An Intelligent Automatic Adaptive Maximum Power Point Tracker for Photovoltaic Module Arrays

Abstract

1. Introduction

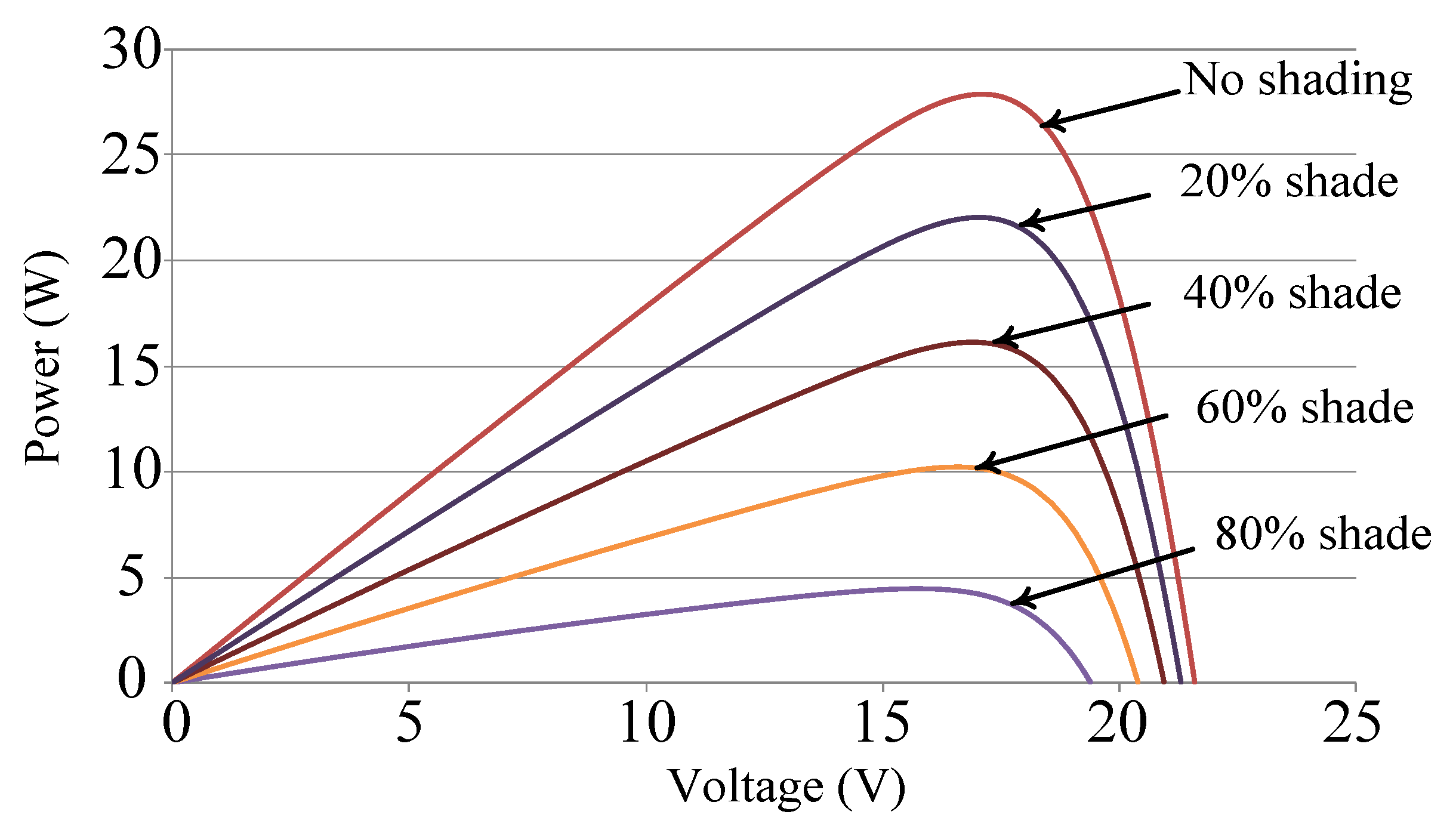

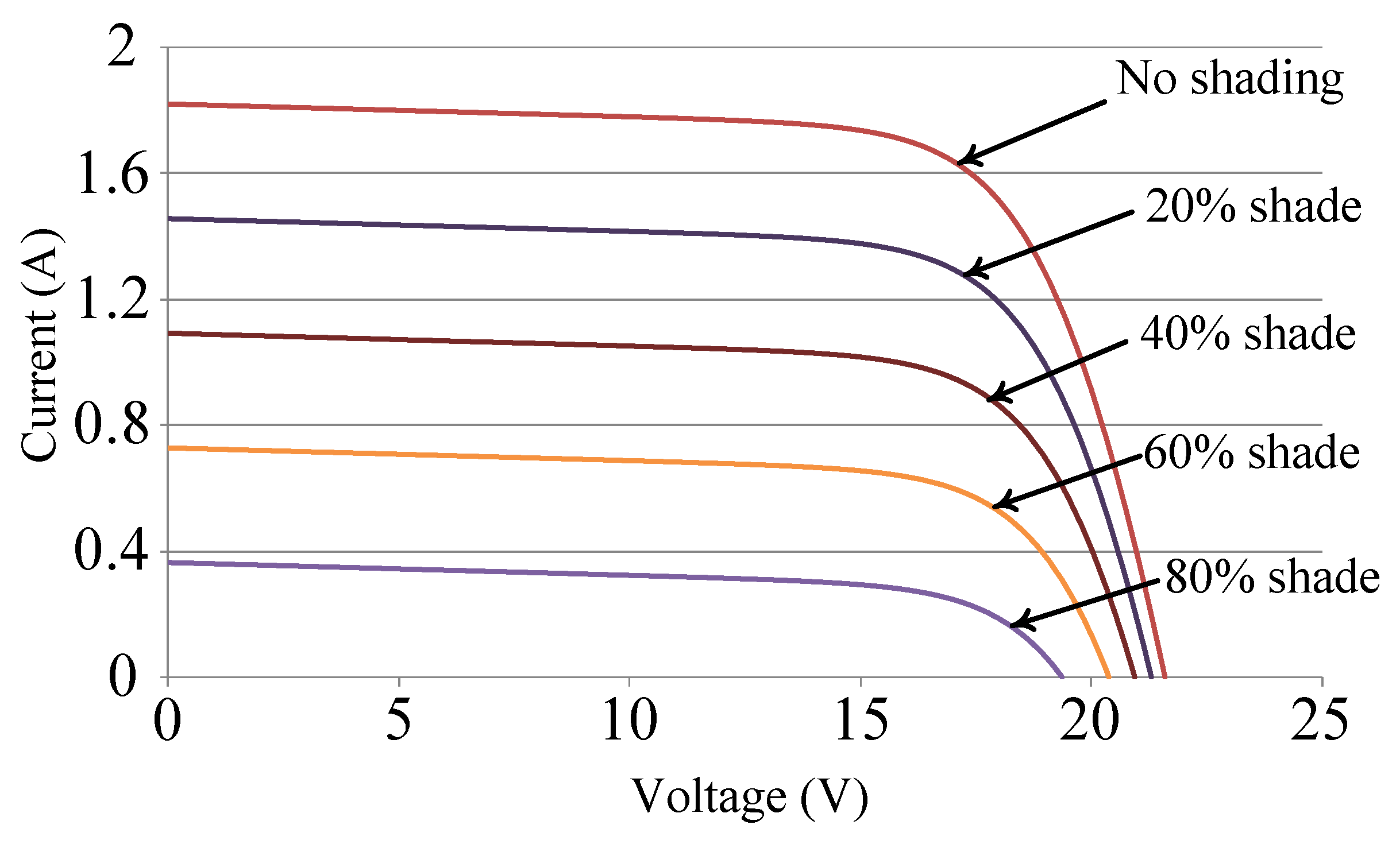

2. Malfunction and Shading Effects of Photovoltaic Module Arrays

3. TLBO Algorithm

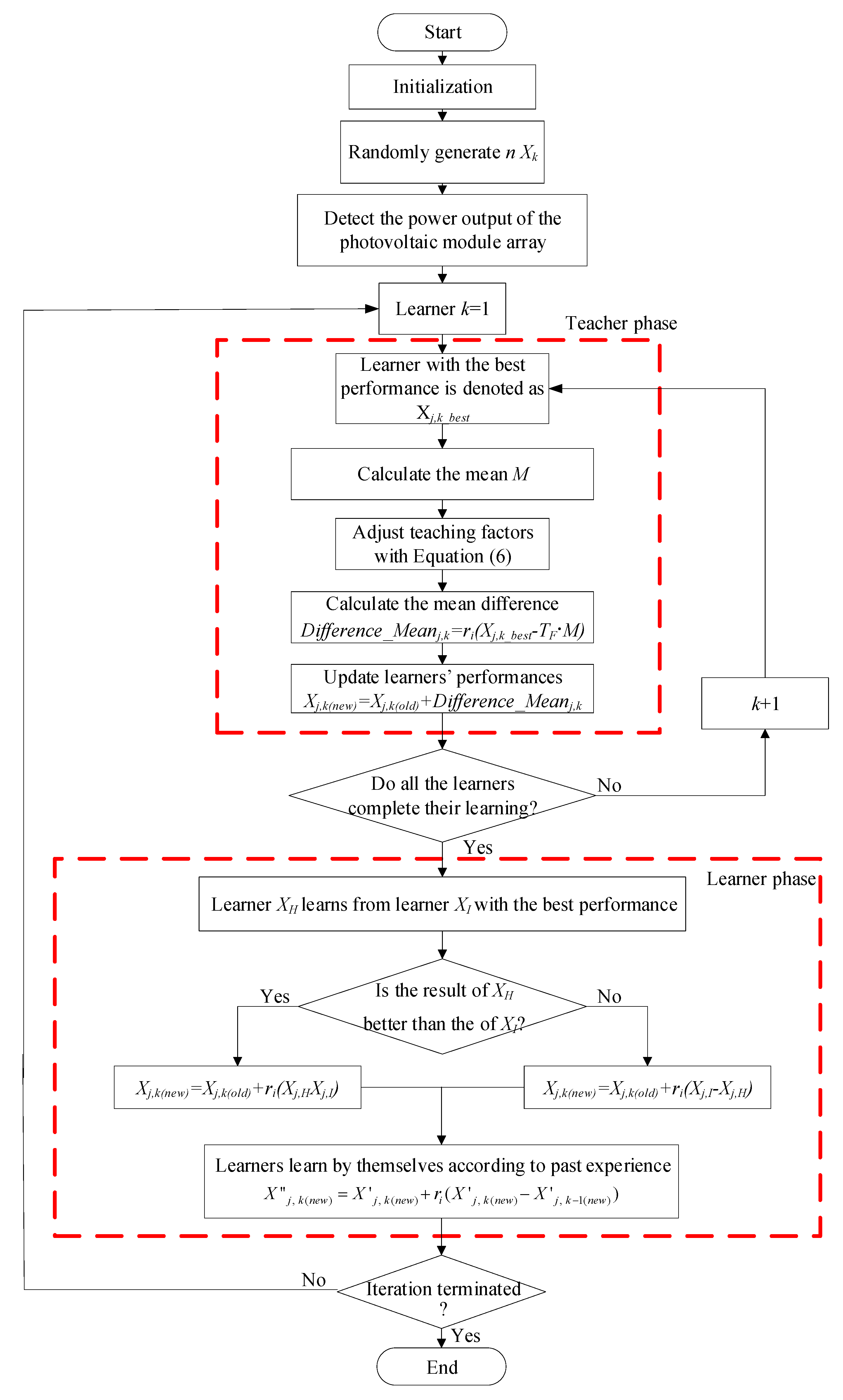

3.1. Conventional TLBO Algorithm

- Step 1:

- Set the number of learners (NP), number of subjects (m), and the number of iterations (E).

- Step 2:

- Initialize the class and define the parameters as follows:

- (1)

- Random learner:

- (2)

- Random subject:

- (3)

- Performance of learner k in subject j: Gj,k

- Step 3:

- In the teacher phase, set the teaching step (ri), teaching factor (TF), and performance of the best learner (Xj,k_best). Calculate the mean result of the class following Equation (1); calculate the learners’ difference mean by applying Equation (2); and renew all the learners’ target performance in the learner phase by following Equation (3).

- Step 4:

- In the learning process, assume that a randomly selected learner XH and learner XI learn from each other. When the performance of XH is superior to that for XI, apply Equation (4). If the performance of XI is superior to that for XH, apply Equation (5).

- Step 5:

- Repeat Steps 4 and 5 until the criterion for terminating the iteration is met.

3.2. Proposed Improved TLBO Algorithm

- Teaching factors are automatically adjusted according to the absorption ability of all the learners in the class. The adjustment measure is presented in Equation (6). The automatic adjustment in the teaching factor allows the teacher to assess the learning level of the entire class and design learning methods that increase the overall performance of the class. In contrast to the TLBO algorithm proposed in Reference [14], the proposed algorithm focuses on the entire class rather than on individual learners.

- Rather than two randomly selected learners learning from each other, all the learners in the class learn from the learner with the best result in the learner phase.

- In the learner phase, a self-learning function is added so that each learner can adjust according to past experience, as presented in Equation (7).

