CFD Based Design for Ejector Cooling System Using HFOS (1234ze(E) and 1234yf)

Abstract

1. Introduction

2. Ejector Refrigeration Cycle

3. Numerical Model Descriptions

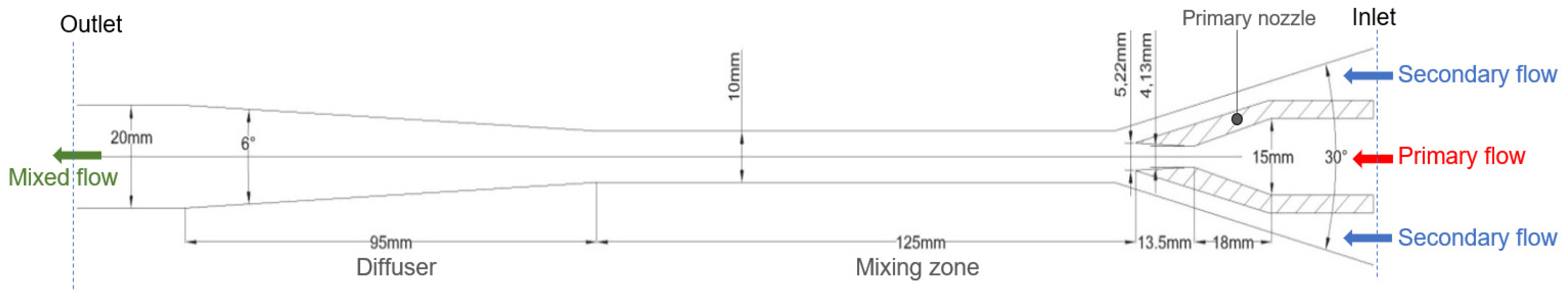

3.1. Ejector Design

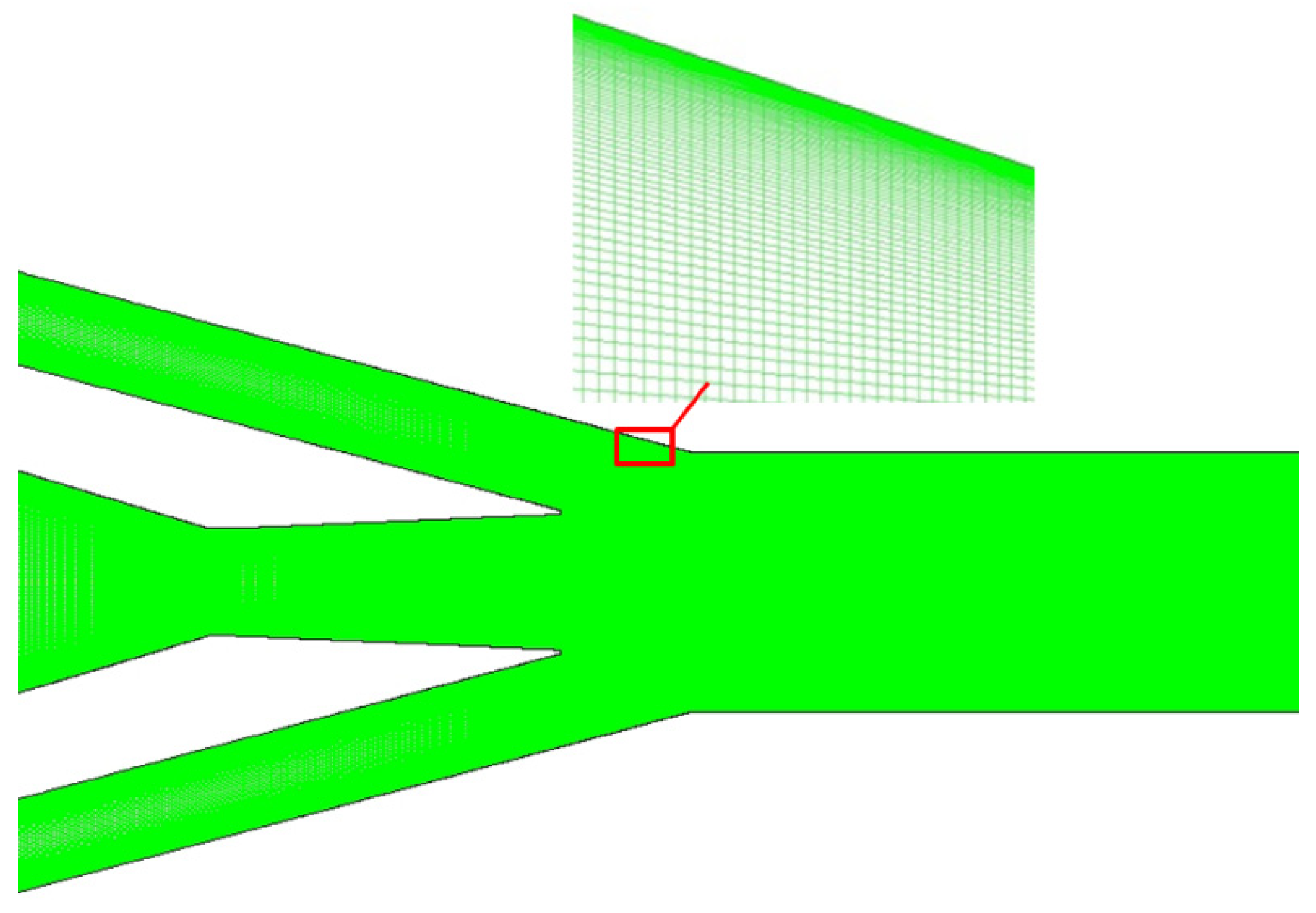

3.2. CFD Implementation

3.3. Boundary Conditions

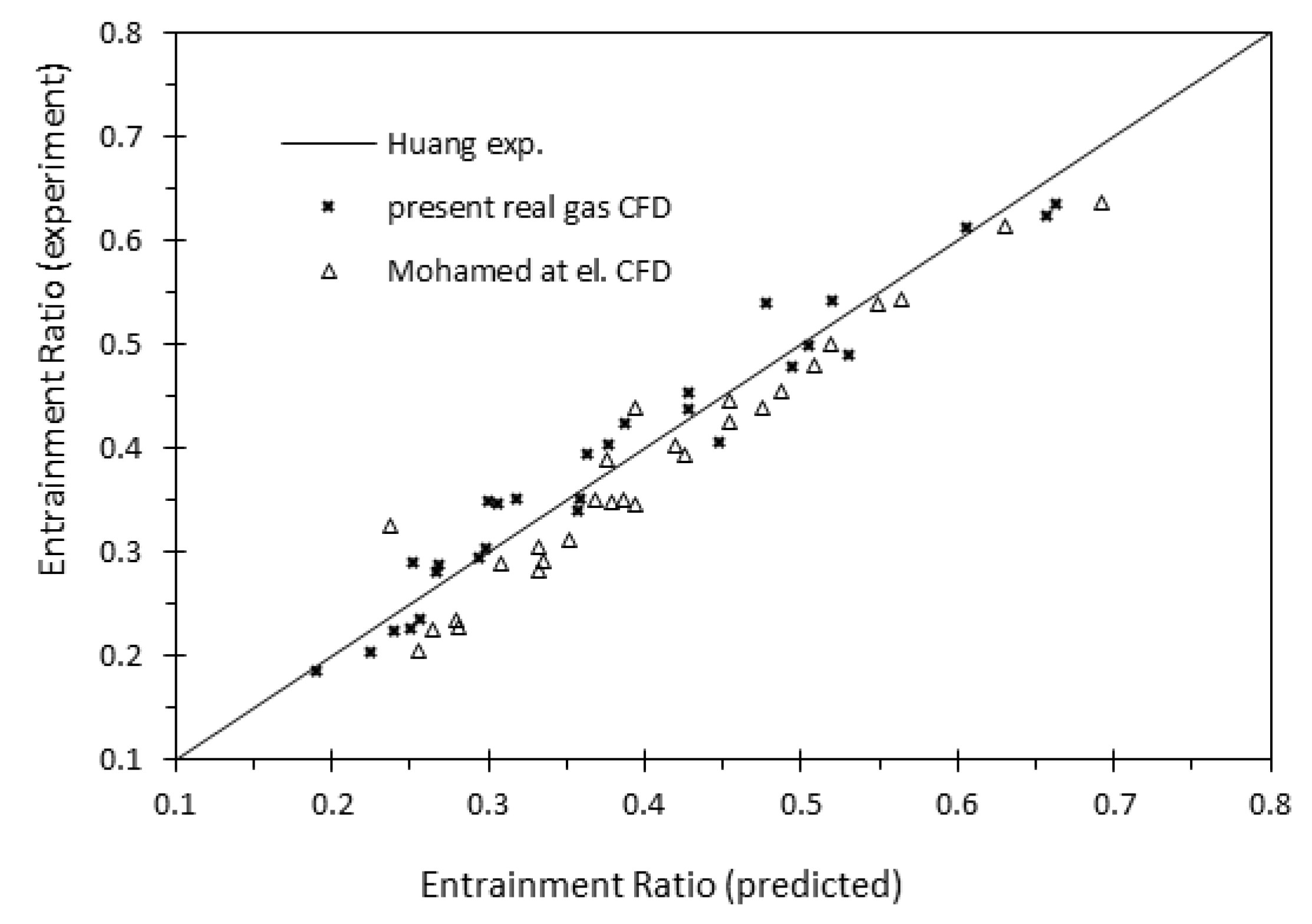

4. Numerical Validation

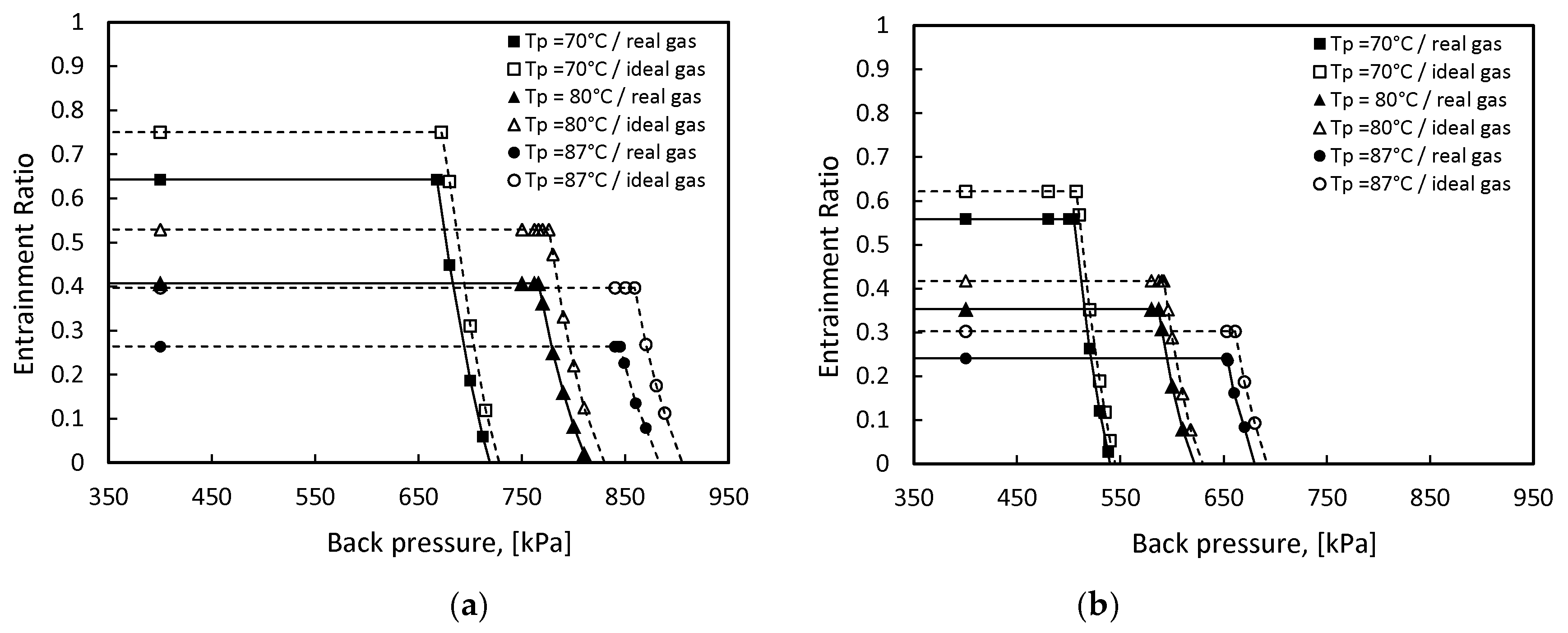

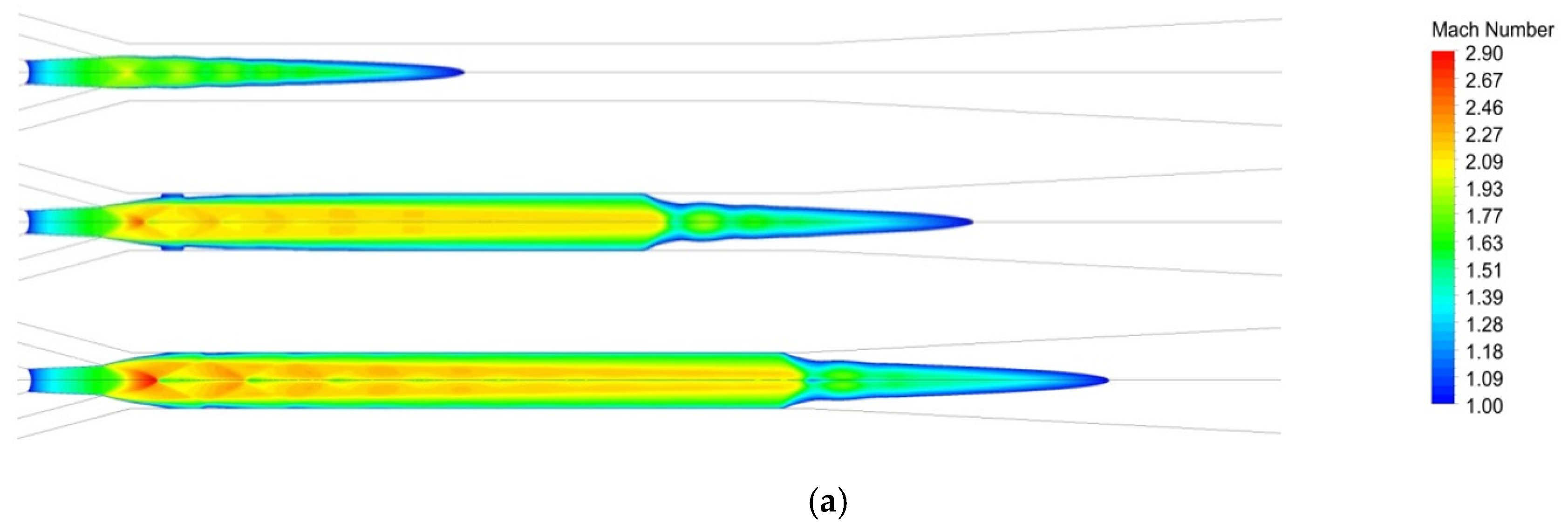

5. Comparison of Real and Ideal Gas Flow Results

6. CFD Analysis of the Ejector

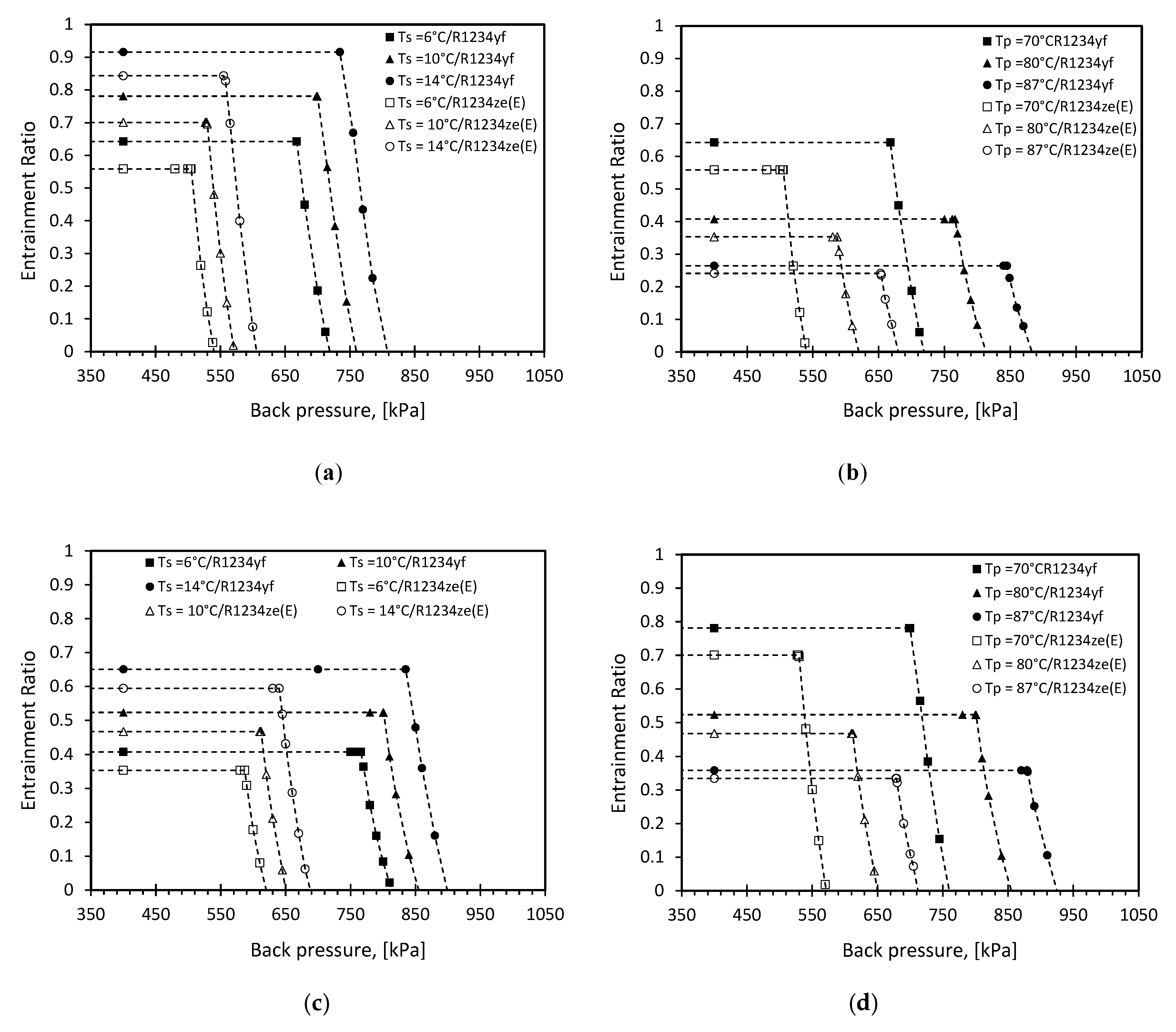

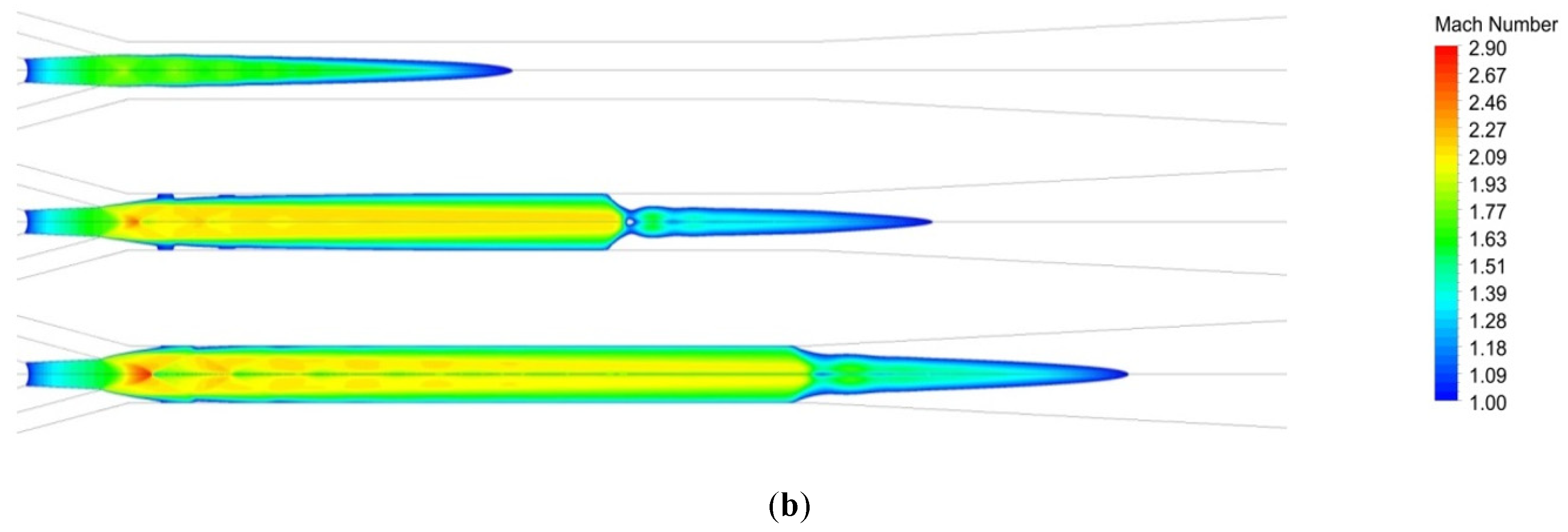

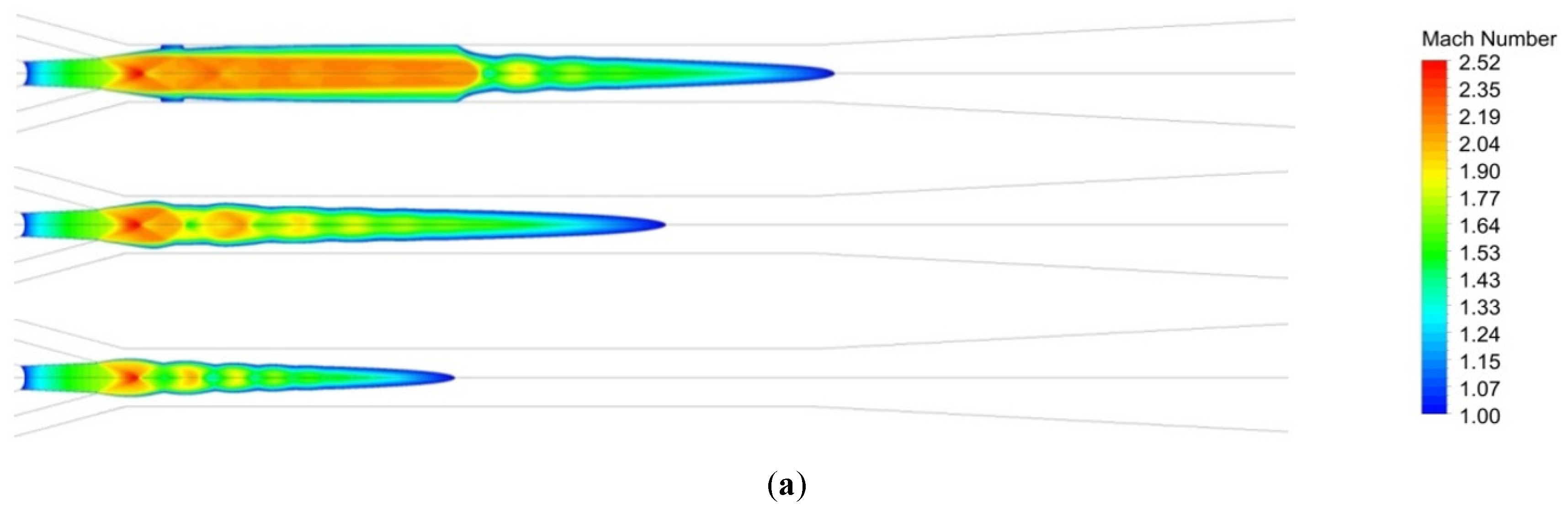

6.1. Effect of Operation Conditions

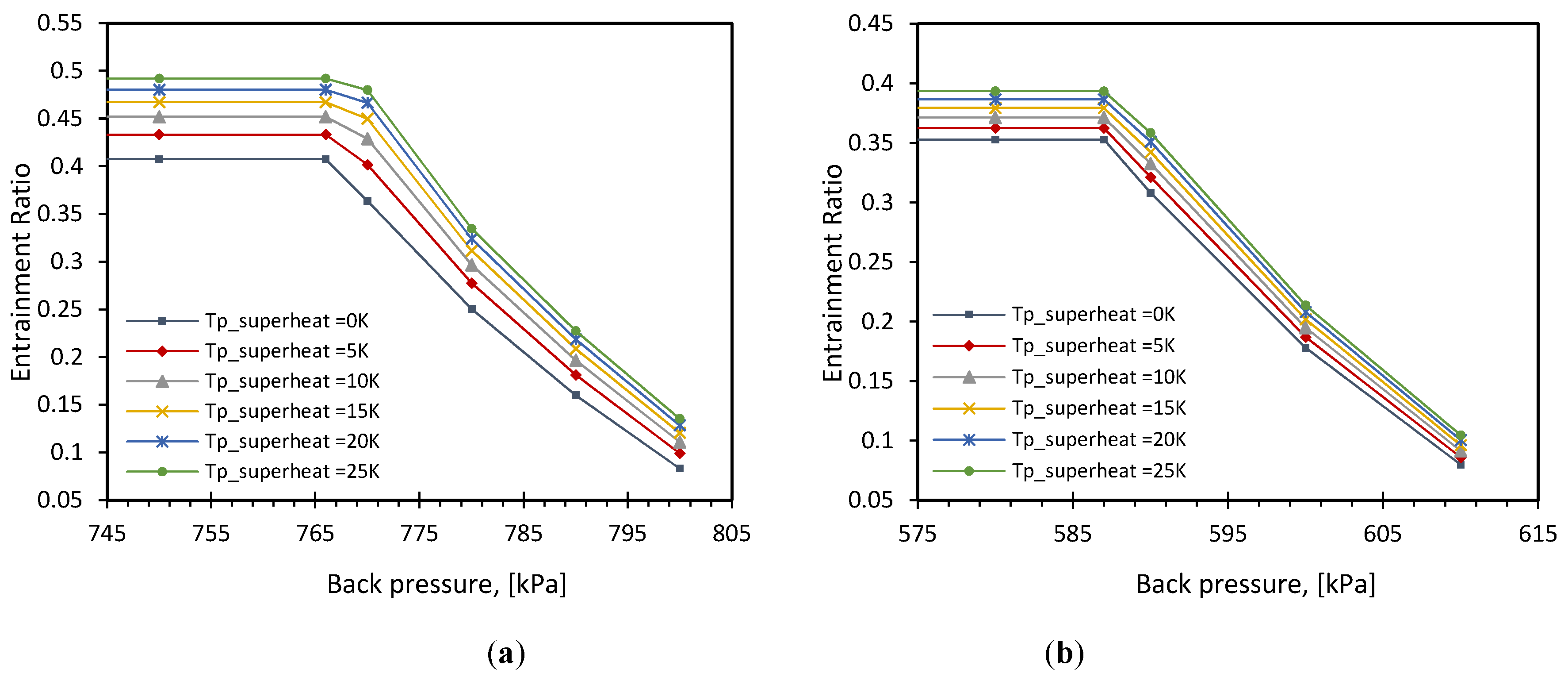

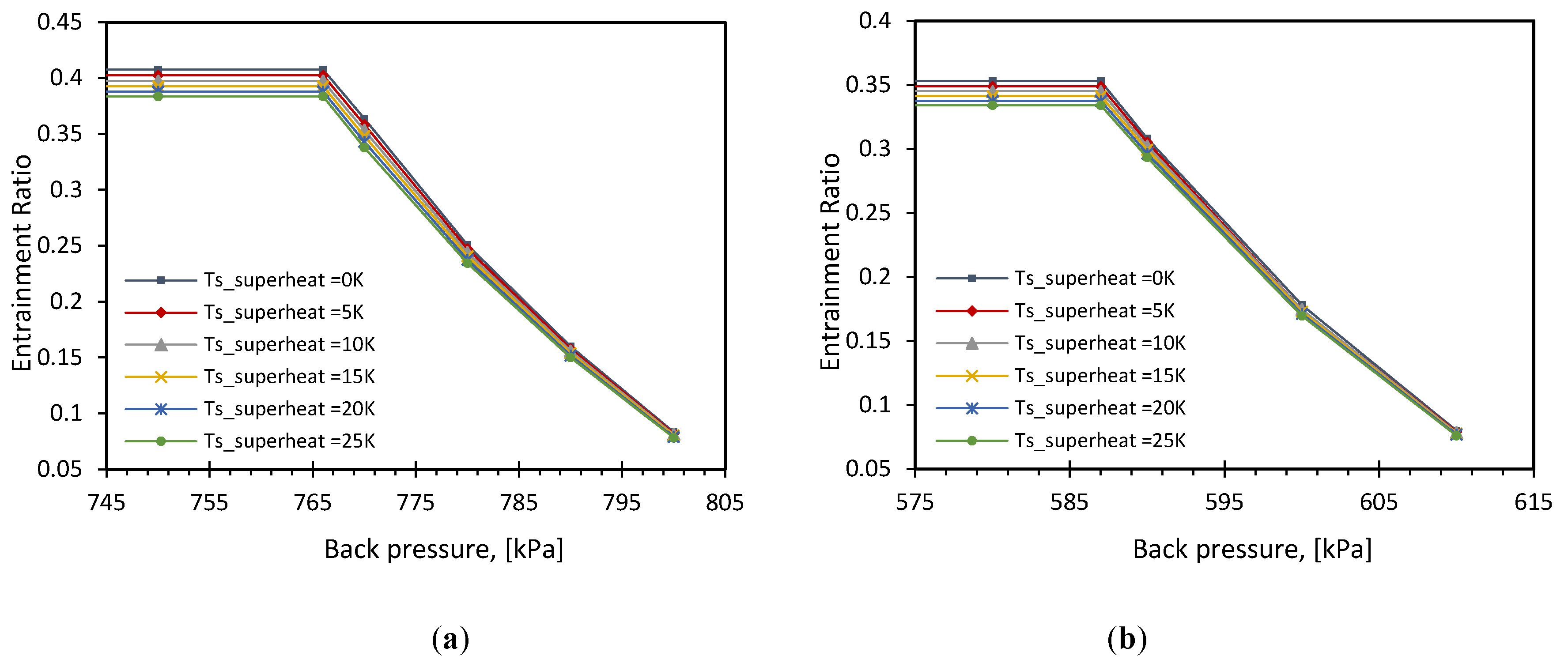

6.2. Effect of Superheat

