Real-Time Construction Simulation Coupling a Concrete Temperature Field Interval Prediction Model with Optimized Hybrid-Kernel RVM for Arch Dams

Abstract

1. Introduction

- Establish a real-time construction simulation model that couples the concrete temperature field to realize a more accurate simulation.

- Propose a concrete temperature interval prediction model based on the hybrid-kernel relevance vector machine (HK-RVM) and the improved grasshopper optimization algorithm (IGOA) to obtain reliable prediction intervals of concrete temperature.

- Develop a concept drift detection method based on the variable window technology to update the prediction model.

2. Research Framework

3. Methodology

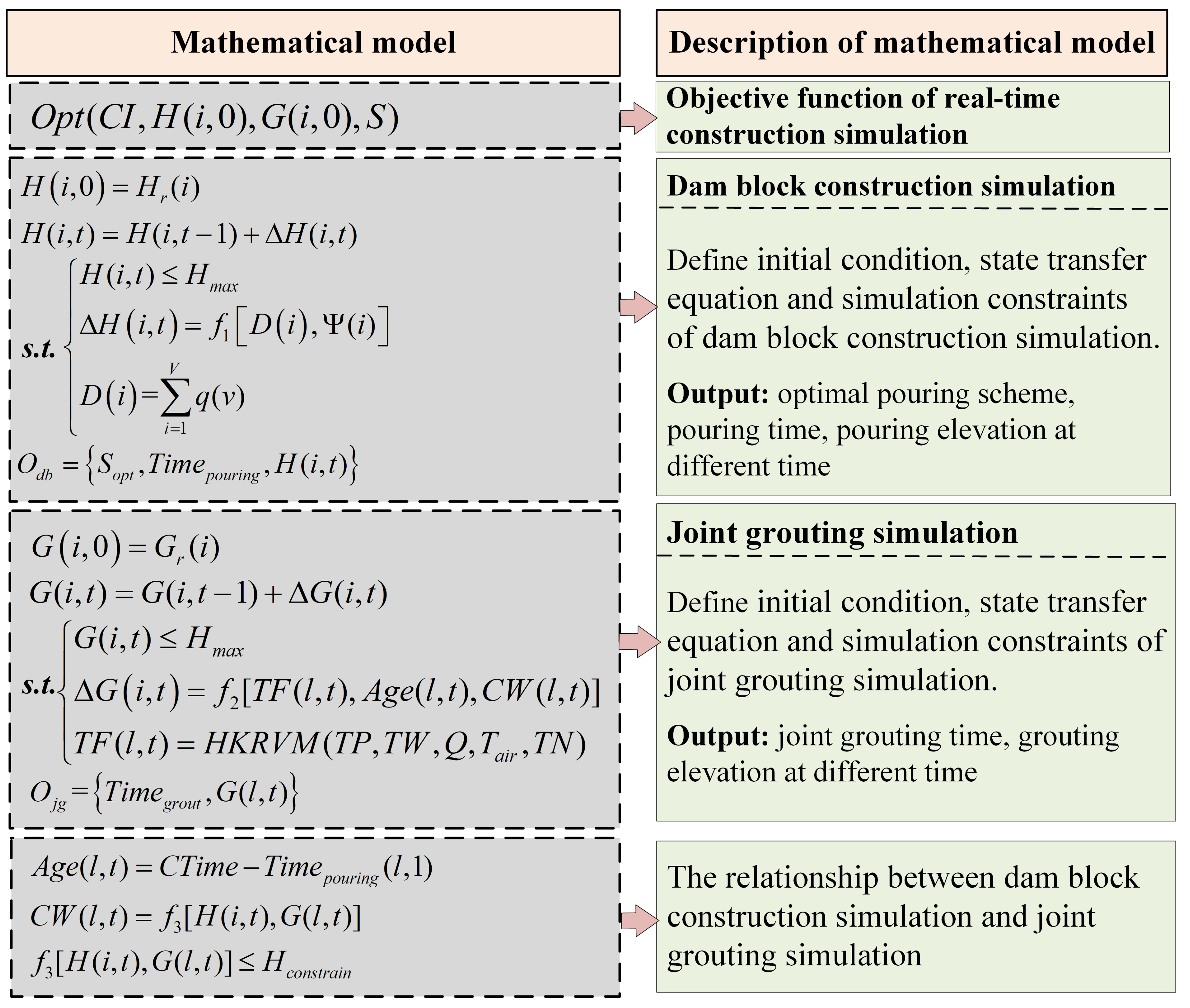

3.1. Problem Formulation

3.2. Concrete Temperature Field Prediction Model

3.2.1. Hybrid-Kernel Relevance Vector Machine

3.2.2. Improved Grasshopper Optimization Algorithm (IGOA)

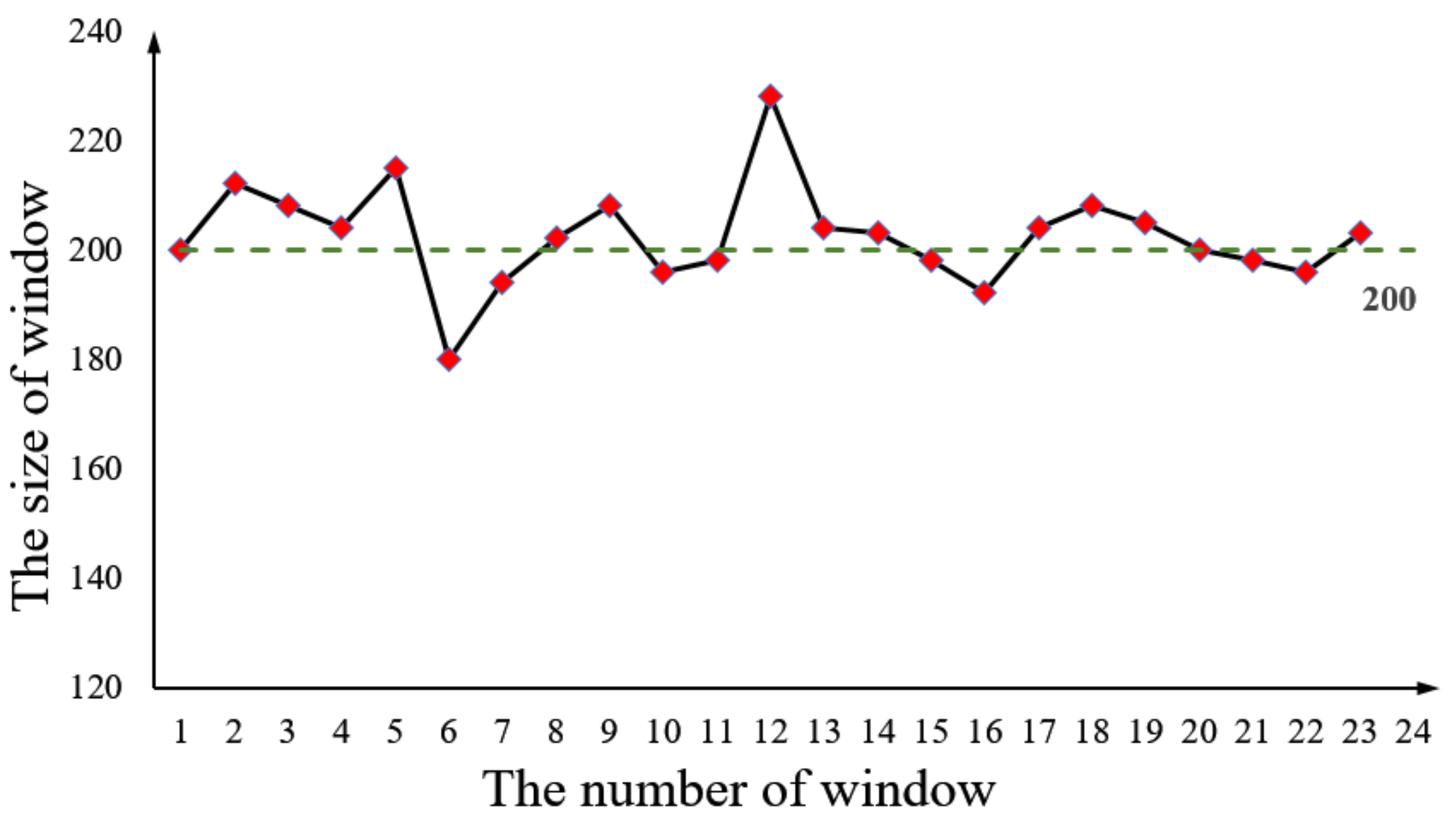

3.2.3. Concept Drift Detection for Model Updating

4. Case Study

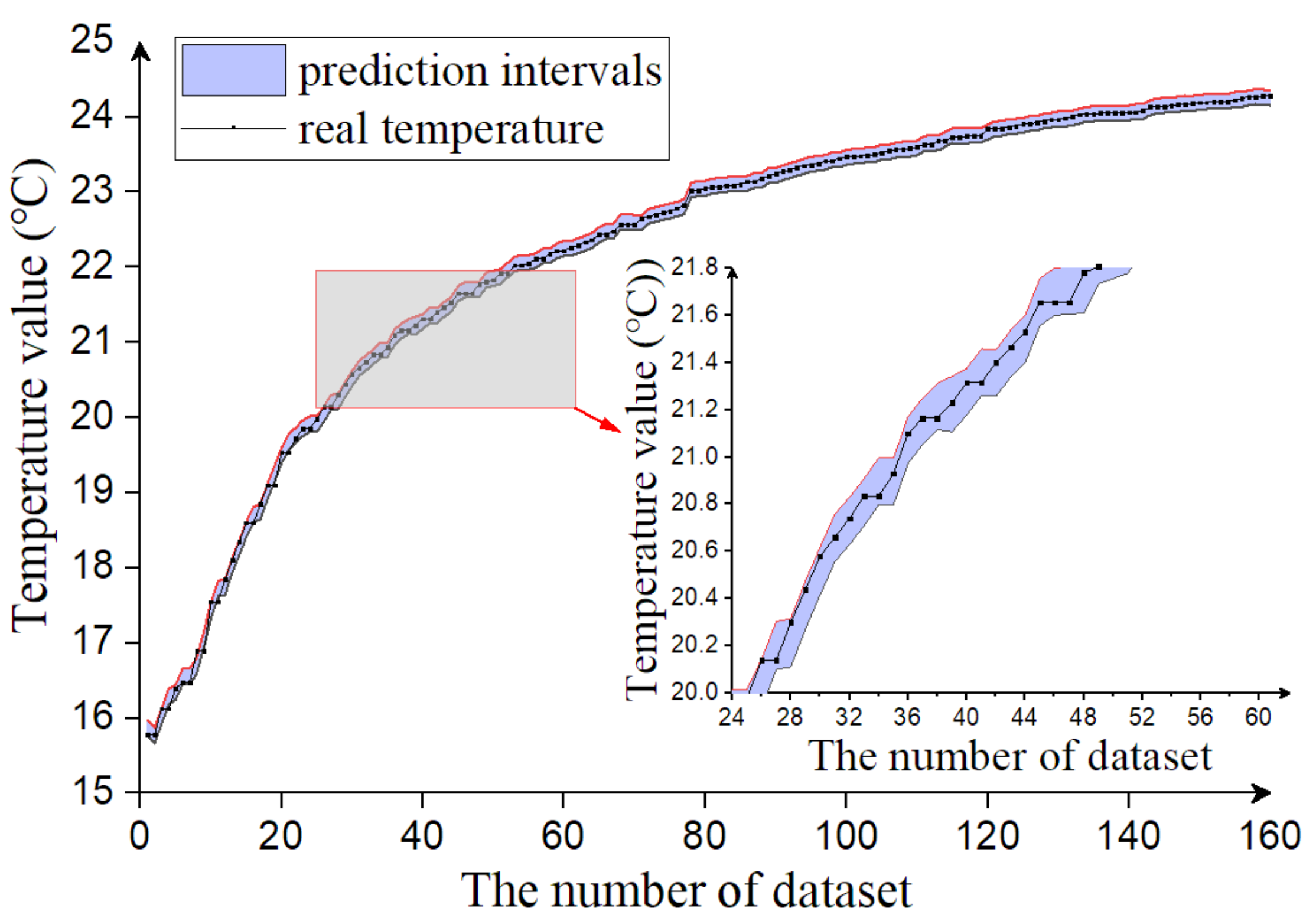