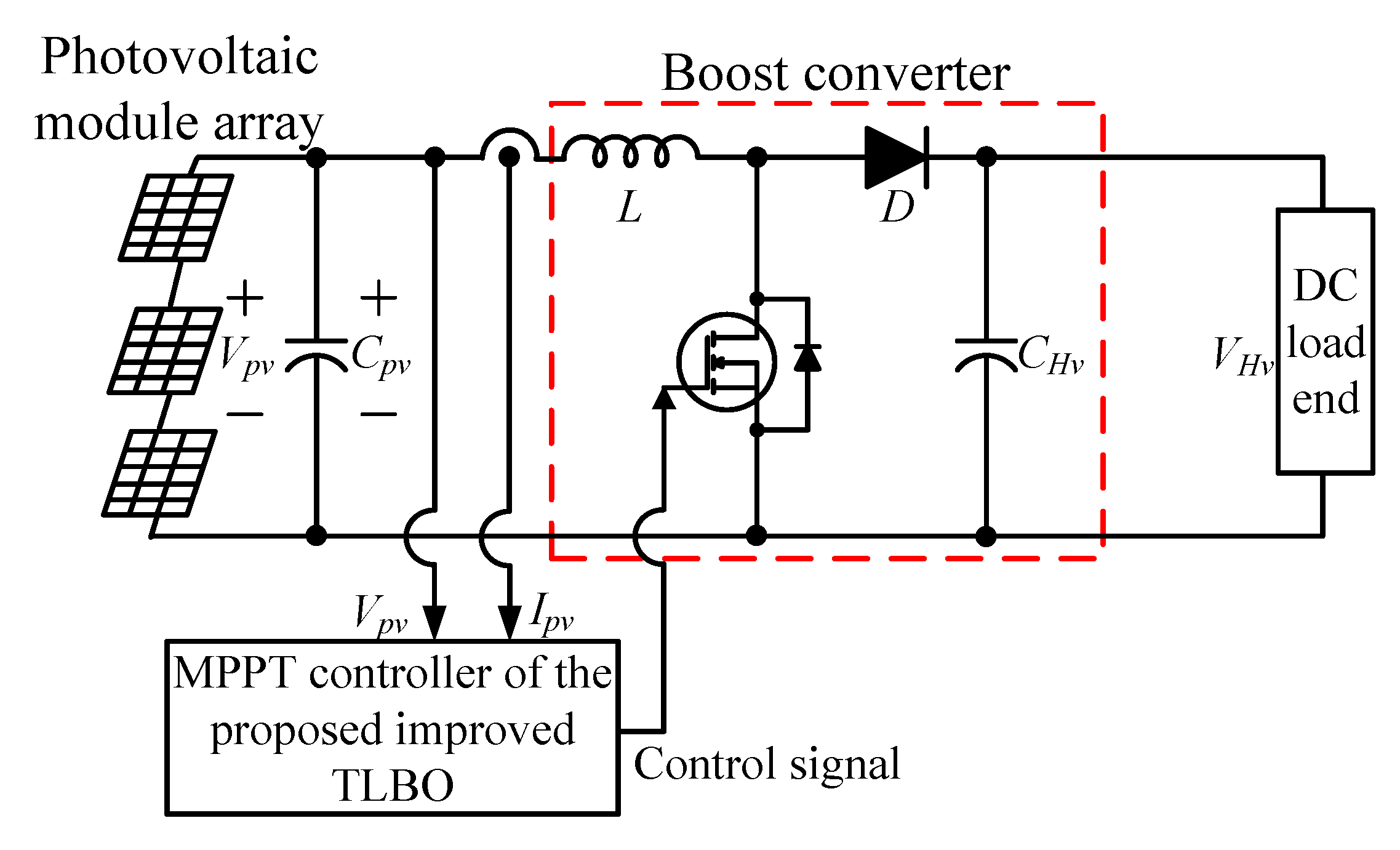

3.3. Maximum Power Tracker of the Proposed Improved TLBO Algorithm

4. Simulation Results

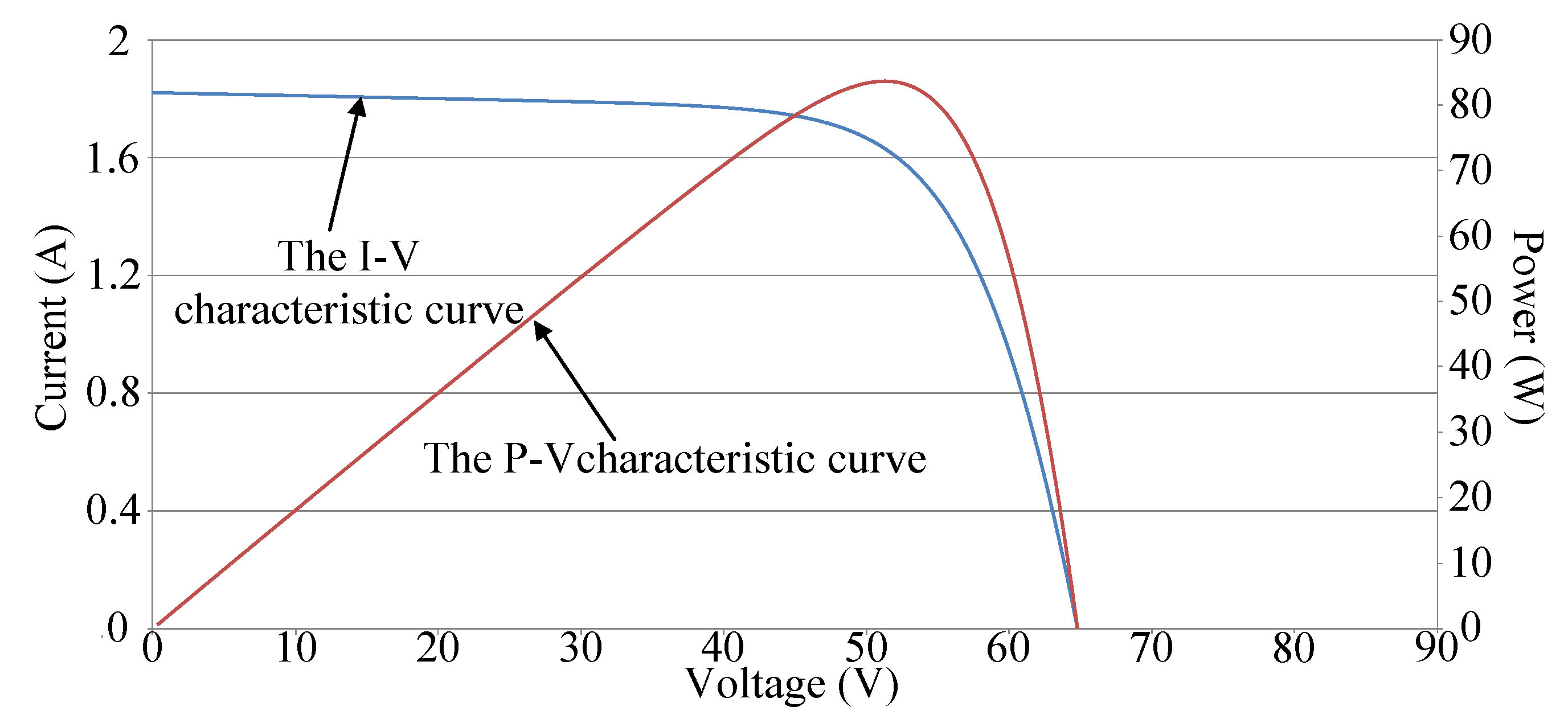

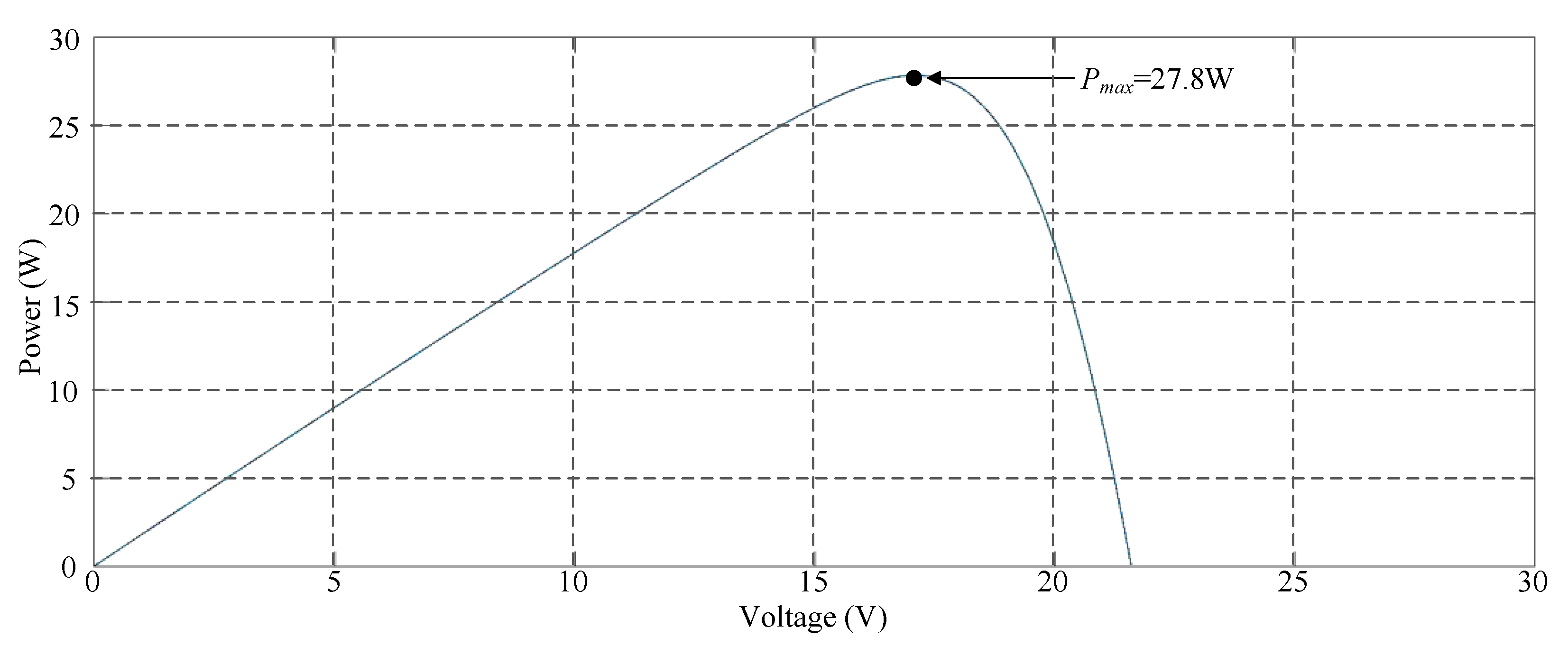

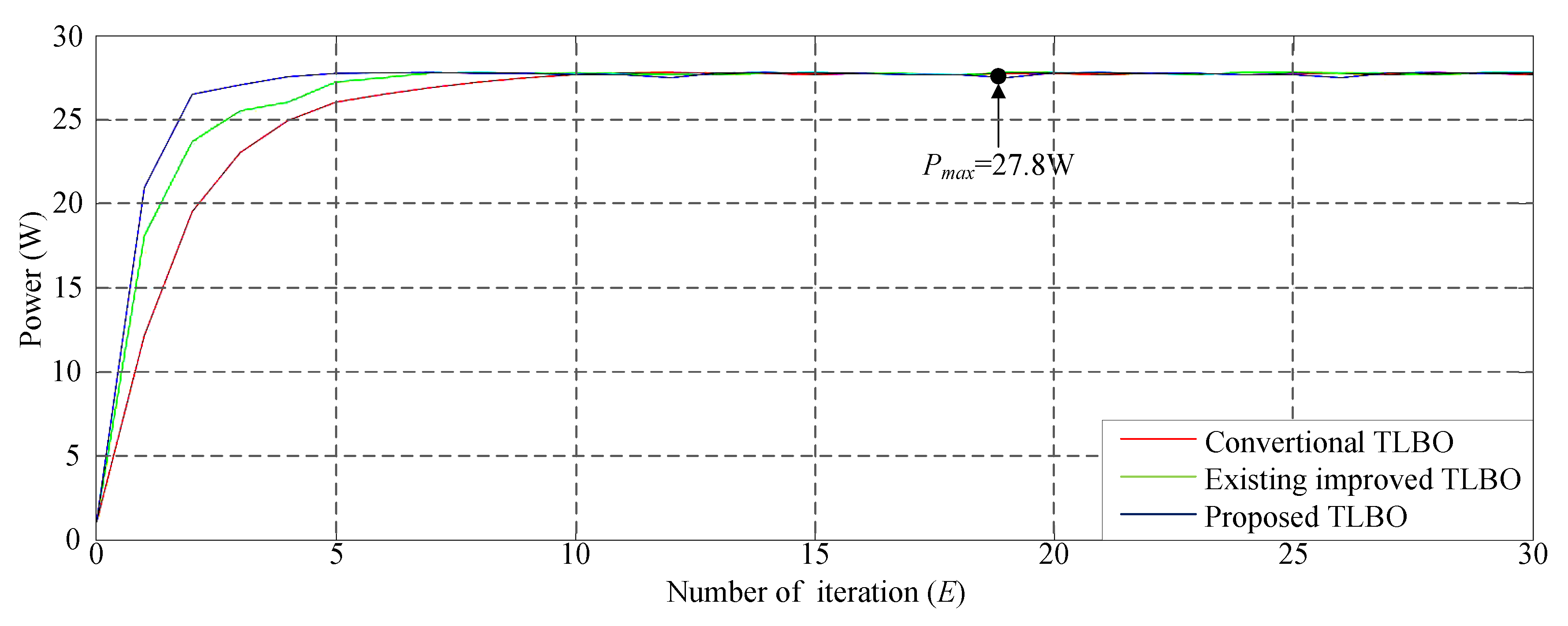

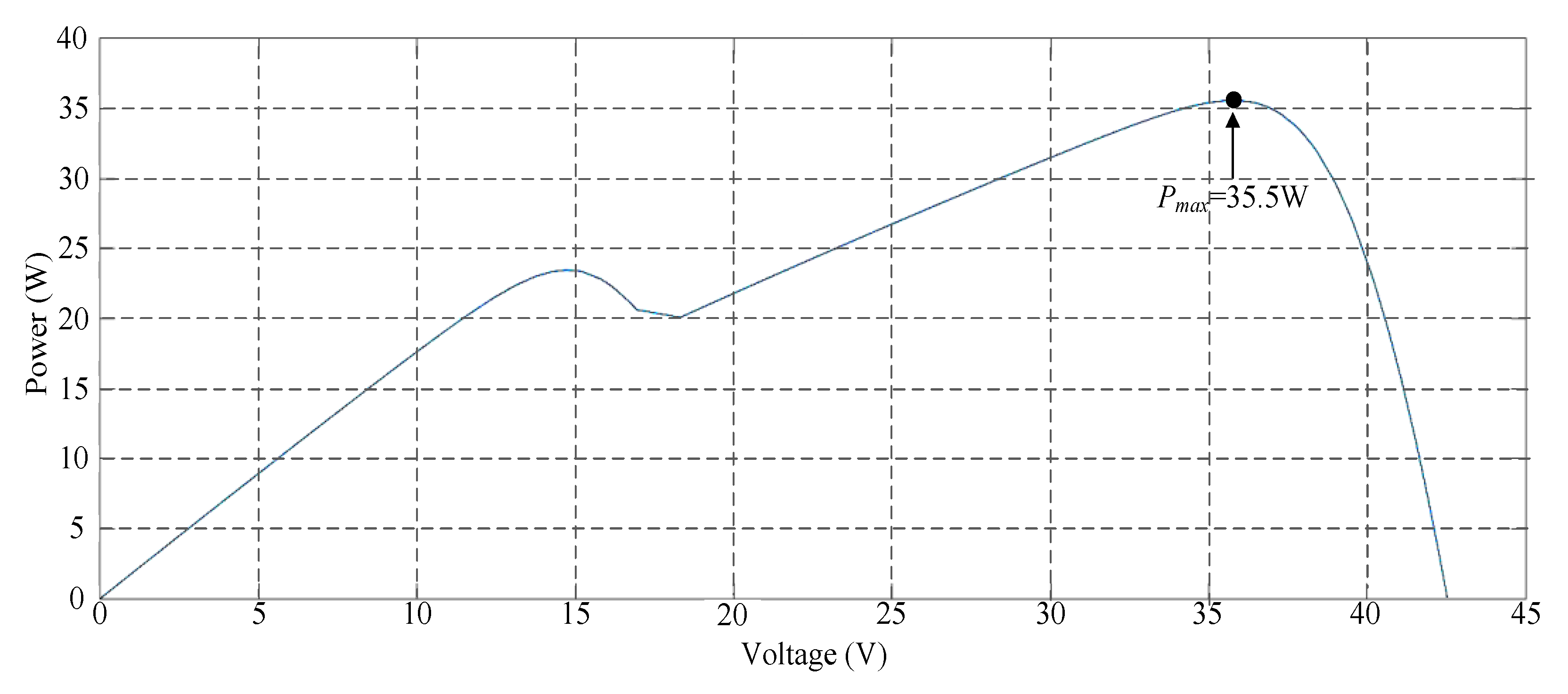

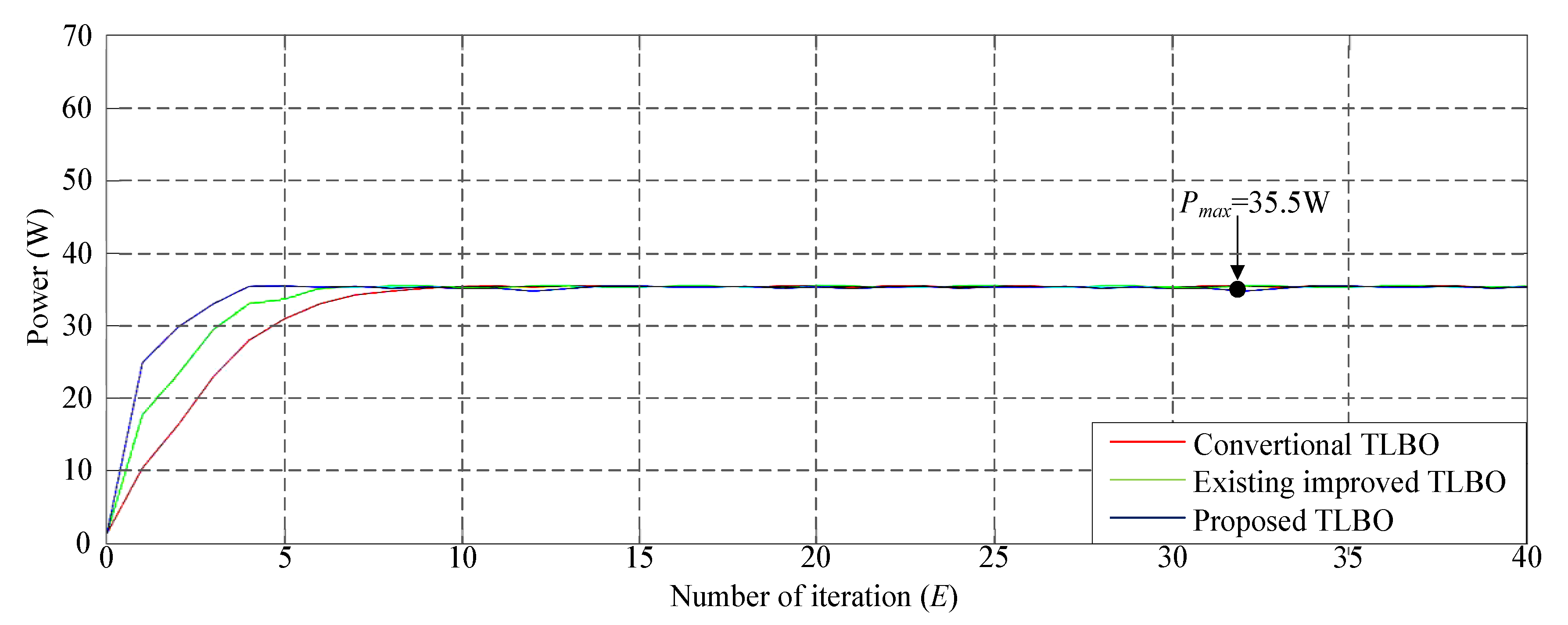

4.1. Case 1: One Series and One Parallel (No Shading)

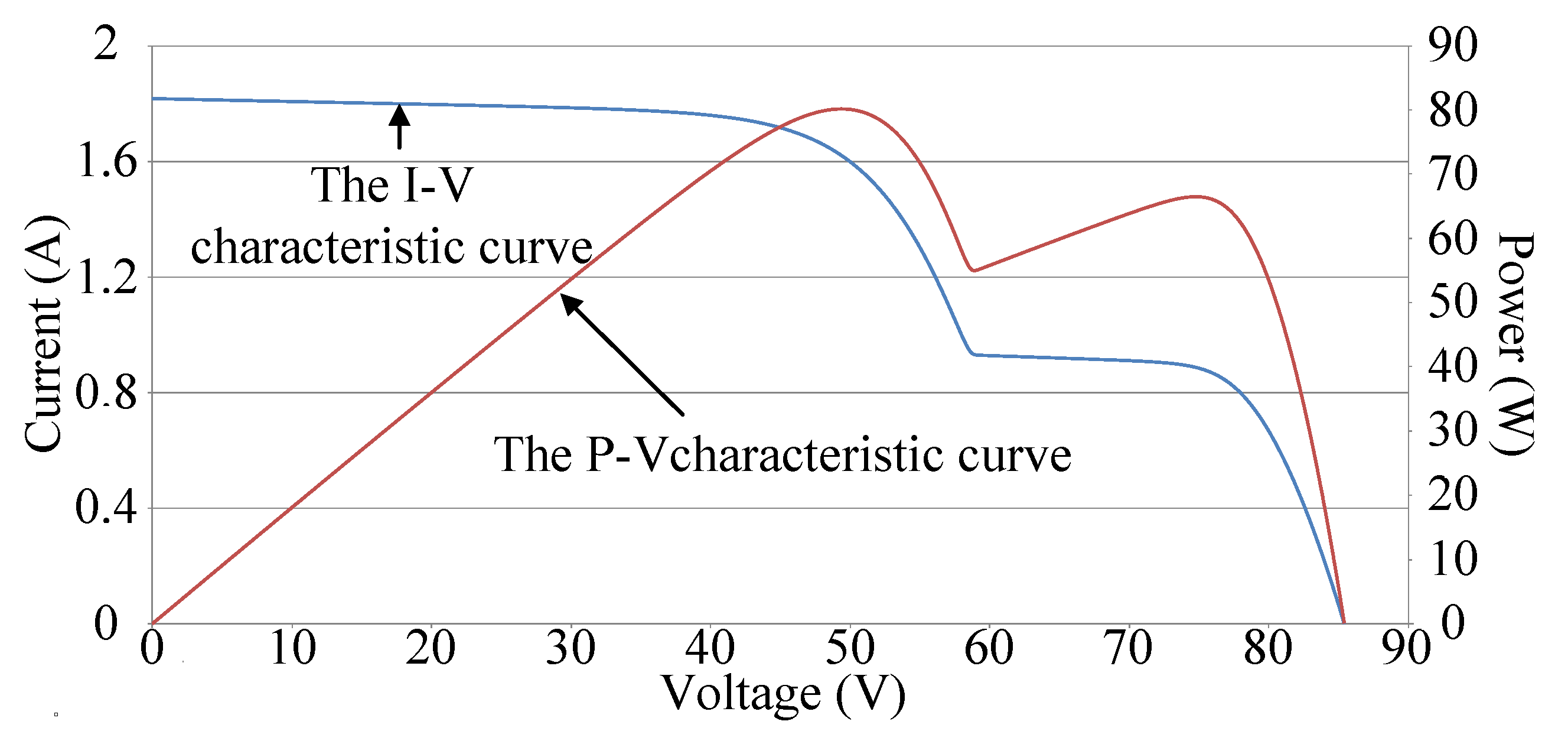

4.2. Case 2: Two Series and One Parallel (0% Shade + 40% Shade)

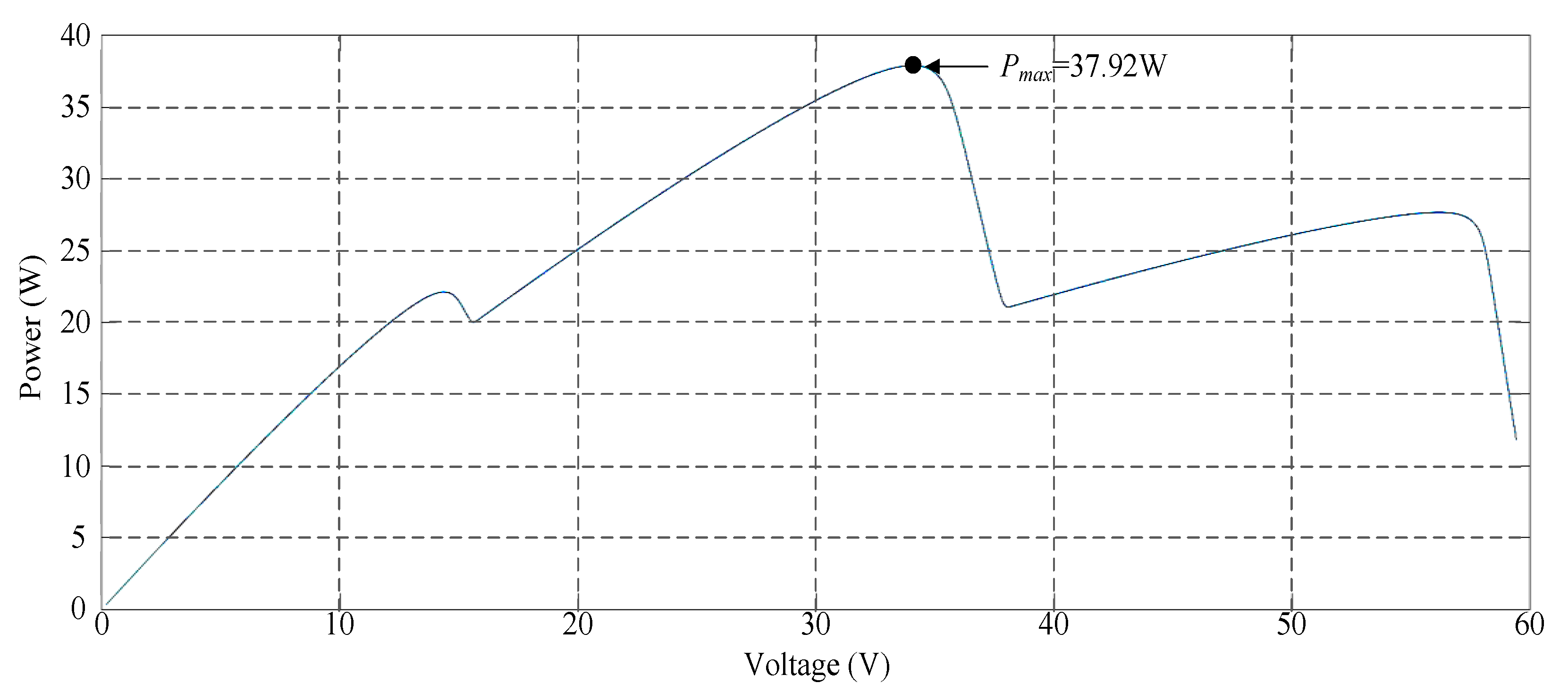

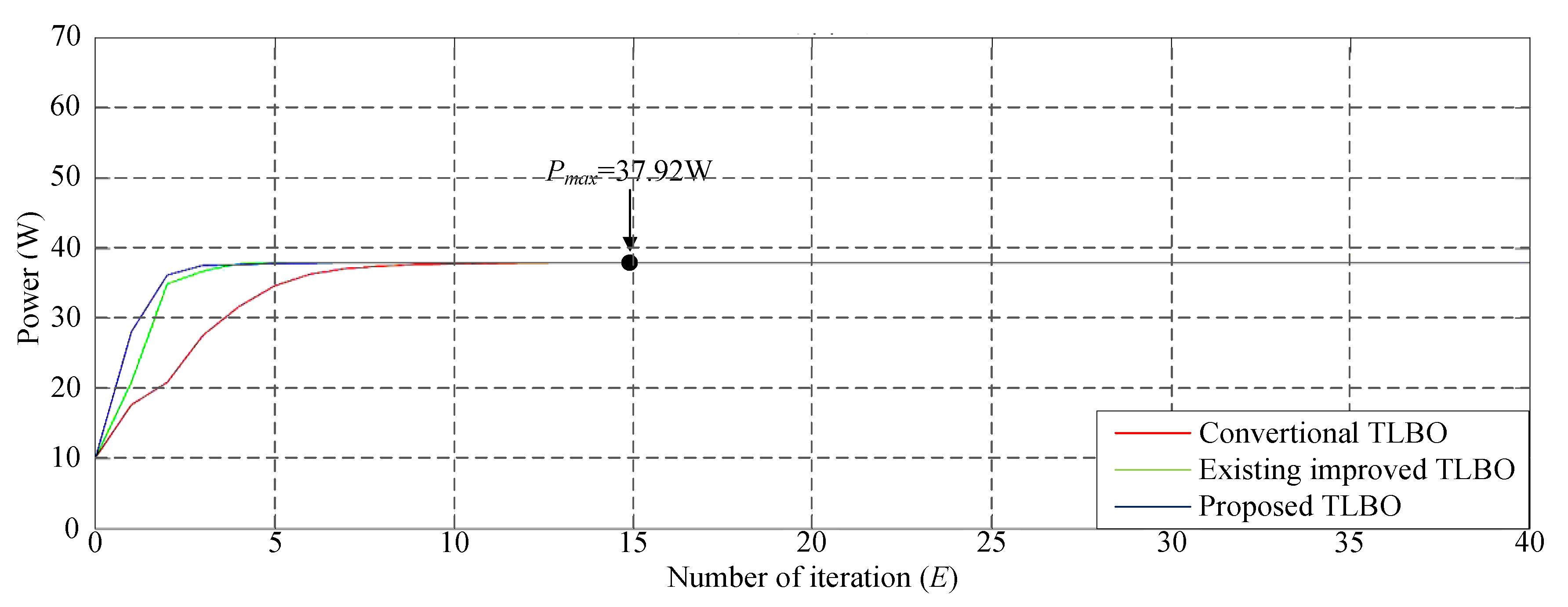

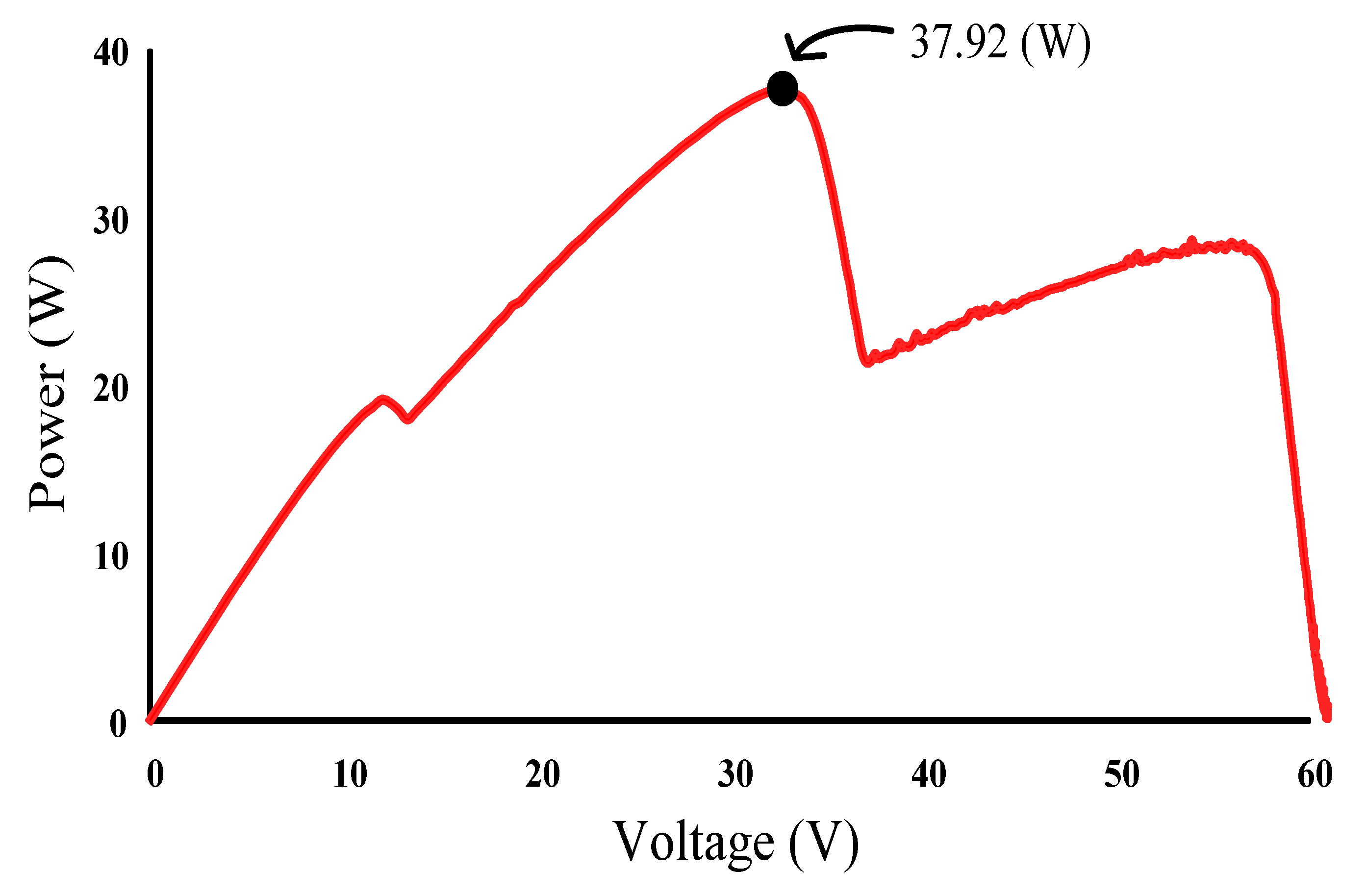

4.3. Case 3: Three Series and One Parallel (0% Shade + 30% Shade + 70% Shade)

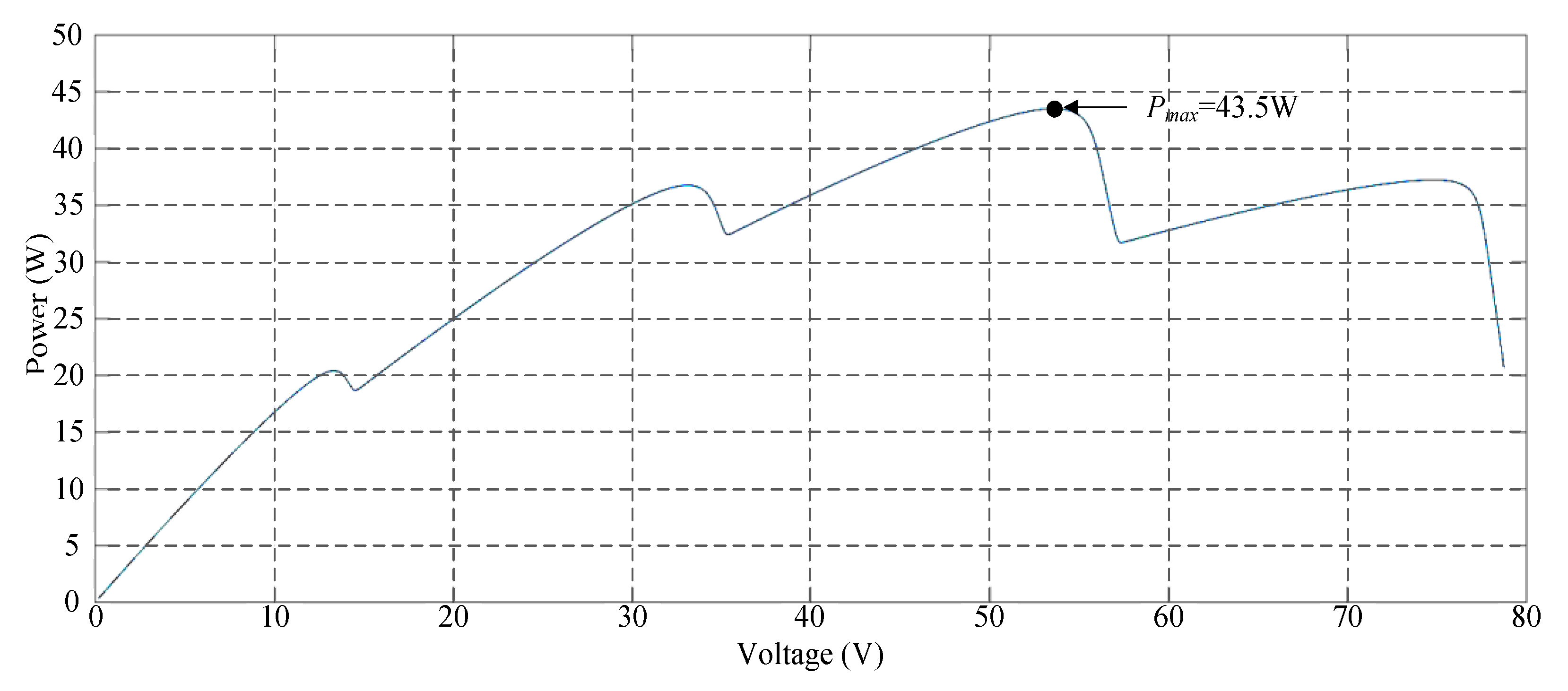

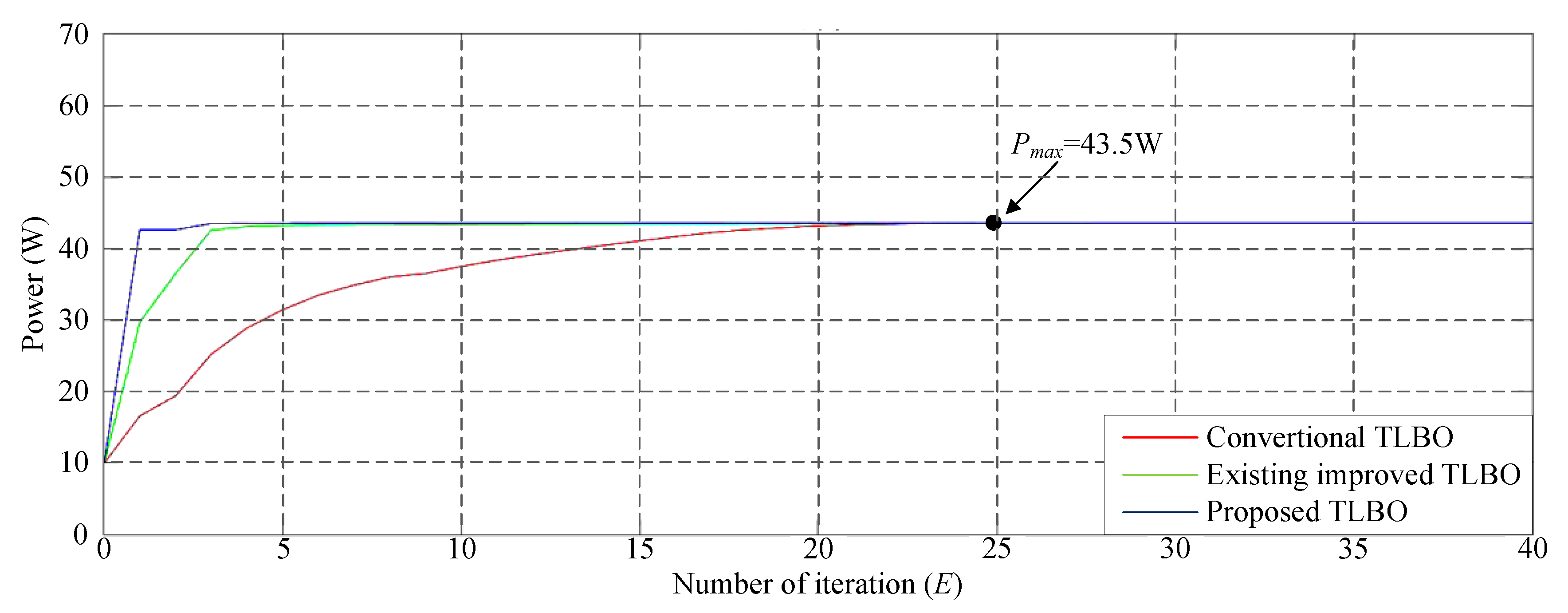

4.4. Case 4: Three Series and One Parallel (0% Shade + 30% Shade + 50% Shade + 70% Shade)

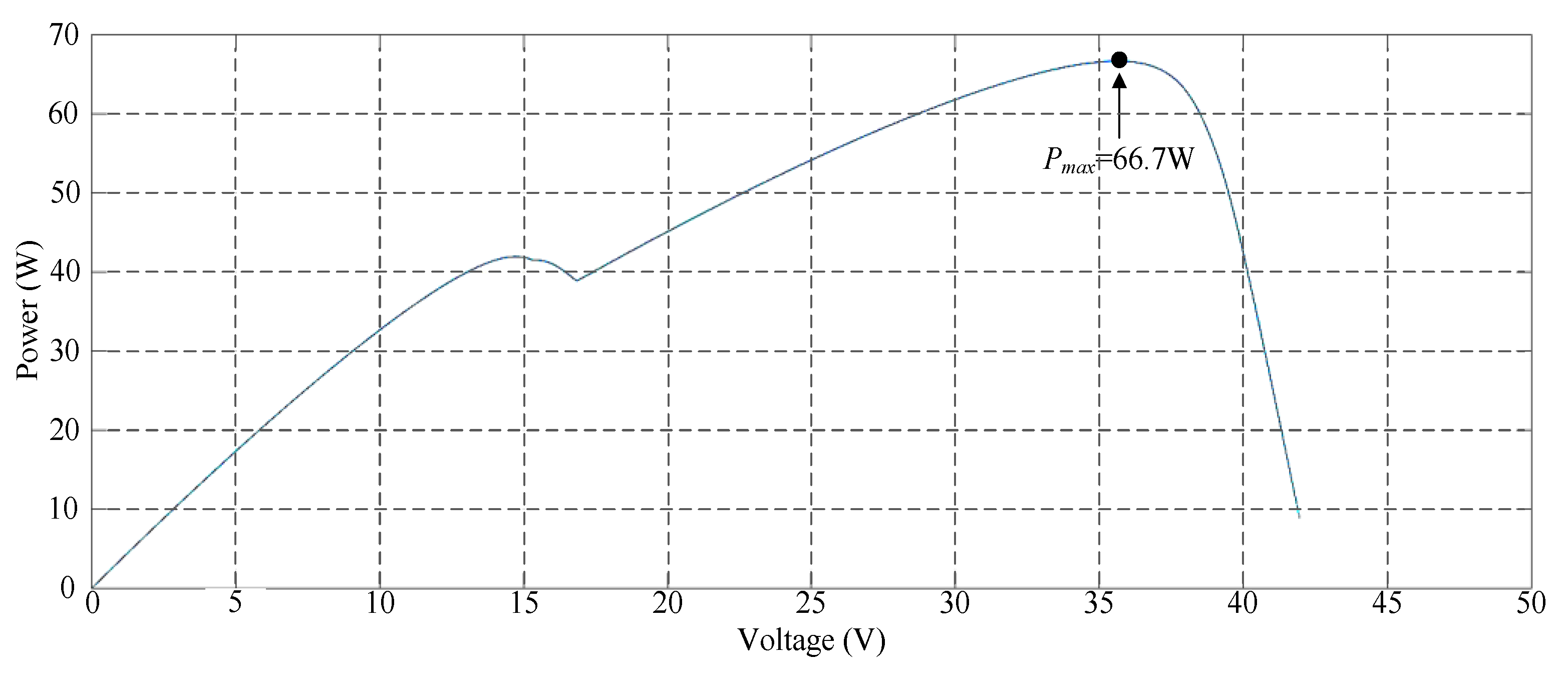

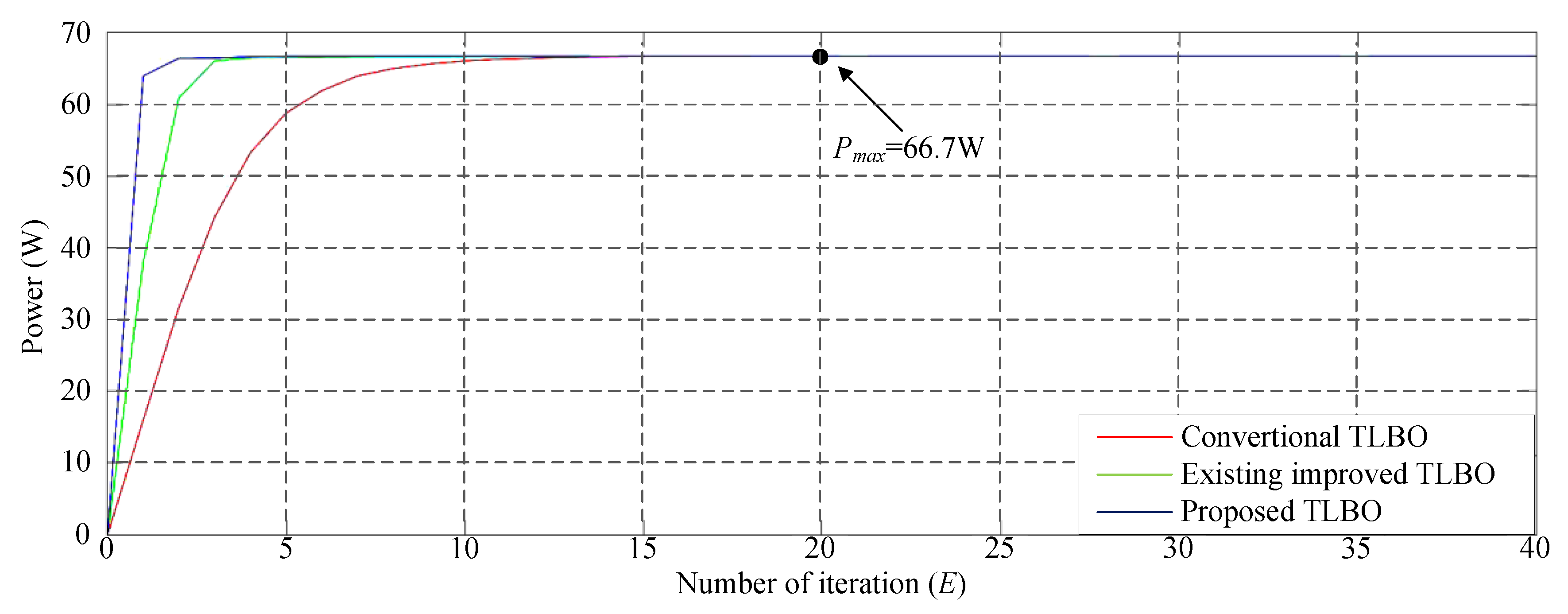

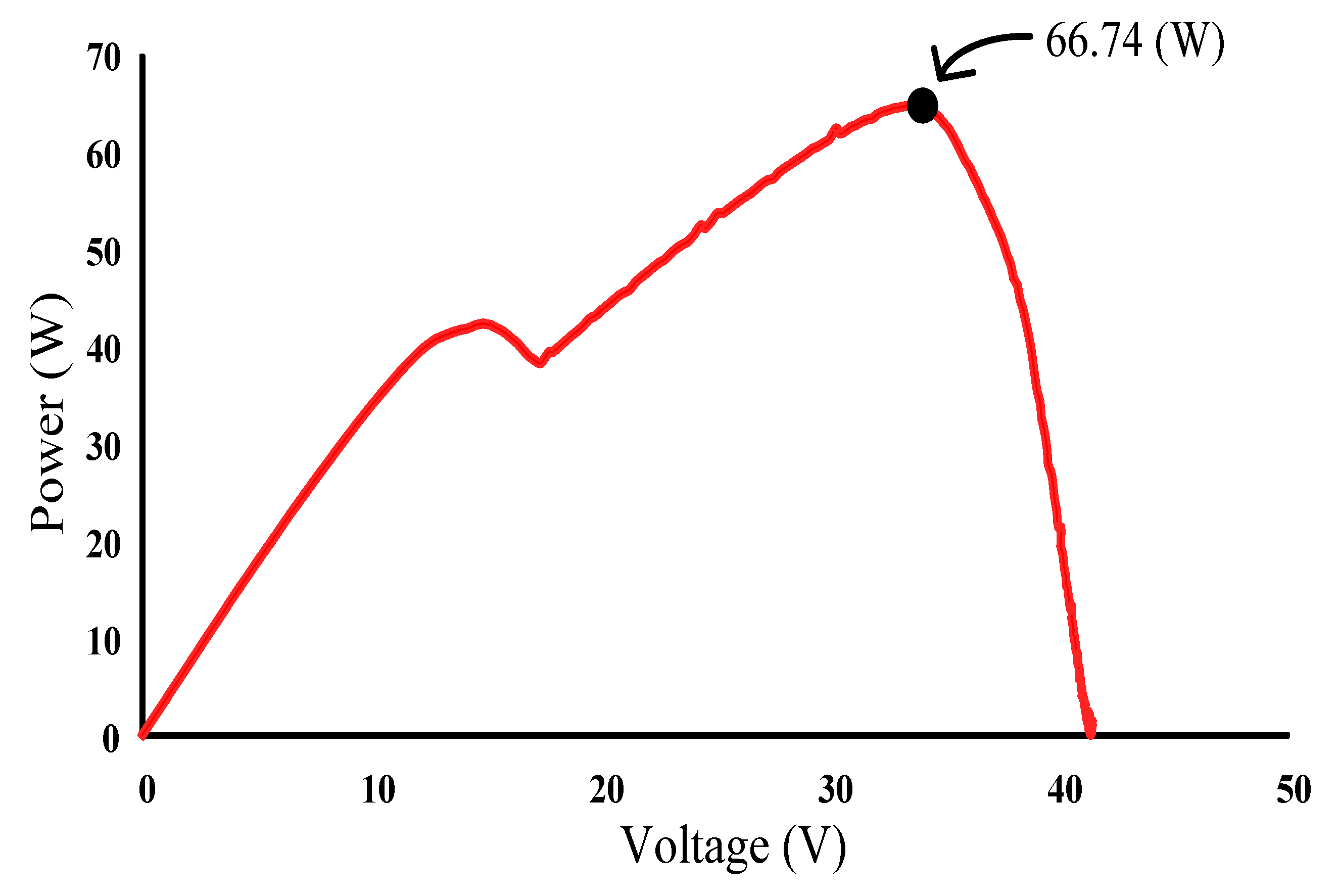

4.5. Case 5: Three Series and Two Parallels (30% Shade +0% Shade)/(0% Shade + 50% Shade)

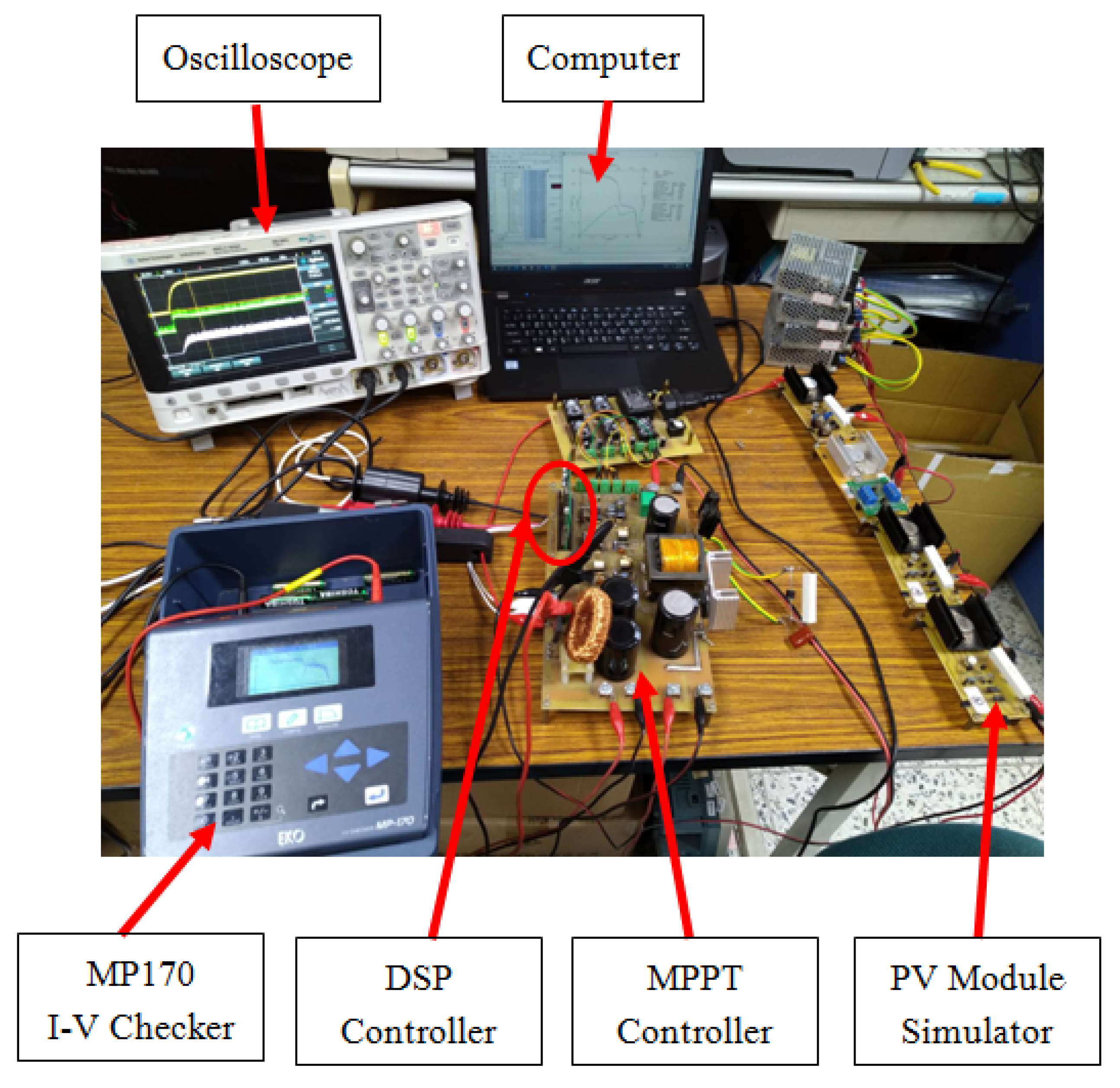

5. Practical Test Results

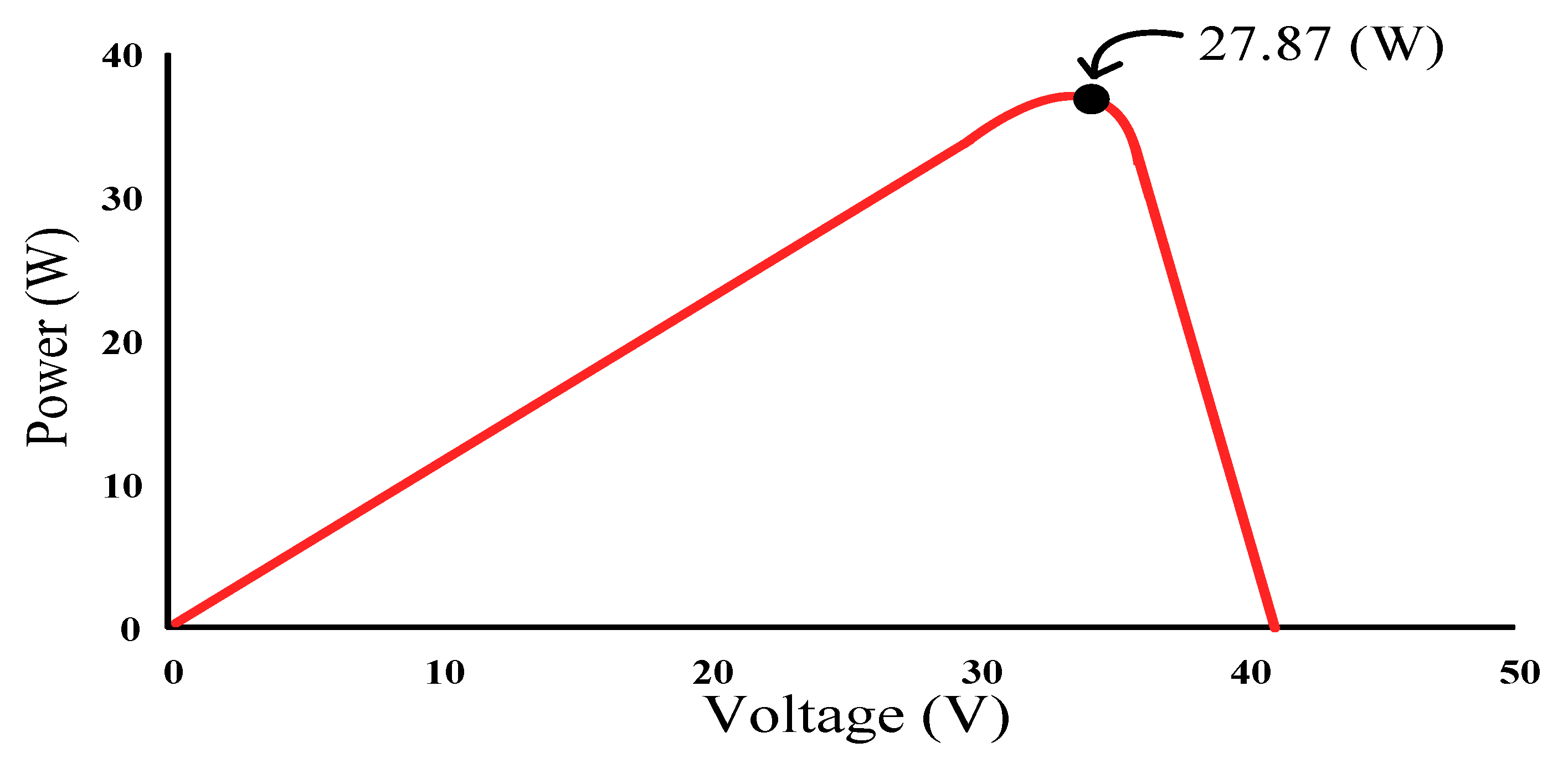

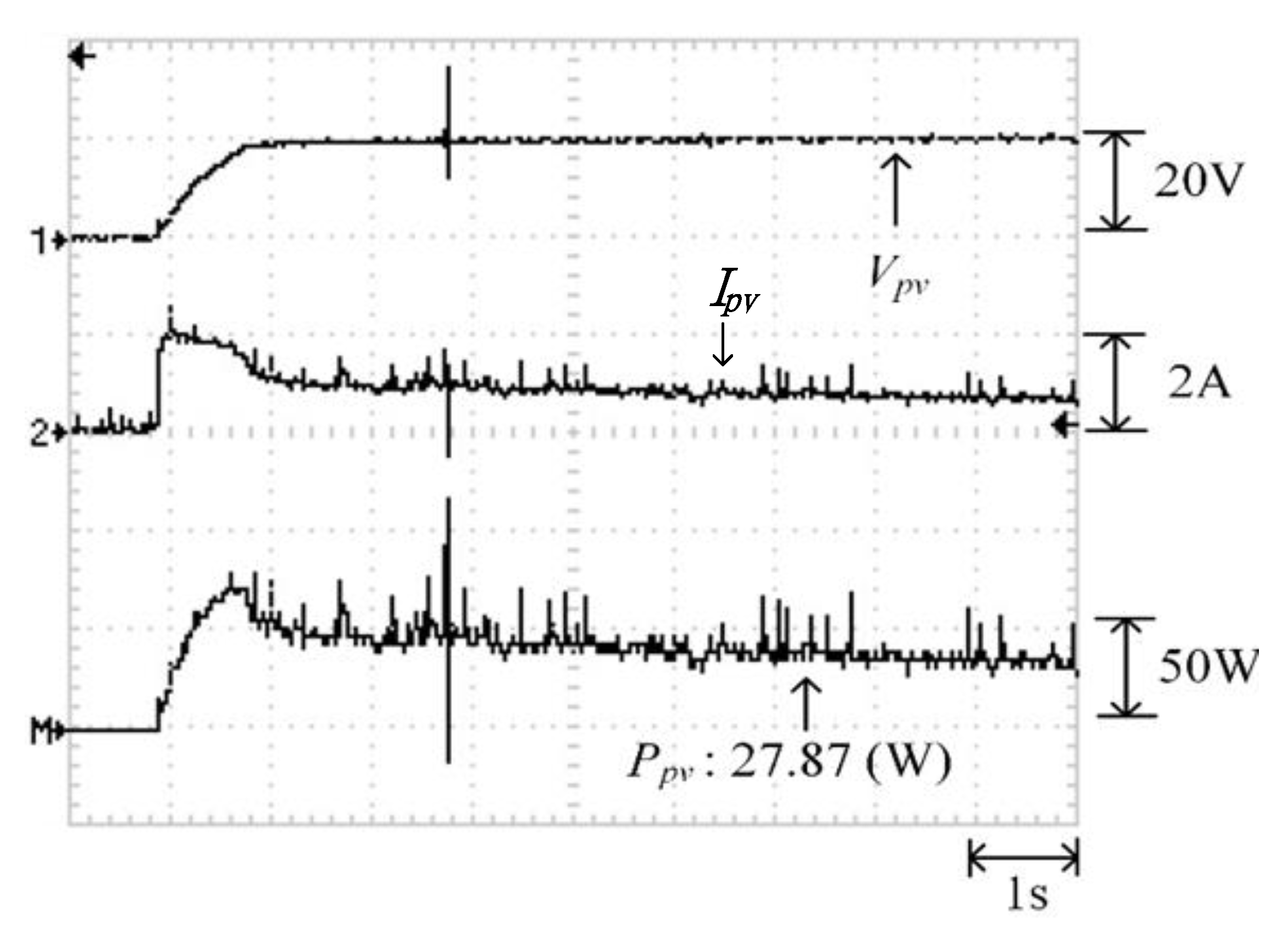

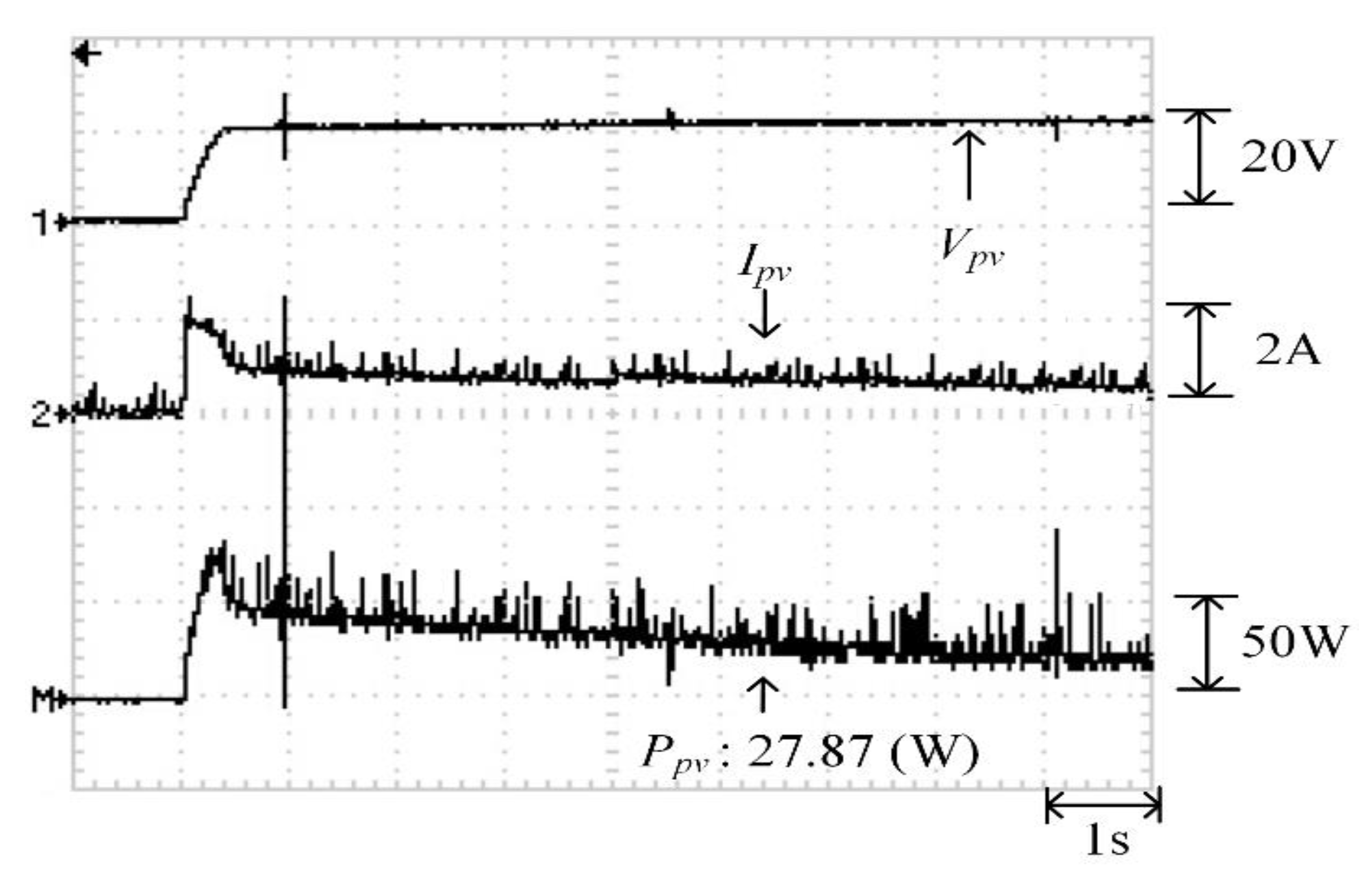

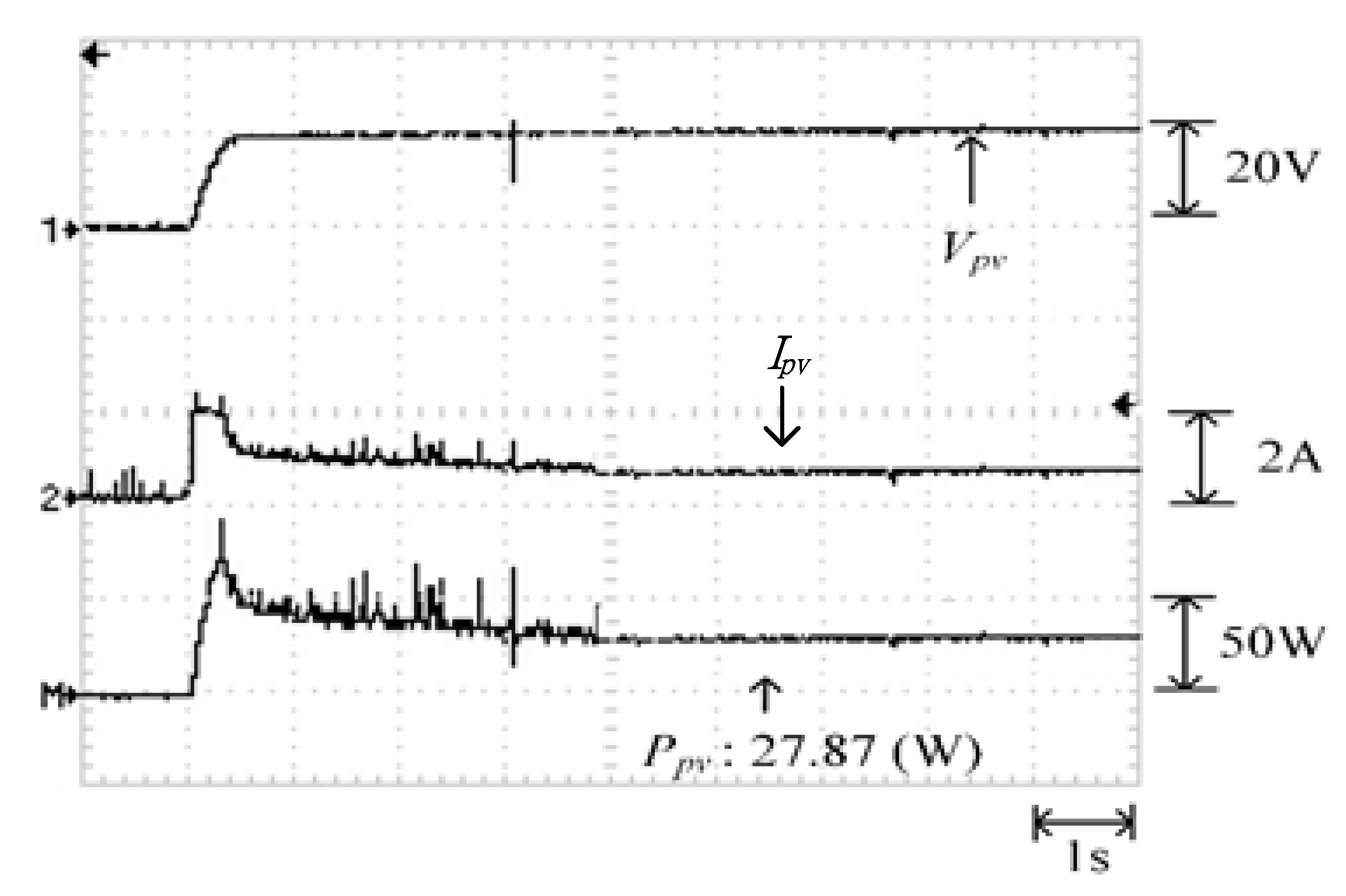

