Investigation of Vortical Structures and Turbulence Characteristics in Corner Separation in an Axial Compressor Stator Using DDES

Abstract

1. Introduction

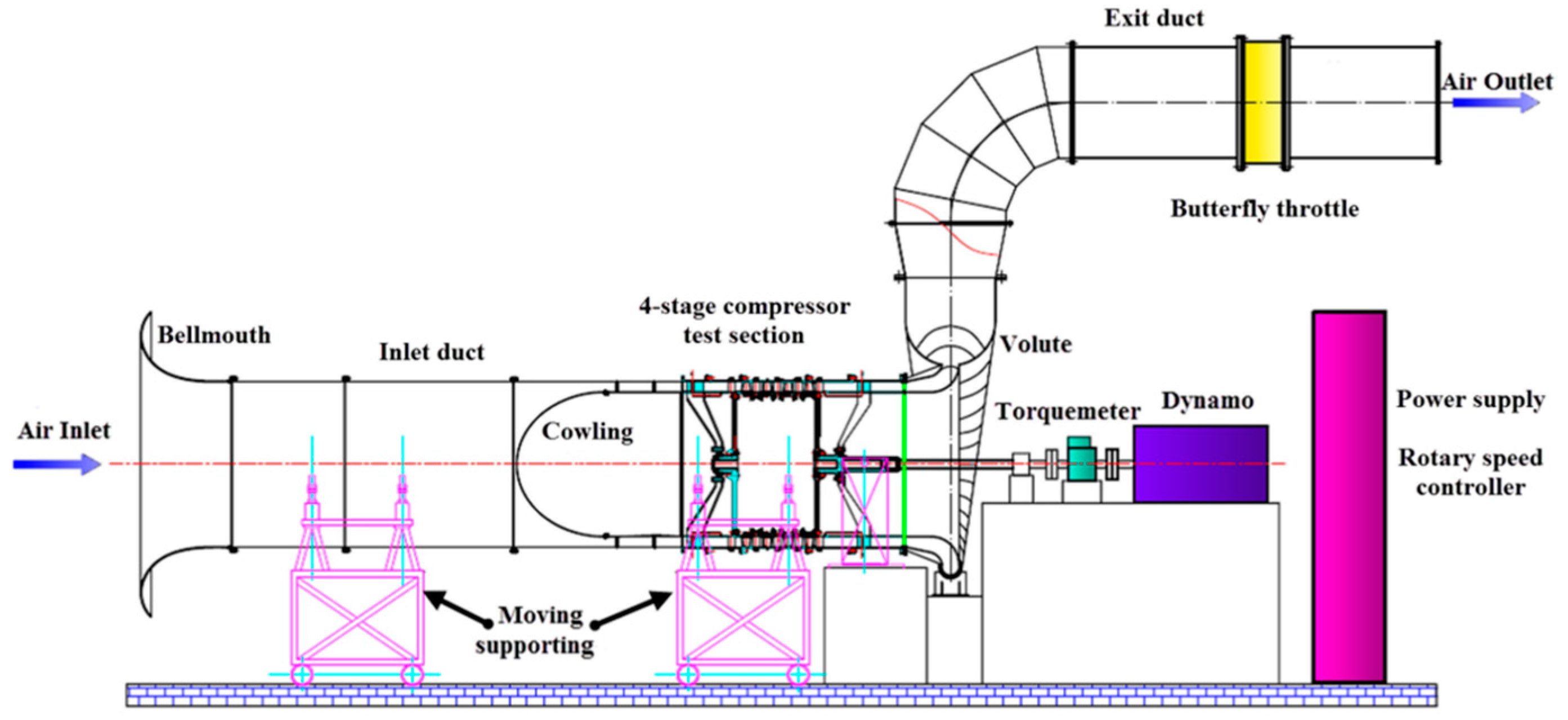

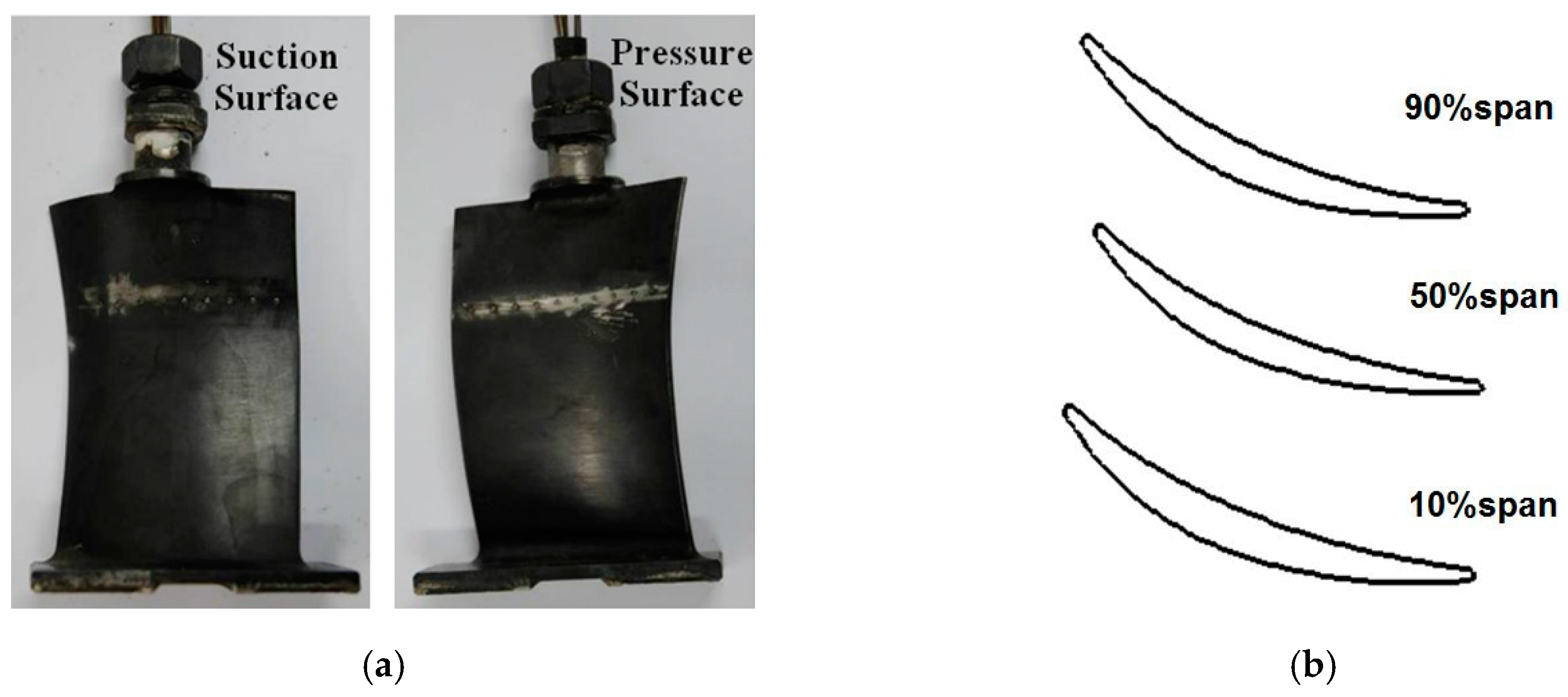

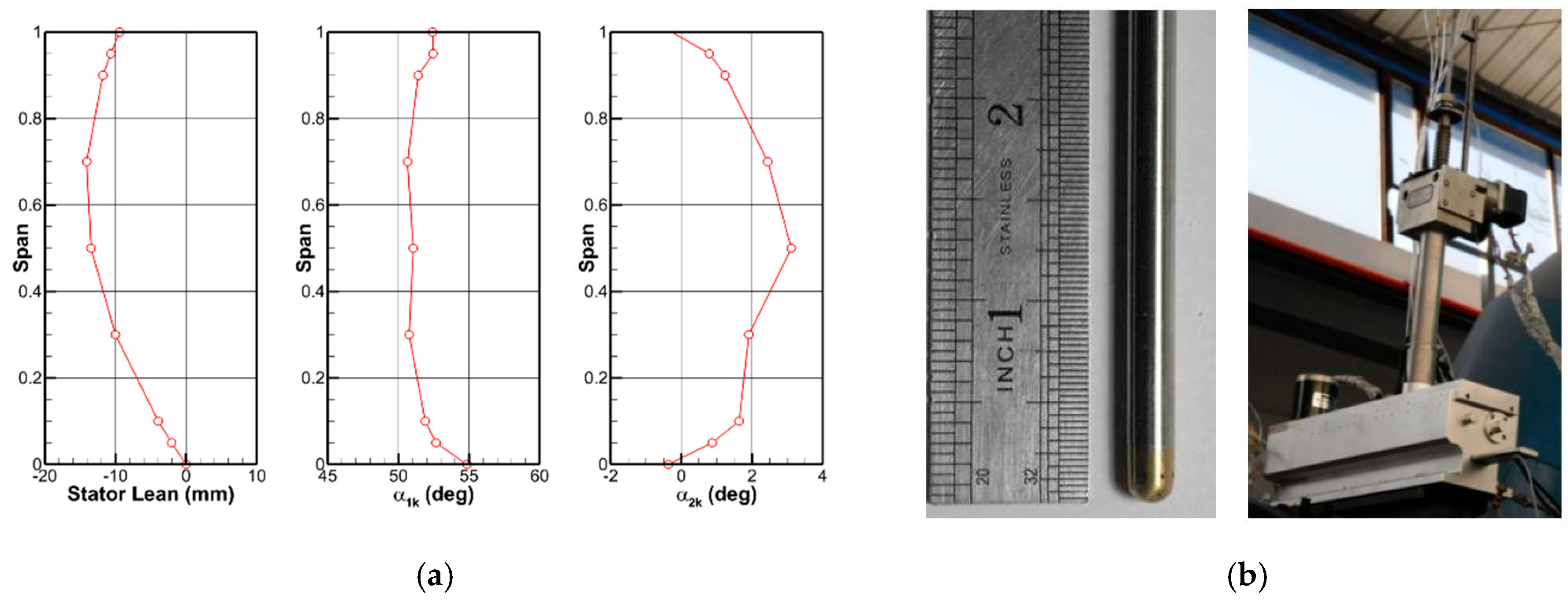

2. Low-Speed Research Stator

