Identification and Classification of Global Theoretical Trends and Supply Chain Development Directions

Abstract

:1. Introduction

- What are the global theoretical trends and supply chain development directions that have appeared over the years?

- What is the developmental potential of the identified trends in the research area?

2. The Context of Global Changes

- Dynamic development of technology and production organization, commonly referred to as the “fourth industrial revolution” or Industry 4.0. The approach of the so-called Industry 4.0—the “fourth industrial revolution”—may be also confirmed by reviewing leading domains in publications [8,9]. Industry 4.0 uses modern technological solutions, which include cyber-physical systems, the Internet of Things and cloud computing [10]. Industry 4.0 is a heterogeneous concept which combines many numbers of solutions of a different nature. Its enormous potential creates many new opportunities, but at the same time it is a challenge resulting from the need to use advanced technologies [11,12,13]. The digitalization related to Industry 4.0 is unavoidably changing the way supply chains (SCs) are designed and managed [14]. It is believed that the integration of all stakeholders involved in value creation throughout the entire flow of goods is the best approach. Therefore, in the context of Industry 4.0, not only manufacturers, but entire supply chains in which manufacturers operate, should be analyzed and redesigned, modeled and managed;

- Highly dynamic global changes related to the COVID-19 pandemic and the resulting consequences for the sustainability and continuity of supply chains, which made everyone realize that creating and resting the supplier base in only one country/region or importing goods from the other side of the world may be too risky. The very nature of the epidemic threatens not only human life but also the foundations of the economy—the free movement of people and goods [15,16]. The social, political and economic shock caused by COVID-19 is self-evident, and the rapidly changing global crisis raises the question of whether our worldview has changed as well [17]. Supply chains had to adapt quickly to demand-related shocks that resulted from unpredictability and panic buying. On the other hand, they had to allow for any supply-related disruptions in their planning, i.e., potential shortages of human resources and transport disturbances [18]. The COVID-19 pandemic has affected supply chains by demonstrating their lack of resilience and effects felt by the negative impact of disruptions on a global scale. This is largely due to unreliable individual connections and nodes in the supply chain. The COVID-19 pandemic is a crisis of unprecedented proportions that has contributed to global changes—the near future is expected to see the beginning of a major redesign and remodeling of supply chains;

- Great changes in consumer behavior, which are the result of, among others, the global COVID-19 pandemic. They have affected the operational activity of supply chains. Additionally, the development of the global economy has caused a significant increase in the worldwide production of goods, including food and services, and an excessive increase in consumption. New organizational, consumer, political and supply chain behavioral patterns are now being identified [17]. Consumption and environmental changes are also related to the new European green deal. It indicates a comprehensive approach and the participation of all actions and policies of the European Union countries. More sustainable, intelligent social engineering systems are needed [19]. The new green deal promises interrelated initiatives (e.g., in climate, environmental, energy, transport, industrial, agricultural and sustainable finance policies). It also points to promoting and working towards a more dynamic, resilient and competitive European industry. This means basing the economy on the principles of competitiveness, single market integration, equivalence, cohesion, inclusiveness, solidarity, circularity and environmental protection while respecting social standards. A shortage of demand can be observed, which collides with overproduction and extensive negative consequences associated with it, such as destructive competition, aggressive advertising of goods, consumerism and degradation of the natural environment. Uncontrolled consumption leads to environmental degradation through the overexploitation of renewable and non-renewable natural resources. Increasing manifestations of the syndrome of the glut economy related to products and services can be noticed, which leads to wasting various resources. It contributes to the wastage of goods and human labor. It also causes significant economic disproportions between people [20]. Improper distribution of products contributes to wastage in highly developed countries and continuing shortages in poor countries [21]. These phenomena are closely related to growing social inequalities. The situation with COVID-19 shows that consumer behavior has changed. One can notice a distinctly newer pattern of consumption and shift to online shopping, delivery and e-commerce [22,23]. The main behavioral problem of the last year (2020/2021) has also been the fact that there is a negative perception of reuse and recycling.

3. Methodology

- The bibliometric analysis conducted employing the systematic literature review method [24] made it possible to evaluate the research results and comprehensively present the global scientific output. It provided essential information about the global structure of science and showed its dynamics. The analysis was carried out in three steps: (1) the scope of the analysis was identified; (2) keywords, document types and kinds and language were identified; (3) the selection, evaluation and synthesis of the existing set of reviewed and registered research papers in the analyzed databases were carried out. The result of this approach is a collection of scientific publications, identified in a systematic, open, comprehensive and repeatable manner, and yielding the same results [25]. The identified set of selected scientific publications was used to move to the second stage and conduct further research. Adopting this approach allows the identification and classification of trends of the supply chain that affect the development of knowledge in a given field in a more objective and scientific.

- The identification and classification of global theoretical trends and supply chain development directions in the context of global changes, performed by cluster analysis using genetic algorithms, made it possible to identify conceptual clusters by singling out a group of similar objects which coexist intensively. The study was conducted using the VOSviewer free software. This stage allowed us to understand the interdisciplinary character of the studied area [26]. This stage of research was creating (generating) knowledge maps as semantic maps. It is an actively developing method of assessing the results of scientific research and a comprehensive approach to global scientific achievements. It provides important information about the structure of science and shows the dynamics of changes in scientific research directions. This stage of research enables the acquisition of both necessary and unique information. Semantic maps are a relatively new form of knowledge presentation [27]. As a result of cluster analysis, key global theoretical trends and supply chain development directions were identified, and the third stage was initiated.