5.1. Case 1: One Series and One Parallel (No Shading)

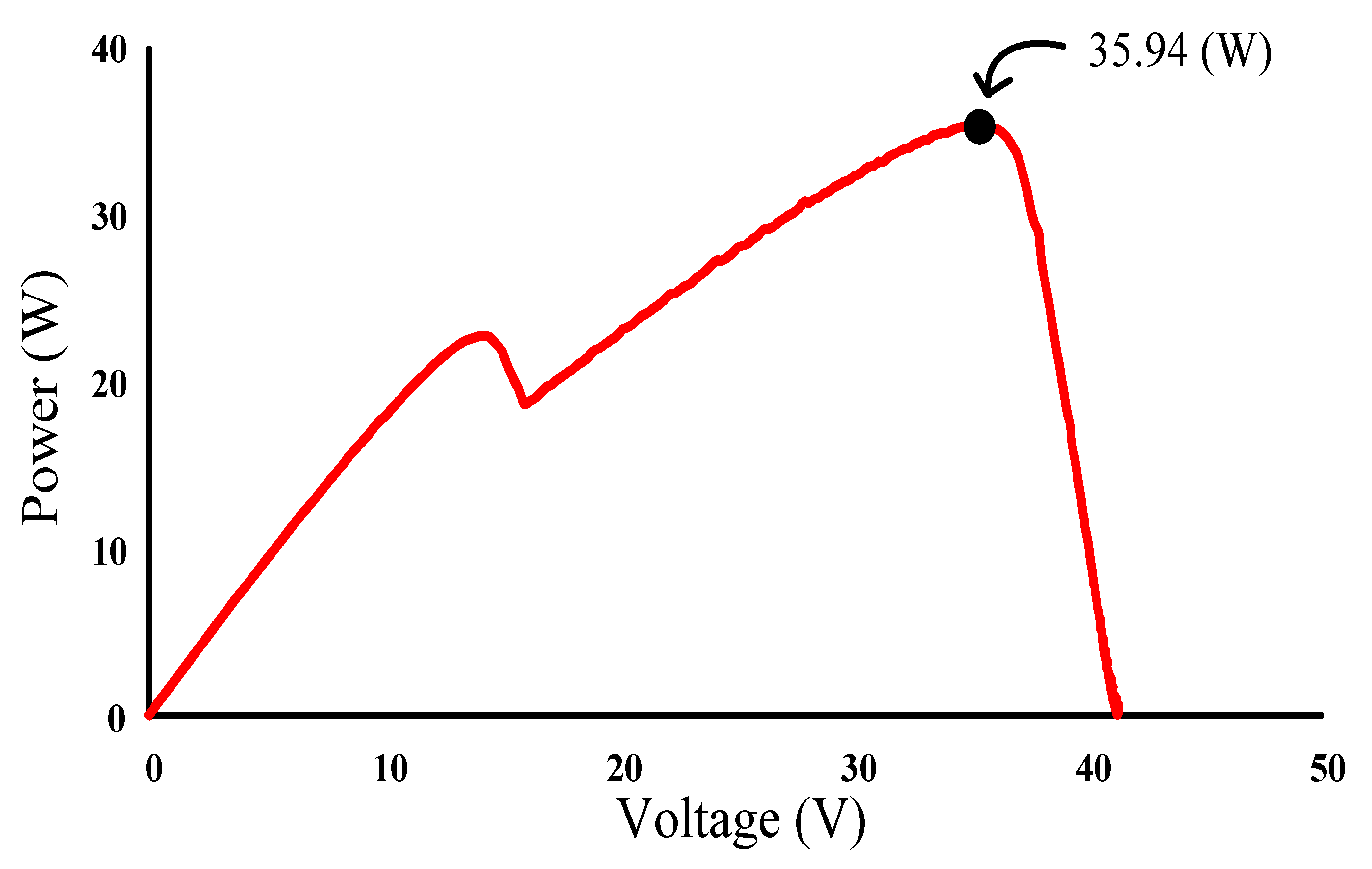

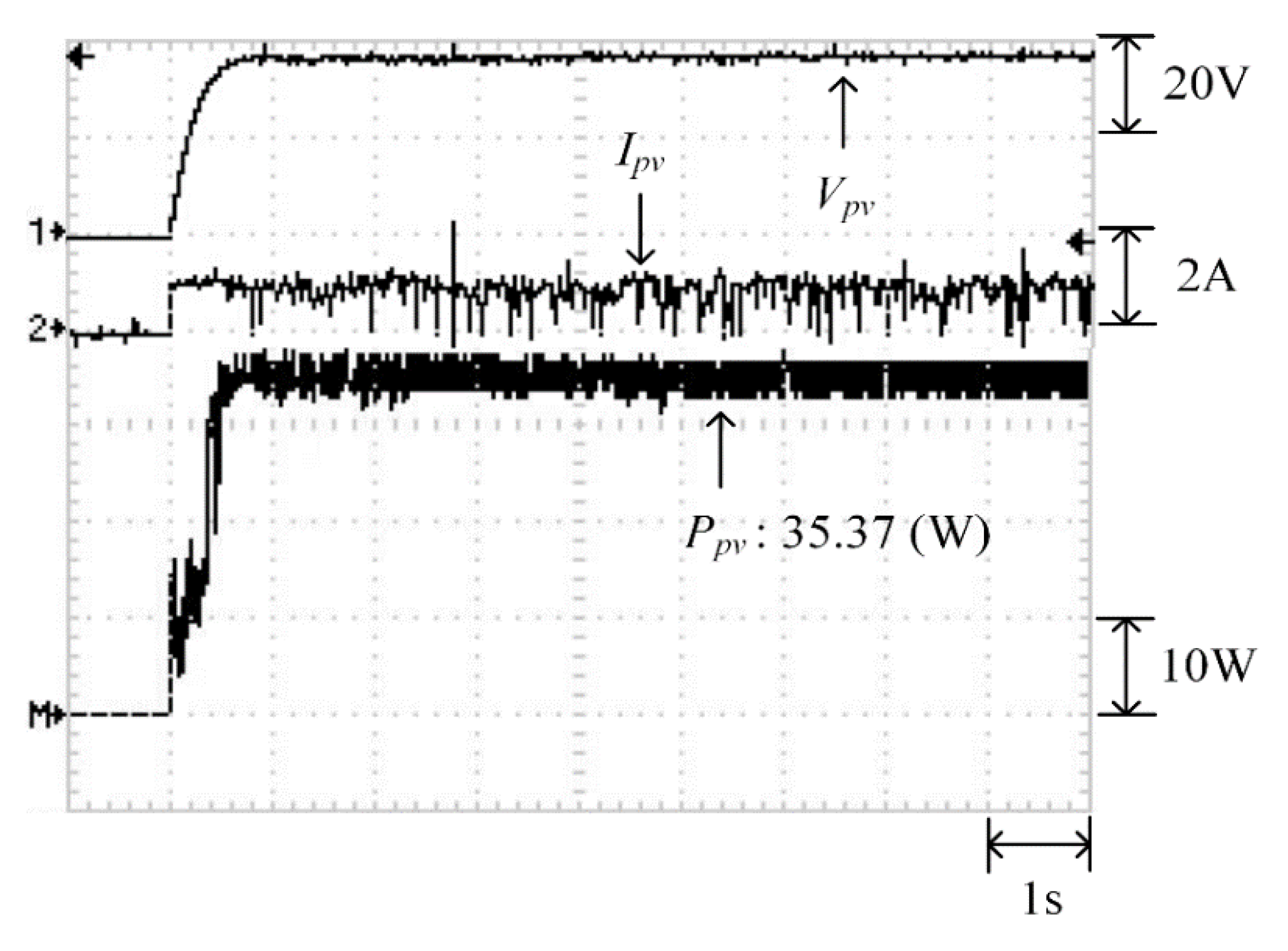

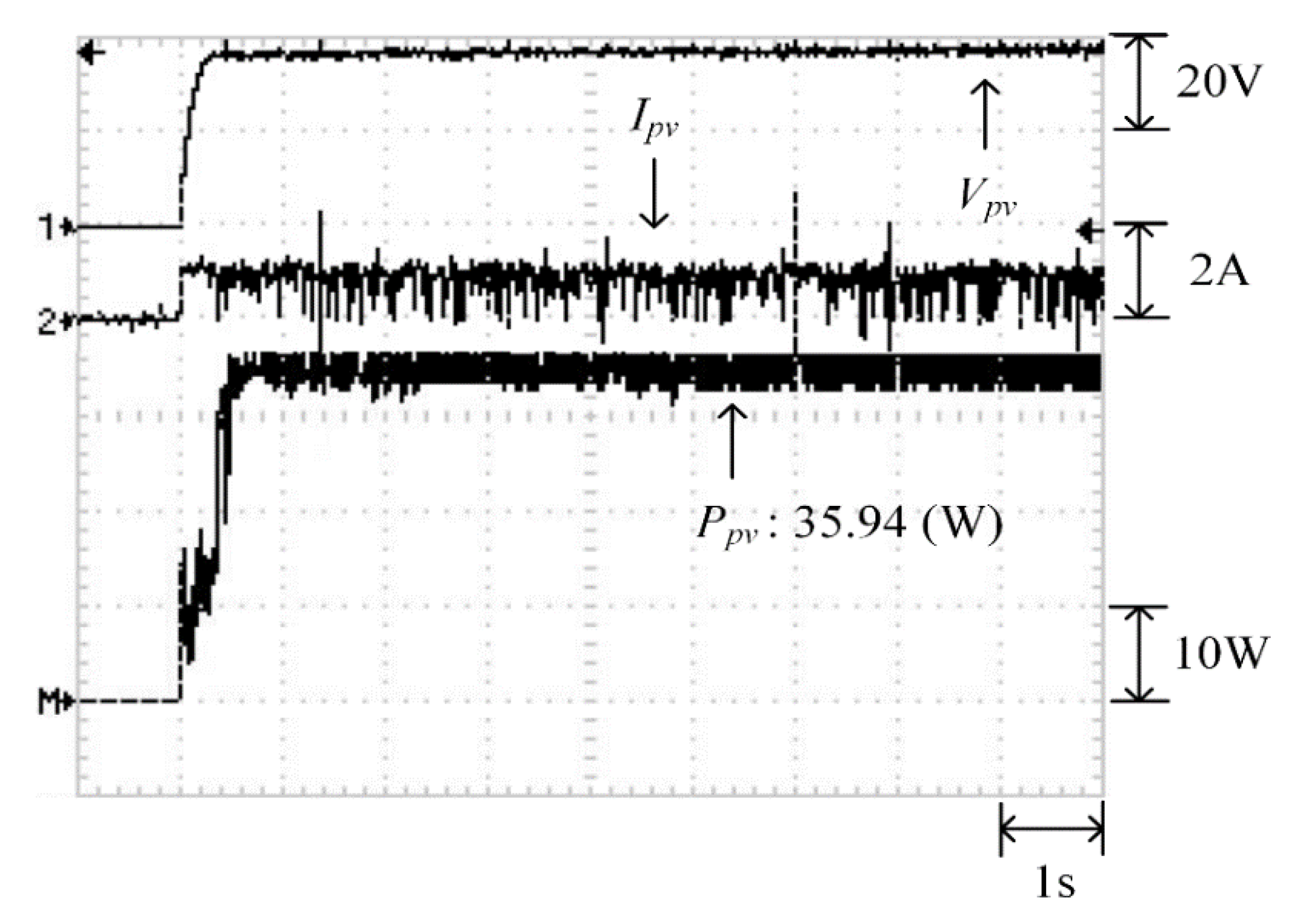

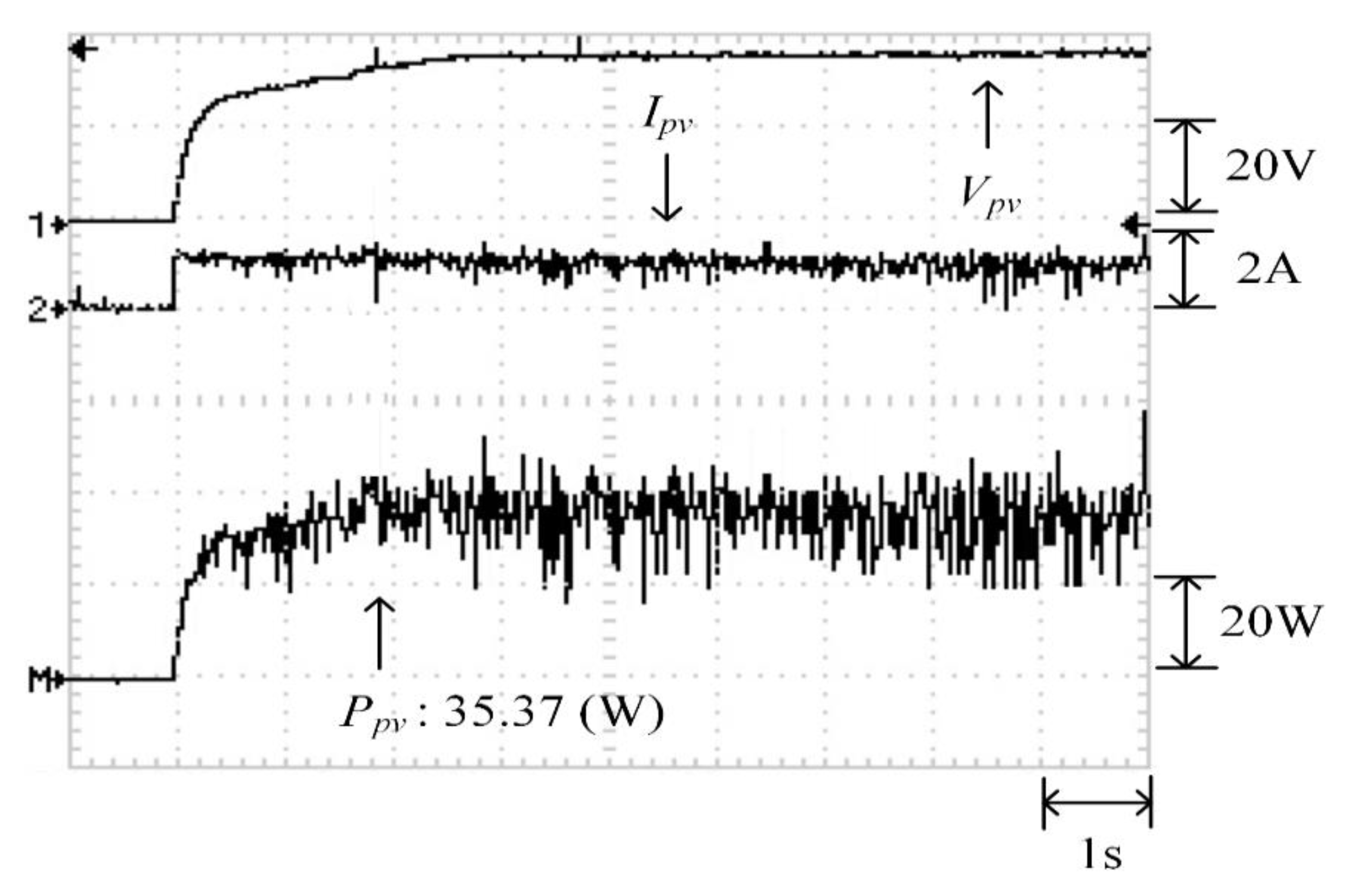

5.2. Case 2: Two Series and One Parallel (0% Shade + 40% Shade)

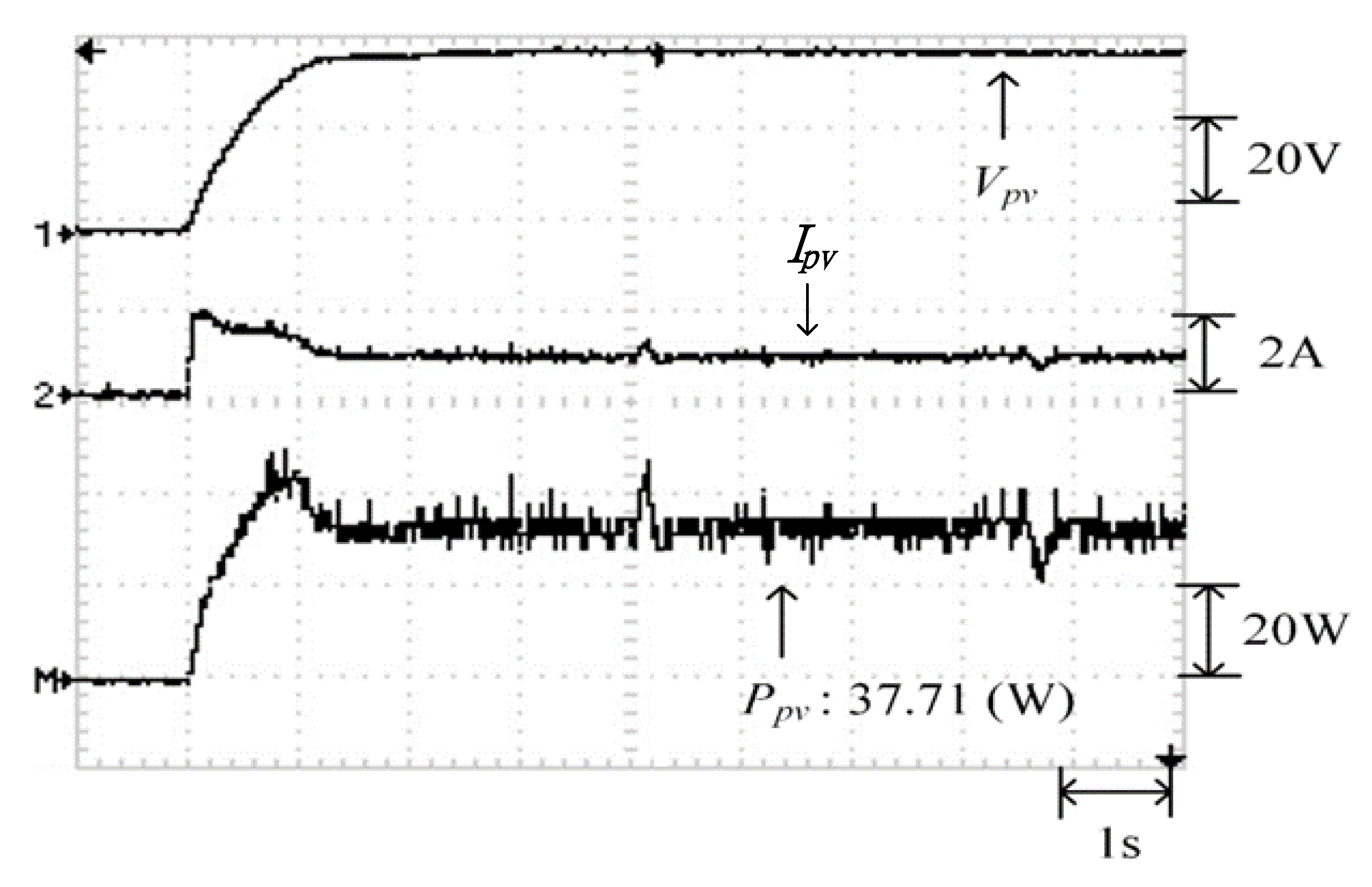

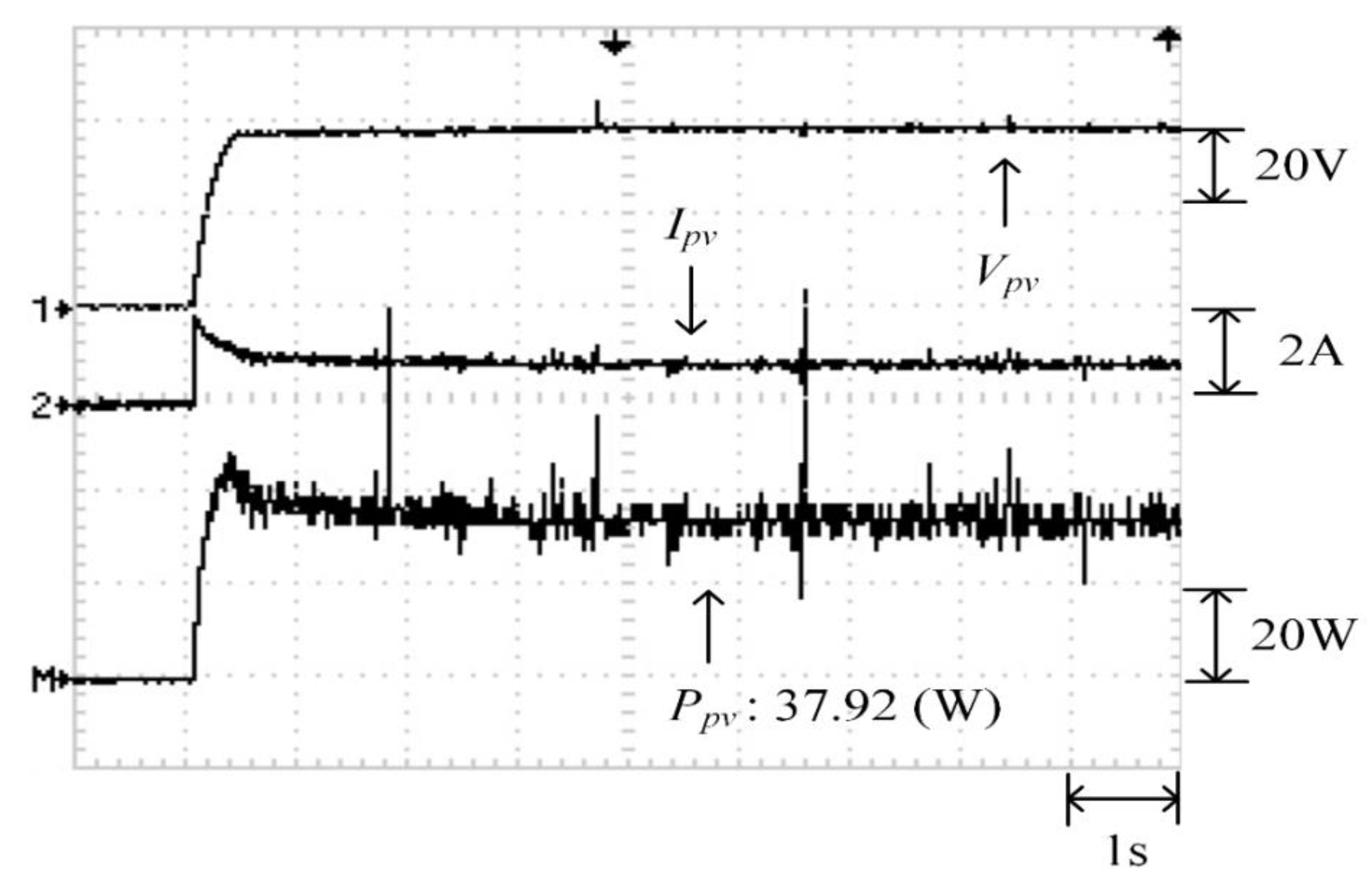

5.3. Case 3: Three Series and One Parallel (0% Shade + 30% Shade + 70% Shade)

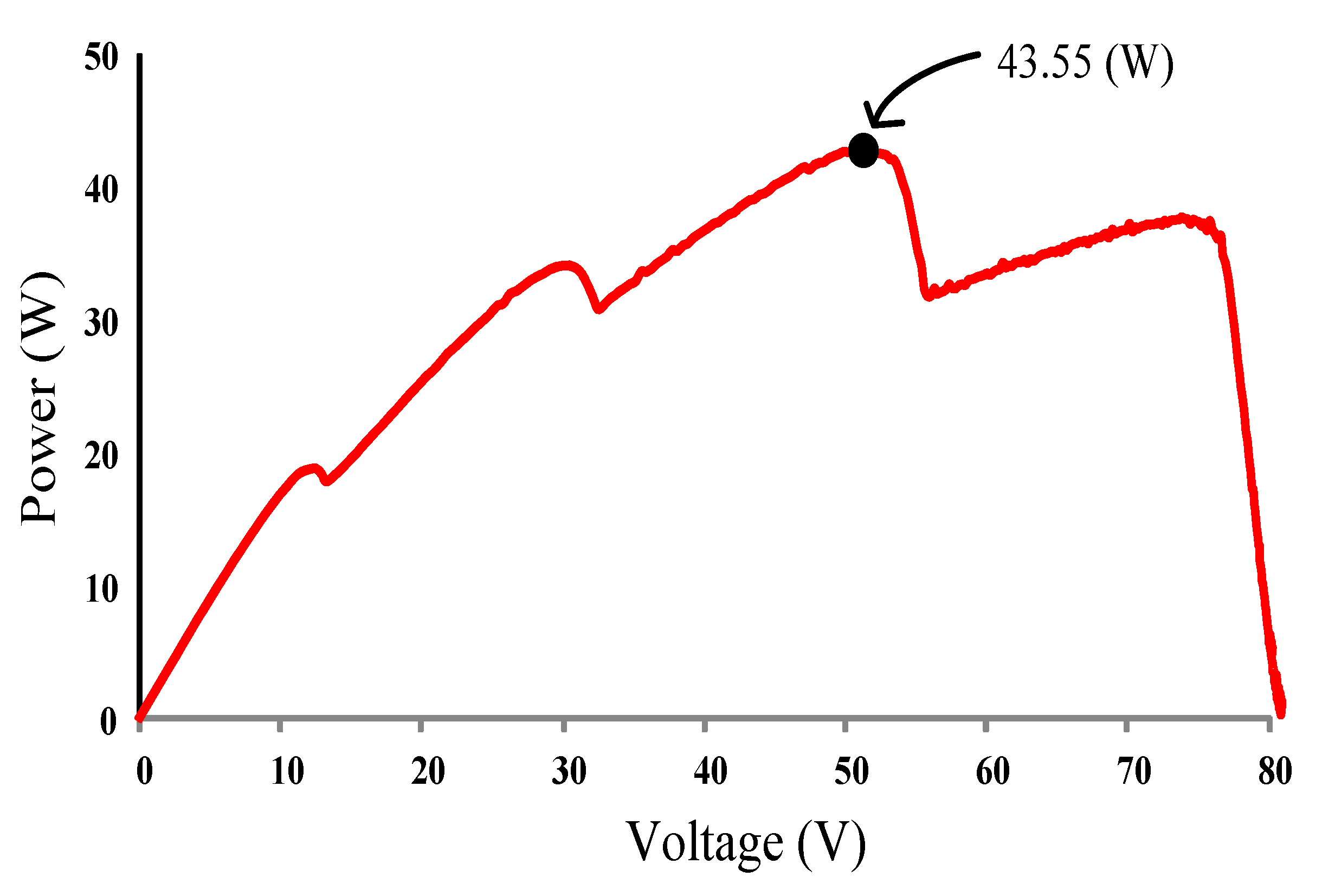

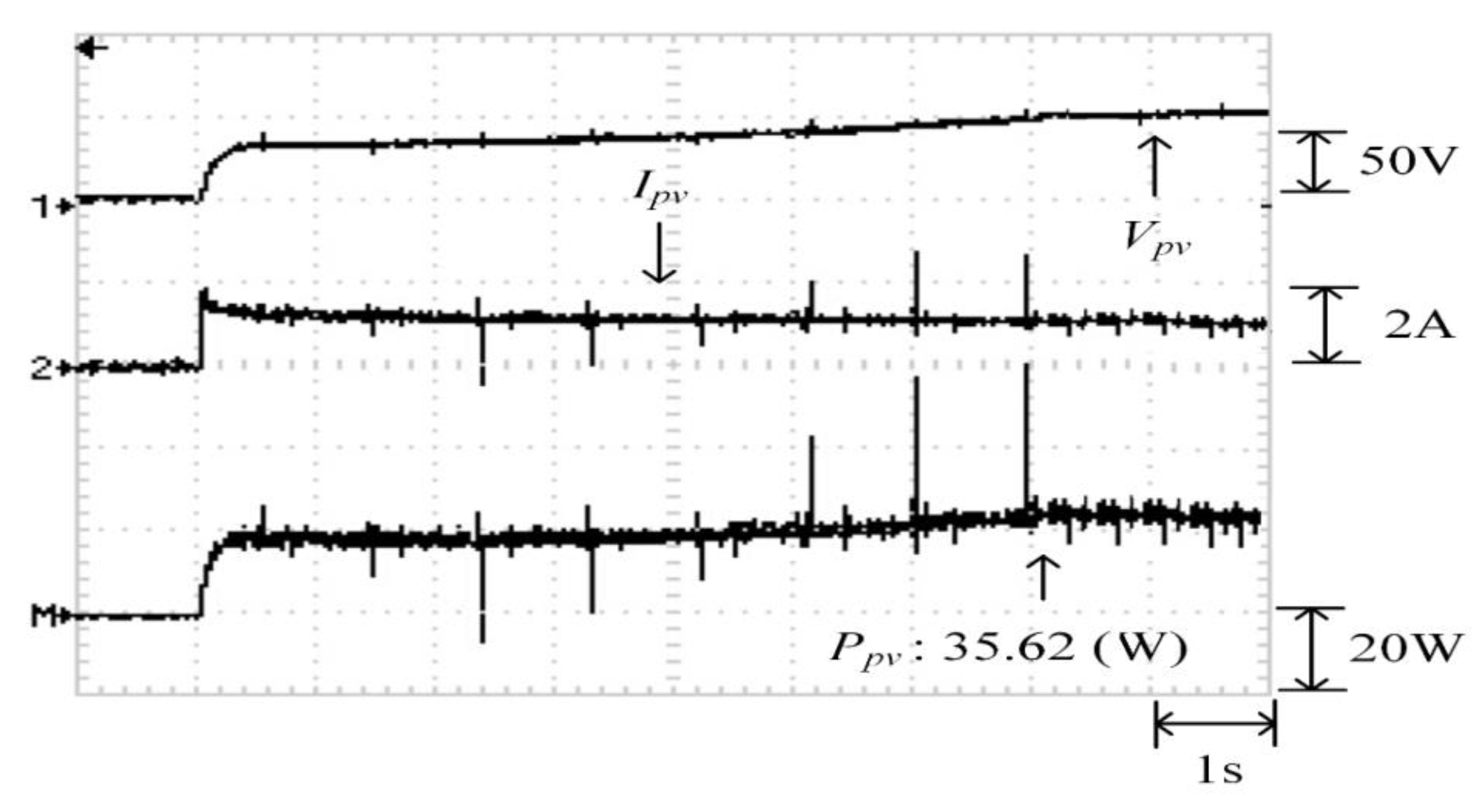

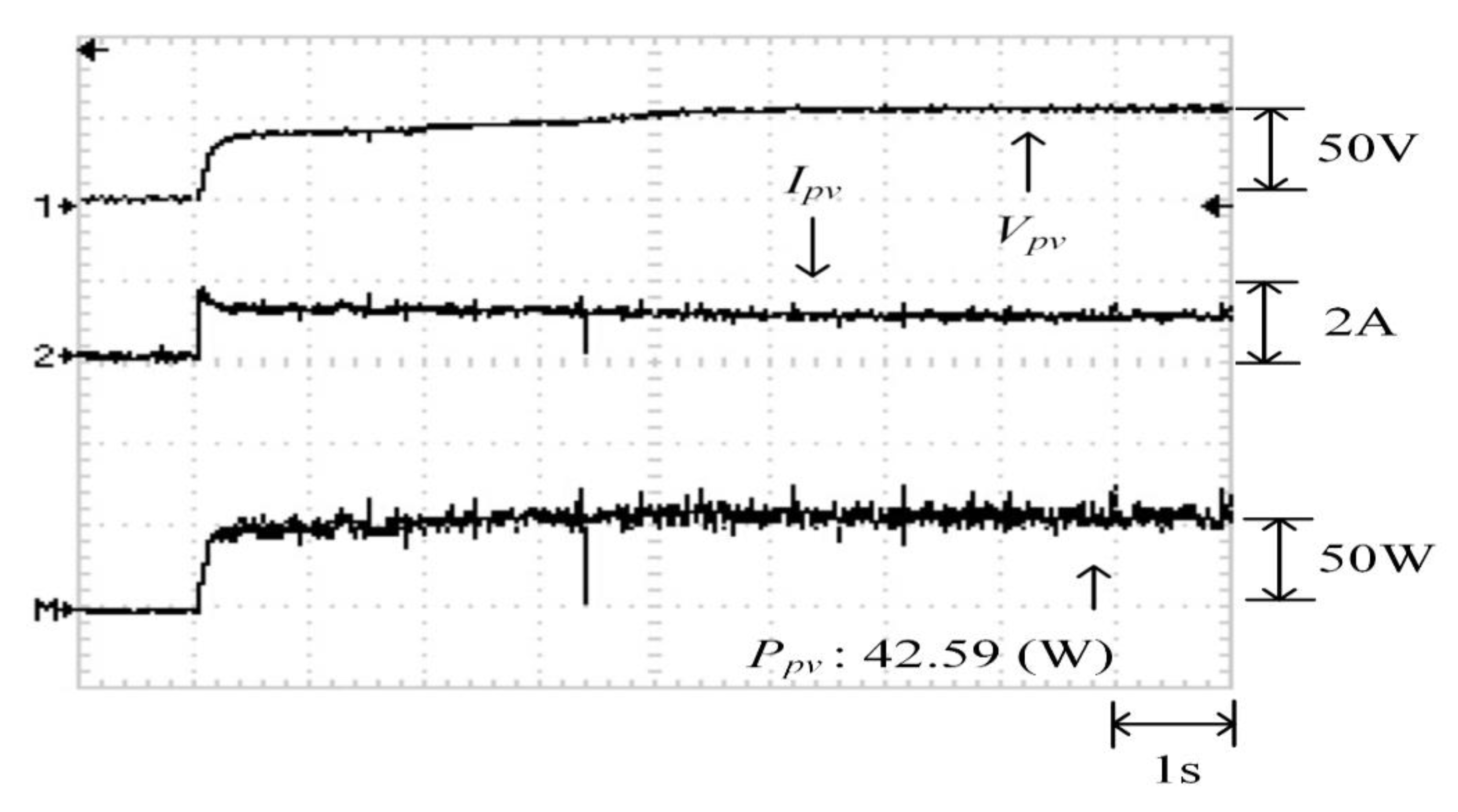

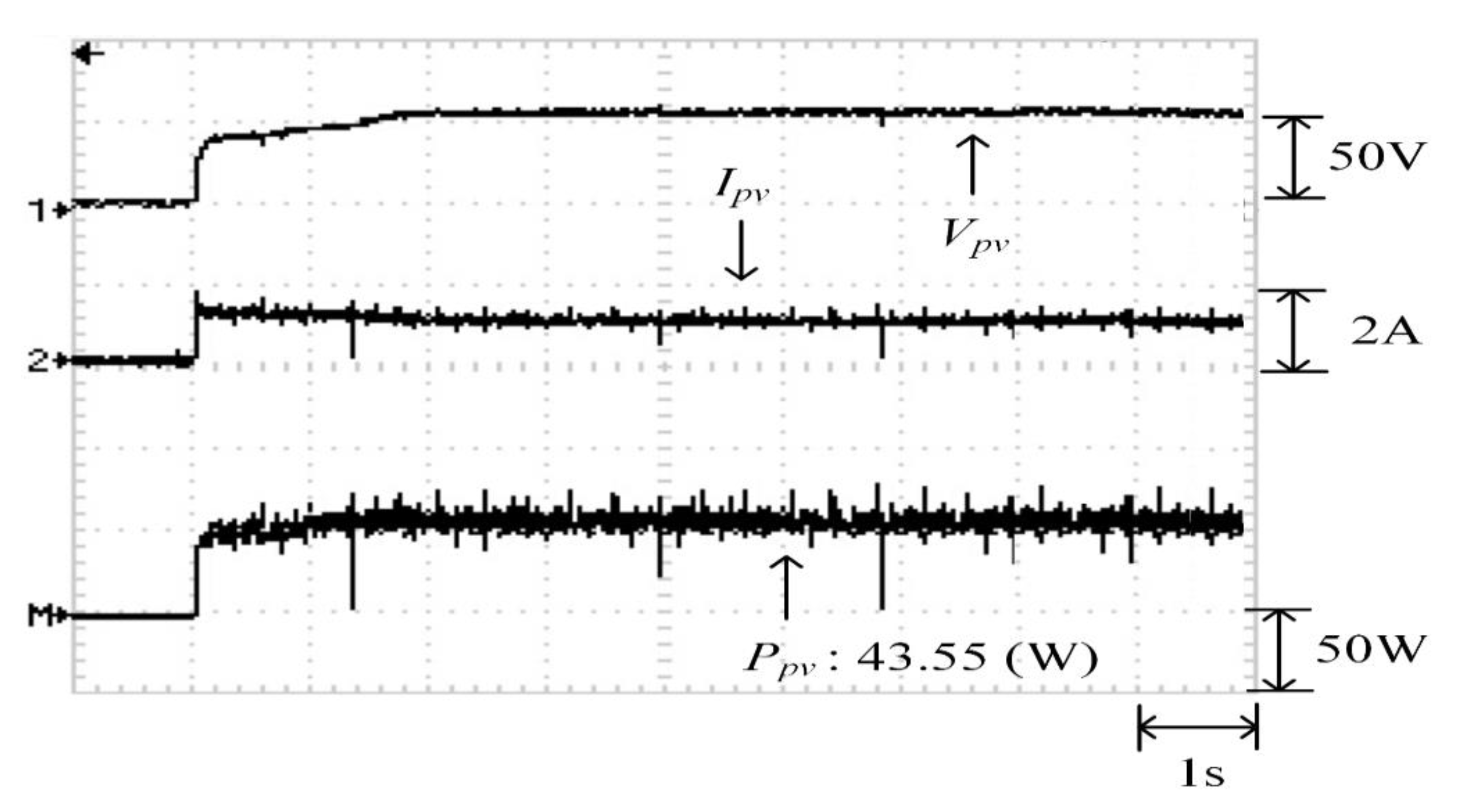

5.4. Case 4: Four Series and One Parallel (0% Shade + 30% Shade + 50% Shade + 70% Shade)

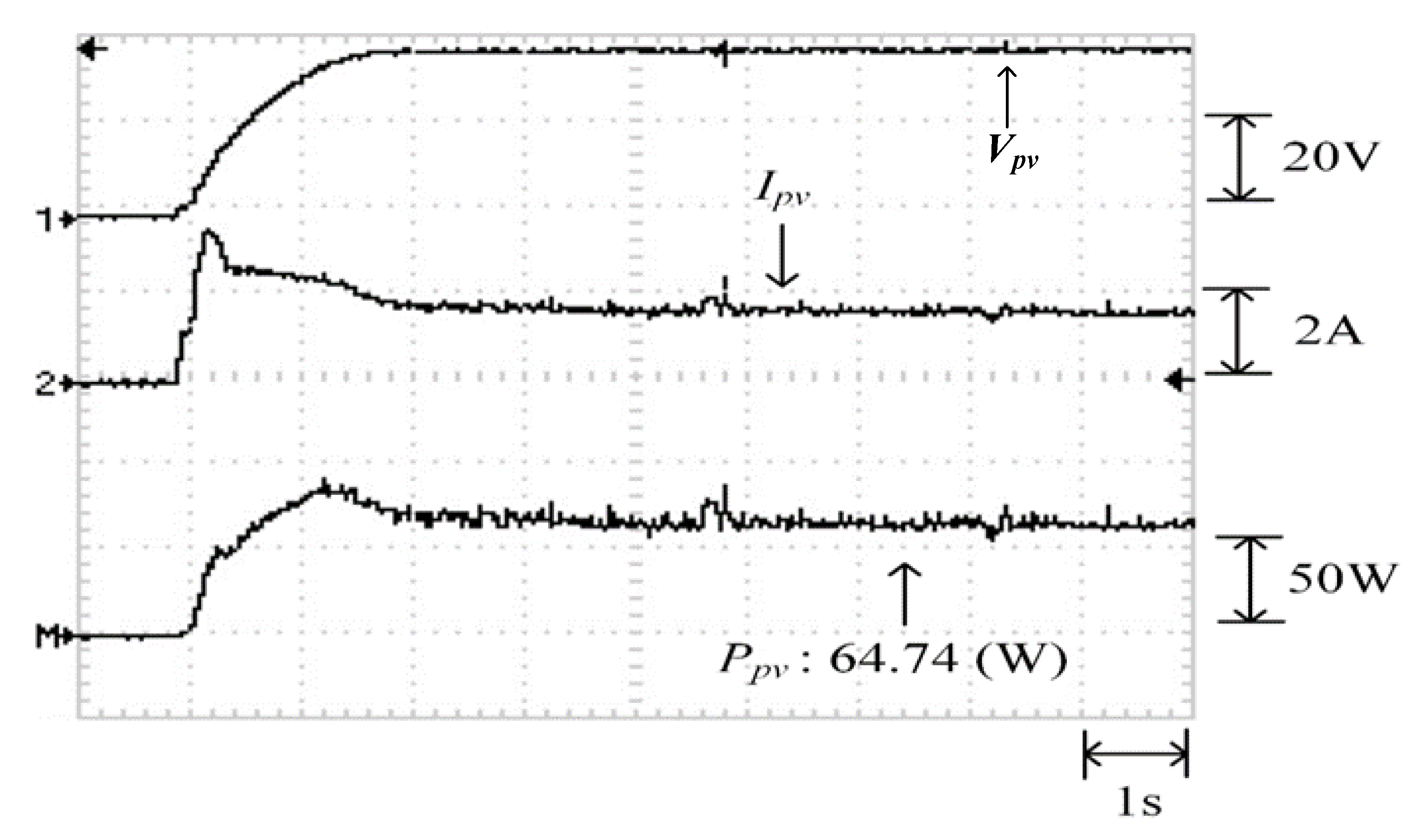

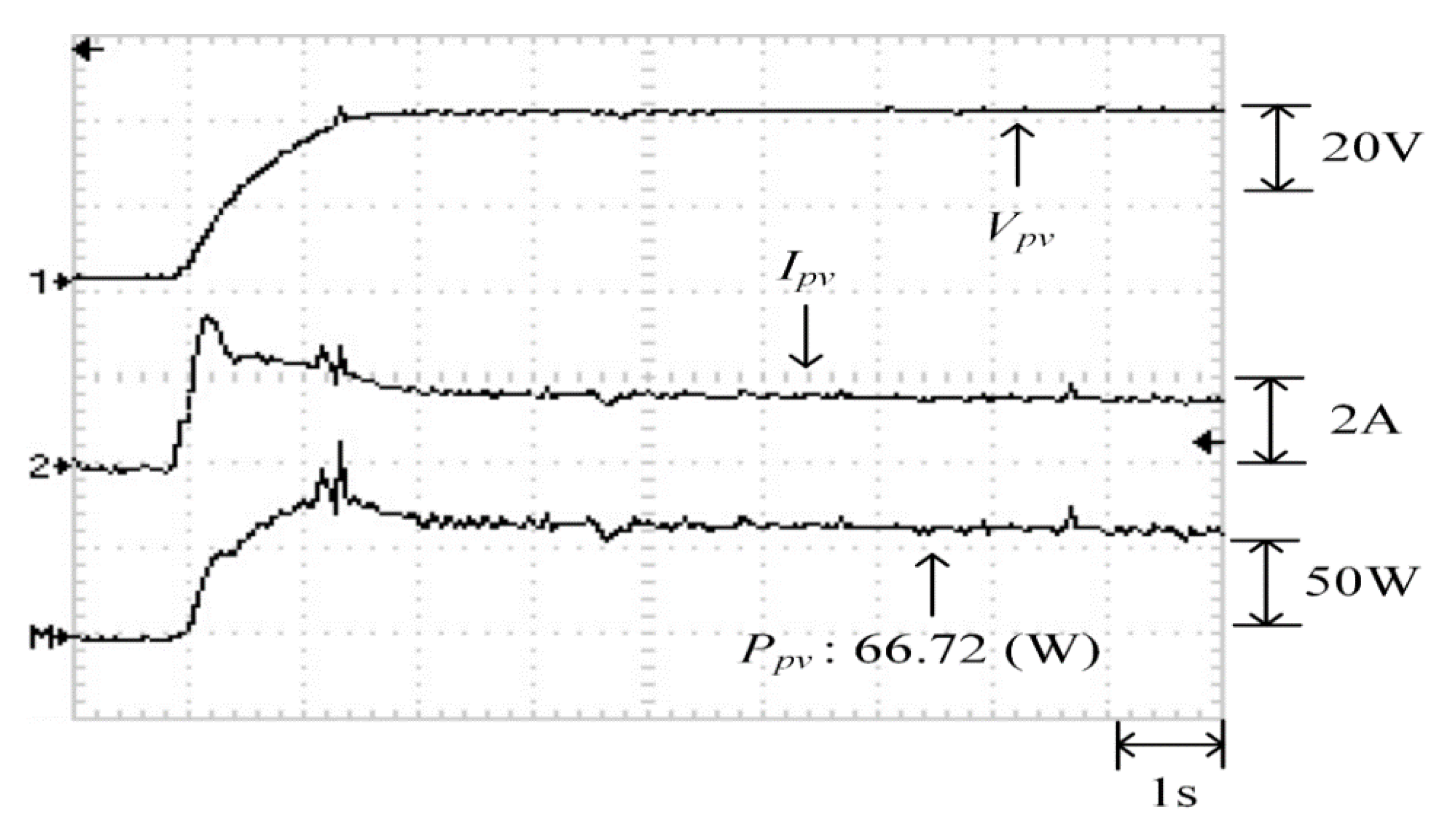

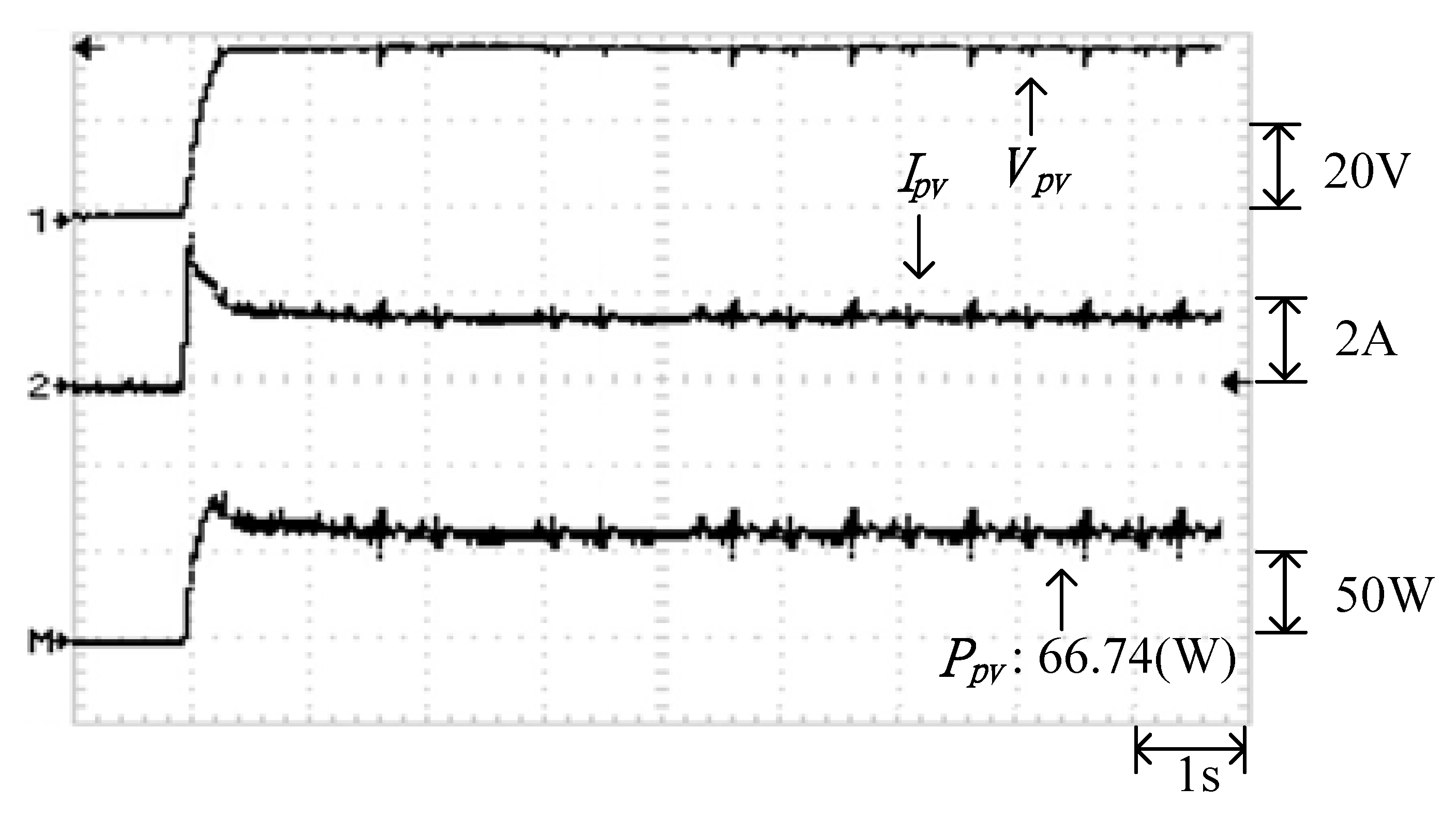

5.5. Case 5: Two Series and Two Parallels (30% Shade + 0% Shade)/(50% Shade + 0% Shade)

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Femia, N.; Granozio, D.; Petrone, G.; Spagnuolo, G.; Vitelli, M. Predictive and adaptive MPPT perturb and observe method. IEEE Trans. Aerosp. Electron. Syst. 2007, 43, 934–950. [Google Scholar] [CrossRef]

- Esram, T.T.; Chapman, P.L. Comparison of photovoltaic array maximum power point tracking techniques. IEEE Trans. Energy Convers. 2007, 22, 439–449. [Google Scholar] [CrossRef]

