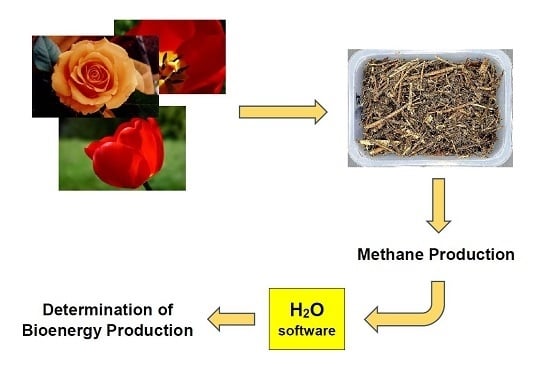

Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material for the Bioenergy Production

2.2. Methods of Calorific Value Determination

- C—heat capacity of the calorimeter (13 122 J/K),

- Dt—general increase in the main period temperature (K),

- k—correction for calorimeter heat exchange with surroundings (K),

- c—heat correction emitted during wire burning (6698,9 J/K),

- m—mass of solid fuel sample (g).

2.3. Methods of Biogas and Methane Production

2.4. Energy Calculations

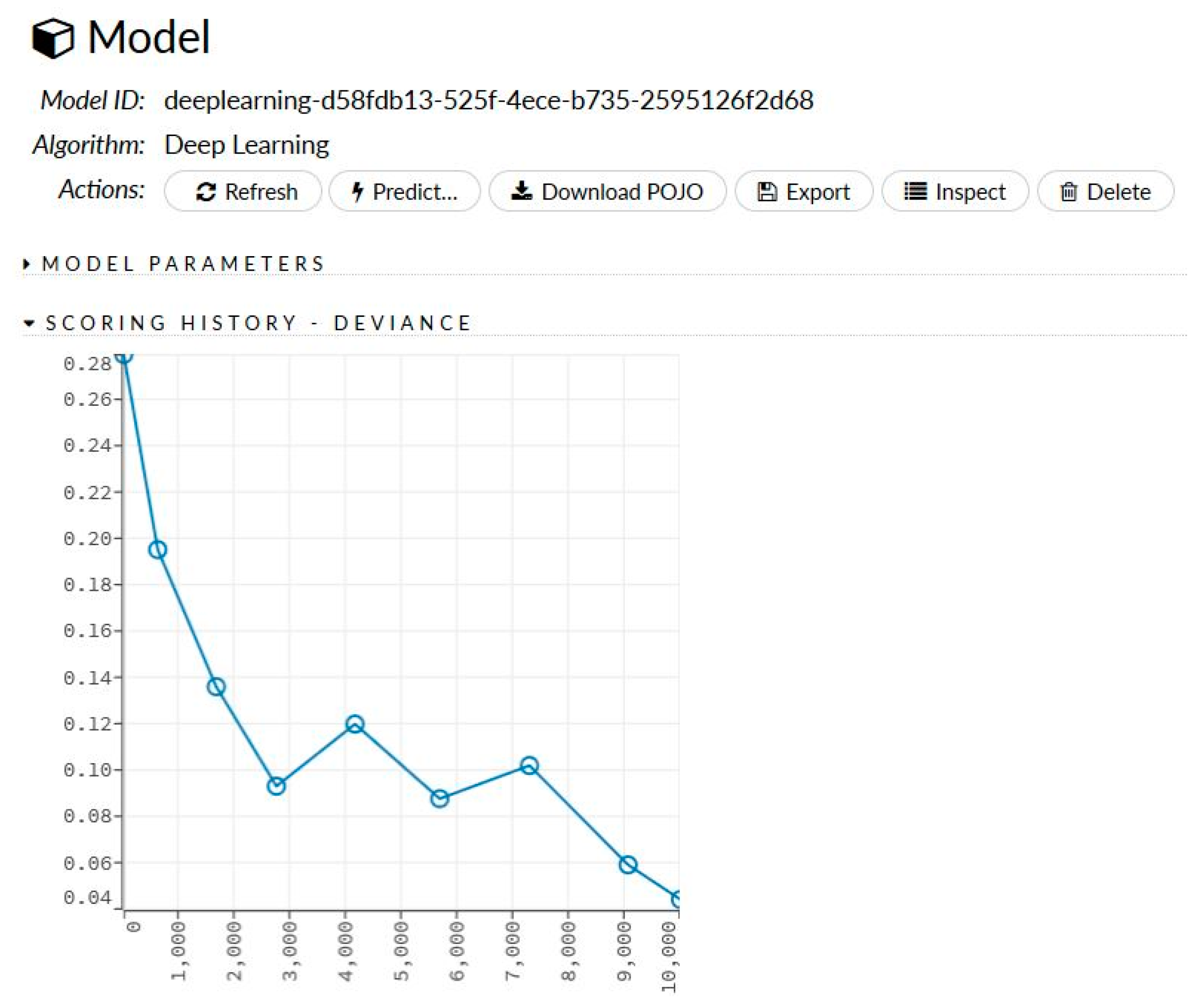

2.5. Neural Modelling

3. Results

3.1. Calorific Value of Floricultural Waste

3.2. Feedstock and Inoculum Initial Parameters

3.3. Biogas Production and Methane Production

3.4. Energy Production

3.5. Result of Neural Modelling Process

- fresh_mass_of_the_batch_[g],

- dry_organic_matter_of_the_feedstock_[g],

- dry_matter_of_the_feedstock_[g],

- dry_matter_of_the_inoculum_[g],

- dry_matter_of_the_batch_[g],

- dry_organic_matter_of_the_batch_[g],

- fresh_mass_of_the_feedstock_[g],

- flower,

- fresh_,mass_of_the_inoculum_[g],

- dry_matter_of_the_inoculum_[g].

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Available online: https://www.nytimes.com/2020/04/12/world/europe/netherlands-tulips-coronavirus.html (accessed on 13 April 2020).

- Council of the European Union. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; Council of the European Union: Brussels, Belgium, 2009; pp. 16–62.

- Dole, J.M.; Wilkins, H.F. Floriculture: Principles and Species; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 1999; p. 613. [Google Scholar]

- Shehrawat, P.S.; Sindhu, N. Agricultural waste utilization for healthy environment and sustainable lifestyle. Ann. Agric. Biol. Res. 2015, 20, 110–114. [Google Scholar]

- Getu, M. Ethiopian floriculture and its impact on the environment. Mizan Law Rev. 2009, 3, 240–270. [Google Scholar] [CrossRef]

- Dobre, P.; Nicolae, F.; Matei, F. Main factors affecting biogas production—An overview. Rom. Biotech. Lett. 2014, 19, 9283–9296. [Google Scholar]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–550. [Google Scholar] [CrossRef]

