Heat Transfer through Wire Cloth Micro Heat Exchanger

Abstract

1. Introduction

2. Materials and Methods

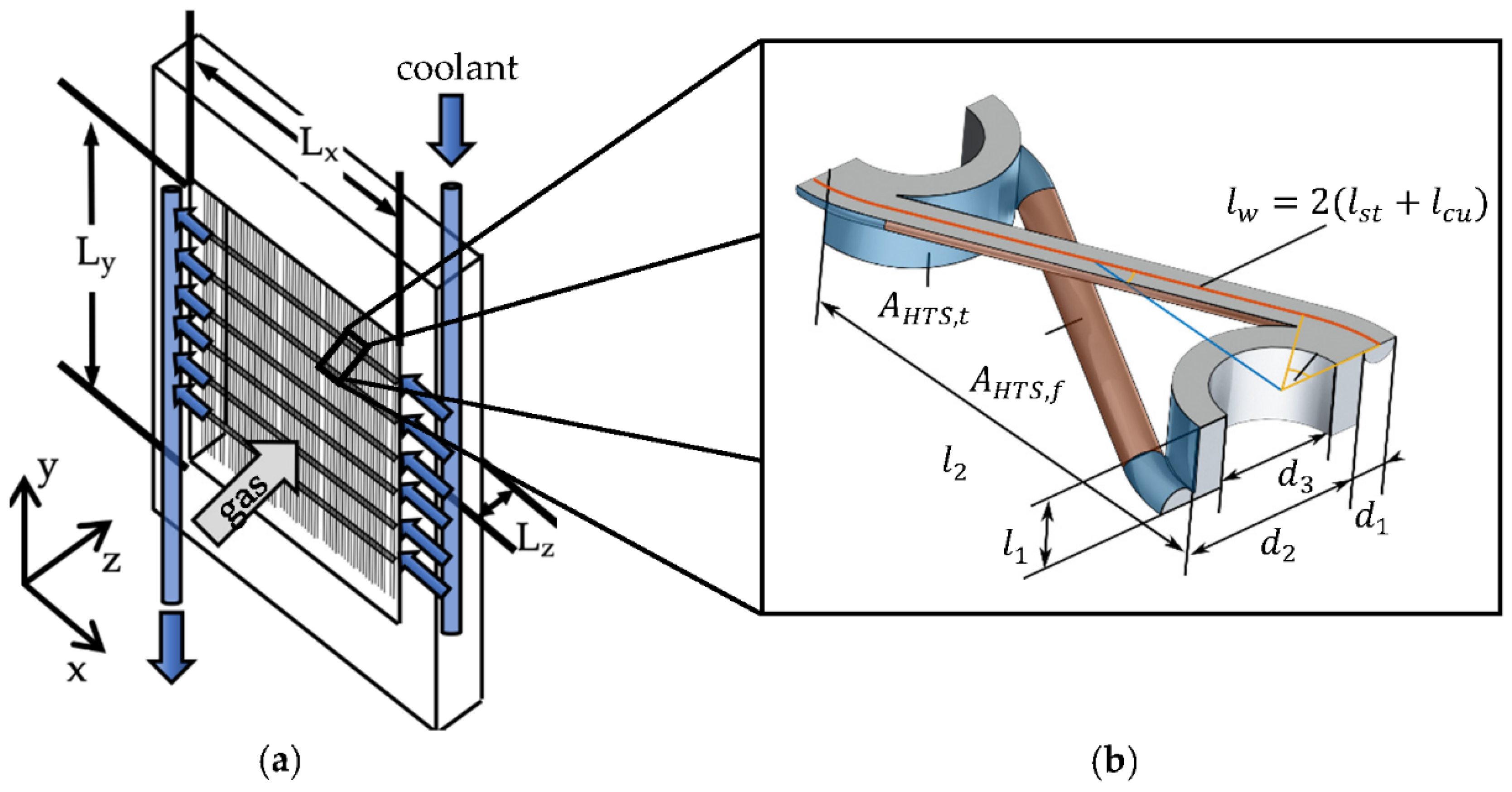

2.1. Geometric Parameters

2.2. Heat Transfer Paths and Mechanisms

- Heat transfer between the coolant and the tubes;

- Heat conduction in the tube walls;

- Heat conduction in the wires;

- Heat transfer between the tubes and curved wire sections and the gas;

- Heat transfer between the straight wire sections as a fin and the gas.

