A Linear Regression Thermal Displacement Lathe Spindle Model

Abstract

:1. Introduction

2. Methods

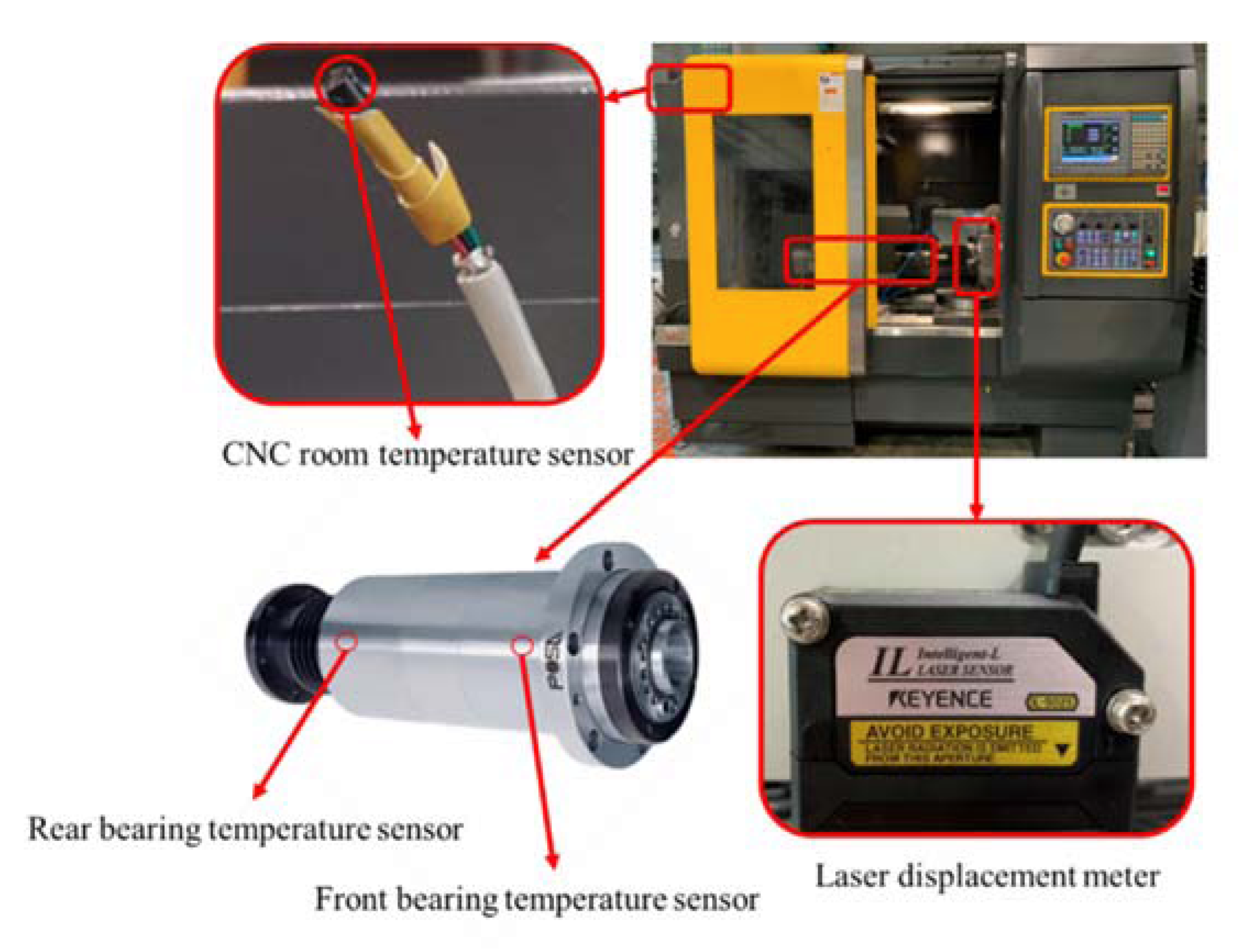

2.1. Experimental Equipment and Architecture

2.1.1. Experimental Model

2.1.2. Linear Regression

2.1.3. Model Specification

2.1.4. Indicator of the Robust Fitting Type

2.2. Calculation of the Relationship between Speed and Temperature Rise

2.3. Model Verification Coefficient

3. Results and Discussions

3.1. Comsol Analysis

3.2. Linear Regression Model Establishment and Parameter Adjustment

3.3. Discussion on the Rise Time and Stable Time of the Optimal Parameter Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Zhao, W.H.; Lan, S.H.; Ni, J.; Wu, W.W.; Lu, B.H. A review on spindle thermal error compensation in machine tools. Int. J. Mach. Tools Manuf. 2015, 95, 20–38. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, Z.D.; Liu, M.Y.; Zhang, E.L.; Chen, M.; Pham, D.T.; Ji, C.Q. Real-time measurement of temperature field in heavy-duty machine tools using fiber Bragg grating sensors and analysis of thermal shift errors. Mechatronics 2015, 31, 16–21. [Google Scholar] [CrossRef]

