Stability Improvement of DFIG-Based Wind Farm Integrated Power System Using ANFIS Controlled STATCOM

Abstract

1. Introduction

2. Materials and Methods

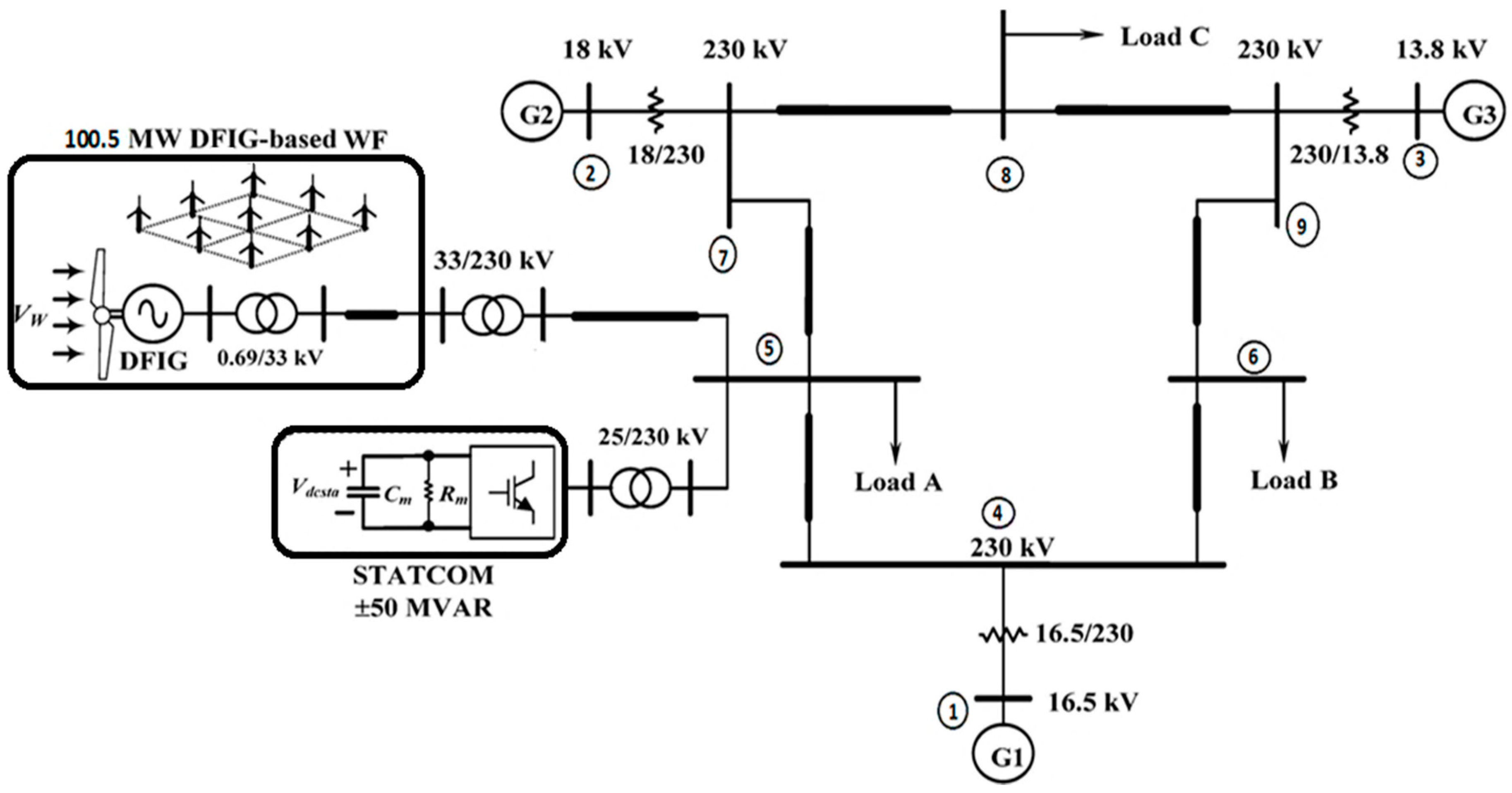

