Study of the Thermochemical Properties of Lignocellulosic Biomass from Energy Crops

Abstract

:1. Introduction

1.1. Context of Biomass Energy

1.2. Wood Fuels and Forest Crops

1.3. Advantages and Drawback of Energy Crops

- -

- Around 90% reduction of CO2 emissions [15]. Part of the CO2 emissions generated in the combustion process is previously immobilized in the biomass structure during its growth associated with photosynthesis. This balance is known as Life Cycle Analysis, being a disagreement in bibliography related to the CO2 percentage “captured” by the plants.

- -

- The use of biomass is not dependent on intermittent weather, such as solar or wind energy.

- -

- Contribution to forest maintenance (reduction of the risk of forest fires and pests) and agriculture (use of set-aside land, reduction of erosion).

- -

- Reduction in SO2 and NOx emissions due to the low content of sulfur and nitrogen in the elemental composition of the biomass.

- -

- Socio-economic development of rural areas: job creation, development of processing and distribution industries, strengthening of agricultural markets, fixing of rural population.

- -

- The handling and management (collection, transport, planting, phytosanitary treatments etc.) implies in turn a significant consumption of energy from fossil sources and high production costs.

- -

- The reduction in CO2 emissions is lower than expected (up to 90% with respect to the emissions generated in the combustion of fossil fuels [16]).

- -

- Impossibility of total replacement of fossil fuels with fuel produced from biomass due to limited availability of farmland.

- -

- Possible alteration of biodiversity because of the introduction of alien species and large areas of monoculture.

- High heating value and quality of the fuel.

- High biomass production in dry basis.

- High youth growth.

- Narrow cups and/or large size of leaves at the top.

- Very fast-growing species.

- Very broad genetic base.

- Brief improvement cycles.

- Ease of vegetative multiplication.

- Regrowth after cutting.

- Adaptability to different soils and climates.

- Resistance to biotic and abiotic stress.

- Low ash content.

- Tolerance to high densities.

2. Materials and Methods

2.1. Plant Material and Location

- -

- Clone I-214 belongs to the species Populus deltoides x Populus nigra, called Populus x Euroamericana (Dode) Clone Guinier I-214 [20].

- -

- Clone AF2 belongs to the species Populus deltoides 145-86 x Populus nigra 40 called Populus x canadensis Mönch [21],

- -

- Ballotino clone belongs to the species Populus x canadensis Mönch, and according to some authors it is called Ballottino [22],

- -

- Clone Monviso belongs to the species Populus x generosa 103-86 (Populus deltoides 583 x Populus trichocarpa 196) x Populus nigra 715-86 (Populus nigra 12 x Populus nigra 7), briefly indicated as Populus x generosa x Populus nigra clone Monviso [21], finally,

- -

- The clone Viriato, which is the least known, belongs to the species Populus deltoides Marsh 20.