3. Computational Procedure

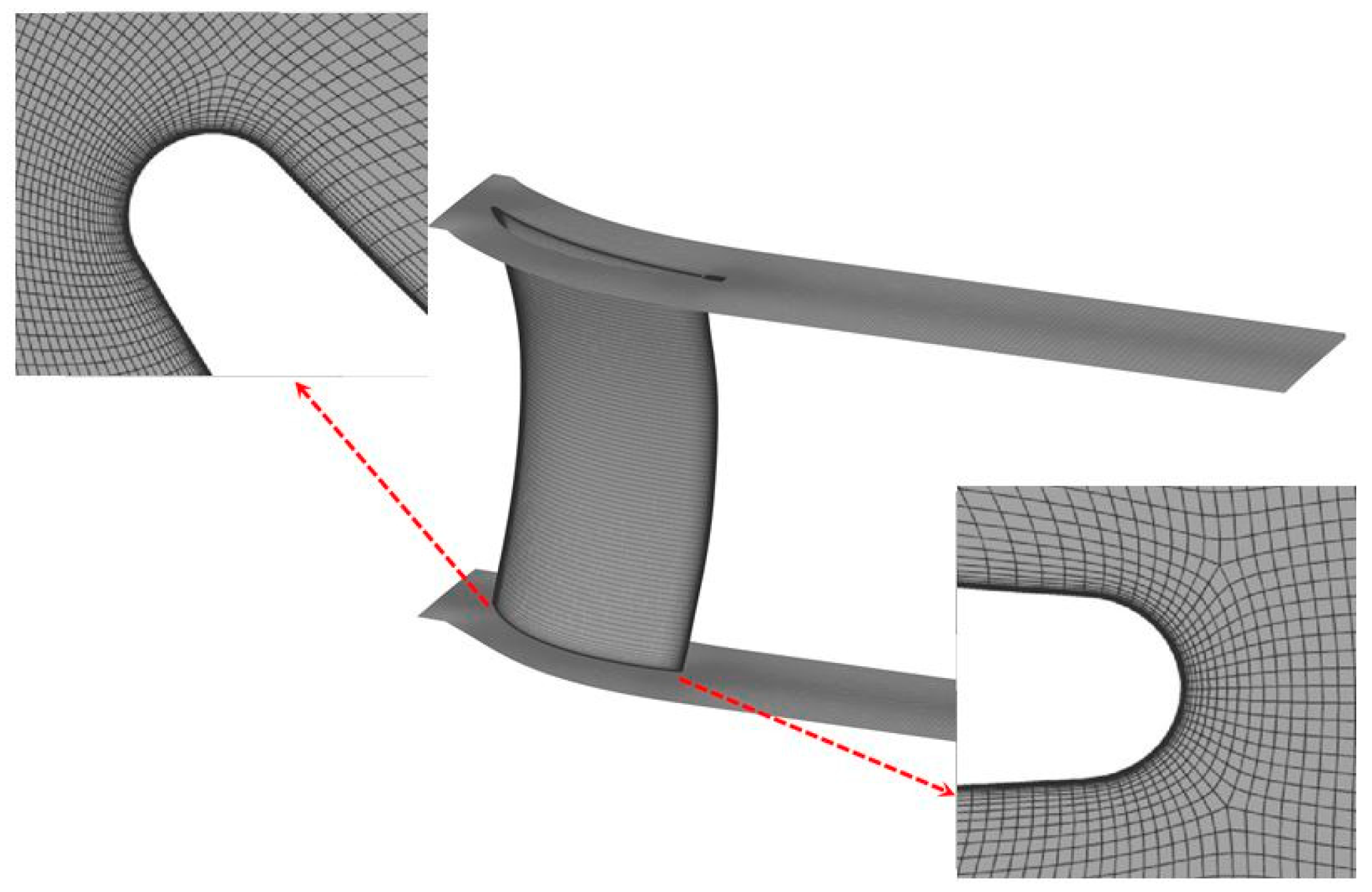

3.1. Computational Grids

3.2. Boundary Conditions

3.3. Numerical Method

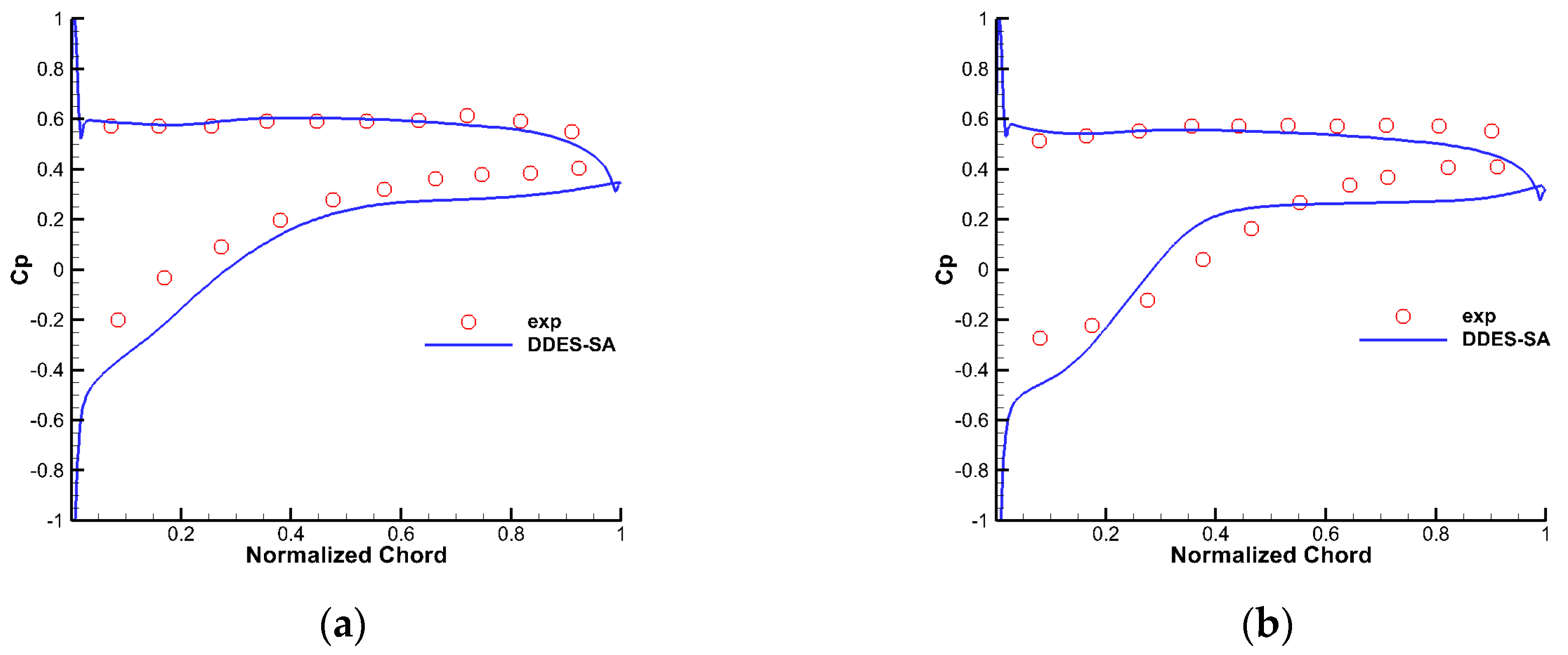

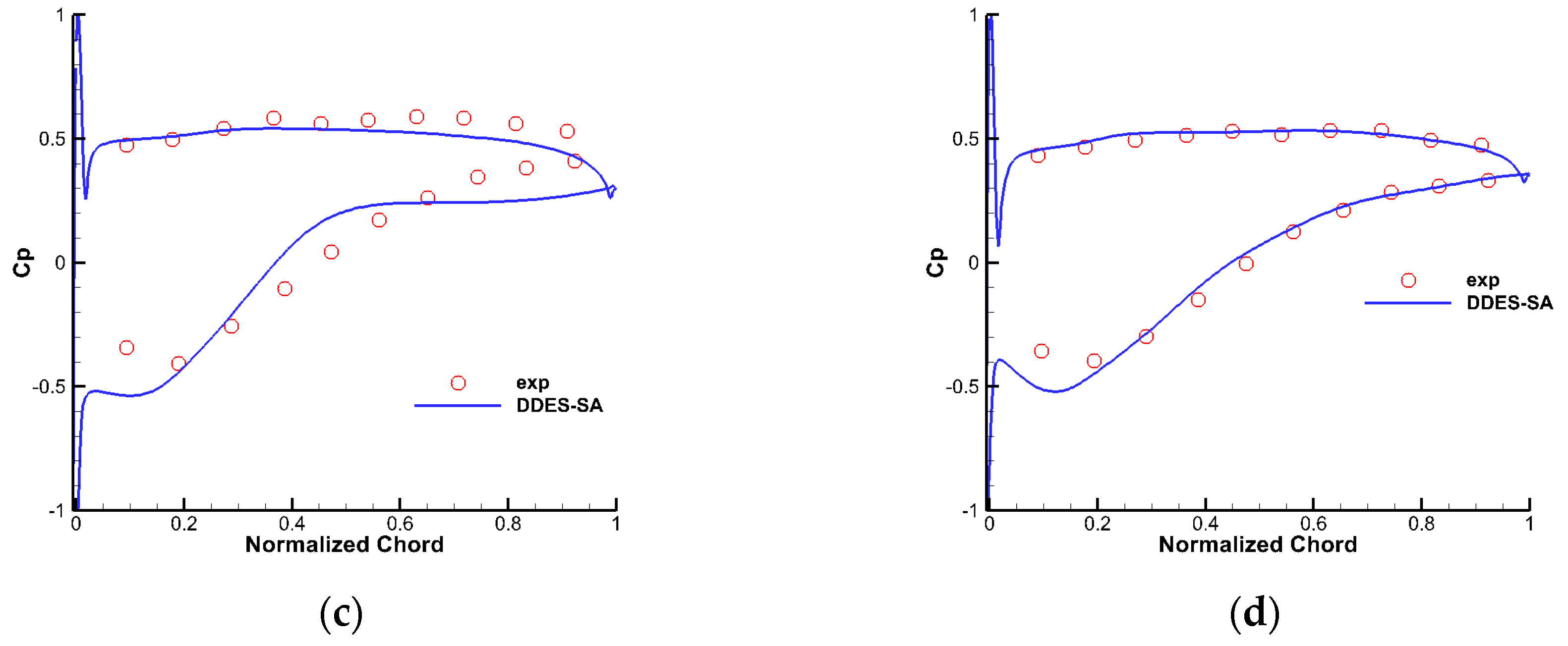

4. Validation of Numerical Results

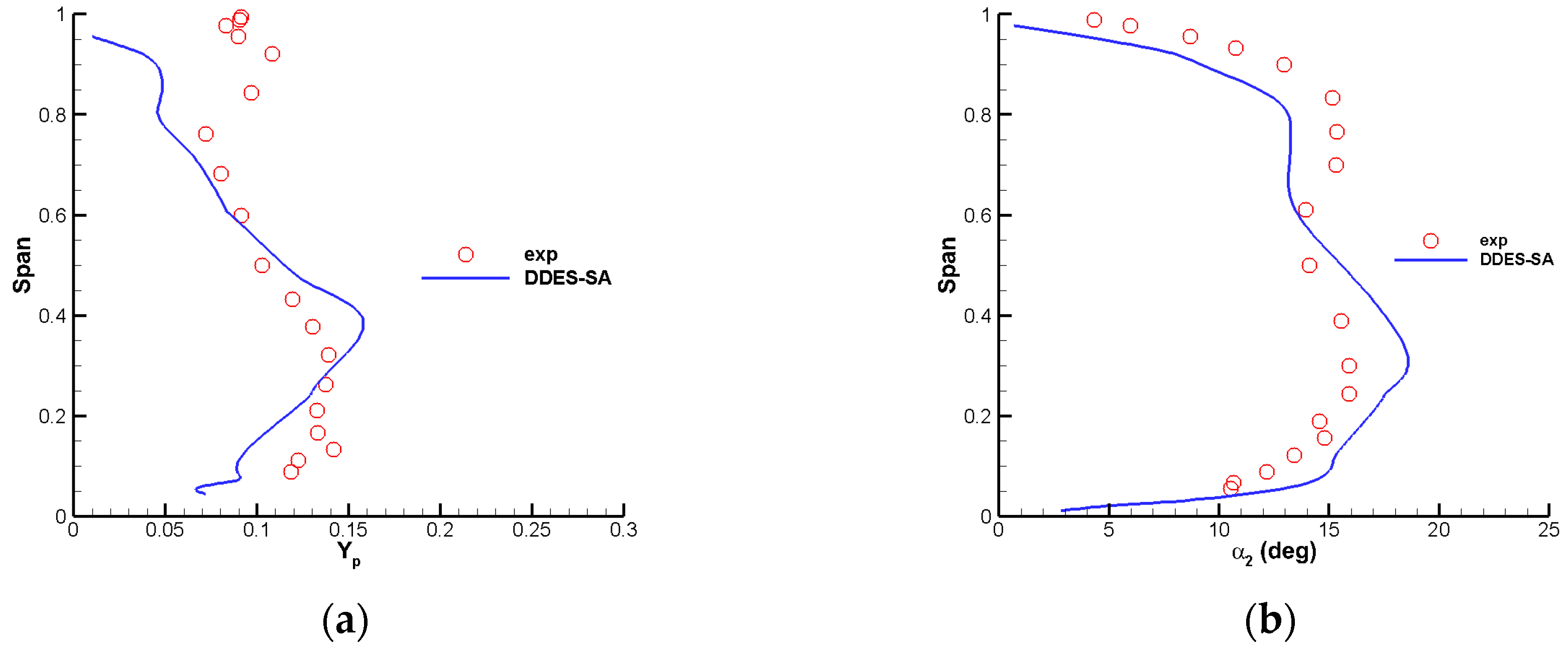

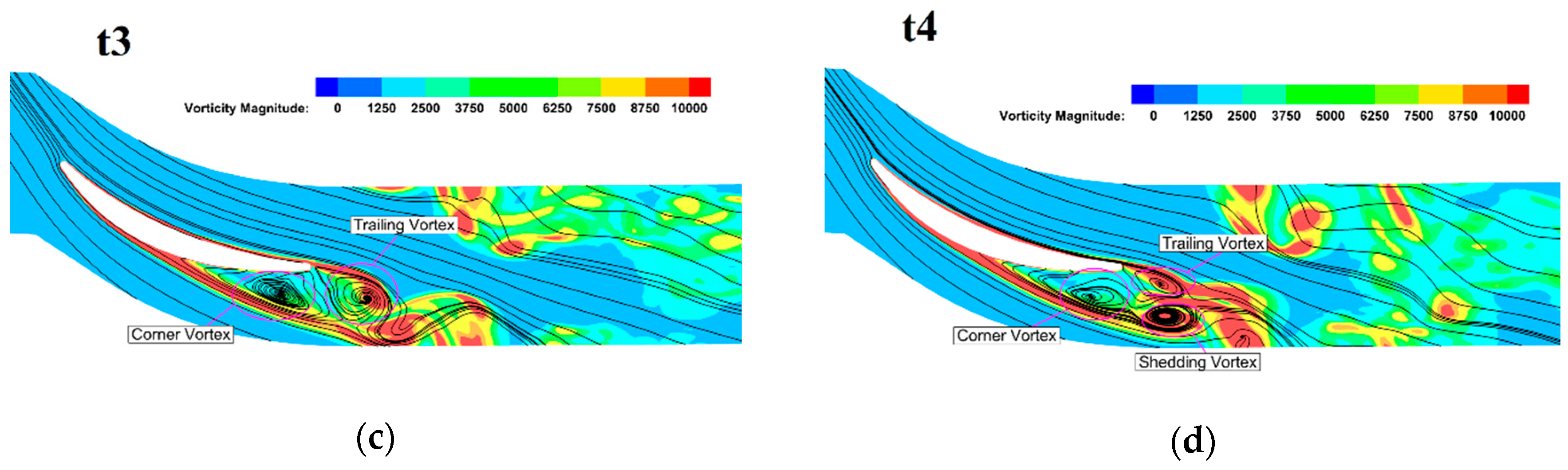

