The Concept, Technical System and Heat Transfer Analysis on Phase-Change Heat Storage Backfill for Exploitation of Geothermal Energy

Abstract

1. Introduction

- ❖

- It is unnecessary for drilling engineering to occur on the earth’s surface, as it can save the cost of geothermal energy exploitation.

- ❖

- Deep space has a considerable scale. High temperature rocks provide a continuous heat source for geothermal energy exploitation.

- ❖

- Deep mining has complete elevation and transportation, as well as complete electric power, water supply, and drainage system, which provides pipeline layout safeguard and power supply for geothermal energy exploitation.

- ❖

- After mining is completed, the abandoned mine can be used as a geothermal energy plant.

2. The Concept of Phase-Change Heat Storage Backfill

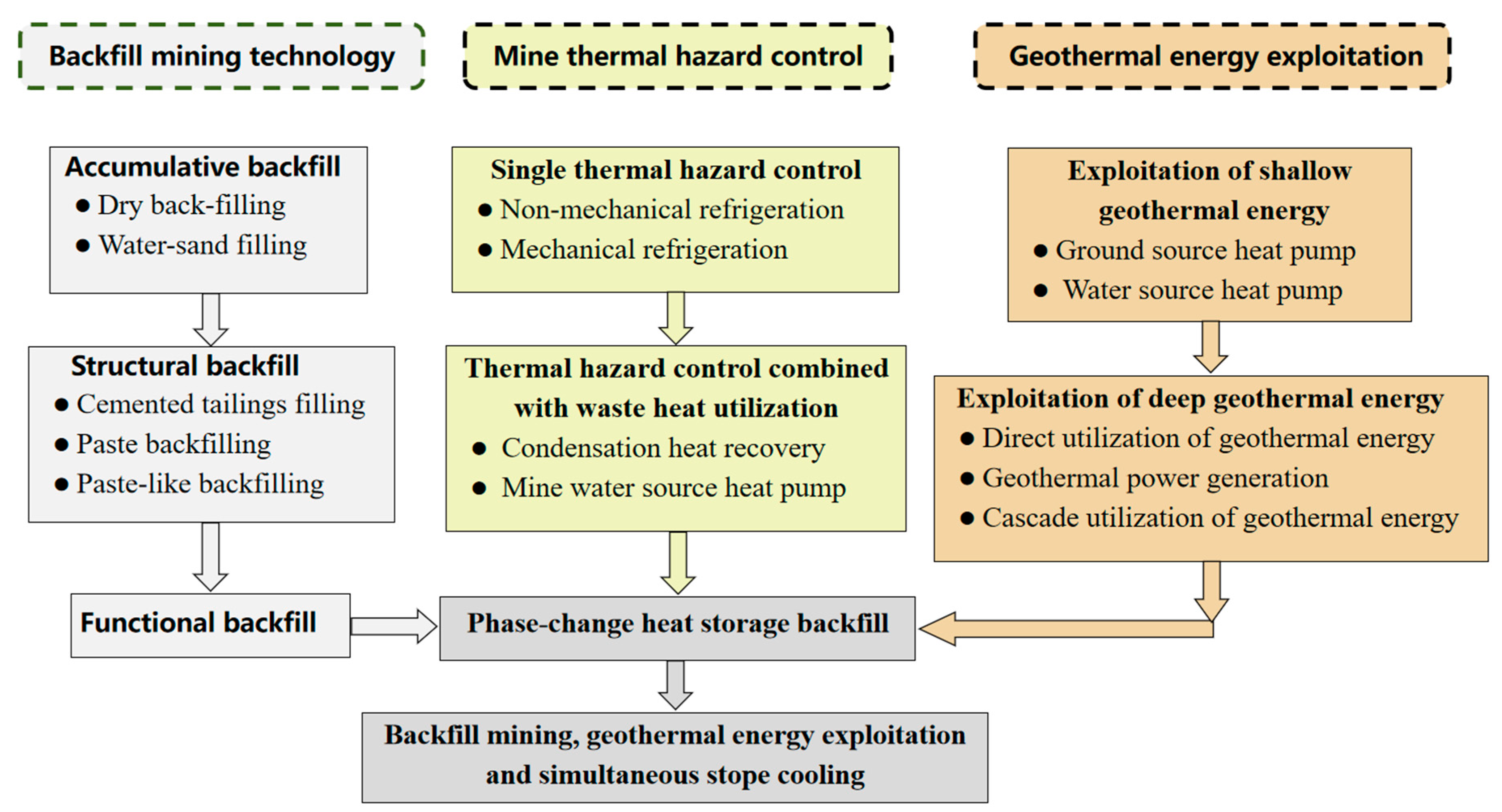

2.1. The Control of Thermal Hazard Development from Single Treatment to Combined with Geothermal Energy Exploitation

2.2. The Extension and Integration from Deep Mineral Mining to Deep Geothermal Energy Exploitation

2.3. The Connotation of Phase-Change Heat Storage Backfill