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S. The application of ANFIS prediction models for thermal error compensation on CNC machine tools. Appl. Soft Comput. 2015, 27, 158–168. [Google Scholar] [CrossRef]

- Bryan, J. International Status of Thermal Error Research. CIRP Ann. 1990, 39, 645–656. [Google Scholar] [CrossRef]

- Liu, K.; Liu, Y.; Sun, M.J.; Li, X.L.; Wu, Y.L. Spindle axial thermal growth modeling and compensation on CNC turning machines. Int. J. Adv. Manuf. Technol. 2016, 87, 2285–2292. [Google Scholar] [CrossRef]

- Du, Z.C.; Yao, S.Y.; Yang, J.G. Thermal Behavior Analysis and Thermal Error Compensation for Motorized Spindle of Machine Tools. Int. J. Precis. Eng. Manuf. 2015, 16, 1571–1581. [Google Scholar] [CrossRef]

- Chen, T.C.; Chang, C.J.; Hung, J.P.; Lee, R.M.; Wang, C.C. Real-Time Compensation for Thermal Errors of the Milling Machine. Appl. Sci. 2016, 6, 101. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Ye, W.H.; Shan, Y.C. Application of sliced inverse regression with fuzzy clustering for thermal error modeling of CNC machine tool. Int. J. Adv. Manuf. Technol. 2016, 85, 9–12. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, J.; Ji, S.J.; Liang, F.S. The selection of temperature-sensitivity points based on K-harmonic means clustering and thermal positioning error modeling of machine tools. Int. J. Adv. Manuf. Technol. 2019, 100, 2333–2348. [Google Scholar] [CrossRef]

- Tseng, P.C.; Ho, J.L. A study of high-precision CNC lathe thermal errors and compensation. Int. J. Adv. Manuf. Technol. 2002, 19, 850–858. [Google Scholar] [CrossRef]

- Cheng, Q.; Qi, Z.; Zhang, G.J.; Zhao, Y.S.; Sun, B.W.; Gu, P.H. Robust modelling and prediction of thermally induced positional error based on grey rough set theory and neural networks. Int. J. Adv. Manuf. Technol. 2016, 83, 753–764. [Google Scholar] [CrossRef]

- Hou, R.S.; Du, H.Y.; Yan, Z.Z.; Yu, W.B.; Tao, T.; Mei, X.S. The modeling method on thermal expansion of CNC lathe headstock in vertical direction based on MOGA. Int. J. Adv. Manuf. Technol. 2019, 103, 3629–3641. [Google Scholar] [CrossRef]

- Li, Q.; Li, H.L. A general method for thermal error measurement and modeling in CNC machine tools’ spindle. Int. J. Adv. Manuf. Technol. 2019, 103, 2739–2749. [Google Scholar] [CrossRef]

- Guo, Q.J.; Xu, R.F.; Yang, T.Y.; He, L.; Cheng, X.; Li, Z.Y.; Yang, J.G. Application of GRAM and AFSACA-BPN to thermal error optimization modeling of CNC machine tools. Int. J. Adv. Manuf. Technol. 2016, 83, 995–1002. [Google Scholar] [CrossRef]

- Tan, F.; Yin, M.; Wang, L.; Yin, G.F. Spindle thermal error robust modeling using LASSO and LS-SVM. Int. J. Adv. Manuf. Technol. 2018, 94, 2861–2874. [Google Scholar] [CrossRef]

- Xiang, S.T.; Zhu, X.L.; Yang, J.G. Modeling for spindle thermal error in machine tools based on mechanism analysis and thermal basic characteristics tests. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 3381–3394. [Google Scholar] [CrossRef]

- Pahk, H.J.; Lee, S.W. Thermal error measurement and real time compensation system for the CNC machine tools incorporating the spindle thermal error and the feed axis thermal error. Int. J. Adv. Manuf. Technol. 2002, 20, 487–494. [Google Scholar] [CrossRef]

- Fan, K.G.; Yang, J.G.; Yang, L.Y. Orthogonal polynomials-based thermally induced spindle and geometric error modeling and compensation. Int. J. Adv. Manuf. Technol. 2013, 65, 9–12. [Google Scholar] [CrossRef]

- Tseng, P.C.; Chen, S.L. The neural-fuzzy thermal error compensation controller on CNC machining center. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2002, 45, 470–478. [Google Scholar] [CrossRef] [Green Version]