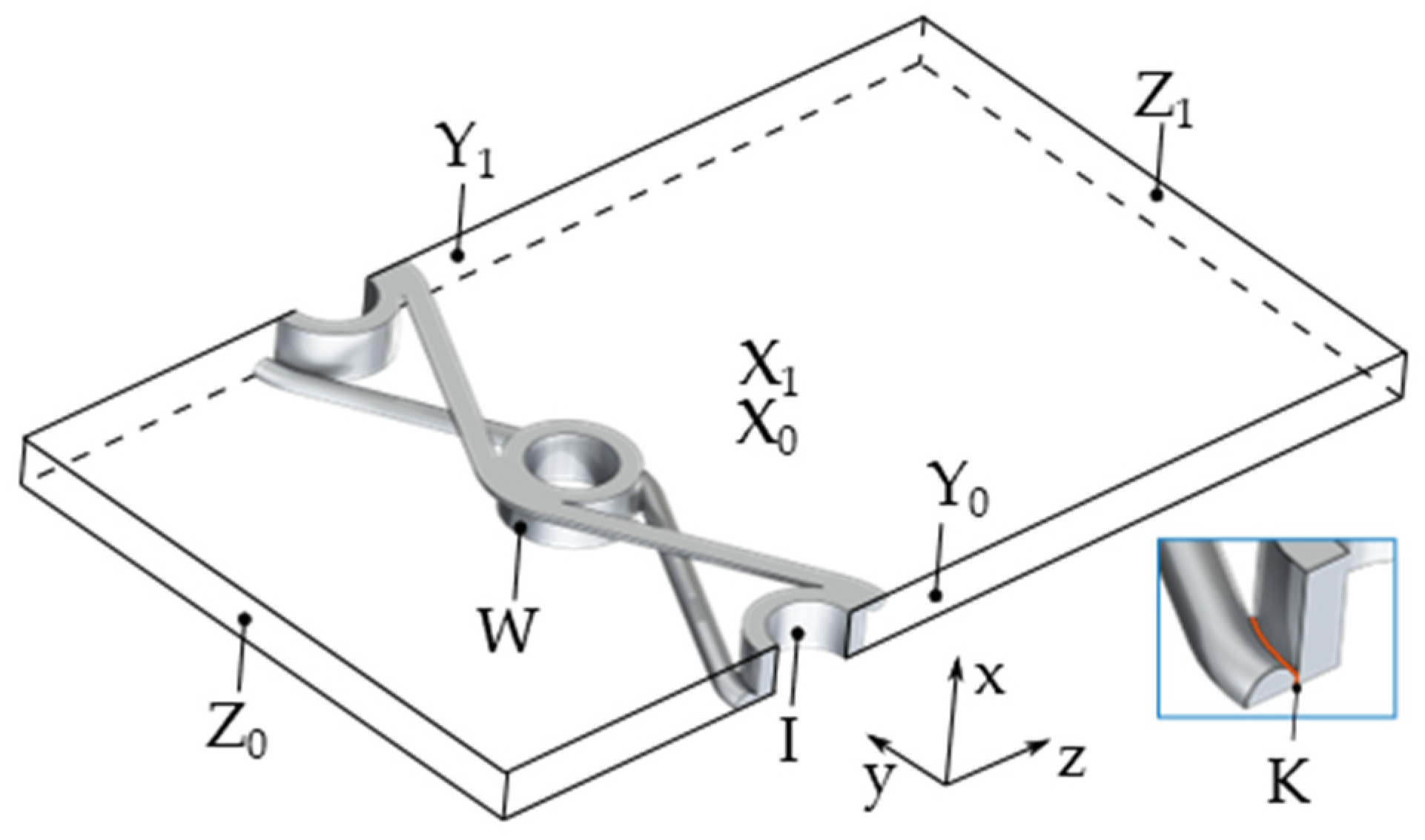

2.3. 3D-Computational Fluid Dynamics Simulation (CFD)

- Gas density is constant and heat generation due to frictional forces is negligible, due to low gas-phase velocities (Mach number << 1);

- All material properties are calculated for a constant temperature;

- Natural convection is negligible compared to the imposed forced convective flow;

- Heat transfer into the environment and radiative heat transfer is negligible.

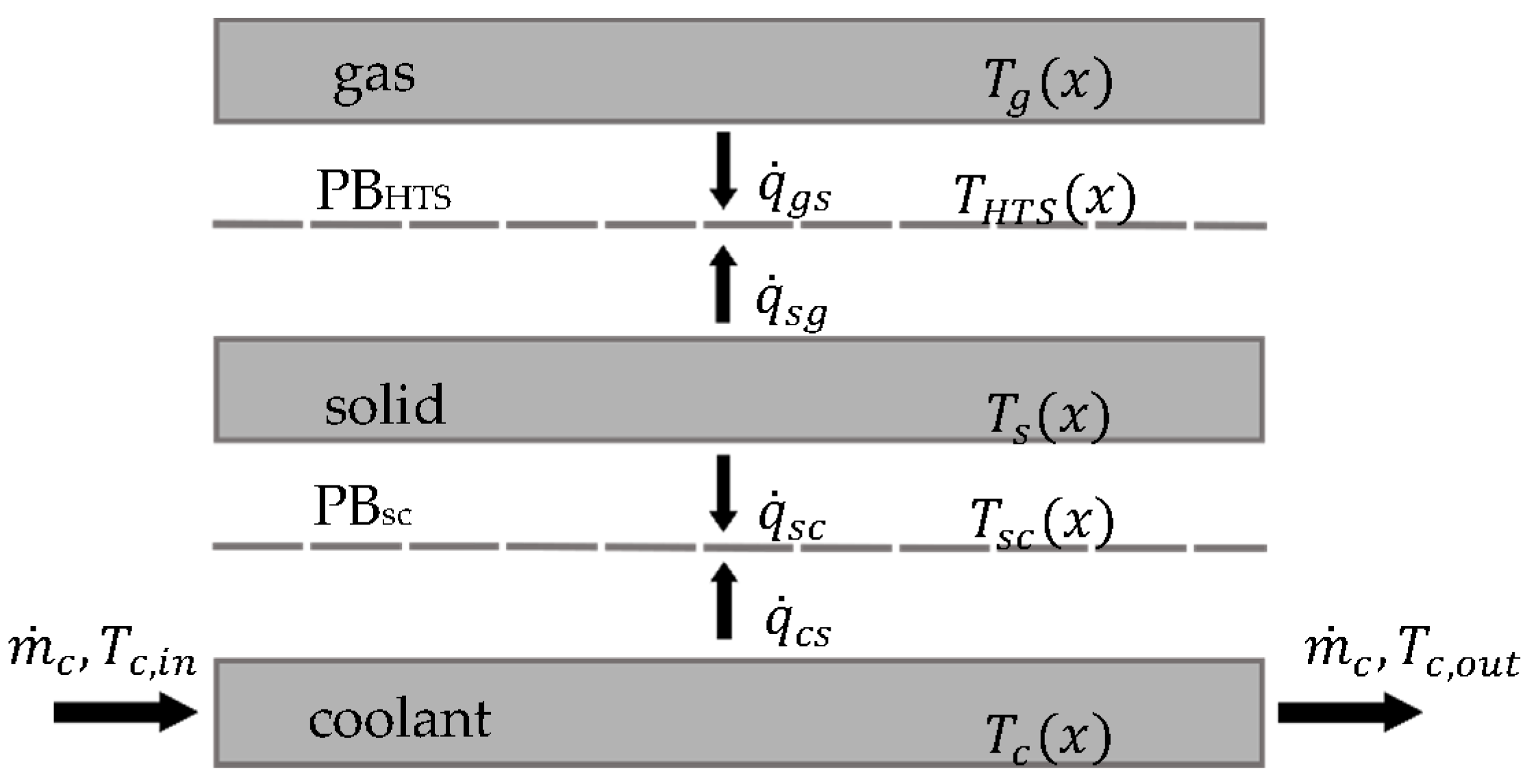

2.4. Effective Heat Transfer Model (EM)

- Laminar flow of the gas-phase in the x-direction ;

- There are no external (thermal) sources or sinks;

- A linear driving force approach for the heat transfer is used;

- The system is in steady-state;

- In a boundary layer, energy transport takes place only by heat conduction.