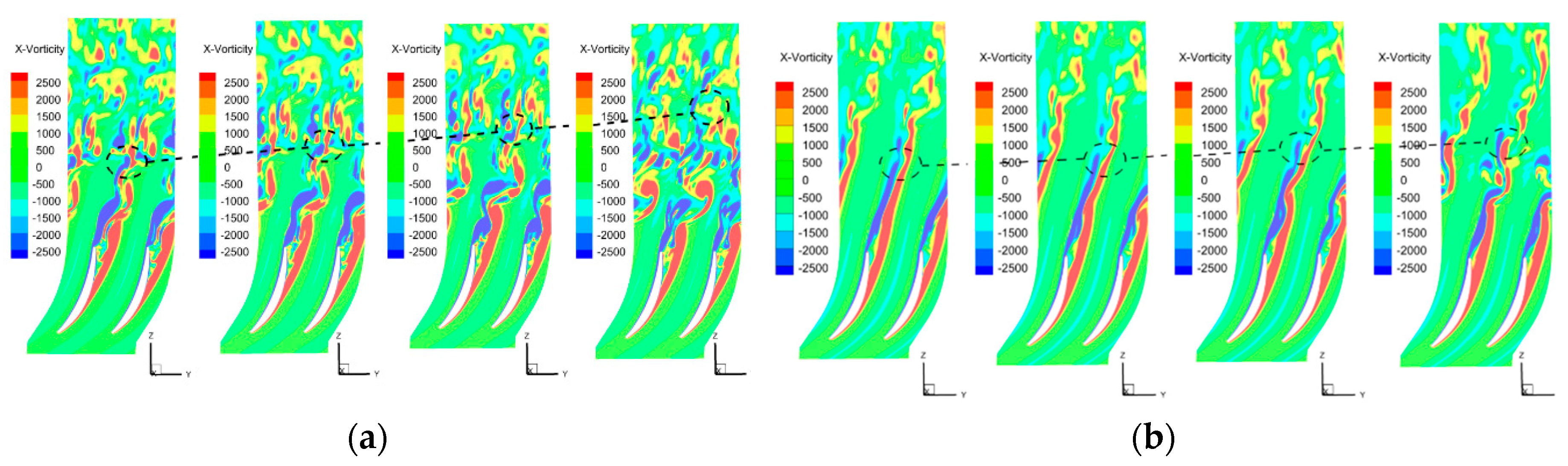

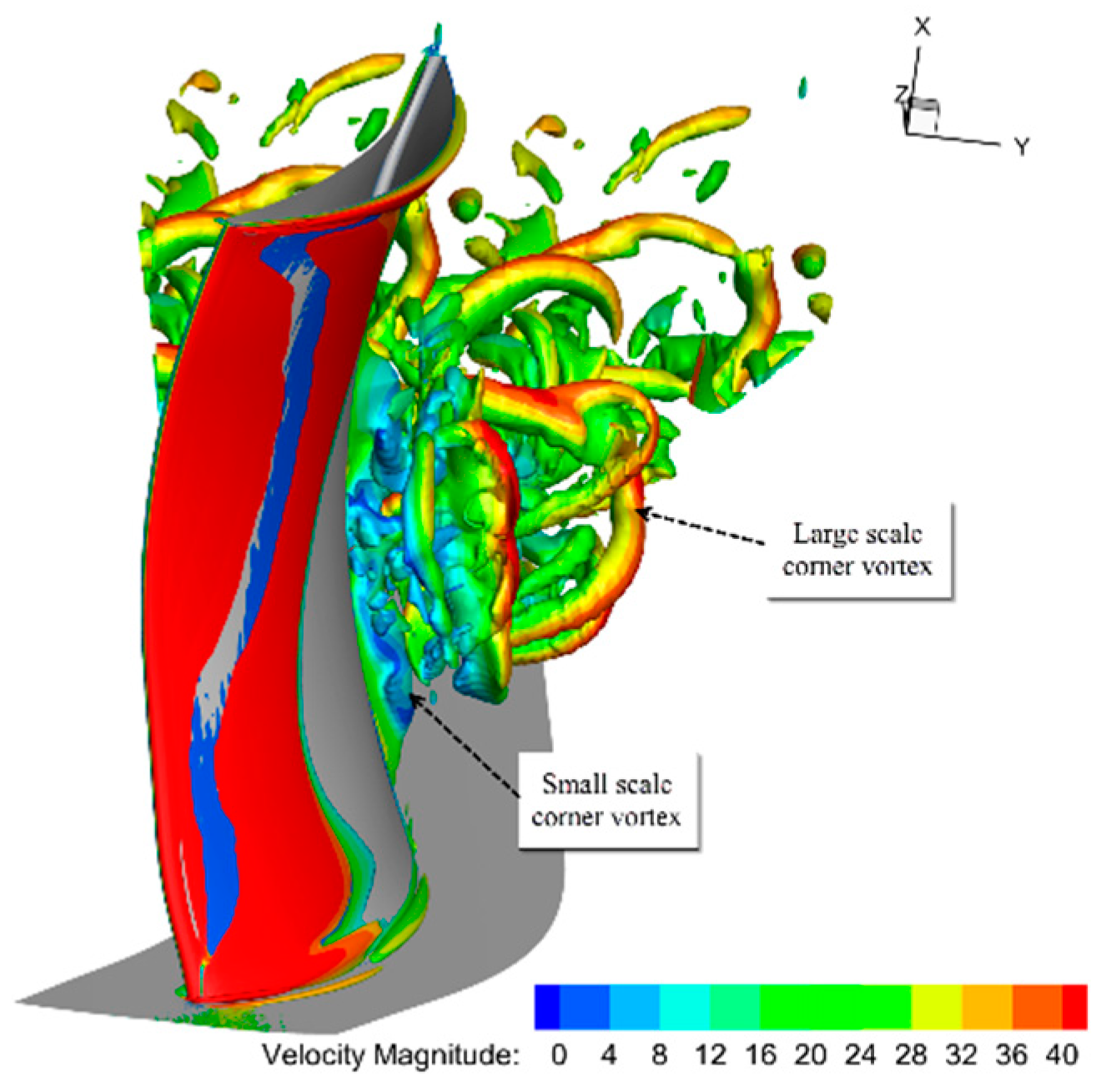

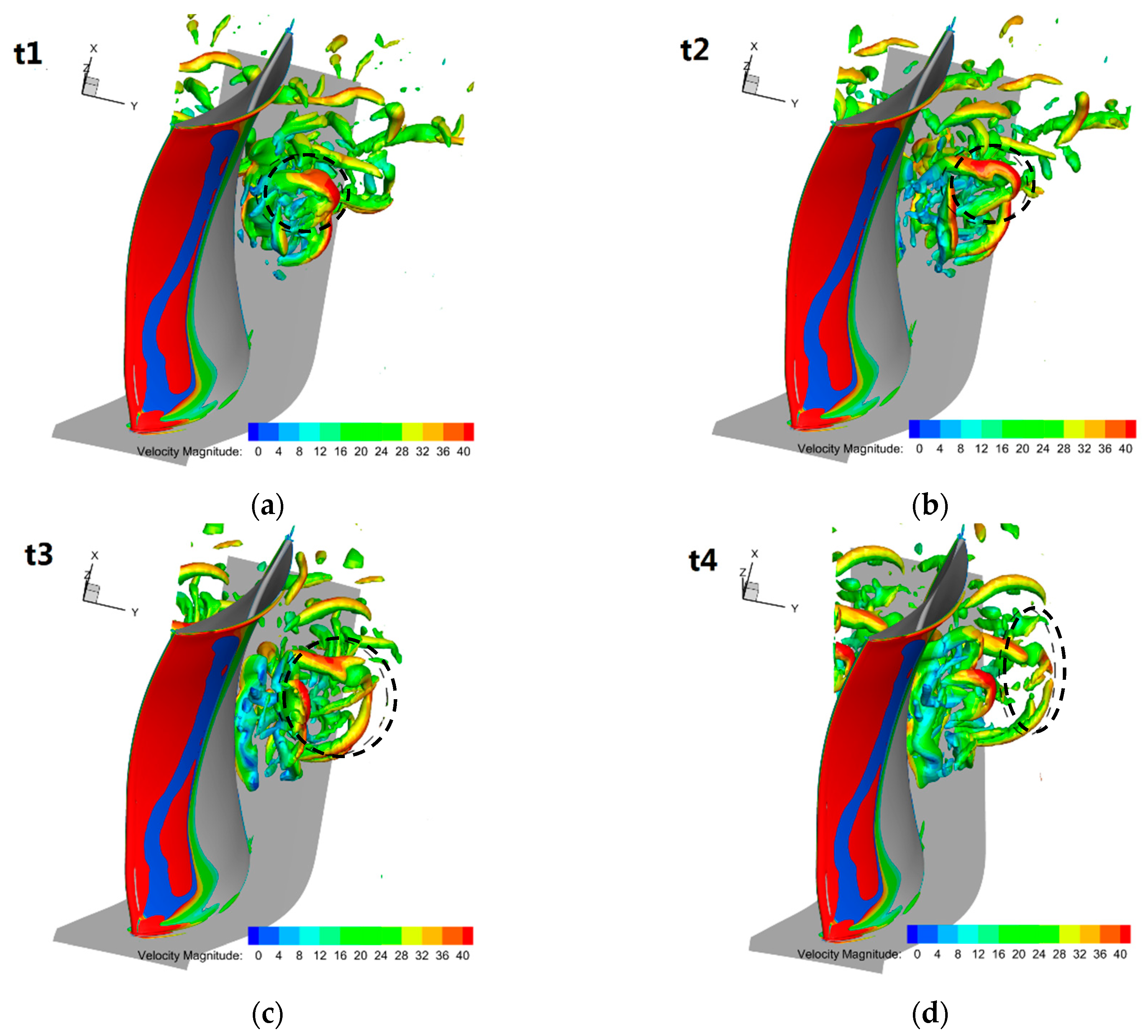

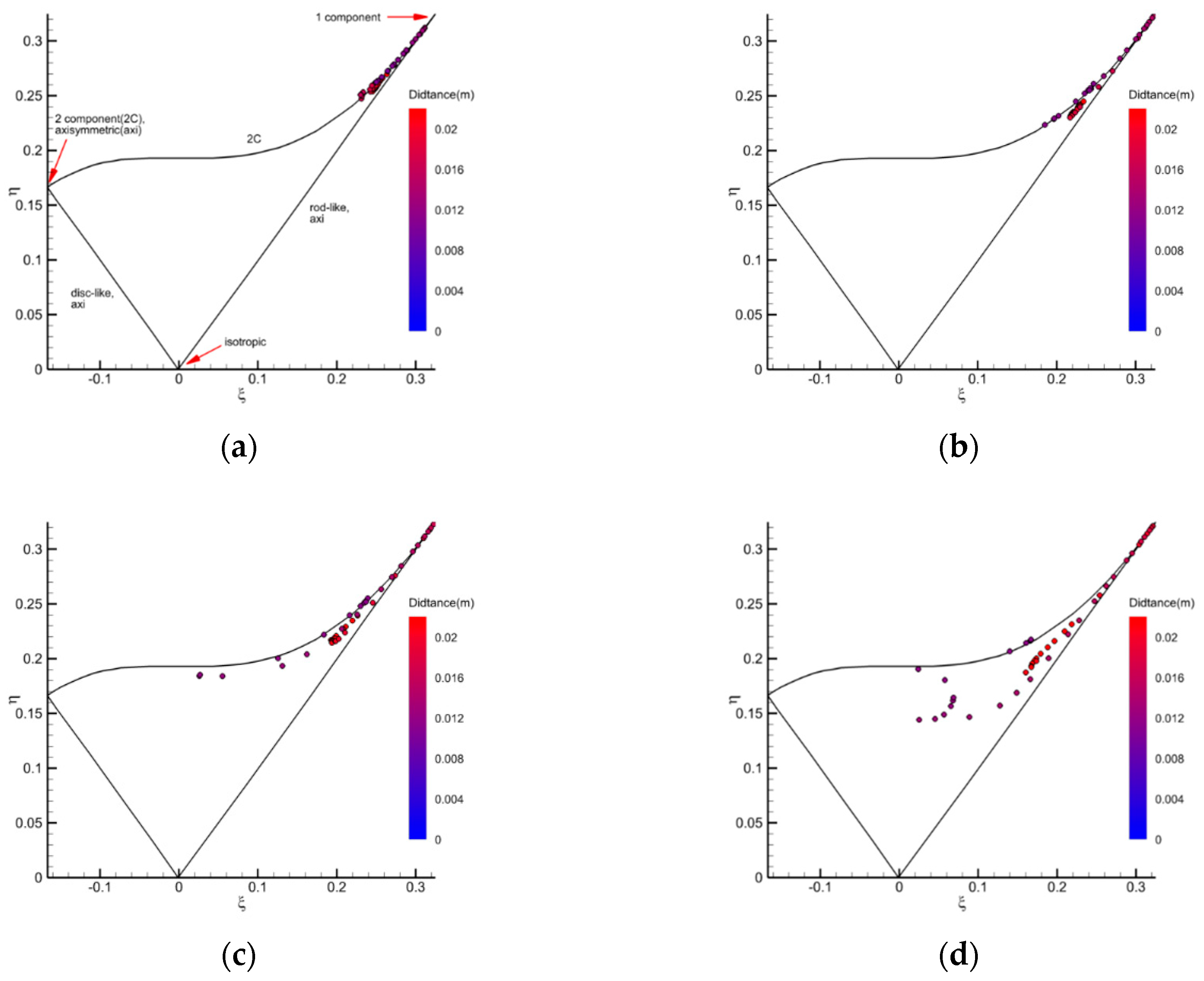

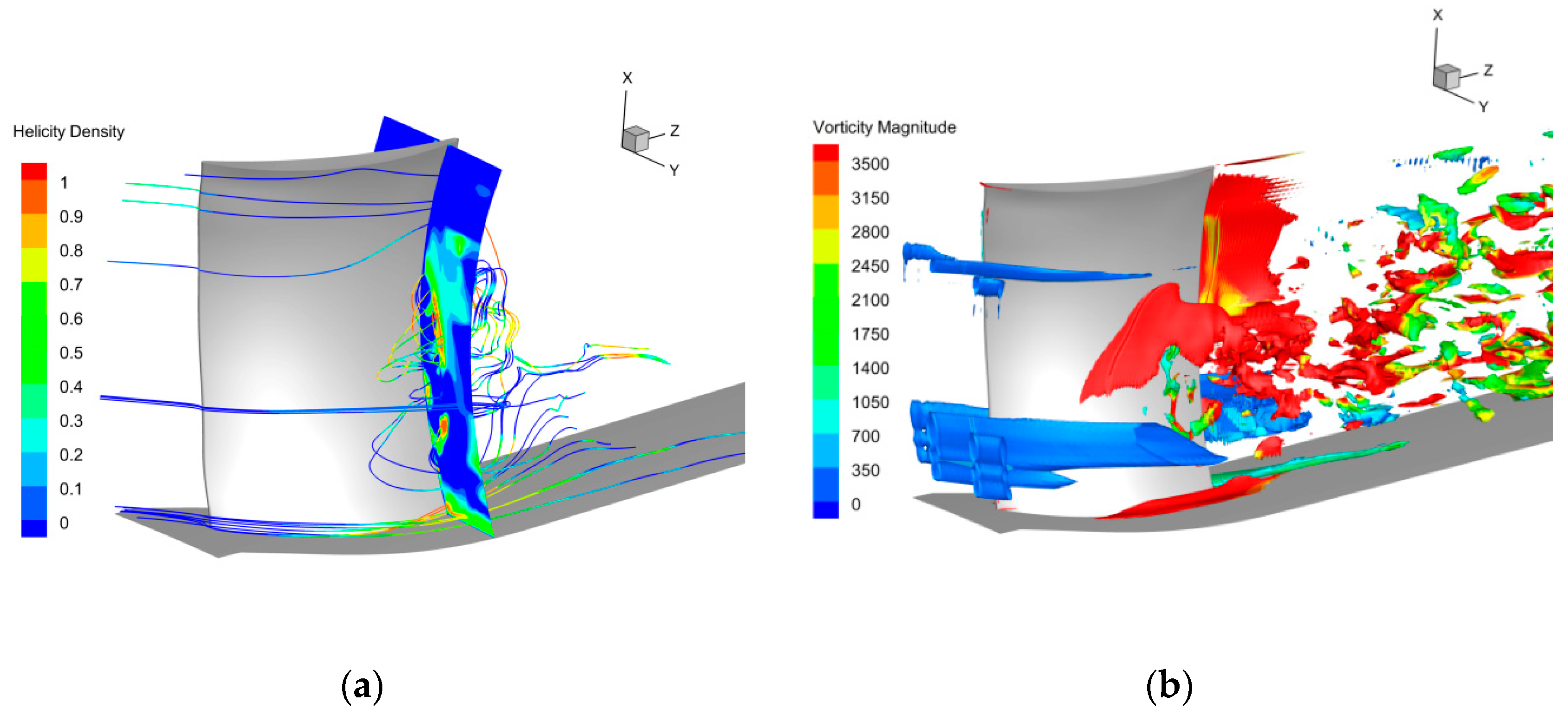

5. Vortical Structures

6. Turbulence Characteristics

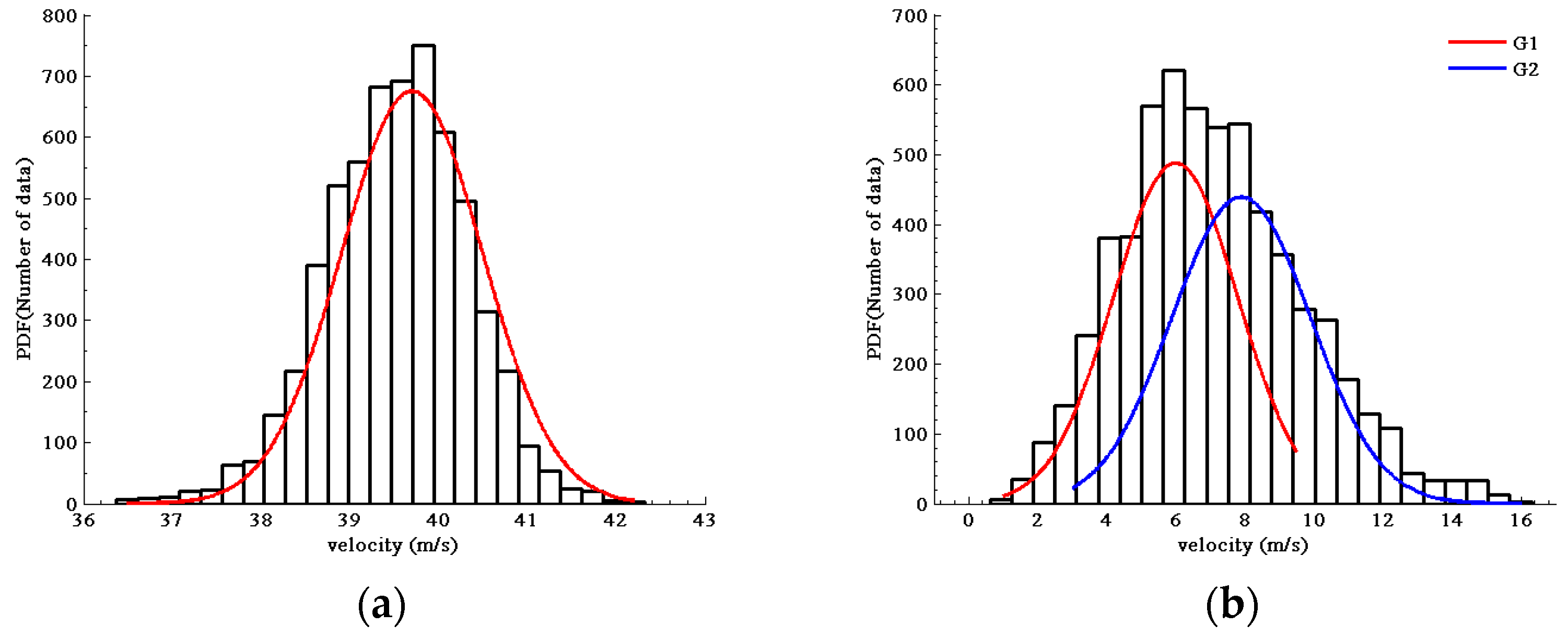