6.3. Ejector Performance Mapping

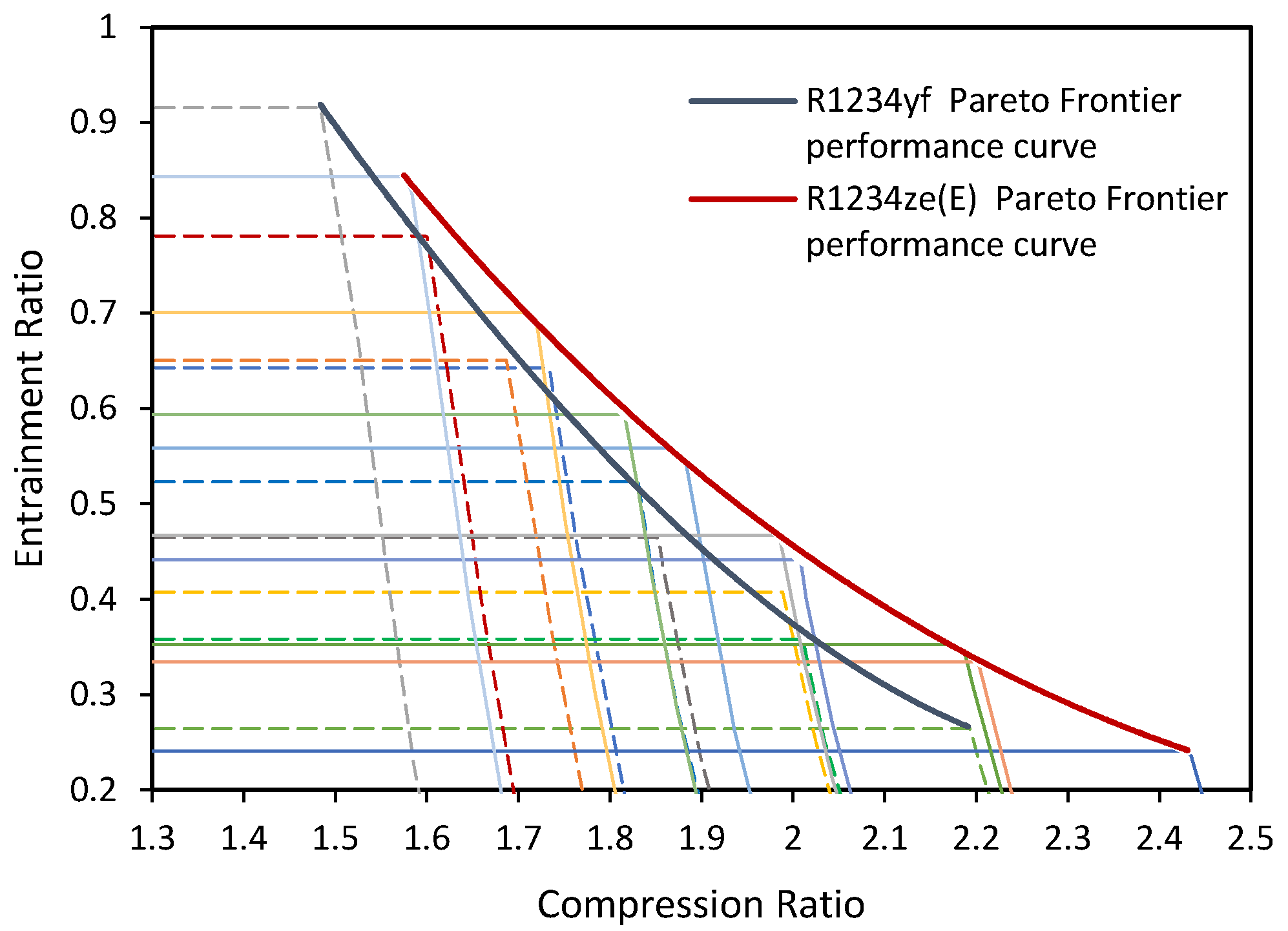

6.4. Pareto Frontier Solution Curve

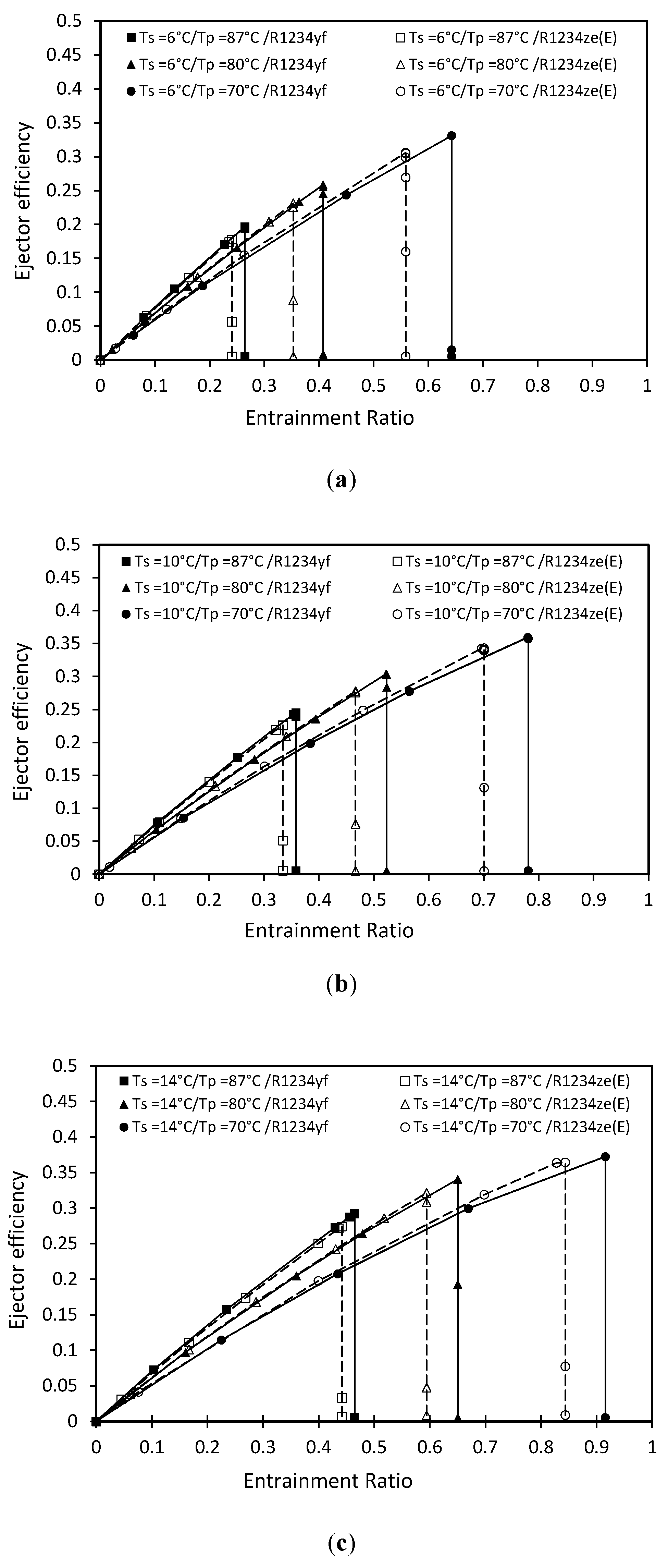

6.5. Ejector Efficiency

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CR | compression ratio parameter |

| ER | expansion ratio |

| NXP | Nozzle Exit Position |

| h | specific enthalpy (kJkg−1) |

| P | Pressure (kPa) |

| T | Temperature (°C) |

| entrainment ratio (-) | |

| efficiency (-) | |

| ṁ | mass flow rate (kg/s) |

| κ | specific heat ratio, (-) |

| Subscripts | |

| p | primary flow |

| s | secondary flow |

| c | outlet mixed flow |

| cri | critical |

| is | isentropic |

References

- Shestopalov, K.O.; Huang, B.J.; Petrenko, V.O.; Volovyk, O.S. Investigation of an experimental ejector refrigeration machine operating with refrigerant R245fa at design and off-design working conditions. Part 1. Theoretical analysis. Int. J. Refrig. 