- Jian, B.-L.; Wang, C.-C.; Hsieh, C.-T.; Kuo, Y.-P.; Houng, M.-C.; Yau, H.-T. Predicting spindle displacement caused by heat using the general regression neural network. Int. J. Adv. Manuf. Technol. 2019, 104, 4665–4674. [Google Scholar] [CrossRef]

- Wei, X.; Gao, F.; Li, Y.; Zhang, D.Y. Study on optimal independent variables for the thermal error model of CNC machine tools. Int. J. Adv. Manuf. Technol. 2018, 98, 664–669. [Google Scholar] [CrossRef]

- Shen, H.Y.; Sun, L.; Zhang, L.C.; Sha, J.F.; Liu, X.H.; Fu, J.Z. Position-independent thermal error compensation and evaluation based on linear correlation filtering technology. Int. J. Adv. Manuf. Technol. 2018, 95, 1357–1367. [Google Scholar]

- Fushiki, T. Estimation of prediction error by using K-fold cross-validation. Stat. Comput. 2011, 21, 137–146. [Google Scholar] [CrossRef]

- Wong, T.T.; Yang, N.Y. Dependency Analysis of Accuracy Estimates in k-Fold Cross Validation. IEEE Trans. Knowl. Data Eng. 2017, 29, 2417–2427. [Google Scholar] [CrossRef]

- Fávero, L.P.; Belfiore, P. Simple and Multiple Regression Models. In Data Science for Business and Decision Making; Fávero, L.P., Belfiore, P., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 443–538. [Google Scholar]

- Li, Y.; Zhao, J.; Ji, S.J. A reconstructed variable regression method for thermal error modeling of machine tools. Int. J. Adv. Manuf. Technol. 2017, 90, 3673–3684. [Google Scholar] [CrossRef]

- Shastry, A.; Sanjay, H.; Bhanusree, E. Prediction of Crop Yield Using Regression Techniques. Int. J. Soft Comput. 2017, 12, 96–102. [Google Scholar]

- Andrews, D.F. A Robust Method for Multiple Linear Regression. Technometrics 1974, 16, 523–531. [Google Scholar] [CrossRef]

- Polat, E. The effects of different weight functions on partial robust M-regression performance: A simulation study. Commun. Stat.-Simul. Comput. 2019, 1–16. [Google Scholar] [CrossRef]

- Holland, P.W.; Welsch, R.E. Robust regression using iteratively reweighted least-squares. Commun. Stat.-Theory Methods 2007, 6, 813–827. [Google Scholar] [CrossRef]

- Liu, K.; Sun, M.J.; Wu, Y.L.; Zhu, T.J. Thermal Error Modeling Method for a CNC Machine Tool Feed Drive System. Math. Prob. Eng. 2015, 4, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Feng, W.L.; Li, Z.H.; Gu, Q.Y.; Yang, J.G. Thermally induced positioning error modelling and compensation based on thermal characteristic analysis. Int. J. Mach. Tools Manuf. 2015, 93, 26–36. [Google Scholar] [CrossRef]

- Dai, Y.; Guo, J.; Yang, L.; You, W. A New Approach of Intelligent Physical Health Evaluation based on GRNN and BPNN by Using a Wearable Smart Bracelet System. Proc. Comput. Sci. 2019, 147, 519–527. [Google Scholar] [CrossRef]

- Yang, H.; Li, X.; Wu, B. Scale Forecast Method for Regional Highway Network Based on BPNN-MOP. Trans. Res. Proc. 2017, 25, 3840–3854. [Google Scholar] [CrossRef]

- Garnier, H.; Mensler, M.; Richard, A. Continuous-time model identification from sampled data: Implementation issues and performance evaluation. Int. J. Control 2003, 76, 1337–1357. [Google Scholar] [CrossRef]

| Model | Equations |

|---|---|

| Linear | |

| Interactions | |

| Pure quadratic | |

| Quadratic |

| Robust Weight Function | Equation | Default Tuning Constant |

|---|---|---|

| Andrews | 1.339 | |

| Bisquare | 4.685 | |

| Cauchy | 2.385 | |

| Fair | 1.4 | |

| Huber | 1.345 | |

| Logistic | 1.205 | |

| Ordinary least squares | Ordinary least squares (no weighting function) | None |

