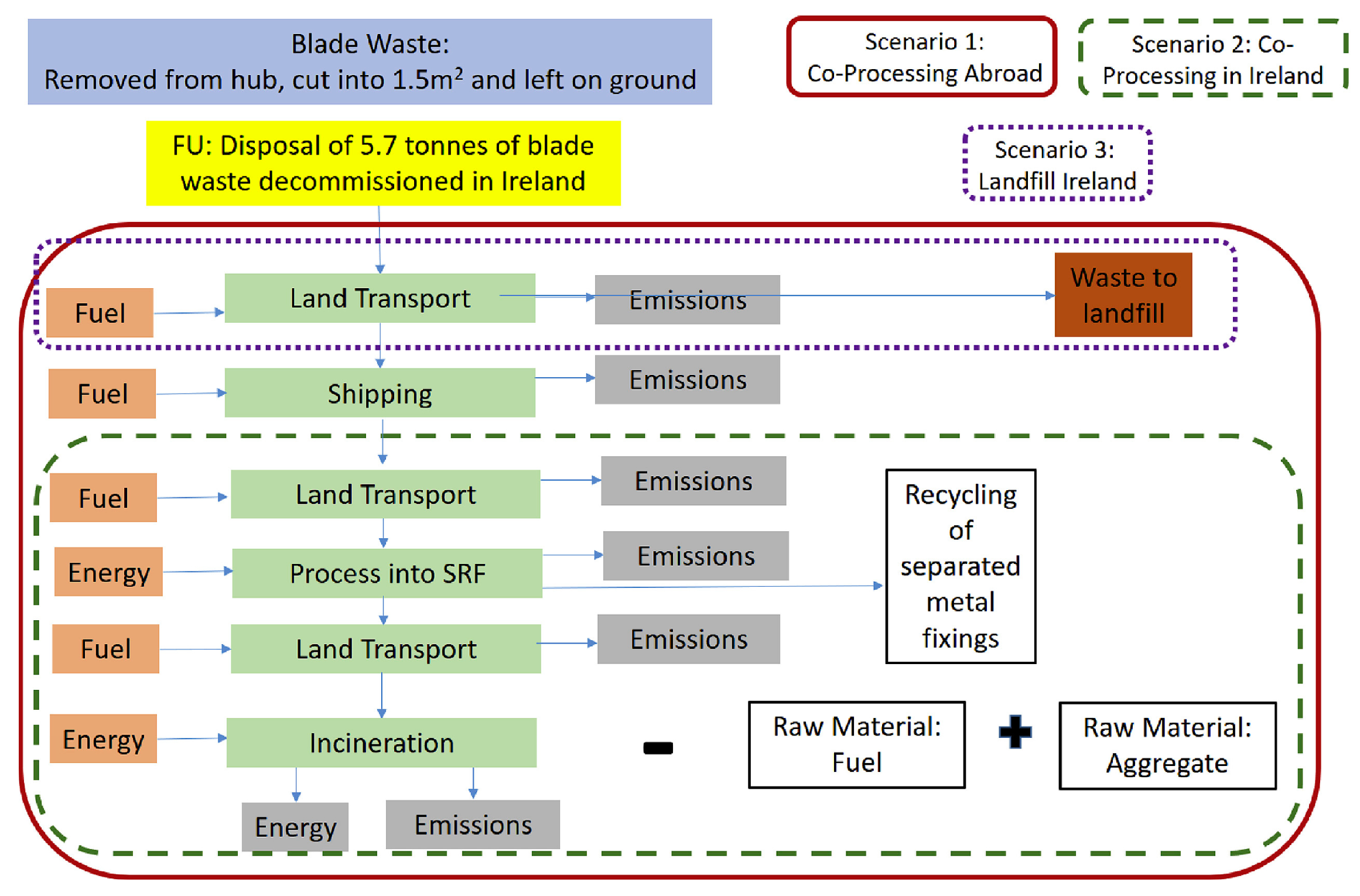

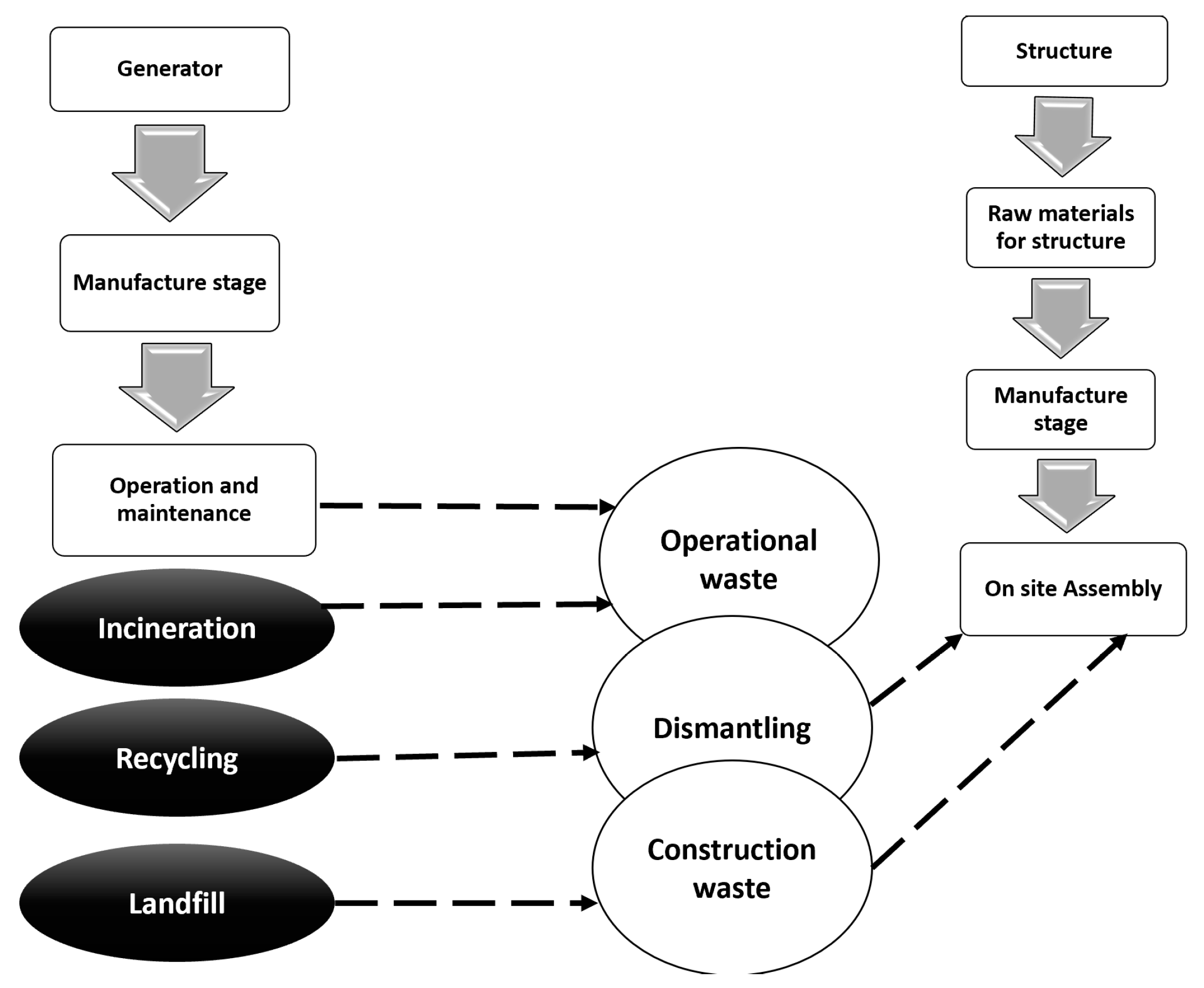

7. End of Life

7.1. Waste Management in a Composite Form

7.2. Composite Materials Recycling Approach

7.3. Mechanical Recycling

7.4. Thermal Recycling

7.4.1. Pyrolysis Recycling Technique

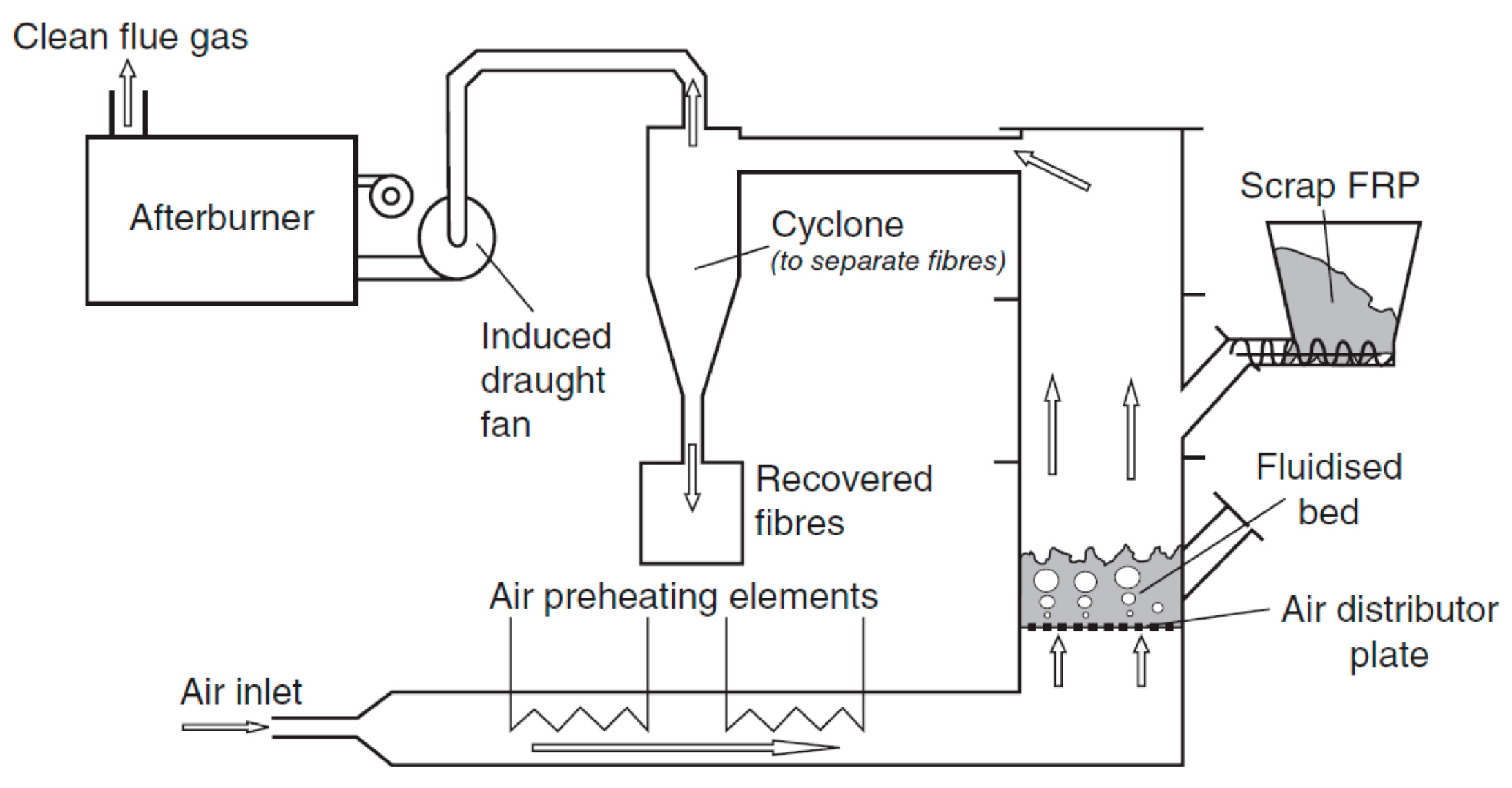

7.4.2. Fluidized Bed Combustion Recycling Process

7.4.3. Chemical Recycling Process

7.5. The Specific Sector

7.5.1. The Life Cycle Method

7.5.2. Materials

7.6. Extension of Life of Turbine Blades

7.7. Repowering

- The WF’s profitability is decreasing with time, as both performance and dependability deteriorate.