2.1. Configuration and Modelling of Test System

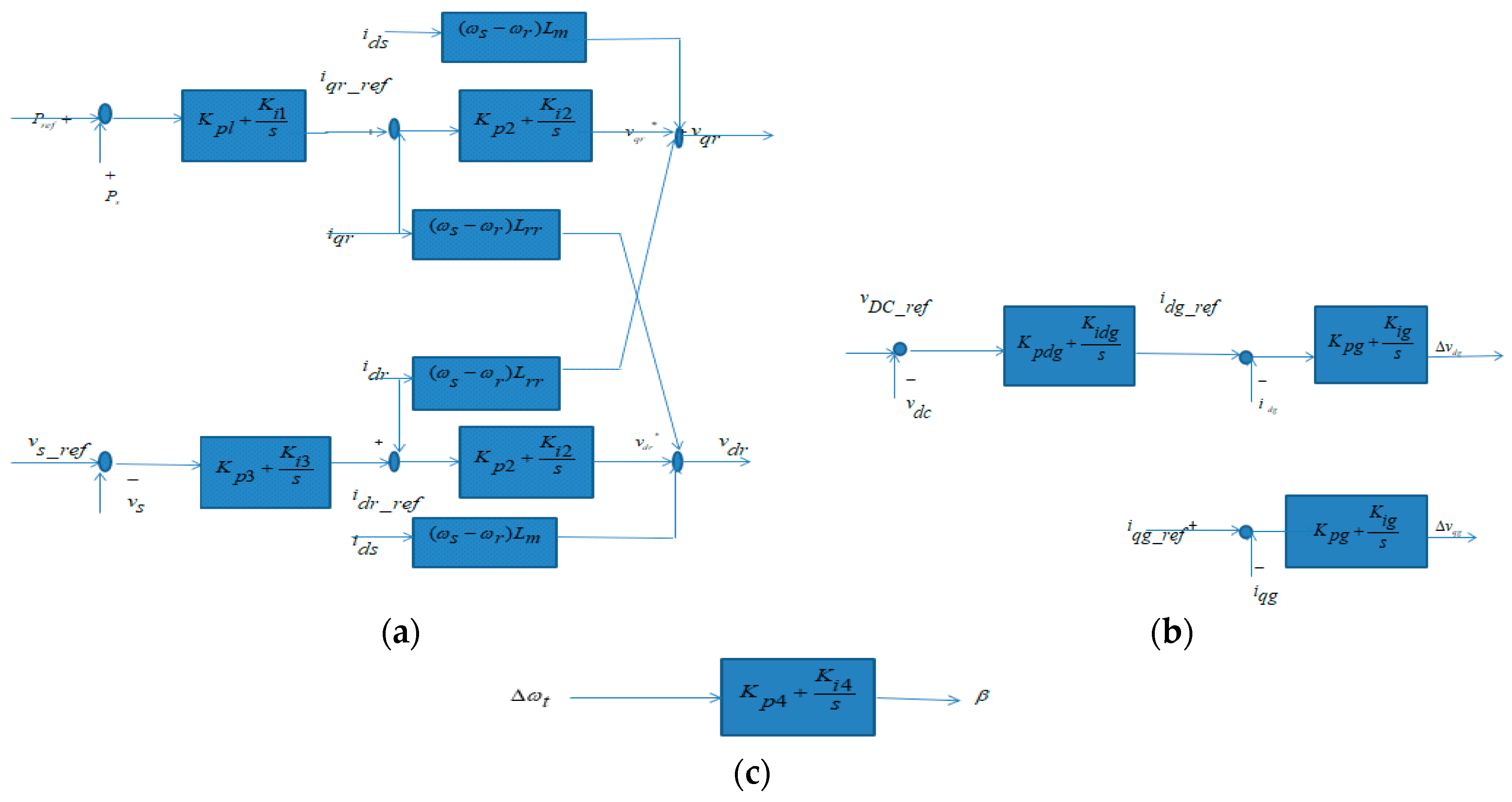

2.2. Mathematical Modeling of DFIG-Based Wind Farm

2.3. Wind Turbine and DFIG Modeling