- Chao, L.; Sang, P.P.; Vijay, R.; Kaushik, R. Low-overhead maximum power point tracking for micro-scale solar energy harvesting systems. In Proceedings of the 25th International conference on VLSI design, Hyderabad, India, 25 August 2011; pp. 215–220. [Google Scholar]

- Bi, Z.; Ma, J.; Man, K.L.; Smith, J.S.; Yue, Y.; Wen, H. Global MPPT method for photovoltaic systems operating under partial shading conditions using the 0.8VOC model. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019; pp. 1–6. [Google Scholar]

- Elif, S.M.; Chao, L.; Vijay, R.; Kaushik, R. Modeling, design and cross-layer optimization of polysilicon solar cell based micro-scale energy harvesting systems. In Proceedings of the 2012 ACM/IEEE International Symposium on Low Power Electronics and Design, Redondo Beach, CA, USA, 30 July–1 August 2012; pp. 123–128. [Google Scholar]

- Rehan, A.; Bernhard, B.; Stefan, D.; Lukas, S.; Pratyush, K. Optimal power management with guaranteed minimum energy utilization for solar energy harvesting systems. ACM Trans. Embed. Comput. Syst. 2019, 18, 1–26. [Google Scholar]

- Patel, H.; Agarwal, V. MATLAB-based modeling to study the effectsof partial shading on PV array characteristics. IEEE Trans. Energy Convers. 2008, 23, 302–310. [Google Scholar] [CrossRef]