- Profit expectations for both life extension and the various repowering alternatives are discussed in detail.

- The cost–benefit ratio that repowering will provide as compared to the complete decommissioning of the wind farm and the recycling of the project’s components.

- The very same tower with a new, lower-capacity turbine: This option combines a smaller WT that may even generate lower electricity, requires less maintenance (resulting in higher availability) and has a nominal service life of an additional 25 years with the same tower that, because the turbine’s power has been reduced, will have fewer applied loads, hence a longer fatigue life.

- Same tower having higher-capacity turbine that will generate more energy and survive an additional 25 years is combined with the same tower, which will be subjected to larger loads as a result of the increased power of the turbine, and its structural integrity should be carefully evaluated. Consequently, unless the structural integrity of the tower will be adequate to meet the new standards, this choice will often be unfavourable in the majority of instances.

- Modern tower with a new, greater-capacity turbine: This option involves the decommissioning of the tower and nacelle in preparation for the commissioning of a new WT later on.

7.8. Decommissioning

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wilberforce, T.; Olabi, A.; Sayed, E.T.; Elsaid, K.; Abdelkareem, M.A. Progress in carbon capture technologies. Sci. Total Environ. 2021, 761, 143203. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Lootah, M.A.; Sayed, E.T.; Wilberforce, T.; Alawadhi, H.; Yousef, B.A.; Olabi, A. Fuel cells for carbon capture applications. Sci. Total Environ. 2021, 769, 144243. [Google Scholar] [CrossRef]

- Elsaid, K.; Kamil, M.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A. Environmental impact of desalination technologies: A review. Sci. Total Environ. 2020, 748, 141528. [Google Scholar] [CrossRef] [PubMed]

- Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Baroutaji, A.; Olabi, A. Environmental impact of desalination processes: Mitigation and control strategies. Sci. Total Environ. 2020, 740, 140125. [Google Scholar] [CrossRef]

- Olabi, A.; Abdelkareem, M.A.; Wilberforce, T.; Sayed, E.T. Application of graphene in energy storage device—A review. Renew. Sustain. Energy Rev. 2021, 135, 110026. [Google Scholar] [CrossRef]

- Tanveer, W.H.; Abdelkareem, M.A.; Kolosz, B.W.; Rezk, H.; Andresen, J.; Cha, S.W.; Sayed, E.T. The role of vacuum based technologies in solid oxide fuel cell development to utilize industrial waste carbon for power production. Renew. Sustain. Energy Rev. 2021, 142, 110803. [Google Scholar] [CrossRef]

- Rabaia, M.K.H.; Abdelkareem, M.A.; Sayed, E.T.; Elsaid, K.; Chae, K.-J.; Wilberforce, T.; Olabi, A. Environmental impacts of solar energy systems: A review. Sci. Total Environ. 2021, 754, 141989. [Google Scholar] [CrossRef] [PubMed]

- Sayed, E.T.; Wilberforce, T.; Elsaid, K.; Rabaia, M.K.H.; Abdelkareem, M.A.; Chae, K.-J.; Olabi, A. A critical review on environmental impacts of renewable energy systems and mitigation strategies: Wind, hydro, biomass and geothermal. Sci. Total Environ. 2021, 766, 144505. [Google Scholar] [CrossRef]

- Bauer, A.; Menrad, K. Standing up for the Paris Agreement: Do global climate targets influence individuals’ greenhouse gas emissions? Environ. Sci. Policy 2019, 99, 72–79. [Google Scholar]

- Abdelkareem, M.A.; Assad, M.E.H.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- History of Wind Turbines. Available online: http://xn--drmstrre-64ad.dk/wp-content/wind/miller/ (accessed on 5 October 2018).

- Webpage of Poul La Cour Museum. Available online: http://www.poullacour.dk (accessed on 5 October 2018).

- Ostachowicz, W.; McGugan, M.; Schröder-Hinrichs, J.U.; Luczak, M. MARE-MINT: New Materials and Reliability in Offshore Wind Turbine Technology; Springer Nature: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Mishnaevsky, L., Jr.; Brøndsted, P.; Nijssen, R.; Lekou, D.J.; Philippidis, T.P. Materials of large wind turbine blades: Recent results in testing and modeling. Wind Energy 2012, 15, 83–97. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for wind turbine blades: An. overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Novais, R.M.; Carvalheiras, J.; Capela, M.; Seabra, M.; Pullar, R.; Labrincha, J. Incorporation of glass fiber fabrics waste into geopolymer matrices: An eco-friendly solution for off-cuts coming from wind turbine blade production. Constr. Build. Mater. 2018, 187, 876–883. [Google Scholar] [CrossRef]

- Brøndsted, P.; Nijssen, R.P.L. Advances in Wind Turbine Blade Design and Materials; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Walker, K. Renewable Energy Embraces Graphene: Improved Wind Turbine Technology. Available online: http://www.azocleantech.com/article.aspx?ArticleID=455 (accessed on 8 October 2018).

- Watson, J.C.; Serrano, J.C. Composite materials for wind blades. Wind Syst. Mag. 2010, 46, 46–51. [Google Scholar]

- Mohamed, M.H.; Wetzel, K.K. 3D woven carbon/glass hybrid spar cap for wind turbine rotor blade. J. Sol. Energy Eng. 2006, 128, 562–573. [Google Scholar] [CrossRef]

- Debel, C. Identification of damage types in wind turbine blades tested to failure. In Proceedings of the Dansk Metallurgisk Selskabs Vintermøde, Kolding, Denmark, 7–9 January 2004. [Google Scholar]

- Dorigato, A. Recycling of thermosetting composites for wind blade application. Adv. Ind. Eng. Polym. Res. 2021, 4, 116–132. [Google Scholar] [CrossRef]

- Garolera, A.C.; Madsen, S.F.; Nissim, M.; Myers, J.D.; Holboell, J. Lightning damage to wind turbine—Newline blades from wind farms in the U.S. IEEE Trans. Power Deliv. 2014, 31, 1043–1049. [Google Scholar] [CrossRef]

- Yasuda, Y.; Yokoyama, S.; Minowa, M.; Satoh, T. Classification of lightning damage to wind turbine blades. IEEJ Trans. Electr. Electron. Eng. 2012, 7, 559–566. [Google Scholar] [CrossRef]

- Sareen, A.; Sapre, C.A.; Selig, M.S. Effects of leading edge erosion on wind turbine blade performance. Wind Energy 2013, 17, 1531–1542. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.H.; Stack, M.M. On erosion issues associated with the leading edge of wind turbine blades. J. Phys. D Appl. Phys. 2013, 46, 383001. [Google Scholar] [CrossRef]

- Cattin, R. Icing of wind turbines. Vindforsk projects, a survey of the development and research needs. Elforsk Rep. 2012, 12, 13. [Google Scholar]

- Zhu, S. An Automated Method for the Layup of Fiberglass Fabric. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2015. [Google Scholar] [CrossRef]

- Teuwen, J.K.R.; Joncas, S.; Bersee, H.E.N. Vacuum Infused Thermoplastic Composites for Wind Turbine Blades. 2008. Available online: https://windpower.sandia.gov/2008BladeWorkshop/PDFs/Tues-14-Teuwen.pdf (accessed on 5 April 2021).

- Vacuum Assisted Resin. Transfer Molding. Available online: https://usa.exportersindia.com/rhino-linings-industrial-company5141729/vacuum-assisted-resin-transfer-molding-3202656.htm (accessed on 23 May 2021).

- Liu, H.-C.; Liu, L.; Liu, N. Risk evaluation approaches in failure mode and effects analysis: A literature review. Expert Syst. Appl. 2013, 40, 828–838. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Brøndsted, P. Statistical modelling of compression and fatigue damage of unidirectional fiber rein-forced composites. Compos. Sci. Technol. 2009, 69, 477–484. [Google Scholar] [CrossRef]

- Ashby, M. Material Process and Selection Charts, 2nd ed.; Reed Educational and Professional Publishing Ltd.: London, UK, 2009. [Google Scholar]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Holmes, J.W.; Sørensen, B.F.; Brøndsted, P. Reliability of wind turbine blades: An overview of materials testing. In Proceedings of the Wind Power Shanghai, Shanghai, China, 1–3 November 2007; pp. 310–315. [Google Scholar]

- Holmes, J.W.; Brøndsted, P.; Sørensen, B.F.; Jiang, Z.; Sun, Z.; Chen, X. Development of a bamboo-based composite as a sustainable green material for wind turbine blades. Wind. Eng. 2009, 33, 197–210. [Google Scholar] [CrossRef]

- Bakri, B.; Chandrabakty, S.; Alfriansyah, R.; Dahyar, A. Potential coir fiber composite for small wind turbine blade application. Int. J. Smart Mater. Mechatron. 2016, 2, 42–44. [Google Scholar] [CrossRef]

- Sparnins, E. Mechanical Properties of Flax Fibers and Their Composites. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2009. [Google Scholar]

- Nasir, A.A.; Azmi, A.; Khalil, A.N.M. Measurement and optimisation of residual tensile strength and delamination damage of drilled flax fiber reinforced composites. Measurements 2015, 75, 298–307. [Google Scholar] [CrossRef]

- Prabhakaran, R.T. Future materials for wind turbine blades-A critical review. In Proceedings of the International Conference on Wind Energy: Materials, Engineering and Policies (WEMEP-2012), Hyderabad, India, 22–23 November 2012. [Google Scholar]

- Fecko, D. High strength glass reinforcements still being discovered. Reinf. Plast. 2006, 50, 40–44. [Google Scholar] [CrossRef]