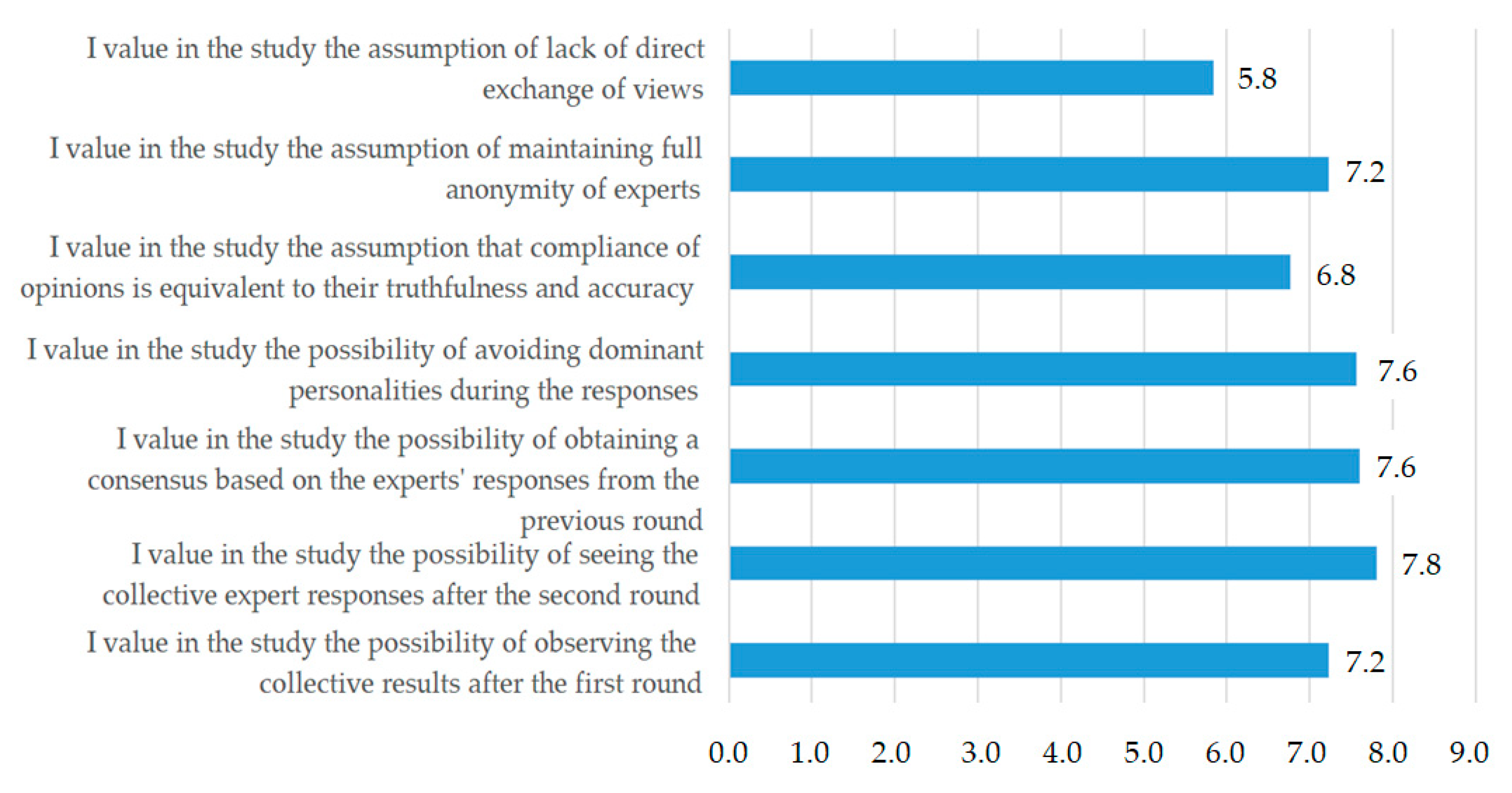

- Expert evaluation and projection of the developmental potential of the identified trends were carried out using the Delphi method. The Delphi method was used as an expert evaluation [28] to investigate possible trends in supply chains regarding their further development. The Delphi method relies on solid concepts to draw conclusions supported by arguments [29]. Experts from the academic community, both from Poland and abroad, who scientifically deal with the subject of supply chains were selected. They had extensive source knowledge. Thanks to this fact, it was possible to confront the experts’ opinions with diverse and independent views representing diverse scientific circles. By analyzing the experts’ opinions selected for the study, it was possible to indicate the potential of the specified trends in supply chains in the context of global changes and the possibility of translating the results of scientific research on these trends into benefits resulting from the industrial implementation of these trends. The study allowed to develop recommendations and indicate further research directions.

- Development of recommendations and indication of further research directions.

- Observing the collective results after the first round;

- Seeing the collective expert responses after the second round;

- Obtaining a consensus based on the experts’ responses from the previous round;

- Avoiding dominant personalities during the responses;

- Compliance of opinions, understood as equivalent to their truthfulness and accuracy;

- Maintaining full anonymity of experts;

- Lack of direct exchange of views;

- Expert opinion feedback available as averaged results with a median.

4. Research Results

- Dynamic development of production technology and organization (Industry 4.0);

- Dynamic global changes related to the COVID-19 pandemic;

- Great changes in consumer behavior.

4.1. Supply Chain from the Point of View of the Dynamic Development of Technology and the Perspective of Production Organization (Industry 4.0)

4.2. Supply Chain from the Point of View of Dynamic Global Changes Caused by the COVID-19 Perspective

4.3. Supply Chain from the Point of View of the Trend from Changes in Consumers’ Behavior Perspective

- Develop a limited number of key development scenarios for changing global supply chains;

- Describe them precisely;

- Perform further analysis.