- Mirjalili, S.S.M.; Lewis, A. Grey wolf optimizer. Engine Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Dorigo, M.; Birattari, M.; Stutzle, T. Ant colony optimization. IEEE Comput. Intell. Mag. 2006, 1, 28–39. [Google Scholar] [CrossRef]

- Gao, W.; Liu, S.; Huang, L. A global best artificial bee colony algorithm for global optimization. J. Comput. Appl. Math. 2012, 236, 2741–2753. [Google Scholar] [CrossRef]

- Pragallapati, N.; Sen, T.; Agarwal, V. Adaptive velocity PSO for global maximum power control of a PV array under nonuniform irradiation conditions. IEEE J. Photovolt. 2017, 7, 624–639. [Google Scholar] [CrossRef]

- Sen, T.; Pragallapati, N.; Agarwal, V.; Kumar, R. Global maximum power point tracking of PV arrays under partial shading conditions using a modified particle velocity-based PSO technique. IET Renew. Power Gener. 2018, 12, 555–564. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching-learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput. Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Chao, K.H.; Wu, M.C. Global maximum power point tracking (MPPT) of a photovoltaic module array constructed through improved teaching-learning-based optimization. Energies 2016, 9, 986. [Google Scholar] [CrossRef]

- SANYO HIP 2717 Datasheet. Available online: http://iris.nyit.edu/~mbertome/solardecathlon/SDClerical/SD_DESIGN+DEVELOPMENT/091804_Sanyo190HITBrochure.pdf (accessed on 18 December 2019).