2.5. P-NTU Method

3. Results

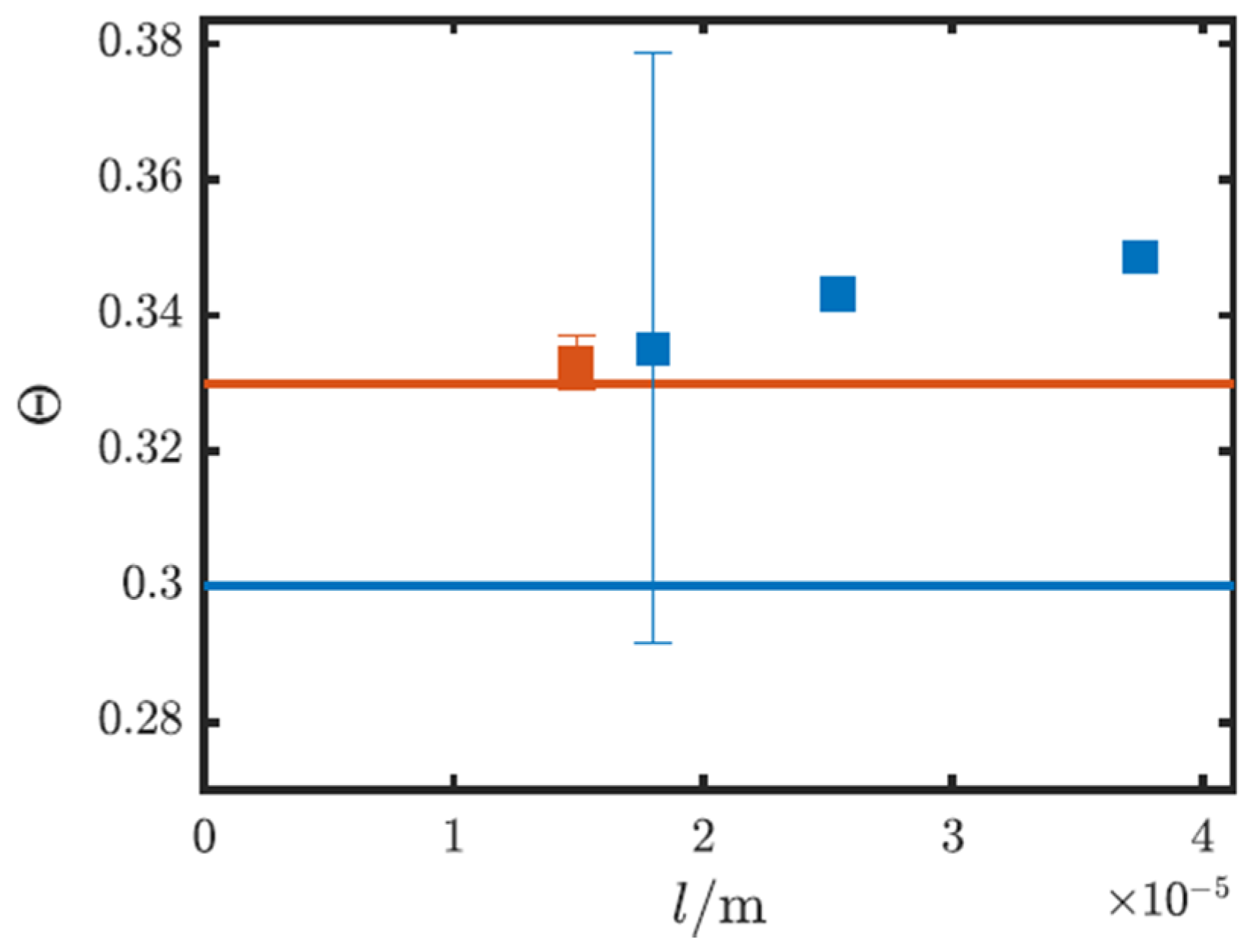

3.1. CFD Grid Convergence Study

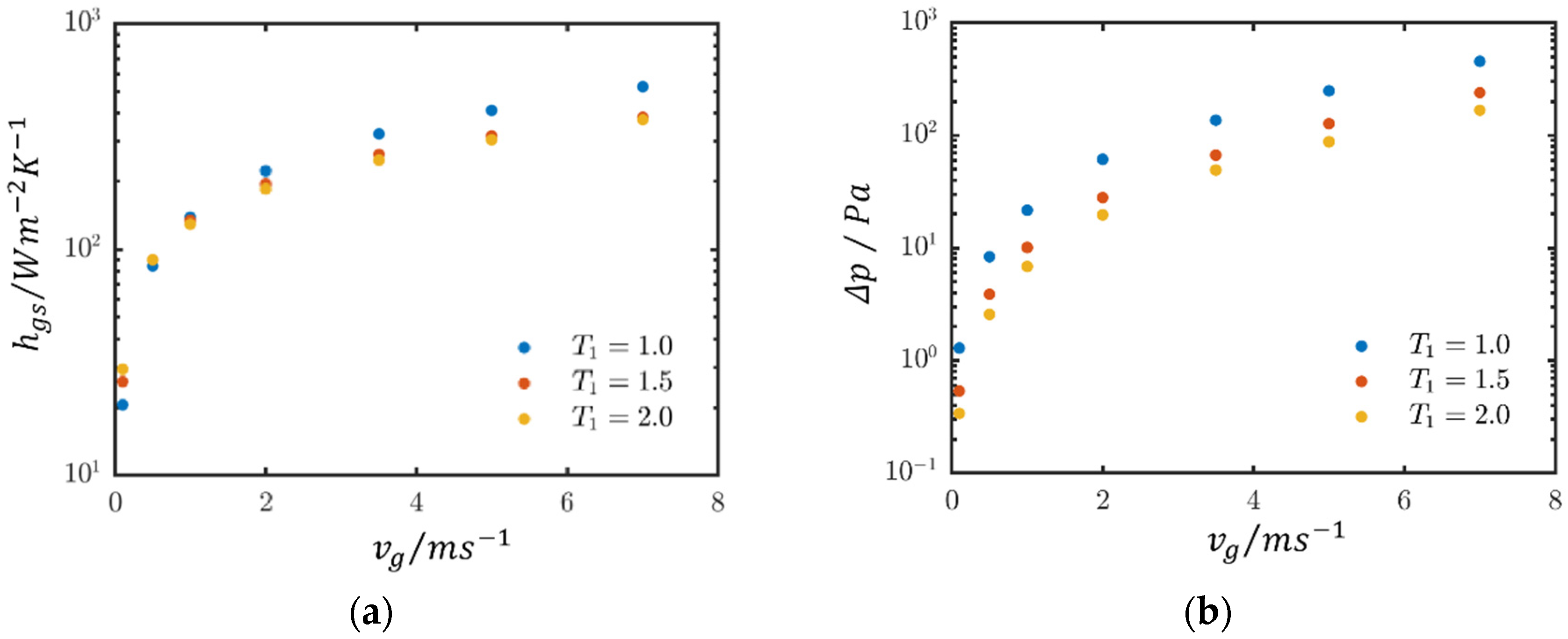

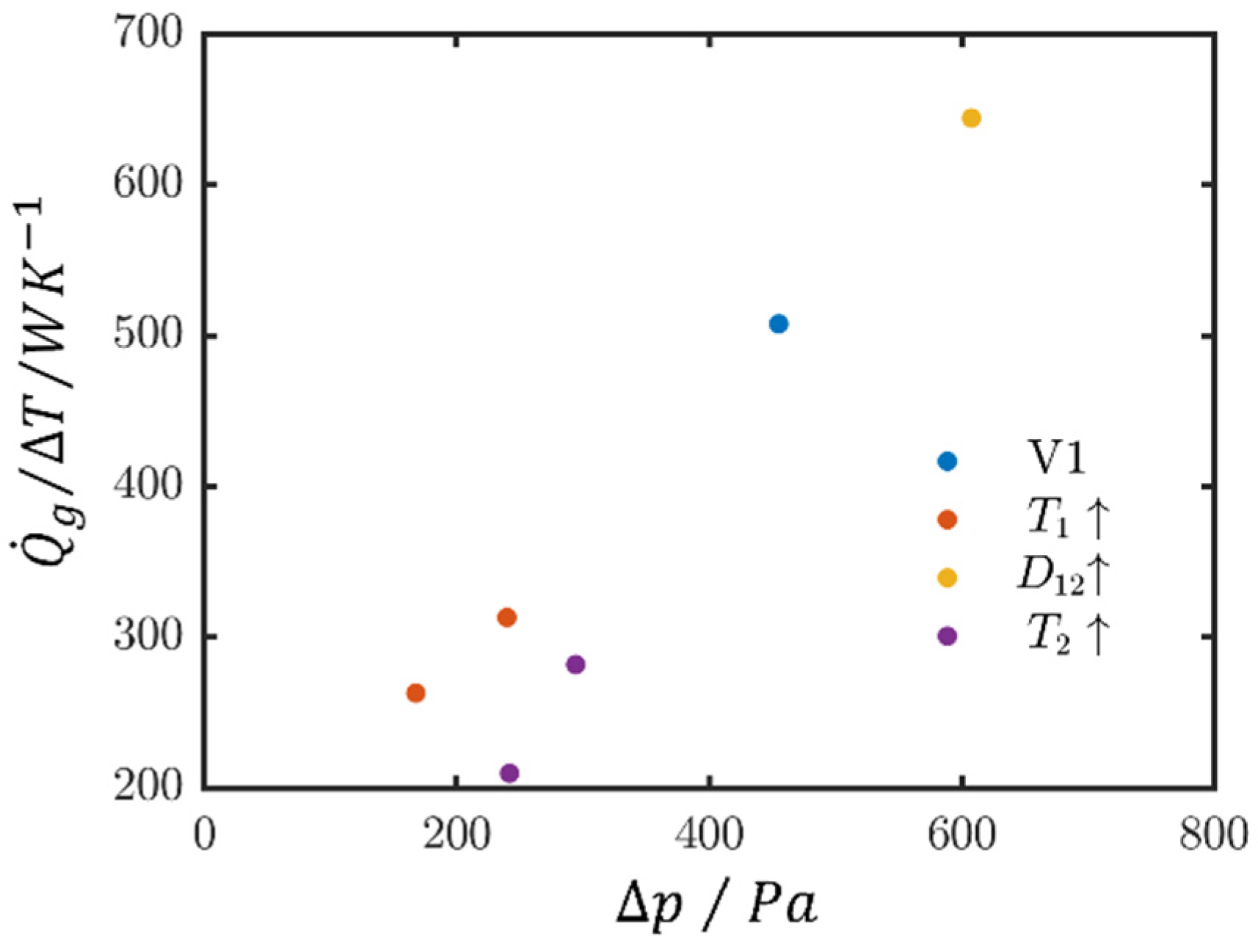

3.2. CFD Analysis Results for Variation of Geometric Parameters

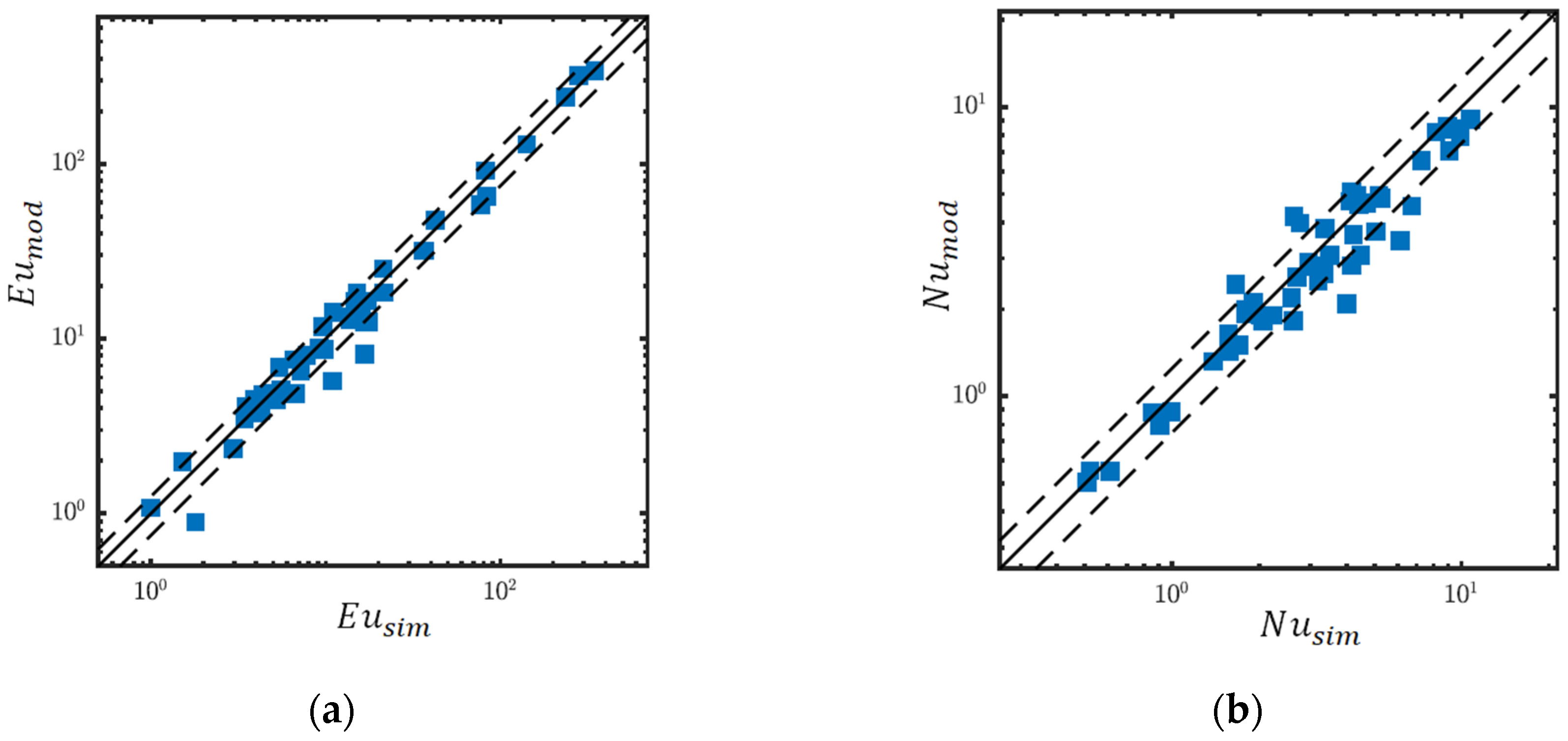

3.3. CFD-Based Eu and Nu-Correlations

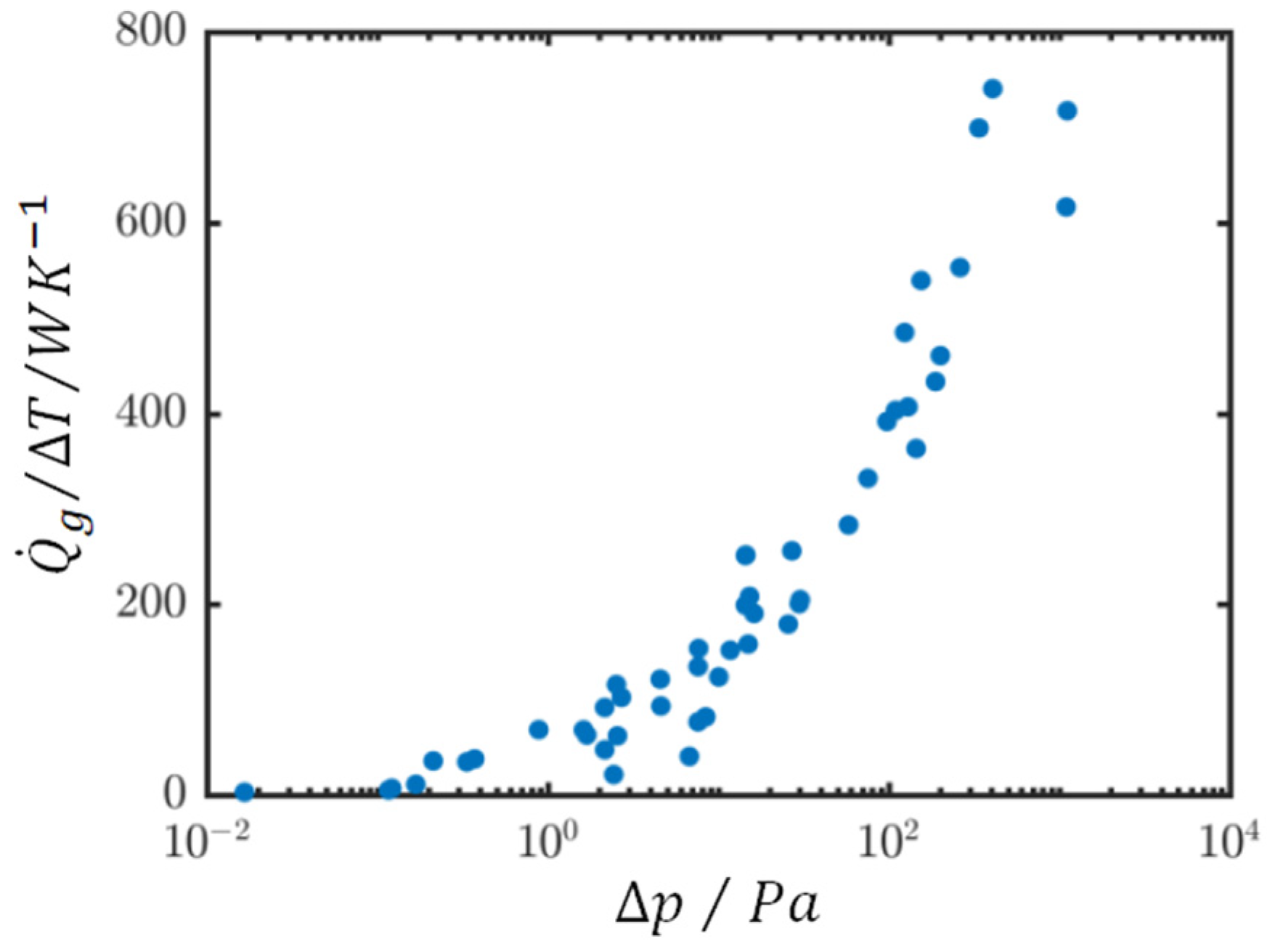

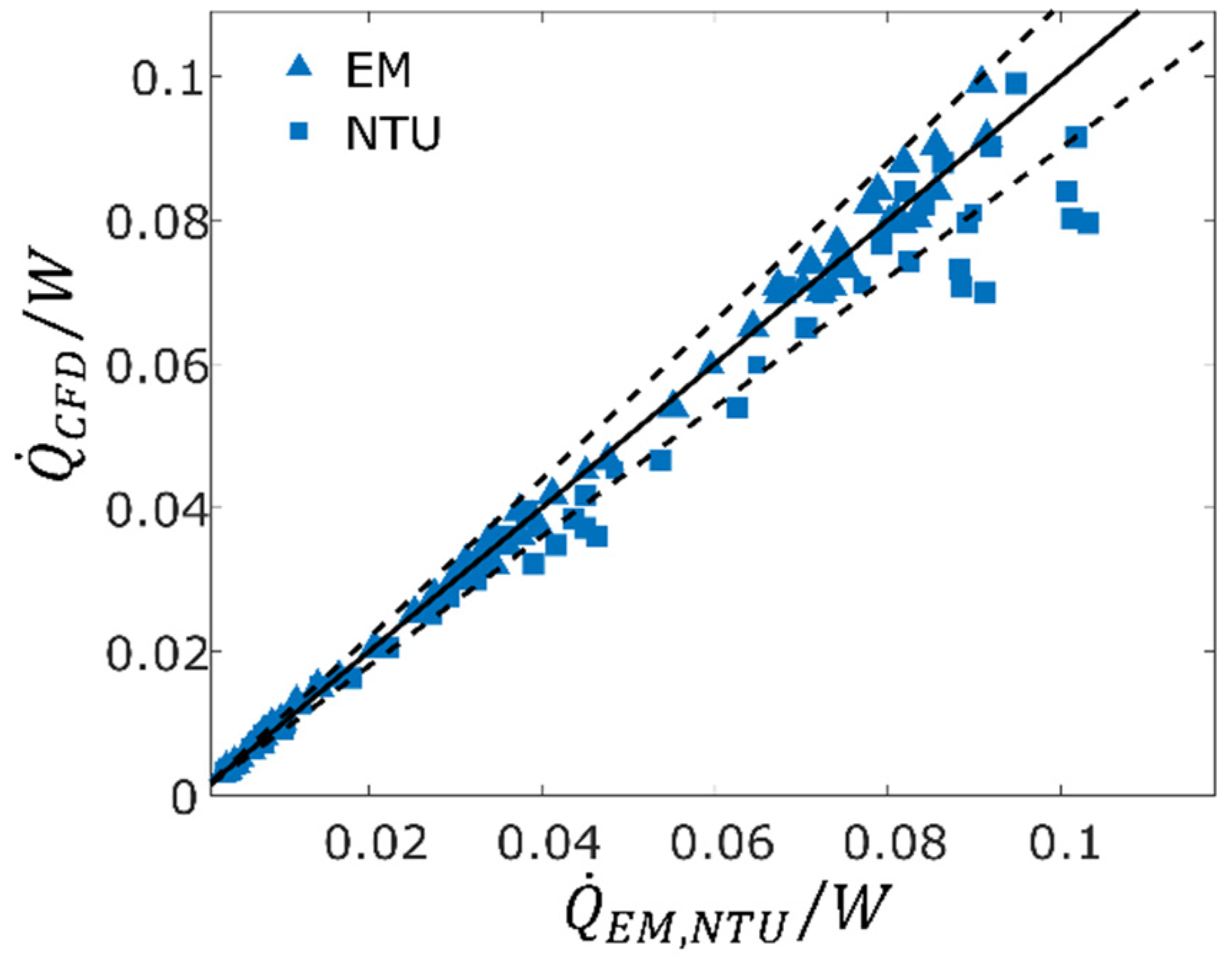

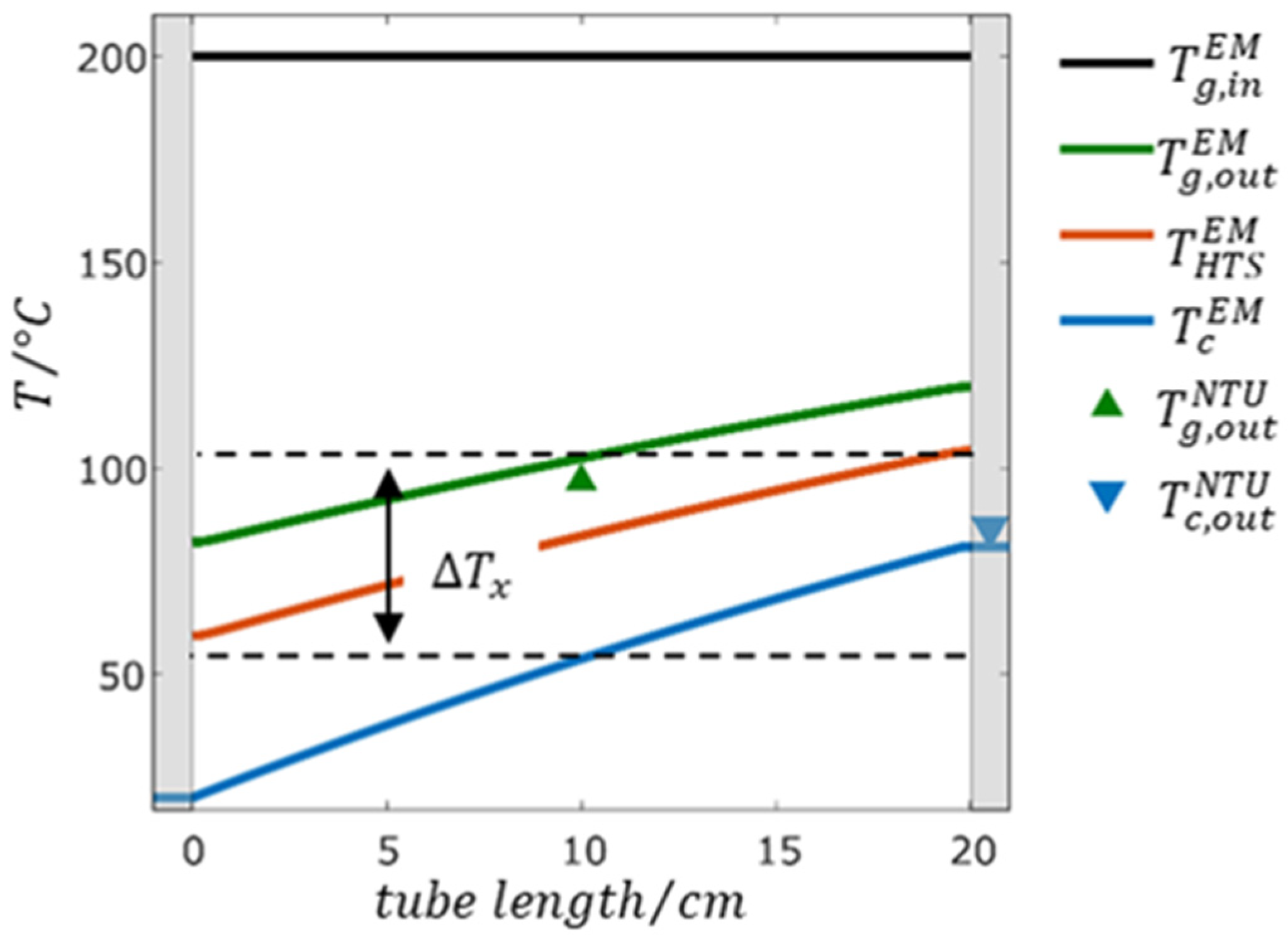

3.4. Numerical Validation of EM and P-NTU Models

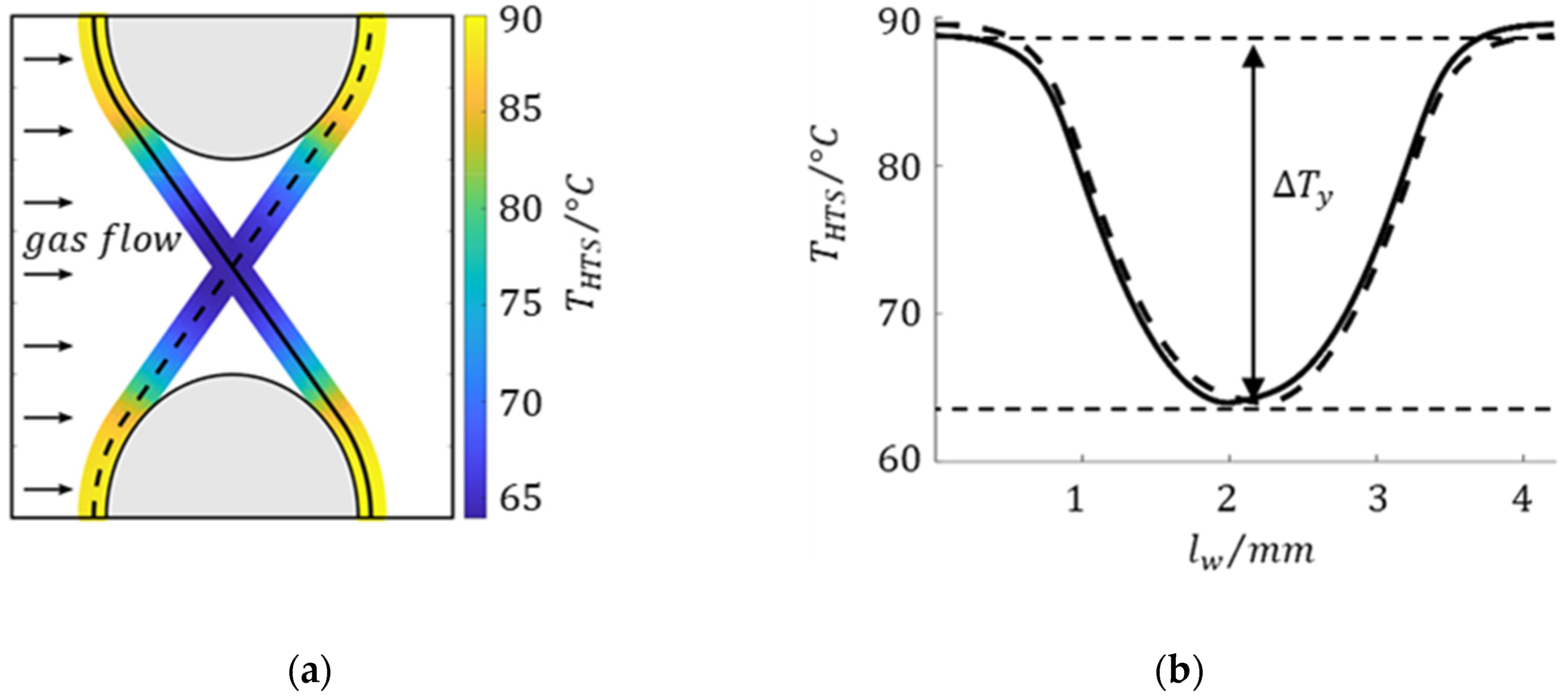

3.5. Estimation of the Temperature Distribution on the Wire Surface

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Greek Symbols | |

| tangential angle of contact (m) | |

| difference of a quantity | |