2.4. Dynamic Model of DFIG-Based Wind Turbine

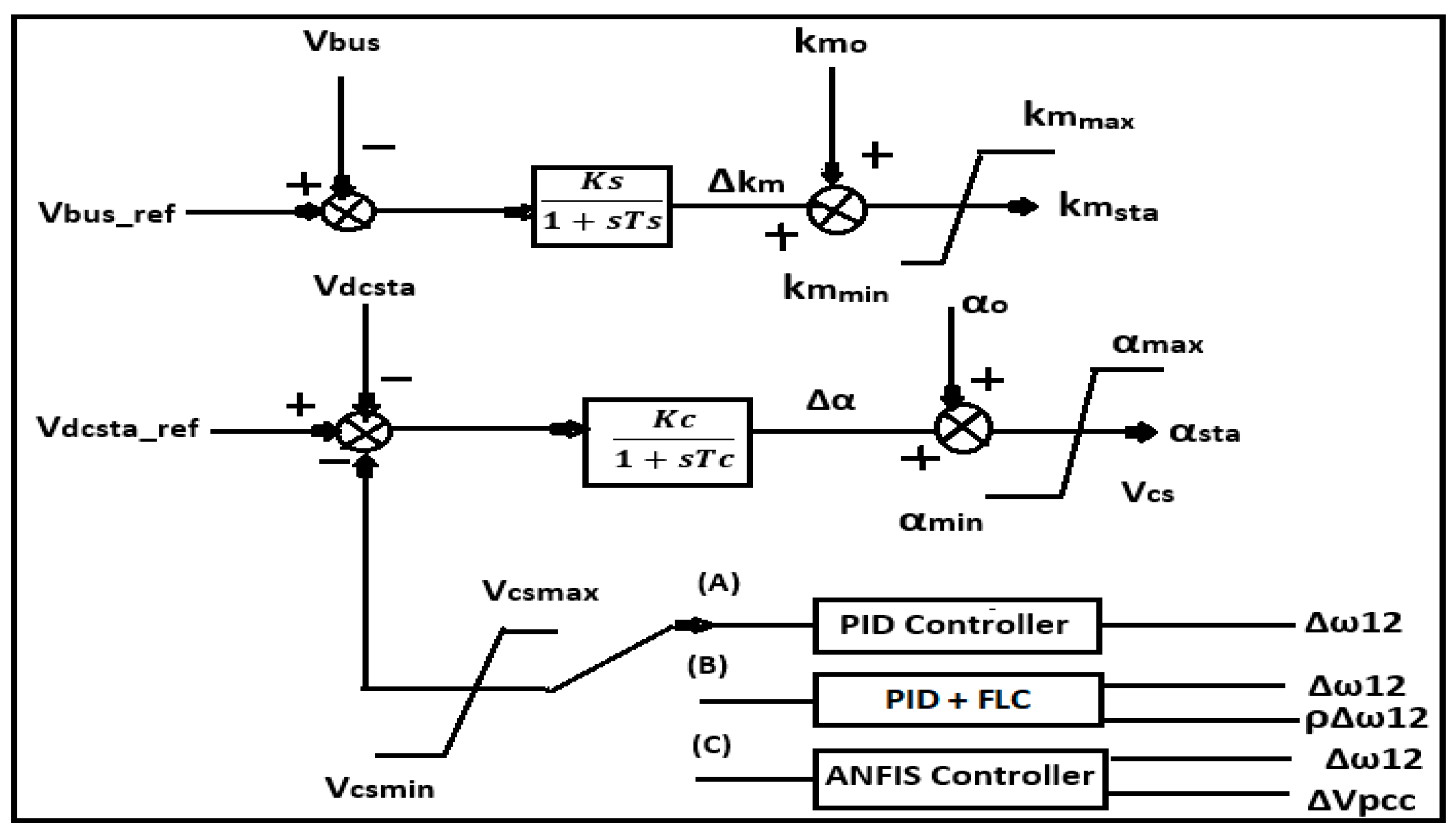

2.5. STATCOM Model

| and | q-and d-axis voltages at the STATCOM output (pu) terminal, respectively |