- Solar Pro Website. Available online: http://www.lapsys.co.jp/english/e_products/e_pamphlet/sp_e.pdf (accessed on 18 December 2019).

- Rao, R.V.; Patel, V. An elitist teaching-learning-based optimization algorithm for solving complex constrained optimization problems. Int. J. Ind. Eng. Comput. 2012, 3, 535–560. [Google Scholar] [CrossRef]

- Hart, D.W. Introduction to Power Electronics; Prentice Hall: New York, NY, USA, 2003. [Google Scholar]

- MP-170 Brochure. Available online: http://www.environmental-expert.com/products/model-mp-170-iv-checker-80092 (accessed on 21 August 2020).

- Chao, K.H.; Chao, Y.W.; Chen, J.P. A circuit-based photovoltaic module simulator with shadow and fault setting. Int. J. Electron. 2016, 103, 424–438. [Google Scholar] [CrossRef]

| Electrical Parameters | Specifications |

|---|---|

| Rated maximum output power (Pmp) | 27.8 W |

| Maximum power point current (Imp) | 1.63 A |

| Maximum power point voltage (Vmp) | 17.1 V |

| Short-circuit current (Isc) | 1.82 A |

| Open-circuit voltage (Voc) | 21.6 V |

| Module length and width specifications | 496 mm × 524 mm |

| Item | Specifications |

|---|---|

| Storage induction (L) | 1.5 mH, withstand current of 10A |

| Filter capacity (Cin) | 470 uF, withstand voltage of 450 V |