- Grand, J.A. Wind power blades energize composites manufacturing. Plast. Technol. 2008, 54, 68–75. [Google Scholar]

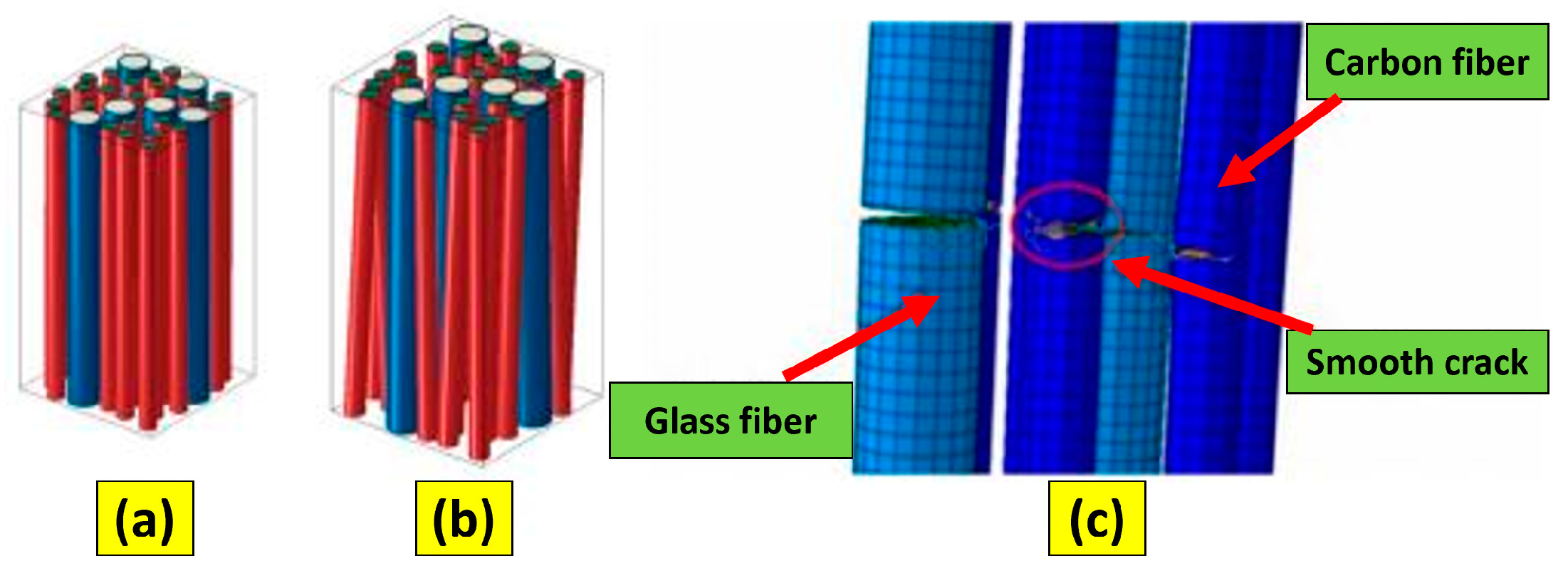

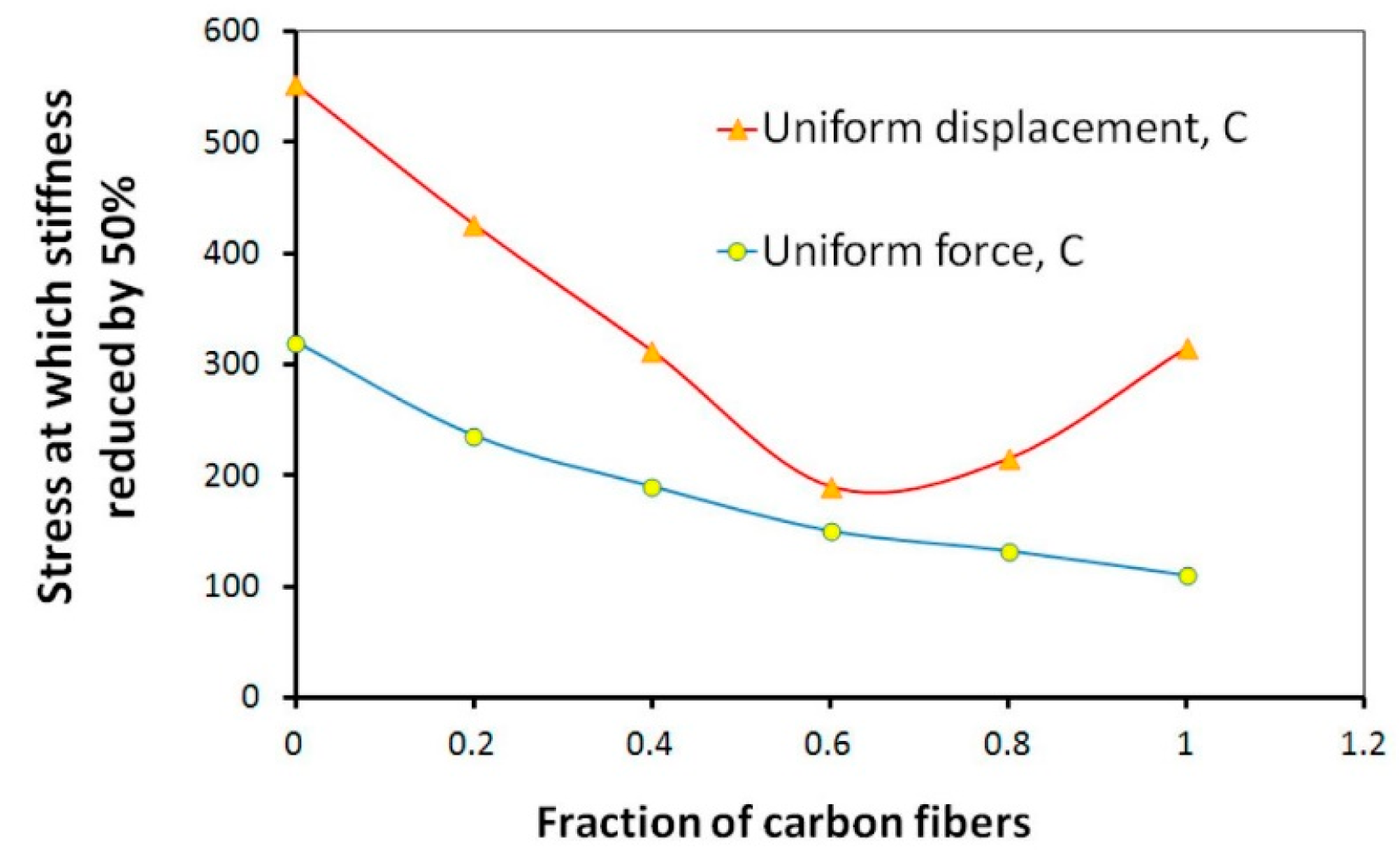

- Mishnaevsky, L., Jr.; Dai, G. Hybrid carbon/glass fiber composites: Micromechanical analysis of structure–damage re-sistance relationships. Comput. Mater. Sci. 2014, 81, 630–640. [Google Scholar] [CrossRef]

- Dai, G.; Mishnaevsky, L., Jr. Fatigue of hybrid carbon/glass composites: 3D Computational modelling. Compos. Sci. Technol. 2014, 94, 71–79. [Google Scholar] [CrossRef]

- Prabhakaran, D.; Andersen, T.L.; Markussen, C.M.; Madsen, B.; Lilholt, H. Tensile and compression properties of hybrid composites—A comparative study. In Proceedings of the 19th International Conference on Composite Materials (ICCM19), Montréal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Chiang, M.Y.; Wang, X.; Schultheisz, C.R.; He, J. Prediction and three-dimensional Monte-Carlo simulation for tensile properties of unidirectional hybrid composites. Compos. Sci. Technol. 2005, 65, 1719–1727. [Google Scholar] [CrossRef]

- Gutans, J.; Tamuzs, V. Strength probability of unidirectional hybrid composites. Theor. Appl. Fract. Mech. 1987, 7, 193–200. [Google Scholar] [CrossRef]

- Mikkelsen, L.P.; Mishnaevsky, L., Jr. Computational modelling of materials for wind turbine blades: Selected DTU wind energy activities. Materials 2017, 10, 1278. [Google Scholar] [CrossRef]

- Summerscales, J.; Short, D. Carbon fiber and glass fiber hybrid reinforced plastics. Composites 1978, 9, 157–166. [Google Scholar] [CrossRef]

- Sinha, R.; Acharya, P.; Freere, P.; Sharma, R.; Ghimire, P.; Mishnaevsky, L. Selection of nepalese timber for small wind turbine blade construction. Wind. Eng. 2010, 34, 263–276. [Google Scholar] [CrossRef]

- Nijssen, R.P.L. Fatigue Life Prediction and Strength Degradation of Wind Turbine Rotor Blade Composites; Contractor Report SAND2006-7810P; Sandia National Laboratorie: Albuquerque, NM, USA, 2006. [Google Scholar]

- Joncas, S. Thermoplastic Composite Wind Turbine Blades: An Integrated Design Approach. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010. [Google Scholar]

- Lystrup, A. Hybrid Yarn for Thermoplastic Fiber Composites. Summary of Technical Results; Risoe National Lab.: Roskilde, Denmark, 1998. [Google Scholar]

- Dai, G.; Mishnaevsky, L. Damage evolution in nanoclay-reinforced polymers: A three-dimensional computational study. Compos. Sci. Technol. 2013, 74, 67–77. [Google Scholar] [CrossRef]

