Silicon Substrate Treated with Diluted NaOH Aqueous for Si/PEDOT: PSS Heterojunction Solar Cell with Performance Enhancement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

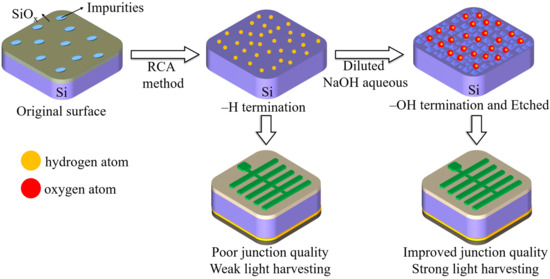

2.2. Experiment and Device Preparation

2.3. Characterizations

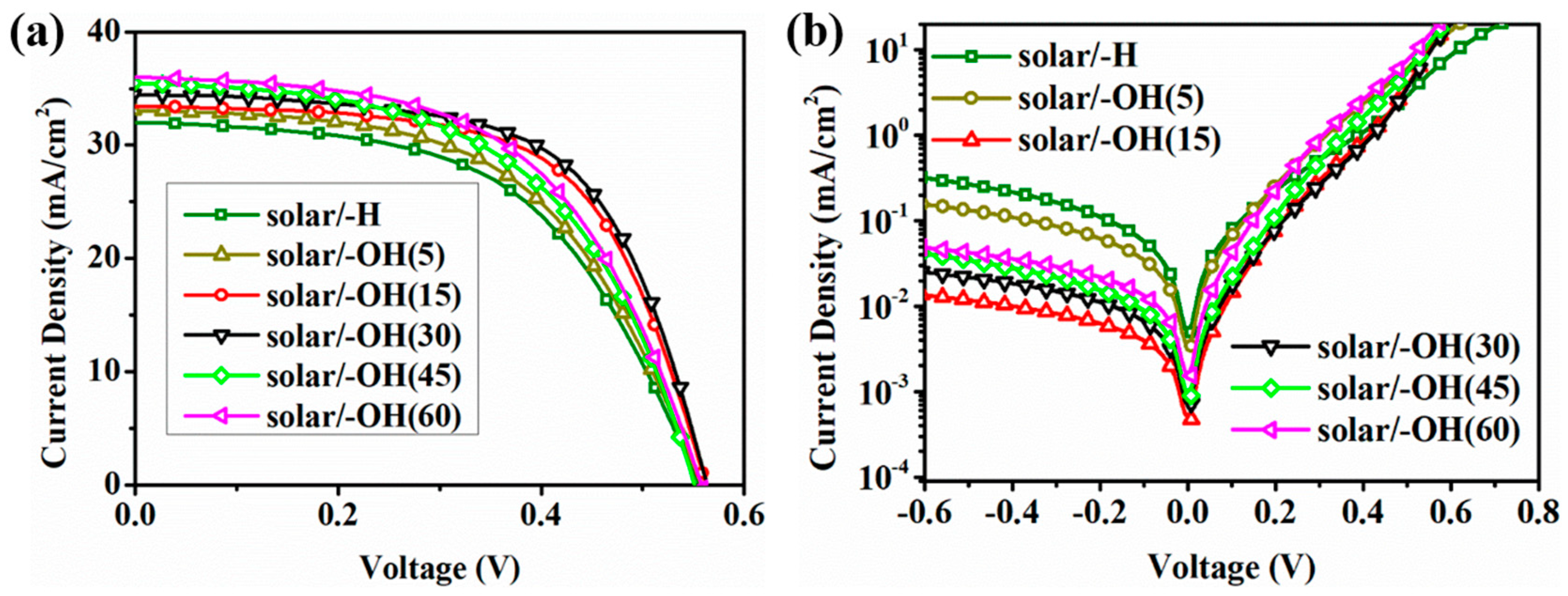

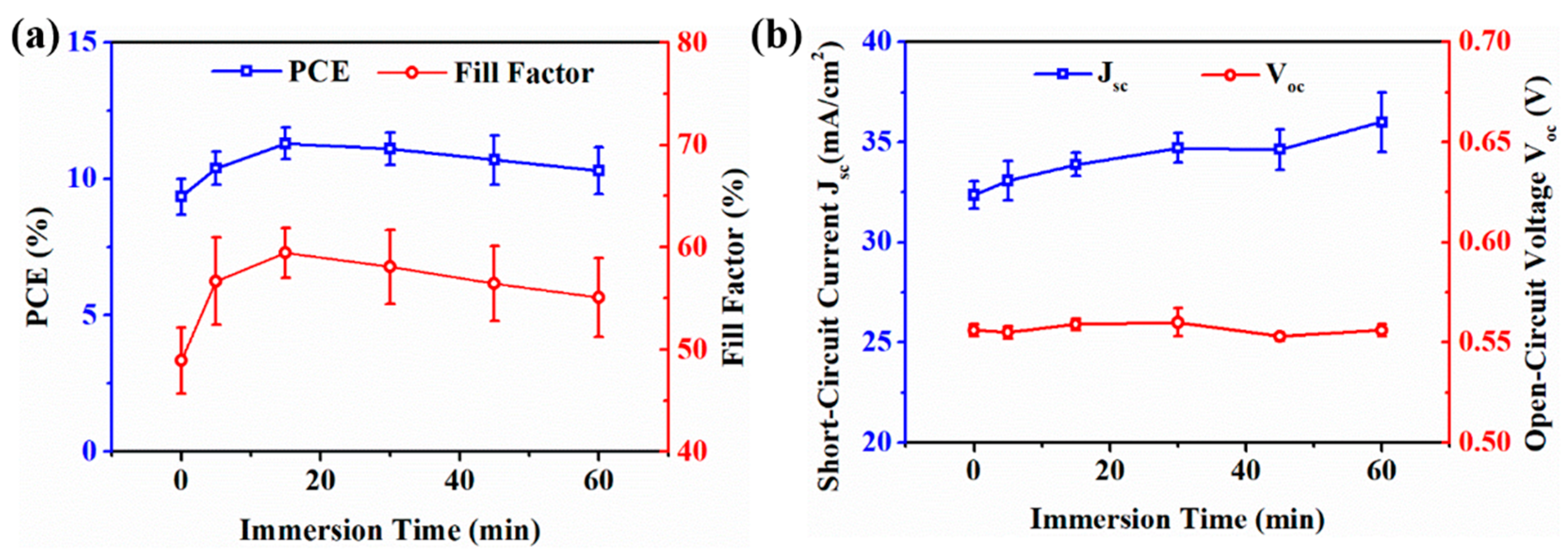

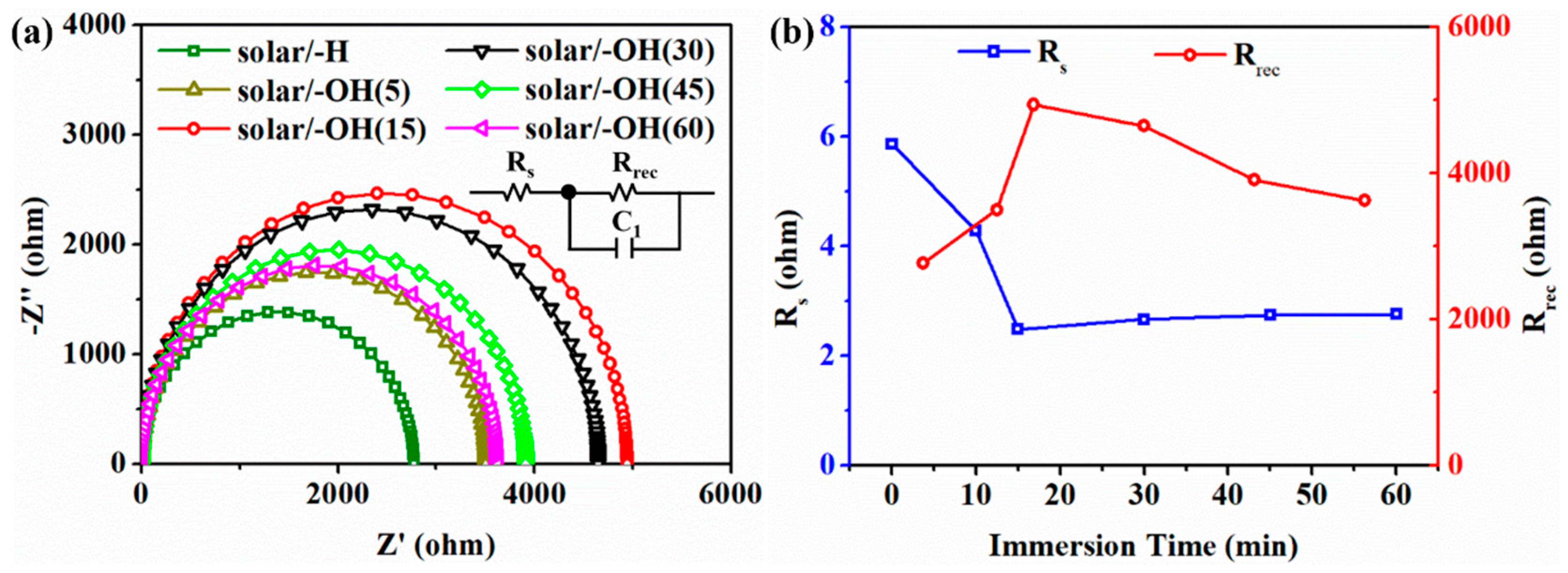

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shiu, S.-C.; Chao, J.-J.; Hung, S.-C.; Yeh, C.-L.; Lin, C.-F. Morphology Dependence of Silicon Nanowire/Poly (3,4-Ethylenedioxythiophene):Poly (Styrenesulfonate) Heterojunction Solar Cells. Chem. Mater. 2010, 22, 3108–3113. [Google Scholar] [CrossRef]

- Zielke, D.; Pazidis, A.; Werner, F.; Schmidt, J. Organic-Silicon Heterojunction Solar Cells on N-Type Silicon Wafers: The Backpedot Concept. Sol. Energy Mater. Sol. Cells 2014, 131, 110–116. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, P.; He, J.; Chen, W.; Yin, W.Y.; Zeng, Y.; Guo, W.; Ye, J.; Cui, Y. Tuning of the Contact Properties for High-Efficiency Si/PEDOT:PSS Heterojunction Solar Cells. ACS Energy Lett. 2017, 2, 556–562. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Rusli. Hybrid Si Nanocones/PEDOT:PSS Solar Cell. Nanoscale Res. Lett. 2015, 10, 191. [Google Scholar] [CrossRef] [PubMed]

- Bhujel, R.; Swain, B.P. Fabrication and Characterization of Silicon Nanowires Hybrid Solar Cells: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012193. [Google Scholar] [CrossRef]

- Thomas, J.P.; Leung, K.T. Defect-Minimized PEDOT:PSS/Planar-Si Solar Cell with Very High Efficiency. Adv. Funct. Mater. 2014, 24, 4978–4985. [Google Scholar] [CrossRef]

- Yoon, S.-S.; Khang, D.-Y. Ag Nanowire/ PEDOT:PSS Bilayer Transparent Electrode for High Performance Si- PEDOT:PSS Hybrid Solar Cells. J. Phys. Chem. Solids 2019, 129, 128–132. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, X.; Yang, Z.; Wang, D.; Gao, P.; Ye, J. Achieving a Record Fill Factor for Silicon-Organic Hybrid Heterojunction Solar Cells by Using a Full-Area Metal Polymer Nanocomposite Top Electrode. Adv. Funct. Mater. 2018, 28, 1705425. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, Q.; Zhou, W.; Xia, X.; Yang, F.; Zhang, N.; Xiao, S.; Li, K.; Gu, X.; Xiao, Z.; et al. Novel Approach to Enhance Efficiency of Hybrid Silicon-Based Solar Cells Via Synergistic Effects of Polymer and Carbon Nanotube Composite Film. Nano Energy 2017, 33, 436–444. [Google Scholar] [CrossRef]

- Cui, W.; Wu, S.; Chen, F.; Xia, Z.; Li, Y.; Zhang, X.; Song, T.; Lee, S.; Sun, B. Silicon/Organic Heterojunction for Photoelectrochemical Energy Conversion Photoanode with a Record Photovoltage. ACS Nano 2016, 10, 9419. [Google Scholar] [CrossRef]

- Young, J.; Shin, M.; Lee, J.B.; Ahn, J.H.; Baik, H.K.; Jeong, U. Effect of Pedot Nanofibril Networks on the Conductivity, Flexibility, and Coatability of Pedot: Pss Films. ACS Appl. Mater. Interfaces 2014, 6, 6954–6961. [Google Scholar]