| Talwar | 2.795 | |

| Welsch | 2.985 |

| Linear Model | Interactions Model | Pure Quadratic Model | Quadratic Model | |

|---|---|---|---|---|

| Andrews | 0.976447776 | 0.985206658 | 0.986315629 | 0.987897428 |

| Bisquare | 0.976446436 | 0.985210897 | 0.986321702 | 0.987890926 |

| Cauchy | 0.976446063 | 0.985446282 | 0.986379913 | 0.987893853 |

| Fair | 0.976453158 | 0.985544495 | 0.986415054 | 0.987896656 |

| Huber | 0.976445855 | 0.985434324 | 0.986359045 | 0.987890844 |

| Logistic | 0.976443716 | 0.985497259 | 0.986394534 | 0.987896652 |

| Ordinary least squares | 0.976489603 | 0.98565211 | 0.98647194 | 0.987913665 |

| Talwar | 0.976480432 | 0.985129585 | 0.98618952 | 0.987909337 |

| Welsch | 0.976438028 | 0.985338684 | 0.986344533 | 0.987895726 |

| Linear Model | Interactions Model | Pure Quadratic Model | Quadratic Model | |

|---|---|---|---|---|

| Andrews | 0.000802692 | 0.00063616 | 0.000611851 | 0.000575403 |

| Bisquare | 0.000802715 | 0.000636069 | 0.000611715 | 0.000575557 |

| Cauchy | 0.000802722 | 0.000630987 | 0.000610412 | 0.000575488 |

| Fair | 0.000802601 | 0.000628854 | 0.000609624 | 0.000575421 |

| Huber | 0.000802725 | 0.000631246 | 0.00061088 | 0.000575559 |

| Logistic | 0.000802762 | 0.000629881 | 0.000610084 | 0.000575421 |

| Ordinary least squares | 0.000801979 | 0.000626509 | 0.000608346 | 0.000575017 |

| Talwar | 0.000802136 | 0.000637815 | 0.000614664 | 0.00057512 |

| Welsch | 0.000802858 | 0.000633315 | 0.000611204 | 0.000575443 |

| Linear Model | Interactions Model | Pure Quadratic Model | Quadratic Model | |

|---|---|---|---|---|

| Andrews | 6.44315 | 4.047 | 3.74362 | 3.31088 |

| Bisquare | 6.44352 | 4.04584 | 3.74195 | 3.31266 |

| Cauchy | 6.44362 | 3.98144 | 3.72603 | 3.31186 |

| Fair | 6.44168 | 3.95457 | 3.71642 | 3.3111 |

| Huber | 6.44368 | 3.98471 | 3.73174 | 3.31269 |

| Logistic | 6.44426 | 3.9675 | 3.72203 | 3.3111 |

| Ordinary least squares | 6.43171 | 3.92513 | 3.70085 | 3.30644 |

| Talwar | 6.43422 | 4.06808 | 3.77811 | 3.30763 |

| Welsch | 6.44582 | 4.01088 | 3.73571 | 3.31135 |

| Linear Model | Interactions Model | Pure Quadratic Model | Quadratic Model | |

|---|---|---|---|---|

| Andrews | 0.000637552 | 0.000490825 | 0.000481137 | 0.00046259 |

| Bisquare | 0.000637602 | 0.000490923 | 0.000481097 | 0.000462721 |

| Cauchy | 0.000637494 | 0.000491214 | 0.000481243 | 0.000462623 |

| Fair | 0.000637465 | 0.000491784 | 0.000481569 | 0.000462626 |

| Huber | 0.000637544 | 0.000491124 | 0.000481322 | 0.000462661 |

| Logistic | 0.000637485 | 0.000491222 | 0.000481383 | 0.000462658 |

| Ordinary least squares | 0.000639 | 0.00049515 | 0.000483696 | 0.000463451 |

| Talwar | 0.000638257 | 0.000491219 | 0.000481589 | 0.000463127 |

| Welsch | 0.000637655 | 0.000490858 | 0.000481141 | 0.00046266 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-J.; Su, X.-Y.; Hu, C.-H.; Jian, B.-L.; Wu, L.-W.; Yau, H.-T. A Linear Regression Thermal Displacement Lathe Spindle Model. Energies 2020, 13, 949. https://doi.org/10.3390/en13040949

Lin C-J, Su X-Y, Hu C-H, Jian B-L, Wu L-W, Yau H-T. A Linear Regression Thermal Displacement Lathe Spindle Model. Energies. 2020; 13(4):949. https://doi.org/10.3390/en13040949

Chicago/Turabian StyleLin, Chih-Jer, Xiao-Yi Su, Chi-Hsien Hu, Bo-Lin Jian, Li-Wei Wu, and Her-Terng Yau. 2020. "A Linear Regression Thermal Displacement Lathe Spindle Model" Energies 13, no. 4: 949. https://doi.org/10.3390/en13040949

APA StyleLin, C.-J., Su, X.-Y., Hu, C.-H., Jian, B.-L., Wu, L.-W., & Yau, H.-T. (2020). A Linear Regression Thermal Displacement Lathe Spindle Model. Energies, 13(4), 949. https://doi.org/10.3390/en13040949