2015, 55, 201–211. [Google Scholar] [CrossRef]

- International Energy Agency. Air Conditioning Use Emerges as One of the Key Drivers of Global Electricity-Demand Growth. Available online: https://www.iea.org/newsroom/news/2018/may/air-conditioning-use-emerges-as-one-of-the-key-drivers-of-global-electricity-dema.html (accessed on 15 October 2019).

- Honra, J.; Berana, M.S.; Danao, L.A.M.; Manuel, M.C.E. CFD analysis of supersonic ejector in ejector refrigeration system for air conditioning application. Lect. Notes Eng. Comput. Sci. 2017, 2230, 1019–1024. [Google Scholar]

- Chen, X.; Omer, S.; Worall, M.; Riffat, S. Recent developments in ejector refrigeration technologies. Renew Sustain Energy Rev. 2013, 19, 629–651. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F. Computational fluid-dynamics modeling of supersonic ejectors: Screening of turbulence modeling approaches. Appl. Therm. Eng. 2017, 117, 122–144. [Google Scholar] [CrossRef]

- He, S.; Li, Y.; Wang, R.Z. Progress of mathematical modeling on ejectors. Renew Sustain Energy Rev. 2009, 13, 1760–1780. [Google Scholar] [CrossRef]

- Scott, D.; Aidoun, Z.; Bellache, O.; Ouzzane, M. CFD Simulations of a Supersonic Ejector for Use in Refrigeration Applications. Refrig. Air Cond. 2008, 2159, 1–8. [Google Scholar]

- ANSYS Fluent Release 15 User’s Guide. Available online: http://www.pmt.usp.br/academic/martoran/notasmodelosgrad/ANSYS Fluent Users Guide.pdf (accessed on 15 October 2019).