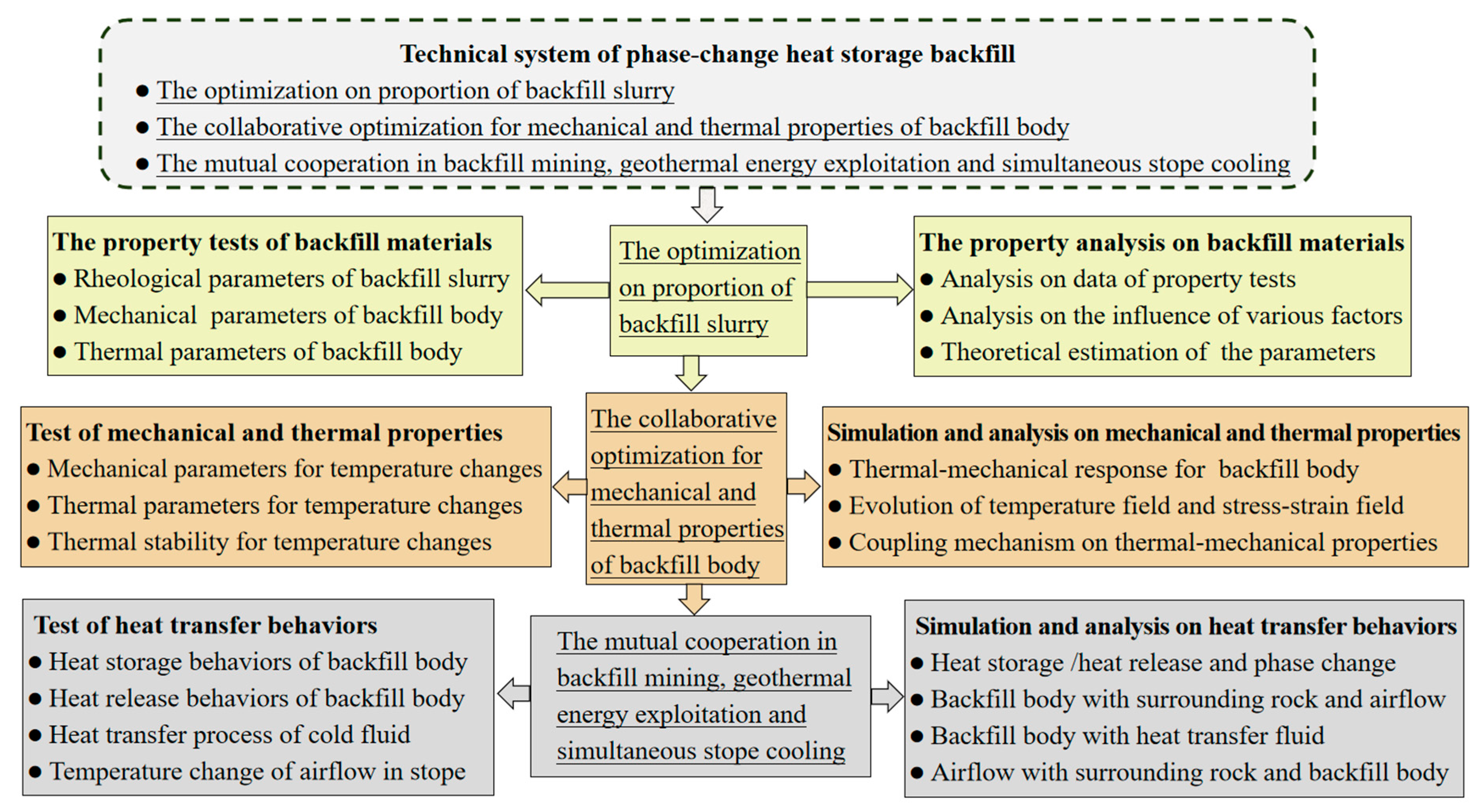

3. The Technical System of Phase-Change Heat Storage Backfill

3.1. The Construction of Technical System

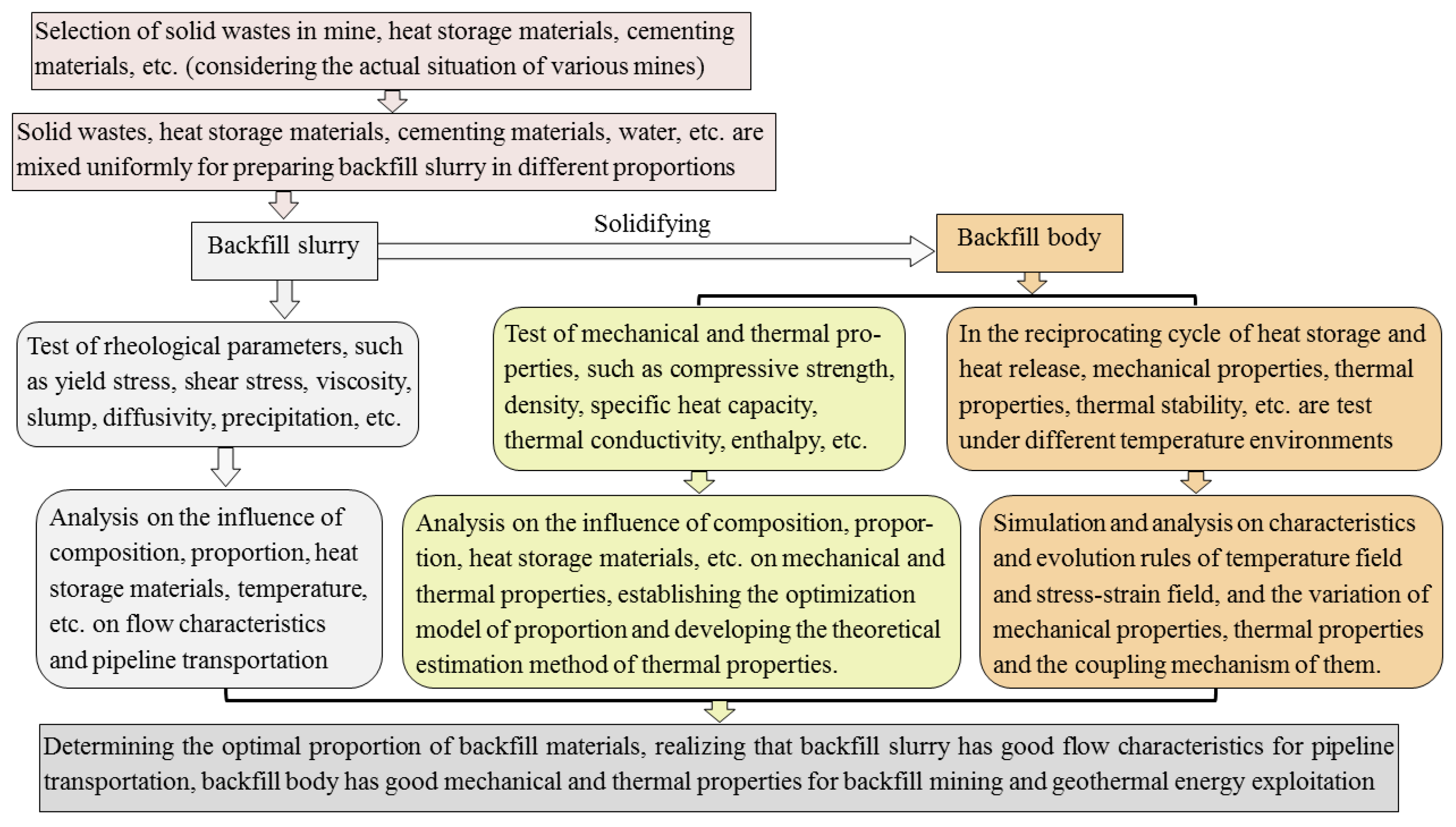

3.2. The Optimized Proportion of Backfill Slurry

3.3. The Collaborative Optimization on Mechanical and Thermal Properties of the Backfill Body

3.4. The Mutual Cooperation on Backfill Mining, Geothermal Energy Exploitation, and Simultaneous Stope Cooling

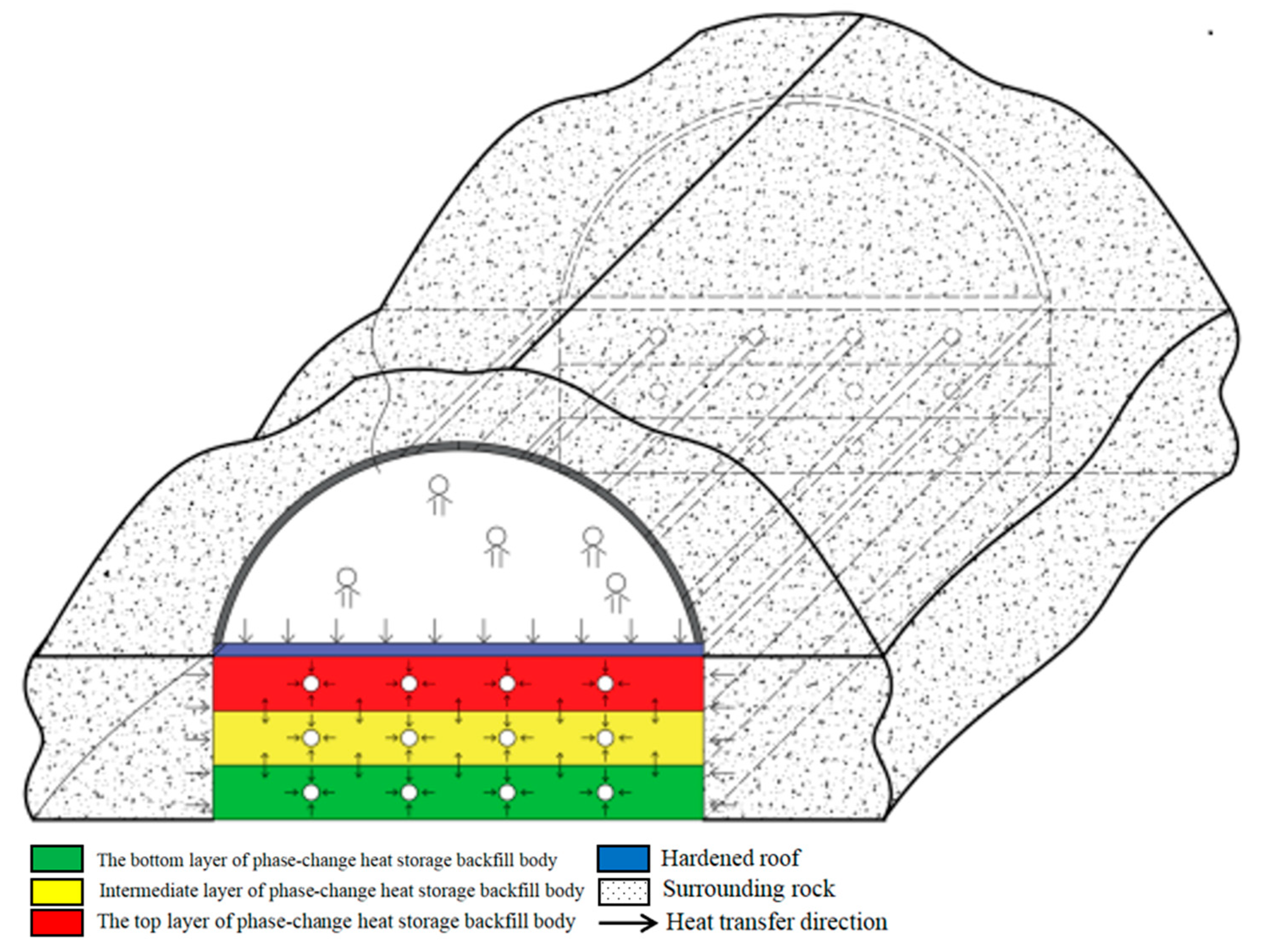

4. The Heat Transfer Analysis of a Phase-Change Heat Storage Backfill

4.1. The Heat Storage/Heat Release Model of the Backfill Body

- ❖

- The backfill body is a homogeneous and isotropic solid, and the thermophysical parameters remain constant.

- ❖

- The backfill body is a porous medium with constant porosity, and all phases are in local thermodynamic equilibrium.

- ❖

- During the heat storage process, the influences of the heat transfer tube and cold fluid are ignored.

- ❖

- During the heat release process, there is no heat transfer in the backfill body to surrounding rocks and airflow.

- ❖

- During the heat release process, the heat transfer along the axial direction of the heat transfer tube is ignored, and the heat transfer of the backfill body is a two-dimensional unsteady heat conduction.

- ❖

- The contact thermal resistance between the backfill body and heat transfer tube is ignored.

- ❖

- In a given temperature range, PCM only undergoes a solid-liquid phase-change, without super-cooling and performance degradation.

- ❖

- We did not consider the natural convection heat transfer of liquid PCM.

4.1.1. The Mathematical Model of the Backfill Body during the Heat Storage Process

- the initial condition:

- the boundary condition of surrounding rocks:

- the boundary condition of stope:

4.1.2. The Mathematical Model of the Backfill Body during the Heat Release Process

- the initial condition:

- the boundary condition:

- (1)

- the boundary condition of the cold fluid’s acting region:

- (2)

- the boundary condition of the contact surface for the outer wall of the heat transfer tube and backfill body: ,

- (3)

- the boundary condition of the cold fluid inlet:

- (4)

- the boundary condition of the contact surface for the heat transfer tube’s inner wall and cold fluid:

4.2. The Phase-Change Heat Transfer Model for the Backfill Body

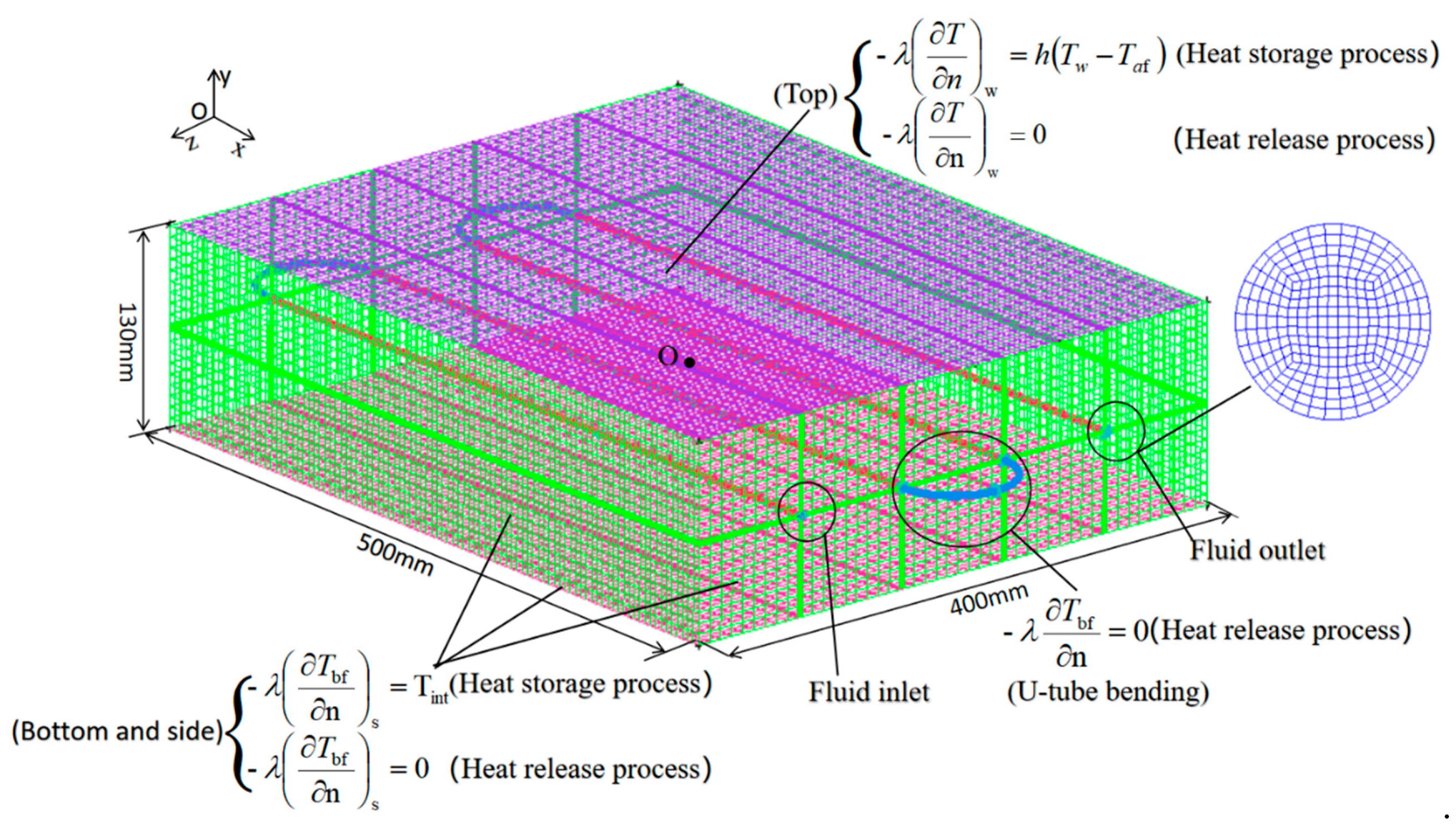

4.3. The Numerical Simulation on Heat Storage/Release Process for the Backfill Body

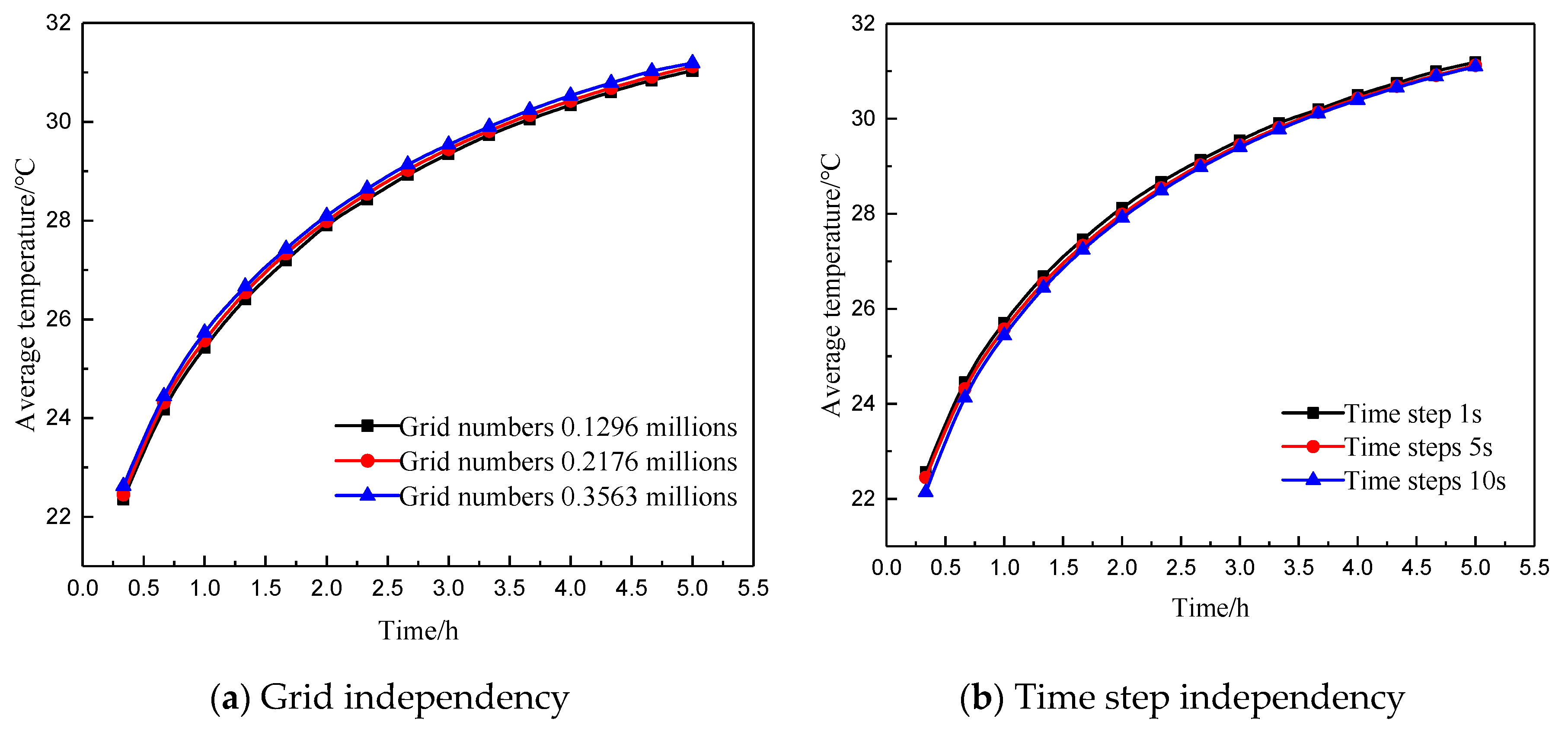

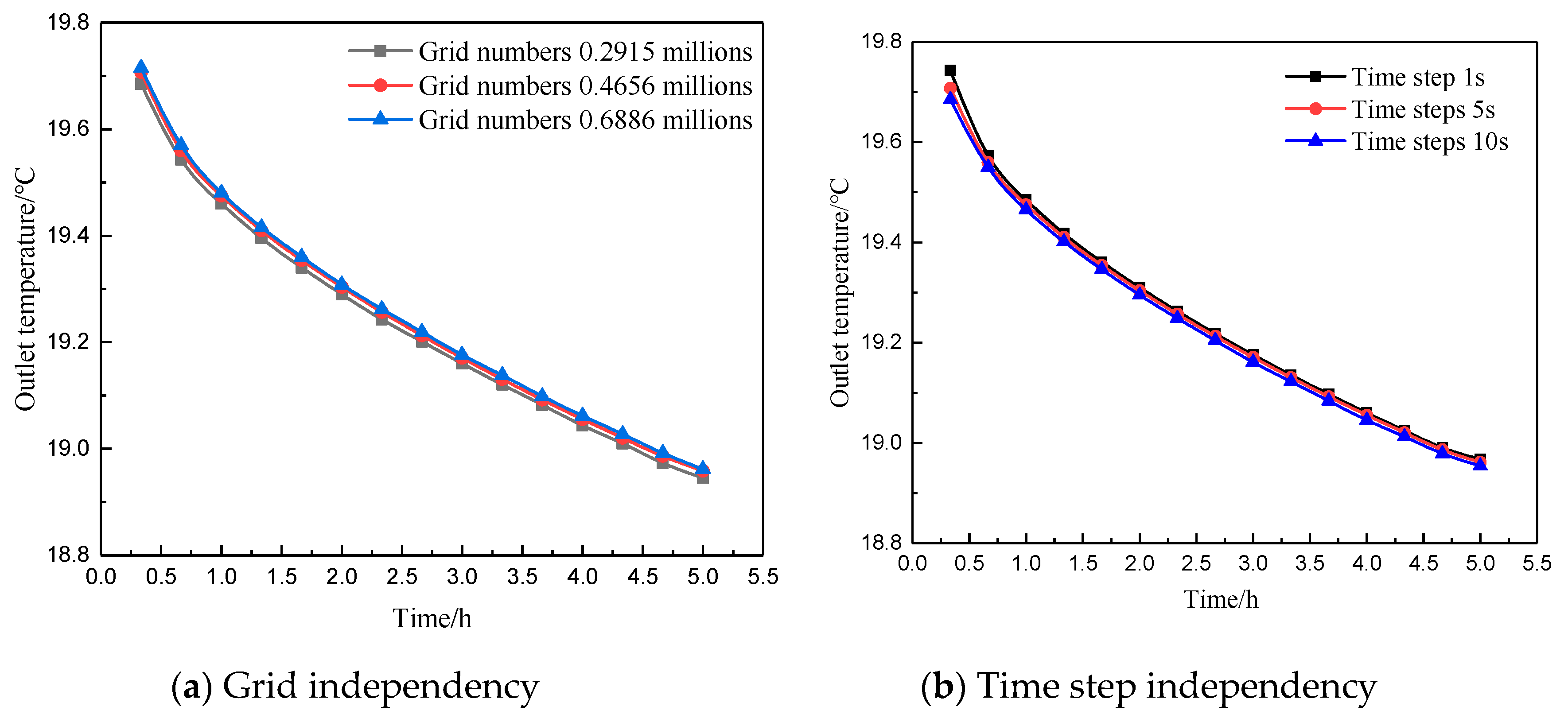

4.3.1. Grid Generation and Independence Verification

4.3.2. Setting Simulation Conditions

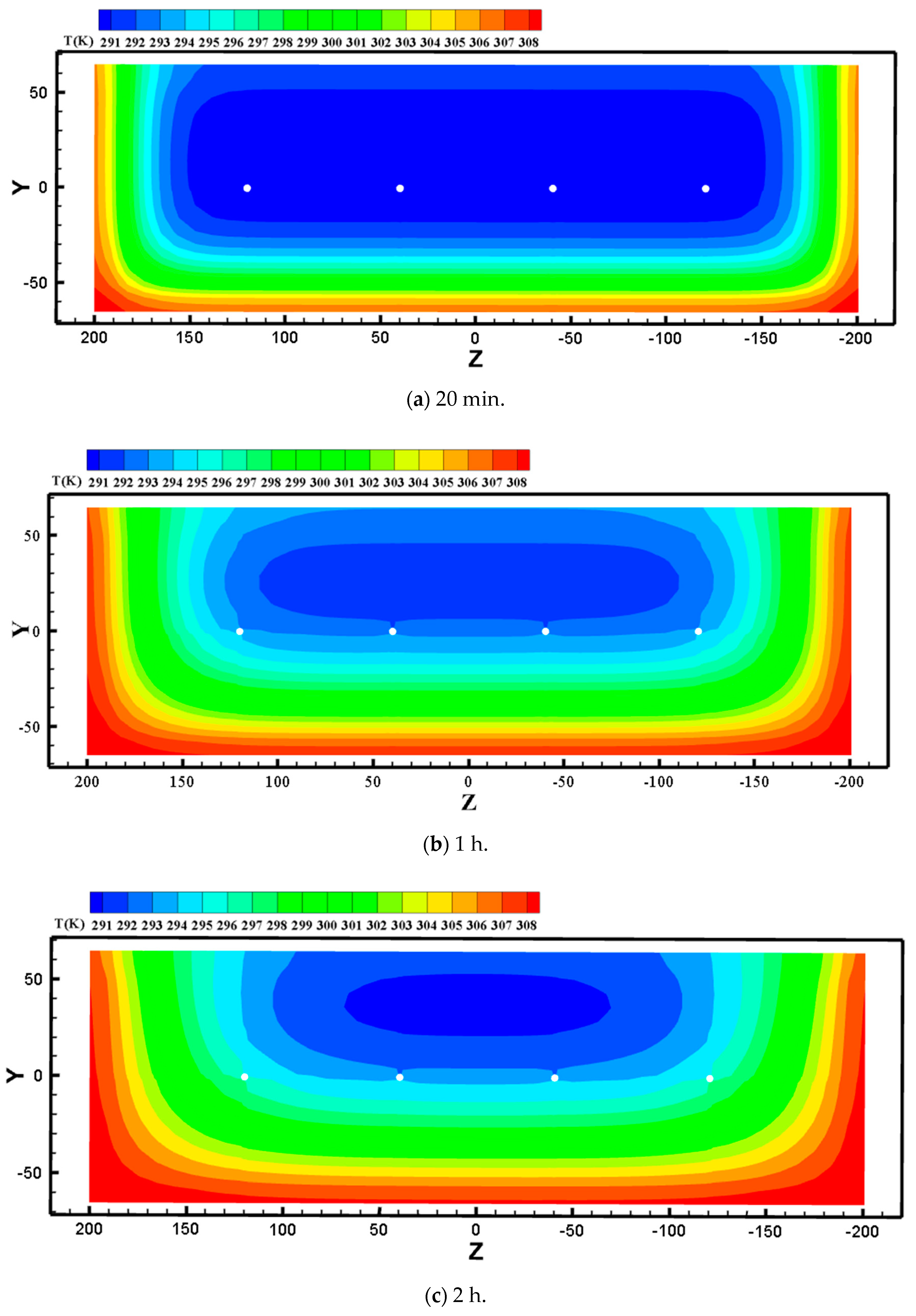

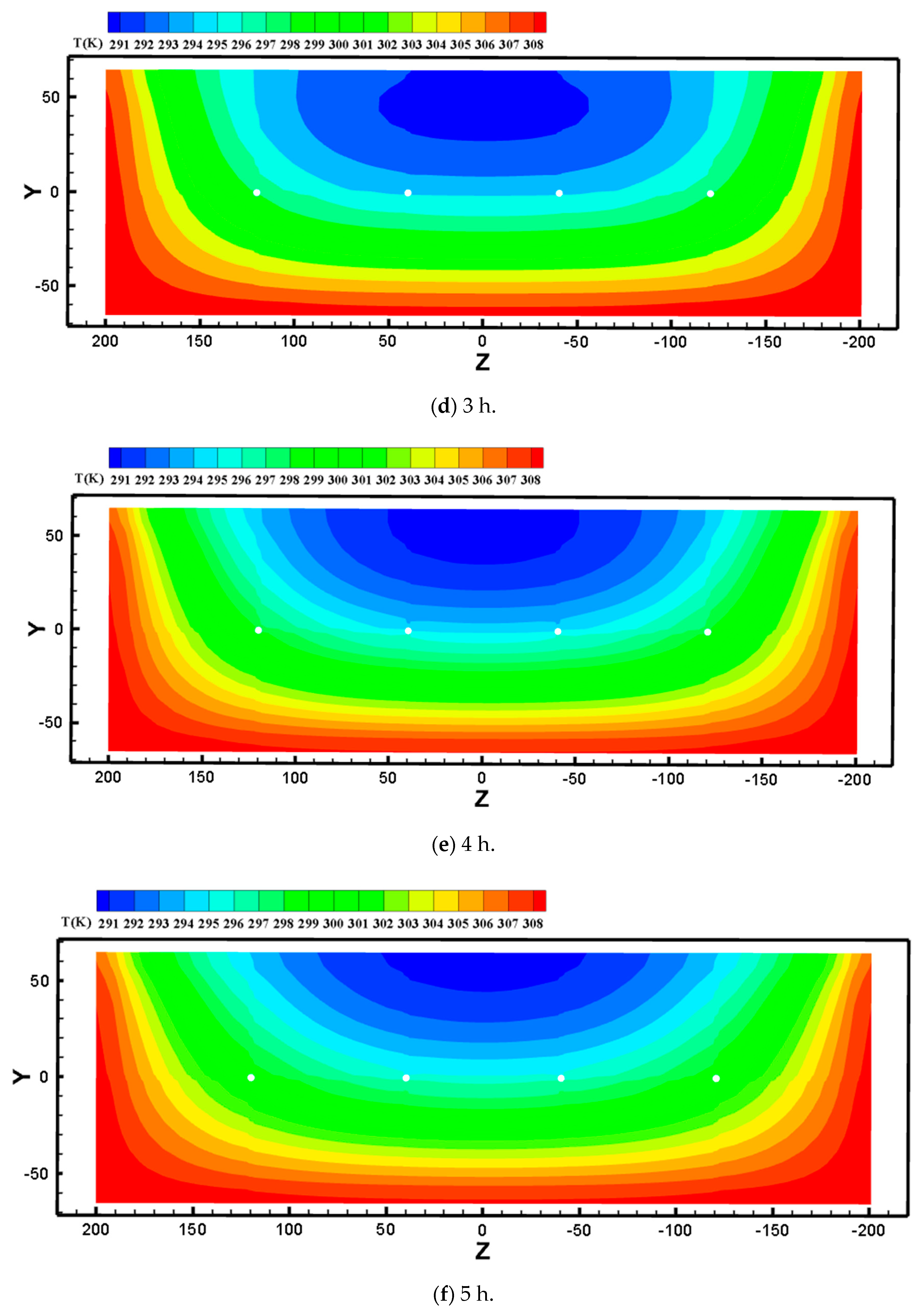

4.3.3. Results and Analysis from the Heat Storage Process

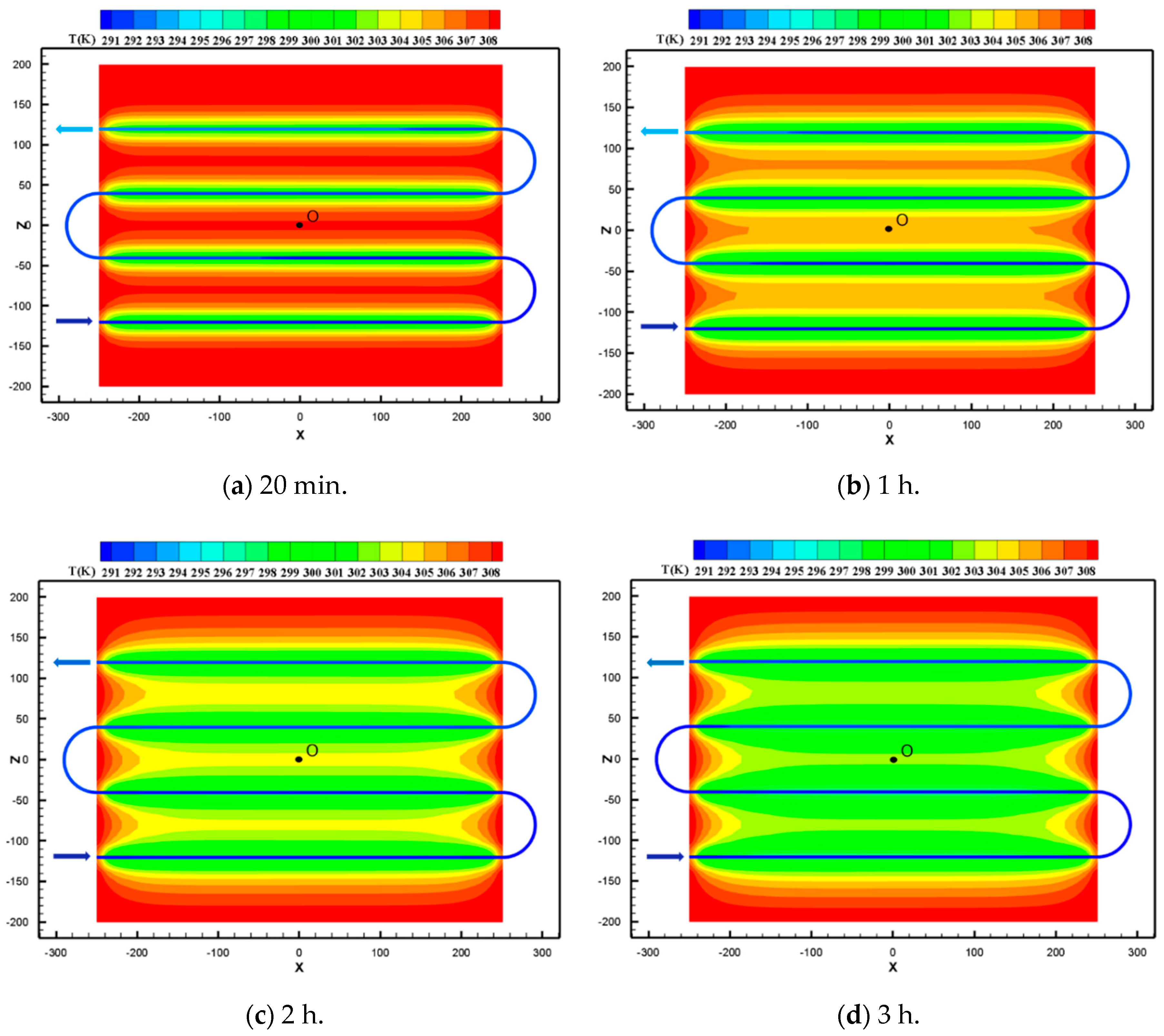

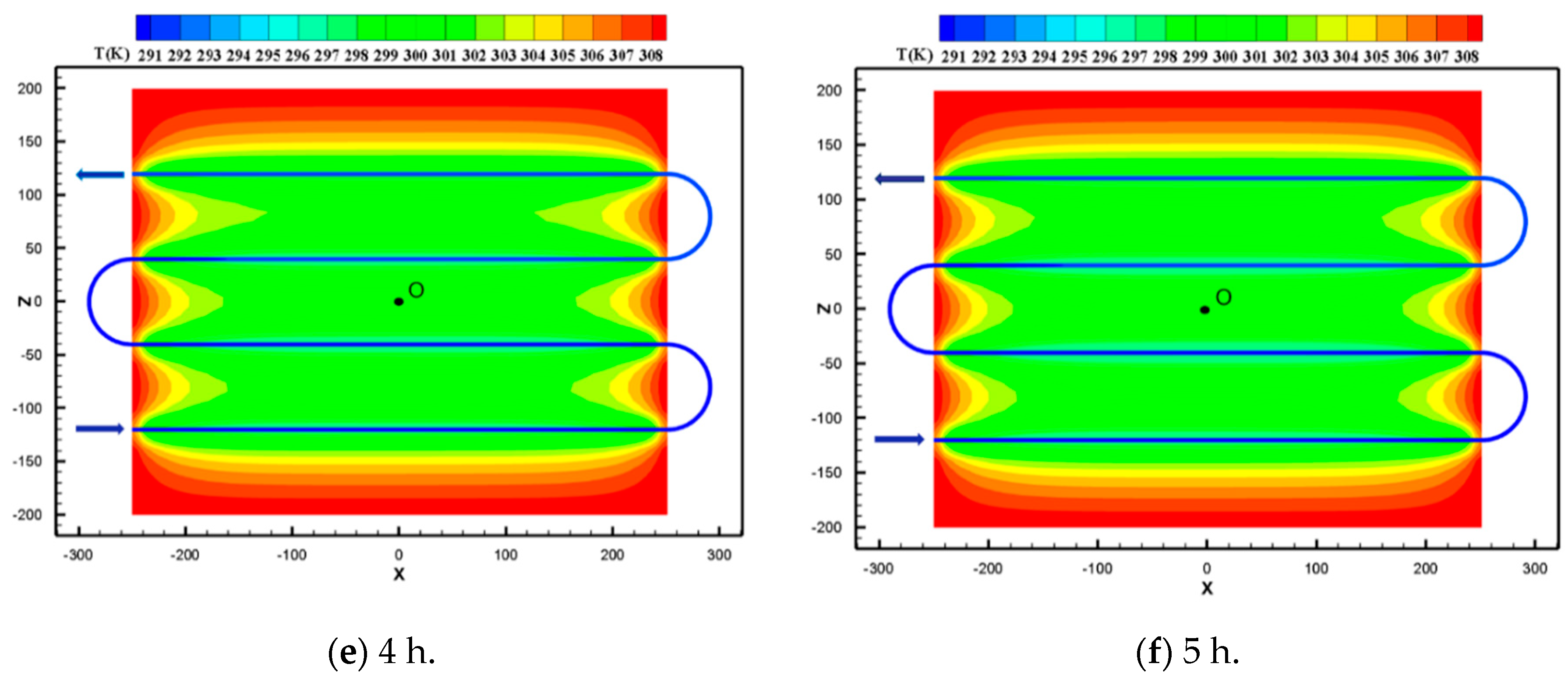

4.3.4. Results and Analysis from the Heat Release Process

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ranjith, P.; Zhao, J.; Ju, M.; De Silva, R.V.; Rathnaweera, T.; Bandara, A.K. Opportunities and challenges in deep mining: A brief review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Cai, M.; Brown, E.T. Challenges in the mining and utilization of deep mineral resources. Engineering 2017, 3, 432–433. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Li, X.; Zhou, J.; Wang, S.; Liu, B. Some developments and new insights of environmental problems and deep mining strategy for cleaner production in the mines. J. Clean. Prod. 2019, 210, 1562–1578. [Google Scholar] [CrossRef]

- Khaldoun, A.; Ouadif, L.; Baba, K.; Bahi, L. Valorization of mining waste and tailings through paste backfilling solution, Imiter operation, Morocco. Int. J. Min. Sci. Technol. 2016, 26, 511–516. [Google Scholar] [CrossRef]