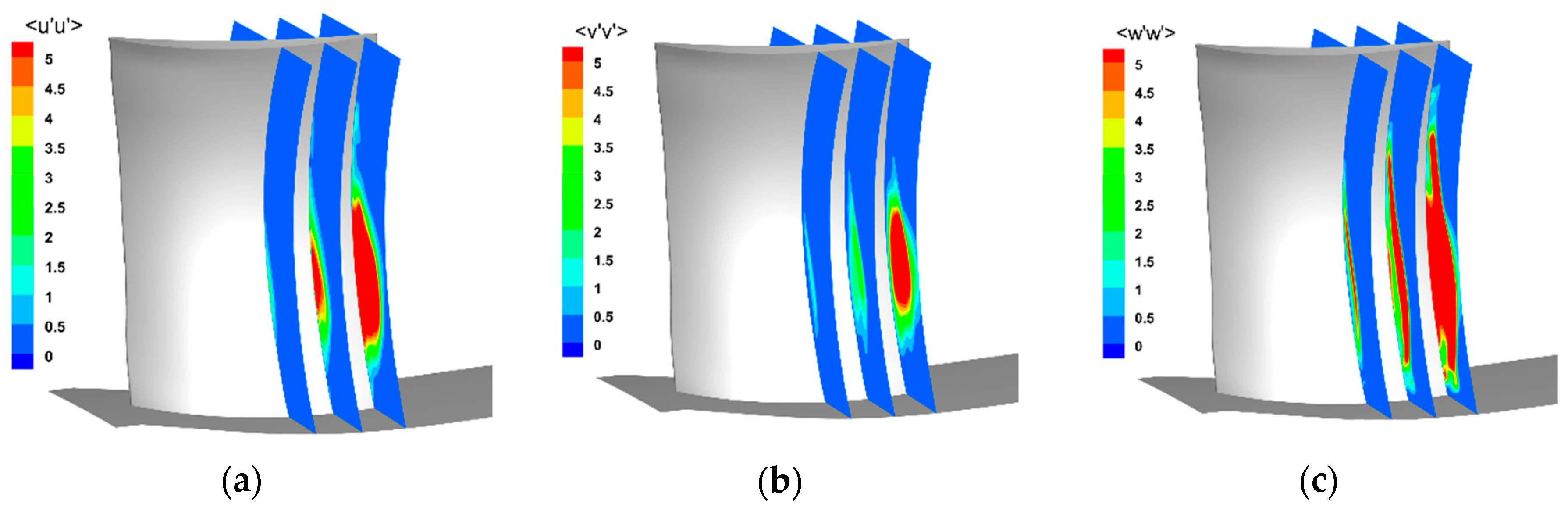

6.1. Statistics Analysis

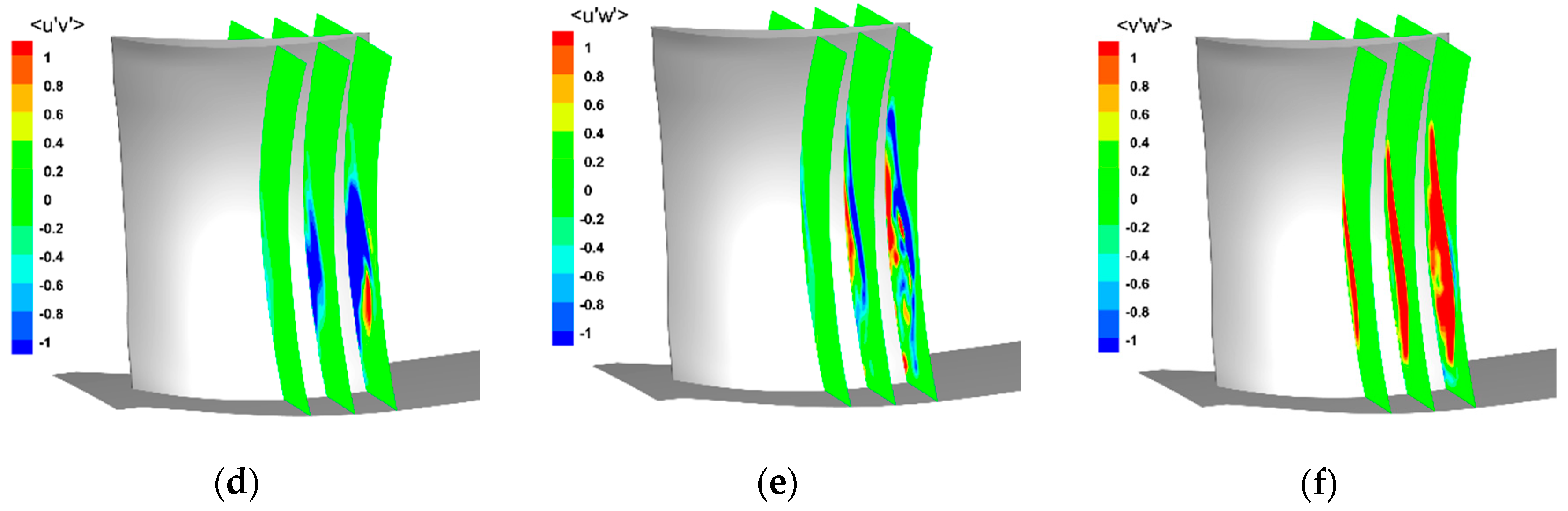

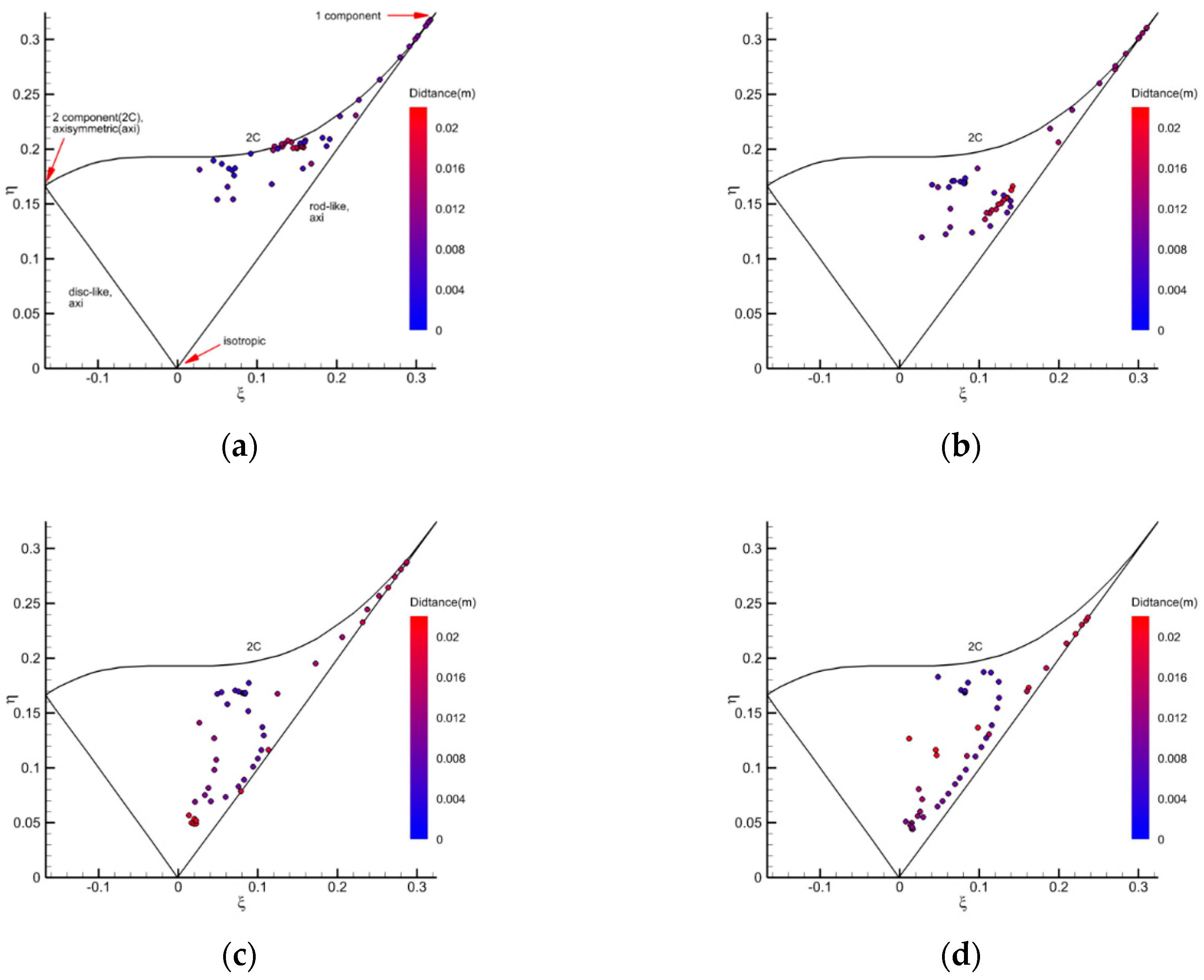

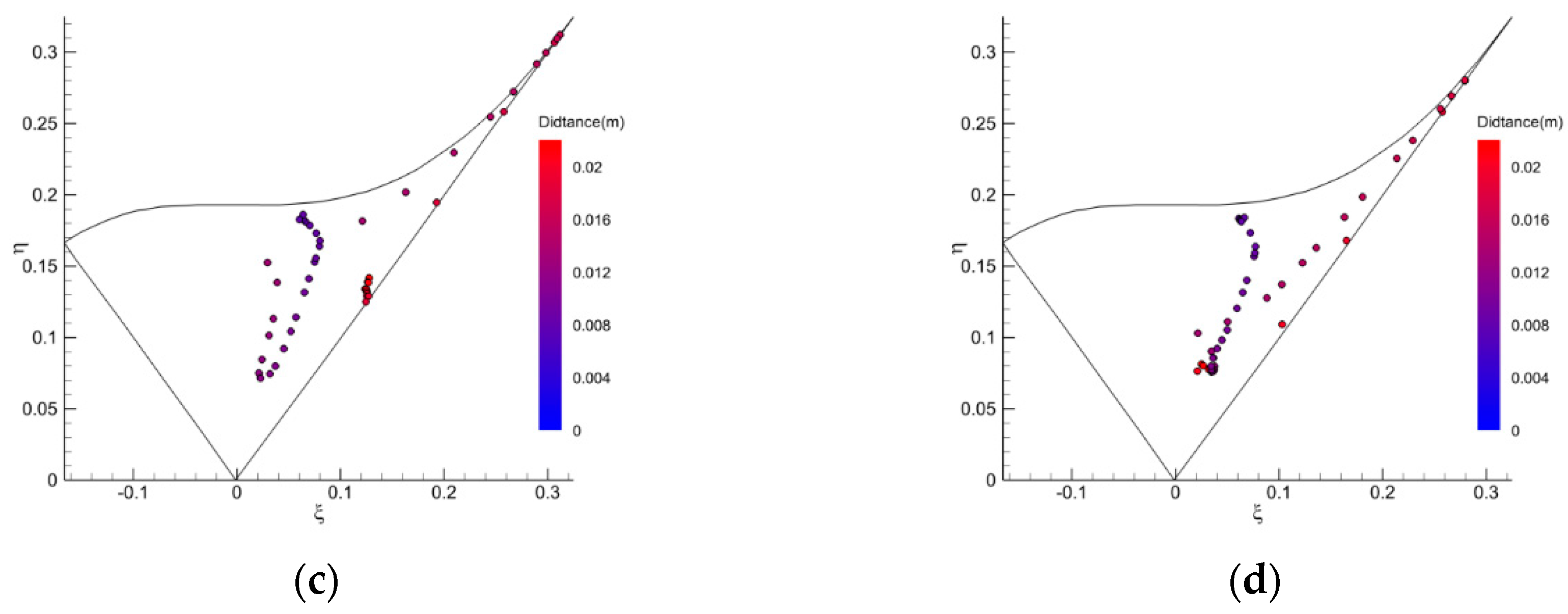

6.2. Turbulence Anisotropy

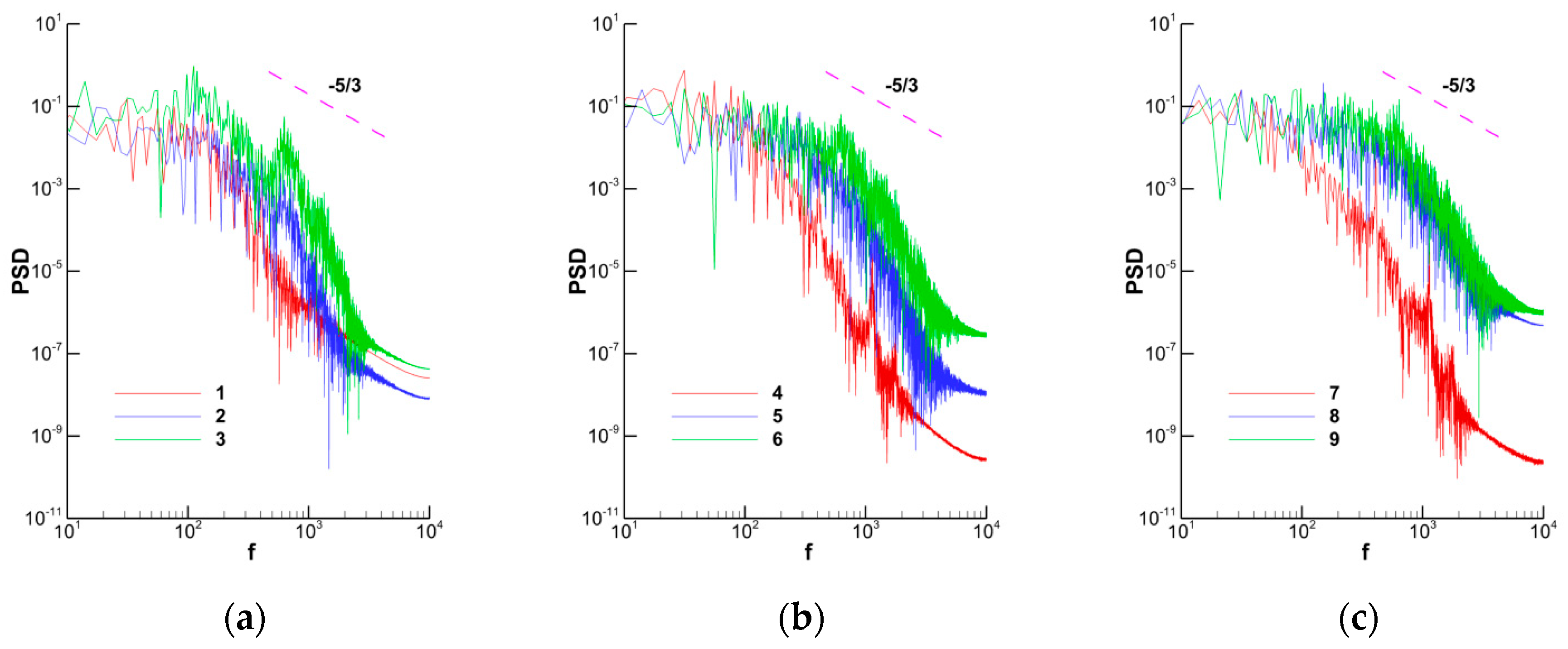

6.3. Turbulence Energy Spectra

7. Discussion

- (1)

- Based on the results of the DDES-SA method, the corner vortex, wake vortex, and shedding vortex exist in the corner separation region. A transverse pressure gradient generated by the lean design will drive the low-energy fluids at the hub into the midspan, making the position of the corner vortex move up along the blade. The corner vortex is a combination of multi-scale vortexes. The large-scale strip vortices with relatively high velocity exist at the outer edge of the separation region. At the same time, the small-scale vortices with relatively low velocity accumulate in the corner region.

- (2)

- The velocity probability density distribution of the monitor points in the corner separation region is approximately the superposition of two Gauss distributions, and the three-direction PDF of the points in the separation region is evenly distributed. The interaction of the vortices in the corner separation region makes the turbulent kinetic energy transport more active.