- Singh, P.; Sanjay, K.; Srivastava, B.; Sivaiah, P.; Prathap, C.; Rauthan, M.S. Enhanced Photovoltaic Performance of Pedot:Pss/Si Solar Cells Using Hierarchical Light Trapping Scheme. Sol. Energy 2018, 170, 221–233. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, P.; Chen, Q.; Li, Y.; Li, J.; He, D. Nanostructural Optimization of Silicon/PEDOT:PSS Hybrid Solar Cells for Performance Improvement. J. Phys. D Appl. Phys. 2017, 50, 175105. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Lin, H.; Wang, W.; Wang, J.; Zhang, H.; Sheng, J.; Wu, S.; Gao, P.; Ye, J. Thickness-Modulated Passivation Properties of PEDOT:PSS Layers over Crystalline Silicon Wafers in Back Junction Organic/Silicon Solar Cells. Nanotechnology 2019, 30, 195401. [Google Scholar] [CrossRef]

- Wu, S.; Cui, W.; Aghdassi, N.; Song, T.; Duhm, S.; Lee, S.T.; Sun, B. Nanostructured Si/Organic Heterojunction Solar Cells with High Open-Circuit Voltage Via Improving Junction Quality. Adv. Funct. Mater. 2016, 26, 5035–5041. [Google Scholar] [CrossRef]

- He, J.; Wan, Y.; Gao, P.; Tang, J.; Ye, J. Over 16.7% Efficiency Organic-Silicon Heterojunction Solar Cells with Solution-Processed Dopant-Free Contacts for Both Polarities. Adv. Funct. Mater. 2018, 28, 1802192. [Google Scholar] [CrossRef]

- He, L.; Jiang, C.; Wang, H.; Lai, D.; Rusli. High Efficiency Planar Si/Organic Heterojunction Hybrid Solar Cells. Appl. Phys. Lett. 2012, 100, 073503. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Guo, H.; Jiang, Q.; Dong, P.; Zhang, C. Efficient Planar Hybrid n-Si/ PEDOT:PSS Solar Cells with Power Conversion Efficiency up to 13.31% Achieved by Controlling the Siox Interlayer. Energies 2018, 11, 1397. [Google Scholar] [CrossRef]

- Nam, Y.-H.; Song, J.-W.; Park, M.-J.; Sami, A.; Lee, J.-H. Ultrathin Al2O3 Interface Achieving an 11.46% Efficiency in Planar n-Si/ PEDOT:PSS Hybrid Solar Cells. Nanotechnology 2017, 28, 155402. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Wu, H.; Cui, W.; Wang, R.; Ding, K.; Lee, S.-T.; Sun, B. Low-Temperature Synthesis TiOx Passivation Layer for Organic-Silicon Heterojunction Solar Cell with a High Open-Circuit Voltage. Nano Energy 2017, 34, 257–263. [Google Scholar] [CrossRef]

- Yadav, T.S.; Sharma, A.K.; Kottantharayil, A.; Basu, P.K. Comparative Study of Different Silicon Oxides Used as Interfacial Passivation Layer (SiNy:H/SiOx/n+-Si) in Industrial Monocrystalline Silicon Solar Cells. Sol. Energy Mater. Sol. Cells 2019, 201, 110077. [Google Scholar] [CrossRef]

- Kern, W. The Evolution of Silicon Wafer Cleaning Technology. J. Electrochem. Soc. 1990, 137, 1887–1892. [Google Scholar] [CrossRef]

- Untila, G.G.; Kost, T.N.; Chebotareva, A.B. F-In-Codoped ZnO (FiZO) Films Produced by Corona-Discharge-Assisted Ultrasonic Spray Pyrolysis and Hydrogenation as Electron-Selective Contacts in FiZo/SiO/p-Si Heterojunction Crystalline Silicon Solar Cells with 10.5% Efficiency. Sol. Energy 2019, 181, 148–160. [Google Scholar] [CrossRef]

- Pollock, K.L.; Junge, J.; Hahn, G. Detailed Investigation of Surface Passivation Methods for Lifetime Measurements on P-Type Silicon Wafers. IEEE J. Photovolt. 2011, 2, 1–6. [Google Scholar] [CrossRef][Green Version]

