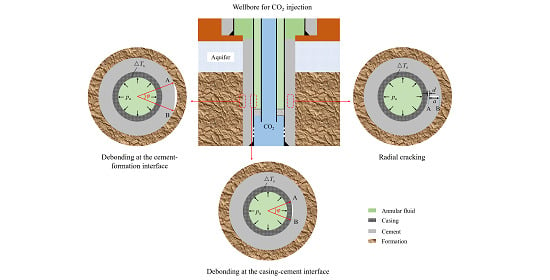

Cement Integrity Loss due to Interfacial Debonding and Radial Cracking during CO2 Injection

Abstract

1. Introduction

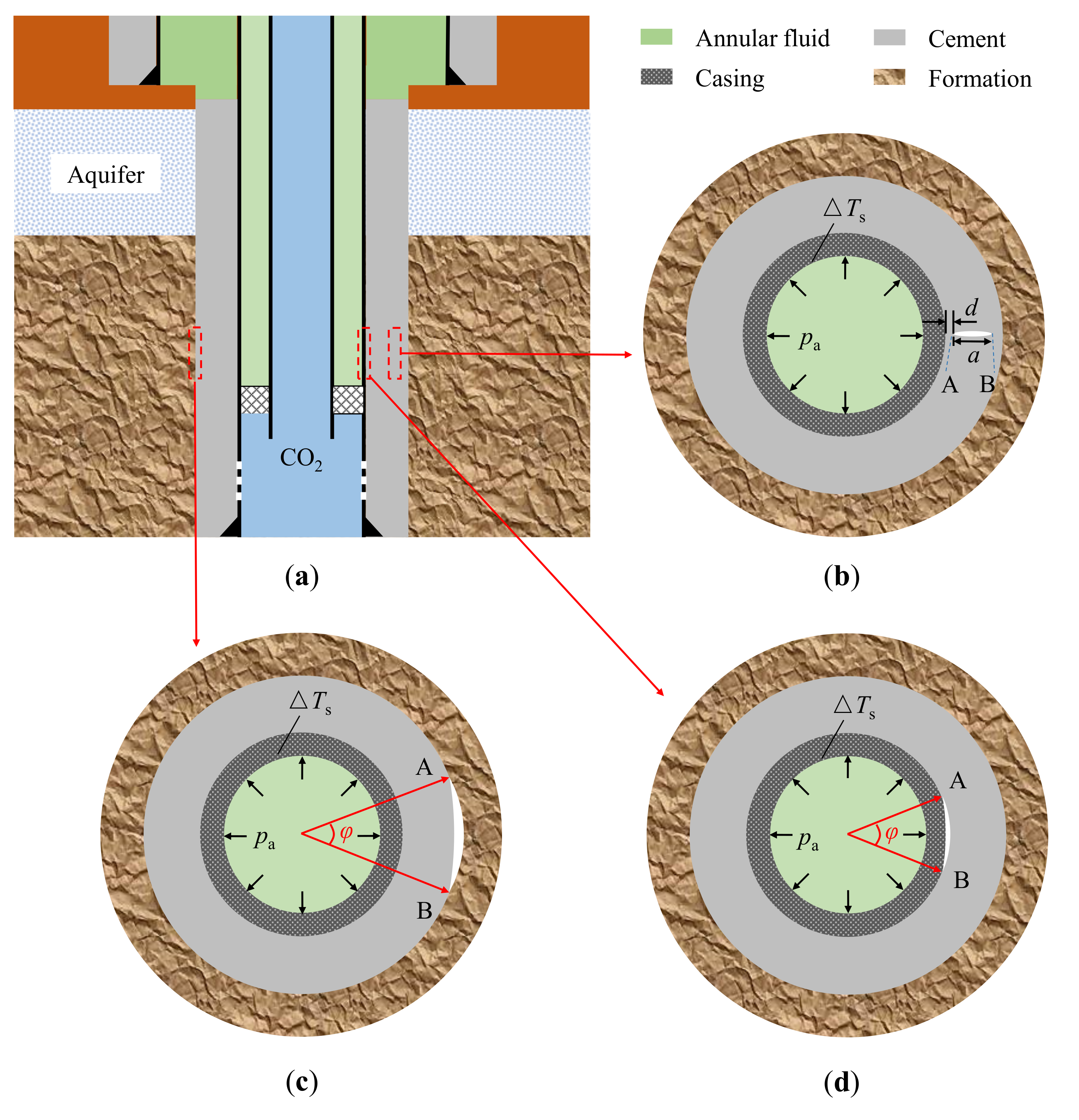

2. Modeling for Crack Propagation

2.1. Basic Features of the Model

- (1)

- The model undertakes a plane strain condition to estimate the stress in the wellbore, since the vertical deformation is much smaller than the horizontal deformation [30];

- (2)

- The casing, cement, and formation are all linear isotropic elastic materials. Although this assumption is not practical, it is sufficient to describe the mechanical responses of cracks and may reduce the computational time [26];

- (3)

- Because of the linear elastic property, once the wellbore is drilled, the stress on its inner surface is released. After this, the current model does not apply in situ stress to the well section;

- (4)

- This model does not consider the cement’s initial stress after setting, since its calculation is controversial both in academia and the industry. The prime purpose of the model is to provide the energy release rates of interfacial and radial cracks caused by the variations of the temperature and pressure;

- (5)

- The wellbore components are bonded rigidly, except for the interfacial cracks at the casing-cement and cement-formation interfaces;

- (6)

- Neglecting the thermal contact resistance at the interfaces, the model determines the temperature distribution through heat conduction analysis in the steady state.