- Shin, H.S.; Youn, J.H.; Kim, S.H. Hydrogen production from food waste in anaerobic mesophilic and thermophilic acidogenesis. Int. J. Hydrog. Energy 2004, 29, 1355–1363. [Google Scholar] [CrossRef]

- Czerwińska, E.; Kalinowska, K. Conditions for conducting the methane fermentation process in a biogas plant. Agric. Hortic. Tech. 2014, 2, 12–14. (In Polish) [Google Scholar]

- Jha, M.N.; Jha, S.; Chourasia, S.K. Agroecology of Agromicrobes. In Agroecology Ecosystems and Sustainability; Benkeblia, N., Ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 81–102. [Google Scholar]

- Łochyńska, M.; Frankowski, J. The biogas production potential from silkworm waste. Waste Manag. 2018, 79, 564–570. [Google Scholar] [CrossRef] [PubMed]

- Polish Standards PN-75/C-04616/01. Wydawnictwo Normalizacyjne. Warszawa. Oznaczanie suchej masy osadu i substancji organicznych. Woda i ścieki. Badania specjalne osadów. Oznaczanie zawartości wody, suchej masy, substancji organicznych i substancji mineralnych w osadach ściekowych [in Polish]: Determination of dry matter of sludge and organic substances. Water and sewage. Special sludge tests. Determination of water content, dry matter, organic substances and mineral substances in sewage sludge.

- Polish Standards PN-Z-15011-3:2001. Kompost z odpadów komunalnych. Oznaczanie: pH, zawartości substancji organicznej, węgla organicznego, azotu, fosforu i potasu [in Polish]: Municipal waste compost. Determination of: PH, organic matter content, organic carbon, nitrogen, phosphorus and potassium.

- Iraji, M.; Tosinia, A. Classification Tomatoes on Machine Vision with Fuzzy the Mamdani Inference, Adaptive Neuro Fuzzy Inference System Based (Anfis-Sugeno). Aust. J. Basic Appl. Sci. 2011, 5, 846–853. [Google Scholar]

- Mutlu, A.C.; Boyaci, I.H.; Genis, H.E.; Ozturk, R.; Basaran-Akgul, N.; Sanal, T.; Evlice, A.K. Prediction of wheat quality parameters using near-infrared spectroscopy and artificial neural networks. Eur. Food Res. Technol. 2011, 233, 267–274. [Google Scholar] [CrossRef]

- Boniecki, P.; Dach, J.; Mueller, W.; Koszela, K.; Przybył, J.; Pilarski, K.; Olszewski, T. Neural prediction of heat loss in the pig manure composting process. Appl. Therm. Eng. 2013, 58, 650–655. [Google Scholar] [CrossRef]

