Multi-State Household Appliance Identification Based on Convolutional Neural Networks and Clustering

Abstract

1. Introduction

2. Related Work

3. Theory

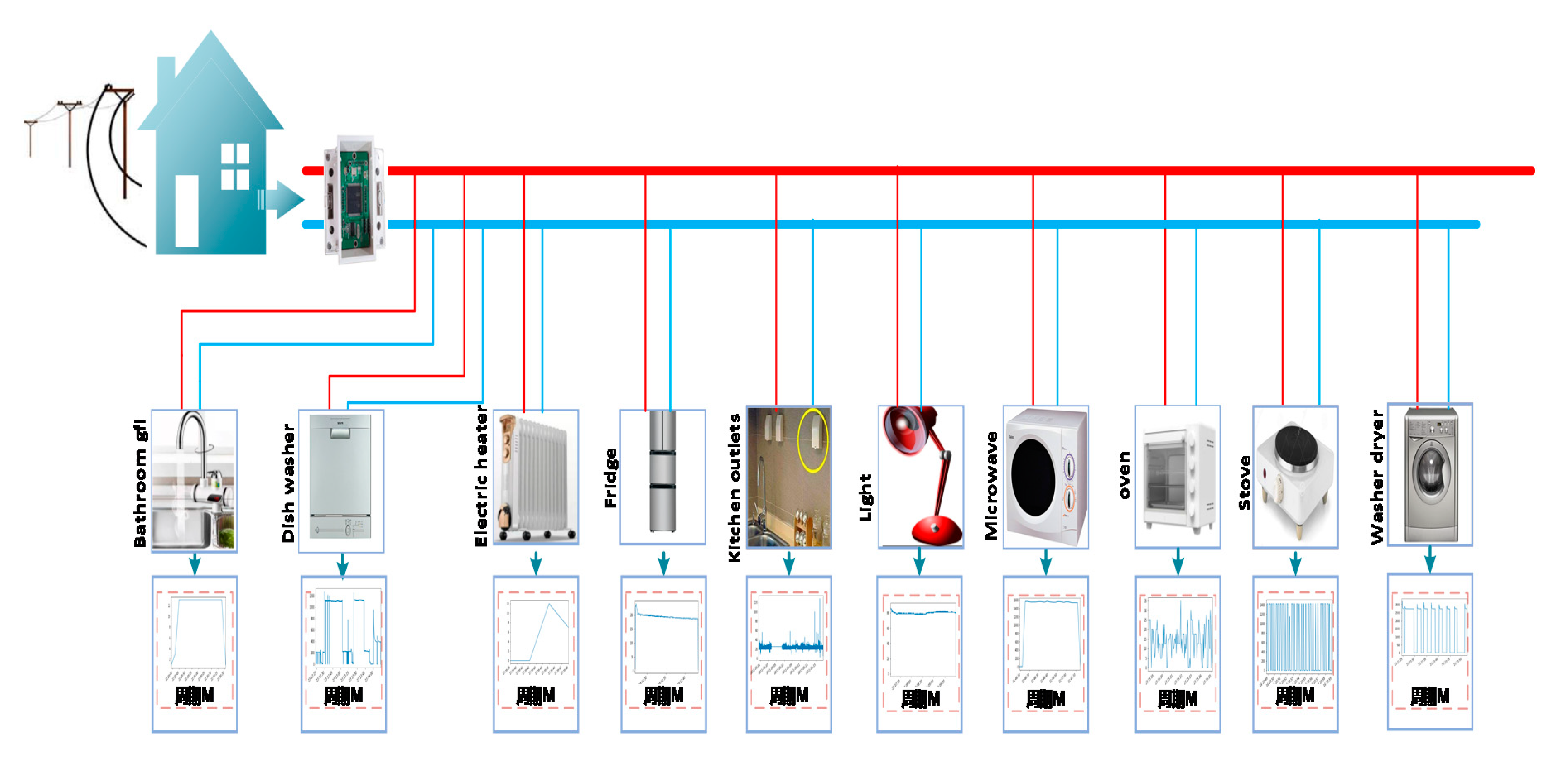

3.1. Convolutional Neural Network Model

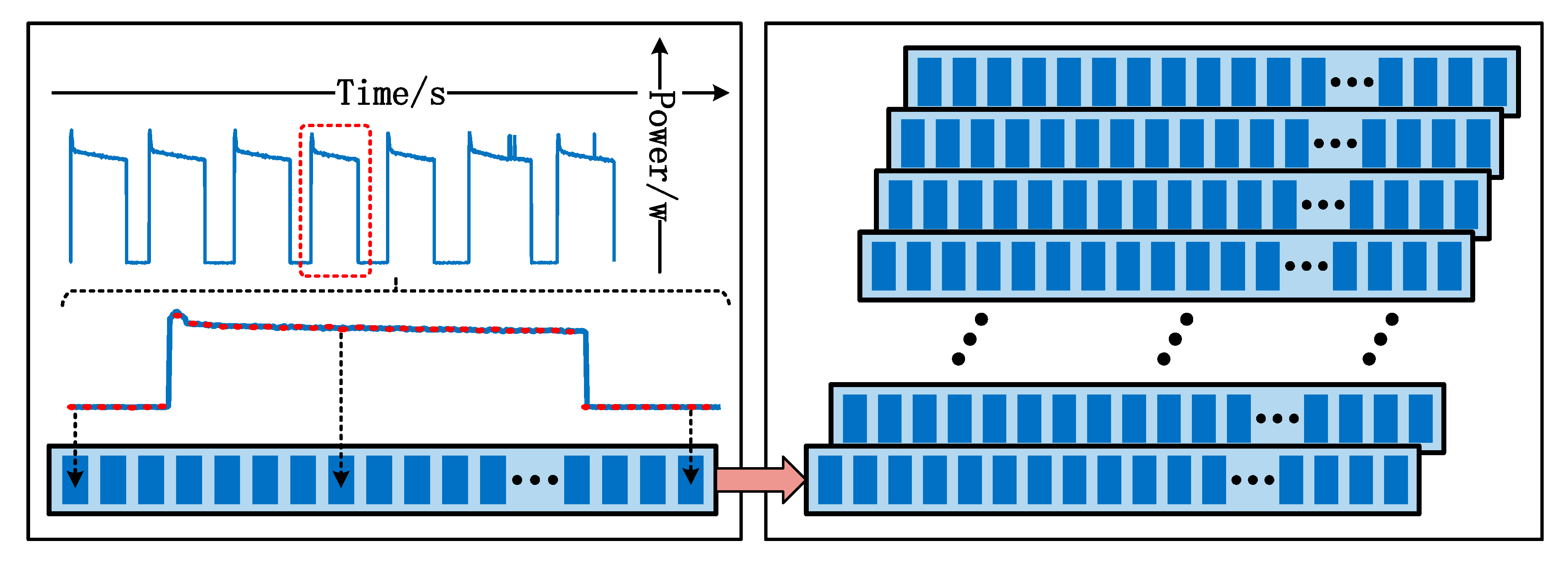

3.1.1. Data Preprocessing

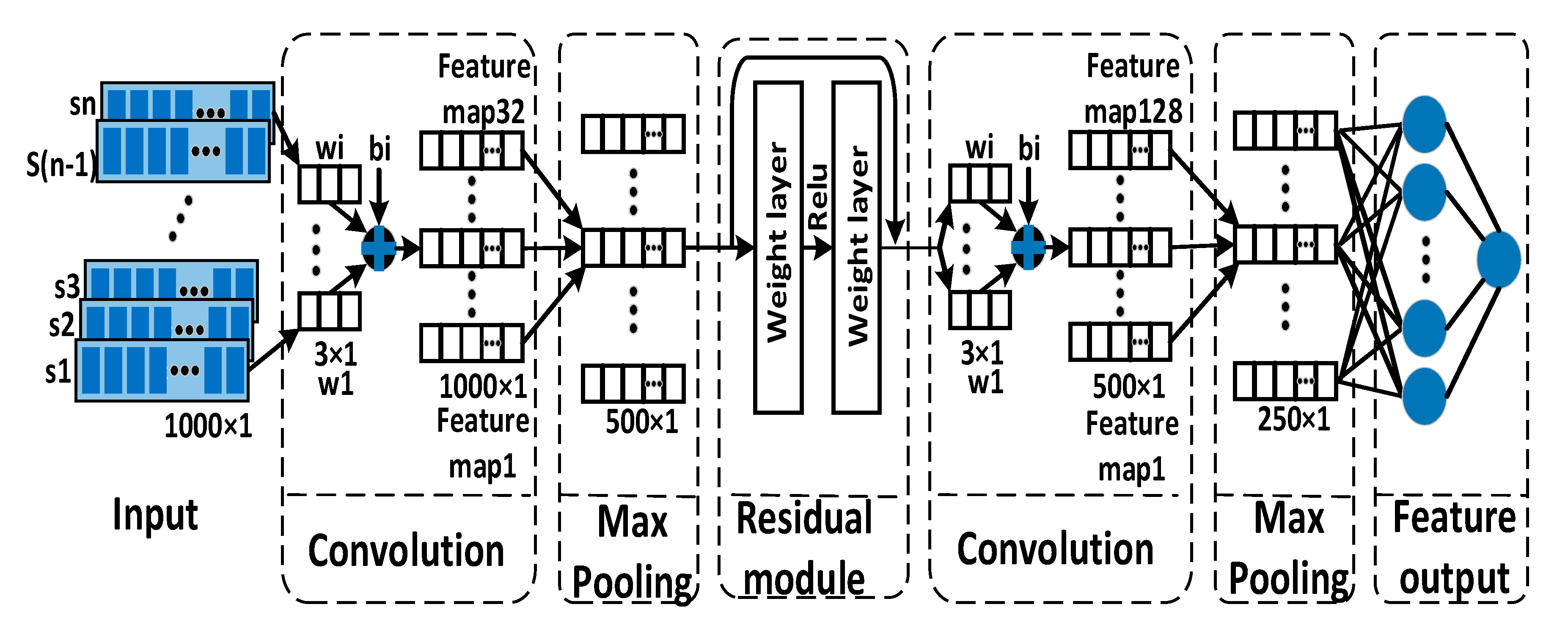

3.1.2. Convolutional Neural Network Model Structure

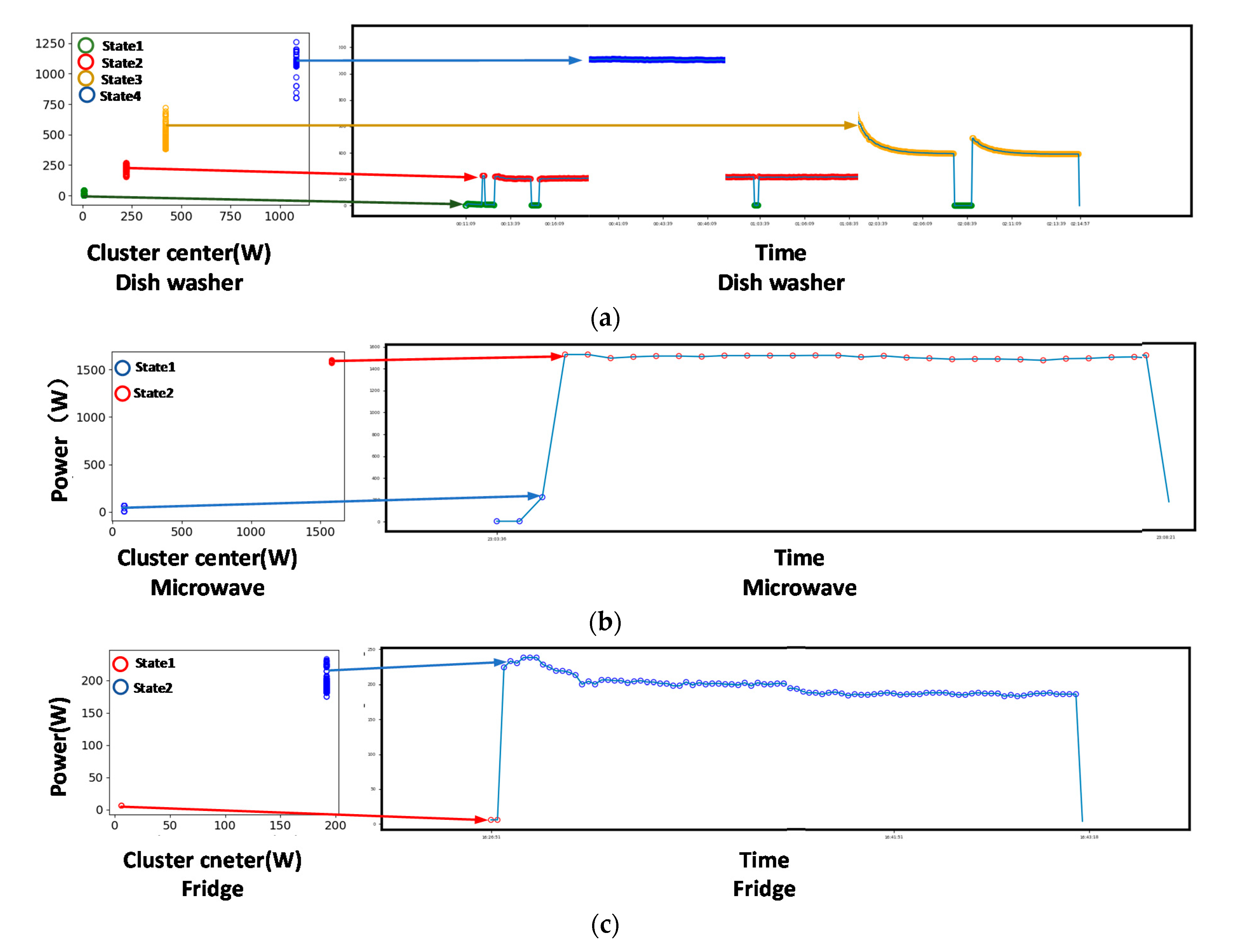

3.2. Construction of the Cluster Model