4.1. Temperature Interval Prediction Model

4.1.1. Temperature Data Description

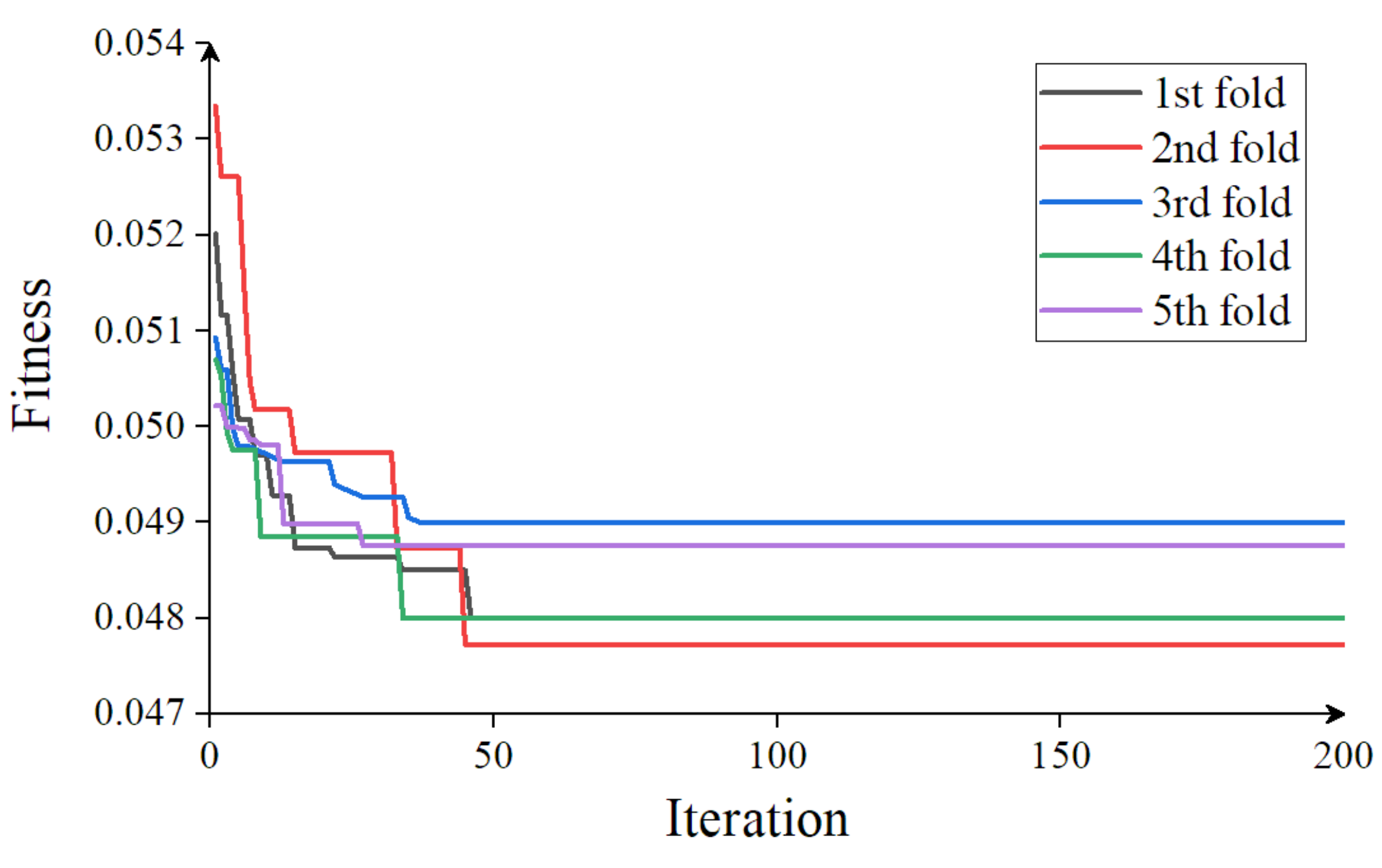

4.1.2. Model Establishment

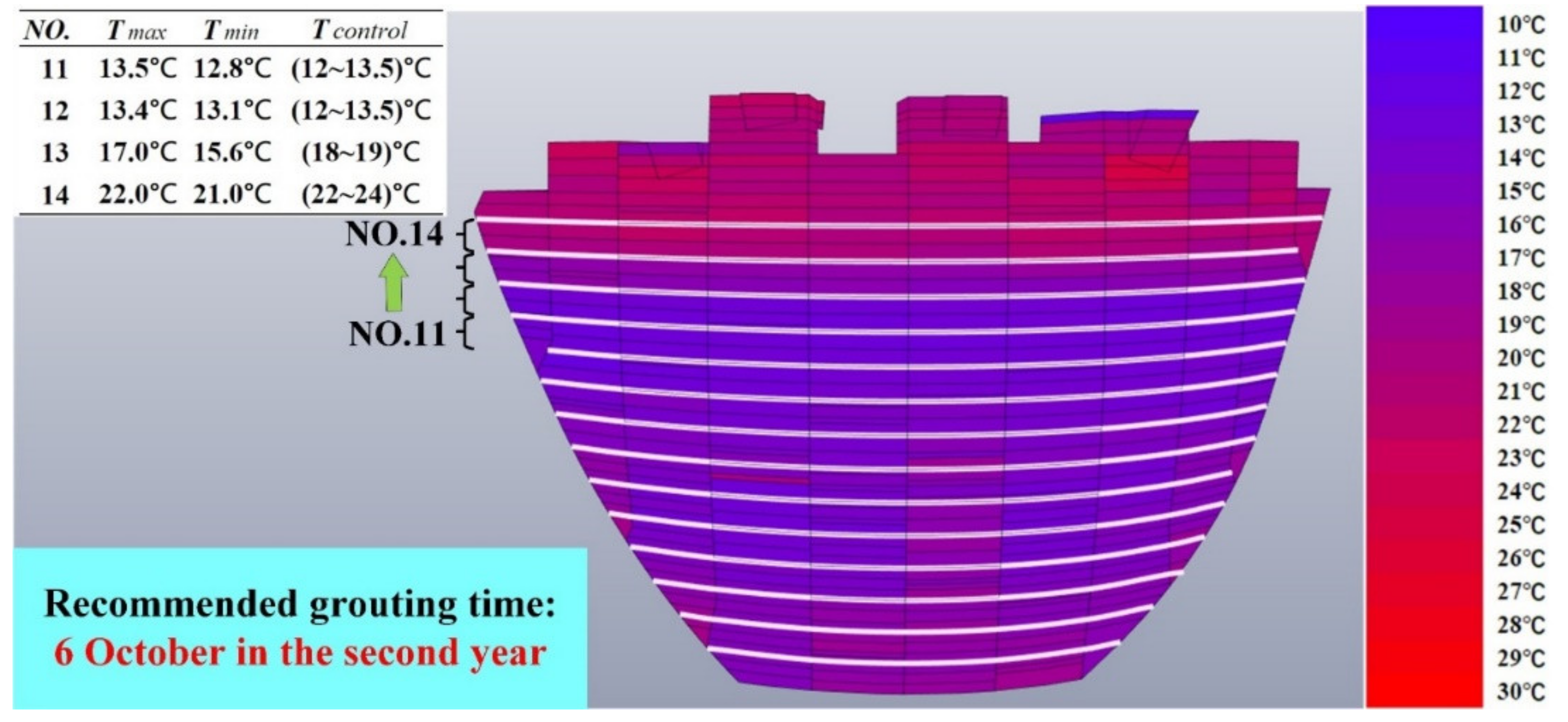

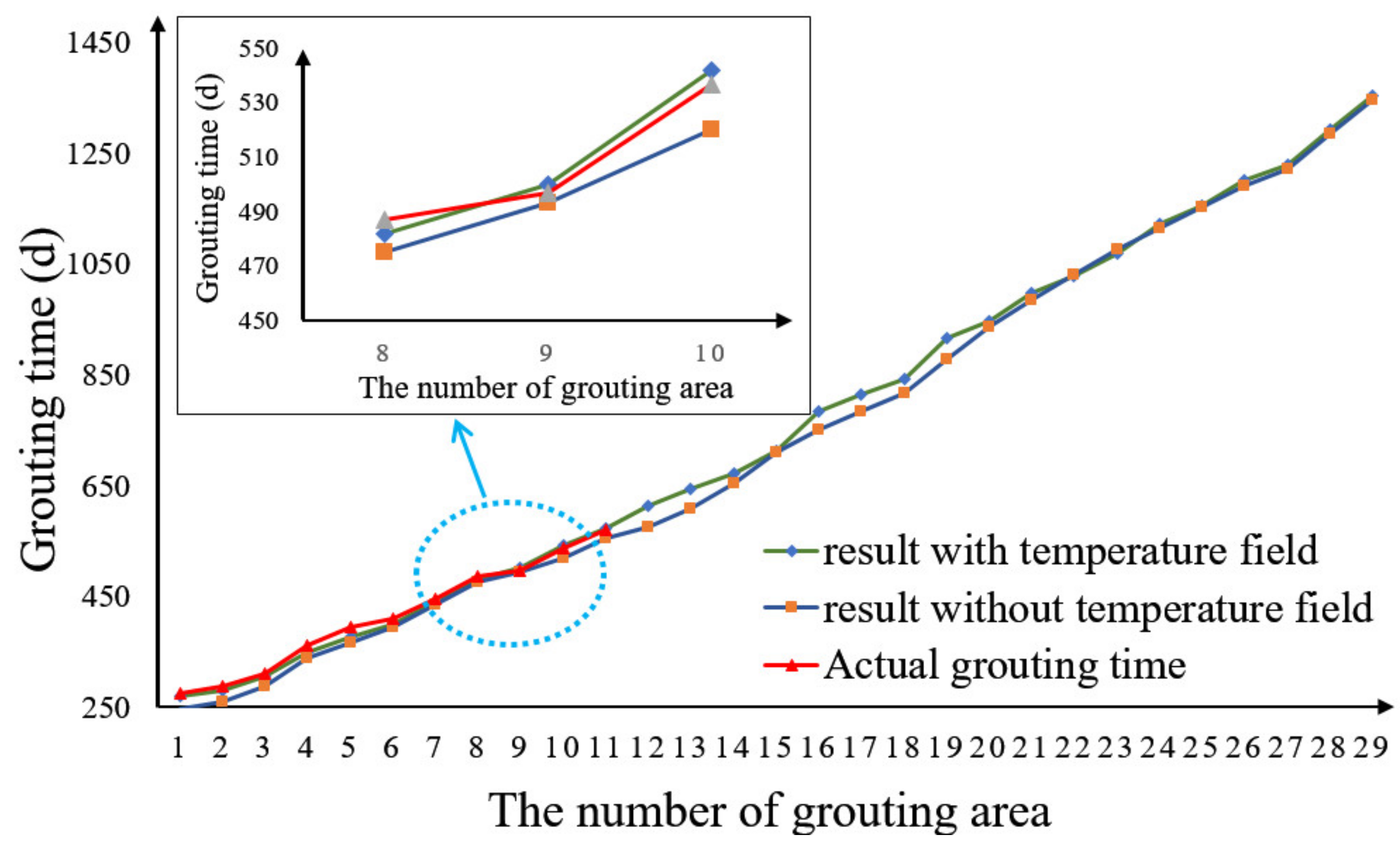

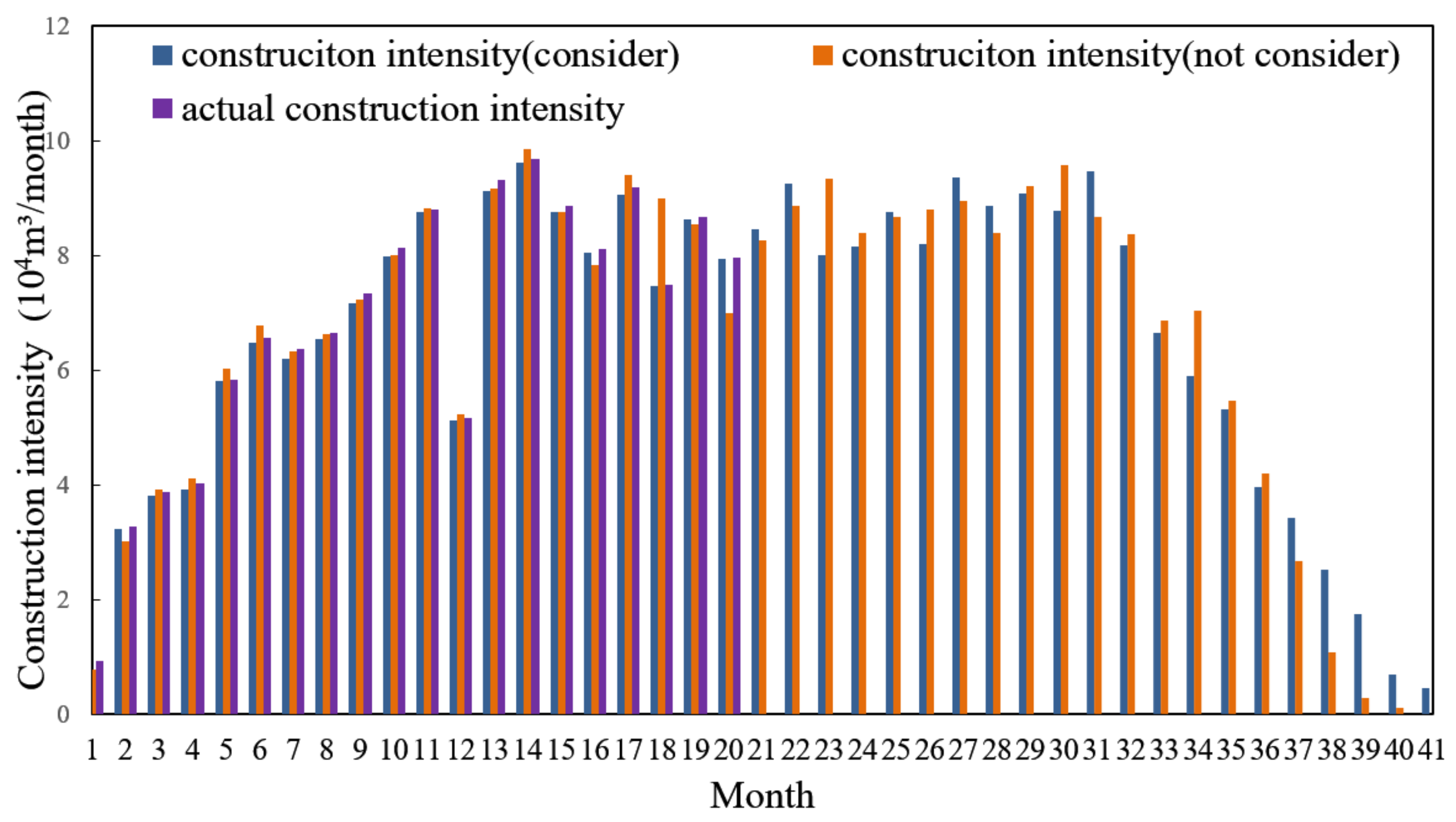

4.2. Construction Simulation Coupling Temperature Field Interval Predictions

5. Discussion

