The Effect of Elliptical Diesel Nozzles on Spray Liquid-Phase Penetration under Evaporative Conditions

Abstract

1. Introduction

2. Experimental Method

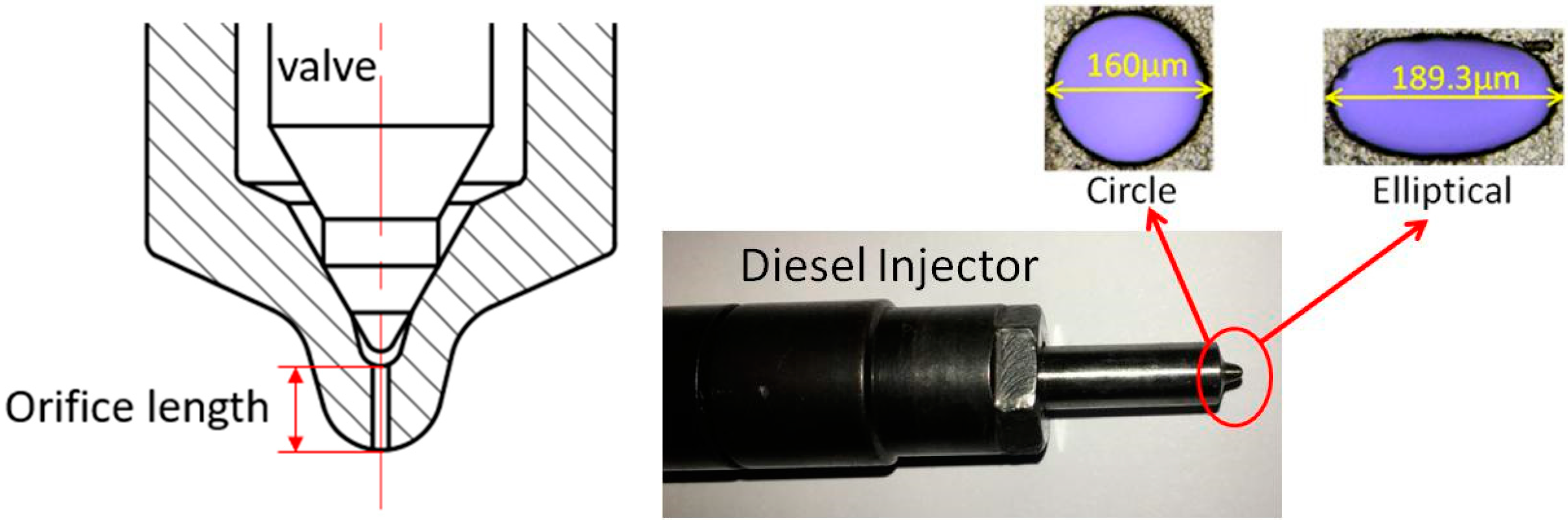

2.1. Diesel Nozzle

2.2. Experimental Visualization Work

2.3. Experimental Test Plan

3. Experimental Procedure

4. Results and Discussion

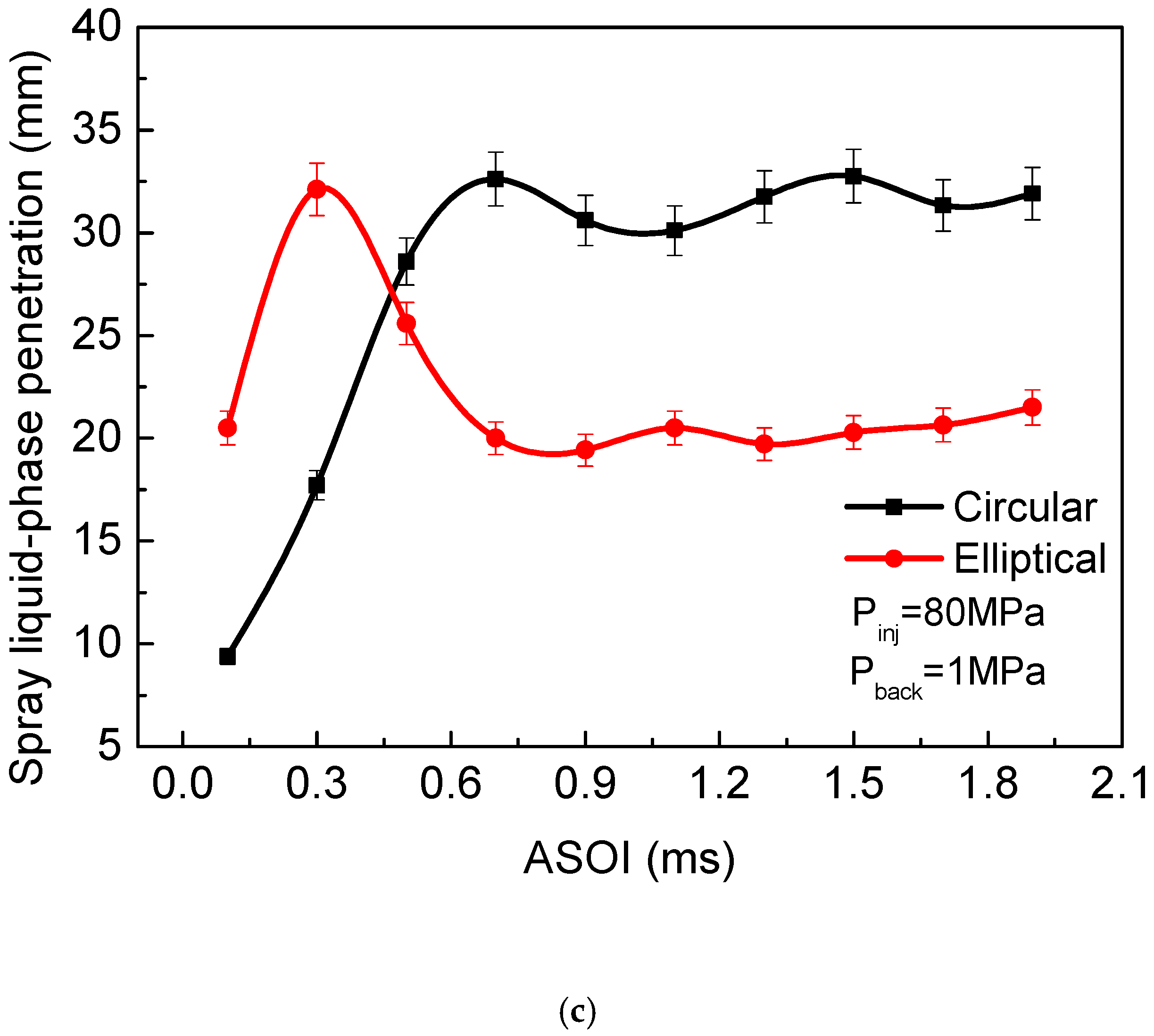

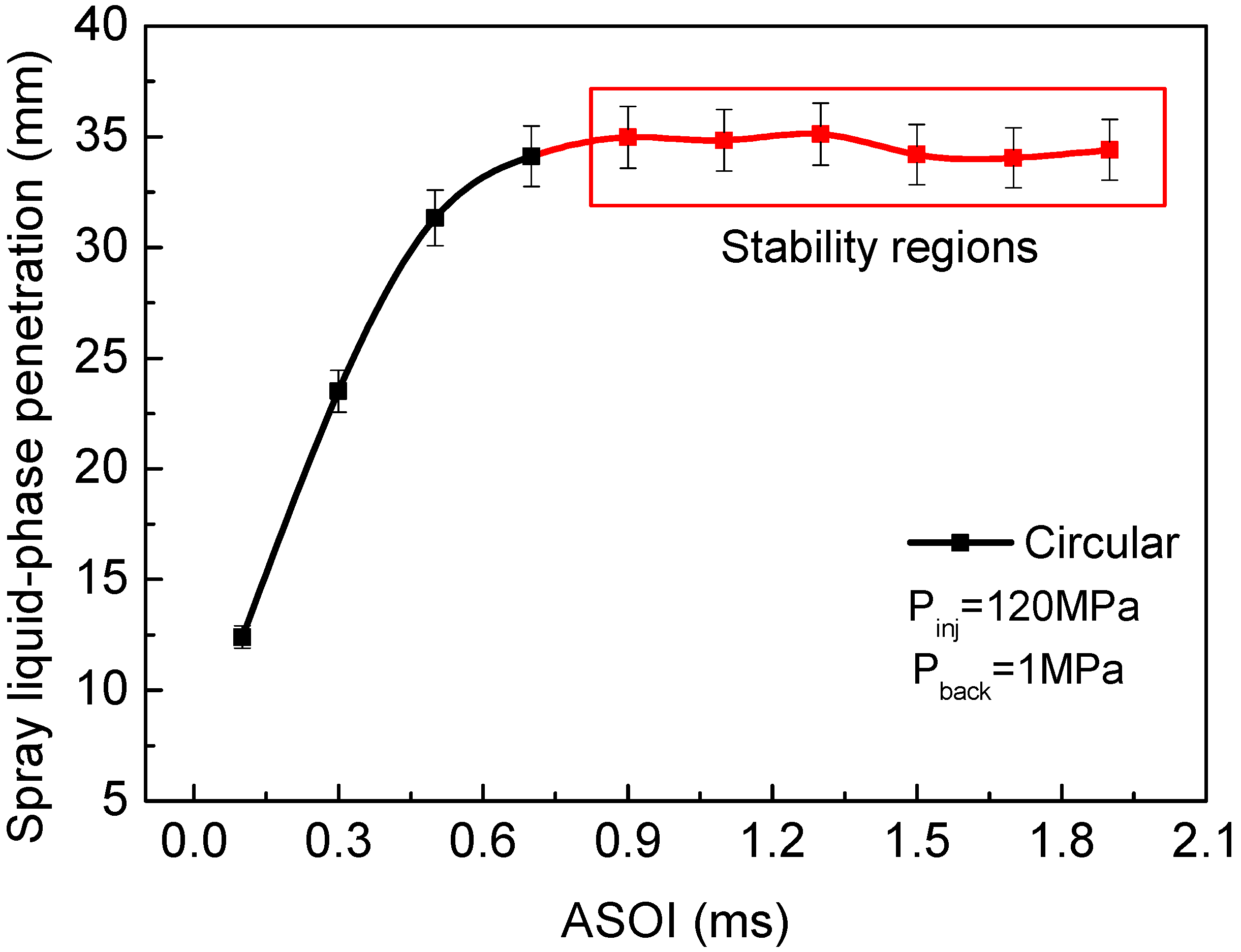

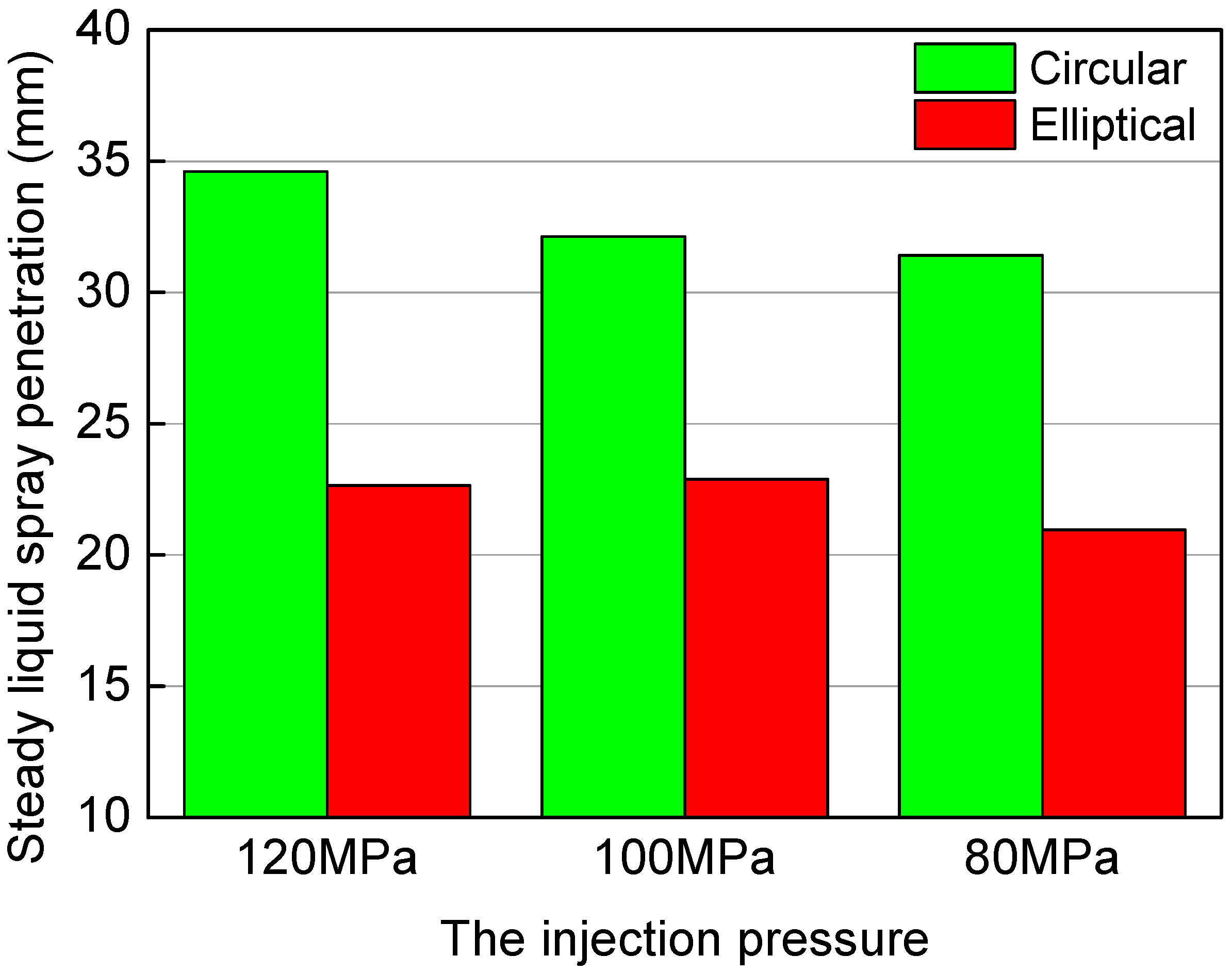

4.1. The Effects of Injection Pressure on the Spray Liquid-Phase Penetration

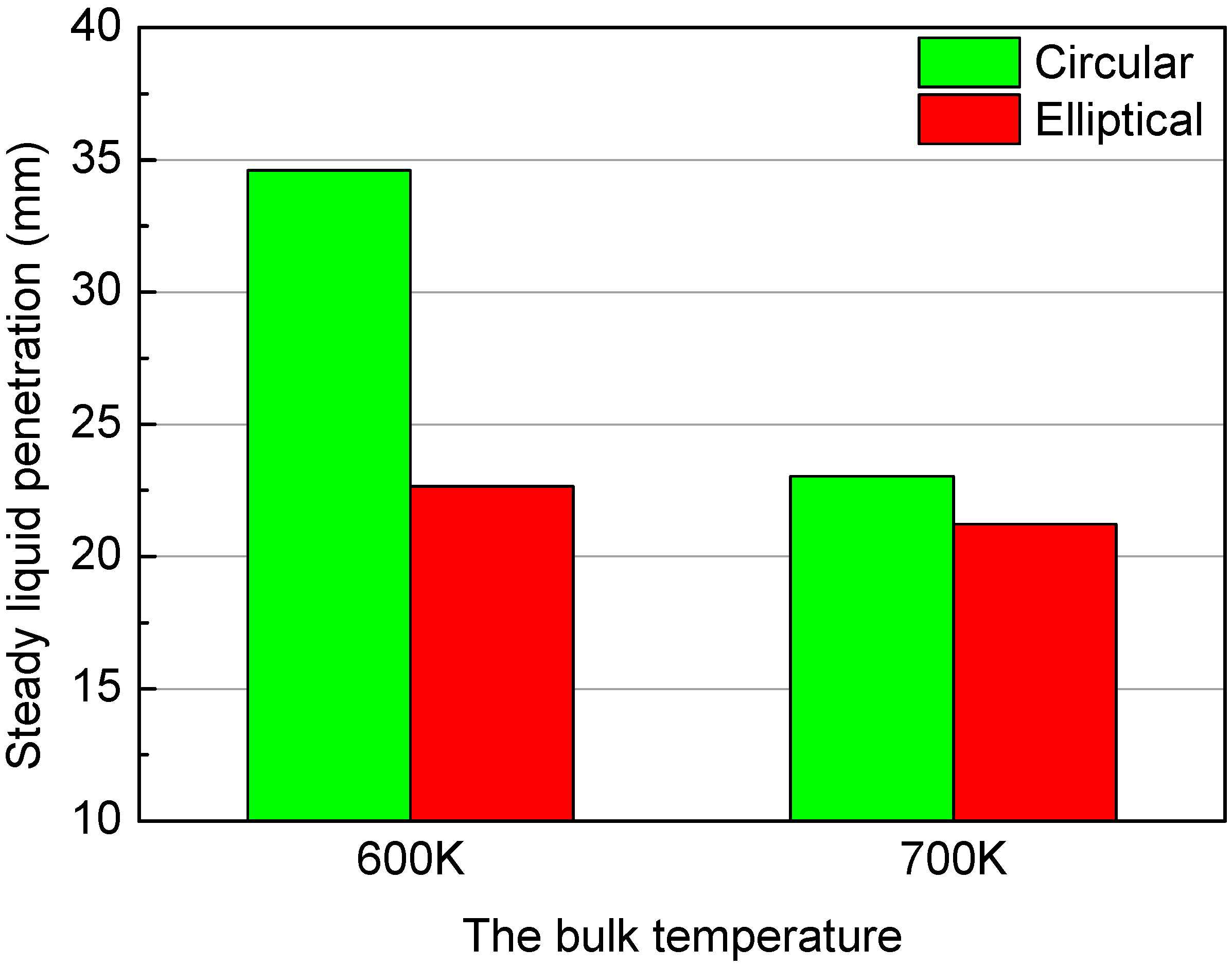