| Filter capacity (Cout) | 470 uF, withstand voltage of 450 V |

| Fast diode (D) IQBD30E60A1 | Withstand voltage VRRM = 600 V, withstand current IFAV = 30 A |

| Power semiconductor IXGH48N60C3D1 | Withstand voltage VDSS = 600 V, withstand current ID = 30 A |

| Parameter Name | Set Parameter Values |

|---|---|

| Number of learners (NP) | 4 |

| Number of iterations (E) | 40 |

| Teaching step (ri) | Randomly selected between 0 and 1 |

| Teaching factor (TF) | 1 or 2 |

| Parameter Name | Set Parameter Values |

|---|---|

| Teaching factor (TF) |

| Case | Connection Patterns and Shade Conditions | Number of Peak(s) in the P–V Curve |

|---|---|---|

| 1 | One series and one parallel: 0% shade | 1 |

| 2 | Two series and one parallel: 0% shade + 40% shade | 2 |

| 3 | Three series and one parallel: 0% shade + 30% shade + 70% shade | 3 |

| 4 | Three series and one parallel: 0% shade + 30% shade + 50% shade + 70% shade | 4 |

| 5 | Three series and two parallels: (30% shade + 0% shade)/(0% shade + 50% shade) | 2 |

| Case | Number of Peak(s) of the P–V Curve | Model Proposed in Reference [4] | Conventional TLBO | TLBO Proposed in Reference [14] | TLBO Proposed in This Study | ||||

|---|---|---|---|---|---|---|---|---|---|

| Average Tracking Time | Average Maximum Power | Average Tracking Time | Average Maximum Power | Average Tracking Time | Average Maximum Power | Average Tracking Time | Average Maximum Power | ||