2.2. Design and Management of Plantation

3. Results and Discussion

3.1. Natural Air-Drying

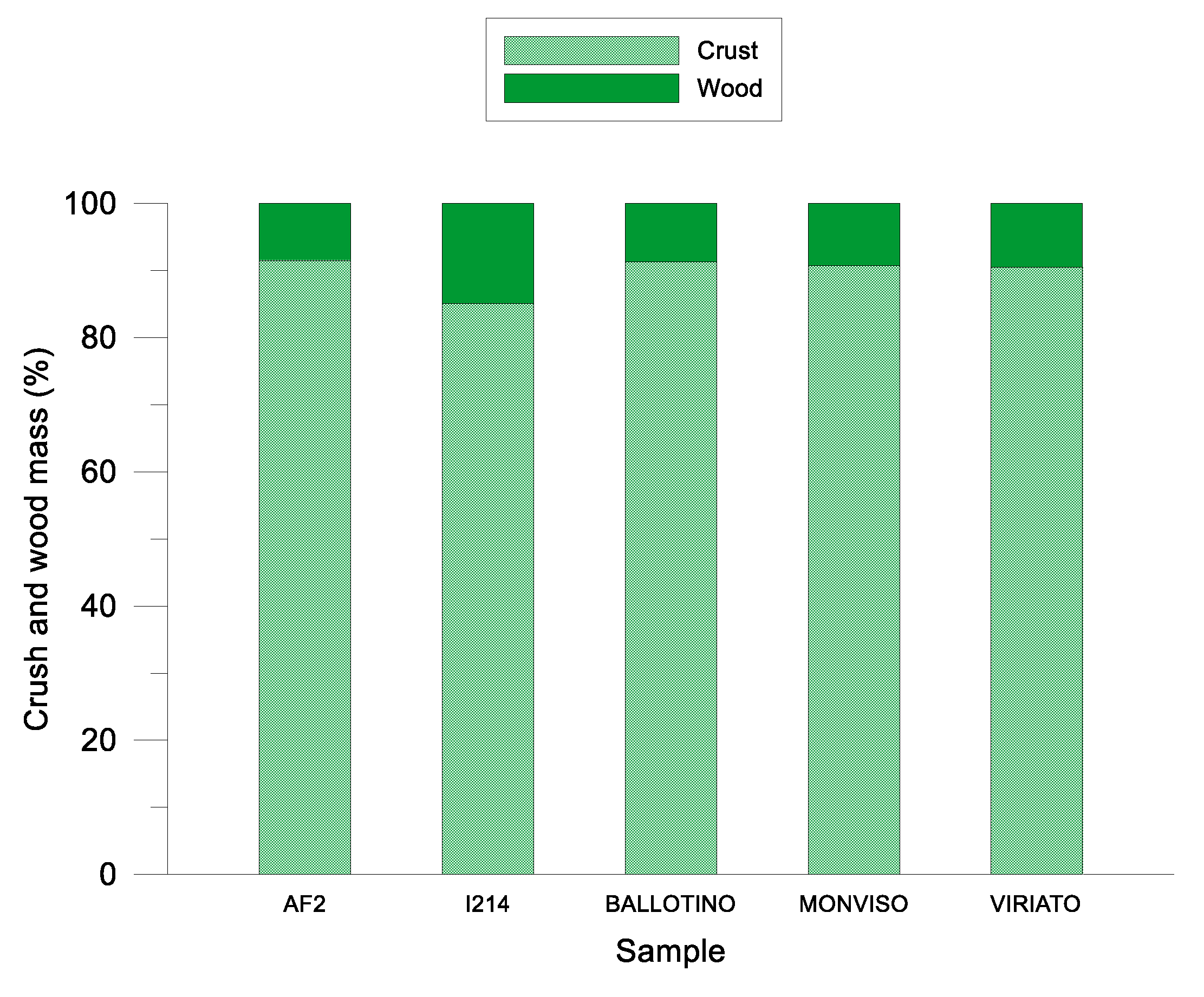

3.2. Samples Crust Content

3.3. Methodology and Standards of the Composition and Properties Measured

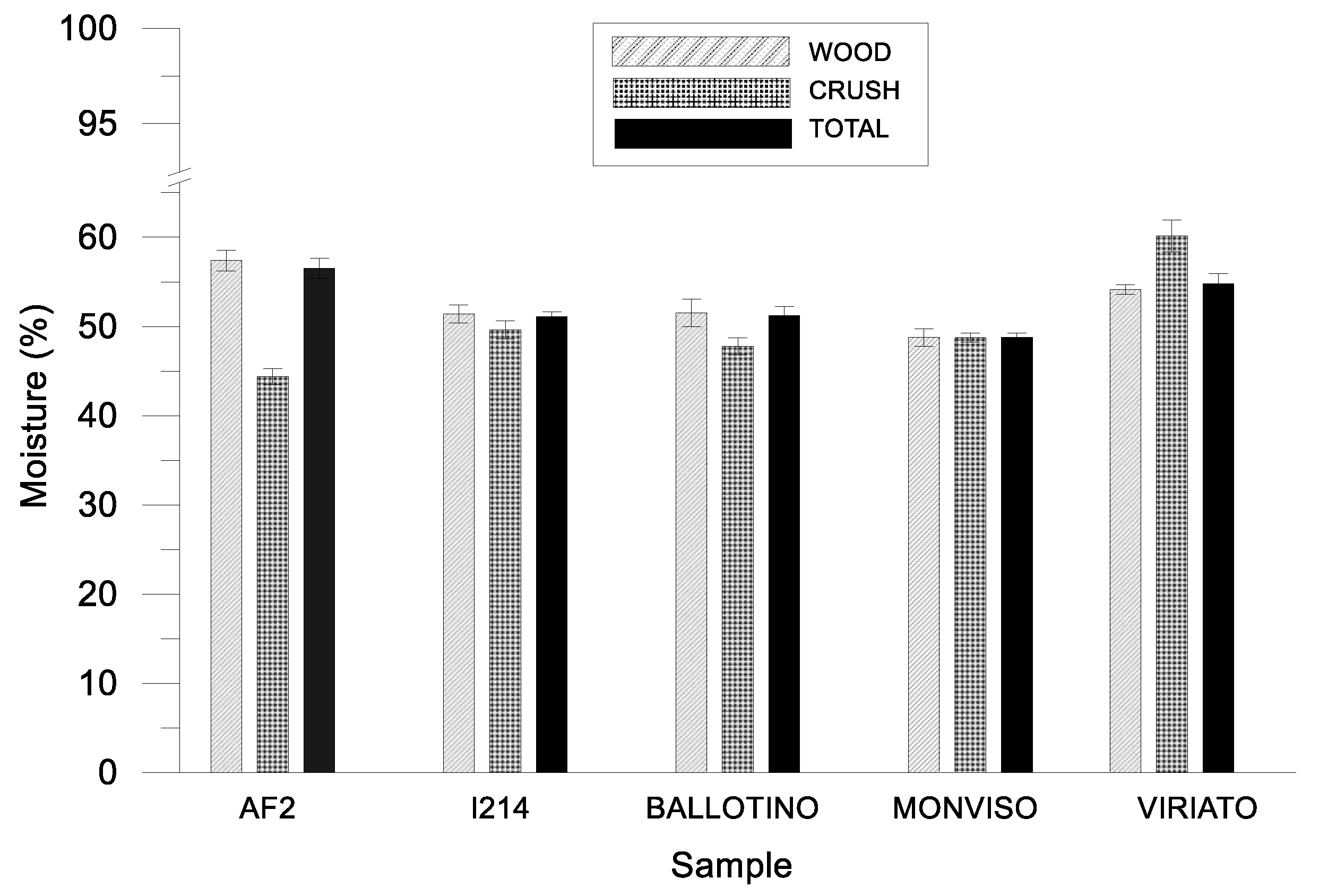

3.4. Moisture Content

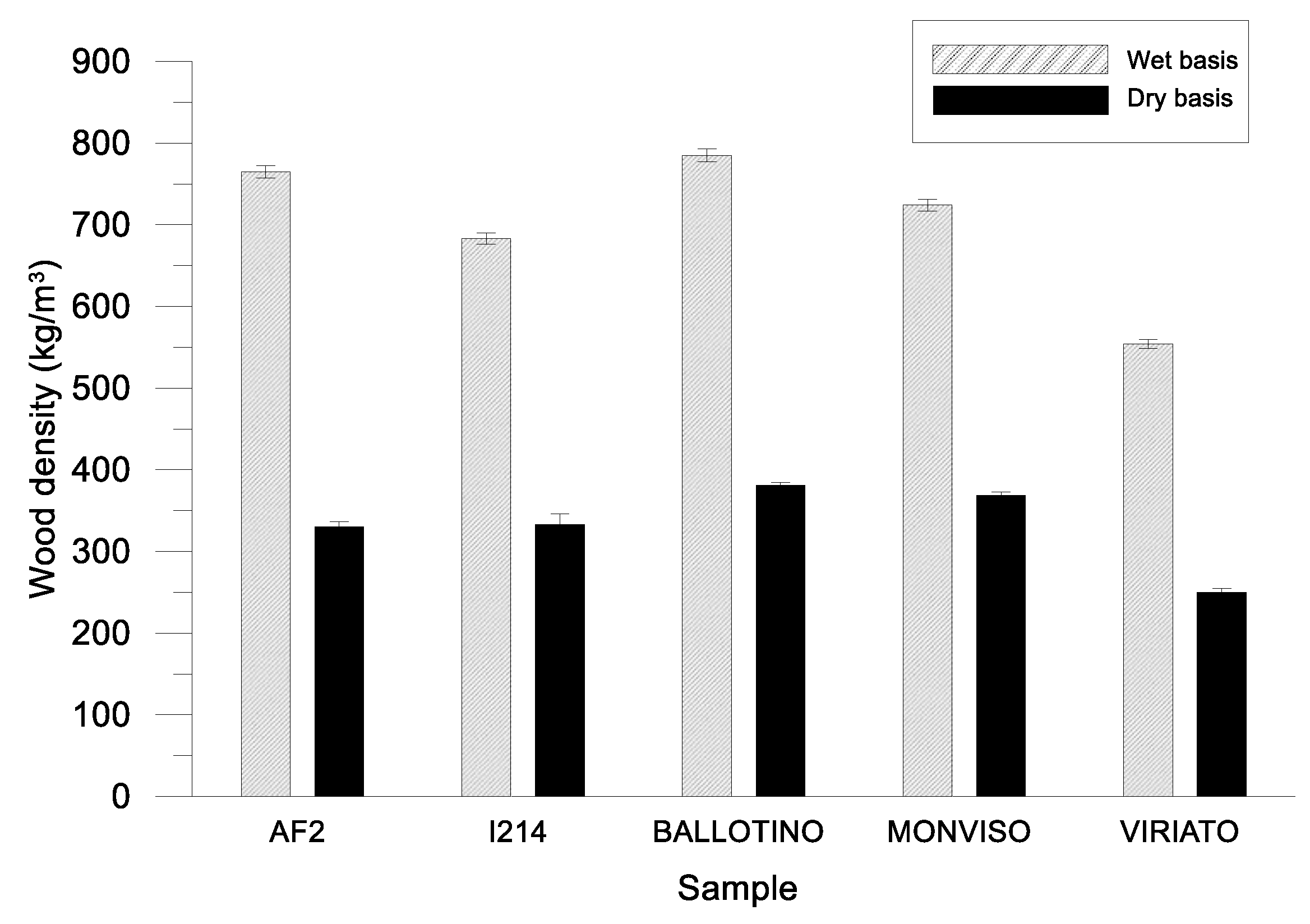

3.5. Density of Wood Samples

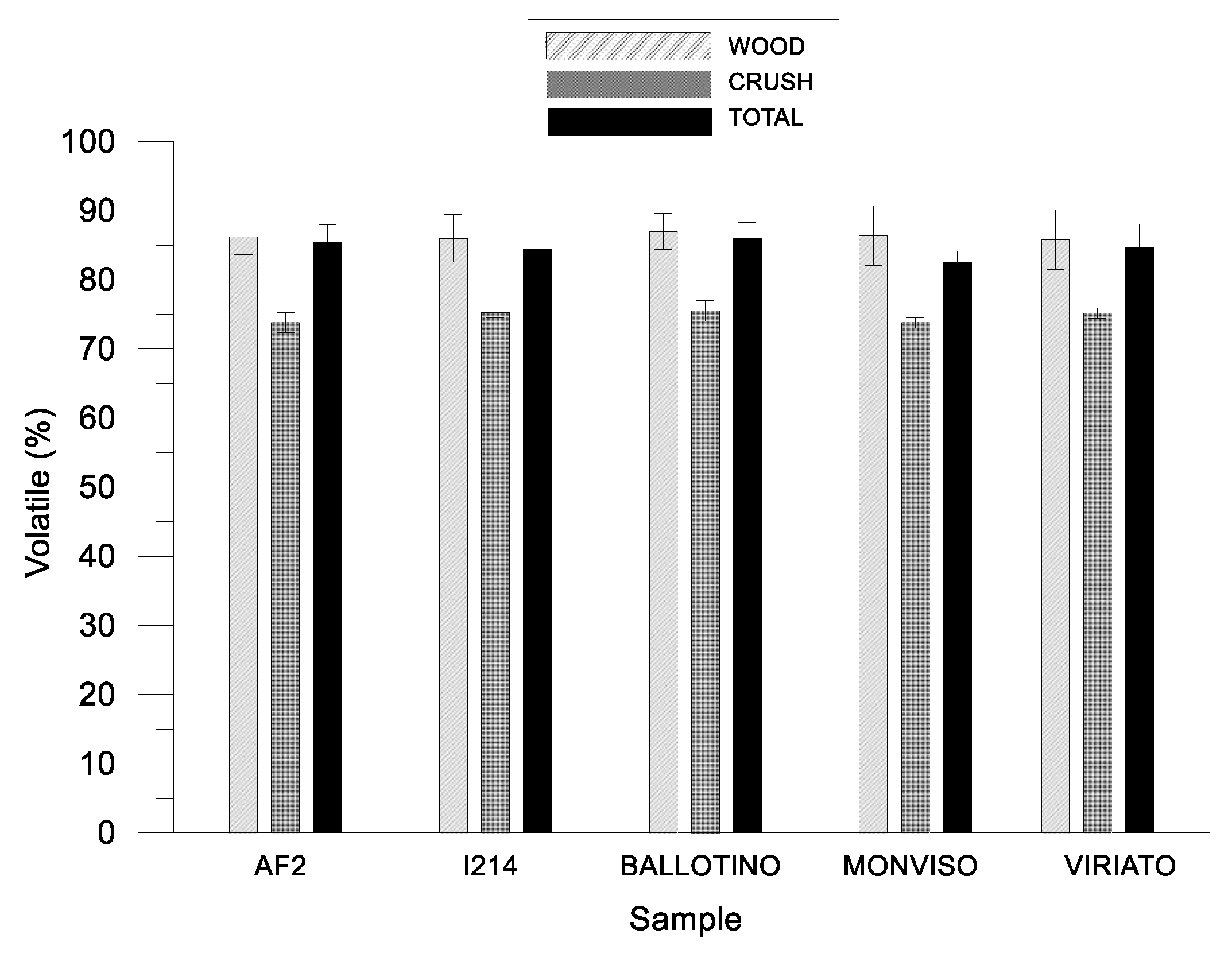

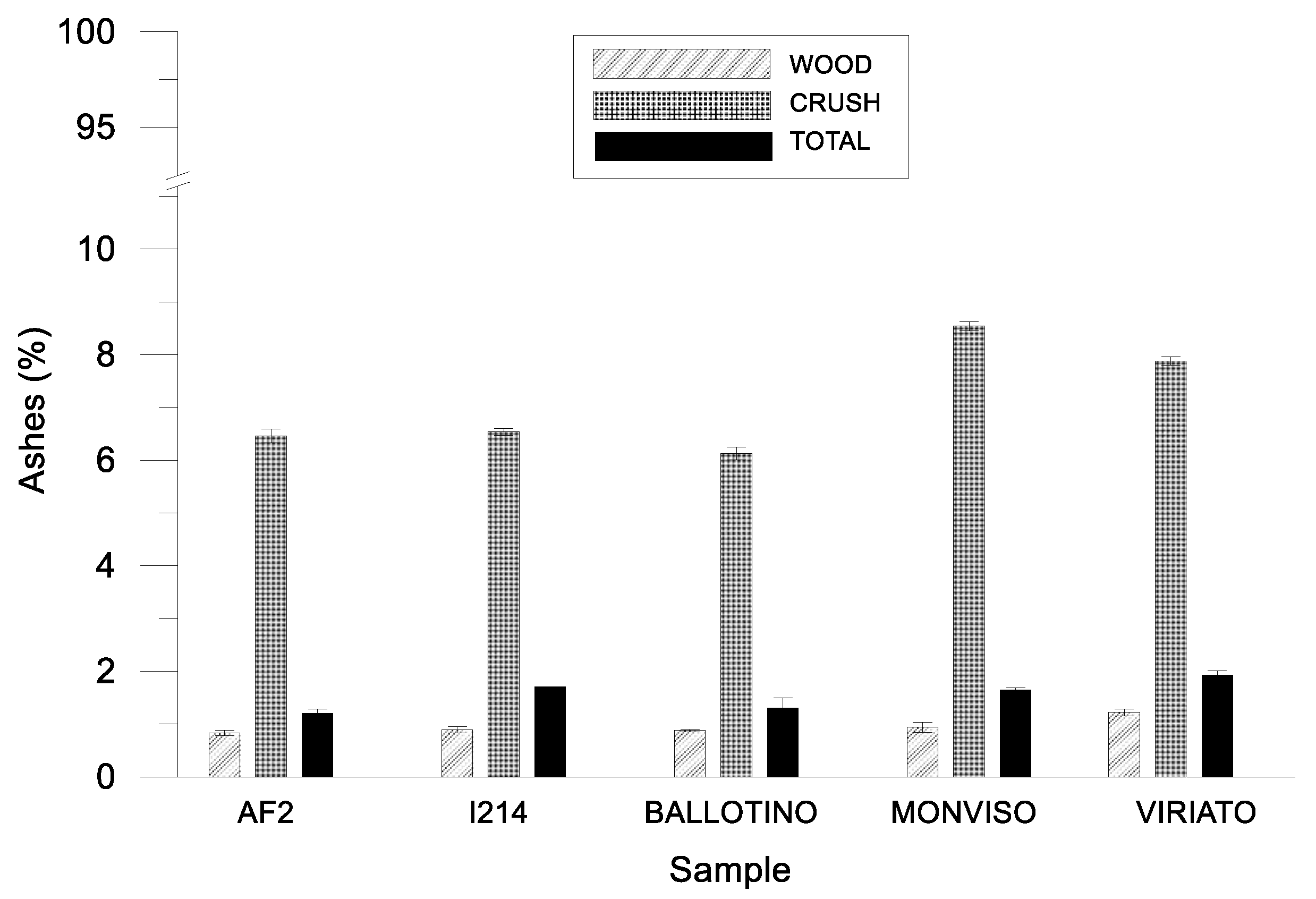

3.6. Proximate Analysis

3.7. Elemental Analysis

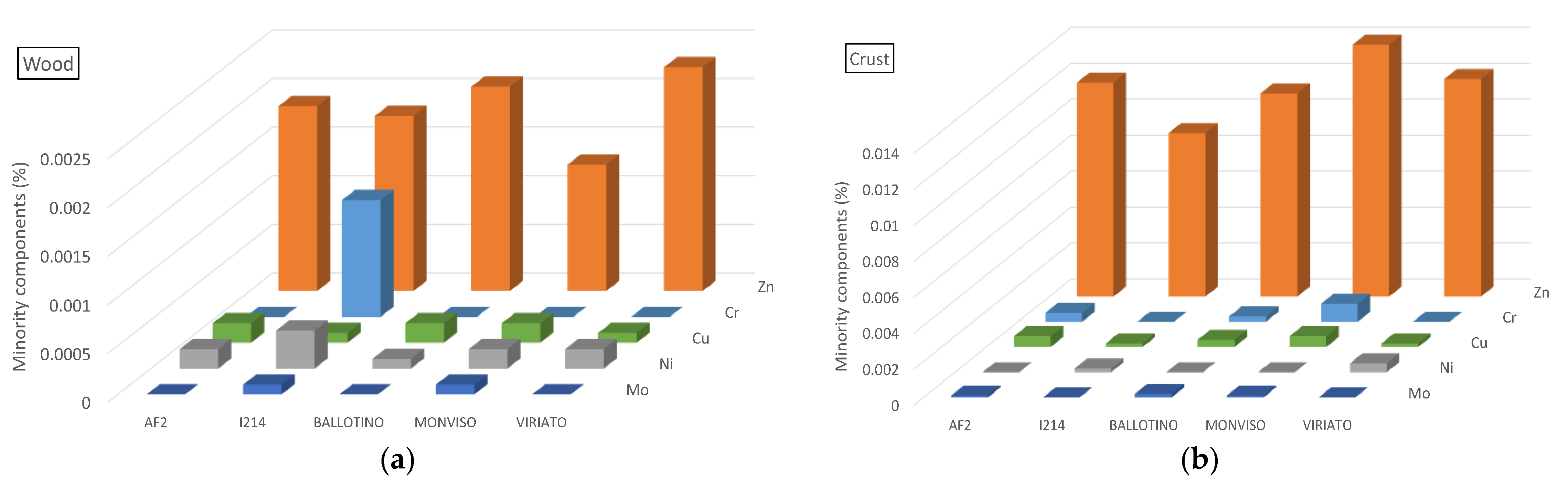

3.8. Analysis of Majority and Minority Elements

- -

- Firstly, the majority compounds present in the samples analyzed are: Ca, followed by K, Mg, Si, P and Al (Figure 7a,b). Regarding the crust, Al acquires a relevant importance (Figure 7c,d) which may be due to the fact Al is toxic to plants, being eliminated and becoming part of the crust. Additionally, since Al is part of the clays (land where the plantation is located) it may be deposited in the crust.

- Flux material in ceramics, being applied as a flux due to its potassium content.

- The amount of potassium, magnesium and phosphorus present in the ash makes it interesting to use it as a soil nutrient for agricultural use.

- This possible application in agriculture is possible thanks to Ca content of the ashes for correction of acidic soils.

- The low content of heavy metals must be evaluated according to the destination of the ashes (dumping or different uses), taking into account the limits allowed for said destination.

- Na and K, which in combination with S and Cl cause ash deposition and fusion problems and increase corrosion.

- K reduces the melting point of the ashes and can cause jams. It’s the high content of this element may be of interest in applications as a flux in ceramic or its use as fertilizers.

- Content of majority and minority elements affects the operation of reactors and boilers (such as in controlling the temperatures of the superheaters) and the maintenance of the plant (periodic cleaning). Other elements such as Mg, Ca, and P increase the melting point of the ash and facilitate the retention of contaminants in them.