5. Conclusions

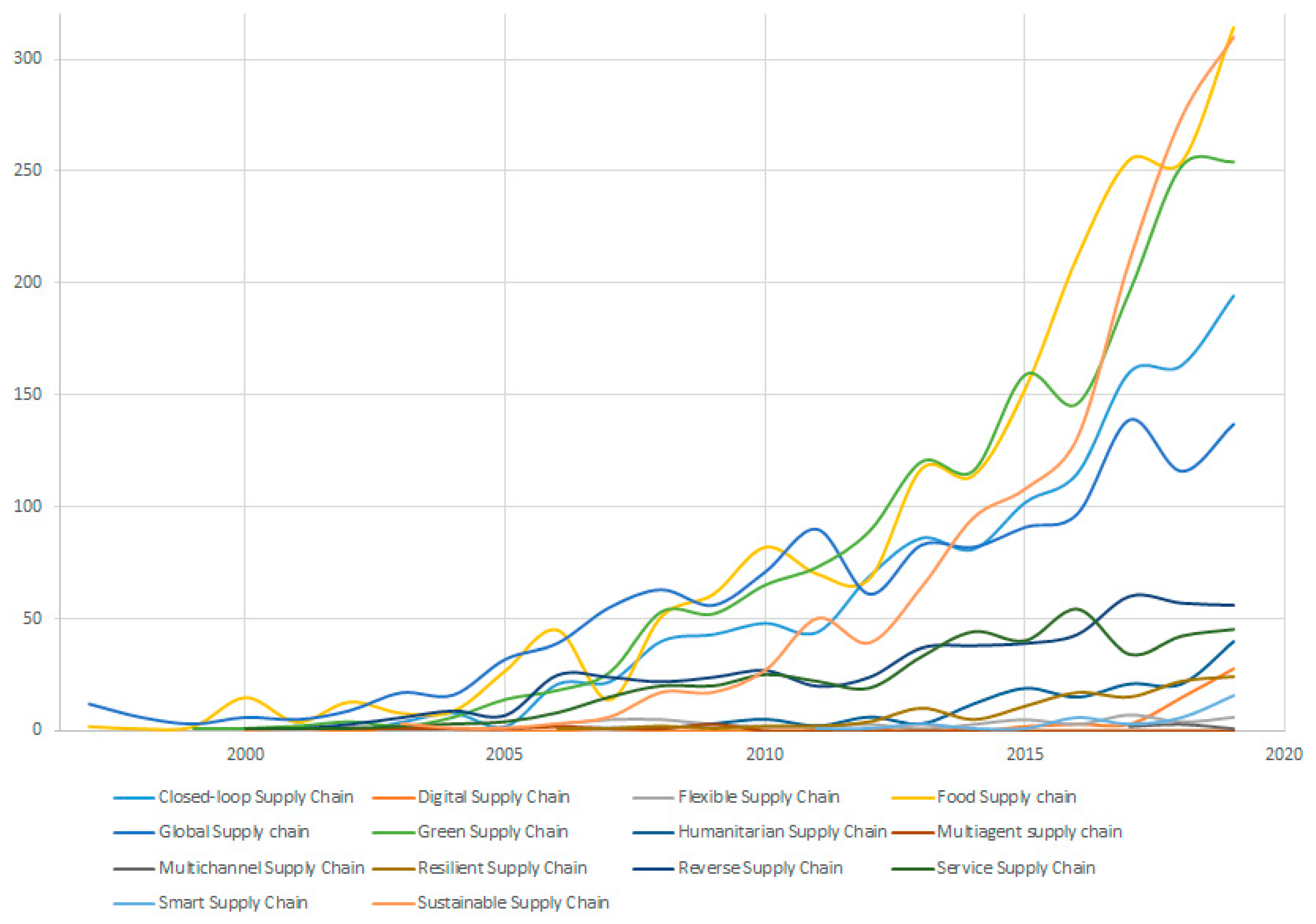

- The digital supply chain to support Industry 4.0. The shift from a traditional supply chain to a digital supply chain appears as a necessity. The digital supply chain can be defined as the development of information systems and the adoption of innovative technologies, strengthening the integration and the agility of the supply chain. A new wave of factory automation (Industry 4.0) will be supported by the next generation of low-cost robotics.

- The resilient supply chain to counterbalance unforeseen black swan events, as is the case with the COVID-19 pandemic. Resilience is defined as the ability of an organization to anticipate, prepare for, respond and adapt to incremental change and sudden disruptions in order to survive and prosper [1]. Supply chain resilience is defined as the ability of a supply chain to decrease the likelihood and/or impacts of possible disruptions, and to reduce the restoring and resuming times [36]. Chowdhury and Quaddus [37] and Hosseini, Ivanov and Dolgui [38] demonstrate that supply chain resilience (SCR) is a multi-dimensional measure.

- The sustainable supply chain to support, among others, the positive behavior of producers and consumers. The approach encompasses three dimensions: economic, social and environmental [39,40], the combination and balance of which is supposed to result in equilibrium in the economy. The sustainable supply chain requires a broadened approach to the supply chain [34]. The sustainable supply chain is not only the trend recognized in research (indexed since 2000; the number of works published is dynamically increasing after 2010) but also the practical approach promoted by organizations and authorities.

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Crook, T.R.; Combs, J.G. Sources and consequences of bargaining power in Supply Chains. J. Oper. Manag. 2007, 25, 546–555. [Google Scholar] [CrossRef]

- Frohlich, M.T.; Westbrook, R. Arcs of integration: An international study of Supply Chain strategies. J. Oper. Manag. 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Świerczek, A. From supply chains to supply networks (In Polish). Logistyka 2007, 1, 74–77. [Google Scholar]

- Grzybowska, K.; Stachowiak, A. Classification of trends and supply chains development directions. In Smart and Sustainable Supply Chain and Logistics—Trends, Challenges, Methods and Best Practices; Golinska-Dawson, P., Tsai, K.M., Kosacka-Olejnik, M., Eds.; EcoProduction (Environmental Issues in Logistics and Manufacturing); Springer: Cham, Switzerland, 2020; pp. 307–322. [Google Scholar]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Martínez-Jurado, P.J.; Moyano-Fuentes, J. Lean Management, Supply Chain Management and Sustainability: A Literature Review. J. Clean. Prod. 2014, 85, 134–150. [Google Scholar] [CrossRef]

- Saniuk, A.; Saniuk, S.; Caganova, D.; Cambal, M. Control of strategy realization in metallurgical production. In Proceedings of the 23rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 21–23 May 2014; pp. 1876–1881. [Google Scholar]

- Mrugalska, B.; Wyrwicka, M.K. Towards Lean Production in Industry 4.0. Procedia Eng. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Rosienkiewicz, M.; Gabka, J.; Helman, J.; Kowalski, A.; Susz, S. Additive Manufacturing Technologies Cost Calculation as a Crucial Factor in Industry 4.0. In Advances in Manufacturing; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 171–183. [Google Scholar]

- Kagermann, H.; Wahlster, W.; Helbig, J. (Eds.) Recommendations for Implementing the Strategic Initiative Industrie 4.0: Final Report of the Industrie 4.0; Acatech—National Academy of Science and Engineering: Berlin, Germany, 2013. [Google Scholar]

- Gehrke, L.; Kühn, A.T.; Rule, D.; Moore, P.; Bellmann Ch Siemes, S.; Dawood, D.; Singh, L.; Kulik, J.; Standley, M. Industry 4.0—A Discussion of Qualifications and Skills in the Factory of the Future: A German and American Perspective; VDI The Association of German Engineers, ASME American Society of Mechanical Engineers: Düsseldorf, Germany, 2015. [Google Scholar]

- Burduk, A. The role of artificial neural network models in ensuring the stability of systems. In 10th International Conference on Soft Computing Models in Industrial and Environmental Applications, Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2015; pp. 427–437. [Google Scholar]

- Tsai, W.-H. Green production planning and control for the textile industry by using mathematical programming and industry 4.0 techniques. Energies 2018, 11, 2072. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The Impact of Digital Technology and Industry 4.0 on the Ripple Effect and Supply Chain Risk Analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Golan, M.S.; Jernegan, L.H.; Linkov, I. Trends and applications of resilience analytics in supply chain modeling: Systematic literature review in the context of the COVID-19 pandemic. Environ. Syst. Decis. 2020, 40, 222–243. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2020, 41, 63–73. [Google Scholar] [CrossRef]

- Hobbs, J.E. Food supply chains during the COVID-19 pandemic. Can. J. Agric. Econ. Rev. Can. D’agroeconomie 2020, 68, 171–176. [Google Scholar] [CrossRef] [Green Version]

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the Circular Economy: A Review of Current Research and Future Trends. Energies 2018, 11, 3009. [Google Scholar] [CrossRef] [Green Version]

- Wasilik, K. Trends in the behavior of contemporary consumers—Consumerism and sustainable consumption (In Polish). Konsumpcja Rozw. 2014, 1, 66–74. [Google Scholar]

- Rosłon-Żmuda, J.; Zielona gospodarka Rewizorski, M.; Bieniek, K. (Eds.) Encyklopedia Globalnego Zarządzania Ekologicznego i Energetycznego; Fundacja na Rzecz Czystej Energii: Chomęcice, Poland, 2018. [Google Scholar]

- Wang, Y.; Xu, R.; Schwartz, M.; Ghosh, D.; Chen, X. COVID-19 and retail grocery management: Insights from a broad-based consumer survey. IEEE Eng. Manag. Rev. 2020, 48, 202–211. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Q. How do you manage online delivery package waste? IEEE Eng. Manag. Rev. 2020, 48, 184–192. [Google Scholar] [CrossRef]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature review on the ‘Smart Factory’ concept using bibliometric tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; Sage Publications: Thousand Oaks, CA, USA, 2010. [Google Scholar]

- Flis, I.; van Eck, N.J. Framing Psychology as a Discipline (1950–1999): A Large-Scale Term Co-Occurrence Analysis of Scientific Literature in Psychology. Hist. Psychol. 2018, 21, 334. [Google Scholar] [CrossRef] [Green Version]