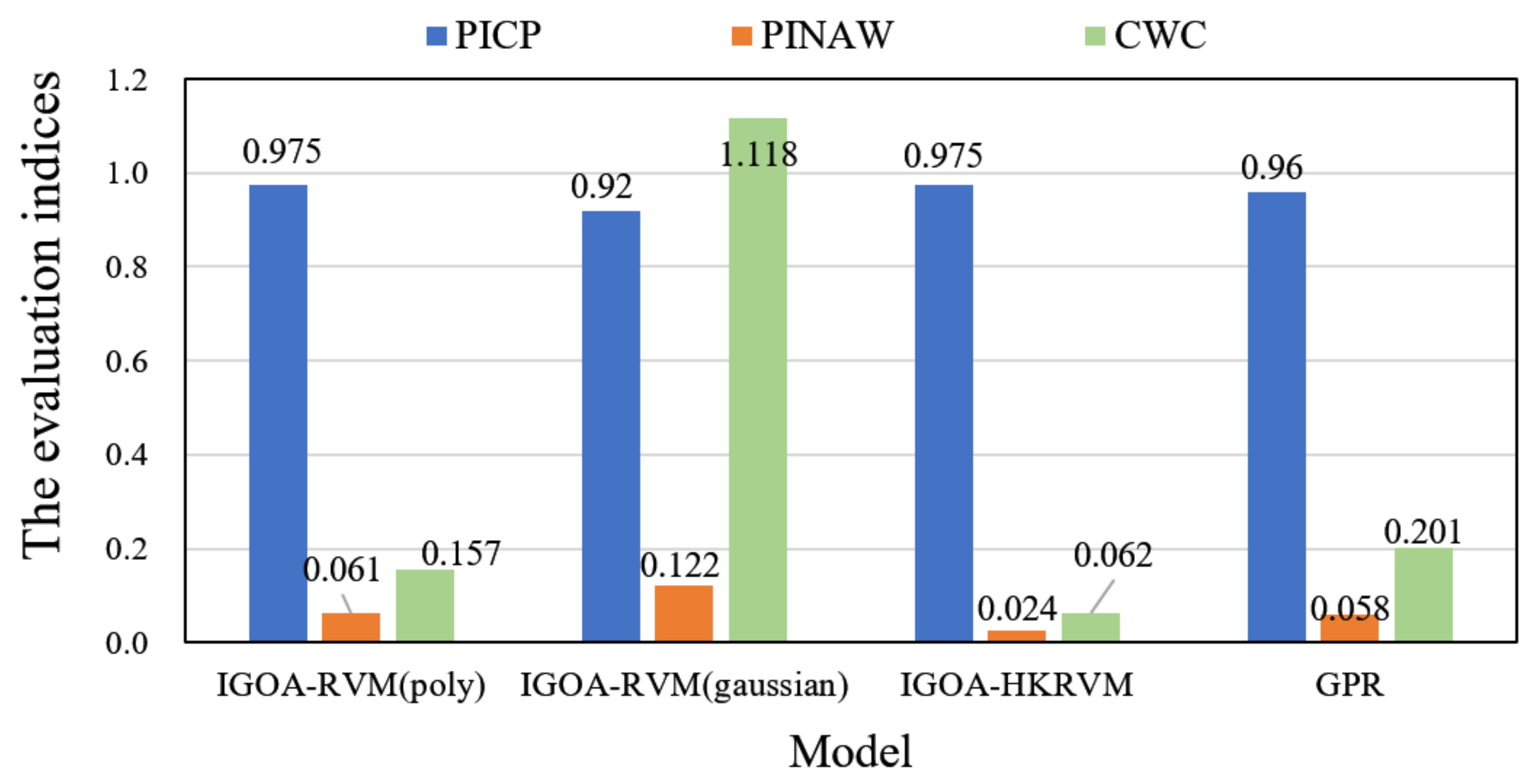

5.1. Prediction Model Comparison

- Model prediction accuracy

- Model generalization ability

5.2. Simulation Results Comparison

6. Conclusions

- A real-time construction simulation model was proposed. The model coupled the dam block simulation and joint grouting simulation, and analyzes the relationship between them.