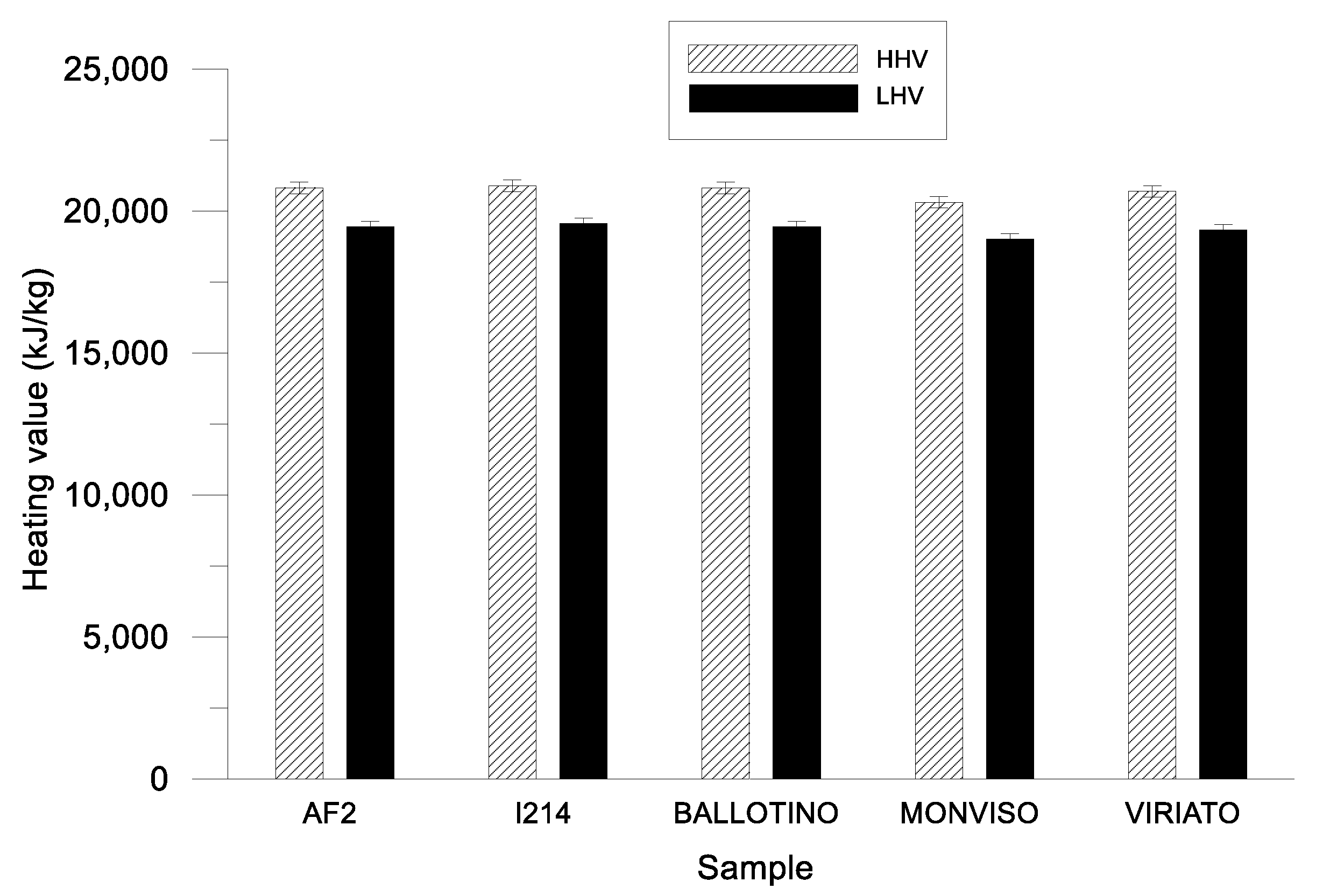

3.9. Heating Value

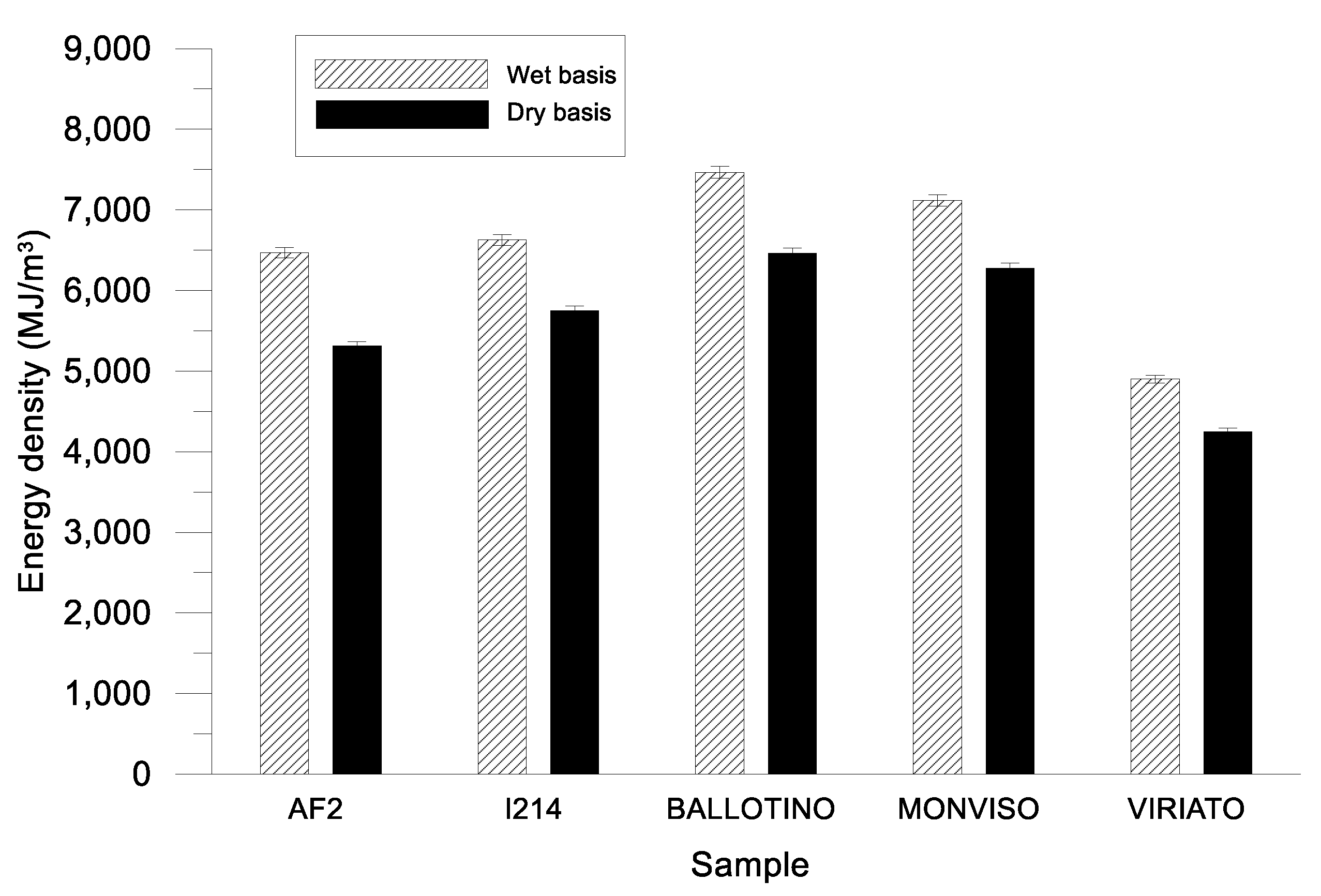

3.10. Wood Energy Density (MJ/m3)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Renewable Energy: White Paper Laying Down a Community Strategy and Action Plan. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=LEGISSUM%3Al27023 (accessed on 5 May 2021).

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:140:0016:0062:en:PDF (accessed on 5 May 2021).

- Institute for Diversification and Energy Saving, Ministry of Industry, Tourism and Commerce, Government of Spain. Biomass Energy. Biomass: Gasification 2007. Available online: https://www.idae.es/sites/default/files/documentos/publicaciones_idae/documentos_10737_biomasa_gasificacion_07_d2adcf3b.pdf (accessed on 5 May 2021).