| STATCOM Modulation Index | |

| STATCOM Phase Angle | |

| Pu voltage of capacitor Cm |

2.6. Modeling of Three-Machine Nine-Bus System

2.7. Excitation System

2.8. Prime Mover and Governing System

2.9. Generation Module Matrix Definition

2.10. PID Damping Controller Design for STATCOM

2.11. PID Plus FLC Damping Controller Desgin for STATCOM

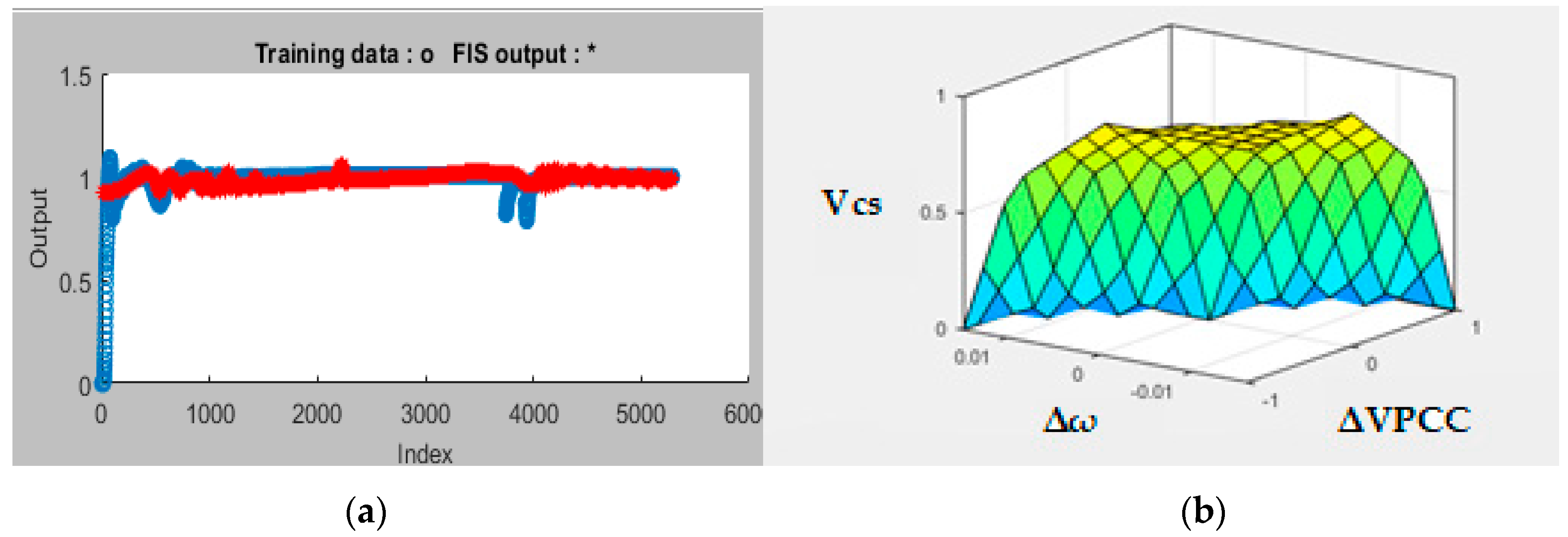

2.12. ANFIS Damping System Configuration for STATCOM

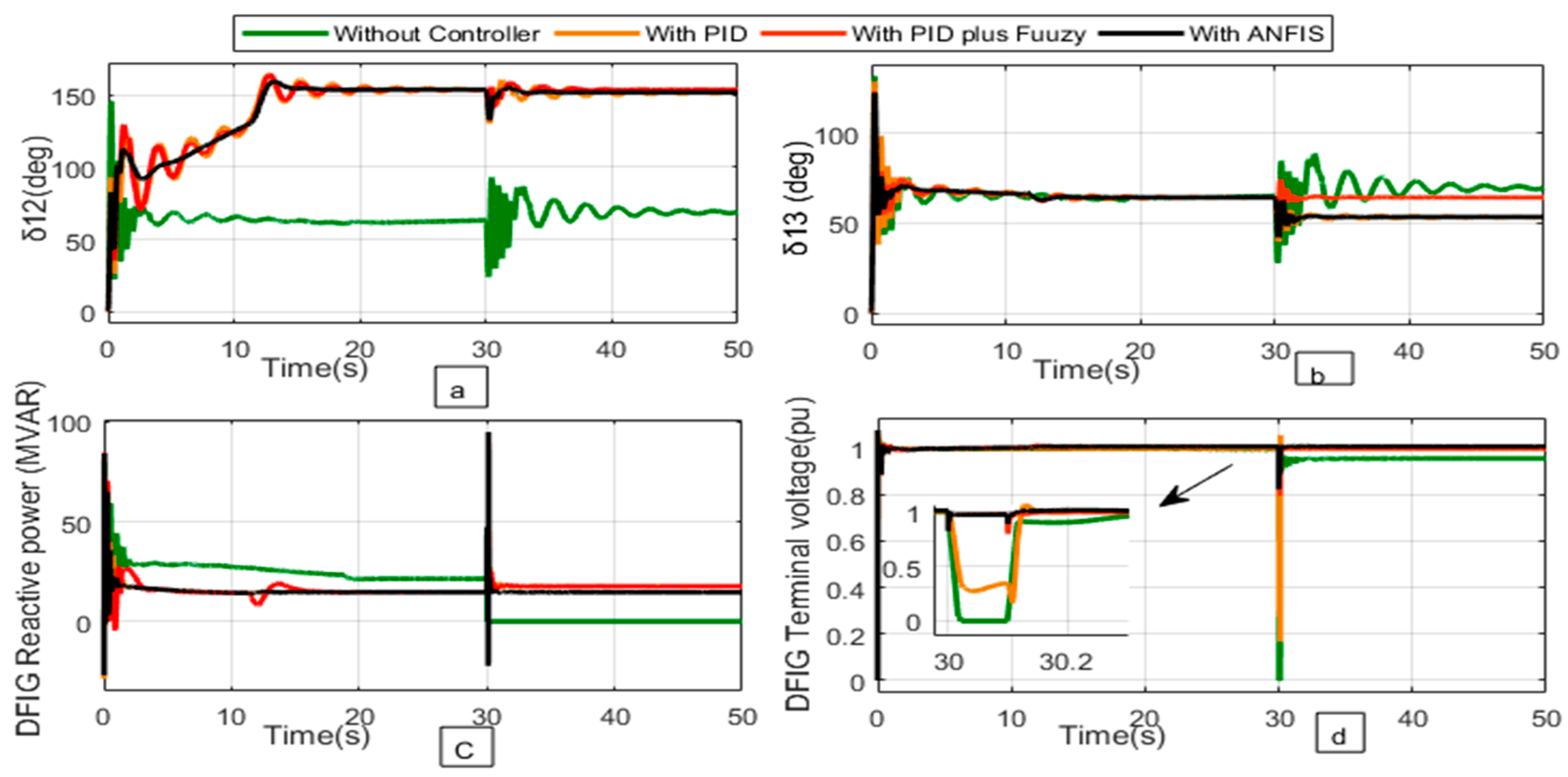

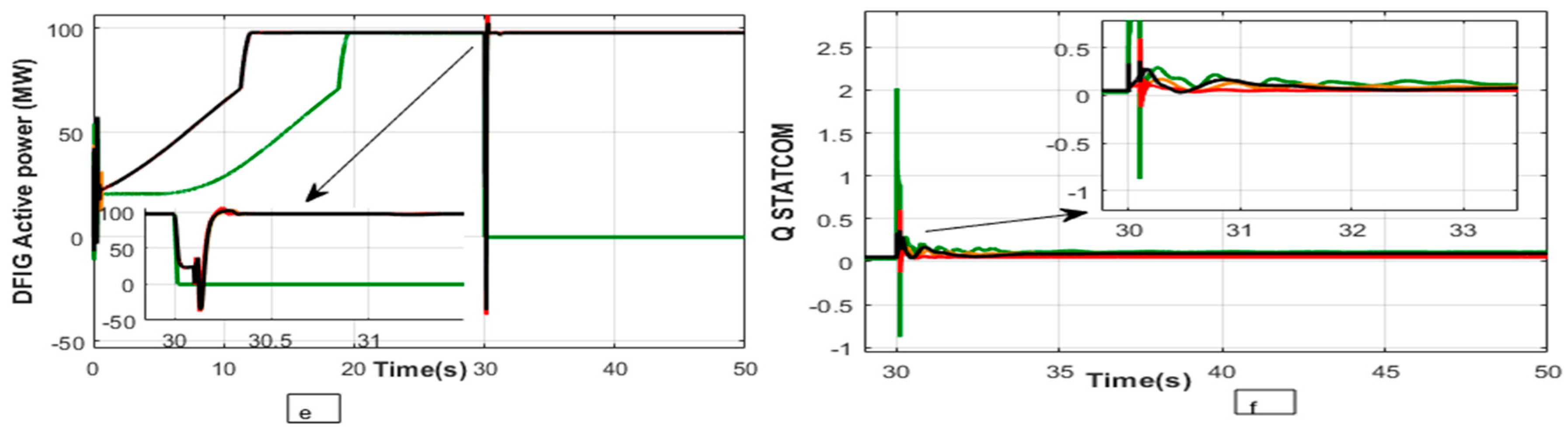

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| WF | Wind Farm |

| STATCOM | Static Synchronous Compensator |

| DFIG | Double-Fed Induction Generator |

| FLC | Fuzzy Logic Controller |

| ANFIS | Adaptive network-based fuzzy inference system |