| logarithmic difference of a quantity | |

| volume fraction (-) | |

| numerical error | |

| fin efficiency (-) | |

| dimensionless temperature (-) | |

| dynamic viscosity (Pa s) | |

| calculation parameter for fin efficiency (-) | |

| density (kg/m3) | |

| stress tensor (kg/(ms2)) | |

| solution of numerical calculation | |

| specific surface area (m2/m3) | |

| Latin Symbols | |

| surface area (m2) | |

| heat capacity flux (W/K) | |

| heat capacity (J/(kg K)) | |

| wire diameter (m) | |

| outer tube diameter (m) | |

| inner tube diameter (m) | |

| dimensionless diameter (-) | |

| Euler number (-) | |

| Grid Convergence Index | |

| heat transfer coefficient (W/(m2 K)) | |

| interface between coolant and inner tube wall | |

| thermal conductivity (W/(m K)) | |

| interface between tube and wire | |

| distances between wires (m) | |

| distances between tubes (m) | |

| length of symmetric section (m) | |

| length of structure (m) | |

| mass flow rate (kg/s) | |

| number of grid cells (-) | |

| Nusselt number (-) | |

| number of transfer units (-) | |

| normal vector (m) | |

| number of tubes (-) | |

| number of wires (-) | |

| pressure (Pa) | |

| temperature ratio (-) | |

| phase boundary | |

| Prandtl number (-) | |

| transferred heat flux density (W/m2) | |

| transferred heat flux (W) | |

| heat capacity ratio (-) | |

| specific thermal resistance ((K m2)/(W)) | |

| Reynolds number (-) | |

| refinement ratio (-) | |

| t | time (s) |

| temperature (K) | |