- Trossero, M.A. An Overview of Woodfuel Issues at the Beginning of the Twenty-First Century—Problems and Opportunities. FAO’s Wood Energy Information System. Available online: https://www.semanticscholar.org/paper/Wood-energy%3A-the-way-ahead.-Trossero/0c14d5392b9fffc7d3dfb0eb8aa40f64b39f0714?p2df (accessed on 5 May 2021).

- Qian, X.; Lee, S.; Chandrasekaran, R.; Yang, Y.; Caballes, M.; Alamu, O.; Chen, G. Evaluation and Emission Characteristics of Poultry Litter Co-Combustion Process. Appl. Sci. 2019, 9, 4116. [Google Scholar] [CrossRef] [Green Version]

- Borek, K.; Romaniuk, W.; Roman, K.; Roman, M.; Kuboń, M. The Analysis of a Prototype Installation for Biogas Production from Chosen Agricultural Substrates. Energies 2021, 14, 2132. [Google Scholar] [CrossRef]

- Prasertsan, S.; Sajjakulnukit, B. Biomass and biogas energy in Thailand: Potential, opportunity and barriers. Renew. Energy 2006, 31, 599–610. [Google Scholar] [CrossRef]

- Qian, X. Statistical Analysis and Evaluation of the Advanced Biomass and Natural Gas Co-Combustion Performance. Ph.D. Thesis, Morgan State University, Baltimore, MD, USA, 2019. [Google Scholar]

- Institute for the Diversification and Saving of Energy, Ministry of Industry, Tourism and Commerce, Government of Spain. Renewable Energy Plan 2005-2010. 2005. Available online: https://www.iea.org/policies/4431-renewable-energy-plan-2005-2010 (accessed on 6 May 2021).

- Cabrera, M.; Vera, A.; Cornejo, J.M.; Ordás, I.; Tolosana, E.; Ambrosio, Y.; Martínez, I.; Vignote, S.; Hotait, N.; Lafarga, A.; et al. Evaluation of the Energy Potential of Biomass. Technical Study PER 2011-2020 Madrid. 2011. Available online: https://www.idae.es/uploads/documentos/documentos_11227_e14_biomasa_A_8d51bf1c.pdf (accessed on 6 May 2021).

- Ministry of Industry, Tourism and Commerce. Government of Spain. IDAE Institute for Energy Diversification and Saving “Renewable Energy Plan (PER) 2011–2020”. 2011. Available online: https://www.idae.es/uploads/documentos/documentos_11227_PER_2011-2020_def_93c624ab.pdf (accessed on 6 May 2021).

- Abdelhady, S.; Shalaby, M.A.; Shaban, A. Techno-Economic Analysis for the Optimal Design of a National Network of Agro-Energy Biomass Power Plants in Egypt. Energies 2021, 14, 3063. [Google Scholar] [CrossRef]

- Piotrowska, N.S.; Czachorowski, S.Z.; Stolarski, M.J. Ground Beetles (Carabidae) in the Short-Rotation Coppice Willow and Poplar Plants—Synergistic Benefits System. Agriculture 2020, 10, 648. [Google Scholar] [CrossRef]

- National Association of Engineers of ICAI and Universidad Pontificia de Comillas. Biomass: Status and Immediate Perspective. 2009. ISBN 978-84-935950-9-B. Available online: https://www.icai.es/contenidos/contenido_texto.php?contenido=1875 (accessed on 6 May 2021).

- Mircea, I.; Falup, O.; Ivan, R.; Ionel, I. Reducing GHG Emissions with SRC EWR REV. CHIM. (Bucharest) 66 No. 1. 2015. Available online: http://bch.ro/pdfRC/MIRCEA%20I..pdf%201%205.pdf (accessed on 6 May 2021).

- Bracmort, K. Biomass Feedstocks for Biopower: Background and Selected Issues. Congressional Research Service the Library of Congress: USA. 2010. Available online: https://www.everycrsreport.com/files/20101006_R41440_97aefb63dd9d2dfd4c1ae046d0d4ad0f5b6d0136.pdf (accessed on 6 May 2021).

- Sixto, H.; Hernández, M.J.; Barrio, M.; Carrasco, J.; Cañellas, I. Plantations of the genus Populus for the production of biomass for energy purposes: A review. J. Agrar. Res. For. Syst. Resour. 2007, 16, 277–294. [Google Scholar] [CrossRef] [Green Version]

- Tharakan, P.J.; Volk, T.A.; Abrahamson, L.P.; White, E.H. Energy feed stock characteristics of willow and hybrid poplar clones at harvest age. Biomass Bioenerg. 2003, 25, 571–580. [Google Scholar] [CrossRef]

- Dini-Papanastasi, O. Effects of clonal selection on biomass production and quality in Robinia pseudoacacia var. monophylla Carr. For. Ecol. Manag. 2008, 256, 849–854. [Google Scholar] [CrossRef]

- Monedero, E.; Hernández, J.J.; Collado, R. Combustion-related properties of poplar, willow and black locust to be used as fuels in power plants. Energies 2017, 10, 997. [Google Scholar] [CrossRef] [Green Version]

- Facciotto, G.; Giorcelli, A.; Vietto, L.; Allegro, G.; Castro, G.; Picco, F. Nuovi cloni di piopo Rev. Agricoltora 2006, 34, 71–78. [Google Scholar]

- Allegro, G.; Bisoffi, S.; Chiarabaglio, P.M.; Coaloa, D.; Castro, G.; Facciotto, G.; Giorcelli, A.; Vietto, L. PIOPPICOLTURA Produzioni di qualità nel rispetto dell‘ambiente. Istituto di Sperimentazione per la Pioppicoltura. Istituto di Sperimentazione per la Pioppicoltura, Regione Lombardia. 2006. Available online: https://lombardia.confagricoltura.it/file_upload/lombardia/files/libretto_pioppicoltura.pdf (accessed on 8 May 2021).

- European Committee for Standardization. CEN/TS 14780: Solid Biofuels—Methods for Sample Preparation. 2004. Available online: https://infostore.saiglobal.com/preview/is/en/2011/i.s.en14780-2011.pdf?sku=1478373 (accessed on 8 May 2021).

- European Committee for Standardization. EN 14774-2: Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. 2009. Available online: https://infostore.saiglobal.com/preview/is/en/2009/i.s.en14774-2-2009.pdf?sku=1382257 (accessed on 8 May 2021).

- Senelwa, K.; Sims, R.E.H. Fuel characteristics of short rotation forest biomass. Biomass Bioenerg. 1999, 17, 127–140. [Google Scholar] [CrossRef]

- Mészáros, E. Comparative study of the thermal behavior of wood and bark of young shoots obtained from an energy plantation. J. Anal. Appl. Pyrolysis 2004, 72, 317–328. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 15104: Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen. Instrumental Methods. 2011. Available online: https://infostore.saiglobal.com/preview/is/en/2011/i.s.en15104-2011.pdf?sku=1461029 (accessed on 8 May 2021).

- European Committee for Standardization. EN 15289: Solid Biofuels. Determination of Total Content of Sulfur and Chlorine. 2011. Available online: https://infostore.saiglobal.com/preview/98702827571.pdf?sku=875144_SAIG_NSAI_NSAI_2080439 (accessed on 8 May 2021).