- A high-precision, high-generalization capability interval prediction model was established for concrete temperature prediction. The interval prediction model was constructed based on the hybrid-kernel relevance vector machine (HK-RVM) and the improved grasshopper optimization algorithm (IGOA). Compared with the unmodified models and the common models, the proposed model demonstrates superiority with regard to the accuracy, generalization ability.

- A concept drift detection method based on the variable window technology was developed for updating the prediction model.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Symbol | Definition | Symbol | Definition |

|---|---|---|---|

| Dam monolith number, i = 1,2,…,n | The grouting elevation variation of the ith dam monolith from (t-1) to t | ||

| Construction index | The temperature of lth dam block at the time t | ||

| The pouring elevation of the ith dam monolith at the time 0 | The concrete age of lth dam block at the time t | ||

| The grouting elevation of the ith dam monolith at the time 0 | The cover weight of lth dam block at the time t | ||

| Alternative construction schemes | Pouring temperature | ||

| The pouring elevation of the ith dam monolith at the time t | Cooling water temperature | ||

| The pouring elevation of the ith dam monolith at the time t | Cooling water flow | ||

| The pouring elevation variation of the ith dam monolith from (t-1) to t | Ambient temperature | ||

| Maximum dam height | The temperatures of upper and lower dam blocks | ||

| The placement duration of a dam block in the ith dam monolith | Hybrid-kernel relevance vector machine | ||

| The appearance requirement of the ith dam monolith | The output of joint grouting simulation | ||

| The duration of the vth working procedure | The grouting time of each grouting area (start time) | ||

| The output of dam block simulation | The current time | ||

| The optimal construction scheme | The pouring time of lth dam block | ||

| The pouring time of each dam block (start time and end time) | The constraint of cantilever height difference |

Appendix B

| Function | Dim | Range | Fmin |

|---|---|---|---|

| 30 | [−100,100] | 0 | |

| 30 | [−10,10] | 0 | |

| 30 | [−100,100] | 0 | |

| 30 | [−100,100] | 0 | |

| 30 | [−100,100] | 0 | |

| 30 | [−100,100] | 0 | |

| 30 | [−32,32] | 0 | |

| 30 | [−600,600] | 0 | |

| 30 | [−50,50] | 0 | |

| 30 | [−50,50] | 0 |

References

- Wang, R. Key Technologies in the Design and Construction of 300 m Ultra-High Arch Dams. Engineering 2016, 2, 350–359. [Google Scholar] [CrossRef]

- Wei, P.; Shi, J.; Lin, P.; Qiao, Y. Study on grouting timing relating to riverbed foundation of Wudongde arch dam. In Proceedings of the 10th Asian Rock Mechanics Symposium, ARMS 2018, Singapore, 29 October–3 November 2018; International Society for Rock Mechanics: Singapore, 2018. [Google Scholar]

- Abourizk, S.; Halpin, D.W.; Mohamed, Y.; Hermann, U. Research in Modeling and Simulation for Improving Construction Engineering Operations. J. Constr. Eng. Manag. 2011, 137, 843–852. [Google Scholar] [CrossRef]

- Martínez, J.C. Methodology for Conducting Discrete-Event Simulation Studies in Construction Engineering and Management. J. Constr. Eng. Manag. 2010, 136, 3–16. [Google Scholar] [CrossRef]

- Mawdesley, M.J.; Al-Jibouri, S. Modelling construction project productivity using systems dynamics approach. Int. J. Prod. Perform. Manag. 2009, 59, 18–36. [Google Scholar] [CrossRef]

- Dabirian, S.; Khanzadi, M.; Moussazadeh, M. Predicting labor costs in construction projects using agent-based modeling and simulation. Sci. Iran. 2016, 23, 91–101. [Google Scholar] [CrossRef][Green Version]

- Moradi, S.; Nasirzadeh, F.; Golkhoo, F. A hybrid SD–DES simulation approach to model construction projects. Constr. Innov. 2015, 15, 66–83. [Google Scholar] [CrossRef]

- Nasirzadeh, F.; Khanzadi, M.; Mir, M. A hybrid simulation framework for modelling construction projects using agent-based modelling and system dynamics: An application to model construction workers’ safety behavior. Int. J. Constr. Manag. 2017, 18, 132–143. [Google Scholar] [CrossRef]

- De Salles, D.C.; Neto, A.C.G.; Marujo, L.G. Using fuzzy logic to implement decision policies in system dynamics models. Expert Syst. Appl. 2016, 55, 172–183. [Google Scholar] [CrossRef]

- Zhong, D.; Wu, K.; Ren, B. Dynamic simulation for high arch dam construction processes based on object-oriented technology. J. Tianjin Univ. Sci. Technol. 2007, 40, 976–982. [Google Scholar]

- Zhong, D.-H.; Ren, B.; Wu, K. Construction simulation and real-time control for high arch dam. Trans. Tianjin Univ. 2008, 14, 248–253. [Google Scholar] [CrossRef]

- Zhong, D.-H.; Ren, B.; Li, M.; Wu, B.; Li, M. Theory on real-time control of construction quality and progress and its application to high arc dam. Sci. China Ser. E Technol. Sci. 2010, 53, 2611–2618. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, C.; Wang, F.; Liang, Z. Feedback Design of Temperature Control Measures for Concrete Dams based on Real-Time Temperature Monitoring and Construction Process Simulation. KSCE J. Civ. Eng. 2017, 22, 1584–1592. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Chang, X.; Zhou, W.; Cheng, Y.; Duan, Y. Precise simulation analysis of the thermal field in mass concrete with a pipe water cooling system. Appl. Therm. Eng. 2015, 78, 449–459. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, Y.; Tan, Y. Simulation of Temperature Field of High Arch Dams Considering Solar Radiation. In Proceedings of the 6th International Conference on Environmental Science and Civil Engineering, ESCE 2020, Nanchang, China, 4–5 January 2020; Institute of Physics Publishing: Nanchang, China, 2020. [Google Scholar]

- Nguyen, T.Q.; Vuong, L.C.; Le, C.M.; Ngo, N.K.; Nguyen-Xuan, H. A data-driven approach based on wavelet analysis and deep learning for identification of multiple-cracked beam structures under moving load. Measurement 2020, 162, 107862. [Google Scholar] [CrossRef]