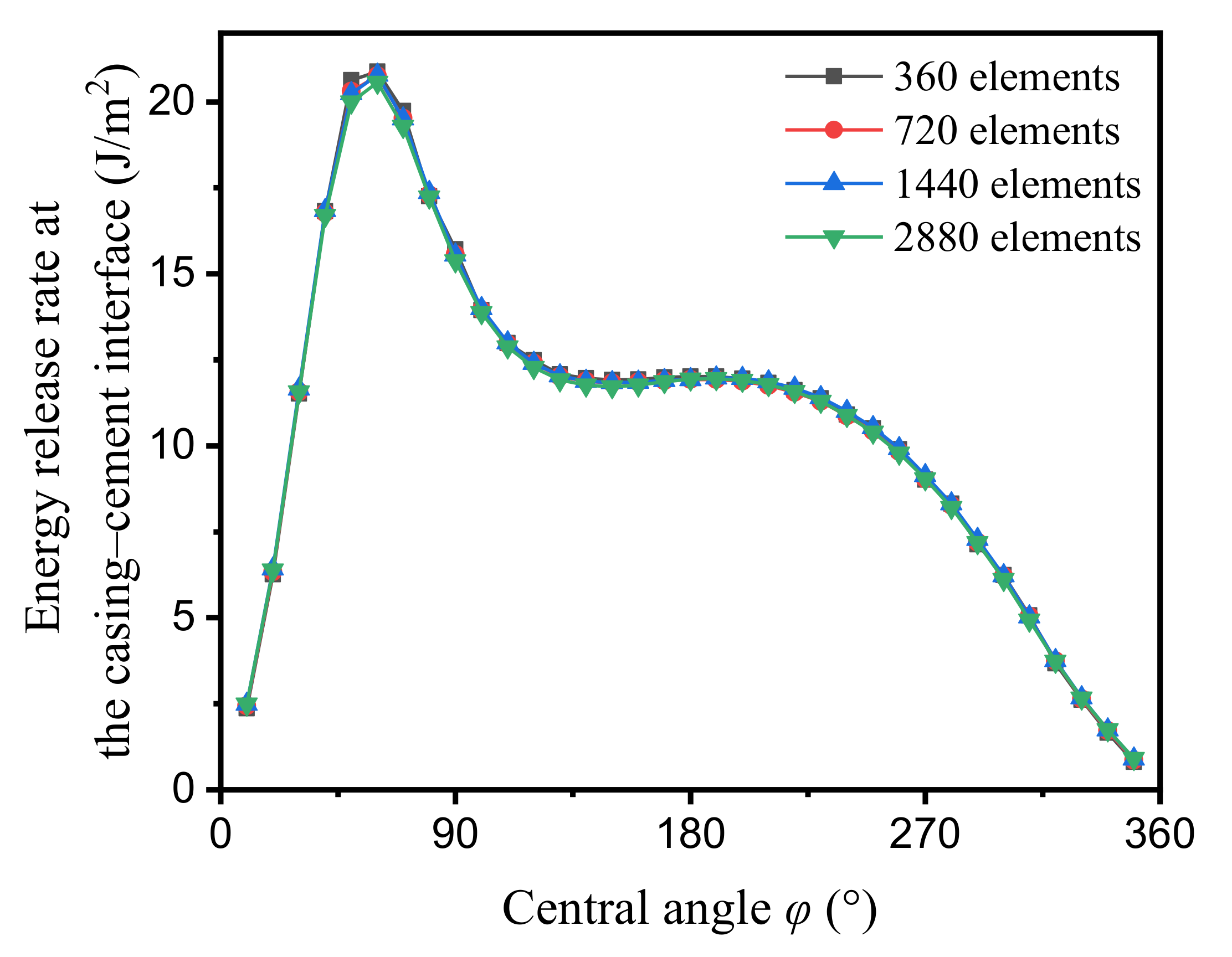

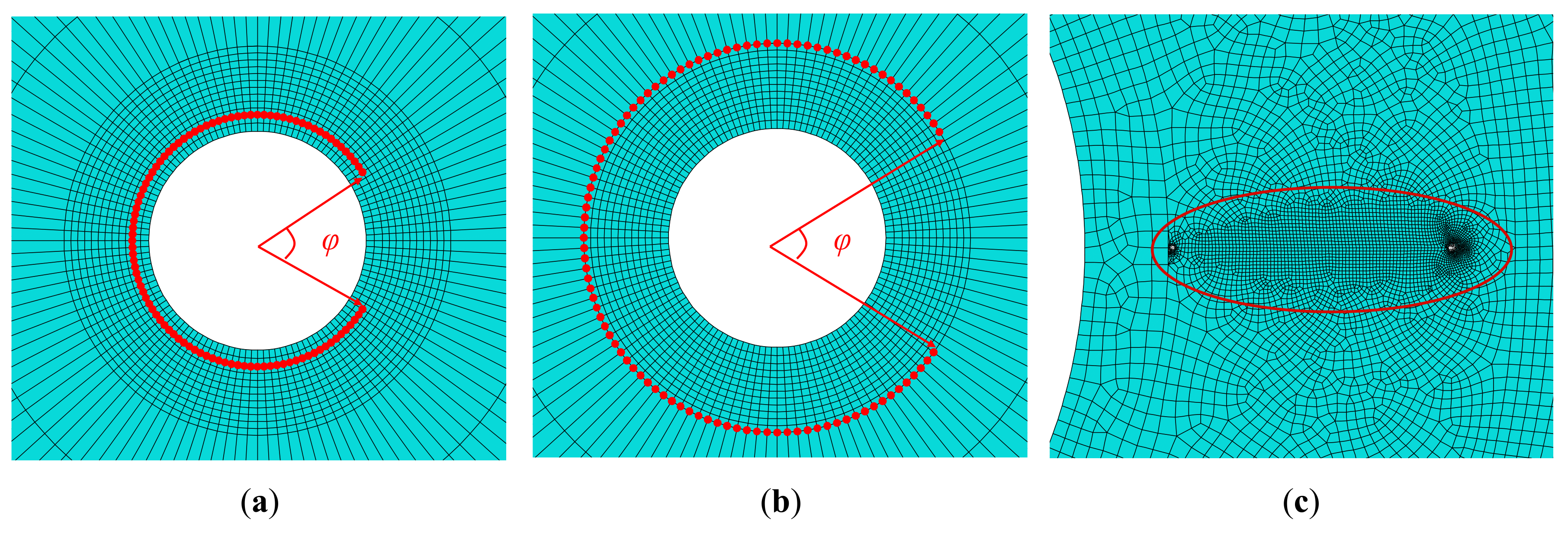

2.2. Modeling Approach

2.3. Model Parameters

3. Results

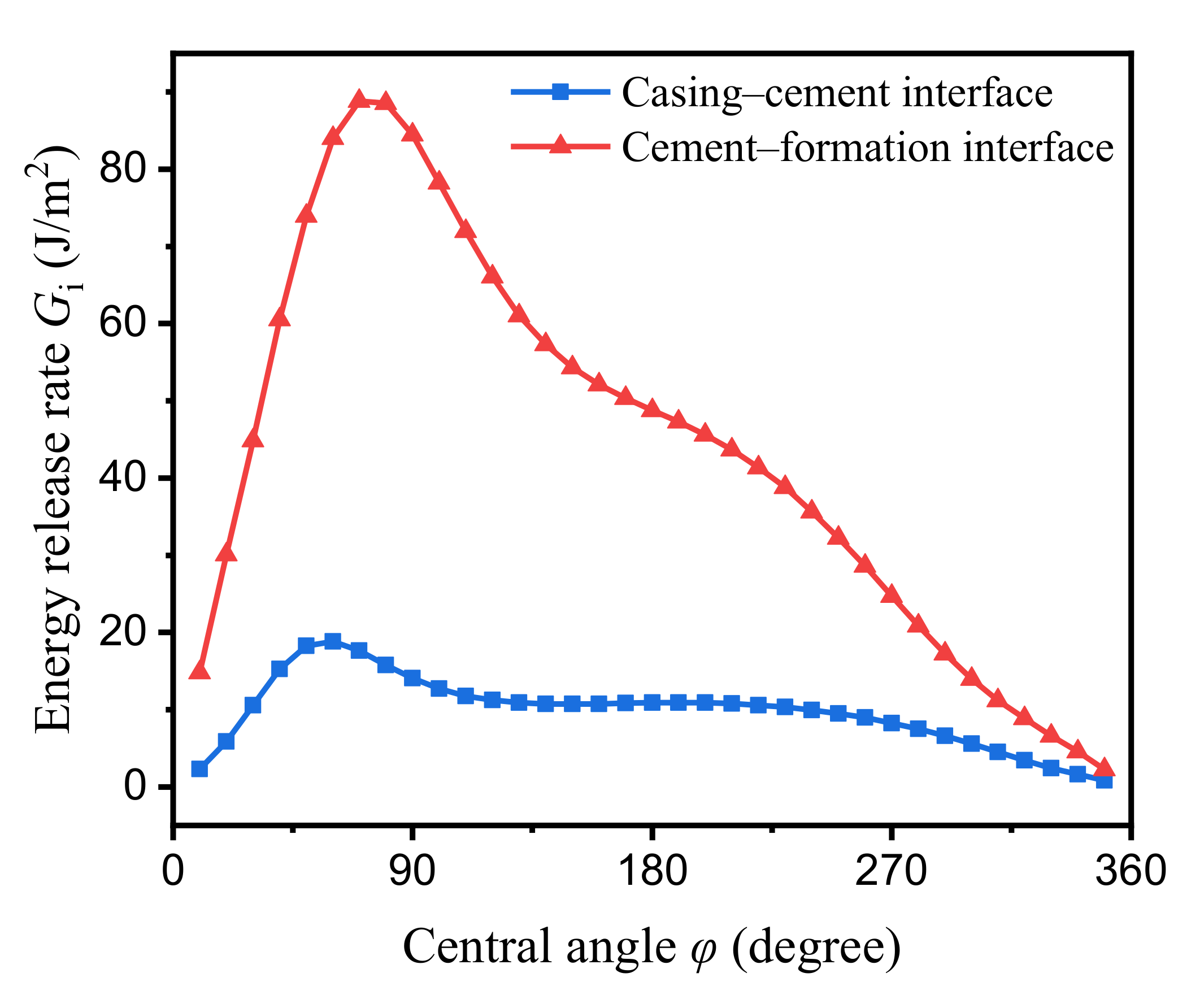

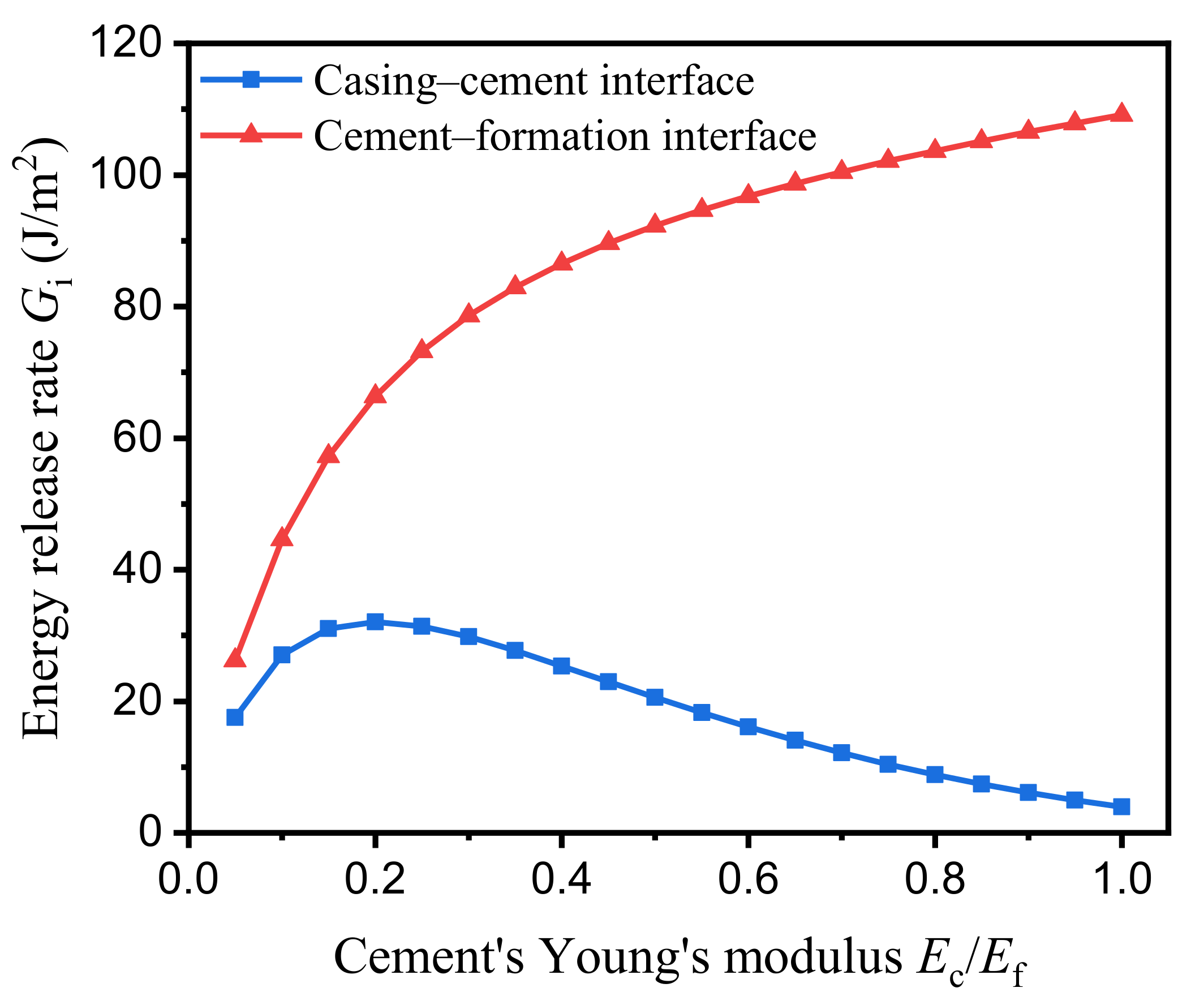

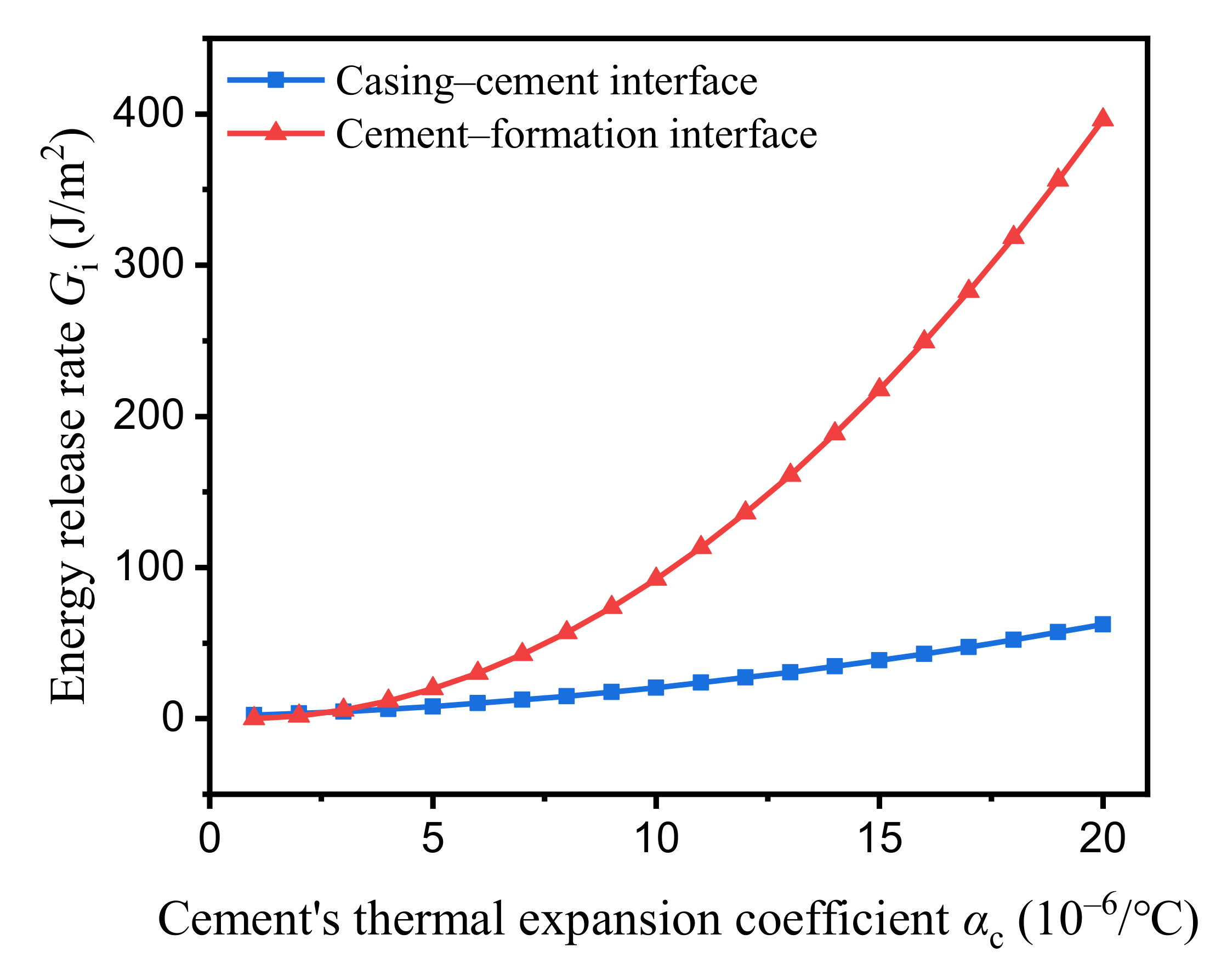

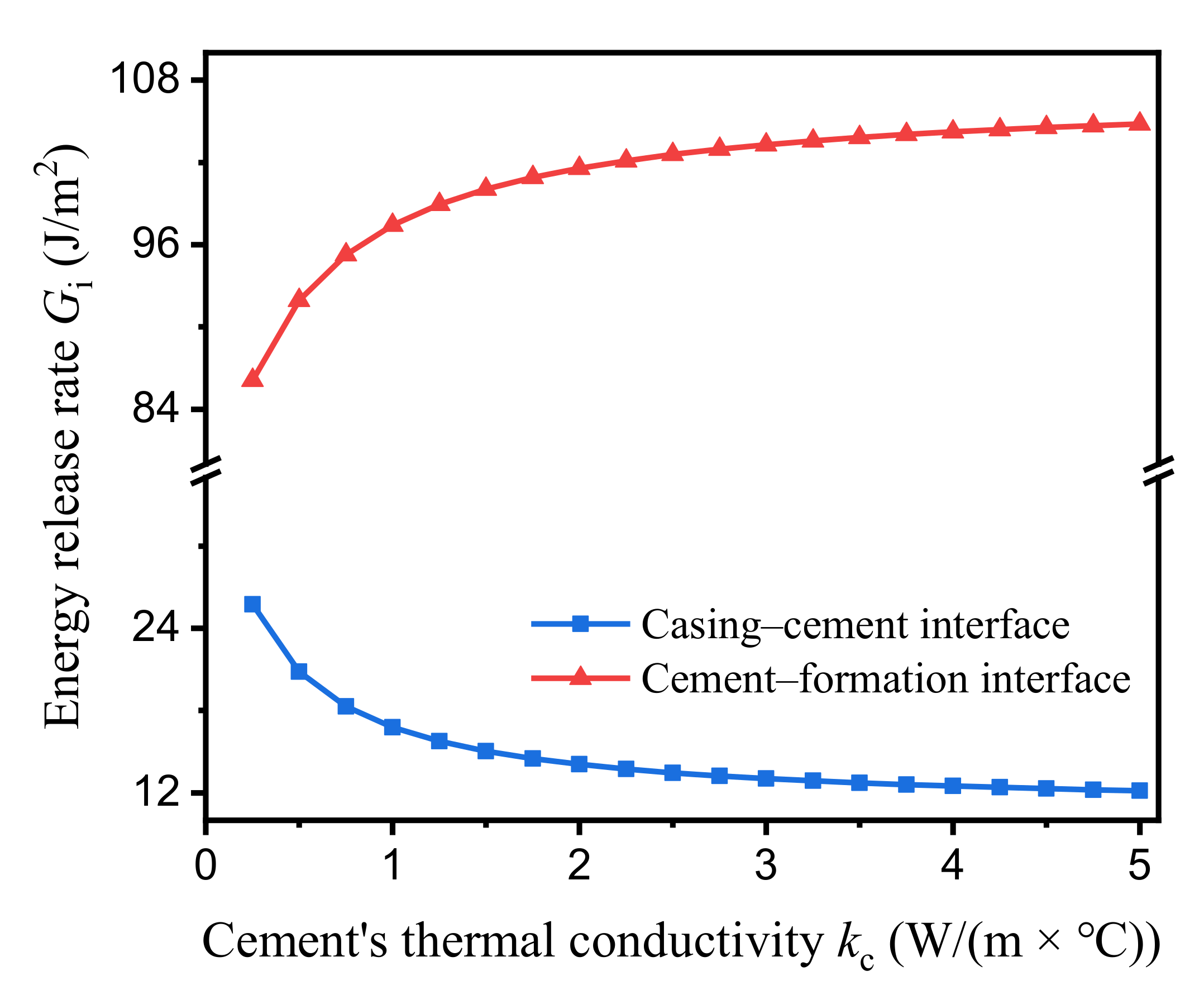

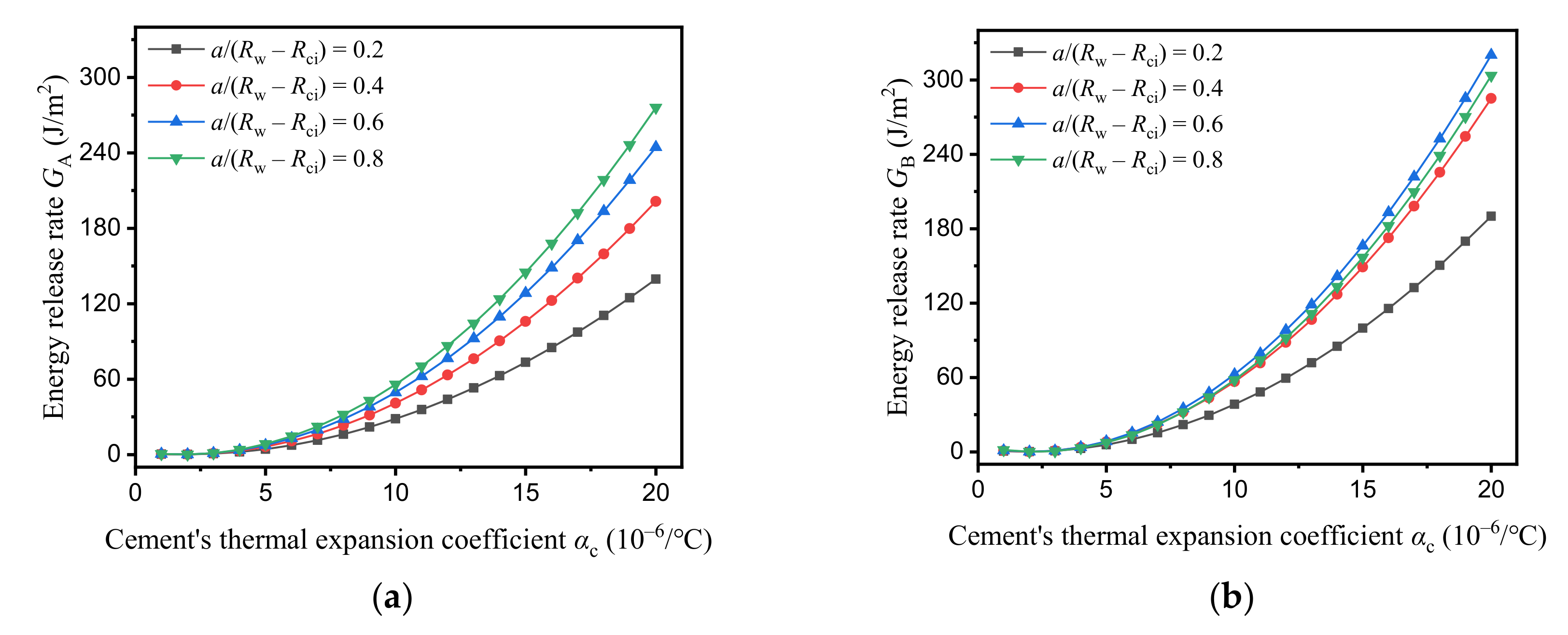

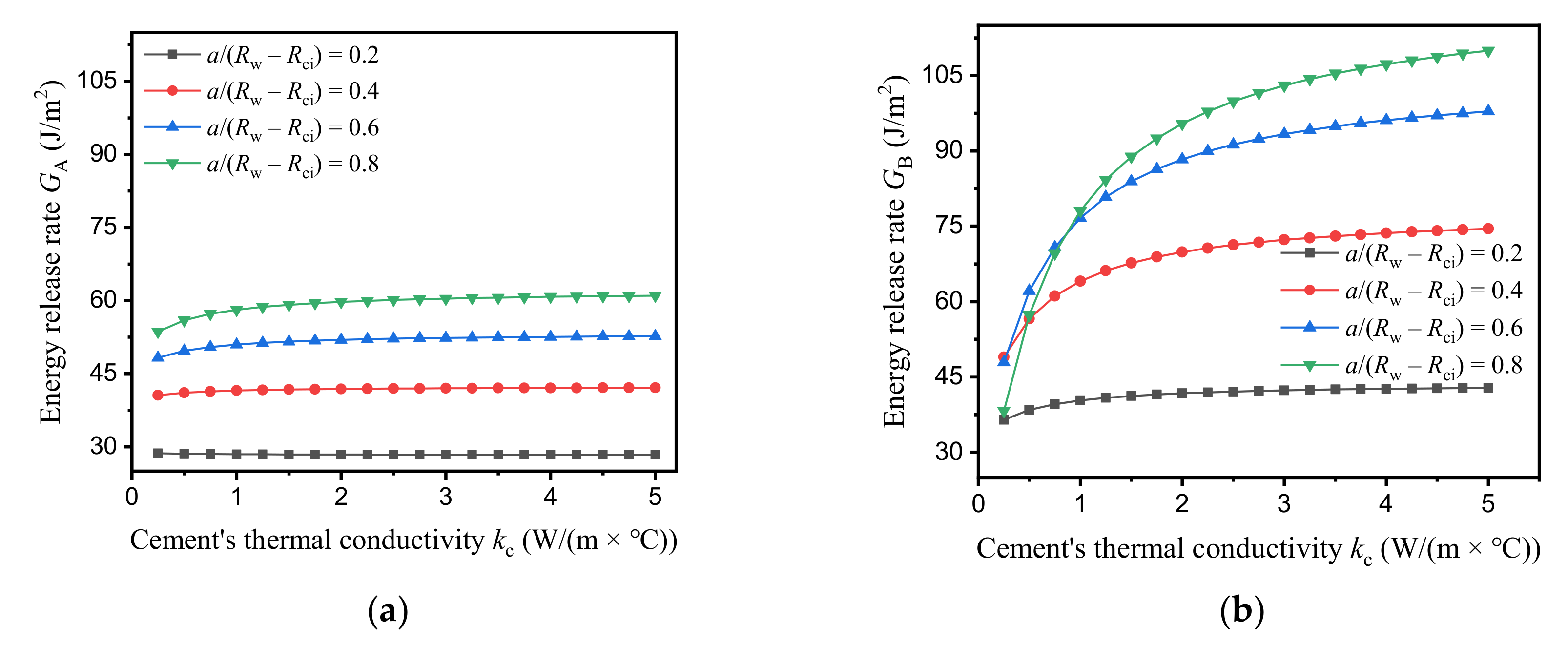

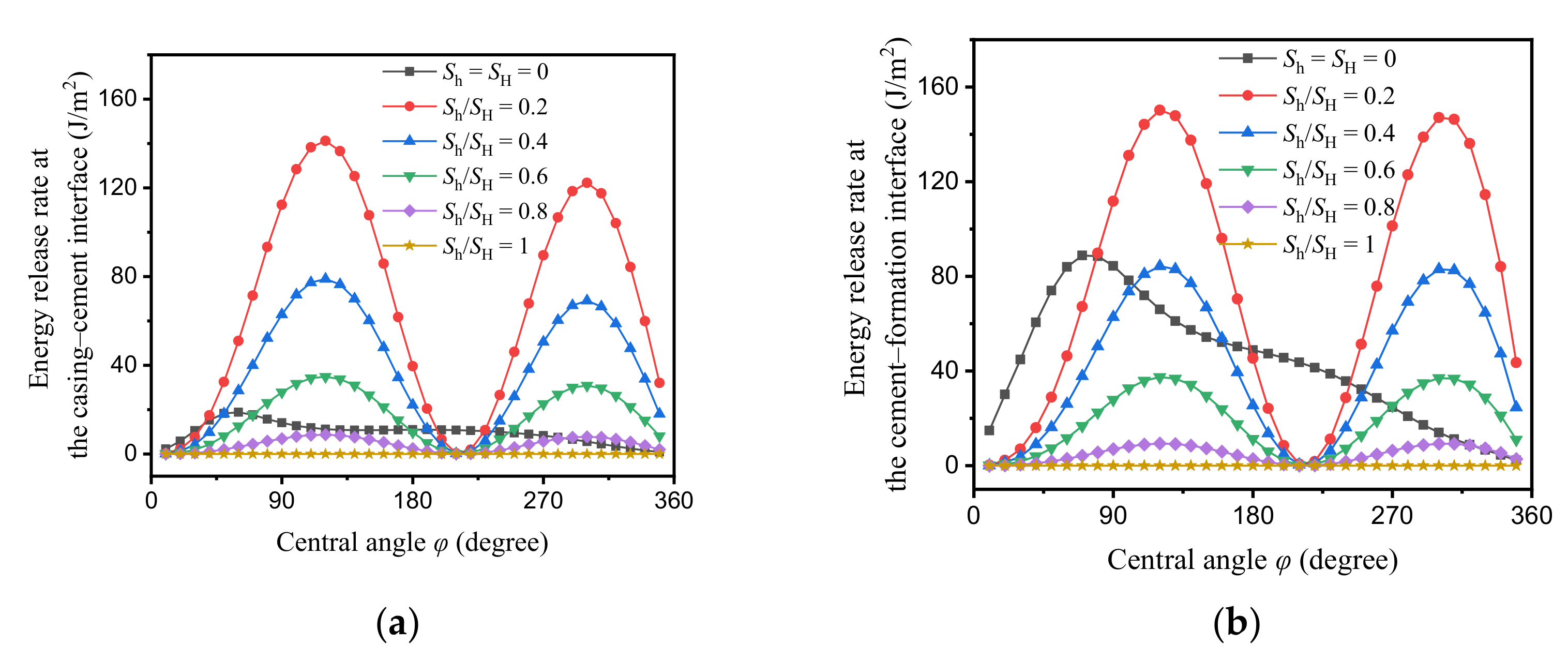

3.1. Interfacial Debonding

3.2. Radial Cracking

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar] [CrossRef]

- Eide, L.I.; Batum, M.; Dixon, T.; Elamin, Z.; Graue, A.; Hagen, S.; Hovorka, S.; Nazarian, B.; Nøkleby, P.H.; Olsen, G.I.; et al. Enabling large-scale carbon capture, utilisation, and