- European Committee for Standardization. EN 14775:2009: Solid Biofuels—Determination of Ash Content. 2009. Available online: https://infostore.saiglobal.com/preview/is/en/2009/i.s.en14775-2009.pdf?sku=1382258 (accessed on 8 May 2021).

- European Committee for Standardization. EN 15148: Solid Biofuels—Determination of the Content of Volatile Matter. 2010. Available online: https://infostore.saiglobal.com/preview/is/en/2009/i.s.en15148-2009.pdf?sku=1382260 (accessed on 8 May 2021).

- European Committee for Standardization. EN 15290: Solid Biofuels. Determination of Major Elements. Al, Ca, Fe, Mg, P, K, Si, Na and Ti. 2011. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwizma6_nq3xAhUDL6YKHWbRA6wQFjACegQIAxAE&url=https%3A%2F%2Fwww.techstreet.com%2Fproducts%2Fpreview%2F1895493&usg=AOvVaw2TnW8Pa_76fD1suHIDeD1y (accessed on 8 May 2021).

- European Committee for Standardization. EN 15297: Solid Biofuels. Determination of Minor Elements. As, Cd, Co, Cr, Cu, Hg, Mn, Mo, Ni, Pb, Sb, V and Zn, 2011. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwj3_p2Sn63xAhUiLqYKHUHzCPIQFjABegQIBBAD&url=https%3A%2F%2Fwww.researchgate.net%2Fprofile%2FM_Ramiro_Pastorinho%2Fpost%2FHow-do-I-measure-cadmium-in-wood-chips%2Fattachment%2F59d64707c49f478072eaec58%2FAS%253A273839429226496%25401442299815379%2Fdownload%2F%255BBS%2BEN%2B15297-2011%255D%2B--%2BSolid%2Bbiofuels.%2BDetermination%2Bof%2Bminor%2Belements.%2BAs%252C%2BCd%252C%2BCo%252C%2BCr%252C%2BCu%252C%2BHg%252C%2BMn%252C%2BMo%252C%2BNi%252C%2BPb%252C%2BSb%252C%2BV%2Band%2BZn..pdf&usg=AOvVaw0sdduJSGbU5QKi51efCL6V (accessed on 8 May 2021).

- Qian, X.; Lee, S.; Soto, A.-M.; Chen, G. Regression Model to Predict the Higher Heating Value of Poultry Waste from Proximate Analysis. Resources 2018, 7, 39. [Google Scholar] [CrossRef] [Green Version]

- Pliura, A.; Zhang, S.Y.; MacKay, J.; Bousquet, J. Genotypic variation in wood density and growth traits of poplar hybrids at four clonal trials. For. Ecol. Manag. 2007, 238, 92–106. [Google Scholar] [CrossRef]

- Kenney, W.A.; Sennerby-Forsse, L.; Layton, P. A review of biomass quality research relevant to the use of poplar and willow for energy conversion. Biomass 1990, 21, 163–188. [Google Scholar] [CrossRef]

- Miles, T.R.; Miles, T.R., Jr.; Baxter, L.L.; Bryers, R.W.; Jenkins, B.M.; Oden, L.L. Alkali deposits found in biomass power plants: A preliminary investigation of their extent and nature. National Renewable Energy Laboratory. 1995. Available online: https://www.nrel.gov/docs/legosti/fy96/8142v1.pdf (accessed on 8 May 2021).

- Khalil, R.A.; Mészáros, E.; Grønli, M.G.; Várhegyi, G. Thermal analysis of energy crops Part I: The applicability of macro-thermobalance for biomass studies. J. Anal. Appl. Pyrol. 2008, 81, 52–59. [Google Scholar] [CrossRef]

- Poplar Short Rotation Coppice Plantations under Mediterranean Conditions: The Case of Spain Nerea Oliveira, César Pérez-Cruzado, Isabel Cañellas, Roque Rodríguez-Soalleiro and Hortensia Sixto. Forests 2020, 11, 1352. [CrossRef]

- Gómez-Martín, J.M.; Castaño-Díaz, M.; Cámara-Obregón, A.; Álvarez-Álvarez, P.; Folgueras-Díaz, M.B.; Diez, M.A. On the chemical composition and pyrolytic behavior of hybrid poplar energy crops from northern Spain. Energy Reports 2020, 6, 764–769. [Google Scholar] [CrossRef]

- Klasnja, B.; Kopitovic, B.; Orlovic, S. Wood and bark of some poplar and willow clones as fuelwood. Biomass Bioenerg. 2002, 23, 427–432. [Google Scholar] [CrossRef]

- Garstang, J.; Weeks, A.; Poulter, R.; Bartlett, D. Identification and Characterisation of Factors Affecting Losses in the Large-Scale, non Ventilated Bulk Storage of Wood Chips and Development of Best Storage Practices. DTI’s New and Renewable Energy Programme. 2002. Available online: https://www.osti.gov/etdeweb/servlets/purl/20350970 (accessed on 8 May 2021).

- Thörnqvist, T. Drying and storage of forest residues for energy production. Biomass 1985, 7, 125–134. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 14961-1: Solid biofuels. Specifications and classes of fuels. Part 1: General Requirements. 2011. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjf1dq0n63xAhXDzjgGHfb-BB0QFjABegQIBBAE&url=https%3A%2F%2Fwww.researchgate.net%2Fpublication%2F47352230_European_Standards_for_Fuel_Specification_and_Classes_of_Solid_Biofuels&usg=AOvVaw3DmxHCsGuBq6gpEIfYuBAa (accessed on 8 May 2021).

- Magasiner, N.; De Kock, J. Design criteria for fibrous fuel fired boilers. Energy World 1987, 150, 4–12. [Google Scholar]

- Qian, X.; Lee, S.W.; Yang, Y. Heat Transfer Coefficient Estimation and Performance Evaluation of Shell and Tube Heat Exchanger Using Flue Gas. Processes 2021, 9, 939. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warminski, K.; Krzyzaniak, M. Energy Value of Yield and Biomass Quality of Poplar Grown in Two Consecutive 4-Year Harvest Rotations in the North-East of Poland. Energies 2020, 13, 1495. [Google Scholar] [CrossRef] [Green Version]

- Ozgen, S.; Cernuschi, S.; Caserini, S. An overview of nitrogen oxides emissions from biomass combustion for domestic heat production. Renew. Sustain. Energy Rev. 2021, 135, 110113. [Google Scholar] [CrossRef]

- Ryu, C.; Yang, Y.B.; Khor, A.; Yates, N.E.; Sharifi, V.N.; Swithenbank, J. Effect of fuel properties on biomass combustion: Part I. Experiments—fuel type, equivalence ratio and particle size. Fuel 2006, 85, 1039–1046. [Google Scholar] [CrossRef]