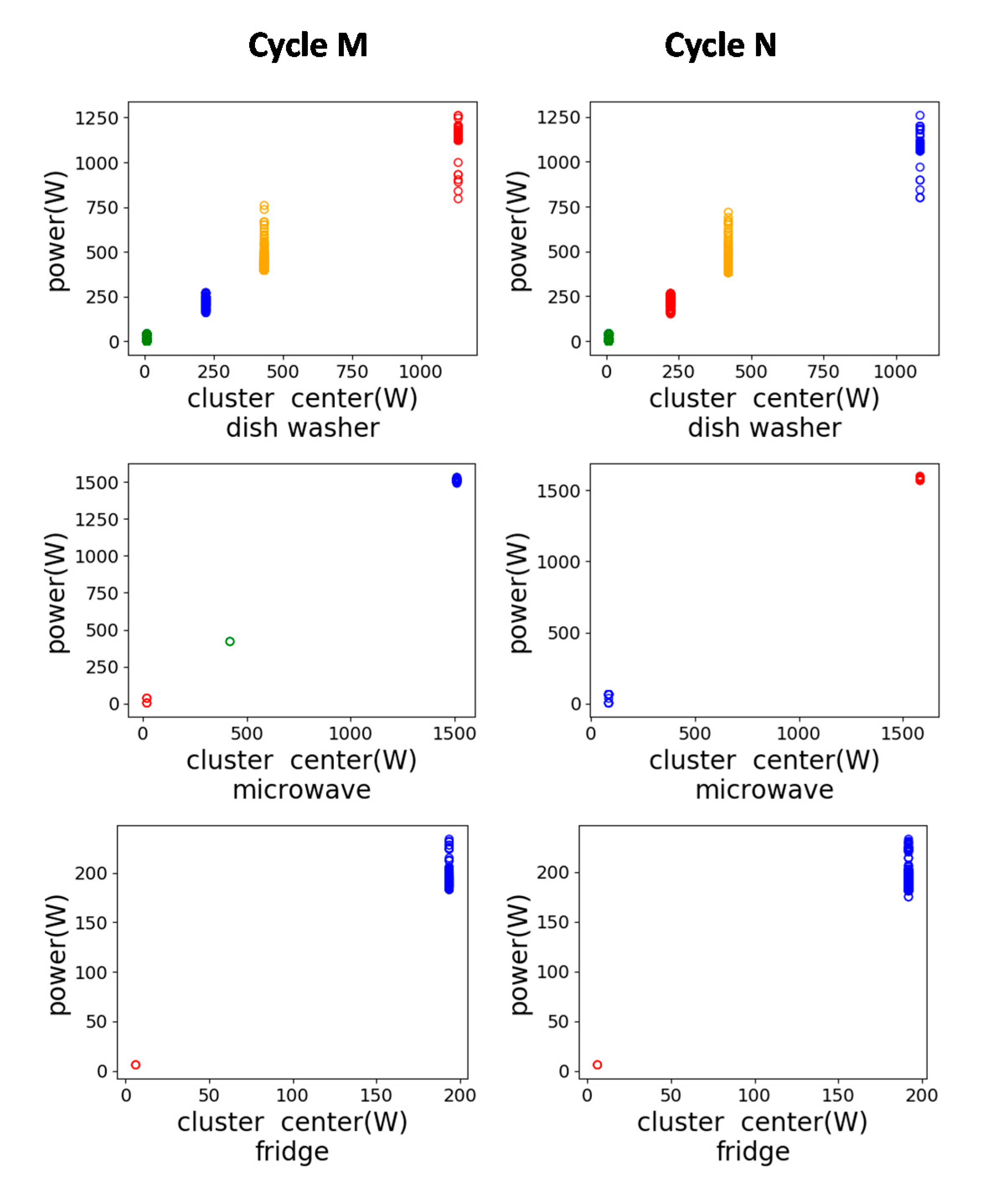

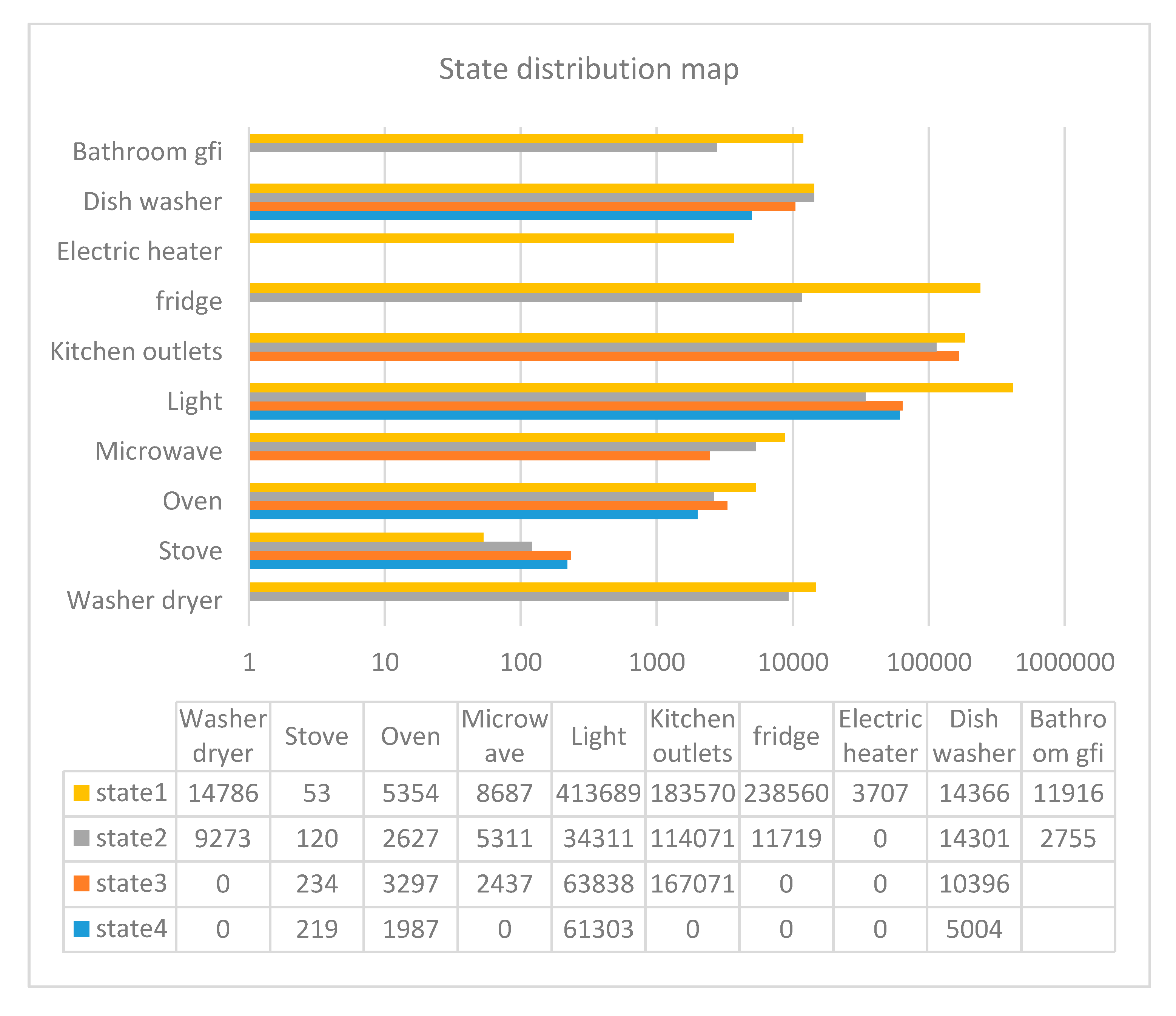

3.2.1. Load Multi-State Detection

3.2.2. Load Multi-State Identification

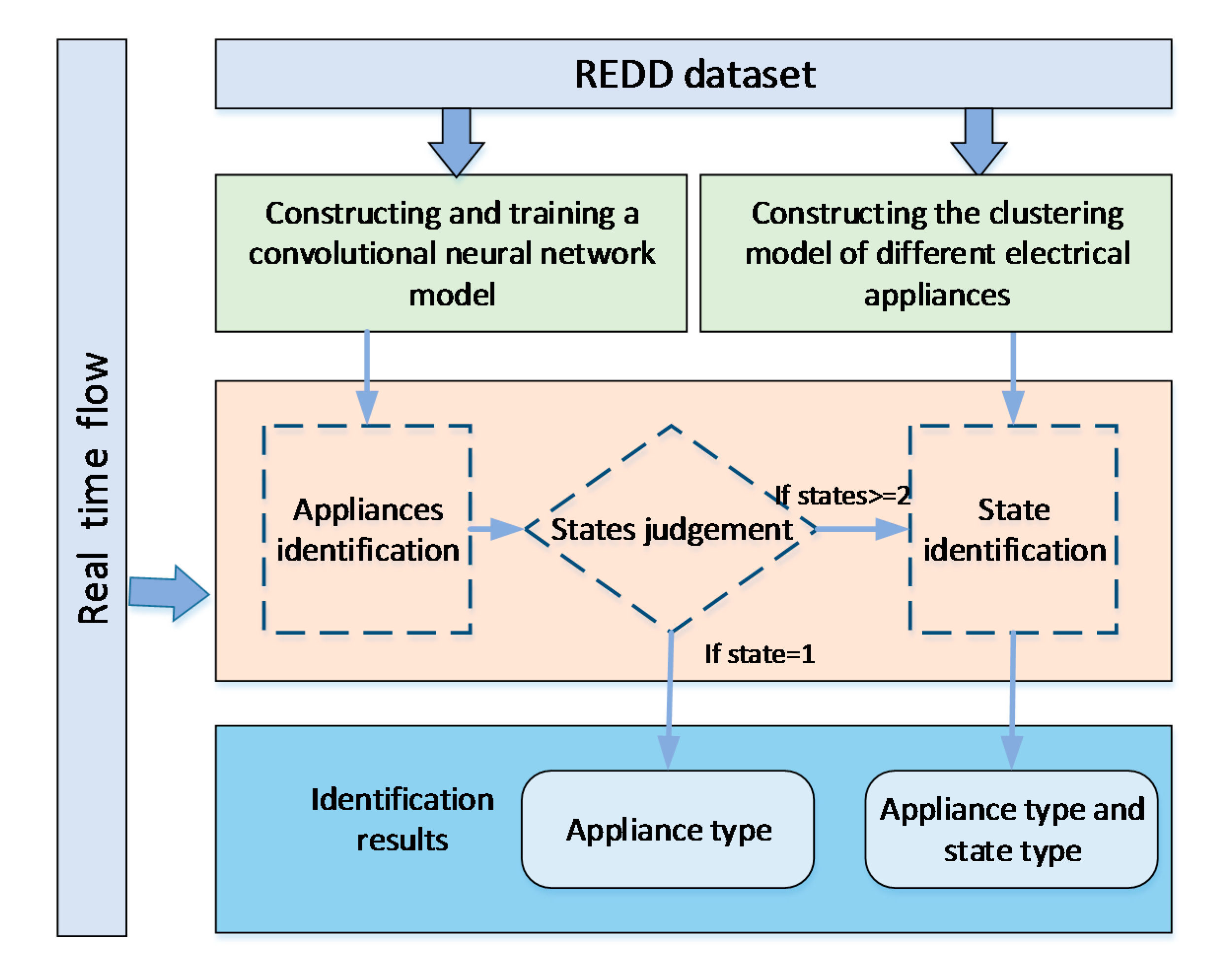

4. Model Fusion

5. Experiment

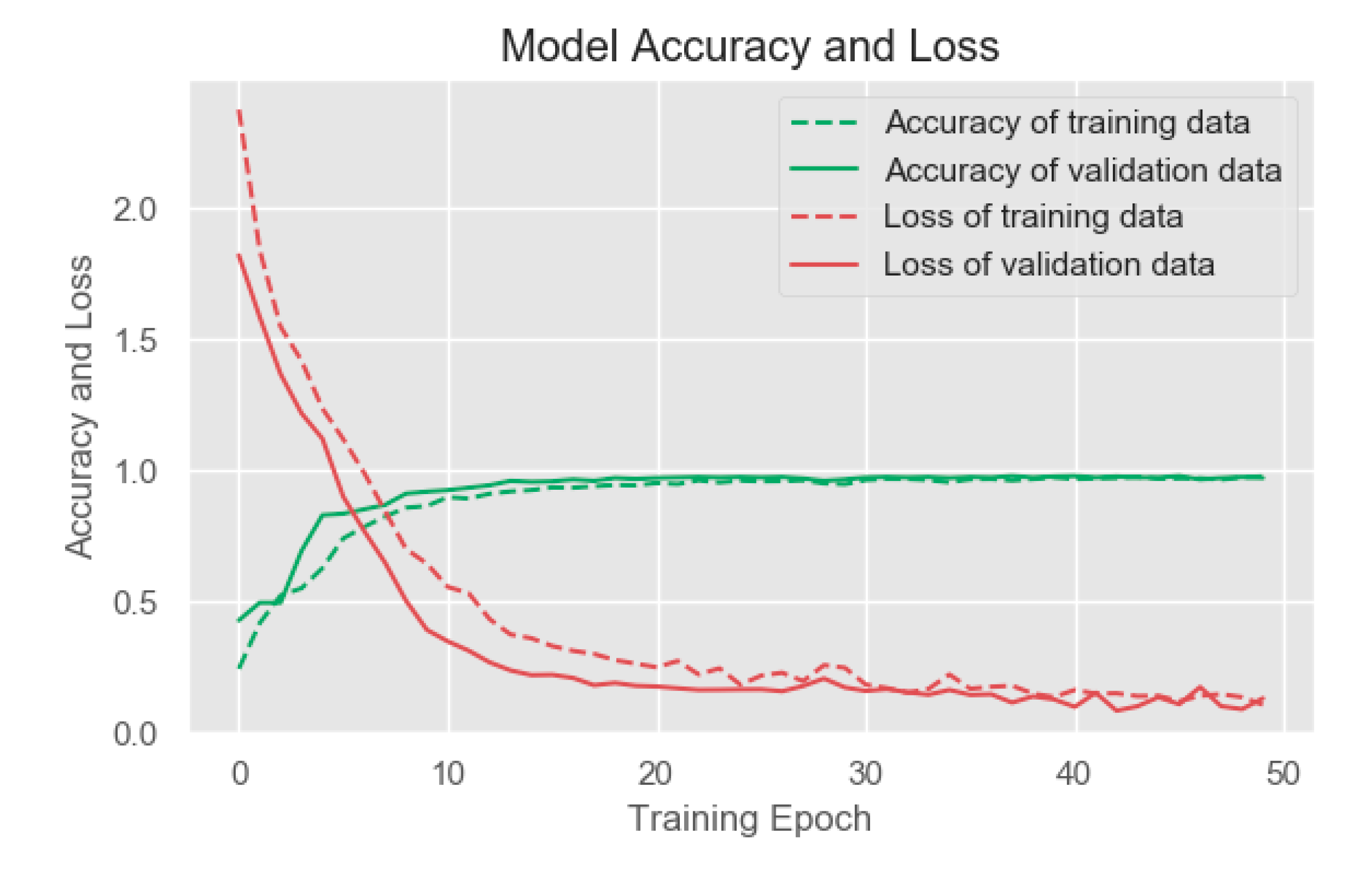

5.1. Model Training

5.2. Experiment Result

5.2.1. Evaluation Criteria

5.2.2. Appliances Type Identification Result

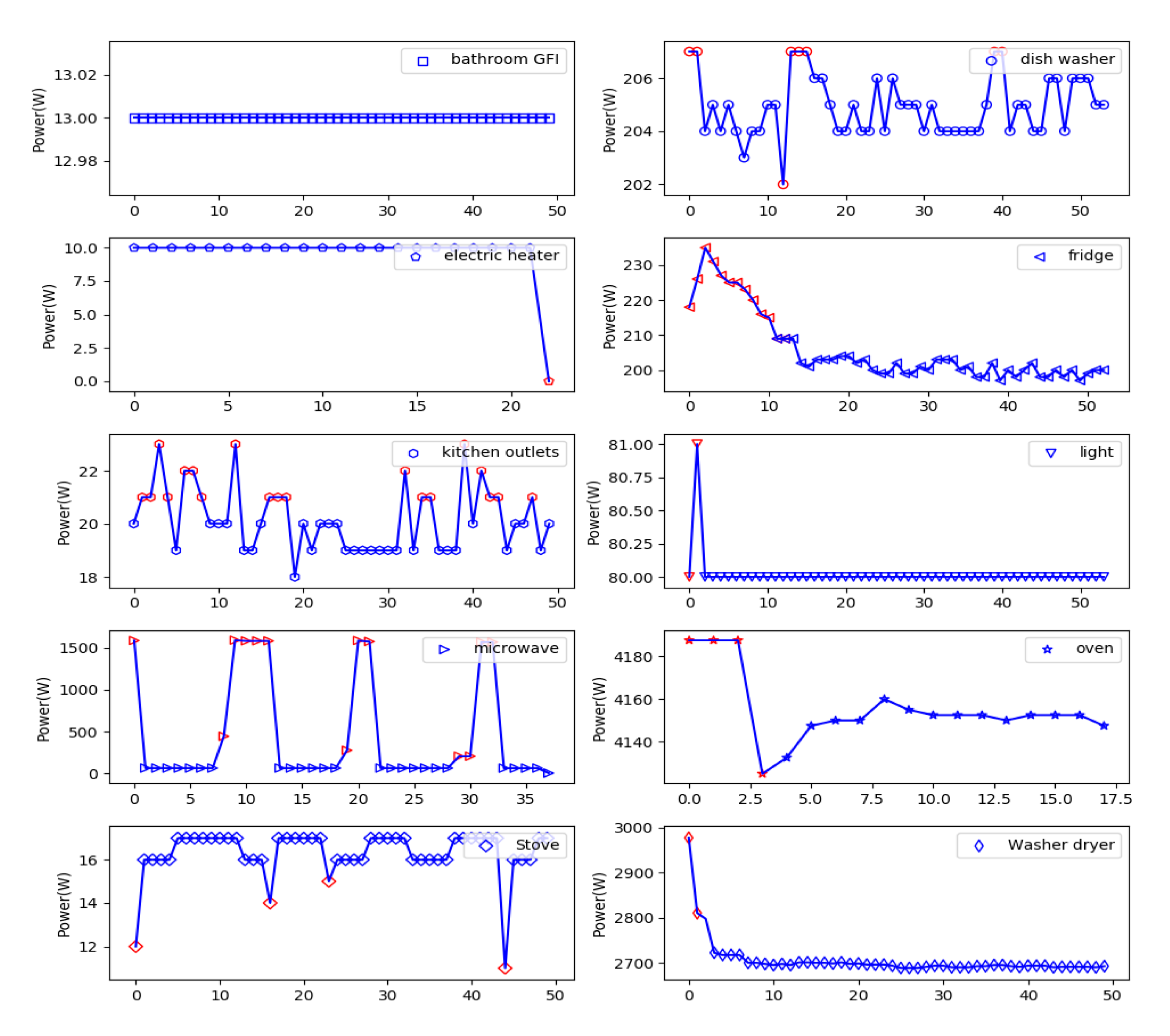

5.2.3. Appliance States Identification Result