- Zhai, X.; Xu, Y.; Yu, Z. Design and Performance Simulation of a Novel Liquid CO2 Cycle Refrigeration System for Heat Hazard Control in Coal Mines. J. Therm. Sci. 2019, 28, 585–595. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.; Chen, L.; Zhang, X.; Zhang, B.; Ji, C. Cold load and storage functional backfill for cooling deep mine. Adv. Civ. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Zhang, X.; Jia, Y.; Wang, M.; Liu, L. Experimental research on heat transfer and strength analysis of backfill with ice grains in deep mines. Sustainability 2019, 11, 2486. [Google Scholar] [CrossRef]

- Belle, B.; Biffi, M. Cooling pathways for deep Australian longwall coal mines of the future. Int. J. Min. Sci. Technol. 2018, 28, 865–875. [Google Scholar] [CrossRef]

- Wang, C.; Huang, Z.; Lu, Y.; Tang, G.; Li, H. Influences of Reservoir Heterogeneity and Anisotropy on CO2 Sequestration and Heat Extraction for CO2-Based Enhanced Geothermal System. J. Therm. Sci. 2019, 28, 319–325. [Google Scholar] [CrossRef]

- Benim, A.C.; Cicek, A.; Eker, A.M. A Computational Investigation of the Thermohydraulics of an EGS Project. J. Therm. Sci. 2018, 27, 405–412. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Liu, L.; Liu, L.; Liu, L.; Jia, Y.-H. Numerical simulation of heat release performance of filling body under condition of heat extracted by fluid flowing in buried tube. J. Cent. South Univ. 2019, 26, 2160–2174. [Google Scholar] [CrossRef]