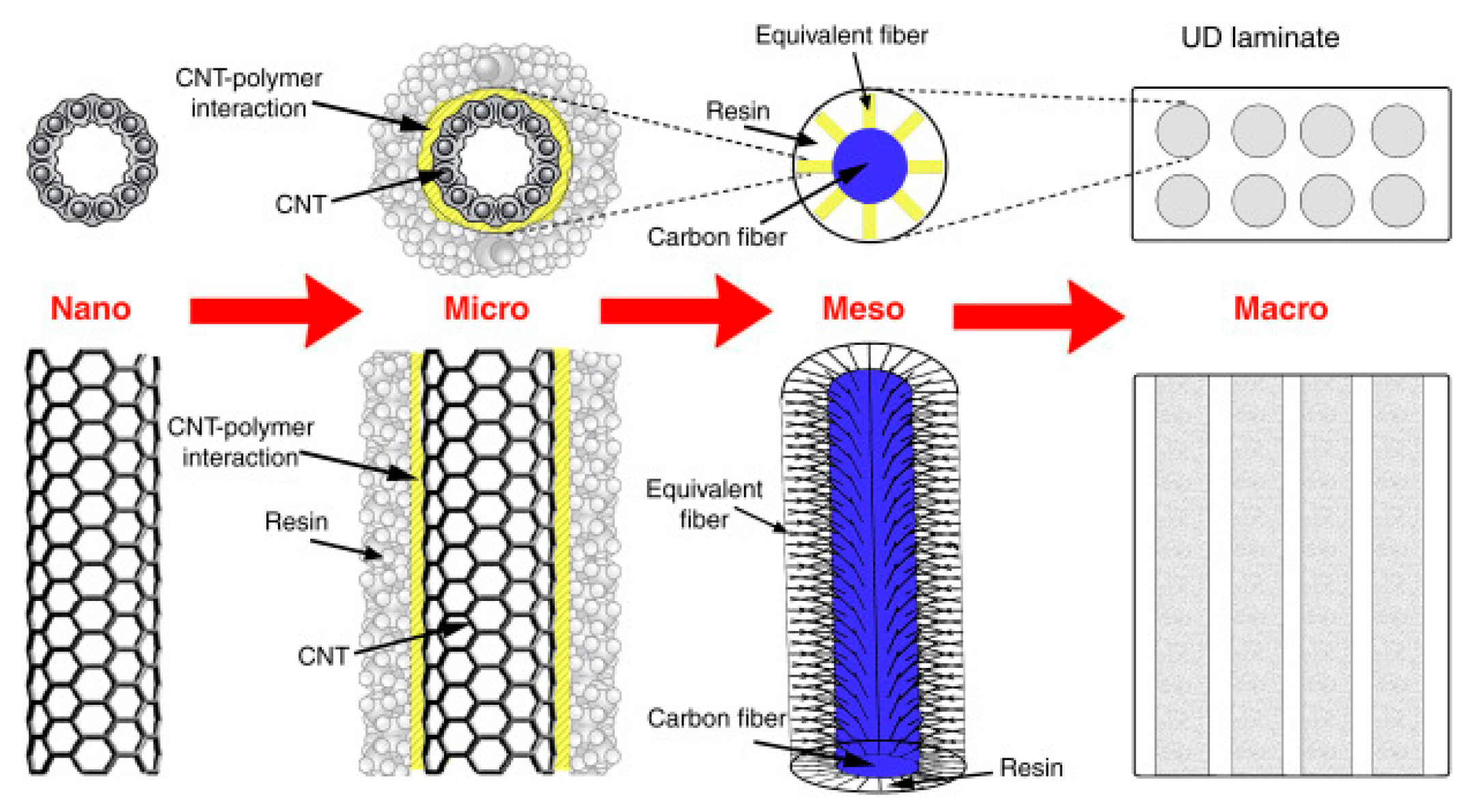

- Zhou, H.; Mishnaevsky, L.; Yi, H.; Liu, Y.; Hu, X.; Warrier, A.; Dai, G. Carbon fiber/carbon nanotube reinforced hierarchical composites: Effect of CNT distribution on shearing strength. Compos. Part B Eng. 2016, 88, 201–211. [Google Scholar] [CrossRef]

- Ma, P.-C.; Zhang, Y. Perspectives of carbon nanotubes/polymer nanocomposites for wind blade materials. Renew. Sustain. Energy Rev. 2014, 30, 651–660. [Google Scholar] [CrossRef]

- Loos, M.; Yang, J. Carbon Nanotube-Reinforced Epoxy Composites for Wind Turbine Blades. ANTEC 2011 PENG-11-2010-0518. (PDF) Epoxy/Carbon Nanotube Composites for Wind Turbine Blades. Available online: Researchgate.net (accessed on 16 June 2021).

- Yavari, F.; Rafiee, M.; Rafiee, J.; Yu, Z.-Z.; Koratkar, N. Dramatic increase in fatigue life in hierarchical graphene composites. ACS Appl. Mater. Interfaces 2010, 2, 2738–2743. [Google Scholar] [CrossRef] [PubMed]

- Merugula, L.; Khanna, V.; Bakshi, B.R. Reinforced wind turbine blades—An environmental life cycle evaluation. Environ. Sci. Technol. 2012, 46, 9785–9792. [Google Scholar] [CrossRef]

- Merugula, L.A.; Khanna, V.; Bakshi, B.R. Comparative life cycle assessment: Reinforcing wind turbine blades with carbon nanofibers. In Proceedings of the 2010 IEEE International Symposium on Sustainable Systems and Technology, Arlington, VA, USA, 17–19 May 2010. [Google Scholar]

- Kinloch, A.J.; Taylor, A.; Techapaitoon, M.; Teo, W.S.; Sprenger, S. From matrix nano- and micro-phase tougheners to composite macro-properties. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150275. [Google Scholar] [CrossRef]

- Pontefisso, A.; Mishnaevsky, L. Nanomorphology of graphene and CNT reinforced polymer and its effect on damage: Micromechanical numerical study. Compos. Part B Eng. 2016, 96, 338–349. [Google Scholar] [CrossRef]

- Rafiee, R.; Ghorbanhosseini, A. Stochastic Modeling of CNT-Grown Fibers. In Micro and Nano Technologies, Carbon Nanotube-Reinforced Polymers; Rafiee, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 521–540. ISBN 9780323482219. [Google Scholar] [CrossRef]

- Ye, J.; Chu, C.; Cai, H.; Hou, X.; Shi, B.; Tian, S.; Chen, X.; Ye, J. A multi-scale model for studying failure mechanisms of composite wind turbine blades. Compos. Struct. 2019, 212, 220–229. [Google Scholar] [CrossRef]

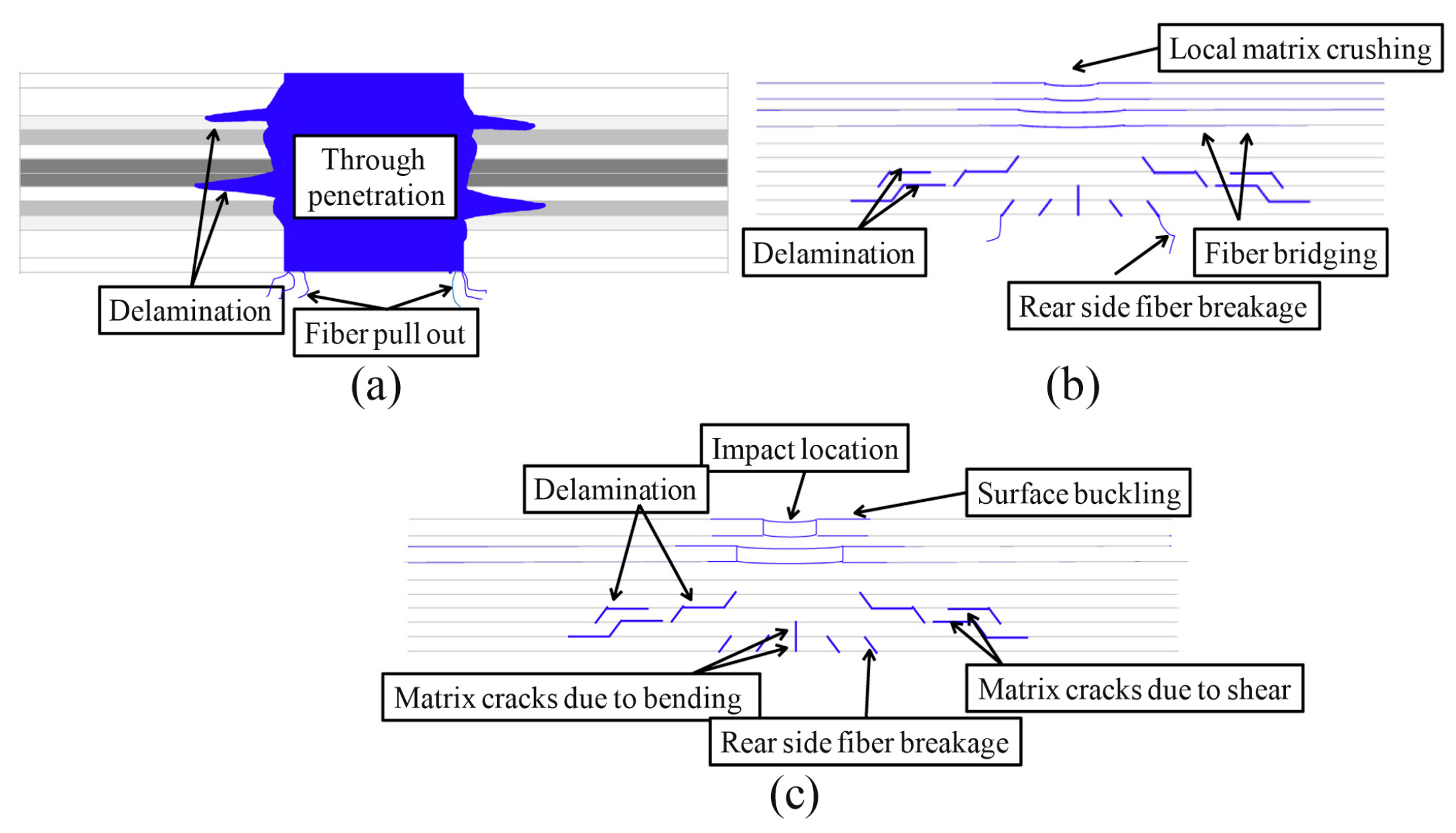

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224, 111007. [Google Scholar] [CrossRef]

- Jefferson, A.J.; Arumugam, V.; Dhakal, H.N. Repair of Polymer Composites: Methodology, Techniques, and Challenges; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Jefferson, A.J.; Arumugam, V.; Santulli, C.; Jennifers, A.; Poorani, M. Failure modes of GFRP after multiple impacts determined by acoustic emission and digital image correlation. J. Eng. Technol. 2015, 6, 29–51. [Google Scholar]

- Tiberkak, R.; Bachene, M.; Rechak, S.; Necib, B. Damage prediction in composite plates subjected to low velocity impact. Compos. Struct. 2008, 83, 73–82. [Google Scholar] [CrossRef]

- Bull, D.; Scott, A.; Spearing, S.; Sinclair, I. The influence of toughening-particles in CFRPs on low velocity impact damage resistance performance. Compos. Part A Appl. Sci. Manuf. 2014, 58, 47–55. [Google Scholar] [CrossRef]

- Hongkarnjanakul, N.; Rivallant, S.; Bouvet, C.; Miranda, A. Permanent indentation characterization for low-velocity impact modelling using three-point bending test. J. Compos. Mater. 2013, 48, 2441–2454. [Google Scholar] [CrossRef]

- Tita, V.; De Carvalho, J.; Vandepitte, D. Failure analysis of low velocity impact on thin composite laminates: Experimental and numerical approaches. Compos. Struct. 2008, 83, 413–428. [Google Scholar] [CrossRef]

- Vieille, B.; Casado, V.M.; Bouvet, C. Influence of matrix toughness and ductility on the compression-after-impact behavior of woven-ply thermoplastic-and thermosetting-composites: A comparative study. Compos. Struct. 2014, 110, 207–218. [Google Scholar] [CrossRef]

