Predicting Conduction Heat Flux through Macrolayer in Nucleate Pool Boiling

Abstract

:1. Introduction

2. Current Model and Analytical Solution

| I.C.: | T(y,0) = Tw; | 0 ≤ y ≤ δ | Tw: wall temperature |

| B.C.: | T(0,t) = Tw; | t > 0 | Ts: surface temperature |

| T(δ,t) = Ts; | t > 0. |

3. Results and Discussion

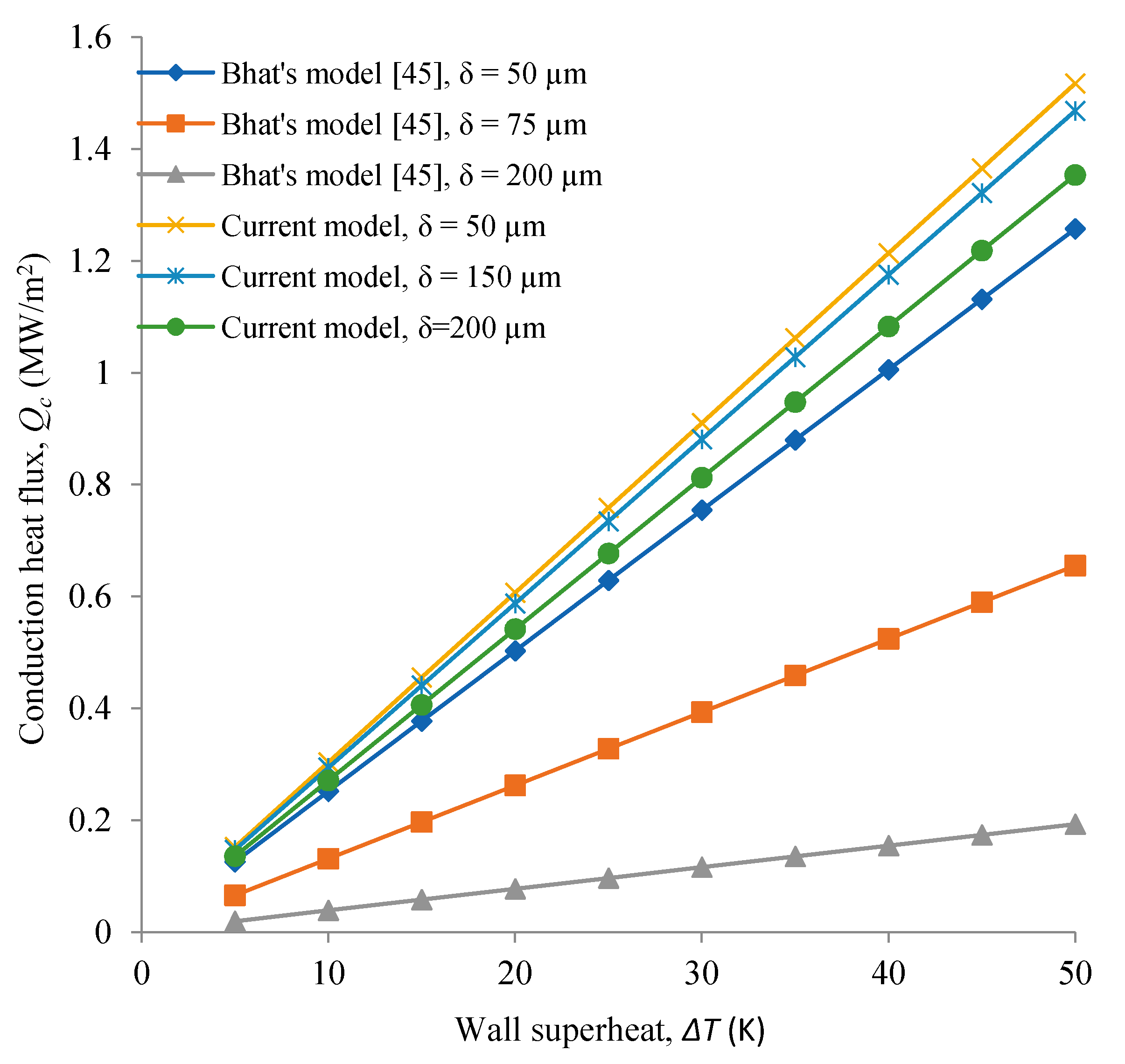

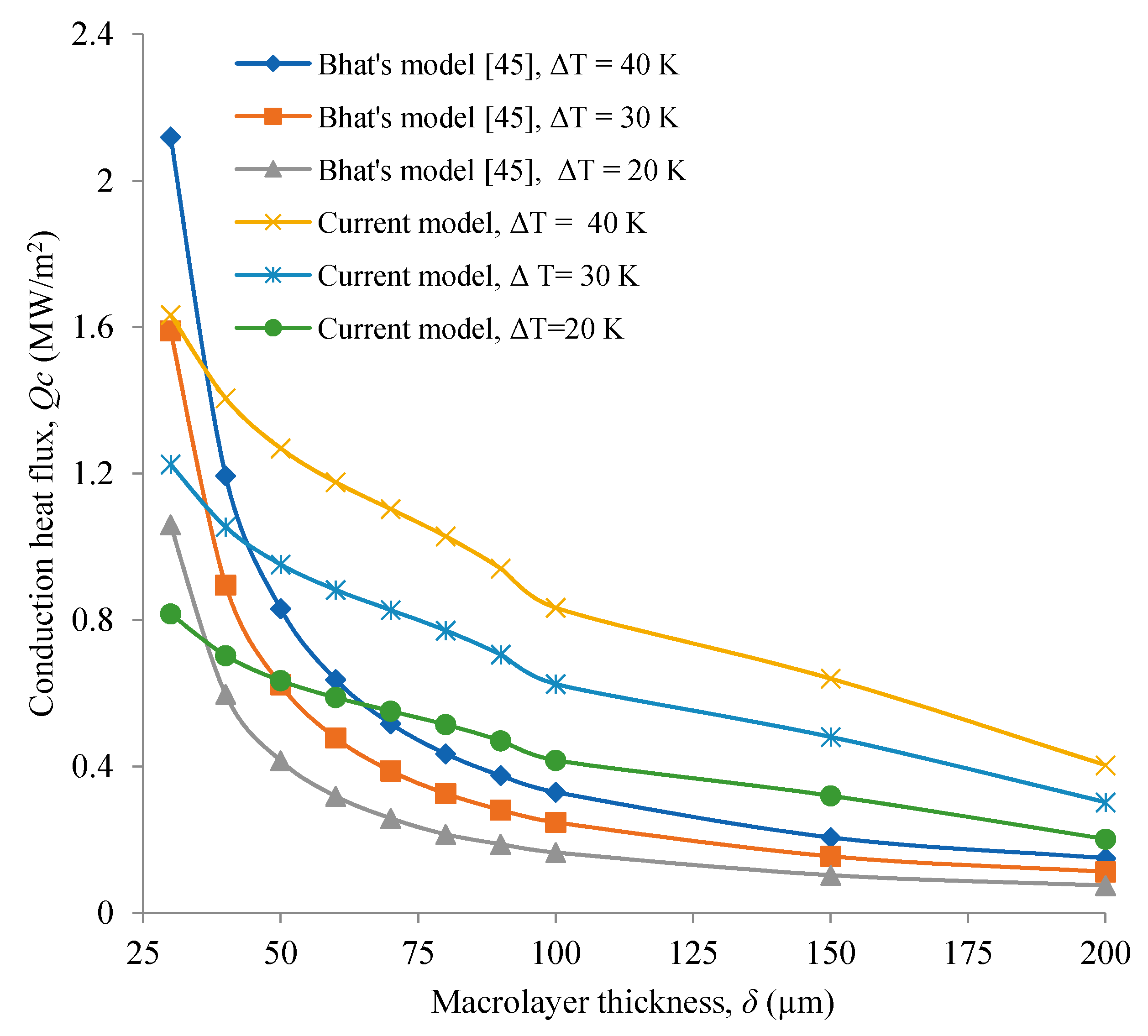

3.1. Instantaneous Heat Fluxes