- Borate, P.; Wang, G.; Wang, Y. Data-Driven Structural Health Monitoring Approach Using Guided Lamb Wave Responses. J. Aerosp. Eng. 2020, 33, 04020033. [Google Scholar] [CrossRef]

- Abba, S.; Usman, A.; Işik, S. Simulation for response surface in the HPLC optimization method development using artificial intelligence models: A data-driven approach. Chemom. Intell. Lab. Syst. 2020, 201, 104007. [Google Scholar] [CrossRef]

- Han, Y.; Huang, D.; Wang, H. Research on optimization of second-stage cooling of high arch dam concrete. J. China Three Gorges Univ. 2007, 29, 109–112. [Google Scholar]

- Fu, X.; Zhou, Y.; Huang, Y.; Zhou, S.; Li, J. BP-neural network based analysis on second-stage cooling of dam concrete. Water Resour. Hydropower Eng. 2012, 43, 50–53. [Google Scholar]

- Zhong, D.-H.; Zhao, C.; Ren, B. Research on analysis method for temperature control information of high arch dam construction. Sci. China Ser. E Technol. Sci. 2011, 54, 40–46. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, Y. Application of MGM(1,N) on Concrete Temperature Prediction of RCC Dam. In Proceedings of the 4th International Conference on Technology of Architecture and Structure (ICTAS 2011), Zurich, Switzerland, 22–24 September 2011; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; pp. 2406–2410. [Google Scholar]

- Bhattarai, S.; Zhou, Y.; Zhao, C.; Zhou, H. Application of soft computing techniques for predicting cooling time required dropping initial temperature of mass concrete. Civ. Eng. J. 2017, 26, 189–203. [Google Scholar] [CrossRef]

- Bhattarai, S.; Zhou, Y.; Zhao, C.; Zhou, H. Predicting temperature drop rate of mass concrete during an initial cooling period using genetic programming. In Proceedings of the 2017 International Conference on Sensors, Materials and Manufacturing, ICSMM 2017, Chiayi, Taiwan, 24–26 November 2017; Institute of Physics Publishing: Chiayi, Taiwan, 2018. [Google Scholar]

- Kang, F.; Li, J.; Dai, J. Prediction of long-term temperature effect in structural health monitoring of concrete dams using support vector machines with Jaya optimizer and salp swarm algorithms. Adv. Eng. Softw. 2019, 131, 60–76. [Google Scholar] [CrossRef]

- Chen, S.; Gu, C.; Lin, C.; Zhao, E.; Song, J. Safety Monitoring Model of a Super-High Concrete Dam by Using RBF Neural Network Coupled with Kernel Principal Component Analysis. Math. Probl. Eng. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Adjenughwure, K.; Papadopoulos, B. Fuzzy-statistical prediction intervals from crisp regression models. Evol. Syst. 2019, 11, 201–213. [Google Scholar] [CrossRef]

- Kodaira, D.; Jung, W.; Han, S. Optimal Energy Storage System Operation for Peak Reduction in a Distribution Network Using a Prediction Interval. IEEE Trans. Smart Grid 2020, 11, 2208–2217. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Y.; Fan, C.; Li, T.; Zhang, X.; Li, J. A generic prediction interval estimation method for quantifying the uncertainties in ultra-short-term building cooling load prediction. Appl. Therm. Eng. 2020, 173, 115261. [Google Scholar] [CrossRef]

- Zhu, X.; Zeng, B.; Dong, H.; Liu, J. An interval-prediction based robust optimization approach for energy-hub operation scheduling considering flexible ramping products. Energy 2020, 194, 116821. [Google Scholar] [CrossRef]

- Hu, J.; Lin, Y.; Tang, J.; Zhao, J. A new wind power interval prediction approach based on reservoir computing and a quality-driven loss function. Appl. Soft Comput. 2020, 92, 106327. [Google Scholar] [CrossRef]

- Yang, X.; Fu, G.; Zhang, Y.; Kang, N.; Gao, F. A Naive Bayesian Wind Power Interval Prediction Approach Based on Rough Set Attribute Reduction and Weight Optimization. Energies 2017, 10, 1903. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Y.; Zhao, J.; Wang, W.; Liu, Q. Prediction intervals for industrial data with incomplete input using kernel-based dynamic Bayesian networks. Artif. Intell. Rev. 2016, 46, 307–326. [Google Scholar] [CrossRef]

- Song, L.; Minku, L.L.; Yao, X. Software Effort Interval Prediction via Bayesian Inference and Synthetic Bootstrap Resampling. ACM Trans. Softw. Eng. Methodol. 2019, 28, 1–46. [Google Scholar] [CrossRef]

- Pokhriyal, H.; Balakrishna, N. Bootstrap prediction intervals for autoregressive conditional duration models. J. Stat. Comput. Simul. 2019, 89, 2930–2950. [Google Scholar] [CrossRef]

- Beyaztas, U.; Arikan, B.B.; Beyaztas, B.H.; Kahya, E. Construction of prediction intervals for Palmer Drought Severity Index using bootstrap. J. Hydrol. 2018, 559, 461–470. [Google Scholar] [CrossRef]

- Zhang, G.; Allaire, D.; McAdams, D.A.; Shankar, V. Generating Technology Evolution Prediction Intervals Using a Bootstrap Method. J. Mech. Des. 2019, 141, 061401. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Z.; Zhang, K.; Zhang, L.; Hua, X.; Wang, Y. Multi-objective interval prediction of wind power based on conditional copula function. J. Mod. Power Syst. Clean Energy 2019, 7, 802–812. [Google Scholar] [CrossRef]

- Pang, J.; Liu, D.; Peng, Y.; Peng, X. Optimize the Coverage Probability of Prediction Interval for Anomaly Detection of Sensor-Based Monitoring Series. Sensors 2018, 18, 967. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, J.; Han, S.; David, I.; Tian, D.; Gao, L. An optimized short-term wind power interval prediction method considering NWP accuracy. Chin. Sci. Bull. 2014, 59, 1167–1175. [Google Scholar] [CrossRef]

- Sachindra, D.; Ahmed, K.; Rashid, M.; Shahid, S.; Perera, B. Statistical downscaling of precipitation using machine learning techniques. Atmospheric Res. 2018, 212, 240–258. [Google Scholar] [CrossRef]

- Gonen, M.; Alpaydin, E. Multiple kernel learning algorithms. J. Mach. Learn. Res. 2011, 12, 2211–2268. [Google Scholar]