- Davies, G.; Zhang, X. Impact damage prediction in carbon composite structures. Int. J. Impact Eng. 1995, 16, 149–170. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Wang, Z.; Peijs, T. The effect of temperature and strain rate on the impact performance of recyclable all-polypropylene compo-sites. Compos. Part B Eng. 2008, 39, 537–547. [Google Scholar] [CrossRef]

- Naik, N.; Shrirao, P.; Reddy, B. Ballistic impact behaviour of woven fabric composites: Formulation. Int. J. Impact Eng. 2006, 32, 1521–1552. [Google Scholar] [CrossRef]

- Andrew, J.J.; Arumugam, V.; Santulli, C. Effect of post-cure temperature and different reinforcements in adhesive bonded repair for damaged glass/epoxy composites under multiple quasi-static indentation loading. Compos. Struct. 2016, 143, 63–74. [Google Scholar] [CrossRef]

- Børvik, T. An Introduction to Impact and Penetration Dynamics; Department of Structural Engineering, Norwegian University of Science and Technology: Trondheim, Norway, 2003. [Google Scholar]

- Olsson, R. Mass criterion for wave controlled impact response of composite plates. Compos. Part A Appl. Sci. Manuf. 2000, 31, 879–887. [Google Scholar] [CrossRef]

- Olsson, R. Closed form prediction of peak load and delamination onset under small mass impact. Compos. Struct. 2003, 59, 341–349. [Google Scholar] [CrossRef]

- Rehman, S.; Alam, M.; Alhems, M.L. A review of wind-turbine structural stability, failure and alleviation. In Proceedings of the Advances in Civil, Environmental, & Materials Research (ACEM18) Songdo Convensia, Incheon, Korea, 27–31 August 2018. [Google Scholar]

- Mothers against Wind Turbine Inc. 2016 Wind Turbine Accident Report. Available online: https://mothersagainstturbines.com/2016/04/07/2016-wind-turbine-accident-report/comment-page-1/ (accessed on 3 May 2021).

- Alam, M.; Zhou, Y.; Yang, H.X.; Guo, H.; Mi, J. The ultra-low Reynolds number airfoil wake. Exp. Fluids 2009, 48, 81–103. [Google Scholar] [CrossRef]

- Qin, B.; Alam, M.; Zhou, Y. Two tandem cylinders of different diameters in cross-flow: Flow-induced vibration. J. Fluid Mech. 2017, 829, 621–658. [Google Scholar] [CrossRef]

- Kim, S.; Alam, M.; Maiti, D.K. Wake and suppression of flow-induced vibration of a circular cylinder. Ocean. Eng. 2018, 151, 298–307. [Google Scholar] [CrossRef]

- Caithness Wind Farm Information Forum. Summary of Wind Turbine Accident Data to 31 March 2021. Available online: http://www.caithnesswindfarms.co.uk/AccidentStatistics.htm (accessed on 2 May 2021).

- Kress, C.; Chokani, N.; Abhari, R. Downwind wind turbine yaw stability and performance. Renew. Energy 2015, 83, 1157–1165. [Google Scholar] [CrossRef]

- Abdallah, I.; Natarajan, A.; Sørensen, J. Impact of uncertainty in airfoil characteristics on wind turbine extreme loads. Renew. Energy 2015, 75, 283–300. [Google Scholar] [CrossRef]

- Lin, Y.; Tu, L.; Liu, H.; Li, W. Fault analysis of wind turbines in China. Renew. Sustain. Energy Rev. 2016, 55, 482–490. [Google Scholar] [CrossRef]

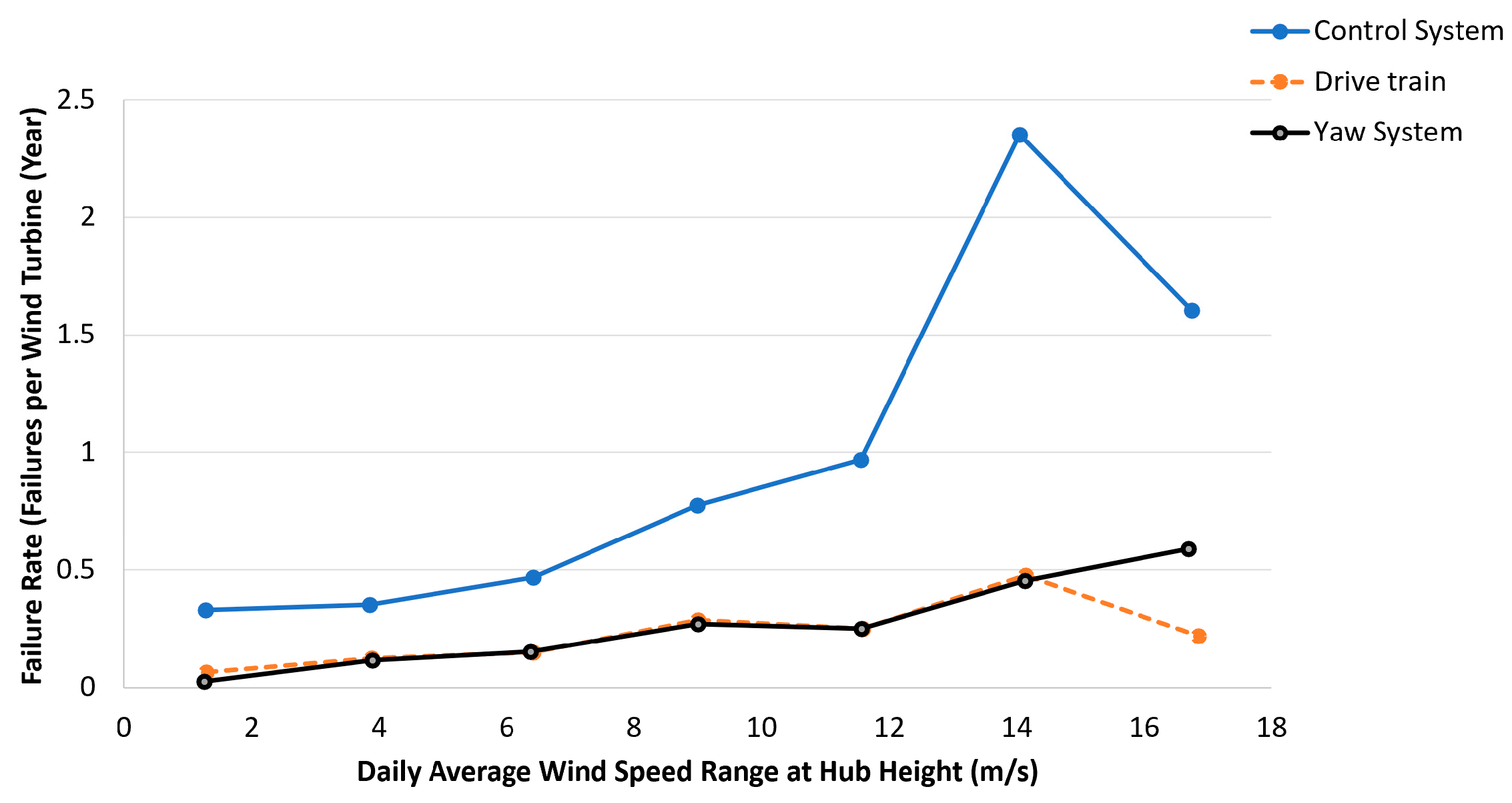

- Tavner, P.; Greenwood, D.M.; Whittle, M.W.G.; Gindele, R.; Faulstich, S.; Hahn, B. Study of weather and location effects on wind turbine failure rates. Wind Energy 2012, 16, 175–187. [Google Scholar] [CrossRef]

- Wilson, G.; McMillan, D. Assessing wind farm reliability using weather dependent failure rates. J. Phys. Conf. Ser. 2014, 524. [Google Scholar] [CrossRef]

- Sathe, A.; Mann, J.; Barlas, A.; Bierbooms, W.; Van Bussel, G. Influence of atmospheric stability on wind turbine loads. Wind Energy 2012, 16, 1013–1032. [Google Scholar] [CrossRef]

- Nuta, E.; Christopoulos, C.; Packer, J.A. Methodology for seismic risk assessment for tubular steel wind turbine towers: Application to Canadian seismic environment. Can. J. Civ. Eng. 2011, 38, 293–304. [Google Scholar] [CrossRef]

- Myers, A.T.; Gupta, A.; Ramirez, C.M.; Chioccarelli, E. Evaluation of the seismic vulnerability of tubular wind tur-bine towers. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Witcher, D. Seismic analysis of wind turbines in the time domain. Wind. Energy 2004, 8, 81–91. [Google Scholar] [CrossRef]

- Stamatopoulos, G.N. Response of a wind turbine subjected to near-fault excitation and comparison with the Greek Aseismic Code provisions. Soil Dyn. Earthq. Eng. 2013, 46, 77–84. [Google Scholar] [CrossRef]

- Nebenführ, B.; Davidson, L. Prediction of wind-turbine fatigue loads in forest regions based on turbulent LES inflow fields. Wind Energy 2016, 20, 1003–1015. [Google Scholar] [CrossRef]

- Sadowski, A.J.; Camara, A.; Málaga-Chuquitaype, C.; Dai, K. Seismic analysis of a tall metal wind turbine support tower with realistic geometric imperfections. Earthq. Eng. Struct. Dyn. 2017, 46, 201–219. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Huang, I.-K.; Chi, K.-N. Failure analysis of wind turbine blade under critical wind loads. Eng. Fail. Anal. 2013, 27, 99–118. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.Z. Structural failure analysis of wind turbines impacted by super typhoon Usagi. Eng. Fail. Anal. 2016, 60, 391–404. [Google Scholar] [CrossRef]

- Collier, B.; DeMarco, T.; Fearey, P. A defined process for project postmortem review. IEEE Softw. 1996, 13, 65–72. [Google Scholar] [CrossRef]

- Dingsøyr, T. Postmortem reviews: Purpose and approaches in software engineering. Inf. Softw. Technol. 2005, 47, 293–303. [Google Scholar] [CrossRef]

- Bjørnson, F.O.; Wang, A.I.; Arisholm, E. Improving the effectiveness of root cause analysis in post mortem analysis: A controlled experiment. Inf. Softw. Technol. 2009, 51, 150–161. [Google Scholar] [CrossRef]

- Gacougnolle, J.L.; Castagnet, S.; Werth, M. Post-mortem analysis of failure in polyvinylidene fluoride pipes tested under constant pressure in the slow crack growth regime. Eng. Fail. Anal. 2006, 13, 96–109. [Google Scholar] [CrossRef]