- Börner, K.; Chen, C.; Boyack, K.W. Visualizing knowledge domains. Annu. Rev. Inf. Sci. Technol. 2005, 37, 179–255. [Google Scholar] [CrossRef]

- Smarandache, F.; Ricardo, J.E.; Caballero, E.G.; Vázquez, M.Y.L.; Hernández, N.B. Delphi method for evaluating scientific research proposals in a neutrosophic environment. Neutrosophic Sets Syst. 2020, 34, 204–213. [Google Scholar]

- García Valdés, M.; Suárez Marín, M. Delphi method for the expert consultation in the scientific research (In Spanish). Rev. Cuba. Salud Pública 2013, 39, 253–267. [Google Scholar]

- Schulze, H.; Bals, L. Implementing sustainable purchasing and supply management (SPSM): A Delphi study on competences needed by purchasing and supply management professionals. J. Purch. Supply Manag. 2020, 26, 100625. [Google Scholar] [CrossRef]

- Okoli, C.; Pawlowski, S.D. The Delphi Method as a Research Tool: An Example, Design Considerations and Applications. Inf. Manag. 2004, 42, 15–29. [Google Scholar] [CrossRef] [Green Version]

- Castro-Calvo, J.; King, D.L.; Stein, D.J.; Brand, M.; Carmi, L.; Chamberlain, S.R.; Billieux, J. Expert appraisal of criteria for assessing gaming disorder: An international Delphi study. Addiction 2021, 1–13. [Google Scholar] [CrossRef]

- Souza, J.P.E.; Alves, J.M. Lean-integrated management system: A model for sustainability improvement. J. Clean. Prod. 2018, 172, 2667–2682. [Google Scholar] [CrossRef]

- Grzybowska, K. Supply Chain Sustainability—analysing the enablers. In Environmental Issues in Supply Chain Management—New Trends and Applications; Golinska, P., Romano, C.A., Eds.; Springer: Cham, Switzerland, 2012; pp. 25–40. [Google Scholar]

- Elkington, J. Enter the triple bottom line. In The Triple Bottom Line: Does it All Add Up; Routledge: London, UK, 2004; pp. 23–28. [Google Scholar]

- Falasca, M.; Zobel, C.W.; Cook, D. A decision support framework to assess supply chain resilience. In Proceedings of the 5th International ISCRAM Conference, Washington, DC, USA, 4–7 May 2008; pp. 596–605. [Google Scholar]

- Chowdhury, M.M.H.; Quaddus, M. Supply Chain Resilience: Conceptualization and Scale Development Using Dynamic Capability Theory. Int. J. Prod. Econ. 2017, 188, 185–204. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of Quantitative Methods for Supply Chain Resilience Analysis. Transp. Res. Part E Logist. Transp. Rev. 2017, 125, 285–307. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 2002. [Google Scholar]

- Dotoli, M.; Fanti, M.P.; Meloni, C.; Zhou, M.C. A Multi-Level Approach for Network Design of Integrated Supply Chains. Int. J. Prod. Res. 2005, 43, 4267–4287. [Google Scholar] [CrossRef]