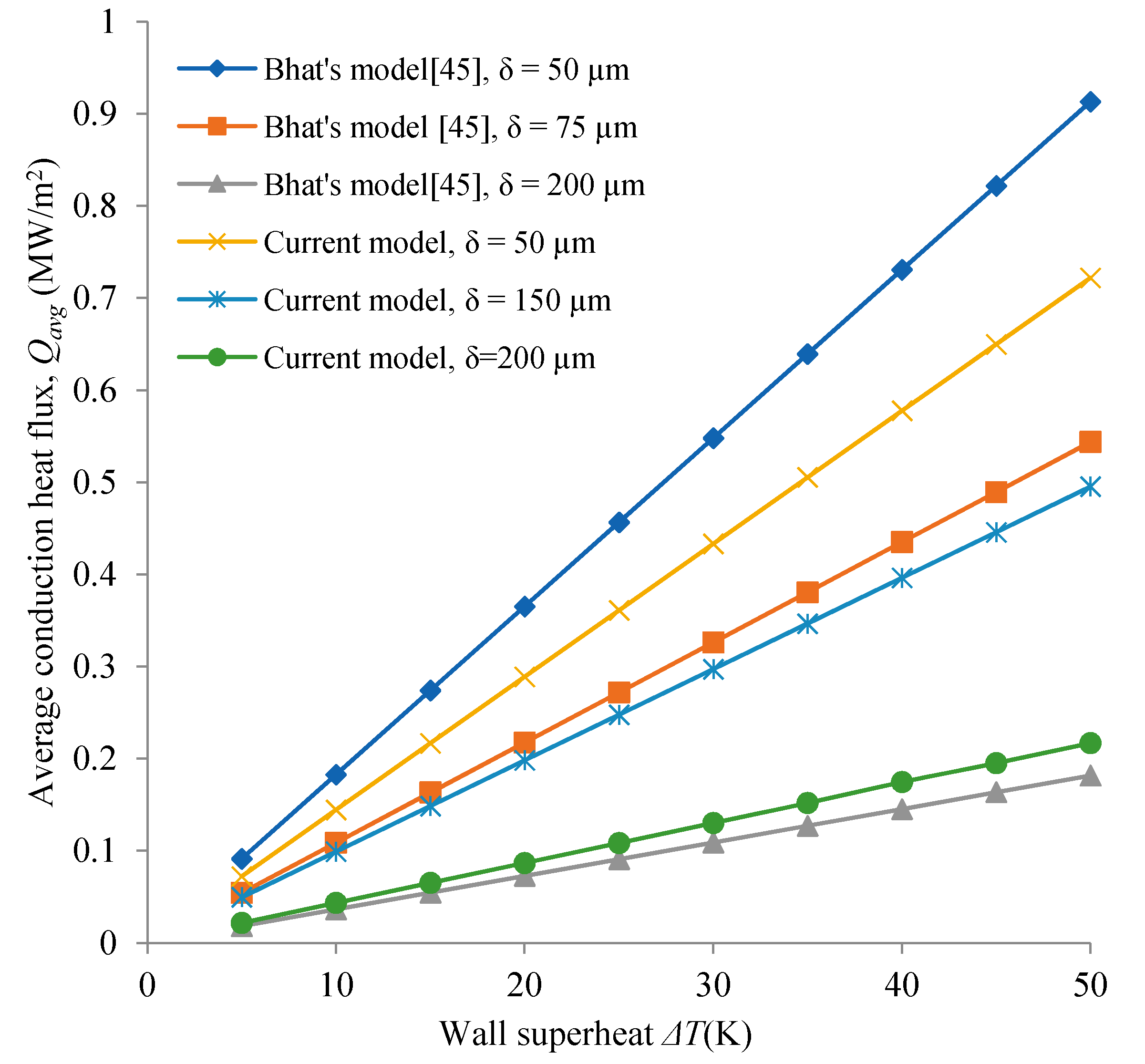

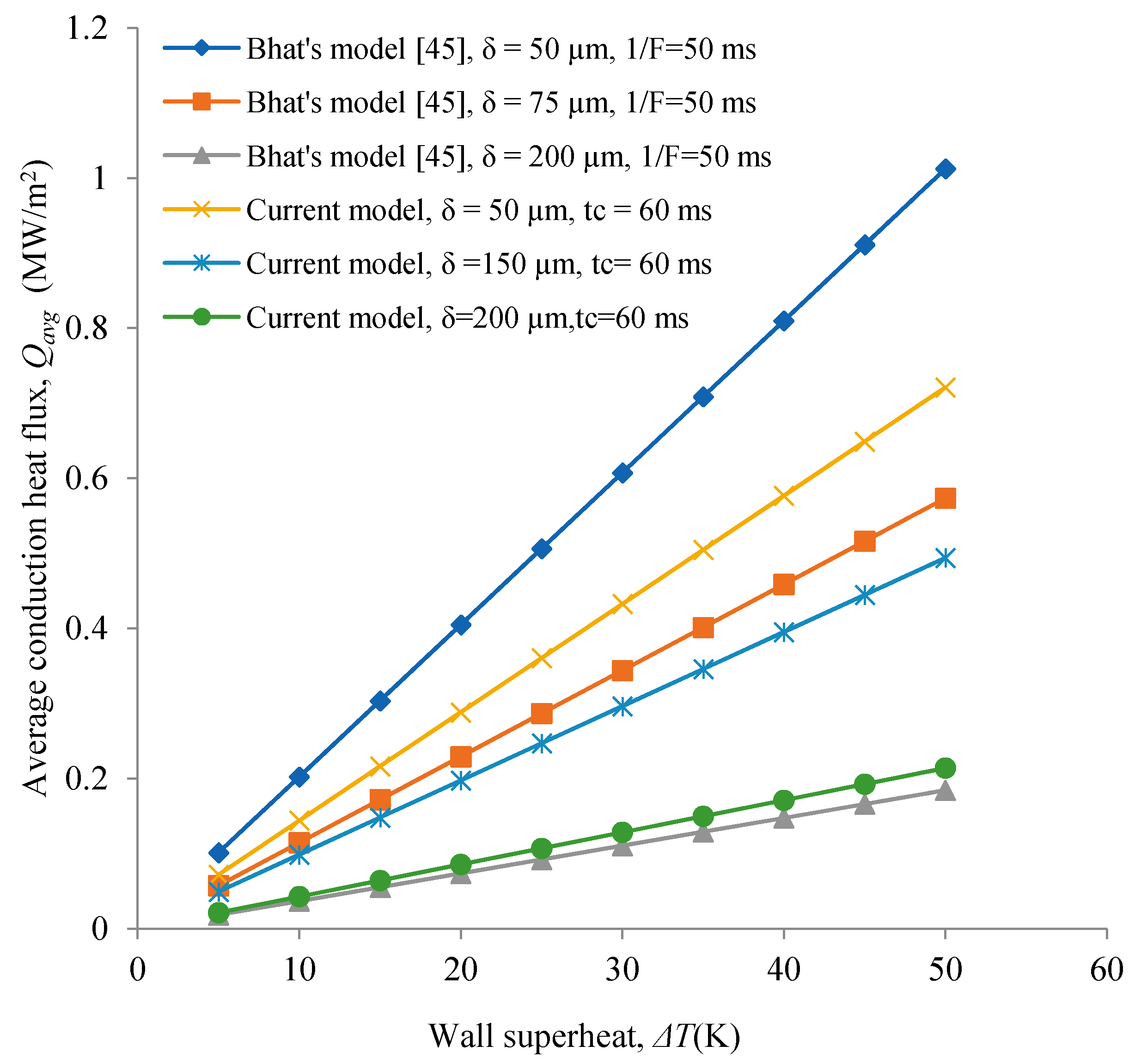

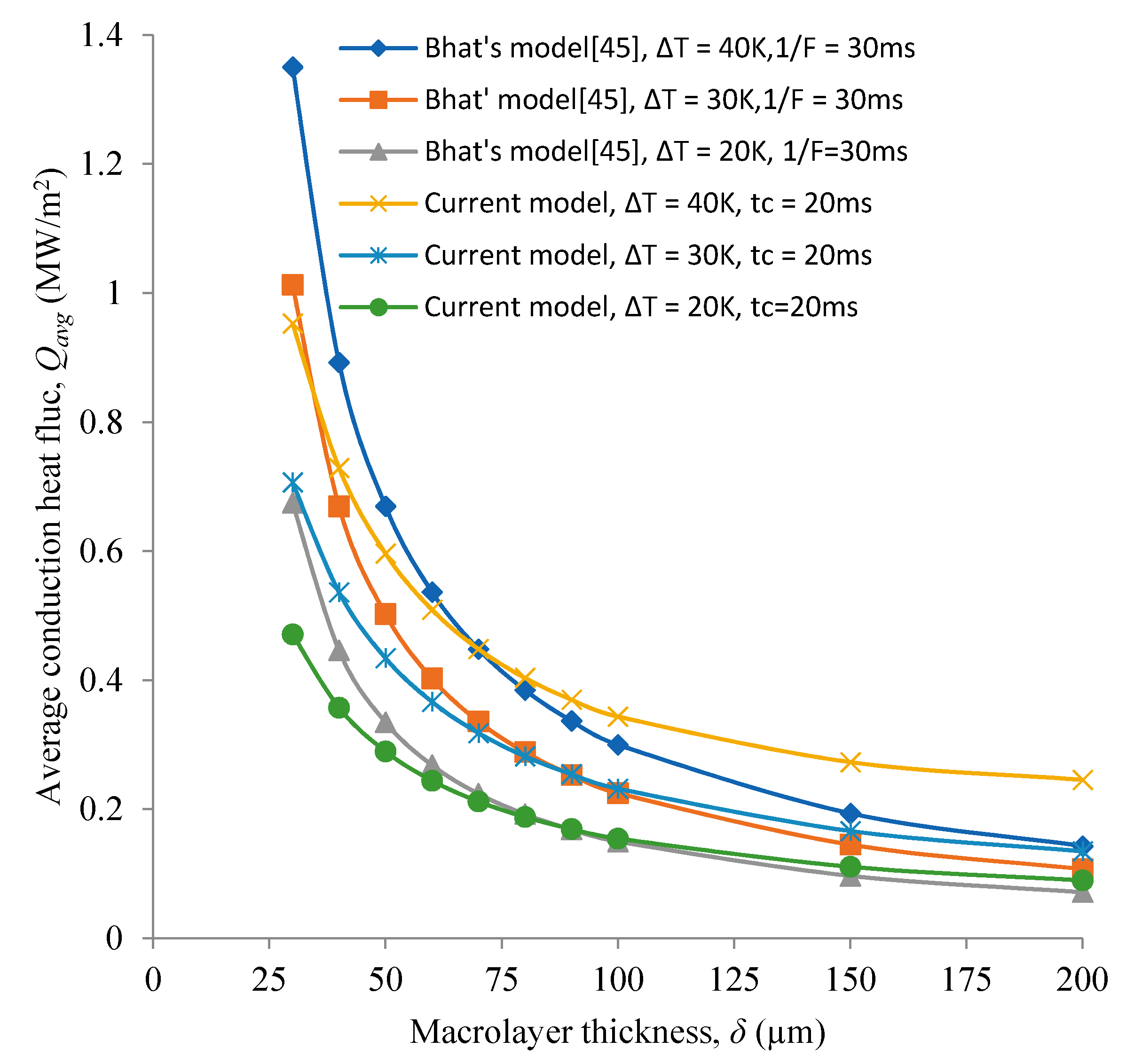

3.2. Average Conduction Heat Fluxes

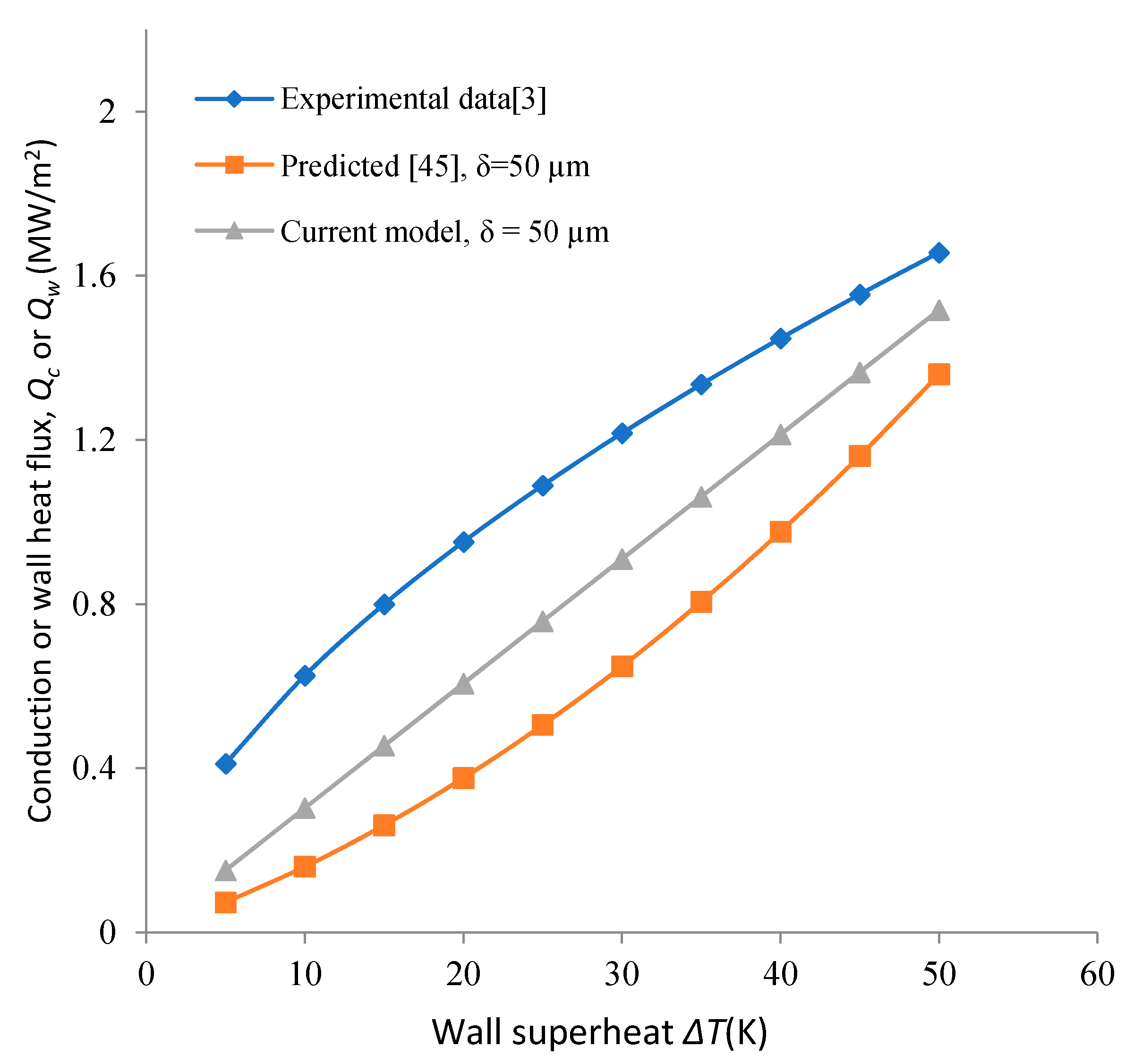