- Carcedo, J.; Fernández, A.O.; Ortiz, A.; Carrascal, I.A.; Delgado, F.; Ortiz, F.; Arroyo, A. Post-mortem estimation of temperature distribution on a power transformer: Physicochemical and mechanical approaches. Appl. Therm. Eng. 2014, 70, 935–943. [Google Scholar] [CrossRef][Green Version]

- Queiroga, J.A.; Campos, K.S.; Silva, E.; Souza, D.F.; Nunes, E.H.; Vasconcelos, W. Post mortem study of refractory lining used in FCC units. Eng. Fail. Anal. 2013, 34, 290–299. [Google Scholar] [CrossRef]

- Asghar, Z.; Requena, G. Three dimensional post-mortem study of damage after compression of cast Al-Si Al-Loys. Mater. Sci. Eng. A 2014, 591, 136–143. [Google Scholar] [CrossRef]

- Ishihara, T.; Yamaguchi, A.; Takahara, K.; Mekaru, T.; Matsuura, S. An analysis of damaged wind turbines by typhoon Maemi. In Proceedings of the Sixth Asia Pacific Conference on Wind Engineering (APCWE-VI), Seoul, Korea, 12–14 September 2005. [Google Scholar]

- Chou, J.-S.; Tu, W.-T. Failure analysis and risk management of a collapsed large wind turbine tower. Eng. Fail. Anal. 2011, 18, 295–313. [Google Scholar] [CrossRef]

- Zhang, Z.; Yin, Z.; Han, T.; Tan, A.C. Fracture analysis of wind turbine main shaft. Eng. Fail. Anal. 2013, 34, 129–139. [Google Scholar] [CrossRef]

- Jensen, F.M.; Weaver, P.; Cecchini, L.; Stang, H.; Nielsen, R.F. The Brazier effect in wind turbine blades and its influence on design. Wind Energy 2011, 15, 319–333. [Google Scholar] [CrossRef]

- Overgaard, L.C.T.; Lund, E.; Thomsen, O.T. Structural collapse of a wind turbine blade. Part A: Static test and equivalent single layered models. Compos. Part A Appl. Sci. Manuf. 2010, 41, 257–270. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, W.; Zhao, X.L.; Xu, J.Z. Preliminary failure investigation of a 52.3 m glass/epoxy composite wind turbine blade. Eng. Fail. Anal. 2014, 44, 345–350. [Google Scholar] [CrossRef]

- Marín, J.; Barroso, A.; París, F.; Cañas, J. Study of fatigue damage in wind turbine blades. Eng. Fail. Anal. 2009, 16, 656–668. [Google Scholar] [CrossRef]

- Lacalle, R.; Cicero, S.; Álvarez, J.; Cicero, R.; Madrazo, V. On the analysis of the causes of cracking in a wind tower. Eng. Fail. Anal. 2011, 18, 1698–1710. [Google Scholar] [CrossRef]

- Karthikeyan, N.; Kalidasa, M.K.; Arun, K.S.; Rajakumar, S. Review of aerodynamic developments on small horizontal axis wind turbine blade. Renew. Sustain. Energy Rev. 2015, 42, 801–822. [Google Scholar] [CrossRef]

- Chehouri, A.; Younes, R.; Ilinca, A.; Perron, J. Review of performance optimization techniques applied to wind turbines. Appl. Energy 2015, 142, 361–388. [Google Scholar] [CrossRef]

- Yang, R.; He, Y.; Zhang, H. Progress and trends in nondestructive testing and evaluation for wind turbine composite blade. Renew. Sustain. Energy Rev. 2016, 60, 1225–1250. [Google Scholar] [CrossRef]

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Guo, X.; Guan, Z.-D.; Nie, H.-C.; Tan, R.-M.; Li, Z.-S. Damage tolerance analysis of adhesively bonded composite single lap joints containing a debond Flaw. J. Adhes. 2016, 93, 216–234. [Google Scholar] [CrossRef]

- Song, M.-G.; Kweon, J.-H.; Choi, J.-H.; Byun, J.-H.; Shin, S.-J.; Lee, T.-J. Effect of manufacturing methods on the shear strength of composite single-lap bonded joints. Compos. Struct. 2010, 92, 2194–2202. [Google Scholar] [CrossRef]

- Wu, G.; Qin, Z.; Zhang, L.; Yang, K. Strain response analysis of adhesively bonded extended composite wind turbine blade suffering unsteady aerodynamic loads. Eng. Fail. Anal. 2017, 85, 36–49. [Google Scholar] [CrossRef]

- Caselitz, P.; Giebhardt, J.; Mevenkamp, M. Application of condition monitoring systems in wind energy convertors. In Proceedings of the European Wind Energy Conference (EWEC’97), Dublin, Ireland, 6–9 October 1997; pp. 579–582. [Google Scholar]

- Brusa, E.; Amati, N. Condition monitoring of rotors on active magnetic bearings (AMB) fed by induction motors. In Proceedings of the IEEE/ASME Advanced Engineering Mechatronics, Como, Italy, 8–12 July 2001; pp. 750–756. [Google Scholar]

- Yang, W.; Tavner, P.J.; Wilkinson, M.R. Condition monitoring and fault diagnosis of a wind turbine synchronous generator drive train. IET Renew. Power Gener. 2009, 3, 1–11. [Google Scholar] [CrossRef]

- Andrawus, J.A.; Watson, J.; Kishk, M.; Adam, A. The selection of a suitable maintenance strategy for wind turbines. Wind Eng. 2006, 30, 471–486. [Google Scholar] [CrossRef]

- Kusiak, A.; Zhang, Z.; Verma, A. Prediction, operations, and condition monitoring in wind energy. Energy 2013, 60, 1–12. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the 2009 Power Electronics and Machines in Wind Applications (PEMWA 2009), Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Tsai, C.-S.; Hsieh, C.-T.; Huang, S.-J. Enhancement of damage-detection of wind turbine blades via CWT-Based approaches. IEEE Trans. Energy Convers. 2006, 21, 776–781. [Google Scholar] [CrossRef]

- Kaylani, H.; Alkhalidi, A.; Al-Oran, F.; Alhababsah, Q. Component-level failure analysis using multi-criteria hybrid approach to ensure reliable operation of wind turbines. Wind Eng. 2021. [Google Scholar] [CrossRef]

- Böger, L.; Wichmann, M.H.; Meyer, L.O.; Schulte, K. Load and health monitoring in glass fiber reinforced composites with an electrically conductive nanocomposite epoxy matrix. Compos. Sci. Technol. 2008, 68, 1886–1894. [Google Scholar] [CrossRef]

- Popa, L.M.; Jensen, B.-B.; Ritchie, E.; Boldea, I. Condition monitoring of wind generators. In Proceedings of the 38th IAS Annual Meeting on Industry Applications Conference, Salt Lake City, UT, USA, 12–16 October 2003; pp. 1839–1846. [Google Scholar]

- Rumsey, M.A.; Paquette, J.A. Structural health monitoring of wind turbine blades. Proc. SPIE 2008, 6933, 69330E. [Google Scholar] [CrossRef]

- Arrigan, J.; Pakrashi, V.; Basu, B.; Nagarajaiah, S. Control of flapwise vibrations in wind turbine blades using semi-active tuned mass dampers. Struct. Control. Health Monit. 2010, 18, 840–851. [Google Scholar] [CrossRef]

- Cotton, I.; Jenkins, N.; Pandiaraj, K. Lightning protection for wind turbine blades and bearings. Wind Energy 2001, 4, 23–37. [Google Scholar] [CrossRef]

- Li, H.; Diaz, H.; Soares, C.G. A developed failure mode and effect analysis for floating offshore wind turbine support structures. Renew. Energy 2021, 164, 133–145. [Google Scholar] [CrossRef]

- Shen, X.; Zhu, X.; Du, Z. Wind turbine aerodynamics and loads control in wind shear flow. Energy 2011, 36, 1424–1434. [Google Scholar] [CrossRef]

- Hansen, M.H. How Hard Can It Be to Pitch a Wind Turbine Blade? RISO Lab, Denmark Technical University. Available online: www.risoe.dtu.dk/rispubl/art/2007_321_presentation.pdf (accessed on 12 August 2020).

- Yang, X.; Li, J.; Liu, W.; Guo, P. Petri net model and reliability evaluation for wind turbine hydraulic variable pitch systems. Energies 2011, 4, 978–997. [Google Scholar] [CrossRef]

- Watton, J. Modelling, Monitoring and Diagnostic Techniques for Fluid Power Systems; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Crabtree, C.J.; Feng, Y.; Tavner, P.J. Detecting incipient wind turbine gearbox failure: A signal analysis method for on-line condition monitoring. In Proceedings of the European Wind Energy Conference (EWEC 2010), 19th Pril, Warsaw, Poland, 20–23 April 2010. [Google Scholar]

- Shen, G.; Xiang, D.; Zhu, K.; Jiang, L.; Shen, Y.; Li, Y. Fatigue failure mechanism of planetary gear train for wind turbine gearbox. Eng. Fail. Anal. 2018, 87, 96–110. [Google Scholar] [CrossRef]

- Wilkinson, M.R.; Spinato, F.; Tavner, P.J. Condition monitoring of generators & other subassemblies in wind turbine drive trains. In Proceedings of the 2007 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cracow, Poland, 6–8 September 20007; pp. 388–392. [Google Scholar] [CrossRef]

- McNiff, B. The gearbox reliability. In Proceedings of the 2nd Sandia National Laboratories Wind Turbine Reliability Workshop, Albuquerque, NM, USA, 17–18 September 2007. [Google Scholar]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition moni-toring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Guo, P.; Bai, N. Wind turbine gearbox condition monitoring with AAKR and moving window statistic methods. Energies 2011, 4, 2077–2093. [Google Scholar] [CrossRef]

- Mobley, R.K. An Introduction to Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar] [CrossRef]

- Faiz, J.; Ojaghi, M. Different indexes for eccentricity faults diagnosis in three-phase squirrel-cage induction motors: A review. Mechatronics 2009, 19, 2–13. [Google Scholar] [CrossRef]

- Orsagh, R.F.; Lee, H.; Watson, M.; Byington, C.S.; Powers, J. Advanced Vibration Monitoring for Wind Turbine Health Management. Available online: http://rlwinc.com/Re-sources/TechnicalPublicationPDFs/PowerandIndustrial/Impact_PI_IMSASD-AWEA%20HUMS.pdf (accessed on 15 January 2021).