4.2. The Effects of Bulk Temperature on Spray Liquid-Phase Penetration

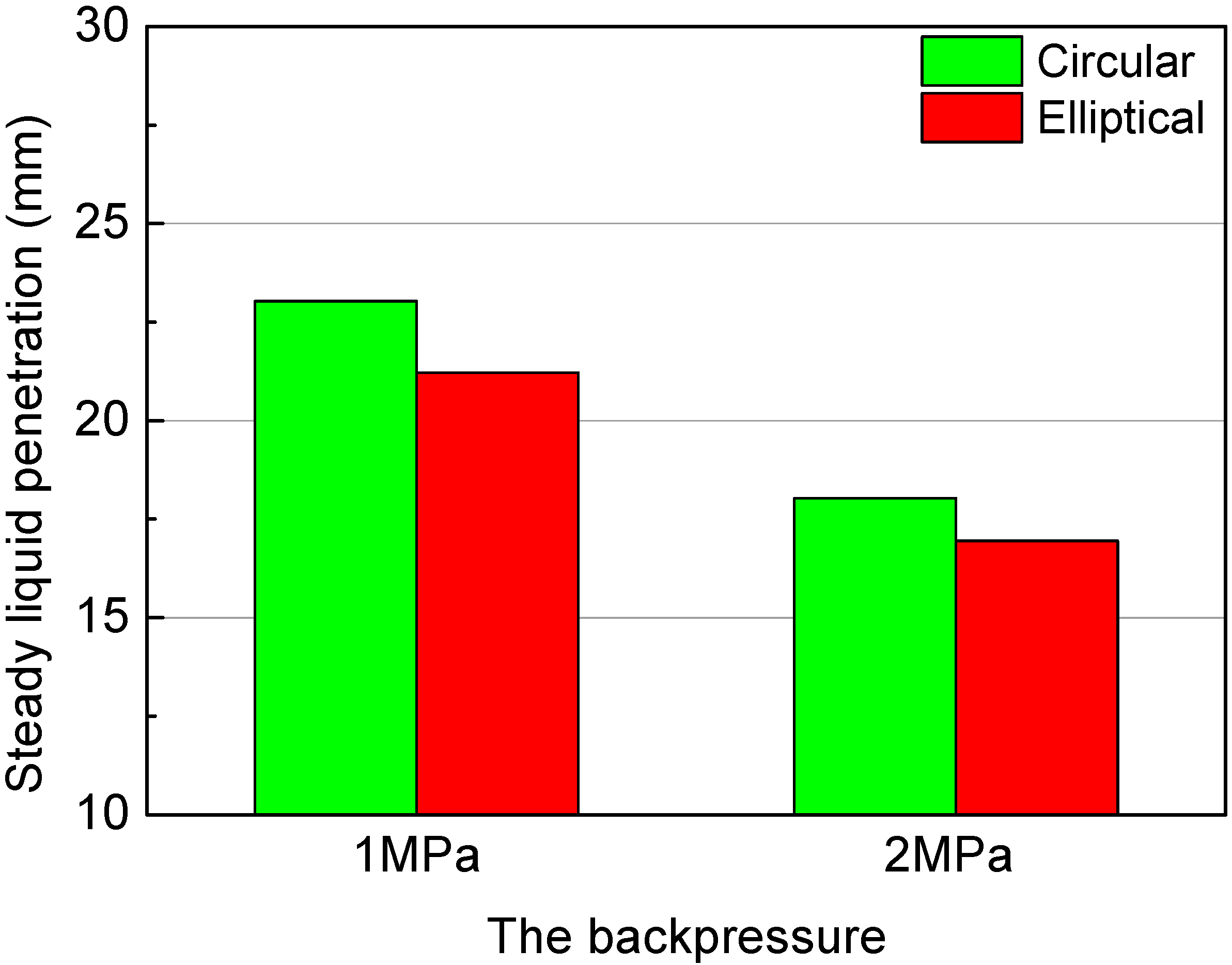

4.3. The Effects of Backpressure on Spray Liquid-Phase Penetration

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Shi, S.; Huang, S.; Tang, J.; Du, T.; Cheng, X.; Huang, R.; Chen, J.-Y. Effects of water content on evaporation and combustion characteristics of water emulsified diesel spray. Appl. Energy 2018, 226, 397–407. [Google Scholar] [CrossRef]

- Tian, J.; Zhao, M.; Long, W.; Nishida, K.; Fujikawa, T.; Zhang, W. Experimental study on spray