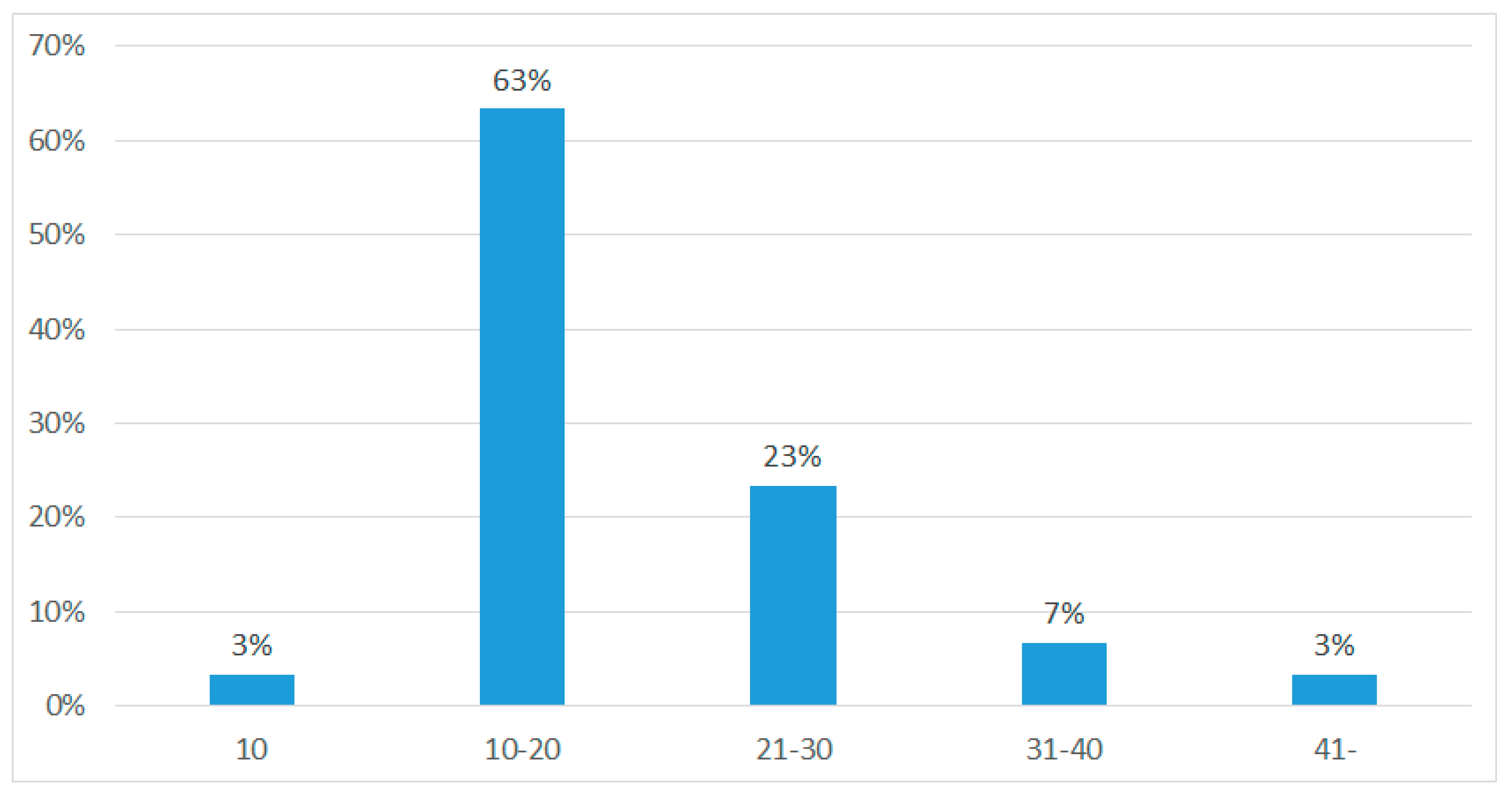

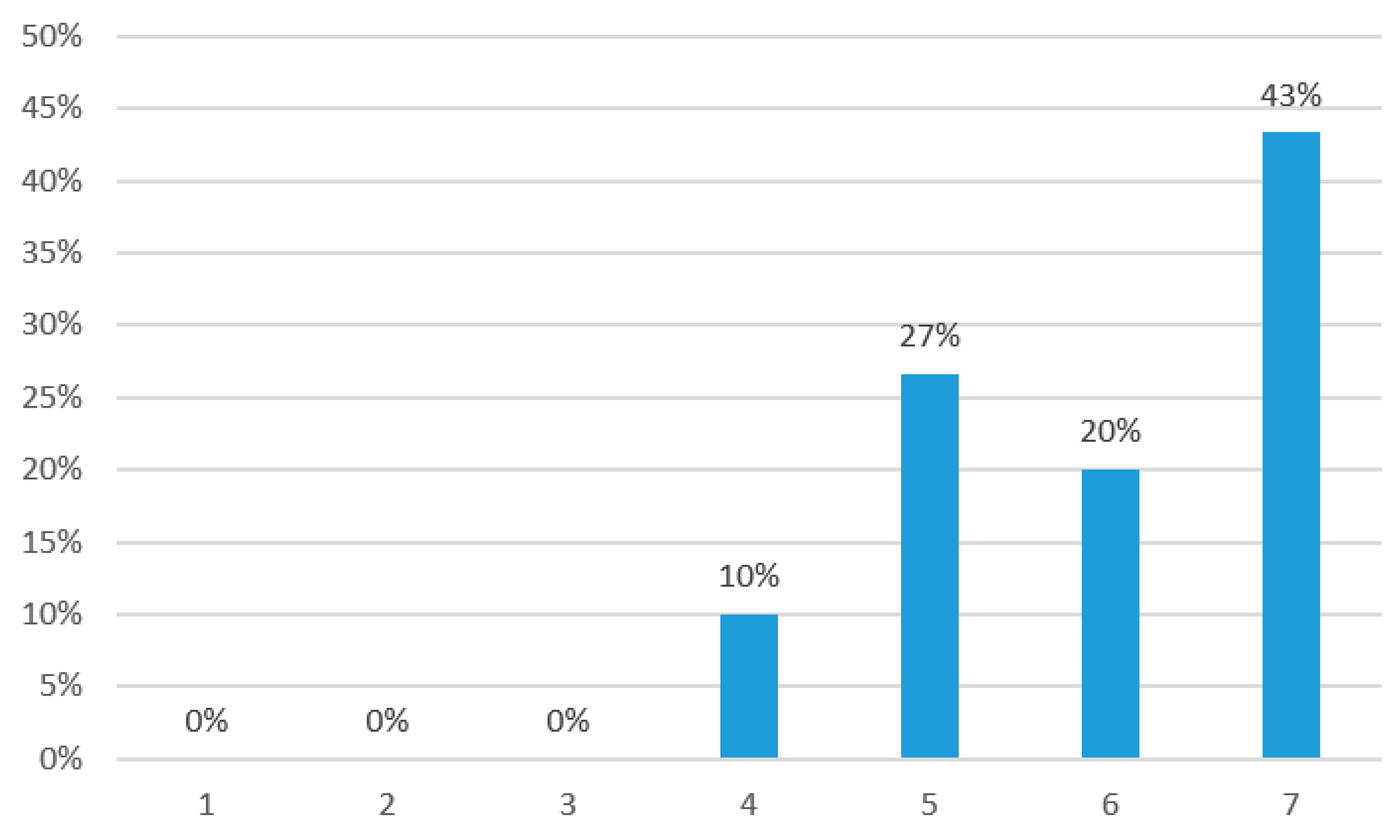

| Delphi Expert | Job Experience Scientific Experience | Level of Expertise | Top-Expert |