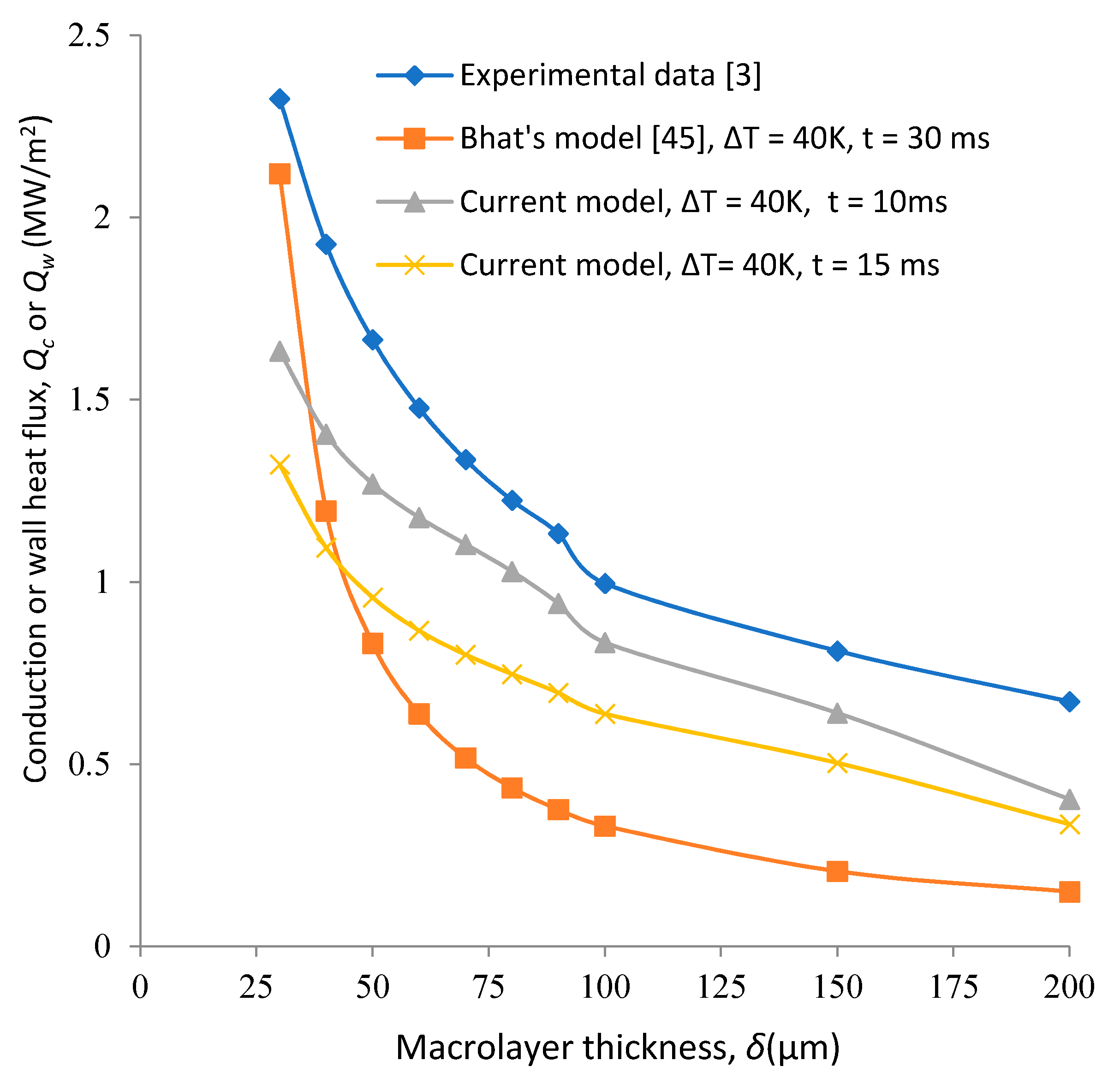

3.3. Model Validation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zuber, N. The Dynamics of Vapor Bubbles in Non uniform Temperature Fields. Int. J. Heat Mass Transf. 1961, 2, 83–98. [Google Scholar] [CrossRef]

- Gaertner, R.F. Photographic Study of Nucleate Pool Boiling on Horizontal Surface. ASME J. Heat Transf. 1965, 87, 17–29. [Google Scholar] [CrossRef]