- (3)

- High anisotropy of turbulence has been observed in the stator corner separation region. The streamwise Reynolds normal stress plays a major role in the corner region, where the turbulence state develops from two-component turbulence along the top curve edge of the Lumley triangle to “rod-like” turbulence along the right edge of the Lumley triangle, when the turbulence flow moves downstream along the blade suction surface. The turbulent flow in the corner separation region is in nonequilibrium, with the slope of the energy spectra is stepper than −5/3.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| α1k | Leading blade angle |

| α2k | Trailing blade angle |

| α2 | Exit flow angle |

| P | Pressure |

| Cp | Static pressure coefficient; (p − p1)/(p01 − p1), 0 and 1 denotes stagnation and inflow quantity, respectively; |

| Yp | Total pressure loss coefficient; (p02 − p01)/(p01 − p1), 1 and 2 denotes inflow and exit quantity, respectively; |

| CFD | Computational Fluid Dynamics |

| LES | Large Eddy Simulation |

| DES | Detached Eddy Simulation |

| DDES | Delayed Detached-Eddy Simulation |

| FFT | Fast Fourier Transformation |

References

- Schulz, H.D.; Gallus, H.E. Experimental Investigations of the Three-Dimensional Flow in an Annular Compressor Cascade. ASME J. Turbomach. 1988, 110, 467–478. [Google Scholar] [CrossRef]

- Hah, C.; Loellbaeh, J. Development of Hub Corner Stall and its Influence on the Performance of Axial Compressor Blade Rows. ASME J. Turbomach. 1999, 121, 67–77. [Google Scholar] [CrossRef]

- Weber, A.; Schreiber, H.-A.; Fuchs, R.; Steinert, W. 3-D Transonic Flow in a Compressor Cascade with Shock-Induce Corner Stall. ASME J. Turbomach. 2002, 124, 358–365. [Google Scholar] [CrossRef]

- Lei, V.M.; Spakovszky, Z.S.; Greitzer, E.M. A criterion for axial compressor hub-corner stall. ASME J. Turbomach. 2008, 130, 031006. [Google Scholar] [CrossRef]

- Gallimore, S.J.; Bolger, J.J.; Cumpsty, N.A.; Taylor, M.J.; Wright, P.I.; Place, J.M. The Use of Sweep and Dihedral in Multistage Axial Flow Compressor Blading—Part I: University Research and Methods Development. ASME J. Turbomach. 2002, 124, 521–532. [Google Scholar] [CrossRef]

- Gbadebo, S.A.; Cumpsty, N.A.; Hynes, T.P. Control of three dimensional separations in axial compressors by tailored boundary layer suction. ASME J. Turbomach. 2008, 130, 011004.1–011004.8. [Google Scholar] [CrossRef]

- Hergt, A.; Dorfner, C.; Steinert, W.; Nicke, E.; Schreiber, H.-A. Advanced Nonaxisymmetric Endwall Contouring for Axial Compressors by Generating an Aerodynamic Separator-Part II: Experimental and Numerical Cascade Investigation. ASME J. Turbomach. 2011, 133, 021027. [Google Scholar] [CrossRef]

- Spalart, P.R. Philosophies and fallacies in turbulence modeling. Prog. Aerosp. Sci. 2014, 74, 1–15. [Google Scholar] [CrossRef]

- Spalart, P.R.; Jou, W.H.; Strelets, M.; Allmaras, S.R. Comments on the Feasibility of LES for Wings and on Hybrid RANS/LES Approach. In Proceedings of the AFOSR International Conference on DNS and LES: Advances in DNS/LES, Ruston, LA, USA, 4–8 August 1997; pp. 137–147. [Google Scholar]

- Wang, Z.; Yuan, X. Unsteady mechanisms of compressor corner separation over a range of incidences based on hybrid LES/RANS. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013; pp. 1–11. [Google Scholar]

- Xia, G.; Medic, G. Hybrid RANS/LES Simulation of Corner Stall in a Linear Compressor Cascade. Paper No. GT2017-63454. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Liu, Y.W.; Yan, H.; Lu, L.P.; Li, Q. Investigation of vortical structures and turbulence characteristics in corner separation in a linear compressor cascade using DDES. J. Fluids Eng. 2017, 139, 021107. [Google Scholar] [CrossRef]

- Taylor, J.; Miller, R. Competing 3D Mechanisms in Compressor Flow. ASME J. Turbomach. 2016, 139, 021009. [Google Scholar] [CrossRef]

- Zhang, C.K.; Hu, J.; Wang, Z.Q.; Gao, X. Design Work of a Compressor Stage Through High-To-Low Speed Compressor Transformation. ASME J. Eng. Gas Turbines Power 2014, 136, 064501. [Google Scholar] [CrossRef]

- Zhang, C.K.; Wang, Z.Q.; Yin, C.; Yan, W.; Hu, J. Low-Speed Model Testing Studies for an Exit Stage of High Pressure Compressor. ASME J. Eng. Gas Turbines Power 2014, 136, 112603. [Google Scholar] [CrossRef]

- Zhang, C.K.; Hu, J.; Wang, Z.Q.; Li, J. Experimental Investigations on 3D Blading Optimization for Low-Speed Model Testing. ASME J. Eng. Gas Turbines Power 2016, 138, 112602. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Hu, J.; Luo, J.; Li, L.; Gao, X. Investigation of Three-Dimension Flow in a Multi-Stage Compressor Stator. J. Propuls. Technol. 2012, 33, 371–376. (In Chinese) [Google Scholar]

- Zhang, C.K.; Hu, J.; Li, J.; Wang, Z.Q. Three-Dimensional Compressor Blading Design Improvements in Low-Speed Model Testing. Aerosp. Sci. Technol. 2017, 63, 179–190. [Google Scholar] [CrossRef]

- Spalart, P.R. Young-Person’s Guide to Detached-Eddy Simulation Grids; Technical Report No. NASA/CR-2001-211032; NASA Langley Research Center: Hampton, VA, USA, 2001.

- Jeong, J.; Hussain, F. On the identification of a vortex. J. Fluid Mech. 1995, 289, 69–94. [Google Scholar] [CrossRef]

- Zambonini, G.; Ottavy, X.; Kriegseis, J. Corner Separation Dynamics in a Linear Compressor Cascade. Paper GT2016-56454. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Simonsen, A.J.; Krogstad, P.A. Turbulent Stress Invariant Analysis: Clarification of Existing Terminology. Phys. Fluids 2005, 17, 088103. [Google Scholar] [CrossRef]

- Liu, Y.W.; Lu, L.P.; Fang, L.; Gao, F. Modification of Spalart–Allmaras model with consideration of turbulence energy backscatter using velocity helicity. Phys. Lett. A 2011, 375, 2377–2381. [Google Scholar] [CrossRef]

| Design Parameter | Value |

|---|---|

| Blade number | 120 |

| Casing diameter (mm) | 1500 |

| Hub-to-tip ratio | 0.88 |

| Mid-span Reynolds Number | 4.6 × 105 |

| Chord (tip/mid/hub) (mm) | 61.0/60/64.8 |

| Solidity (tip/mid/hub) | 1.61/1.64/1.91 |

| Mass flow rate coefficient | 0.385 |

| Tip clearance/blade height (%) | 0 |

| r/R | Chord (mm) | Stagger Angle γ (°) | Leading Blade Angle α1k (°) | Trailing Blade Angle α2k (°) | Maximum Relative Thickness Cmax |

|---|---|---|---|---|---|

| 0.00 | 61.0 | 54.82 | 61.71 | −0.25 | 0.0795 |

| 0.05 | 61.1 | 52.53 | 61.14 | 0.42 | 0.0791 |

| 0.10 | 60.2 | 51.43 | 60.65 | 1.17 | 0.0861 |

| 0.30 | 59.7 | 51.61 | 59.74 | 2.28 | 0.0822 |

| 0.50 | 60.0 | 51.48 | 59.87 | 2.89 | 0.0820 |

| 0.70 | 60.9 | 51.57 | 60.99 | 2.64 | 0.0848 |

| 0.90 | 63.5 | 52.14 | 63.57 | 1.65 | 0.0969 |

| 0.95 | 64.2 | 53.43 | 64.23 | 1.20 | 0.1020 |

| 1.00 | 64.8 | 53.82 | 64.85 | 0.24 | 0.1066 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Hu, J.; Zhang, C. Investigation of Vortical Structures and Turbulence Characteristics in Corner Separation in an Axial Compressor Stator Using DDES. Energies 2020, 13, 2123. https://doi.org/10.3390/en13092123

Li J, Hu J, Zhang C. Investigation of Vortical Structures and Turbulence Characteristics in Corner Separation in an Axial Compressor Stator Using DDES. Energies. 2020; 13(9):2123. https://doi.org/10.3390/en13092123

Chicago/Turabian StyleLi, Jun, Jun Hu, and Chenkai Zhang. 2020. "Investigation of Vortical Structures and Turbulence Characteristics in Corner Separation in an Axial Compressor Stator Using DDES" Energies 13, no. 9: 2123. https://doi.org/10.3390/en13092123

APA StyleLi, J., Hu, J., & Zhang, C. (2020). Investigation of Vortical Structures and Turbulence Characteristics in Corner Separation in an Axial Compressor Stator Using DDES. Energies, 13(9), 2123. https://doi.org/10.3390/en13092123