characteristics under ultra-high injection pressure for DISI engines. Fuel 2016, 186, 365–374. [Google Scholar] [CrossRef]

- Nishida, K.; Zhu, J.; Leng, X.; He, Z. Effects of micro-hole nozzle and ultra-high injection pressure on air entrainment, liquid penetration, flame lift-off and soot formation of diesel spray flame. Int. J. Engine Res. 2017, 18, 51–65. [Google Scholar] [CrossRef]

- Kiplimo, R.; Tomita, E.; Kawahara, N.; Yokobe, S. Effects of spray impingement, injection parameters, and EGR on the combustion and emission characteristics of a PCCI diesel engine. Appl. Therm. Eng. 2012, 37, 165–175. [Google Scholar] [CrossRef]

- Ge, M.; Liang, X.; Yu, H.; Wang, Y.; Zhang, H. Effect of Lube Oil Film Thickness on Spray/Wall Impingement with Diesel, M20 and E20 Fuels; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2017; 01-0847. [Google Scholar]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the diesel and biodiesel spray characteristics emerging from equilateral triangular orifice under real diesel engine operation conditions. Fuel 2018, 224, 357–365. [Google Scholar] [CrossRef]

- Yunyi, G.; Changwen, L.; Yezhou, H.; Zhijun, P. An Experimental Study on Droplet Size Characteristics and Air Entrainment of Elliptic Sprays; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the spray characteristics discharging from elliptical diesel nozzle at typical diesel engine conditions. Fuel 2018, 221, 28–34. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Internal flow and spray characteristics for elliptical orifice with large aspect ratio under typical diesel engine operation conditions. Fuel 2018, 228, 62–73. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. An experimental comparison of the elliptical and circular nozzles spray and mixing characteristics under different injection pressures. Fuel 2019, 236, 1474–1482. [Google Scholar] [CrossRef]

- Ku, K.-W.; Lee, Y.-J.; Kim, I.-S.; Lee, C.-W. Experimental study of the effects of nozzle hole geometry for di diesel engine. J. ILASS-Korea 2007, 12, 154–159. [Google Scholar]

- Matsson, A.; Jacobsson, L.; Andersson, S. The Effect of Elliptical Nozzle Holes on Combustion and Emission Formation in a Heavy Duty Diesel Engine; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2000; 01-1251. [Google Scholar]