storage (CCUS) using offshore carbon dioxide (CO2) infrastructure developments—A review. Energies 2019, 12, 1945. [Google Scholar] [CrossRef]

- IEA Transforming Industry through CCUS. 2019. Available online: https://www.iea.org/reports/transforming-industry-through-ccus (accessed on 31 May 2019).

- Alcalde, J.; Flude, S.; Wilkinson, M.; Johnson, G.; Edlmann, K.; Bond, C.E.; Scott, V.; Smv, G.; Ogaya, X.; Haszeldine, R.S. Estimating geological CO2 storage security to deliver on climate mitigation. Nat. Commun. 2018, 9, 2201. [Google Scholar] [CrossRef]

- Bois, A.-P.; Vu, M.-H.; Ghabezloo, S.; Sulem, J.; Garnier, A.; Laudet, J.-B. Cement sheath integrity for CO2 storage—An integrated perspective. Energy Procedia 2013, 37, 5628–5641. [Google Scholar] [CrossRef]

- Lackey, G.; Vasylkivska, V.S.; Huerta, N.J.; King, S.; Dilmore, R.M. Managing well leakage risks at a geologic carbon storage site with many wells. Int. J. Greenh. Gas Control 2019, 88, 182–194. [Google Scholar] [CrossRef]

- Wu, Y.; Patel, H.; Salehi, S.; Mokhtari, M. Experimental and finite element modelling evaluation of cement integrity under diametric compression. J. Petrol. Sci. Eng. 2020, 188, 106844. [Google Scholar] [CrossRef]

- Lavrov, A.; Torsæter, M. Physics and Mechanics of Primary Well Cementing; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Carroll, S.; Carey, J.W.; Dzombak, D.; Huerta, N.J.; Li, L.; Richard, T.; Um, W.; Walsh, S.D.C.; Zhang, L. Review: Role of