|---|---|---|---|

| Expert 1 | 35 | 7 | Yes |

| Expert 2 | 15 | 5 | |

| Expert 3 | 18 | 5 | |

| Expert 4 | 27 | 7 | Yes |

| Expert 5 | 18 | 7 | Yes |

| Expert 6 | 16 | 5 | |

| Expert 7 | 19 | 6 | |

| Expert 8 | 24 | 6 | |

| Expert 9 | 22 | 5 | |

| Expert 10 | 25 | 7 | Yes |

| Expert 11 | 13 | 5 | |

| Expert 12 | 15 | 7 | Yes |

| Expert 13 | 15 | 7 | Yes |

| Expert 14 | 27 | 7 | Yes |

| Expert 15 | 40 | 7 | Yes |

| Expert 16 | 25 | 7 | Yes |

| Expert 17 | 20 | 7 | Yes |

| Expert 18 | 14 | 7 | Yes |

| Expert 19 | 20 | 5 | |

| Expert 20 | 23 | 5 | |

| Expert 21 | 15 | 5 | |

| Expert 22 | 19 | 6 | |

| Expert 23 | 15 | 5 | |

| Expert 24 | 18 | 7 | Yes |

| Expert 25 | 18 | 5 | |

| Expert 26 | 45 | 7 | Yes |

| Expert 27 | 14 | 6 | |

| Expert 28 | 17 | 6 | |

| Expert 29 | 15 | 5 | |

| Expert 30 | 10 | 5 |

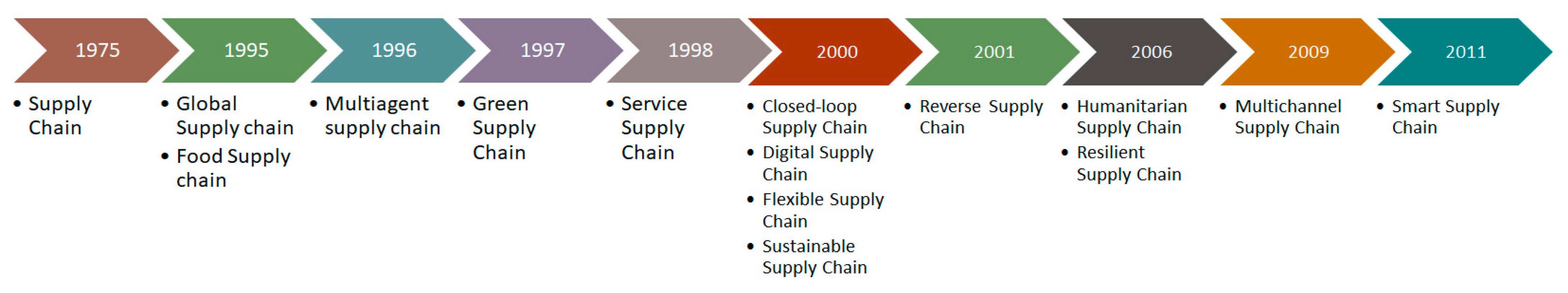

| No. | Supply Chain Trends |

|---|---|

| 1 | Closed-loop Supply Chain |

| 2 | Digital Supply Chain |

| 3 | Flexible Supply Chain |

| 4 | Food Supply Chain |

| 5 | Global Supply Chain |

| 6 | Green Supply Chain |

| 7 | Humanitarian Supply Chain |

| 8 | Multiagent Supply Chain |

| 9 | Multichannel Supply Chain |

| 10 | Resilient Supply Chain |

| 11 | Reverse Supply Chain |

| 12 | Service Supply Chain |

| 13 | Smart Supply Chain |

| 14 | Sustainable Supply Chain |

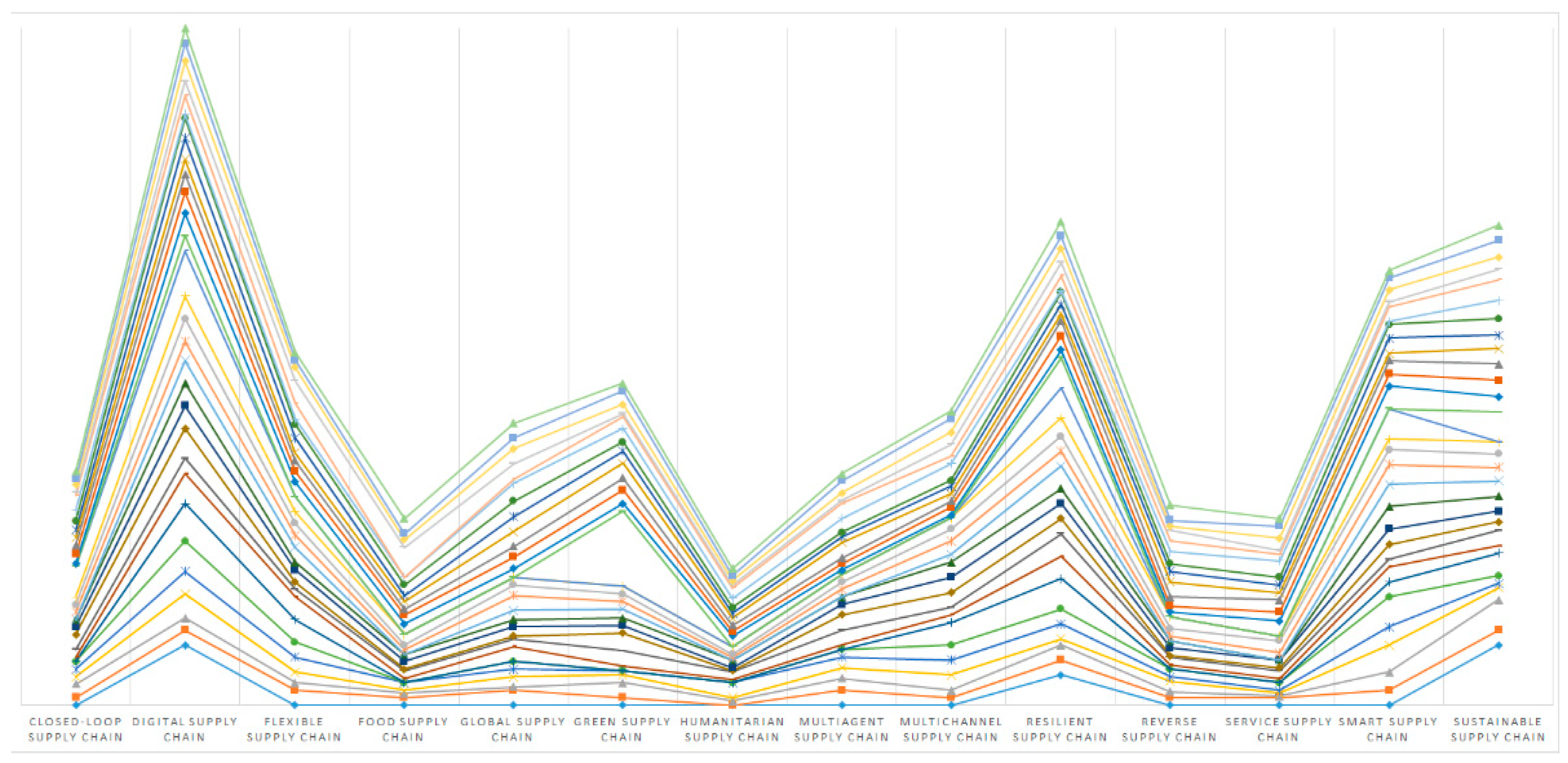

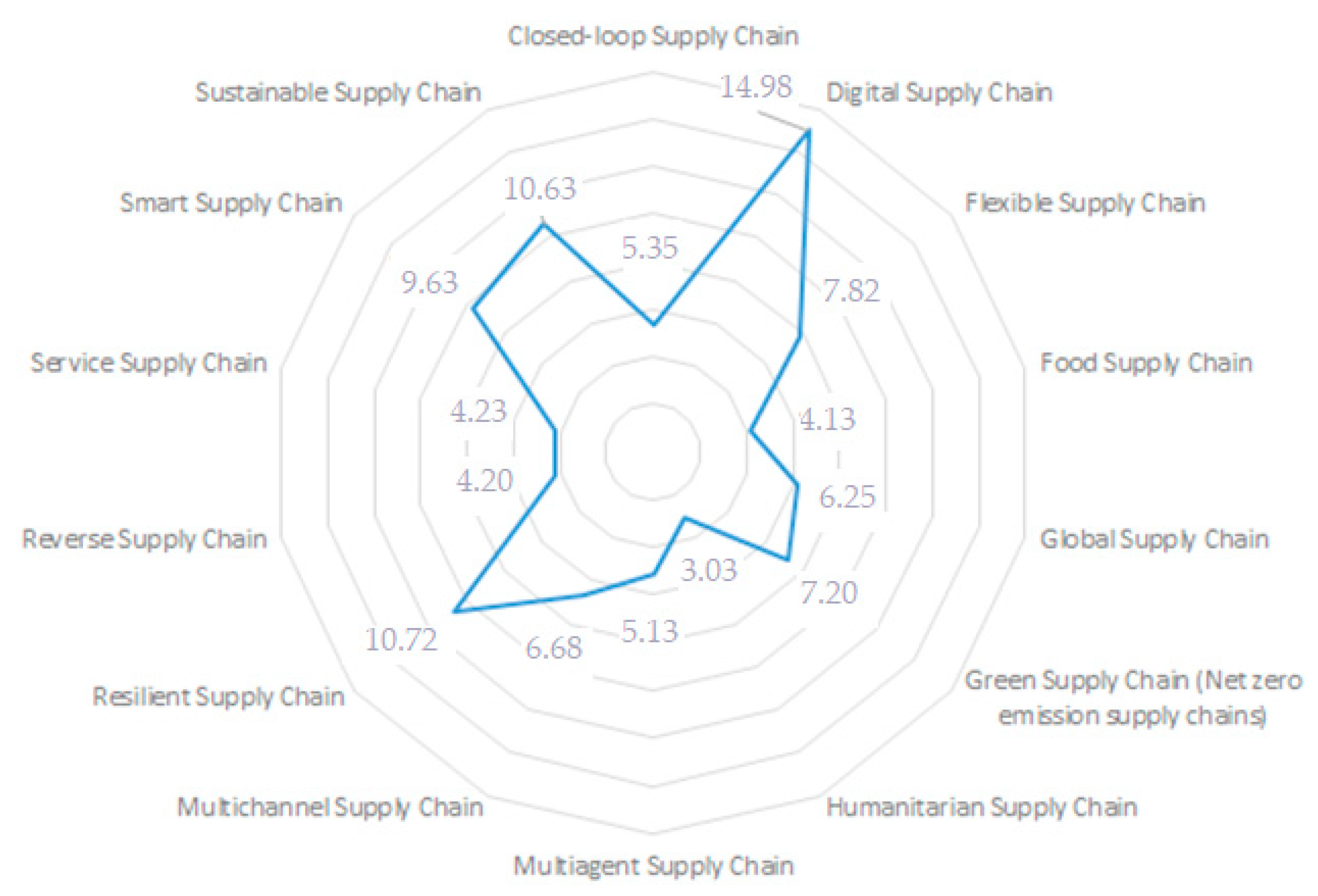

| Supply Chain Trends | Mean | Median | Min | Max | Deviation | Mode |

|---|---|---|---|---|---|---|

| Digital Supply Chain | 14.98 | 13.75 | 3 | 40 | 6.976 | 15 |

| Resilient Supply Chain | 10.72 | 10.00 | 1 | 20 | 4.759 | 10 |

| Sustainable Supply Chain | 10.63 | 10.00 | 0 | 40 | 6.911 | 10 |