| BESS | Battery Energy Storage System |

| PCC | Point of Common Coupling |

| LVRT | Low Voltage Ride Through |

| SVC | Static VAR Compensator |

| SMES | Superconducting Magnetic Energy Storage |

| PSS | Power System Stabilizer |

| SSSC | Static Synchronous Series Compensator |

| CWF | Combined wind farm |

| MOGA | Multiobjective Genetic Algorithm based |

| WOA | Whale optimization algorithm |

| SGs | Synchronous Generators |

| RSC | Rotor Side Converter |

| GSC | Grid Side Converter |

References

- Wang, L.; Wang, K.H. Dynamic stability analysis of a DFIG-based offshore wind farm connected to a power grid through an HVDC link. IEEE Trans. Power Syst. 2010, 26, 1501–1510. [Google Scholar] [CrossRef]

- Muljadi, E.; Nguyen, T.B.; Pai, M.A. Impact of wind power plants on voltage and transient stability of power systems. In Proceedings of the Conference on IEEE Energy 2030, Atlanta, GA, USA, 17–18 November 2008. [Google Scholar]

- Pokharel, B.; Gao, W. Mitigation of disturbances in DFIG-based wind farm connected to weak distribution system using STATCOM. In Proceedings of the IEEE Conference on North American Power Symposium (NAPS), Arlington, TX, USA, 26–28 September 2010. [Google Scholar]

- Mak, L.O.; Ni, Y.X.; Shen, C.M. STATCOM with fuzzy controllers for interconnected power systems. Elect. Power Syst. Res. 2000, 55, 87–95. [Google Scholar] [CrossRef]

- Reznik, L.; Ghanayem, O.; Bourmistrov, A. PID plus fuzzy controller structures as a design base for industrial applications. Eng. Appl. Artif. Intell. 2000, 13, 419–430. [Google Scholar] [CrossRef]