- Thomson, W.T.; Gilmore, R.J. Motor current signature analysis to detect faults in induction motordrives: Fundamentals, data interpretation and industrial case histories. In Proceedings of the 32nd Turbomachinery Symposium, Houston, TX, USA, 9–11 September 2003; pp. 45–156. [Google Scholar]

- Cameron, J.R.; Thomson, W.T.; Dow, A.B. Vibration and current monitoring for detecting airgap eccentricity in large induction motors. IEEE Proc. B Electr. Power Appl. 1986, 133, 155–163. [Google Scholar] [CrossRef]

- Mehrjou, M.R.; Mariun, N.; Marhaban, M.H.; Misron, N. Rotor fault condition monitoring techniques for squirrel-cage in-duction machine. Mech. Syst. Signal Process 2011, 25, 2827–2848. [Google Scholar] [CrossRef]

- Ilonen, J.; Kamarainen, J.-K.; Lindh, T.; Ahola, J.; Kalviainen, H.; Partanen, J. Diagnosis tool for motor condition monitoring. IEEE Trans. Ind. Appl. 2005, 41, 963–971. [Google Scholar] [CrossRef]

- Lu, B.; Sharma, S.K. A literature review of IGBT fault diagnostic and protection methods for power inverters. IEEE Trans. Ind. Appl. 2009, 45, 1770–1777. [Google Scholar] [CrossRef]

- Màrquez-Dominguez, S.; Sørensen, J.D. Fatigue reliability and calibration of fatigue design factors for offshore wind turbines. Energies 2012, 5, 1816–1834. [Google Scholar] [CrossRef]

- Sørensen, J.D. Reliability assessment of wind turbines. In Proceedings of the European Safety and Reliability Conference (ESREL 2013), Amsterdam, The Netherlands, 29 September–2 October 2013. [Google Scholar]

- Van der Woude, C.; Narasimhan, S. A study on vibration isolation for wind turbine structures. Eng. Struct. 2014, 60, 223–234. [Google Scholar] [CrossRef]

- Fleming, K.; Weltman, A.; Randolph, M.; Elson, K. Piling Engineering; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Andersen, K.H.; Puech, A.A.; Jardine, R.J. Design for cycling loading: Piles and other foundations. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering (ICSMGE), Paris, France, 2–6 September 2013. [Google Scholar]

- Brennan, F.; Kolios, A. Structural integrity considerations for the H2Ocean multi modal wind-wave platform. In Proceedings of the European Wind Energy Association (EWEA) Conference and Exhibition 2014, Barcelona, Spain, 10–13 March 2014. [Google Scholar]

- Sørensen, B.F.; Jørgensen, E.; Debel, C.P.; Jensen, F.M.; Jensen, H.M.; Jacobsen, T.K.; Halling, K. Improved Design of Large Wind Turbine Blade of Fiber Composites Based on Studies of Scale Effects (Phase 1); Summary Report; Risø-R-1390(EN); Riso National Laboratory: Roskilde, Denmark, 2004; 36p. [Google Scholar]

- Jensen, F.M.; Kling, A.; Sorensen, J.D. Change in Failure type when wind turbines blades scale up. In Proceedings of the Sandia Wind Turbine Workshop; 2012. Available online: https://energy.sandia.gov/wp-content//gallery/uploads/2B-A-1-Jensen1.pdf (accessed on 15 January 2021).

- Branner, K.; Ghadirian, A. Database about blade faults. DTU Wind Energy. (DTU Wind Energy E; No. 0067). 2014. Available online: https://core.ac.uk/download/pdf/43253602.pdf (accessed on 5 August 2021).

- Mone, C.; Hand, M.; Bolinger, M.; Rand, J.; Heimiller, D.; Ho, J. Cost of Wind Energy Review; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2017. [CrossRef]

- Carlos, S.; Sánchez, A.; Martorell, S.; Marton, I. Onshore wind farms maintenance optimization using a stochastic model. Math. Comput. Model. 2013, 57, 1884–1890. [Google Scholar] [CrossRef]

- Guess, F.M.; Hoyland, A.; Rausand, M. System reliability theory: Models and statistical methods. J. Am. Stat. Assoc. 1996, 91, 436. [Google Scholar] [CrossRef]

- Glavind, L.; Olesen, I.S.; Skipper, B.F.; Kristensen, M. Fiber-optical grating sensors for wind turbine blades: A review. Opt. Eng. 2013, 52, 030901. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Tobias, A.M.; Pinar Pérez, J.M.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Rogelj, D.S.J.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; Mundaca, L.; et al. Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development, Global Warming of 1.5 °C. In An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018. [Google Scholar]

- Luz, T.; Moura, P. 100% Renewable energy planning with complementarity and flexibility based on a multi-objective assess-ment. Appl. Energy 2019, 255, 113819. [Google Scholar] [CrossRef]

- Jacobson, M.Z.; Delucchi, M.A.; Bauer, Z.A.; Goodman, S.C.; Chapman, W.E.; Cameron, M.; Bozonnat, C.; Chobadi, L.; Clonts, H.A.; Enevoldsen, P.; et al. 100% Clean and renewable wind, water, and sunlight all-sector energy roadmaps for 139 countries of the world. Joule 2017, 1, 108–121. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy Statistics 2019; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Kost, C.; Shammugam, S.; Jülch, V.; Nguyen, H.-T.; Schlegl, T. Levelized Cost of Electricity Renewable Energy Technologies; Fraunhofer Institute for Solar Energy Systems—ISE: Freiburg im Breisgau, Germany, 2018. [Google Scholar]

- Aldersey-Williams, J.; Rubert, T. Levelised cost of energy—A theoretical justification and critical assessment. Energy Policy 2018, 124, 169–179. [Google Scholar] [CrossRef]

- Elia, A.; Taylor, M.; Gallachóir, B.; Rogan, F. Wind turbine cost reduction: A detailed bottom-up analysis of innovation drivers. Energy Policy 2020, 147, 111912. [Google Scholar] [CrossRef]

- Clarke, L.; Weyant, J.; Edmonds, J. On the sources of technological change: What do the models assume? Energy Econ. 2008, 30, 409–424. [Google Scholar] [CrossRef]

- Junginger, M.; Hittinger, E.; Williams, E.; Wiser, R. Chapter 6—Onshore wind energy. In Technological Learning in the Transition to a Low-Carbon Energy System; Junginger, M., Louwen, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 87–102. [Google Scholar]

- Samadi, S. The experience curve theory and its application in the field of electricity generation technologies—A literature re-view. Renew. Sustain. Energy Rev. 2018, 82, 2346–2364. [Google Scholar] [CrossRef]

- Yu, Y.; Li, H.; Che, Y.; Zheng, Q. The price evolution of wind turbines in China: A study based on the modified multi-factor learning curve. Renew. Energy 2017, 103, 522–536. [Google Scholar] [CrossRef]

- Hayashi, D.; Huenteler, J.; Lewis, J.I. Gone with the wind: A learning curve analysis of Chinas’ wind power industry. Energy Policy 2018, 120, 38–51. [Google Scholar] [CrossRef]

- Candelise, C.; Winskel, M.; Gross, R. The dynamics of solar PV costs and prices as a challenge for technology forecasting. Renew. Sustain. Energy Rev. 2013, 26, 96–107. [Google Scholar] [CrossRef]

- Qiu, Y.; Anadon, L.D. The price of wind power in China during its expansion: Technology adoption, learning-by-doing, economies of scale, and manufacturing localization. Energy Econ. 2012, 34, 772–785. [Google Scholar] [CrossRef]

- Lin, B.; He, J. Learning curves for harnessing biomass power: What could explain the reduction of its cost during the expan-sion of China? Renew. Energy 2016, 99, 280–288. [Google Scholar] [CrossRef]

- Neij, L. Cost development of future technologies for power generation—A study based on experience curves and complemen-tary bottom-up assessments. Energy Policy 2008, 36, 2200–2211. [Google Scholar] [CrossRef]

- Kavlak, G.; McNerney, J.; Trancik, J.E. Evaluating the causes of cost reduction in photovoltaic modules. Energy Policy 2018, 123, 700–710. [Google Scholar] [CrossRef]

- McNerney, J.; Farmer, J.D.; Trancik, J.E. Historical costs of coal-fired electricity and implications for the future. Energy Policy 2011, 39, 3042–3054. [Google Scholar] [CrossRef]

- IEA. Global Energy Review 2020. Available online: https://www.iea.org/reports/global-energy-review-2020/renewables (accessed on 17 January 2021).

- Obane, H. Forecasting photovoltaic and wind energy capital costs in Japan: A Bayesian approach. Energy Procedia 2019, 158, 3576–3582. [Google Scholar] [CrossRef]

- Irena. Renewable Energy Technologies: Cost Analysis Series; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2012; Volume 1. [Google Scholar]

- Steffen, B.; Beuse, M.; Tautorat, P.; Schmidt, T.S. Experience curves for operations and maintenance costs of renewable energy technologies. Joule 2020, 4, 359–375. [Google Scholar] [CrossRef]

- El-Thalji, I.; Liyanage, J.P. On the operation and maintenance practices of wind power asset A status review and observations. J. Qual. Mainten. Eng. 2012, 18, 232–266. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, X.; Liu, M.; Zeng, J. Based on wavelet transform of fault diagnosis and analysis of wind generator transmission system. J. Basic Sci. Eng. 2011, 19 (Suppl. S1), 210–218. [Google Scholar]

- Kusiak, A.; Li, W. The prediction and diagnosis of wind turbine faults. Renew. Energy 2011, 36, 16–23. [Google Scholar] [CrossRef]

- Brandão, R.F.M.; Carvalho, J.A.B.; Barbosa, F.P.M. Condition monitoring of the wind turbine generator slip ring. In Proceedings of the Universities Power Engineering Conference, London, UK, 4–7 September 2012. [Google Scholar]

- Tamilselvan, P.; Wang, Y.; Wang, P. Optimization of wind turbines operation and maintenance using failure prognosis. In Proceedings of the PHM 2012–2012 IEEE International Conference on Prognostics and Health Management: Enhancing Safety, Efficiency, Availability, and Effectiveness of Systems through PHM Technology and Application, Conference Program, Denver, CO, USA, 18–21 June 2012. [Google Scholar]

- Lau, B.C.P.; Ma, E.W.M.; Pecht, M. Review of offshore wind turbine failures and fault prognostic methods. In Proceedings of the PHM 2012–2012 IEEE International Conference on Prognostics and Health Management: Enhancing Safety, Efficiency, Availability, and Effectiveness of Systems through PHM Technology and Application, Conference Program, Beijing, China, 23–25 May 2012. [Google Scholar]

- Hofmann, M.A. Review of decision support models for offshore wind farms with an emphasis on operation and maintenance strategies. Wind. Eng. 2011, 35, 1–15. [Google Scholar] [CrossRef]

- Tracht, K.; Westerholt, J.; Schuh, P. Spare parts planning for offshore wind turbines subject to restrictive maintenance conditions. Procedia Cirp. 2013, 7, 563–568. [Google Scholar] [CrossRef]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2013, 53, 365–376. [Google Scholar] [CrossRef]

- Aguilar, S.; Telles, G.R.; Medina, P.; Quaresma, B.; Cyrino, F.L.; Castro, R. Wind power generation: A review and a research agenda. J. Clean Prod. 2019, 218, 850–870. [Google Scholar]