- Bhat, A.M.; Prakash, R.; Saini, J.S. On the Mechanism of Macrolayer Formation in the Nucleate Pool Boiling at High Heat Flux. Int. J. Heat Mass Transf. 1983, 26, 735–740. [Google Scholar] [CrossRef]

- Gaertner, R.F.; Westwater, J.W. Population of Active Sites in Nucleate Boiling in Nucleate Boiling Heat Transfer. Chem. Eng. Prog. Symp. Se. 1960, 56, 39–48. [Google Scholar]

- Katto, Y.; Yokoya, S. Principle Mechanism of Boiling Crisis in Pool Boiling. Int. J. Heat Mass Transf. 1968, 11, 993–1002. [Google Scholar] [CrossRef]

- Moissis, R.; Berenson, P.J. On the hydrodynamic transition in nucleate boiling. ASME J. Heat Transf. 1953, 85, 221–229. [Google Scholar]

- Dhir, V.K. Mechanistic Prediction of Nucleate Boiling Heat Transfer-achievable of a Hopeless Task? J. Heat Transf. 2006, 128, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.M.; Pollack, J.; McCarthy, M. Increasing Boiling Heat Transfer using Low Conductivity Materials. Nat. Sci. Rep. 2016, 5, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Dhillon, N.S.; Buongiorno, J.; Varanasi, K.K. Critical Heat Flux Maxima During Boiling Crisis on Textured Surfaces. Nat. Commun. 2015, 6, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Rohsenow, W.M. A Method Correlating Heat Transfers Data for Surface Boiling Liquids. Trans. ASME 1952, 74, 876–969. [Google Scholar]

- Zuber, N. Nucleate Boiling—The Regions of Isolated Bubbles and Similarity with Natural Convection. Int. J. Heat Mass Transf. 1963, 6, 53–78. [Google Scholar] [CrossRef]

- Hoang, N.H.; Song, C.-H.; Chu, I.-C.; Euh, D.-J. A bubble dynamics-based model for wall heat flux portioning during nucleate pool boiling. Int. J. Heat Mass Transf. 2017, 112, 454–464. [Google Scholar] [CrossRef]

- Xu, J.J.; Lu, Z.Q. Boiling Heat Transfer and Gas Liquid Two Phase Flow; Nuclear Energy; China Atomic Energy Press: Beijing, China, 2001; pp. 64–68. [Google Scholar]

- Carey, V.P. Pool Boiling, Liquid-Vapor Phase-Change Phenomena: An Introduction to the Thermophysics of Vaporization and Condensation Process in Heat Transfer Equipment; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Rostamzadeh, A.; Jafarpur, K.; Rad, E.G. Numerical Investigation of Pool Boiling in Nanofluid with Lattice Boltzmann Method. J. Theor. Appl. Mech. 2016, 54, 811–825. [Google Scholar] [CrossRef] [Green Version]

- Gong, S.; Cheng, P. Numerical Simulation of Pool Boiling Heat Transfer on Smooth Surfaces with Mixed Wettability by Lattice Boltzmann Method. Int. J. Heat Mass Transf. 2015, 80, 206–216. [Google Scholar] [CrossRef]

- Pezo, M.L.; Stevanovic, V.D. Numerical Prediction of Nucleate Pool Boiling Heat Transfer Coefficient under High Heat Fluxes. Therm. Sci. 2016, 20, 113–123. [Google Scholar] [CrossRef]

- Gupta, R.R.; Bhambi, S.; Agarwal, V.K. CFD modeling of nucleate bool boiling of nanofluids. Numer. Heat Transf. A 2019, 75, 402–412. [Google Scholar] [CrossRef]

- Son, G.; Dhir, V.K. Numerical Simulation of Nucleate Boiling on Horizontal Surfaces at High Heat Fluxes. Int. J. Heat Mass Transf. 2008, 54, 2566–2582. [Google Scholar] [CrossRef]

- Deb, S.; Das, M.; Das, D.C.; Pal, S.; Das, A.K. Significance of surface modifications on nucleate pool boiling heat transfer characteristics of refrigerant R-141b. Int. J. Heat Mass Transf. 2021, 170, 120994. [Google Scholar] [CrossRef]

- Nunes, J.M.; de Souza, R.R.; Rodrigues, A.R.; Safaei, M.R.; Cardoso, E.M. Influence of coated surface and gap size on boiling heat transfer of deionized water. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–14. [Google Scholar] [CrossRef]

- Safaei, M.R.; Tlili, I.; Gholamalizadeh, E.; Abbas, T.; Alkanhal, T.A.; Goodarzi, M.; Dahari, M. Thermal analysis of a binary base fluid in pool boiling system of glucol-water alumina naon-suspension. J. Therm. Anal. Calorim. 2021, 143, 2453–2462. [Google Scholar] [CrossRef]

- Stojanovic, A.; Stevanovic, V.; Petrovic, M.; Zivkovic, D. Numerical Study of Heat Transfer During Nucleate Pool Boiling. Adv. Technol. 2016, 5, 73–80. [Google Scholar] [CrossRef] [Green Version]

- Lee, G.L.; Law, M.C.; Lee, V.C.-C. Model development and simulation of nucleate pool boiling in openFOAM: Boiling physics in bulk liquid and role of freeboard region. Int. J. Therm. Sci. 2019, 140, 255–279. [Google Scholar] [CrossRef]

- He, Y.; Shoji, M.; Maruyama, S. Numerical Study of High Heat Flux Pool Boiling Heat Transfer. Int. J. Heat Mass Transf. 2001, 44, 2357–2373. [Google Scholar] [CrossRef]