- Jenkins, B.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Jenkins, B.M. Physical properties of biomass. In Biomass Handbook; Kitani, O., Hall, C.W., Eds.; Gordon & Breach: New York, NY, USA, 1989; Chapter 5.2. [Google Scholar]

| Latitude (°) | 37° 10′4.61″ N |

| Longitude (°) | 3° 38′21.76″ W |

| Altitude (m, asl) | 590 |

| Annual mean temperature (°C) | 15.9 |

| Mean Maximum/minimum temperature (°C) | 29.3/3.7 |

| Absolute maximum/minimum temperature (°C) | 40.3/−5.8 |

| Annual precipitation (mm) | 368 |

| K (pmm–peat mineral soil mix- or mg/kg ms) by atomic emission | 76 |

| Mg (meq/100 g) by atomic absorption | 2.13 |

| Organic Matter (%) by Walkey-Black | 0.9 |

| Electric conductivity (mS/cm) by 1:2.5 | 0.2 |

| P (pmm or mg/kg ms) by Olsen | 4.1 |

| pH by 1:2.5 | 8.5 |

| Active lime (%) | 4.3 |

| Clay/Lime/Sand (%) by ISSS | 26.7/46.3/27.7 |

| Species | Clone | Trees per Hectare | Plants Age (Years) |

|---|---|---|---|

| Populus x Euroamericana (Dode) Guinier | I-214 | 13,200 | 3 |

| Populus deltoides 145-86 x Populus nigra 40 | AF2 | 13,200 | 3 |

| Populus x canadensis Mönch | Ballottino | 13,200 | 3 |

| Populus x generosa x Populus nigra | Monviso | 13,200 | 3 |

| Populus deltoides Marsh | Viriato | 15,000 | 2 |

| Property | Standard |

|---|---|

| Sample preparation | EN 14780 |

| Moisture content (Mc) | EN 14774-3/EN 14774-2 |

| Wood density | UNE 15150 |

| Heating value (LHV, HHV) | UNE 164001 |

| Ash content (A) | EN 14775 |

| Volatile matter (V) | EN 15148 |

| Carbon (C) | EN 15104 |

| Hydrogen (H) | EN 15104 |

| Nitrogen (N) | EN 15104 |

| Sulfur (S) | EN 15289 |

| Chlorine (Cl) | EN 15289 |

| Oxygen (O) | By difference between C, H, N and S |

| Mayor elements | EN 15290 |

| Minor elements | EN 15297 |

| Element | AF2 | I-214 | BALLOTINO | MONVISO | VIRIATO | |

|---|---|---|---|---|---|---|

| Mean/SD | Mean/SD | Mean/SD | Mean/SD | Mean/SD | ||

| Wood | C | 49.49/1.20 | 49.11/1.01 | 48.93/1.16 | 49.1/0.97 | 49.09/0.88 |

| H | 6.36/0.12 | 6.19/0.10 | 6.31/0.05 | 6.05/0.13 | 6.29/0.12 | |

| O | 43.15/1.1 | 43.63/1.05 | 43.69/0.99 | 43.65/0.96 | 43.16/0.79 | |

| Others (Cl, S, N) | 0.16/0.00 | 0.17/0.06 | 0.19/0.03 | 0.27/0.06 | 0.24/0.03 | |

| Ashes | 0.83/0.1 | 0.89/0.05 | 0.88/0.07 | 0.94/0.03 | 1.22/0.12 | |

| N | 0.14/0.02 | 0.15/0.05 | 0.16/0.01 | 0.24/0.03 | 0.21/0.03 | |

| S | 0.02/0.00 | 0.02/0.00 | 0.03/0.01 | 0.03/0.01 | 0.02/0.00 | |

| Cl | -/- | 0/0.00 | -/- | -/- | 0.01/0.00 | |

| Crust | C | 48.44/1.25 | 48.57/0.90 | 49.33/1.12 | 46.46/0.97 | 46.84/1.01 |

| H | 5.77/0.15 | 5.87/0.09 | 5.65/0.06 | 5.41/0.10 | 5.74/0.15 | |

| O | 38.82/1.1 | 38.59/0.95 | 38.34/1.12 | 38.8/0.96 | 38.77/0.75 | |

| Others (Cl, S, N) | 0.5/0.04 | 0.45/0.11 | 0.55/0.10 | 0.78/0.09 | 0.78/0.10 | |

| Ashes | 6.46/0.11 | 6.54/0.05 | 6.13/0.09 | 8.54/0.05 | 7.88/0.06 | |

| N | 0.45/0.03 | 0.39/0.04 | 0.5/0.01 | 0.7/0.03 | 0.68/0.03 | |

| S | 0.05/0.00 | 0.05/0.00 | 0.05/0.00 | 0.08/0.01 | 0.08/0.00 | |

| Cl | -/- | 0.01/0.00 | -/- | -/- | 0.02/0.00 | |

| Biomass sample (wood and crust) | C | 49.42/1.20 | 49.03/0.99 | 48.96/1.16 | 48.85/0.97 | 48.85/0.89 |

| H | 6.32/0.12 | 6.14/0.10 | 6.26/0.05 | 5.99/0.13 | 6.23/0.12 | |

| O | 42.86/1.1 | 42.90/1.04 | 43.25/1.00 | 43.20/0.96 | 42.69/0.79 | |

| Others (Cl, S, N) | 0.18/0.00 | 0.21/0.07 | 0.22/0.04 | 0.32/0.06 | 0.30/0.04 | |

| Ashes | 1.20/0.1 | 1.71/0.05 | 1.31/0.07 | 1.65/0.03 | 1.93/0.11 | |

| N | 0.16/0.01 | 0.18/0.05 | 0.19/0.01 | 0.28/0.03 | 0.26/0.03 | |

| S | 0.02/0.00 | 0.02/0.00 | 0.03/0.01 | 0.03/0.01 | 0.03/0.00 | |

| Cl | -/- | 0.00/0.00 | -/- | -/- | 0.01/0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soriano, J.A.; García-Contreras, R.; Carpio de Los Pinos, A.J. Study of the Thermochemical Properties of Lignocellulosic Biomass from Energy Crops. Energies 2021, 14, 3780. https://doi.org/10.3390/en14133780

Soriano JA, García-Contreras R, Carpio de Los Pinos AJ. Study of the Thermochemical Properties of Lignocellulosic Biomass from Energy Crops. Energies. 2021; 14(13):3780. https://doi.org/10.3390/en14133780

Chicago/Turabian StyleSoriano, José Antonio, Reyes García-Contreras, and Antonio José Carpio de Los Pinos. 2021. "Study of the Thermochemical Properties of Lignocellulosic Biomass from Energy Crops" Energies 14, no. 13: 3780. https://doi.org/10.3390/en14133780

APA StyleSoriano, J. A., García-Contreras, R., & Carpio de Los Pinos, A. J. (2021). Study of the Thermochemical Properties of Lignocellulosic Biomass from Energy Crops. Energies, 14(13), 3780. https://doi.org/10.3390/en14133780