| Smart Supply Chain | 9.63 | 10.00 | 0 | 20 | 5.129 | 10 |

| Flexible Supply Chain | 7.82 | 8.00 | 0 | 15 | 3.668 | 10 |

| Green Supply Chain | 7.20 | 5.00 | 0 | 50 | 8.723 | 5 |

| Multichannel Supply Chain | 6.68 | 6.25 | 0 | 15 | 3.607 | 5 |

| Global Supply Chain | 6.25 | 6.50 | 0 | 12 | 3.593 | 10 |

| Closed-loop Supply Chain | 5.35 | 5.00 | 0 | 20 | 3.684 | 5 |

| Multiagent Supply Chain | 5.13 | 5.00 | 0 | 10 | 3.060 | 5 |

| Service Supply Chain | 4.23 | 5.00 | 0 | 11 | 3.159 | 5 |

| Reverse Supply Chain | 4.20 | 4.50 | 0 | 10 | 2.941 | 5 |

| Food Supply Chain | 4.13 | 4.00 | 0 | 20 | 3.980 | 5 |

| Humanitarian Supply Chain | 3.03 | 3.00 | 0 | 10 | 2.526 | 0 |

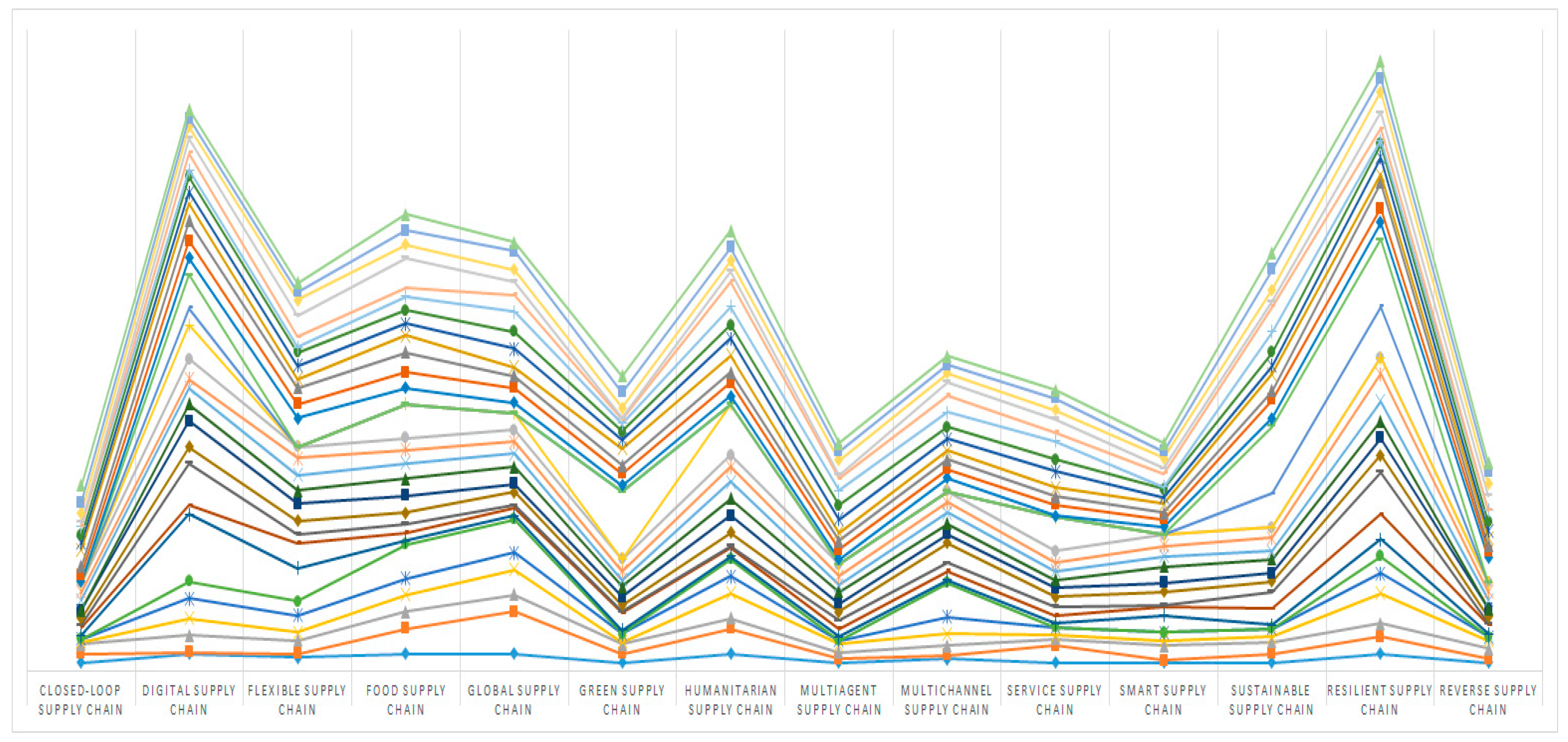

| Supply Chain Trends | Mean | Median | Min | Max | Deviation | Mode |

|---|---|---|---|---|---|---|

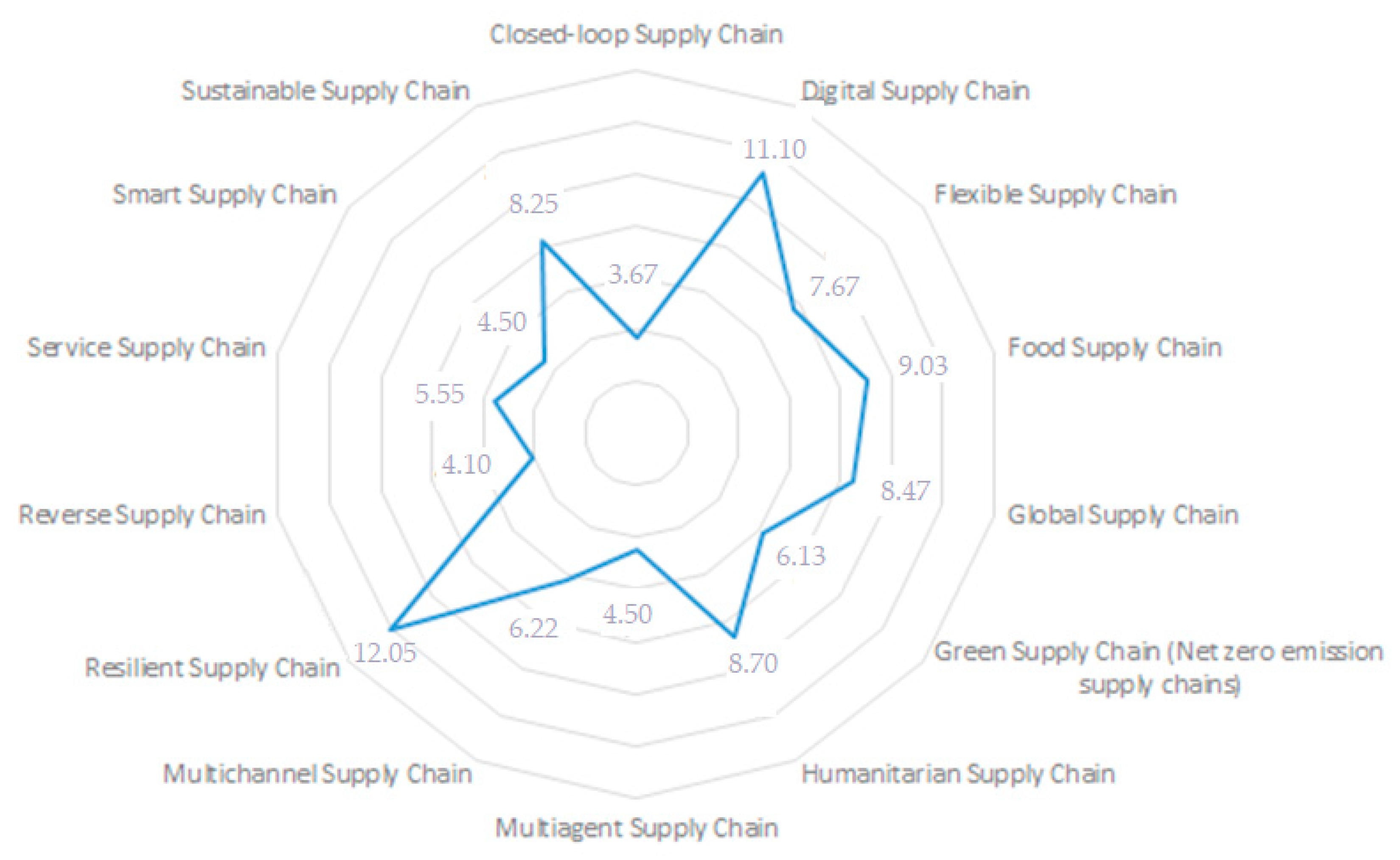

| Resilient Supply Chain | 12.05 | 10.00 | 0 | 40 | 7.819 | 10 |

| Digital Supply Chain | 11.10 | 10.00 | 1 | 40 | 7.341 | 10 |

| Food Supply Chain | 9.03 | 9.00 | 0 | 20 | 4.745 | 10 |

| Humanitarian Supply Chain | 8.70 | 8.50 | 0 | 30 | 5.603 | 10 |

| Global Supply Chain | 8.47 | 8.00 | 0 | 25 | 5.237 | 10 |

| Sustainable Supply Chain | 8.25 | 6.50 | 0 | 40 | 7.347 | 5 |

| Flexible Supply Chain | 7.67 | 8.00 | 0 | 20 | 4.611 | 8 |

| Multichannel Supply Chain | 6.22 | 6.00 | 0 | 20 | 3.863 | 5 |

| Green Supply Chain | 6.13 | 5.00 | 0 | 40 | 7.050 | 5 |

| Service Supply Chain | 5.55 | 5.00 | 0 | 20 | 3.878 | 5 |

| Multiagent Supply Chain | 4.50 | 5.00 | 0 | 9 | 2.610 | 5 |

| Smart Supply Chain | 4.50 | 5.00 | 0 | 10 | 2.883 | 5 |

| Reverse Supply Chain | 4.10 | 5.00 | 0 | 15 | 3.241 | 5 |

| Closed-loop Supply Chain | 3.67 | 4.00 | 0 | 10 | 2.820 | 5 |