- Dixit, P.; Chen, X.; Miao, J.; Divakaran, S.; Preisser, R. Study of Surface Treatment Processes for Improvement in the Wettability of Silicon-Based Materials Used in High Aspect Ratio through-Via Copper Electroplating. Appl. Surf. Sci. 2007, 253, 8637–8646. [Google Scholar] [CrossRef]

- Song, J.-W.; Nam, Y.-H.; Park, M.-J.; Shin, S.-M.; Wehrspohn, R.B.; Lee, J.-H. Hydroxyl Functionalization Improves the Surface Passivation of Nanostructured Silicon Solar Cells Degraded by Epitaxial Regrowth. RSC Adv. 2015, 5, 39177–39181. [Google Scholar] [CrossRef]

- Allongue, P.; Kieling, V.C.; Gerischer, H. Etching of Silicon in NaOH Solutions I. In Situ Scanning Tunneling Microscopic Investigation of n-Si(111). J. Electrochem. Soc. 1993, 140, 1009–1018. [Google Scholar] [CrossRef]

- Allongue, P.; Kieling, V.C.; Gerischer, H. Etching of Silicon in Naoh Solutions II. Electrochemical Studies of n-Si(111) and (100) and Mechanism of the Dissolution. J. Electrochem. Soc. 1993, 140, 1018–1026. [Google Scholar] [CrossRef]

- Bressers, P.M.M.C.; Kelly, J.J.; Gardeniers, J.G.E.; Elwenspoek, M. Surface Morphology of p-Type (100) Silicon Etched in Aqueous Alkaline Solution. J. Electrochem. Soc. 1996, 143, 1744–1750. [Google Scholar] [CrossRef]

- Hu, W.; Xu, C.Y.; Niu, L.B.; Elseman, A.M.; Wang, G.; Liu, B.; Yao, Y.Q.; Liao, L.P.; Zhou, G.D.; Song, Q.L. High Open-Circuit Voltage of 1.134 V for Inverted Planar Perovskite Solar Cells with Sodium Citrate-Doped PEDOT:PSS as a Hole Transport Layer. ACS Appl. Mater. Interfaces 2019, 11, 22021–22027. [Google Scholar] [CrossRef]