- Molinas, M.; Suul, J.A.; Undeland, T. Low voltage ride through of wind farms with cage generators: STATCOM versus SVC. IEEE Trans. Power Electron. 2008, 23, 1104–1117. [Google Scholar] [CrossRef]

- Hemeida, M.G.; Rezk, H.; Hamada, M.M. A comprehensive comparison of STATCOM versus SVC-based fuzzy controller for stability improvement of wind farm connected to multi-machine power system. Springer Electr. Eng. 2018, 100, 935–951. [Google Scholar] [CrossRef]

- Muyeen, S.M.; Hasanien, H.M.; Al-Durra, A. Transient stability enhancement of wind farms connected to a multi-machine power system by using an adaptive ANN-controlled SMES. Energy Convers. Manag. 2014, 70, 412–420. [Google Scholar] [CrossRef]

- Ni, Z.; Tang, Y.; Sui, X.; He, H.; Wen, J. An adaptive neuro-control approach for multi-machine power systems. Electr. Power Energy Syst. 2016, 75, 108–116. [Google Scholar] [CrossRef]

- Taj, T.A.; Hasanien, H.M.; Alolah, A.I.; Muyeen, S.M. Transient stability enhancement of a grid connected wind farm using an adaptive neuro fuzzy controlled-flywheel energy storage system. IET Renew. Power Gener. 2015, 9, 792–800. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Kamel, S.; Rashad, A.; Nasrat, L.; Jurado, F. Performance Enhancement of Wind Farms Using Tuned SSSC Based on Artificial Neural Network. Int. J. Interact. Multimed. Artif. Intell. 2019, 5, 1–7. [Google Scholar] [CrossRef]

- Rashad, A.; Kamel, S.; Jurado, F.; Abdel-Nasser, M.; Mahmoud, K. ANN-Based STATCOM Tuning for Performance Enhancement of Combined Wind Farms. Electr. Power Compon. Syst. 2019, 47, 10–26. [Google Scholar] [CrossRef]

- Jang, J.S. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Muyeen, S.M.; Ali, M.H.; Takahashi, R.; Murata, T.; Tamura, J.; Tomaki, Y.; Sakahara, A.; Sasano, E. Transient stability analysis of wind generator system with the consideration of multi-mass shaft model. In Proceedings of the International conference on Power Electronics and Drives Systems, Kuala Lumpur, Malaysia, 28 November–1 December 2005. [Google Scholar]

- Wu, F.; Zhang, X.P.; Godfrey, K.; Ju, P. Small signal stability analysis and optimal control of a wind turbine with doubly fed induction generator. Gener. Transm. Distrib. IET 2007, 1, 751–760. [Google Scholar] [CrossRef]

- Wang, L.; Hsiung, C.T. Dynamic stability improvement of an integrated grid-connected offshore wind farm and marine-current farm using a STATCOM. IEEE Trans. Power Syst. 2011, 26, 690–698. [Google Scholar] [CrossRef]

- Wang, X.F.; Song, Y.; Irving, M. Modern Power Systems Analysis; Springer Science & Business Media: New York, NY, USA, 2010. [Google Scholar]

- Ma, J.; Dong, Z.Y.; Zhang, P. Eigenvalue sensitivity analysis for dynamic power system. In Proceedings of the International Conference on Power System Technology, (POWERCON 2006), Chongqing, China, 22–26 October 2006. [Google Scholar]

- Wang, L.; Truong, D. Stability Enhancement of DFIG-Based Offshore Wind Farm Fed to a Multi-Machine System Using a STATCOM. IEEE Trans. Power Syst. 2013, 28, 2882–2889. [Google Scholar] [CrossRef]

- Lee, C. Fuzzy logic in control system: Fuzzy logic controller, Part I and II. IEEE Trans. Syst. Man Cybern. 1990, 20, 404–435. [Google Scholar] [CrossRef]