chemistry, mechanics, and transport on well integrity in CO2 storage environments. Int. J. Greenh. Gas Control 2016, 49, 149–160. [Google Scholar] [CrossRef]

- Wang, W.; Taleghani, A.D. Three-dimensional analysis of cement sheath integrity around Wellbores. J. Petrol. Sci. Eng. 2014, 121, 38–51. [Google Scholar] [CrossRef]

- Todorovic, J.; Gawel, K.; Lavrov, A.; Torsæter, M. Integrity of downscaled well models subject to cooling. In SPE Bergen One Day Semina; Society of Petroleum Engineers: Grieghallen, Bergen, Norway, 2016. [Google Scholar]

- Albawi, A.; De Andrade, J.; Torsæter, M.; Opedal, N.; Stroisz, A.; Vrålstad, T. Experimental set-up for testing cement sheath integrity in Arctic wells. In Proceedings of the OTC Arctic Technology Conference, Houston, TX, USA, 10–12 February 2014. [Google Scholar]

- De Andrade, J.; Sangesland, S.; Todorovic, J.; Vrålstad, T. Cement sheath integrity during thermal cycling: A novel approach for experimental tests of cement systems. In Proceedings of the SPE Bergen One Day Seminar, Bergen, Norway, 22 April 2015. [Google Scholar]

- Carpenter, R.B.; Brady, J.L.; Blount, C.G. The effects of temperature and cement admixes on bond strength. J. Petrol. Technol. 1992, 44, 936–941. [Google Scholar] [CrossRef]

- Bois, A.-P.; Garnier, A.; Galdiolo, G.; Laudet, J.-B. Use of a mechanistic model to forecast cement-sheath integrity. SPE Drill. Complet. 2012, 27, 303–314. [Google Scholar] [CrossRef]

- Liu, K.; Gao, D.; Taleghani, A.D. Impact of casing eccentricity on cement sheath. Energies 2018, 11, 2557. [Google Scholar] [CrossRef]

- Thiercelin, M.J.; Dargaud, B.; Baret, J.F.; Rodriquez, W.J. Cement Design Based on Cement Mechanical Response. SPE Drill. Complet. 1998, 13, 266–273. [Google Scholar] [CrossRef]

- Wu, J.; Knauss, M.E. Casing temperature and stress analysis in steam-injection wells. In Proceedings of the International Oil & Gas Conference and Exhibition in China, Beijing, China, 5–7 December 2006. [Google Scholar]

- Zhang, L.; Yan, X.; Yang, X.; Zhao, X. Evaluation of wellbore integrity for HTHP gas wells under solid-temperature coupling using a new analytical model. J. Nat. Gas Sci. Eng. 2015, 25, 347–358. [Google Scholar] [CrossRef]