- Cai, L.; He, M. A numerical study on the supersonic steam ejector use in steam turbine system. Math Probl. Eng. 2013, 2013, 1–10. [Google Scholar] [CrossRef]

- Chen, W.; Shi, C.; Zhang, S.; Chen, H.; Chong, D.; Yan, J. Theoretical analysis of ejector refrigeration system performance under overall modes. Appl. Energy. 2017, 185, 2074–2084. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. REGULATION (EU) No 517/2014. Off. J. Eur. Union. 2014, 57, 195–230. [Google Scholar]

- Mohamed, S.; Shatilla, Y.; Zhang, T.J. CFD-based design and simulation of hydrocarbon ejector for cooling. Energy 2019, 167, 346–358. [Google Scholar] [CrossRef]

- Chunnanond, K.; Aphornratana, S. Ejectors: Applications in refrigeration technology. Renew Sustain Energy Rev. 2004, 8, 129–155. [Google Scholar] [CrossRef]

- Besagni, G.; Mereu, R.; Inzoli, F. Ejector refrigeration: A comprehensive review. Renew Sustain Energy Rev. 2016, 53, 373–407. [Google Scholar] [CrossRef]

- Little, A.B.; Garimella, S. A Review of Ejector Technology for Refrigeration Applications. Int. J. Air-Cond. Refrig. 2011, 19, 1–15. [Google Scholar] [CrossRef]

- Huang, B.J.; Chang, J.M.; Wang, C.P.; Petrenko, V.A. 1-D analysis of ejector performance. Int. J. Refrig. 1999, 22, 354–364. [Google Scholar] [CrossRef]

- Zhang, T.; Mohamed, S. Conceptual Design and Analysis of Hydrocarbon-Based Solar Thermal Power and Ejector Cooling Systems in Hot Climates. J. Sol. Energy Eng. 2014, 137, 021001. [Google Scholar] [CrossRef]

- Grazzini, G.; Milazzo, A.; Mazzelli, F. Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid Dynamics. Available online: https://link.springer.com/book/10.1007/978-3-319-75244-0 (accessed on 15 October 2019).