- Ho, C.-M.; Gutmark, E. Vortex induction and mass entrainment in a small-aspect-ratio elliptic jet. J. Fluid Mech. 1987, 179, 383–405. [Google Scholar] [CrossRef]

- Hong, J.G.; Ku, K.W.; Kim, S.R.; Lee, C.W. Effect of cavitation in circular nozzle and elliptical nozzles on the spray characteristic. At. Sprays 2010, 20, 877–886. [Google Scholar] [CrossRef]

- Hong, J.G.; Ku, K.W.; Lee, C.-W. Numerical simulation of the cavitating flow in an elliptical nozzle. At. Sprays 2011, 21, 237–248. [Google Scholar] [CrossRef]

- Sharma, P.; Fang, T. Spray and atomization of a common rail fuel injector with non-circular orifices. Fuel 2015, 153, 416–430. [Google Scholar] [CrossRef]

- Sharma, P.; Fang, T. Breakup of liquid jets from non-circular orifices. Exp. Fluids 2014, 55. [Google Scholar] [CrossRef]

- Cung, K.; Moiz, A.A.; Shah, B.; Kalaskar, V.; Miwa, J.; Abidin, Z. Evaluation of Diesel Spray with Non-Circular Nozzle—Part I: Inert Spray; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2019; 01-0065. [Google Scholar]

- Srinivasan, R.; Bowersox, R.D.W. Transverse Injection through Diamond and Circular Ports into a Mach 5.0 Freestream. AIAA J. 2008, 46, 1944–1962. [Google Scholar] [CrossRef]

- Jadidi, M.; Sreekumar, V.; Dolatabadi, A. Breakup of elliptical liquid jets in gaseous crossflows at low Weber numbers. J. Vis. 2018, 22, 259–271. [Google Scholar] [CrossRef]

- Kasyap, T.V.; Sivakumar, D.; Raghunandan, B.N. Breakup of liquid jets emanating from elliptical orifices at low flow conditions. At. Sprays 2008, 18, 645–668. [Google Scholar] [CrossRef]

- Kasyap, T.; Sivakumar, D.; Raghunandan, B. Flow and breakup characteristics of elliptical liquid jets. Int. J. Multiph. Flow 2009, 35, 8–19. [Google Scholar] [CrossRef]

- Morad, M.R.; Khosrobeygi, H. Penetration of Elliptical Liquid Jets in Low-Speed Crossflow. J. Fluids Eng. 2018, 141, 011301. [Google Scholar] [CrossRef]

- Molina, S.; Salvador, F.; Carreres, M.; Jaramillo, D.; Rubio, F.J.S. A computational investigation on the influence of the use of elliptical orifices on the inner nozzle flow and cavitation development in diesel injector nozzles. Energy Convers. Manag. 2014, 79, 114–127. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Palmieri, F.; Pompei, R. On the Influence of the Slot Orifice in Diesel Common Rail Nozzle. Open Fuels Energy Sci. J. 2018, 11, 55–69. [Google Scholar] [CrossRef][Green Version]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the spray and mixing characteristics for equilateral triangular and circular nozzles with diesel and biodiesel under high injection pressures. Fuel 2019, 239, 97–107. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.; Gimeno, J.; Zapata, L.; Rubio, F.J.S. Diesel nozzle geometry influence on spray liquid-phase fuel penetration in evaporative conditions. Fuel 2008, 87, 1165–1176. [Google Scholar] [CrossRef]

- Pastor, J.V.; Arrègle, J.; Palomares, A. Diesel spray image segmentation with a likelihood ratio test. Appl. Opt. 2001, 40, 2876–2885. [Google Scholar] [CrossRef]

- Pastor, J.V.; Arrègle, J.; García, J.M.; Zapata, L.D. Segmentation of diesel spray images with log-likelihood ratio test algorithm for non-Gaussian distributions. Appl. Opt. 2007, 46, 888–899. [Google Scholar] [CrossRef]

- Zheng, L.; Ma, X.; Wang, Z.; Wang, J. An optical study on liquid-phase penetration, flame lift-off location and soot volume fraction distribution of gasoline–diesel blends in a constant volume vessel. Fuel 2015, 139, 365–373. [Google Scholar] [CrossRef]