- Bois, A.-P.; Garnier, A.; Rodot, F.; Sain-Marc, J.; Aimard, N. How to prevent loss of zonal isolation through a comprehensive analysis of microannulus formation. SPE Drill. Complet. 2011, 26, 13–31. [Google Scholar] [CrossRef]

- Nygaard, R.; Salehi, S.; Weideman, B.; Lavoie, R.G. Effect of dynamic loading on wellbore leakage for the Wabamun area CO2-sequestration project. J. Can. Petrol. Technol. 2014, 53, 69–82. [Google Scholar] [CrossRef]

- Aursand, P.; Hammer, M.; Lavrov, A.; Lund, H.; Munkejord, S.T.; Torsæter, M. Well integrity for CO2 injection from ships: Simulation of the effect of flow and material parameters on thermal stresses. Int. J. Greenh. Gas Control 2017, 62, 130–141. [Google Scholar] [CrossRef]

- Kiran, R.; Teodoriu, C.; Dadmohammadi, Y.; Nygaard, R.; Wood, D.; Mokhtari, M.; Salehi, S. Identification and evaluation of well integrity and causes of failure of well integrity barriers (A review). J. Nat. Gas Sci. Eng. 2017, 45, 511–526. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 3rd ed; Taylor Francis: Milton Park, UK, 2005. [Google Scholar]

- Petersen, T.A.; Ulm, F.-J. Radial fracture in a three-phase composite: Application to wellbore cement liners at early ages. Eng. Fract. Mech. 2016, 154, 272–287. [Google Scholar] [CrossRef]

- Dong, X.; Duan, Z.; Qu, Z.; Gao, D. Failure analysis for the cement with radial cracking in HPHT wells based on stress intensity factors. J. Petrol. Sci. Eng. 2019, 179, 558–564. [Google Scholar] [CrossRef]

- Wang, Z.; Lou, Y.; Suo, Z. Crack tunneling in cement sheath of hydrocarbon well. J. Appl. Mech. 2016, 83, 011002. [Google Scholar] [CrossRef]

- Andrade, J.D.; Sangesland, S. Cement sheath failure mechanisms: Numerical estimates to design for long-term well integrity. J. Petrol. Sci. Eng. 2016, 147, 682–698. [Google Scholar] [CrossRef]

- Roy, P.; Morris, J.P.; Walsh, S.D.C.; Iyer, J.; Carroll, S. Effect of thermal stress on wellbore integrity during CO2 injection. Int. J. Greenh. Gas Control 2018, 77, 14–26. [Google Scholar] [CrossRef]

- Dong, X.; Duan, Z.; Gao, D. Assessment on the cement integrity of CO2 injection wells through a wellbore flow model and stress analysis. J. Nat. Gas Sci. Eng. 2020, 74, 103097. [Google Scholar] [CrossRef]

- Hutchinson, J.W.; Suo, Z. Mixed Mode Cracking in Layered Materials. Adv. Appl. Mech. 1991, 29, 63–191. [Google Scholar]

- Xie, D.; Biggers, S.B. Progressive crack growth analysis using interface element based on the virtual crack closure technique. Finite Elem. Anal. Des. 2006, 42, 977–984. [Google Scholar] [CrossRef]

- Bachu, S.; Shaw, J.C.; Pearson, R.M. Estimation of oil recovery and CO2 storage capacity in CO2 EOR incorporating the effect of underlying aquifers. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar]

- Hwang, J.; Ahmed, R.; Tale, S.; Shah, S. Shear bond strength of oil well cement in carbonic acid environment. J. CO2 Util. 2018, 27, 60–72. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Taleghani, A.D.; Alem, N. Measurement of mixed mode interfacial strengths with cementitious materials. Eng. Fract. Mech. 2020, 223, 106739. [Google Scholar] [CrossRef]

- Lin, Y.; Karadelis, J.N. Interfacial fracture toughness of composite concrete beams. Constr. Build. Mater. 2019, 213, 413–423. [Google Scholar] [CrossRef]

- Lavrov, A. Stiff cement, soft cement: Nonlinearity, arching effect, hysteresis, and irreversibility in CO2-well integrity and near-well geomechanics. Int. J. Greenh. Gas Control 2018, 70, 236–242. [Google Scholar] [CrossRef]

- Loiseau, A. Thermal expansion of cement and well integrity of heavy oil wells. In Proceedings of the SPE Heavy and Extra Heavy Oil Conference: Latin America, Medellín, Colombia, 24–26 September 2014. [Google Scholar]

| Parameter | Casing | Cement | Formation |

|---|---|---|---|

| Inner radius (mm) | 60.68 | 69.85 | 107.95 |

| Outer radius (mm) | 69.85 | 107.96 | 1000 |

| Young’s modulus (GPa) | 200 | 10 | 20 |

| Poisson’s ratio | 0.3 | 0.23 | 0.2 |

| Thermal expansion coefficient (10−6/°C) | 12 | 10 | 11 |

| Thermal conductivity (w/(m × °C)) | 47 | 0.52 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, H.; Dong, X.; Duan, Z.; Ma, Y.; Gao, D. Cement Integrity Loss due to Interfacial Debonding and Radial Cracking during CO2 Injection. Energies 2020, 13, 4589. https://doi.org/10.3390/en13174589

Dou H, Dong X, Duan Z, Ma Y, Gao D. Cement Integrity Loss due to Interfacial Debonding and Radial Cracking during CO2 Injection. Energies. 2020; 13(17):4589. https://doi.org/10.3390/en13174589

Chicago/Turabian StyleDou, Haoyu, Xuelin Dong, Zhiyin Duan, Yinji Ma, and Deli Gao. 2020. "Cement Integrity Loss due to Interfacial Debonding and Radial Cracking during CO2 Injection" Energies 13, no. 17: 4589. https://doi.org/10.3390/en13174589

APA StyleDou, H., Dong, X., Duan, Z., Ma, Y., & Gao, D. (2020). Cement Integrity Loss due to Interfacial Debonding and Radial Cracking during CO2 Injection. Energies, 13(17), 4589. https://doi.org/10.3390/en13174589