- Pianthong, K.; Seehanam, W.; Behnia, M.; Sriveerakul, T.; Aphornratana, S. Investigation and improvement of ejector refrigeration system using computational fluid dynamics technique. Energy Convers. Manag. 2007, 48, 2556–2564. [Google Scholar] [CrossRef]

- Lemmon Eric, W.; Bell Marcia, L.H.; Mark, O.M. REFPROP Documentation Release 10. Reference Fluid Thermodynamic and Transport Properties. Available online: https://data.nist.gov/od/id/ECBCC1C130222ED9E04306570681B10740 (accessed on 15 October 2019).

- Bartosiewicz, Y.; Aidoun, Z.; Desevaux, P.; Mercadier, Y. Numerical and experimental investigations on supersonic ejectors. Int. J. Heat Fluid Flow. 2005, 26, 56–70. [Google Scholar] [CrossRef]

- Besagni, G.; Mereu, R.; Chiesa, P.; Inzoli, F. An Integrated Lumped Parameter-CFD approach for off-design ejector performance evaluation. Energy Convers. Manag. 2015, 105, 697–715. [Google Scholar] [CrossRef]

- Kracik, J.; Dvorak, V.; Nguyen Van, V.; Smierciew, K. Experimental and Numerical Study on Supersonic Ejectors Working with R-1234ze(E). EPJ Web. Conf. 2018, 180, 02047. [Google Scholar] [CrossRef][Green Version]

- Croquer, S.; Poncet, S.; Aidoun, Z. Turbulence modeling of a single-phase R134a supersonic ejector. Part 1: Numerical benchmark Modélisation de la turbulence d ’ un éjecteur supersonique au R134a monophasé. Partie 1: Référence numérique. Int. J. Refrig. 2016, 61, 140–152. [Google Scholar] [CrossRef]

- Zheng, P.; Li, B.; Qin, J. CFD simulation of two-phase ejector performance influenced by different operation conditions. Energy 2018, 155, 1129–1145. [Google Scholar] [CrossRef]

- Hart, J.H. Supersonic Ejector Simulation and Optimisation. Ph.D. Thesis, Department of Mechanical Engineering, Sheffield University, Sheffield, UK, 2002. [Google Scholar]

- Ali, A. A Theoretical and Experimental Investigation of Jet- Pump Refrigeration System. Ph.D. Thesis, University of Nottingham, Nottingham, UK, May 2006. [Google Scholar]

- Hanafi, A.S.; Mostafa, G.M.; Waheed, A.; Fathy, A. 1-D Mathematical Modeling and CFD Investigation on Supersonic Steam Ejector in MED-TVC. Energy Procedia. 2015, 75, 3239–3252. [Google Scholar] [CrossRef]

- Aidoun, Z.; Ouzzane, M. The effect of operating conditions on the performance of a supersonic ejector for refrigeration. Int. J. Refrig. 2004, 27, 974–984. [Google Scholar] [CrossRef]

- Chen, J.; Havtun, H.; Palm, B. Screening of working fluids for the ejector refrigeration system. Int. J. Refrig. 2014, 47, 1–14. [Google Scholar] [CrossRef]

- Grazzini, G.; Milazzo, A.; Piazzini, S. Prediction of condensation in steam ejector for a refrigeration system. Int. J. Refrig. 2011, 34, 1641–1648. [Google Scholar] [CrossRef]

- Chen, J.; Havtun, H.; Palm, B. Parametric analysis of ejector working characteristics in the refrigeration system. Appl. Therm. Eng. 2014, 69, 130–142. [Google Scholar] [CrossRef]

- Huang, B.J.; Jiang, C.B.; Hu, F.L. Ejector performance characteristics and design analysis of jet refrigeration system. J. Eng. Gas Turbines Power. 1985, 107, 792–802. [Google Scholar] [CrossRef]

- Eames, I.W.; Ablwaifa, A.E.; Petrenko, V. Results of an experimental study of an advanced jet-pump refrigerator operating with R245fa. Appl. Therm. Eng. 2007, 27, 2833–2840. [Google Scholar] [CrossRef]

- Köhler, J.; Richter, C.; Tegethoff, W.; Tischendorf, C. Experimental and Theoretical Study of a CO2 Ejector Refrigeration Cycle. In Proceedings of the VDA Winter Meeting, Saalfelden, Austria, 14–15 February 2007. [Google Scholar]

- Elbel, S.; Hrnjak, P. Experimental validation of a prototype ejector designed to reduce throttling losses encountered in transcritical R744 system operation. Int. J. Refrig. 2008, 31, 411–422. [Google Scholar] [CrossRef]

- Haida, M.; Smolka, J.; Hafner, A. Performance mapping of the R744 ejectors for refrigeration and air conditioning supermarket application: A hybrid reduced-order model. Energy 2018, 153, 933–948. [Google Scholar] [CrossRef]

- Lucas, C.; Koehler, J. Experimental investigation of the COP improvement of a refrigeration cycle by use of an ejector. Int. J. Refrig. 2012, 35, 1595–1603. [Google Scholar] [CrossRef]

- Zheng, L.; Deng, J. Research on CO2 ejector component efficiencies by experiment measurement and distributed-parameter modeling. Energy Convers. Manag. 2017, 142, 244–256. [Google Scholar] [CrossRef]

- Václav, D.; Tomáš, V. Experimental and Numerical Study of Constant Area Mixing. Available online: fluids.fs.cvut.cz/akce/konference/istp_2005/full/160.pdf (accessed on 15 October 2019).