- Payri, R.; Giraldo, J.S.; Ayyapureddi, S.; Versey, Z. Experimental and analytical study on vapor phase and liquid penetration for a high pressure diesel injector. Appl. Therm. Eng. 2018, 137, 721–728. [Google Scholar] [CrossRef]

- Martínez-Martínez, S.; Sánchez-Cruz, F.; Riesco-Ávila, J.; Gallegos, A.; Aceves, S. Liquid penetration length in direct diesel fuel injection. Appl. Therm. Eng. 2008, 28, 1756–1762. [Google Scholar] [CrossRef]

- Kook, S.; Pickett, L.M. Liquid length and vapor penetration of conventional, Fischer–Tropsch, coal-derived, and surrogate fuel sprays at high-temperature and high-pressure ambient conditions. Fuel 2012, 93, 539–548. [Google Scholar] [CrossRef]

- Xu, M.; Cui, Y.; Deng, K. One-dimensional model on liquid-phase fuel penetration in diesel sprays. J. Energy Inst. 2016, 89, 138–149. [Google Scholar] [CrossRef]

- Payri, R.; Gimeno, J.; Bardi, M.; Plazas, A.H. Study liquid length penetration results obtained with a direct acting piezo electric injector. Appl. Energy 2013, 106, 152–162. [Google Scholar] [CrossRef]

- Shang, W.; He, Z.; Wang, Q.; Cao, J.; Li, B.; Leng, X.; Tamilselvan, P.; Li, D. Experimental and analytical study on capture spray liquid penetration and combustion characteristics simultaneously with Hydrogenated Catalytic Biodiesel/Diesel blended fuel. Appl. Energy 2018, 226, 947–956. [Google Scholar] [CrossRef]

- Li, D.; He, Z.; Xuan, T.; Zhong, W.; Cao, J.; Wang, Q.; Wang, P. Simultaneous capture of liquid length of spray and flame lift-off length for second-generation biodiesel/diesel blended fuel in a constant volume combustion chamber. Fuel 2017, 189, 260–269. [Google Scholar] [CrossRef]

| Nozzle | Major Axis [μm] | Minor Axis [μm] | Cross-Section Area [μm2] | Perimeter [μm] | Orifice Length [mm] | Hydraulic Diameter [mm] |

|---|---|---|---|---|---|---|

| Circle | 160 | 160 | 20,106.2 | 205.7 | 1.23 | 160 |

| Elliptical | 189.3 | 135.2 | 20,106.2 | 533.0 | 1.23 | 150.9 |

| Parameter | Value-Type |

|---|---|

| Fuel | Biodiesel |

| Injection pressure (Pinj) | 80 MPa, 100 MPa, 120 MPa |

| Backpressure (Pback) | 1 MPa, 2 MPa |

| Gas property | Nitrogen |

| Ambient temperature (Tbulk) | 600 K, 700 K |

| Physical Properties | Biodiesel |

|---|---|

| Density (kg/m3) | 876 |

| Kinetic viscosity (mm2/s)(40 °C) | 4.52 |

| Surface tension (mN/m) | 35.2 |

| Flashpoint temperature (°C) | 169.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, B.; Xu, B.; Jia, H.; Yu, S. The Effect of Elliptical Diesel Nozzles on Spray Liquid-Phase Penetration under Evaporative Conditions. Energies 2020, 13, 2234. https://doi.org/10.3390/en13092234

Yin B, Xu B, Jia H, Yu S. The Effect of Elliptical Diesel Nozzles on Spray Liquid-Phase Penetration under Evaporative Conditions. Energies. 2020; 13(9):2234. https://doi.org/10.3390/en13092234

Chicago/Turabian StyleYin, Bifeng, Bin Xu, Hekun Jia, and Shenghao Yu. 2020. "The Effect of Elliptical Diesel Nozzles on Spray Liquid-Phase Penetration under Evaporative Conditions" Energies 13, no. 9: 2234. https://doi.org/10.3390/en13092234

APA StyleYin, B., Xu, B., Jia, H., & Yu, S. (2020). The Effect of Elliptical Diesel Nozzles on Spray Liquid-Phase Penetration under Evaporative Conditions. Energies, 13(9), 2234. https://doi.org/10.3390/en13092234