| dimensionless warp wire pitch (-) | |

| dimensionless weft tube pitch (-) | |

| overall thermal transmittance (W/K) | |

| velocity (m/s) | |

| velocity vector (m/s) | |

| V | volume (m3) |

| interface between solid and gas | |

| fin coordinate (m) | |

| boundary wall in the x-direction | |

| boundary wall in the y-direction | |

| boundary wall in the z-direction | |

| Subscripts | |

| ambient condition | |

| related to the coolant phase | |

| related to the coolant-solid surface | |

| related to the curved wire | |

| related to the fin surface | |

| related to the grid | |

| related to the gas-phase | |

| related to the gas–solid surface | |

| heat exchanger | |

| related to the heat transfer surface on the air-side | |

| related to the effective heat transfer surface on the air-side | |

| inflow | |

| outflow | |

| related to the solid phase | |

| related to the solid-coolant surface | |

| related to the solid-gas surface | |

| related to the straight wire | |

| related to the tube surface | |

| related to the wire | |

| geometrical directions | |

References

- Dixit, T.; Ghosh, I. Review of micro- and mini-channel heat sinks and heat exchangers for single phase fluids. Renew. Sustain. Energy Rev. 2015, 41, 1298–1311. [Google Scholar] [CrossRef]

- Smakulski, P.; Pietrowicz, S. A review of the capabilities of high heat flux removal by porous materials, microchannels and spray cooling techniques. Appl. Therm. Eng. 2016, 104, 636–646. [Google Scholar] [CrossRef]

