Study on the Effect of Second Injection Timing on the Engine Performances of a Gasoline/Hydrogen SI Engine with Split Hydrogen Direct Injecting

Abstract

:1. Introduction

2. Proposed Models and Validation

2.1. Computational Model

2.2. Validation

3. Results and Analysis

3.1. Hydrogen Mixture Distribution

3.2. Combustion

3.3. Emissions

4. Conclusions

- SHDI can form a better HMD. The HMD of SHDI is not only rich near the spark plug but also homogenous in other zones. Therefore, combustion can be accelerated and completed. As a result, SHDI can achieve better engine performance.

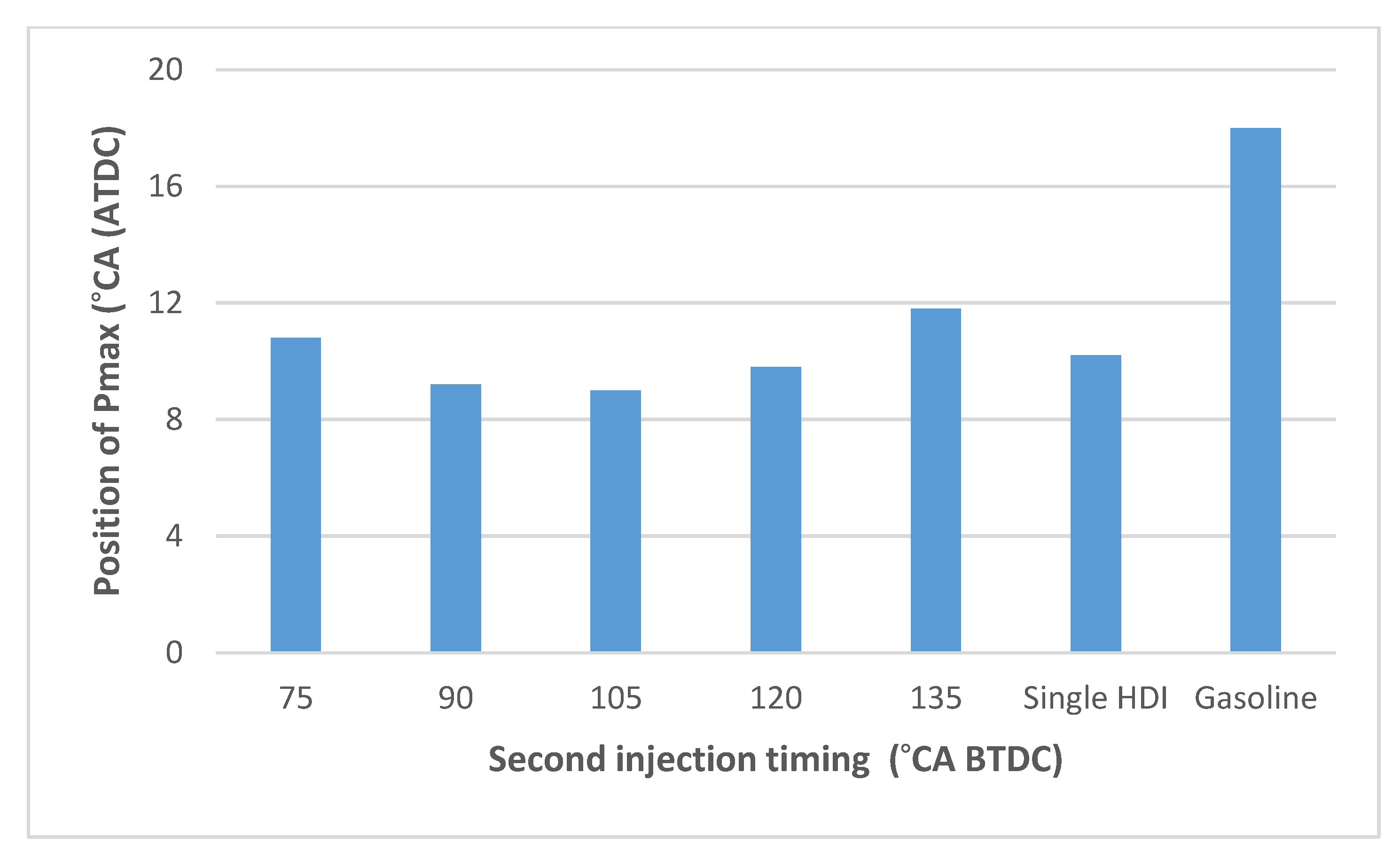

- With hydrogen addition, cylinder pressure increases obviously. The best second injection timing is 105°CA BTDC. This is because early injecting timing would make the mixture too homogenous and late injection timing would make the mixture too rich on one side of the cylinder. When the second injection timing is 105°CA BTDC, Pmax is the highest and the position of Pmax is earliest of all values measured.