- Jia, H.W.; Zhang, P.; Fu, X.; Jiang, S.C. A Numerical Investigation of Nucleate Boiling at a Constant Surface Temperature. Appl. Therm. Eng. 2015, 88, 248–257. [Google Scholar] [CrossRef]

- Sato, Y.; Niceno, B. A depletable micro-layer model for nucleate boiling. J. Comput. Phys. 2015, 300, 20–52. [Google Scholar] [CrossRef]

- Xiaobin, Z.; Wei, X.; Jianye, C.; Yuchen, W.; Tang, K. CFD Simulations and Experimental Verification on Nucleate Pool Boiling of Liquid Nitrogen. Phys. Procedia 2015, 67, 569–575. [Google Scholar] [CrossRef] [Green Version]

- Sanna, A.; Hutter, C.; Kenning, D.B.R.; Karayiannis, T.G.; Sefiane, K.; Nelson, R.A. Numerical Investigation of Nucleate Boiling Heat Transfer. Int. J. Heat Mass Transf. 2014, 76, 45–64. [Google Scholar] [CrossRef] [Green Version]

- Georgoulas, A.; Andredaki, M.; Marengo, M. An enhance VOF method with heat transfer and phase change to characterize bubble detachment in saturated pool boiling. Energy 2017, 10, 1–35. [Google Scholar]

- Chouarfa, F.; Benhamza, M.E.H.; Bendjaballah, M. New Model of Heat Transfer in the Process of Nucleate Boiling in Pool: Prediction and Assessment. J. Eng. Phys Thermophys. 2014, 87, 743–752. [Google Scholar] [CrossRef]

- Utaka, Y.; Kashiwabara, Y.; Ozaki, M.; Chen, Z. Heat Transfer Characteristics Based on Microlayer Structure in Nucleate Pool Boiling for Water and Ethanol. Int. J. Heat Mass Transf. 2014, 68, 479–488. [Google Scholar] [CrossRef] [Green Version]

- Hameed, M.S.; Khan, A.R.; Mahdi, A. Modeling a General Equation for Pool Boiling Heat Transfer. Adv. Chem. Eng. Sci. 2013, 3, 294–303. [Google Scholar] [CrossRef] [Green Version]

- Suriyawong, A.; Dalkilic, A.S.; Wongwises, S. Nucleate Pool Boiling Heat Transfer Correlations for TiO2-water Nanofluids. J. ASTM Int. 2012, 9, 1–12. [Google Scholar] [CrossRef]

- Chu, H.; Yu, B. A New Comprehensive Model for Nucleate Pool Boiling of Pure Liquid at Low to High Heat Flux Including CHF. Int. J. Heat Mass Transf. 2009, 52, 4203–4210. [Google Scholar] [CrossRef]

- Mukherjee, A.; Kandlikar, S.G. Numerical Study of Single Bubbles with Dynamic Contact Angle during Nucleate Pool Boiling. Int. J. Heat Mass Transf. 2007, 50, 127–138. [Google Scholar] [CrossRef]

- Kandlikar, S.G. A Theoretical Model to Predict Pool Boiling CHF Incorporating Effects of Contact Angle and Orientation. ASME J. Heat Transf. 2001, 123, 1071–1079. [Google Scholar] [CrossRef]

- Maruyama, M.; Shoji, M.; Shimizu, S.A. Numerical Simulation of Transition Boiling, Heat Transfers. In Proceedings of the 2nd JSME-KSME Thermal Engineering Conference, Kitakyushu, Japan, 19–21 October 1992; pp. 345–348. [Google Scholar]

- Zhao, Y.H.; Masuoka, T.; Tsuruta, T.M. Theoretical Studies on Transient Pool Boiling Based on Microlayer Model. Trans. JSME B 1997, 63, 218–223. [Google Scholar] [CrossRef] [Green Version]

- Haramura, Y.; Katto, Y. A New Hydrodynamic Model of Critical Heat Flux Applicable Widely to Both Pool and Forced Convection Boiling on Submerged Bodies in Saturated Liquid. Int. J. Heat Mass Transf. 1983, 26, 389–399. [Google Scholar] [CrossRef]

- Pan, C.; Hwang, J.Y.; Lin, T.L. The Mechanism of Heat Transfer in Transition Boiling. Int. J. Heat Mass Transf. 1989, 32, 1337–1349. [Google Scholar]

- Zuber, N. On the stability of boiling heat transfer. Trans. ASME 1985, 80, 711–720. [Google Scholar]

- Dhir, V.K.; Liaw, S.P. Framework for Unified Model for Nucleate and Transition Pool Boiling. ASME J. Heat Transf. 1989, 111, 739–746. [Google Scholar] [CrossRef]

- Bhat, A.M.; Saini, J.S.; Prakash, R. Role of Macrolayer Evaporation in Pool Boiling at High Heat Flux. Int. J. Heat Mass Transf. 1986, 29, 1953–1961. [Google Scholar] [CrossRef]

- Bhat, A.M.; Prakash, R.; Saini, J.S. Heat Transfer in Nucleate Pool Boiling at High Heat Flux. Int. J. Heat Mass Transf. 1983, 26, 833–840. [Google Scholar] [CrossRef]

- Prasad, N.R. Investigation on Pool Boiling Heat Transfer in High Heat Flux. Ph.D. Thesis, University of Roorkee, Roorkee, India, 1984. [Google Scholar]

- Jairajpuri, A.M.; Saini, J.S. A New Model for Heat Flow Through Macrolayer in Pool Boiling at Heat Flux. Int. J. Heat Mass Transf. 1991, 34, 1579–1591. [Google Scholar] [CrossRef]