| 1 | 1 | 0.9 s | 27.87 W | 0.8 s | 27.87 W | 0.4 s | 27.87 W | 0.2 s | 27.87 W |

| 2 | 2 | 1.2 s | 35.25 W | 1.0 s | 35.22 W | 0.6 s | 35.37 W | 0.3 s | 35.94 W |

| 3 | 3 | 1.91 s | 35.47 W | 1.89 s | 35.37 W | 1.1 s | 37.71 W | 0.45 s | 37.92 W |

| 4 | 4 | Tracking failed | 35.71 W | Tracking failed | 35.73 W | 3.5 s | 42.59 W | 1.2 s | 43.55 W |

| 5 | 2 | 1.31 s | 64.58 W | 1.22 s | 64.68 W | 0.67 s | 66.74 W | 0.4 s | 66.74 W |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, K.-H.; Lai, Y.-J. An Intelligent Automatic Adaptive Maximum Power Point Tracker for Photovoltaic Module Arrays. Energies 2020, 13, 4775. https://doi.org/10.3390/en13184775

Chao K-H, Lai Y-J. An Intelligent Automatic Adaptive Maximum Power Point Tracker for Photovoltaic Module Arrays. Energies. 2020; 13(18):4775. https://doi.org/10.3390/en13184775

Chicago/Turabian StyleChao, Kuei-Hsiang, and Yu-Ju Lai. 2020. "An Intelligent Automatic Adaptive Maximum Power Point Tracker for Photovoltaic Module Arrays" Energies 13, no. 18: 4775. https://doi.org/10.3390/en13184775

APA StyleChao, K.-H., & Lai, Y.-J. (2020). An Intelligent Automatic Adaptive Maximum Power Point Tracker for Photovoltaic Module Arrays. Energies, 13(18), 4775. https://doi.org/10.3390/en13184775