- Guo, S.; Zhao, H.; Zhao, H. A New Hybrid Wind Power Forecaster Using the Beveridge-Nelson Decomposition Method and a Relevance Vector Machine Optimized by the Ant Lion Optimizer. Energies 2017, 10, 922. [Google Scholar] [CrossRef]

- Qiao, W.; Huang, K.; Azimi, M.; Han, S. A Novel Hybrid Prediction Model for Hourly Gas Consumption in Supply Side Based on Improved Whale Optimization Algorithm and Relevance Vector Machine. IEEE Access 2019, 7, 88218–88230. [Google Scholar] [CrossRef]

- Bui, D.T.; Shahabi, H.; Shirzadi, A.; Chapi, K.; Hoang, N.-D.; Pham, B.T.; Bui, Q.-T.; Tran, C.-T.; Panahi, M.; Ahmed, B.; et al. A Novel Integrated Approach of Relevance Vector Machine Optimized by Imperialist Competitive Algorithm for Spatial Modeling of Shallow Landslides. Remote Sens. 2018, 10, 1538. [Google Scholar] [CrossRef]

- Nhat Duc, H.; Dieu Tien, B. A novel relevance vector machine classifier with Cuckoo search optimization for spatial prediction of landslides. J. Comput. Civ. Eng. 2016, 30, 04016001. [Google Scholar]

- Xiang, Q.; Yuan, Y.; Yu, Y.; Chen, K. Rotor Position Self-Sensing of SRM Using PSO-RVM. Energies 2018, 11, 66. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, Z.; Zhang, Z.; Liu, X. A novel shearer cutting pattern recognition model with chaotic gravitational search optimization. Measurement 2019, 144, 225–233. [Google Scholar] [CrossRef]

- Lou, J.; Jiang, Y.; Shen, Q.; Wang, R. Failure prediction by relevance vector regression with improved quantum-inspired gravitational search. J. Netw. Comput. Appl. 2018, 103, 171–177. [Google Scholar] [CrossRef]

- Saremi, S.; Mirjalili, S.; Lewis, A. Grasshopper Optimisation Algorithm: Theory and application. Adv. Eng. Softw. 2017, 105, 30–47. [Google Scholar] [CrossRef]

- Heidari, A.A.; Faris, H.; Aljarah, I.; Mirjalili, S. An efficient hybrid multilayer perceptron neural network with grasshopper optimization. Soft Comput. 2018, 23, 7941–7958. [Google Scholar] [CrossRef]

- Gama, J.; Žliobaitė, I.; Bifet, A.; Pechenizkiy, M.; Bouchachia, A. A survey on concept drift adaptation. ACM Comput. Surv. 2014, 46, 1–37. [Google Scholar] [CrossRef]

- Wares, S.; Isaacs, J.P.; Elyan, E. Data stream mining: Methods and challenges for handling concept drift. SN Appl. Sci. 2019, 1, 1412. [Google Scholar] [CrossRef]

- Liu, G.; Cheng, H.; Qin, Z.; Liu, Q.; Liu, C. E-CVFDT: An improving CVFDT method for concept drift data stream. In Proceedings of the 2013 International Conference on Communications, Circuits and Systems, ICCCAS 2013, Chengdu, China, 15–17 November 2013; IEEE Computer Society: Chengdu, China, 2013; pp. 315–318. [Google Scholar]

- Bifet, A.; Gavalda, R. Learning from time-changing data with adaptive windowing. In Proceedings of the 7th SIAM International Conference on Data Mining, Minneapolis, MN, USA, 26–28 April 2007; Society for Industrial and Applied Mathematics Publications: Minneapolis, MN, USA, 2007; pp. 443–448. [Google Scholar]

- Li, R.; Jin, Y. A wind speed interval prediction system based on multi-objective optimization for machine learning method. Appl. Energy 2018, 228, 2207–2220. [Google Scholar] [CrossRef]

| Functions | IGOA | GOA | ||

|---|---|---|---|---|

| Mean | Standard | Mean | Standard | |

| F1 | 0.0455 | 0.0005 | 0.0725 | 0.0009 |

| F2 | 0.0007 | 0.0000 | 0.0004 | 0.0000 |

| F3 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| F4 | 0.0000 | 0.0000 | 0.0001 | 0.0000 |

| F5 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| F6 | 0.1049 | 0.0180 | 0.1582 | 0.0512 |

| F7 | 0.0593 | 0.0098 | 0.0659 | 0.1041 |

| F8 | 0.0000 | 0.0000 | 0.0124 | 0.0076 |

| F9 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| F10 | 0.9980 | 0.0000 | 0.9980 | 0.0000 |

| Models | IGOA-RVMpoly | IGOA-RVMgauss | IGOA-HKRVM | GPR | |

|---|---|---|---|---|---|

| Measurements | |||||

| PICP | 0.938 | 0.942 | 0.944 | 0.942 | |

| PINAW | 0.061 | 0.032 | 0.023 | 0.042 | |

| CWC | 0.351 | 0.167 | 0.114 | 0.219 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Guan, T.; Ren, B.; Yu, J.; Wang, J.; Wu, B. Real-Time Construction Simulation Coupling a Concrete Temperature Field Interval Prediction Model with Optimized Hybrid-Kernel RVM for Arch Dams. Energies 2020, 13, 4487. https://doi.org/10.3390/en13174487

Song W, Guan T, Ren B, Yu J, Wang J, Wu B. Real-Time Construction Simulation Coupling a Concrete Temperature Field Interval Prediction Model with Optimized Hybrid-Kernel RVM for Arch Dams. Energies. 2020; 13(17):4487. https://doi.org/10.3390/en13174487

Chicago/Turabian StyleSong, Wenshuai, Tao Guan, Bingyu Ren, Jia Yu, Jiajun Wang, and Binping Wu. 2020. "Real-Time Construction Simulation Coupling a Concrete Temperature Field Interval Prediction Model with Optimized Hybrid-Kernel RVM for Arch Dams" Energies 13, no. 17: 4487. https://doi.org/10.3390/en13174487

APA StyleSong, W., Guan, T., Ren, B., Yu, J., Wang, J., & Wu, B. (2020). Real-Time Construction Simulation Coupling a Concrete Temperature Field Interval Prediction Model with Optimized Hybrid-Kernel RVM for Arch Dams. Energies, 13(17), 4487. https://doi.org/10.3390/en13174487