- Butrymowicz, D.; Śmierciew, K.; Karwacki, J.; Gagan, J. Experimental investigations of low-temperature driven ejection refrigeration cycle operating with isobutane. Int. J. Refrig. 2014, 39, 196–209. [Google Scholar] [CrossRef]

- Liu, F. Review on Ejector Efficiencies in Various Ejector Systems. 15th Int. Refrig. Air Cond Conf. 2014, 1533, 1–10. [Google Scholar]

| Working Fluid | Case | Mesh [Cells] | ṁs [kg/s] | ṁp [kg/s] | ω [-] | Tc [K] |

|---|---|---|---|---|---|---|

| R1234ze(E) | 1 | 270,182 | 0.0516 | 0.0924 | 0.5585 | 308.9 |

| R1234ze(E) | 2 | 1,074,146 | 0.0518 | 0.0919 | 0.5639 | 308.8 |

| R1234ze(E) | 3 | 4,196,330 | 0.0519 | 0.0917 | 0.5665 | 308.9 |

| R1234yf | 1 | 274,241 | 0.0791 | 0.1230 | 0.6427 | 298.6 |

| R1234yf | 2 | 1,076,795 | 0.0794 | 0.1224 | 0.6489 | 298.5 |

| R1234yf | 3 | 4,198,463 | 0.0796 | 0.1224 | 0.6500 | 298.5 |

| Huang et al. 1999 (Experimental) [16] | Present Work (Numerical) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ejector | Pp [kPa] | Ps [kPa] | Pc [kPa] | ω [-] | ω [-] | Error % | ṁp [kg/s] | ṁs [kg/s] | Tc [°C] | Cells No. |

| AA | 538.20 | 39.97 | 128.13 | 0.2246 | 0.2393 | 6.56 | 0.01194 | 0.00286 | 340.35 | 211,900 |

| AA | 465.68 | 39.97 | 114.22 | 0.2880 | 0.2685 | −6.79 | 0.01038 | 0.00279 | 335.04 | 211,900 |

| AA | 604.79 | 47.26 | 144.26 | 0.2350 | 0.2564 | 9.10 | 0.01336 | 0.00343 | 343.76 | 211,900 |

| AA | 604.79 | 39.97 | 142.39 | 0.1859 | 0.1896 | 2.02 | 0.01336 | 0.00253 | 346.14 | 211,900 |

| AA | 538.20 | 47.26 | 130.72 | 0.2946 | 0.2943 | −0.11 | 0.01194 | 0.00351 | 338.88 | 211,900 |

| AA | 465.68 | 47.26 | 116.19 | 0.3398 | 0.3577 | 5.27 | 0.01038 | 0.00371 | 332.74 | 211,900 |

| AG | 604.79 | 47.26 | 127.28 | 0.3503 | 0.3175 | −9.37 | 0.013345 | 0.00424 | 340.83 | 210,100 |

| AG | 538.20 | 47.26 | 116.19 | 0.4034 | 0.3769 | −6.56 | 0.011921 | 0.00449 | 335.54 | 210,100 |

| AG | 465.68 | 47.26 | 102.59 | 0.4790 | 0.4938 | 3.08 | 0.010366 | 0.00512 | 328.35 | 210,100 |

| AG | 400.74 | 47.26 | 91.59 | 0.6132 | 0.6059 | −1.18 | 0.008968 | 0.00543 | 322.19 | 210,100 |

| AC | 604.79 | 39.97 | 117.38 | 0.2814 | 0.2671 | −5.09 | 0.013362 | 0.00357 | 341.92 | 237,600 |

| AC | 538.20 | 39.97 | 107.72 | 0.3488 | 0.3005 | −13.85 | 0.011936 | 0.00359 | 337.23 | 237,600 |

| AC | 465.68 | 39.97 | 95.94 | 0.4241 | 0.3872 | −8.71 | 0.010379 | 0.00402 | 330.27 | 237,600 |

| AC | 400.74 | 39.97 | 84.262 | 0.4889 | 0.5304 | 8.48 | 0.00898 | 0.00476 | 322.50 | 237,600 |

| AD | 604.79 | 39.97 | 106.98 | 0.3457 | 0.3056 | −11.60 | 0.013356 | 0.00408 | 339.96 | 235,200 |

| AD | 465.68 | 39.97 | 87.70 | 0.5387 | 0.4770 | −11.45 | 0.010375 | 0.00495 | 327.24 | 235,200 |

| AD | 400.74 | 39.97 | 76.834 | 0.6227 | 0.6567 | 5.45 | 0.008975 | 0.00589 | 319.27 | 235,200 |

| AD | 604.79 | 47.26 | 110.36 | 0.4541 | 0.4276 | −5.85 | 0.013356 | 0.00571 | 336.43 | 235,200 |

| AD | 538.20 | 47.26 | 101.16 | 0.5422 | 0.5198 | −4.13 | 0.011931 | 0.0062 | 330.727 | 235,200 |

| AD | 465.68 | 47.26 | 90.60 | 0.6350 | 0.6624 | 4.31 | 0.010375 | 0.00687 | 323.88 | 235,200 |

| AD | 400.74 | 47.26 | 80.629 | 0.7412 | 0.8231 | 11.05 | 0.008975 | 0.00739 | 317.66 | 235,200 |

| EG | 604.79 | 39.97 | 137.36 | 0.2043 | 0.2251 | 10.18 | 0.015341 | 0.00345 | 344.27 | 196,860 |

| EC | 604.79 | 39.97 | 177.70 | 0.2273 | 0.2508 | 10.35 | 0.015339 | 0.00385 | 342.85 | 195,829 |

| EC | 604.79 | 47.26 | 129.85 | 0.3040 | 0.2976 | −2.12 | 0.015339 | 0.00456 | 341.64 | 195,829 |

| ED | 604.79 | 39.97 | 120.61 | 0.2902 | 0.2512 | −13.45 | 0.015229 | 0.00383 | 342.63 | 240,400 |

| EE | 604.79 | 39.97 | 109.23 | 0.3505 | 0.3580 | 2.15 | 0.015229 | 0.00545 | 337.89 | 236,800 |

| EE | 604.79 | 47.26 | 109.23 | 0.4048 | 0.4477 | 10.59 | 0.015229 | 0.00682 | 335.65 | 236,800 |

| EF | 604.79 | 39.97 | 104.77 | 0.3937 | 0.3635 | −7.68 | 0.015148 | 0.00551 | 337.55 | 233,600 |

| EF | 604.79 | 47.26 | 105.13 | 0.4989 | 0.5044 | 1.11 | 0.015148 | 0.00764 | 333.76 | 233,600 |

| EH | 604.79 | 39.97 | 98.70 | 0.4377 | 0.4272 | −2.40 | 0.015263 | 0.00652 | 335.03 | 242,300 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elbarghthi, A.F.A.; Mohamed, S.; Nguyen, V.V.; Dvorak, V. CFD Based Design for Ejector Cooling System Using HFOS (1234ze(E) and 1234yf). Energies 2020, 13, 1408. https://doi.org/10.3390/en13061408

Elbarghthi AFA, Mohamed S, Nguyen VV, Dvorak V. CFD Based Design for Ejector Cooling System Using HFOS (1234ze(E) and 1234yf). Energies. 2020; 13(6):1408. https://doi.org/10.3390/en13061408

Chicago/Turabian StyleElbarghthi, Anas F A, Saleh Mohamed, Van Vu Nguyen, and Vaclav Dvorak. 2020. "CFD Based Design for Ejector Cooling System Using HFOS (1234ze(E) and 1234yf)" Energies 13, no. 6: 1408. https://doi.org/10.3390/en13061408

APA StyleElbarghthi, A. F. A., Mohamed, S., Nguyen, V. V., & Dvorak, V. (2020). CFD Based Design for Ejector Cooling System Using HFOS (1234ze(E) and 1234yf). Energies, 13(6), 1408. https://doi.org/10.3390/en13061408