- Liu, L.; Xin, J.; Zhang, B.; Zhang, X.Y.; Wang, M.; Qiu, H.F.; Chen, L. Basic theories and applied exploration of functional backfill in the mines. J. China Coal Soc. 2018, 43, 1811–1820. [Google Scholar]

- Wang, M.; Liu, L.; Zhang, X.-Y.; Chen, L.; Wang, S.-Q.; Jia, Y.-H. Experimental and numerical investigations of the heat transfer and phase-change characteristics of cemented paste backfill with PCM. Appl. Therm. Eng. 2019, 150, 121–131. [Google Scholar] [CrossRef]

- Pretorius, J.G.; Mathews, M.J.; Maré, P.; Kleingeld, M.; Van Rensburg, J. Implementing a DIKW model on a deep mine cooling system. Int. J. Min. Sci. Technol. 2019, 29, 319–326. [Google Scholar] [CrossRef]

- Guo, P.; He, M.; Zheng, L.; Zhang, N. A geothermal recycling system for cooling and heating in deep mines. Appl. Therm. Eng. 2017, 116, 833–839. [Google Scholar] [CrossRef]

- Du Plessis, G.E.; Arndt, D.C.; Mathews, E.H. The development and integrated simulation of a variable water flow energy saving strategy for deep-mine cooling systems. Sustain. Energy Technol. Assess. 2015, 10, 71–78. [Google Scholar] [CrossRef]

- Lyu, W.; Li, X.; Yan, S.; Jiang, S. Utilizing shallow geothermal energy to develop an energy efficient HVAC system. Renew. Energy 2020, 147, 672–682. [Google Scholar] [CrossRef]

- Falcone, G.; Liu, X.; Okech, R.R.; Seyidov, F.; Teodoriu, C. Assessment of deep geothermal energy exploitation methods: The need for novel single-well solutions. Energy 2018, 160, 54–63. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Y.; Zhang, S.; Fu, L.; Hu, Z.; Yu, Z.; Li, L.; Zhou, J. Electricity generation from a three-horizontal-well enhanced geothermal system in the Qiabuqia geothermal field, China: Slickwater fracturing treatments for different reservoir scenarios. Renew. Energy 2020, 145, 65–83. [Google Scholar] [CrossRef]

- Olabi, A.G.; Mahmoud, M.; Soudan, B.; Wilberforce, T.; Ramadan, M. Geothermal based hybrid energy systems, toward eco-friendly energy approaches. Renew. Energy 2020, 147, 2003–2012. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Dou, J.; Li, M.; Zeng, M. Geothermal energy in China: Status, challenges, and policy recommendations. Util. Policy 2020, 64, 101020. [Google Scholar] [CrossRef]

- Mohamad, K.; Mohammed, A.K.; Ferri, H. Optimal utilization of geothermal heat from abandoned oil wells for power generation. Appl. Therm. Eng. 2019, 153, 536–542. [Google Scholar] [CrossRef]

- Hu, X.; Banks, J.; Wu, L.; Liu, W.V. Numerical modeling of a coaxial borehole heat exchanger to exploit geothermal energy from abandoned petroleum wells in Hinton, Alberta. Renew. Energy 2020, 148, 1110–1123. [Google Scholar] [CrossRef]

- Cheng, S.W.; Kurnia, J.C.; Ghoreishi-Madiseh, S.A.; Sasmito, A.P. Optimization of geothermal energy extraction from abandoned oil well with a novel well bottom curvature design utilizing Taguchi method. Energy 2019, 188, 116098. [Google Scholar] [CrossRef]

- Wang, Z.; Li, R.; Hu, J.; Hu, X.; Gu, Z. Experimental Study on Hybrid Organic Phase-change Materials Used for Solar Energy Storage. J. Therm. Sci. 2020. [Google Scholar] [CrossRef]