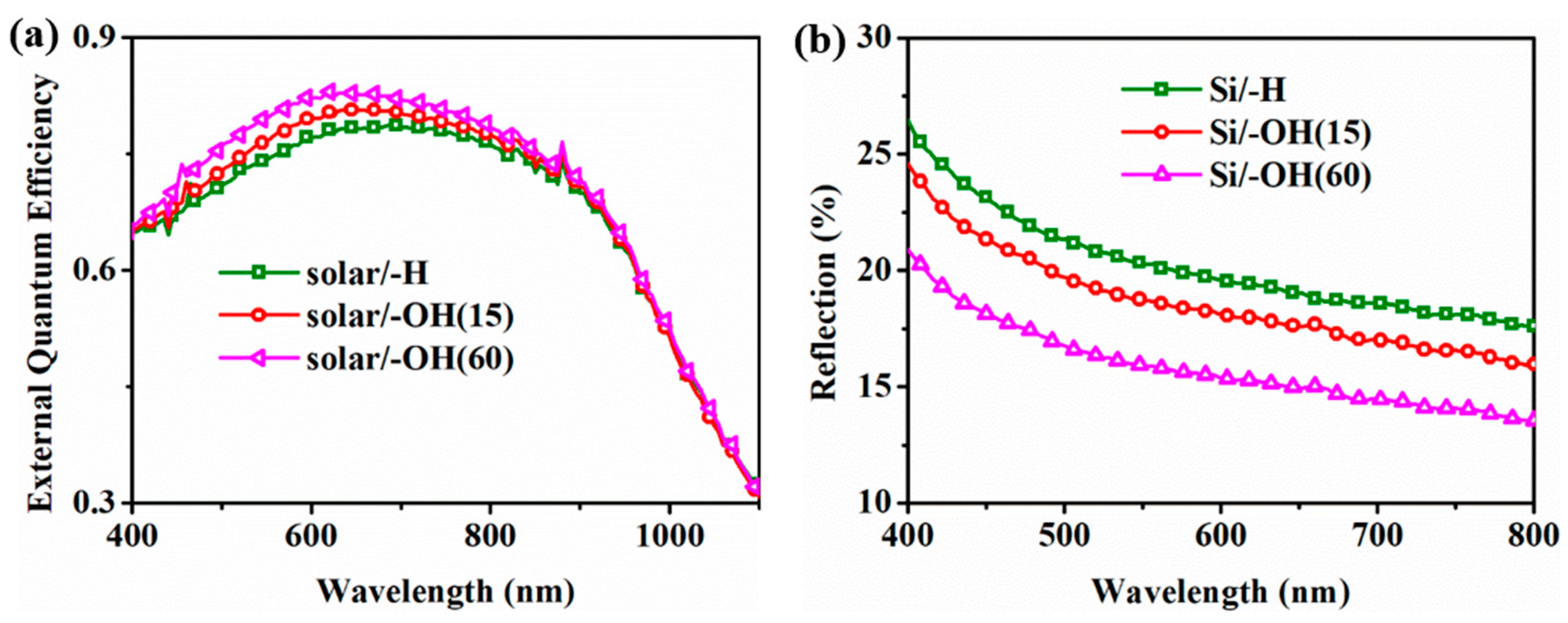

| Performance Parameter | PCE (%) | Voc (eV) | Jsc (mA/cm2) | FF (%) |

|---|---|---|---|---|

| solar/–H | 9.4 ± 0.7 | 556 ± 3 | 32.4 ± 0.7 | 48.9 ± 3.2 |

| (10.01) | (553) | (33.24) | (53.6) | |

| solar/–OH(5) | 10.4 ± 0.6 | 555 ± 3 | 33.1 ± 1.0 | 56.7 ± 4.3 |

| (11.04) | (556) | (33.56) | (59.2) | |

| solar/–OH(15) | 11.3 ± 0.6 | 559 ± 3 | 33.9 ± 1.0 | 59.5 ± 2.4 |

| (12.05) | (559) | (34.95) | (61.73) | |

| solar/–OH(30) | 11.1 ± 0.6 | 560 ± 7 | 34.7 ± 0.7 | 58.1 ± 3.6 |

| (11.98) | (555) | (35.67) | (60.58) | |

| solar/–OH(45) | 10.7 ± 0.9 | 553 ± 2 | 34.4 ± 1.0 | 56.4 ± 3.7 |

| (11.10) | (555) | (35.48) | (58.91) | |

| solar/–OH(60) | 10.3 ± 0.8 | 556 ± 3 | 36.0 ± 1.5 | 55.1 ± 3.9 |

| (10.83) | (555) | (36.29) | (55.23) |

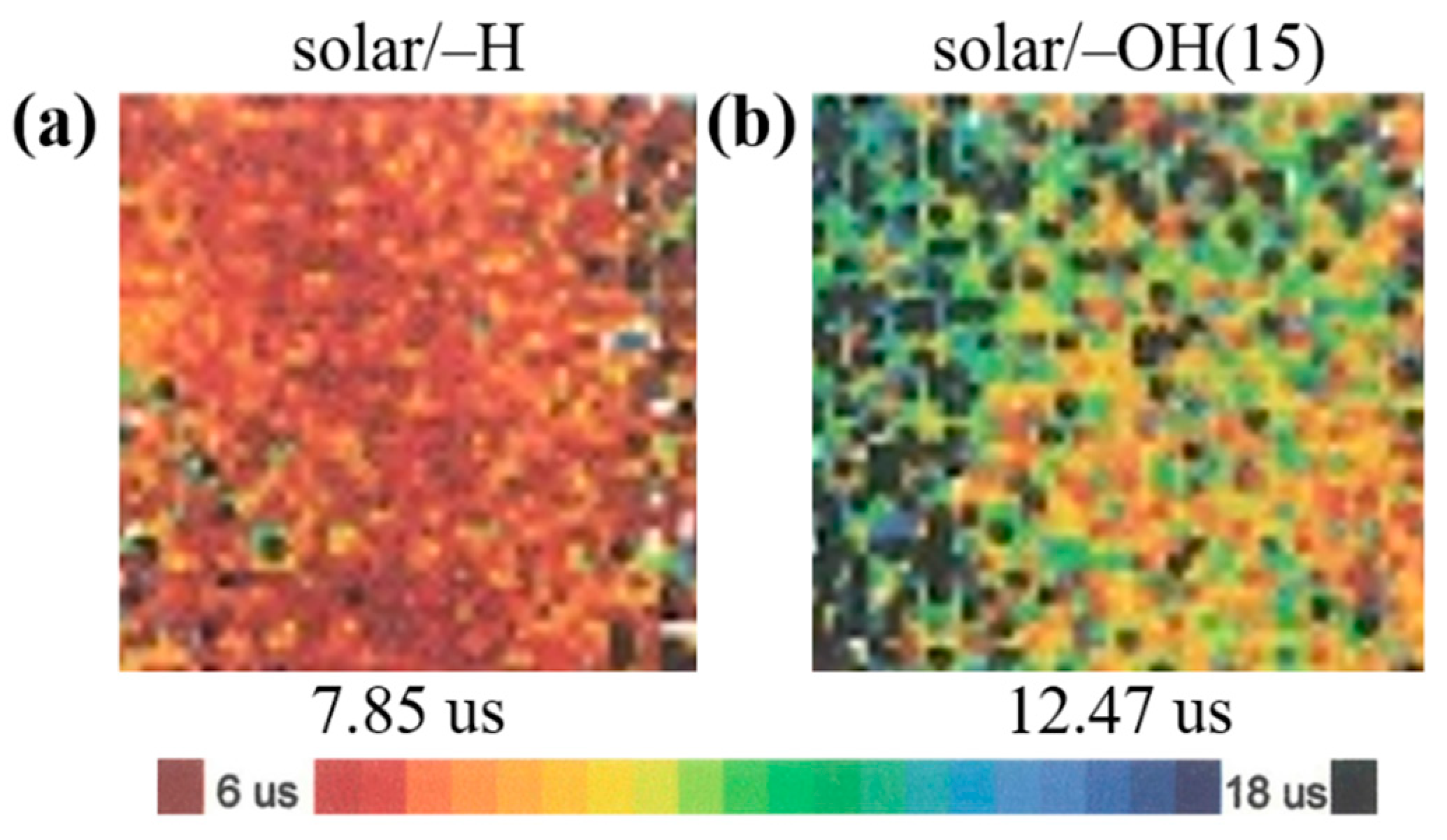

| Device | Rs (ohm) | Rrec (ohm) | C1 (F) | τ (μs) |

|---|---|---|---|---|

| solar/–H | 5.872 | 2770 | 1.33 × 10−7 | 368.41 |

| solar/–OH(5) | 4.284 | 3500 | 1.39 × 10−7 | 486.5 |

| solar/–OH(15) | 2.489 | 4938 | 1.33 × 10−7 | 656.75 |

| solar/–OH(30) | 2.667 | 4647 | 1.36 × 10−7 | 631.99 |