- NOX emissions increase by 140% after hydrogen addition compared to gasoline. NOX emissions with SHDI are reduced by an average of 20% compared to single HDI. The main reason is that the HMD of SHDI is more homogenous and the maximum temperature is lower compared to single HDI. As the second injection timing advances, the NOX emissions change a little.

- CO and HC emissions are respectively reduced by 60% and 95% after hydrogen addition compared to gasoline. This is because the HMD of SHDI is more homogenous than that of HDI and hydrogen can affect the majority zone of the cylinder. Compared with single HDI, the CO and HC emissions with SHDI are respectively reduced by 40% and 72%. As the second injection timing advances, the CO and HC emissions continue to decline. When the second injection timing is 135°CA BTDC, the CO and HC emissions respectively decrease by 20% and 40% compared to the emissions associated with a second injection timing of 75°CA BTDC.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ATDC | After Top Dead Center |

| BTDC | Before Top Dead Center |

| CA | Crank Angle |

| CO | Carbon Monoxide |

| ECU | Electronic Control Unit |

| EGR | Exhaust Gas Recirculation |

| HC | Hydrocarbon |

| HDI | Hydrogen Direct Injection |

| HMD | Hydrogen Mixture Distribution |

| NOX | Nitrogen Oxides |

| SHDI | Split Hydrogen Direct Injection |

| SI | Spark Ignition |

References

- Kamil, M.; Rahman, M.M. Performance prediction of spark-ignition engine running on gasoline-hydrogen and methane-hydrogen blends. Appl. Energy 2015, 158, 556–567. [Google Scholar] [CrossRef]

- Açıkgöz, B.; Çelik, C.; Soyhan, H.S.; Gökalp, B.; Karabağ, B. Emission characteristics of an hydrogen–CH4 fuelled spark ignition engine. Fuel 2015, 159, 298–307. [Google Scholar] [CrossRef]

- Ceviz, M.A.; Sen, A.K.; Küleri, A.K.; Öner, I.V. Engine performance, exhaust emissions, and cyclic variations in a lean-burn SI engine fueled by gasoline–hydrogen blends. Appl. Therm. Eng. 2012, 36, 314–324. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S.; Zhang, B.; Liu, X. Emissions performance of a hybrid hydrogen–gasoline engine-powered passenger car under the New European Driving Cycle. Fuel 2013, 106, 873–875. [Google Scholar] [CrossRef]

- Wang, S.; Ji, C. Cyclic variation in a hydrogen-enriched spark-ignition gasoline engine under various operating conditions. Int. J. Hydrog. Energy 2012, 37, 1112–1119. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S.; Zhang, B. Effect of spark timing on the performance of a hybrid hydrogen–gasoline engine at lean conditions. Int. J. Hydrog. Energy 2010, 35, 2203–2212. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S. Experimental study on combustion and emissions performance of a hybrid hydrogen–gasoline engine at lean burn limits. Int. J. Hydrog. Energy 2010, 35, 1453–1462. [Google Scholar] [CrossRef]

- Ji, C.; Cong, X.; Wang, S.; Shi, L.; Su, T.; Wang, D. Performance of a hydrogen-blended gasoline direct injection engine under various second gasoline direct injection timings. Energy Convers. Manag. 2018, 171, 1704–1711. [Google Scholar] [CrossRef]

- Hao, L.; Xu, X.; Guo, X.; Ji, C.; Wang, X.; Tan, J.; Ge, Y. Investigation of cold-start emission control strategy for a bi-fuel hydrogen/gasoline engine. Int. J. Hydrog. Energy 2016, 41, 18273–18281. [Google Scholar] [CrossRef]

- Wang, S.; Ji, C.; Zhang, M.; Zhang, B. Reducing the idle speed of a spark-ignited gasoline engine with hydrogen addition. Int. J. Hydrog. Energy 2010, 35, 10580–10588. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S.; Zhang, B. Combustion and emissions characteristics of a hybrid hydrogen–gasoline engine under various loads and lean conditions. Int. J. Hydrog. Energy 2010, 35, 5714–5722. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, J.; Liu, B.; Zeng, K.; Yu, J.; Jiang, D. Combustion characteristics of a direct-injection engine fueled with natural gas−hydrogen mixtures. Energy Fuels 2006, 20, 540–546. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, J.; Liu, B.; Zeng, K.; Yu, J.; Jiang, D. Combustion characteristics of a direct-injection engine fueled with natural gas−hydrogen blends under various injection timings. Energy Fuels 2006, 20, 1498–1504. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Z.; Fang, Y.; Liu, B.; Zeng, K.; Miao, H.; Jiang, D. Combustion behaviors of a direct-injection engine operating on various fractions of natural gas–hydrogen blends. Int. J. Hydrog. Energy 2007, 32, 3555–3564. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Z.; Tang, C.; Zheng, J. Effect of hydrogen addition on early flame growth of lean burn natural gas–air mixtures. Int. J. Hydrog. Energy 2010, 35, 7246–7252. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Z.; Zheng, J.; Miao, H. Effect of partially premixed and hydrogen addition on natural gas direct-injection lean combustion. Int. J. Hydrog. Energy 2009, 34, 9239–9247. [Google Scholar] [CrossRef]