- Kalkanis, K.; Psomopoulos, C.; Kaminaris, S.; Ioannidis, G.; Pachos, P. Wind turbine blade composite materials—End of life treatment methods. Energy Procedia 2019, 157, 1136–1143. [Google Scholar] [CrossRef]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Assessing the life cycle costs and environmental performance oflight-weight materials in automobile applications. Compos. Part A 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- Suzuki, T.; Takahashi, J. Prediction of energy intensity of carbon fiber reinforced plastics for mass-produced passenger car. In Proceedings of the 9th Japan International SAMPE Symposium, Japan, Tokyo, 29 November–2 December 2005; pp. 14–19. [Google Scholar]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Goodship, V. Management, Recycling and Reuse of Waste Composites; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar] [CrossRef]

- Henshaw, J.M. Recycling and disposal of polymer–matrix composites. In ASM Handbook, Volume 21: Composites; Miracle, D.B., Donaldson, S.L., Eds.; ASM International®: Materials Park, OH, USA, 2001; pp. 1006–1012. [Google Scholar]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Pickering, S.J. Thermal methods for recycling waste composites. In Management, Recycling and Reuse of Waste Composites; Goodship, V., Ed.; WP and CRC Press: Cambridge, UK, 2010; pp. 65–101. [Google Scholar]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A Comparative Life Cycle Assessment between landfilling and Co-Processing of waste from decommissioned Irish wind turbine blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

- Papadakis, N. Designing composite wind turbine blades disposal recycling and reuse. In Management, Recycling and Reuse of Waste Composites; Goodship, V., Ed.; WP and CRC Press: Cambridge, UK, 2010; pp. 443–457. [Google Scholar]

- Lee, Y.-M.; Tzeng, Y.-E.; Su, C.-L. Life cycle assessment of wind power utilization in Taiwan. In Proceedings of the 7th International Conference on EcoBalance, Tsukuba, Japan, 14–16 November 2006. [Google Scholar]

- Andersen, P.D.; Bonou, A.; Beauson, J.; Brøndsted, P. Recycling of wind turbines. In DTU International Energy Report 2014: Wind Energy—Drivers and Barriers for Higher Shares of Wind in the Global Power Generation Mix; Larsen, H., Sønderberg, P.L., Eds.; Technical University of Denmark: Lyngbly, Denmark, 2014; pp. 91–97. [Google Scholar]

- Operational and Maintenance Costs for Wind Turbines. Available online: http://www.windmeasurementinternational.com/wind-turbines/om-turbines.php (accessed on 12 April 2021).

- Renewable Energy Technologies: Cost Analysis Series. Volume 1 Power Sector Issue 5/5 Wind Power. 2012. Available online: https://www.irena.org/DocumentDownloads/Publications/RE_Technologies_Cost_Analysis-WIND_POWER.pdf (accessed on 3 January 2020).

- Staffell, I.; Green, R. How does wind farm performance decline with age? Renew. Energy 2014, 66, 775–786. [Google Scholar] [CrossRef]

- Energy Economics. Statistical Review of World Energy. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/electricity.html (accessed on 22 July 2021).

- Griffith, D.T.; Yoder, N.C.; Resor, B.; White, J.; Paquette, J. Structural health and prognostics management for the enhance-ment of OWT operations and maintenance strategies. Wind Energy 2014, 17, 1737–1751. [Google Scholar] [CrossRef]

- Levitt, A.C.; Kempton, W.; Smith, A.P.; Musial, W.; Firestone, J. Pricing offshore wind power. Energy Policy 2011, 39, 6408–6421. [Google Scholar] [CrossRef]

- Musial, W.; Ram, B. Large-Scale Offshore Wind Energy for the United State: Assessment of Opportunities and Barriers; No. NREL/TP-500-40745; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2010. [Google Scholar]

- Griffith, D.T.; Yoder, N.C.; Resor, B.; White, J.; Paquette, J.; Ogilvie, A.; Peters, V. Prognostic control to enhance offshore wind turbine operation and maintenance strategies. In Proceedings of the European Wind Energy Conference (EWEA) Annual Event, Copenhagen, Denmark, 16–19 April 2012. [Google Scholar]

- Besnard, F.; Fischer, K.; Bertling, L. Reliability-centered asset maintenance: A step towards enhanced reliability, availability, and profitability of wind power plants. In Proceedings of the IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT Europe), Gothenburg, Sweden, 11–13 October 2010. [Google Scholar]

- Amirat, Y.; Benbouzid, M.E.H.; Bensaker, B.; Wamkeue, R. Condition monitoring and fault diagnosis in wind energy conver-sion systems: A review. In Proceedings of the 2007 IEEE International Electric Machines and Drives Conference, Antalya, Turkey, 3–5 May 2007; pp. 1434–1439. [Google Scholar]

- Ciang, C.C.; Lee, J.-R.; Bang, H.-J. Structural health monitoring for a wind turbine system: A review of damage detection methods. Meas. Sci. Technol. 2008, 19, 122001. [Google Scholar] [CrossRef]

- Energy for Sustainable Development (ESD) Ltd. for Greenpeace. Offshore Wind, Onshore Jobs: A New Industry for Britain; Energy for Sustainable Development (ESD) Ltd. for Greenpeace: London, UK, 2009; Available online: yumpu.com (accessed on 3 May 2020).

- Tsai, L. An Integrated Assessment of Offshore Wind Farm Siting: A Case Study in the Great Lakes of Michigan. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2013. [Google Scholar]

- Aakre, D.; Hangen, R. Wind Turbine Considerations for Landowners. NDSU Extension Service; North Dakota State University: Fargo, ND, USA, 2009; Available online: http://www.ag.ndsu.edu/pubs/agecon/market/ec1394.pdf (accessed on 12 March 2020).

| Mode of Failure | Image | Classification | Reason for Failure |

|---|---|---|---|

| Interlaminar failure |  | V2–V3 | Brazier effect, bending moment |

| Delamination–Faulty injection |  | V1 | Wear |

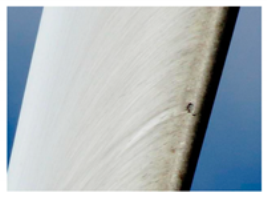

| Peeling/Wear |  | V1 | Wear |

| Erosion of the sealing of the root | V2 | Wear | |

| Flaking of the topcoat |  | V1 | Air bubbles from the manufacturing/poor quality |

| Missing external parts |  | V2–V3 | Flaking and external objects impact |

| Fine cracks in topcoat | V1 | Low quality of material | |

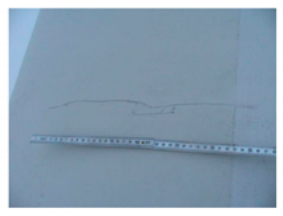

| Transverse cracks from trailing edge | V2–V3 | Poor design | |

| Transverse cracks on blade surface |  | V2–V3 | Poor design |

| Front edge cracks (transverse and longitudinal) |  | ||

| Web failure | V3 | Brazier effect, bending moment, poor design | |

| Fatigue failure in root connection | V3 | Poor design | |

| Fatigue failure in root transition area | V1–V2 | ||

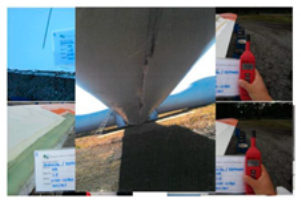

| Fatigue failure in bond lines, longitudinal cracks in the trailing edge |  | V1–V2 | Transversal shear distortion, deformation of trailing edge panels, trailing edge buckling |

| UV effect on the fibers | V1 | Wear, flaking | |

| Lightning damage |  | V3 | Lightning |

| Tower hit by blade | V3 | High tip deflection | |

| Balsa/composite cracking (transverse and longitudinal) | |||

| Transport damage |  | V0–V3 | |

| Complete separation | V0 |

| Wind Turbine Subsystems | Composition | Potential Failures | Monitoring Technique | |

|---|---|---|---|---|

| Rotor | Blades | Deterioration, cracking and adjustment error | Ultrasound, and active thermography | Torque, AE, SM and VI |

| Bearings | Spalling, wear, defect of bearing shells and rolling element | Vibration, OA, AE, SPM and performance monitoring | ||

| Shaft | Fatigue and crack formation | Vibration | ||

| Drivetrain | Main shaft bearing | Wear and high vibration | Vibration, SPM, temperature and AE | Torque, power signal analysis, thermography, AE and performance monitoring |

| Mechanical brake | Locking position | Temperature | ||

| Gearbox | Wearing, fatigue, oil leakage, insufficient lubrication, braking in teeth, displacement and eccentricity of toothed wheels | Temperature, vibration, SPM, OA and AE | ||

| Generator | Wearing, electrical problems, slip rigs, winding damage, rotor asymmetries, bar break, overheating and over speed | Generated effect, temperature, vibration, SPM, torque, power signal analysis, electrical effects, performance monitoring and thermography | ||

| Auxiliary system | Pitch system | Pitch motor problem | - | |

| Hydraulic system | Pump motor problems and oil leakage | Performance monitoring | ||

| Sensors | Broken and wrong indication | Thermography | ||

| Electrical system | Control system | Short circuit, component fault and bad connection | Current consumption and temperature | Arc guard, temperature |

| Power electronics | Short circuit, component fault and bad connection | Current consumption and temperature | ||

| High Voltage | Contamination and arcs | Arc guard, temperature | ||

| Tower | Nacelle | Fire and yaw error | Smoke, heat, flame detection | Vibration, SPM, SM and VI |

| Tower | Crack formation, fatigue, vibration and foundation weakness | - | ||

| System transformer | Problem with contamination, breakers, disconnectors and isolators | Thermography | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Salameh, T.; Abdelkareem, M.A.; Baroutaji, A. A Review on Failure Modes of Wind Turbine Components. Energies 2021, 14, 5241. https://doi.org/10.3390/en14175241

Olabi AG, Wilberforce T, Elsaid K, Sayed ET, Salameh T, Abdelkareem MA, Baroutaji A. A Review on Failure Modes of Wind Turbine Components. Energies. 2021; 14(17):5241. https://doi.org/10.3390/en14175241

Chicago/Turabian StyleOlabi, Abdul Ghani, Tabbi Wilberforce, Khaled Elsaid, Enas Taha Sayed, Tareq Salameh, Mohammad Ali Abdelkareem, and Ahmad Baroutaji. 2021. "A Review on Failure Modes of Wind Turbine Components" Energies 14, no. 17: 5241. https://doi.org/10.3390/en14175241

APA StyleOlabi, A. G., Wilberforce, T., Elsaid, K., Sayed, E. T., Salameh, T., Abdelkareem, M. A., & Baroutaji, A. (2021). A Review on Failure Modes of Wind Turbine Components. Energies, 14(17), 5241. https://doi.org/10.3390/en14175241