- Danish, M.; Mesfer, M.K.A. Analytical Solution of Nucleate Pool Boiling Heat Transfer Model Based on Macrolayer. Heat Mass Transf. 2018, 54, 313–324. [Google Scholar] [CrossRef]

- Prasad, N.R.; Saini, J.S.; Prakash, R. The Effect of Heater Wall Thickness on Heat Transfer in Nucleate Pool Boiling at High Heat Flux. Int. J. Heat Mass Transf. 1985, 28, 1367–1375. [Google Scholar] [CrossRef]

- Bhat, A.M. Studies on Bubble Dynamics and Heat Transfer in Nucleate Pool Boiling at High Heat Flux. Ph.D. Thesis, University of Roorkee, Roorkee, India, 1982. [Google Scholar]

- Zhang, C.; Cheng, P. Mesoscale Simulations of Boiling Curves and Boiling Hysteresis under Constant Wall Temperature and Constant Heat Flux Conditions. Int. J. Heat Mass Transf. 2017, 110, 319–329. [Google Scholar] [CrossRef]

- Huger, G.; Tanguy, S.; Sagan, M.; Coiln, C. Direct Numerical Simulation of Nucleate Pool Boiling at Large Microscopic Contact Angle and Moderate Jakob Number. Int. J. Heat Mass Transf. 2017, 113, 662–682. [Google Scholar]

- Salehi, H.; Hormozi, F. Numerical Study of Silica-water Based Nanofluid Nucleate Pool Boiling by Two-phase Eulerian Scheme. Heat Mass Transf. 2018, 54, 773–784. [Google Scholar] [CrossRef]

- Ma, X.; Cheng, P.; Gong, S.; Quan, X. Mesoscale Simulations of Saturated Pool Boiling Heat Transfer under Microgravity Conditions. Int. J. Heat Mass Transf. 2017, 114, 453–457. [Google Scholar] [CrossRef]

- Zhang, L.; Fan, L.; Yu, Z.; Cen, K. An Experimental Investigation of Transient Pool Boiling of Aqueous Nanofluids with Graphene Oxide Nanosheets as Characterized by the Quenching Method. Int. J. Heat Mass Transf. 2014, 73, 410–414. [Google Scholar] [CrossRef]

- Kim, J.M.; Kim, J.H.; Park, S.C.; Kim, M.H.; Ahn, H.S. Nucleate Boiling in Graphene Oxide Colloids: Morphological Change and Critical Heat Flux Enhancement. Int. J. Multiph. Flow 2015, 85, 209–222. [Google Scholar] [CrossRef]

- Das, S.; Saha, B.; Bhaumik, S. Experimental Study of Nucleate Pool Boiling Heat Transfer of Water by Surface Functionalization with SiO2 Nanostructure. Exp. Therm. Fluid Sci. 2017, 81, 454–465. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Pool Boiling Critical Heat Flux (CHF)—Part 1: Review of Mechanism, Models and Correlations. Int. J. Heat Mass Transf. 2018, 117, 1352–1367. [Google Scholar] [CrossRef]

- Kiyomura, I.S.; Mogaji, T.S.; Manetti, L.L.; Cardoso, E.M. A Predictive Model for Confined and Unconfined Nucleate Boiling Heat Transfer Coefficient. Appl. Therm. Eng. 2017, 127, 1274–1284. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Wu, F.; Utaka, Y. Numerical Simulation of Thermal Property Effect on Bubble Growth with Microlayer Evaporation during Nucleate Pool Boiling. Int. J. Heat Mass Transf. 2018, 118, 989–996. [Google Scholar] [CrossRef]

- Dang, C.; Jio, L.; Peng, Q.; Qian, H.; Zhang, X. Experimental and Analytical Study on Nucleate Pool Boiling Heat Transfer of R134a/R245fa Azeotropic Mixtures. Int. J. Heat Mass Transf. 2018, 119, 508–522. [Google Scholar] [CrossRef]

- Mori, S.; Utaka, Y. Critical Heat Flux Enhancement by Surface Modification in a Saturated Pool Boiling—A Review. Int. J. Heat Mass Transf. 2017, 108, 2534–2557. [Google Scholar] [CrossRef]

- Li, R.; Huang, Z. A New CHF Model for Enhanced Pool Boiling Heat Transfer on Surfaces with Micro-Scale Roughness. Int. J. Heat Mass Transf. 2017, 108, 1084–1093. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Danish, M.; Al Mesfer, M.K.; Ansari, K.B.; Hasan, M.; Amari, A.; Azeem, B. Predicting Conduction Heat Flux through Macrolayer in Nucleate Pool Boiling. Energies 2021, 14, 3893. https://doi.org/10.3390/en14133893

Danish M, Al Mesfer MK, Ansari KB, Hasan M, Amari A, Azeem B. Predicting Conduction Heat Flux through Macrolayer in Nucleate Pool Boiling. Energies. 2021; 14(13):3893. https://doi.org/10.3390/en14133893

Chicago/Turabian StyleDanish, Mohd, Mohammed K. Al Mesfer, Khursheed B. Ansari, Mudassir Hasan, Abdelfattah Amari, and Babar Azeem. 2021. "Predicting Conduction Heat Flux through Macrolayer in Nucleate Pool Boiling" Energies 14, no. 13: 3893. https://doi.org/10.3390/en14133893

APA StyleDanish, M., Al Mesfer, M. K., Ansari, K. B., Hasan, M., Amari, A., & Azeem, B. (2021). Predicting Conduction Heat Flux through Macrolayer in Nucleate Pool Boiling. Energies, 14(13), 3893. https://doi.org/10.3390/en14133893