- He, F.; Li, S.; Yu, X.; Du, Y.; Zuo, X.; Dong, W.; Sun, P.; He, L. Comparison study and synthetic evaluation of combined injection in a spark ignition engine with hydrogen-blended at lean burn condition. Energy 2018, 157, 1053–1062. [Google Scholar] [CrossRef]

- Yu, X.; Zuo, X.; Wu, H.; Du, Y.; Sun, Y.; Wang, Y. Study on combustion and emission characteristics of a combined injection engine with hydrogen direct injection. Energy Fuels 2017, 31, 5554–5560. [Google Scholar] [CrossRef]

- Shi, W.; Yu, X.; Zhang, H.; Li, H. Effect of spark timing on combustion and emissions of a hydrogen direct injection stratified gasoline engine. Int. J. Hydrog. Energy 2016, 42, 5619–5626. [Google Scholar] [CrossRef]

- Yao, S.; Yu, X.; Dong, W.; Yang, T. Effects of hydrogen direct injection on engine stability and optimization of control parameters fora combined injection engine. Int. J. Hydrog. Energy 2018, 43, 6723–6733. [Google Scholar]

- Yu, X.; Wu, H.; Du, Y.; Yang, T.; Liu, L.; Niu, R. Research on cycle-by-cycle variations of an SI engine with HDI under lean burn conditions. Appl. Therm. Eng. 2016, 109, 569–581. [Google Scholar] [CrossRef]

- Du, Y.; Yu, X.; Wang, J.; Wu, H.; Dong, W.; Gu, J. Research on combustion and emission characteristics of a lean burn gasoline engine with hydrogen direct-injection. Int. J. Hydrog. Energy 2016, 41, 3240–3248. [Google Scholar] [CrossRef]

- Niu, R.; Yu, X.; Du, Y.; Xie, H.; Wu, H.; Sun, Y. Effect of hydrogen proportion on lean burn performance of a dual fuel SI engine using hydrogen direct-injection. Fuel 2016, 186, 792–799. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, X.; Jiang, L. Effects of direct hydrogen injection on particle number emissions from a lean burn gasoline engine. Int. J. Hydrog. Energy 2016, 41, 18631–18640. [Google Scholar] [CrossRef]

- Du, Y.; Yu, X.; Liu, L.; Li, R.; Zuo, X.; Sun, Y. Effect of addition of hydrogen and exhaust gas recirculation on characteristics of hydrogen gasoline engine. Int. J. Hydrog. Energy 2017, 42, 8288–8298. [Google Scholar] [CrossRef]

- Yu, X.; Li, G.; Yu, X.; Guo, Z.; Shang, Z.; He, F.; Shen, Q.; Li, D.; Li, Y. A comparative study on effects of homogeneous or stratified hydrogen on combustion and emissions of a gasoline/hydrogen SI engine. Int. J. Hydrog. Energy 2019, 44, 25974–25984. [Google Scholar] [CrossRef]

- Li, G.; Yu, X.; Shi, W.; Yao, C.; Wang, S.; Shen, Q. Effects of split injection proportion and the second injection timings on combustion and emissions of a dual fuel SI engine with SHDI. Int. J. Hydrog. Energy 2019, 44, 11194–11204. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Li, D.; Liu, J.; Si, X.; Yu, J.; Huang, W.; Liu, F.; Han, Y. Numerical investigation of hydrogen addition effects on methanol-air mixtures combustion in premixed laminar flames under lean burn conditions. Renew. Energy 2018, 127, 56–63. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Chen, Y.; Liu, J.; Liu, F.; Han, J. Influence of ignition timing on combustion and emissions of a spark-ignition methanol engine with added hydrogen under lean-burn conditions. Fuel 2019, 2351, 227–238. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Yi, L.; Liu, F. Comparative study on combustion and emissions between methanol port-injection engine and methanol direct-injection engine with H2-enriched port-injection under lean-burn conditions. Energy Convers. Manag. 2019, 200, 112096. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Yi, L.; Huang, K.; Liu, F. Research on the performance of a hydrogen/methanol dual-injection assisted spark-ignition engine using late-injection strategy for methanol. Fuel 2020, 260, 116403. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Yi, L.; Liu, F. Experimental investigation of equivalence ratio effects on combustion and emissions characteristics of an H2/methanol dual-injection engine under different spark timings. Fuel 2020, 262, 116463. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Yi, L.; Sun, J.; Liu, F. Comparative analysis of various combustion phase control methods in a lean-burn H2/methanol fuel dual-injection engine. Fuel 2020, 262, 116592. [Google Scholar] [CrossRef]