| solar/–OH(45) | 2.749 | 3907 | 1.35 × 10−7 | 527.45 |

| solar/–OH(60) | 2.758 | 3626 | 1.32 × 10−7 | 478.63 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Guo, H.; Yu, L.; Sun, T.; Yang, Y. Silicon Substrate Treated with Diluted NaOH Aqueous for Si/PEDOT: PSS Heterojunction Solar Cell with Performance Enhancement. Energies 2020, 13, 4659. https://doi.org/10.3390/en13184659

Chen T, Guo H, Yu L, Sun T, Yang Y. Silicon Substrate Treated with Diluted NaOH Aqueous for Si/PEDOT: PSS Heterojunction Solar Cell with Performance Enhancement. Energies. 2020; 13(18):4659. https://doi.org/10.3390/en13184659

Chicago/Turabian StyleChen, Tao, Hao Guo, Leiming Yu, Tao Sun, and Yu Yang. 2020. "Silicon Substrate Treated with Diluted NaOH Aqueous for Si/PEDOT: PSS Heterojunction Solar Cell with Performance Enhancement" Energies 13, no. 18: 4659. https://doi.org/10.3390/en13184659

APA StyleChen, T., Guo, H., Yu, L., Sun, T., & Yang, Y. (2020). Silicon Substrate Treated with Diluted NaOH Aqueous for Si/PEDOT: PSS Heterojunction Solar Cell with Performance Enhancement. Energies, 13(18), 4659. https://doi.org/10.3390/en13184659