- Mansour, I.; Abdeslam, D.O.; Wira, P.; Merckle, J. Fuzzy logic control of a SVC to improve the transient stability of ac power systems. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009. [Google Scholar]

- Anderson, P.M.; Fouad, A.A. Power System Control and Stability; Iowa State Univ. Press: Ames, IA, USA, 1977. [Google Scholar]

| Eigenvalue No. | Studied System Excluding of WF | System Including WF and STATCOM | System with Wind Farm, STATCOM, and PID Controller |

|---|---|---|---|

| λ1 | −52.79 + 0.000i | −52.654 + 0.000i | −52.986 + 0.000i |

| λ2 | −51.764 + 0.000i | −50.321 + 0.000i | −51.875 + 0.000i |

| λ3 | −30.543 + 0.000i | −30.896 + 0.000i | −30.974 + 0.000i |

| λ4 | −28.647 + 0.000i | −28.643 + 0.0000i | −28.647 + 0.000i |

| λ5–6 | −0.787 ± 12.8449i 0.0592 | −0.538 ± 14.2469i 0.0378 | −0.85 ± 14i 0.060 |

| λ7–8 | −0.531 ± 8.9071i 0.0795 | −0.486 ± 8.0504i 0.061 | −0.90 ± 8i 0.1117 |

| λ9 | −4.4512 ± 0.4563i | −4.8762 ± 0.4657i | −4.7651 ± 0.4342i |

| λ10 | −0.1919 + 0.00i | −0.1754 + 0.00i | −0.2112 + 0.00i |

| λ11–12 | −1.135 ± 3.3182i | −1.2311 ± 3.658i | −2.9077 ± 4.212i |

| λ13–14 | −0.4501 ± 0.618i | −0.4501 ± 0.718i | −0.5765 ± 0.438i |

| λ15 | −7.5477 | −7.7609 | −7.6654 |

| ∆ω12 | NB | NM | NS | ZR | PS | PM | PB | |

|---|---|---|---|---|---|---|---|---|

| P(∆ω12) | ||||||||

| PB | KV | IS | IM | IB | IB | IB | IB | |

| PM | DS | KV | IS | IM | IB | IB | IB | |

| PS | DM | DS | KV | IS | IM | IB | IB | |

| ZR | DB | DM | DS | KV | IS | IM | IB | |

| NS | DB | DB | DM | DS | KV | IS | IM | |

| NM | DB | DB | DB | DM | DS | KV | IS | |

| NB | DB | DB | DB | DB | DM | DS | KV | |

| Membership function type | Gauss |

| Number of epochs | 30 |

| Learning algorithm | Hybrid (mixed least squares and back-propagation) |

| Total nodes | 131 |

| Linear parameters (no.) | 49 |

| Nonlinear parameters (no.) | 42 |

| Total number of parameters | 91 |

| Training data pairs | 5288 |

| Fuzzy rules | 49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, V.; Pandey, A.S.; Sinha, S.K. Stability Improvement of DFIG-Based Wind Farm Integrated Power System Using ANFIS Controlled STATCOM. Energies 2020, 13, 4707. https://doi.org/10.3390/en13184707

Kumar V, Pandey AS, Sinha SK. Stability Improvement of DFIG-Based Wind Farm Integrated Power System Using ANFIS Controlled STATCOM. Energies. 2020; 13(18):4707. https://doi.org/10.3390/en13184707

Chicago/Turabian StyleKumar, Varun, Ajay Shekhar Pandey, and Sunil Kumar Sinha. 2020. "Stability Improvement of DFIG-Based Wind Farm Integrated Power System Using ANFIS Controlled STATCOM" Energies 13, no. 18: 4707. https://doi.org/10.3390/en13184707

APA StyleKumar, V., Pandey, A. S., & Sinha, S. K. (2020). Stability Improvement of DFIG-Based Wind Farm Integrated Power System Using ANFIS Controlled STATCOM. Energies, 13(18), 4707. https://doi.org/10.3390/en13184707