- Shang, Z.; Yu, X.; Shi, W.; Huang, S.; Li, G.; Guo, Z.; He, F. Numerical research on effect of hydrogen blending fractions on idling performance of an n-butanol ignition engine with HDI. Fuel 2019, 258, 1–12. [Google Scholar] [CrossRef]

- Li, G.; Yu, X.; Jin, Z.; Shang, Z. Study on effects of split injection proportion on hydrogen mixture distribution, combustion and emissions of a gasoline/hydrogen SI engine with split hydrogen direct injection under lean burn condition. Fuel 2020, 270, 117488. [Google Scholar] [CrossRef]

- Yang, J.; Ji, C.; Wang, S.; Zhang, Z.; Wang, D.; Ma, Z. Numerical investigation of the effects of hydrogen enrichment on combustion and emissions formation processes in a gasoline rotary engine. Energy Convers. Manag. 2017, 151, 136–146. [Google Scholar] [CrossRef]

- He, L.; Jingyuan, L.; Yu, X.; Mengliang, L.; Tian, Y. Numerical study on combustion and emission characteristics of a PFI gasoline engine with hydrogen direct-injection. Energy Procedia 2019, 158, 1449–1454. [Google Scholar] [CrossRef]

- Liu, Y.D.; Jia, M.; Xie, M.Z.; Pang, B. Enhancement on a skeletal kinetic model for primary reference fuel oxidation by using a semi decoupling methodology. Energy Fuel 2012, 26, 7069–7083. [Google Scholar] [CrossRef]

- Available online: http://www-cms.llnl.gov/combustion/archive.html (accessed on 20 June 2017).

| Item | Characteristics |

|---|---|

| Engine Type | Four Cylinders; Dual Injection; Spark Ignited |

| Bore × Stroke | 82.5 mm × 92.8 mm |

| Compression Ratio | 9.6 |

| Displacement Volume | 1984 ml |

| Turbulence model | RNG k-ε Model |

| Ignition model | Spark-energy Deposition Model |

| Combustion model | SAGE Model |

| Heat transfer model | O’Rourke and Amsden Model |

| Combustion chamber top surface | 550 K |

| Piston | 600 K |

| Intake port wall | 363 K |

| Exhaust port wall | 500 K |

| Cylinder wall | 450 K |

| Intake air | 363 K |

| Cylinder inside | 800 K |

| Inlet pressure | 0.035 MPa |

| Outlet pressure | 0.1 MPa |

| Measuring Project | Measurement Error | Production Type |

|---|---|---|

| Speed | ≤ ± 1 rpm | CW160 |

| Brake power | ≤ ± 0.4 kW | CW160 |

| Fuel consumption of gasoline | ≤ ± 0.01 g/s | Ono Sokki DF-2420 flow meter |

| Hydrogen volumetric flow meter | ≤ ± 0.2% | DMF-1-1AB |

| Crank angle position | ≤ ± 0.01°CA | Ono Sokki DS 9028 |

| Heat release rate | ≤ ± 1% | Ono Sokki DS 9028 |

| Cylinder pressure | ≤ ± 0.3 bar | Ono Sokki DS 9028 |

| Flow pressure of intake air | ≤ ± 0.1 kPa | BOSCH flow meter |

| Excess air coefficient | ≤ ± 0.15 | LSU4.2 oxygen sensor |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Yu, X.; Sun, P.; Li, D. Study on the Effect of Second Injection Timing on the Engine Performances of a Gasoline/Hydrogen SI Engine with Split Hydrogen Direct Injecting. Energies 2020, 13, 5223. https://doi.org/10.3390/en13195223

Li G, Yu X, Sun P, Li D. Study on the Effect of Second Injection Timing on the Engine Performances of a Gasoline/Hydrogen SI Engine with Split Hydrogen Direct Injecting. Energies. 2020; 13(19):5223. https://doi.org/10.3390/en13195223

Chicago/Turabian StyleLi, Guanting, Xiumin Yu, Ping Sun, and Decheng Li. 2020. "Study on the Effect of Second Injection Timing on the Engine Performances of a Gasoline/Hydrogen SI Engine with Split Hydrogen Direct Injecting" Energies 13, no. 19: 5223. https://doi.org/10.3390/en13195223

APA StyleLi, G., Yu, X., Sun, P., & Li, D. (2020). Study on the Effect of Second Injection Timing on the Engine Performances of a Gasoline/Hydrogen SI Engine with Split Hydrogen Direct Injecting. Energies, 13(19), 5223. https://doi.org/10.3390/en13195223