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yoon, S.-H.; Kim, S.-Y.; Park, G.-H.; Kim, Y.-K.; Cho, C.-H.; Park, B.-H. Multiple power-based building energy management system for efficient management of building energy. Sustain. Cities Soc. 2018, 42, 462–470. [Google Scholar] [CrossRef]

- Hart, G.W. Nonintrusive appliance load monitoring. Proc. IEEE 1992, 80, 1870–1891. [Google Scholar] [CrossRef]

- Houidi, S.; Auger, F.; Sethom, H.B.A.; Miègeville, L.; Fourer, D.; Jiang, X. Statistical Assessment of Abrupt Change Detectors for Non Intrusive Load Monitoring. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018. [Google Scholar]

- Niu, L.; Jia, H. Transient event detection algorithm for non-intrusive load monitoring. Autom. Electr. Power Syst. 2011, 35, 30–35. [Google Scholar]

- Afzalan, M.; Jazizadeh, F.; Wang, J. Self-configuring event detection in electricity monitoring for human-building interaction. Energy Build. 2019, 187, 95–109. [Google Scholar] [CrossRef]

- Mauch, L.; Yang, B. A new approach for supervised power disaggregation by using a deep recurrent LSTM network. IEEE Global Conf. Signal Inf. Process. 2015, 63–67. [Google Scholar] [CrossRef]

- Schirmer, P.A.; Mporas, I. Statistical and Electrical Features Evaluation for Electrical Appliances Energy Disaggregation. Sustainability 2019, 11, 3222. [Google Scholar] [CrossRef]

- Machlev, R.; Belikov, J.; Beck, Y.; Levron, Y. MO-NILM: A multi-objective evolutionary algorithm for NILM classification. Energy Build. 2019, 199, 134–144. [Google Scholar] [CrossRef]

- de Baets, L.; Ruyssinck, J.; Develder, C.; Dhaene, T.; Deschrijver, D. Appliance classification using VI trajectories and convolutional neural networks. Energy Build. 2018, 158, 32–36. [Google Scholar] [CrossRef]

- Hamdi, M.; Messaoud, H.; Bouguila, N. A new approach of electrical appliance identification in residential buildings. Electr. Power Syst. Res. 2020, 178, 106037. [Google Scholar] [CrossRef]

- Fagiani, M.; Bonfigli, R.; Principi, E.; Squartini, S.; Mandolini, L. A Non-Intrusive Load Monitoring Algorithm Based on Non-Uniform Sampling of Power Data and Deep Neural Networks. Energies 2019, 12, 1371. [Google Scholar] [CrossRef]

- Gagliano, S.; Cairone, F.; Amenta, A.; Bucolo, M. A Real Time Feed Forward Control of Slug Flow in Microchannels. Energies 2019, 12, 2556. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Zhao, L.; Liu, Y. Admittance-based load signature construction for non-intrusive appliance load monitoring. Energy Build. 2018, 171, 209–219. [Google Scholar] [CrossRef]