- Fugmann, H. Investigation of Wire Structures for Heat Transfer Enhancement in Compact Heat Exchanger. Ph.D. Thesis, Karlsruher Institut für Technologie, Karlsuhe, Germany, 2019. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, J.F.; Fan, H.L.; Shao, C.L. Experimental Study on Enhanced Heat Transfer Capability of the Array of Microtubes. Procedia Eng. 2015, 130, 250–255. [Google Scholar] [CrossRef]

- Lee, T.; Yun, J.; Lee, J.; Park, J.; Lee, K. Determination of airside heat transfer coeffcient on wire-on-tube type heat exchanger. Int. J. Heat Mass Transf. 2001, 44, 1767–1776. [Google Scholar] [CrossRef]

- Choi, S.; Cho, W.; Kim, J.; Kim, J. A study on the development of the wire woven heat exchanger using small diameter tubes. Exp. Therm. Fluid Sci. 2004, 28, 153–158. [Google Scholar] [CrossRef]

- Xu, J.; Tian, J.; Lu, T.J.; Hodson, H.P. On the thermal performance of wire-screen meshes as heat exchanger material. Int. J. Heat Mass Transf. 2007, 50, 1141–1154. [Google Scholar] [CrossRef]

- Balzer, R. Wärmetauschvorrichtung für Einen Wärmeaustausch Zwischen Medien und Webstruktur. Patent DE102006022629, 15 November 2007. [Google Scholar]

- Martens, S. Modellierung und Numerische Berechnung der Thermofluiddynamischen Eigenschaften Gewebebasierter Wärmeübertrager. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2019. [Google Scholar]

- Fugmann, H.; Laurenz, E.; Schnabel, L. Wire Structure Heat Exchangers—New Designs for Efficient Heat Transfer. Energies 2017, 10, 1341. [Google Scholar] [CrossRef]

- Fugmann, H.; Martens, S.; Balzer, R.; Brenner, M.; Schnabel, L.; Mehring, C. Performance Evaluation of Wire Cloth Micro Heat Exchangers. Energies 2020, 13, 715. [Google Scholar] [CrossRef]

- Rehman, D.; Joseph, J.; Morini, G.L.; Delanaye, M.; Brandner, J. A Hybrid numerical methodology based on CFD and porous medium for thermal performance evaluation of gas to gas micro heat exchanger. Micromachines 2020, 11, 218. [Google Scholar] [CrossRef] [PubMed]

- Kumra, A.; Rawal, N.; Samui, P. Prediction of heat transfer rate of a Wire-on-Tube type heat exchanger: An Artificial Intelligence approach. Procedia Eng. 2013, 64, 74–83. [Google Scholar] [CrossRef]

- Beshr, M.; Aute, V.; Radermacher, R. Multi-objective optimization of a residential air source heat pump with small-diameter tubes using genetic algorithms. Int. J. Refrig. 2016, 67, 134–142. [Google Scholar] [CrossRef]

- Nakaso, K.; Mitani, H.; Fukai, J. Convection heat transfer in a shell-and-tube heat exchanger using sheet fins for effective utilization of energy. Int. J. Heat Mass Transf. 2015, 82, 581–587. [Google Scholar] [CrossRef]

- Radermacher, R.; Bacellar, D.; Aute, V.; Huang, Z.; Hwang, Y.; Ling, J.; Muehlbauer, J.; Tancabel, J.; Abdelaziz, O.; Zhang, M. Miniaturized Air-to-Refrigerant Heat Exchangers; University of Maryland: College Park, MD, USA, 2017. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical Data; Irvine, T.F., Hartnett, J.P., Eds.; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Baehr, H.D.; Stephan, K. Wärme-und Stoffübertragung; Springer: Berlin, Germany, 2016. [Google Scholar]

- MATLAB. 9.7.0.1190202 (R2019b); The MathWorks Inc.: Natick, MA, USA, 2018. [Google Scholar]

- Shah, R.K.; Sekulic, D.P. Fundamentals of Heat Exchanger Design; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Roache, P.J. Perspective: A Method for Uniform Reporting of Grid Refinement Studies. J. Fluids Eng. 1994, 116, 405. [Google Scholar] [CrossRef]

- Roache, P.J. Conservatism of the Grid Convergence Index in Finite Volume Computations on Steady-State Fluid Flow and Heat Transfer. J. Fluids Eng. 2003, 125, 731. [Google Scholar] [CrossRef]

- Kopf, P.; Piesche, M.; Schütz, S. Beschreibung des Druckverlusts von Drahtgeweben mit Hilfe von Ähnlichkeitsgesetzen. Filtr. Sep. 2007, 21, 330–335. [Google Scholar]

) and fine (

) and fine ( ) mesh. Legend: (lines) predicted values, (squares) simulations.

) mesh. Legend: (lines) predicted values, (squares) simulations.

) and fine (

) and fine ( ) mesh. Legend: (lines) predicted values, (squares) simulations.

) mesh. Legend: (lines) predicted values, (squares) simulations.

analysis point, — parity, --- ±10% deviation.

analysis point, — parity, --- ±10% deviation.

analysis point, — parity, --- ±10% deviation.

analysis point, — parity, --- ±10% deviation.

| Boundary | Temperature | Pressure | Velocity |

|---|---|---|---|

| I | |||

| W | from Equation (27) | ||

| K | from Equation (28) |

| 0.2 | 2 | 1.6 | 0.2 | 3.5 |

| min | 1 | 0.05 | 1.0 | 1.6 | 650 |

| max | 500 | 0.2 | 3.0 | 3.5 | 18,000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walter, C.; Martens, S.; Zander, C.; Mehring, C.; Nieken, U. Heat Transfer through Wire Cloth Micro Heat Exchanger. Energies 2020, 13, 3567. https://doi.org/10.3390/en13143567

Walter C, Martens S, Zander C, Mehring C, Nieken U. Heat Transfer through Wire Cloth Micro Heat Exchanger. Energies. 2020; 13(14):3567. https://doi.org/10.3390/en13143567

Chicago/Turabian StyleWalter, Christian, Sebastian Martens, Christian Zander, Carsten Mehring, and Ulrich Nieken. 2020. "Heat Transfer through Wire Cloth Micro Heat Exchanger" Energies 13, no. 14: 3567. https://doi.org/10.3390/en13143567

APA StyleWalter, C., Martens, S., Zander, C., Mehring, C., & Nieken, U. (2020). Heat Transfer through Wire Cloth Micro Heat Exchanger. Energies, 13(14), 3567. https://doi.org/10.3390/en13143567