- Mahdi, J.; Lohrasbi, S.; Ganji, D.D.; Nsofor, E.C. Simultaneous energy storage and recovery in the triplex-tube heat exchanger with PCM, copper fins and Al2O3 nanoparticles. Energy Convers. Manag. 2019, 180, 949–961. [Google Scholar] [CrossRef]

- Pooria, P.; Siamak, H. Numerical study of a Phase-change Material (PCM) embedded solar thermal energy operated cool store: A feasibility study. Int. J. Refrig. 2020, 117, 114–123. [Google Scholar] [CrossRef]

- Singh, R.P.; Kaushik, S.C.; Rakshit, D. Performance evaluation of charging process in a cascade latent heat storage system (C-LHSS) based on heat flux DSC results. Int. J. Therm. Sci. 2020, 151, 106274. [Google Scholar] [CrossRef]

- Zayed, M.E.; Zhao, J.; Li, W.; Elsheikh, A.H.; Elbanna, A.M.; Jing, L.; Geweda, A. Recent progress in phase-change materials storage containers: Geometries, design considerations and heat transfer improvement methods. J. Energy Storage 2020, 30, 101341. [Google Scholar] [CrossRef]

- Xu, Q.; Akkurt, N.; Zou, Z.; Liu, Y.; Feng, J.; Yu, C.; Ding, C.; Xiong, Y.; Zhou, J.; Zang, Y.; et al. Synthesis and Characterization of Disodium Hydrogen Phosphate Dodecahydrate-Lauric-Palmitic Acid Used for Indoor Energy Storage Floor Units. J. Therm. Sci. 2020. [Google Scholar] [CrossRef]

- Xu, H.; Magro, F.D.; Sadiki, N.; Mancaux, J.-M.; Py, X.; Romagnoli, A. Compatibility study between aluminium alloys and alternative recycled ceramics for thermal energy storage applications. Appl. Energy 2018, 220, 94–105. [Google Scholar] [CrossRef]

- Michał, R.; Ewa, K.R. Possibilities and benefits of a new method of modifying conventional building materials with phase-change materials (PCMs). Constr. Build. Mater. 2019, 211, 1013–1024. [Google Scholar] [CrossRef]

- Qi, C.C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Sun, Q.; Tian, S.; Sun, Q.; Li, B.; Cai, C.; Xia, Y.; Wei, X.; Mu, Q. Preparation and microstructure of fly ash geopolymer paste backfill material. J. Clean. Prod. 2019, 225, 376–390. [Google Scholar] [CrossRef]

- Sarı, A.; Bicer, A.; Al-Sulaiman, F.; Karaipekli, A.; Tyagi, V. Diatomite/CNTs/PEG composite PCMs with shape-stabilized and improved thermal conductivity: Preparation and thermal energy storage properties. Energy Build. 2018, 164, 166–175. [Google Scholar] [CrossRef]

- Diani, A.; Campanale, M. Transient melting of paraffin waxes embedded in aluminum foams: Experimental results and modeling. Int. J. Therm. Sci. 2019, 144, 119–128. [Google Scholar] [CrossRef]

- Zhang, S.; Feng, D.; Shi, L.; Wang, L.; Jin, Y.; Tian, L.; Li, Z.; Wang, G.; Zhao, L.; Yan, Y. A review of phase-change heat transfer in shape-stabilized phase-change materials (ss-PCMs) based on porous supports for thermal energy storage. Renew. Sustain. Energy Rev. 2021, 135, 110127. [Google Scholar] [CrossRef]

- Qu, Y.; Wang, S.; Tian, Y.; Zhou, D. Comprehensive evaluation of Paraffin-HDPE shape stabilized PCM with hybrid carbon nano-additives. Appl. Therm. Eng. 2019, 163, 114404. [Google Scholar] [CrossRef]

- Praveen, B.; Suresh, S.; Pethurajan, V. Heat transfer performance of graphene nano-platelets laden micro-encapsulated PCM with polymer shell for thermal energy storage based heat sink. Appl. Therm. Eng. 2019, 156, 237–249. [Google Scholar] [CrossRef]

- Mankel, C.; Caggiano, A.; Koenders, E. Thermal energy storage characterization of cementitious composites made with recycled brick aggregates containing PCM. Energy Build. 2019, 202, 109395. [Google Scholar] [CrossRef]

- Li, C.; Guan, Y.; Jiang, C.; Deng, S.; Lu, Z. Numerical study on the heat transfer, extraction, and storage in a deep-buried pipe. Renew. Energy 2020, 152, 1055–1066. [Google Scholar] [CrossRef]

- El Ouali, A.; El Rhafiki, T.; Kousksou, T.; Allouhi, A.; Mahdaoui, M.; Jamil, A.; Zeraouli, Y. Heat transfer within mortar containing micro-encapsulated PCM: Numerical approach. Constr. Build. Mater. 2019, 210, 422–433. [Google Scholar] [CrossRef]

- Buonomo, B.; Celik, H.; Ercole, D.; Manca, O.; Mobedi, M. Numerical study on latent thermal energy storage systems with aluminum foam in local thermal equilibrium. Appl. Therm. Eng. 2019, 159, 113980. [Google Scholar] [CrossRef]

- Li, X.; Tong, C.; Duanmu, L.; Liu, L. Research on U-tube Heat Exchanger with Shape-stabilized Phase-change Backfill Material. Procedia Eng. 2016, 146, 640–647. [Google Scholar] [CrossRef]

| Item | Material | Density (kg/m3) | Specific Heat Capacity (J/(kg⋅K)) | Thermal Conductivity (W/(m⋅K)) | Latent Heat (kJ/kg) | Phase-Change Temperature (K) |

|---|---|---|---|---|---|---|

| Cold fluid | Water | 998.5 | 4185 | 0.594 | - | - |

| Tube material | Polyethylene (PE) | 950 | 2100 | 0.46 | - | - |

| PCM | RT28 | 790 | 2020 | 0.28 | 186 | 301/299 |

| Backfill body | - | 1682 | 1650 | 0.6936 | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Xu, M.; Liu, L.; Liu, L.; Wang, M.; Ji, H.; Song, K.-I. The Concept, Technical System and Heat Transfer Analysis on Phase-Change Heat Storage Backfill for Exploitation of Geothermal Energy. Energies 2020, 13, 4755. https://doi.org/10.3390/en13184755

Zhang X, Xu M, Liu L, Liu L, Wang M, Ji H, Song K-I. The Concept, Technical System and Heat Transfer Analysis on Phase-Change Heat Storage Backfill for Exploitation of Geothermal Energy. Energies. 2020; 13(18):4755. https://doi.org/10.3390/en13184755

Chicago/Turabian StyleZhang, Xiaoyan, Muyan Xu, Li Liu, Lang Liu, Mei Wang, Haiwei Ji, and KI-IL Song. 2020. "The Concept, Technical System and Heat Transfer Analysis on Phase-Change Heat Storage Backfill for Exploitation of Geothermal Energy" Energies 13, no. 18: 4755. https://doi.org/10.3390/en13184755

APA StyleZhang, X., Xu, M., Liu, L., Liu, L., Wang, M., Ji, H., & Song, K.-I. (2020). The Concept, Technical System and Heat Transfer Analysis on Phase-Change Heat Storage Backfill for Exploitation of Geothermal Energy. Energies, 13(18), 4755. https://doi.org/10.3390/en13184755