| Supply Chain Trends | Mean | Median | Min | Max | Deviation | Mode |

|---|---|---|---|---|---|---|

| Sustainable Supply Chain | 12.80 | 12.00 | 0 | 40 | 6.483 | 10 |

| Food Supply Chain | 9.97 | 9.50 | 0 | 30 | 6.371 | 10 |

| Digital Supply Chain | 9.85 | 8.50 | 1 | 40 | 7.560 | 10 |

| Green Supply Chain | 9.67 | 9.00 | 0 | 50 | 8.836 | 10 |

| Multichannel Supply Chain | 7.75 | 7.00 | 0 | 30 | 5.870 | 7 |

| Closed-loop Supply Chain | 7.20 | 8.00 | 0 | 15 | 3.595 | 10 |

| Global Supply Chain | 6.52 | 6.50 | 0 | 20 | 4.186 | 10 |

| Humanitarian Supply Chain | 6.42 | 7.00 | 0 | 15 | 4.287 | 7 |

| Reverse Supply Chain | 6.30 | 5.75 | 0 | 17 | 4.076 | 5 |

| Flexible Supply Chain | 5.62 | 5.50 | 0 | 15 | 3.269 | 5 |

| Smart Supply Chain | 5.27 | 5.00 | 0 | 10 | 2.993 | 5 |

| Resilient Supply Chain | 5.17 | 5.00 | 0 | 20 | 3.668 | 5 |

| Service Supply Chain | 4.12 | 5.00 | 0 | 10 | 2.572 | 5 |

| Multiagent Supply Chain | 3.37 | 3.00 | 0 | 10 | 2.399 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzybowska, K. Identification and Classification of Global Theoretical Trends and Supply Chain Development Directions. Energies 2021, 14, 4414. https://doi.org/10.3390/en14154414

Grzybowska K. Identification and Classification of Global Theoretical Trends and Supply Chain Development Directions. Energies. 2021; 14(15):4414. https://doi.org/10.3390/en14154414

Chicago/Turabian StyleGrzybowska, Katarzyna. 2021. "Identification and Classification of Global Theoretical Trends and Supply Chain Development Directions" Energies 14, no. 15: 4414. https://doi.org/10.3390/en14154414

APA StyleGrzybowska, K. (2021). Identification and Classification of Global Theoretical Trends and Supply Chain Development Directions. Energies, 14(15), 4414. https://doi.org/10.3390/en14154414