- Baets, L.D.; Dhaene, T.; Deschrijver, D.; Develder, C.; Berges, M. VI-Based Appliance Classification Using Aggregated Power Consumption Data. In Proceedings of the 2018 IEEE International Conference on Smart Computing (SMARTCOMP), Taormina, Italy, 18–20 June 2018; pp. 179–186. [Google Scholar] [CrossRef]

- Liu, H.; Wu, H.; Yu, C. A hybrid model for appliance classification based on time series features. Energy Build. 2019, 196, 112–123. [Google Scholar] [CrossRef]

- Ghosh, S.; Chatterjee, A.; Chatterjee, D. Improved non-intrusive identification technique of electrical appliances for a smart residential system. IET Gener. Transm. Distrib. 2019, 13, 695–702. [Google Scholar] [CrossRef]

- Dinesh, C.; Welikala, S.; Liyanage, Y.; Ekanayake, M.P.B.; Godaliyadda, R.I.; Ekanayake, J. Non-intrusive load monitoring under residential solar power influx. Appl. Energy 2017, 205, 1068–1080. [Google Scholar] [CrossRef]

- Choksi, K.A.; Jain, S.K. Pattern matrix and decision tree based technique for non-intrusive monitoring of home appliances. In Proceedings of the 2017 7th International Conference on Power Systems (ICPS), Pune, India, 21–23 December 2017; pp. 824–829. [Google Scholar] [CrossRef]

- Kolter, J.Z.; Johnson, M.J. REDD: A Public Data Set for Energy Disaggregation Research. In Proceedings of the SustKDD workshop on Data Mining Applications in Sustainability, San Diego, CA, USA, 21 August 2011; p. 6. [Google Scholar]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Batra, N.; Kelly, J.; Parson, O.; Dutta, H.; Knottenbelt, W.; Rogers, A.; Singh, A.; Srivastava, M. NILMTK: An Open Source Toolkit for Non-intrusive Load Monitoring. In Proceedings of the 5th international conference on Future energy systems - e-Energy, Melbourne, Australia, 14 June 2014; pp. 265–276. [Google Scholar] [CrossRef]

- Yang, C.C.; Soh, C.S.; Yap, V.V. A systematic approach to ON-OFF event detection and clustering analysis of non-intrusive appliance load monitoring. Front. Energy 2015, 9, 231–237. [Google Scholar] [CrossRef]

- Makonin, S.; Popowich, F. Nonintrusive load monitoring (NILM) performance evaluation: A unified approach for accuracy reporting. Energy Effic. 2015, 8, 809–814. [Google Scholar] [CrossRef]

| Logogram | Full Name |

|---|---|

| NILM | Non-intrusive load monitoring |

| PLAID | Plug Load Appliance Identification Dataset |

| REDD | Reference Energy Disaggregation Data Set |

| NILMtk | Non-intrusive load monitoring tool kit |

| SGD | Stochastic gradient descent |

| TP | True Positive |

| TN | True Negative |

| FP | False Positive |

| FN | False Negative |

| Appliance | States |

|---|---|

| Bathroom gfi | 2 |

| Dish washer | 4 |

| Electric heater | 1 |

| Fridge | 2 |

| Kitchen outlets | 3 |

| Light | 4 |

| Microwave | 3 |

| Oven | 4 |

| Stove | 4 |

| Washer/dryer | 2 |

| Appliance | Recall | Precision | F1-Score |

|---|---|---|---|

| Bathroom gfi | 0.96 | 0.99 | 0.97 |

| Dish washer | 0.79 | 0.68 | 0.73 |

| Electric heater | 0.40 | 1.00 | 0.57 |

| Fridge | 0.99 | 1.00 | 0.99 |

| Kitchen outlets | 1.00 | 1.00 | 1.00 |

| Light | 0.97 | 0.99 | 0.98 |

| Microwave | 1.00 | 1.00 | 1.00 |

| Oven | 1.00 | 0.60 | 0.75 |

| Stove | 1.00 | 0.11 | 0.20 |

| Washer/dryer | 0.96 | 0.93 | 0.94 |

| Appliance | Accuracy |

|---|---|

| Bathroom gfi | 100% |

| Dish washer | 85% |

| Electric heater | 92% |

| Fridge | 79% |

| Kitchen outlets | 62% |

| Light | 91% |

| Microwave | 65% |

| Oven | 77% |

| Stove | 92% |

| Washer dryer | 96% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yin, B.; Cong, Y.; Du, Z. Multi-State Household Appliance Identification Based on Convolutional Neural Networks and Clustering. Energies 2020, 13, 792. https://doi.org/10.3390/en13040792

Zhang Y, Yin B, Cong Y, Du Z. Multi-State Household Appliance Identification Based on Convolutional Neural Networks and Clustering. Energies. 2020; 13(4):792. https://doi.org/10.3390/en13040792

Chicago/Turabian StyleZhang, Ying, Bo Yin, Yanping Cong, and Zehua Du. 2020. "Multi-State Household Appliance Identification Based on Convolutional Neural Networks and Clustering" Energies 13, no. 4: 792. https://doi.org/10.3390/en13040792

APA StyleZhang, Y., Yin, B., Cong, Y., & Du, Z. (2020). Multi-State Household Appliance Identification Based on Convolutional Neural Networks and Clustering. Energies, 13(4), 792. https://doi.org/10.3390/en13040792