- Boniecki, P.; Piekarska-Boniecka, H.; Koszela, K.; Zaborowicz, M.; Przybył, K.; Wojcieszak, D.; Zbytek, Z.; Ludwiczak, A.; Przybylak, A.; Lewicki, A. Neural classifier in the estimation process of maturity of selected varieties of apples. In Proceedings of the Seventh International Conference on Digital Image Processing (ICDIP 2015), Kuala Lumpur, Malaysia, 6 July 2015. [Google Scholar] [CrossRef]

- Martelo-Vidal, M.J.; Vázquez, M. Application of artificial neural networks coupled to UV–VIS–NIR spectroscopy for the rapid quantification of wine compounds in aqueous mixtures. CyTA J. Food 2015, 13, 32–39. [Google Scholar] [CrossRef]

- Przybylak, A.; Boniecki, P.; Koszela, K.; Ludwiczak, A.; Zaborowicz, M.; Lisiak, D.; Stanisz, M.; Ślósarz, P. Estimation of intramuscular level of marbling among Whiteheaded Mutton Sheep lambs. J. Food Eng. 2016, 168, 199–204. [Google Scholar] [CrossRef]

- Rafiq, A.; Makroo, H.A.; Hazarika, M.K. Artificial Neural Network-Based Image Analysis for Evaluation of Quality Attributes of Agricultural Produce. J. Food Process. Preserv. 2016, 40, 1010–1019. [Google Scholar] [CrossRef]

- Aghajani, N.; Kashaninejad, M.; Dehghani, A.A.; Daraei, G.A. Comparison between artificial neural networks and mathematical models for moisture ratio estimation in two varieties of green malt. Qual. Assur. Saf. Crop. Foods 2012, 4, 93–101. [Google Scholar] [CrossRef]

- Zaborowicz, M.; Boniecki, P.; Koszela, K.; Przybylak, A.; Przybył, J. Application of neural image analysis in evaluating the quality of greenhouse tomatoes. Sci. Hortic. 2017, 218, 222–229. [Google Scholar] [CrossRef]

- Sidelko, R.; Janowska, B.; Walendzik, B.; Siebielska, I. Two composting phases running in different process conditions timing relationship. Bioresour. Technol. 2010, 101, 6692–6698. [Google Scholar] [CrossRef] [PubMed]

- Bayram, A.; Kankal, M.; Ozsahin, T.S.; Saka, F. Estimation of the Carbon to Nitrogen (C:N) Ratio in Compostable Solid Waste Using Artificial Neural Networks. Fresenius Environ. Bull. 2011, 20, 3250–3257. [Google Scholar]

- Boniecki, P.; Nowakowski, K.; Ślósarz, P.; Dach, J.; Pilarski, K. Neural Image Analysis for Estimating Aerobic and Anaerobic Decomposition of Organic Matter Based on The Example of Straw Decomposition. In Proceedings of the Fourth International Conference on Digital Image Processing (ICDIP 2012), Kuala Lumpur, Malaysia, 8 June 2012; Volume 8334. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Lewicki, A.; Ludwiczak, A.; Przybylak, A.; Boniecki, P.; Koszela, K.; Zaborowicz, M.; Przybył, K.; Witaszek, K. Use of neural image analysis methods in the process of determine the dry matter content in the compost. In Proceedings of the Seventh International Conference on Digital Image Processing (ICDIP 2015), Kuala Lumpur, Malaysia, 6 July 2015; Volume 963118. [Google Scholar] [CrossRef]

- Yildiz, S.; Degirmenci, M. Estimation of Oxygen Exchange during Treatment Sludge Composting through Multiple Regression and Artificial Neural Networks (Estimation of Oxygen Exchange during Composting). Int. J. Environ. Res. 2015, 9, 1173–1182. [Google Scholar]

- Chitsan, L.; Chih-Chiang, W.; Chia-Cheng, T. Prediction of Influential Operational Compost Parameters for Monitoring Composting Process. Environ. Eng. Sci. 2016, 33, 494–506. [Google Scholar] [CrossRef]

- Zaborowicz, M.; Wojcieszak, D.; Górna, K.; Kujawa, S.; Kozłowski, R.J.; Przybył, K.; Mioduszewska, N.; Idziaszek, P.; Boniecki, P. Determination of dry matter content in composted material based on digital images of compost taken under mixed visible and UV-A light. In Proceedings of the Eighth International Conference on Digital Image Processing (ICDIP 2016), Kuala Lumpur, Malaysia, 29 August 2016. [Google Scholar] [CrossRef]

- Zou, H.F.; Xia, G.P.; Yang, F.T.; Wang, H.Y. An investigation and comparison of artificial neural network and time series models for Chinese food grain price forecasting. Neurocomputing 2007, 70, 2913–2923. [Google Scholar] [CrossRef]

- Cervone, G.; Clemente-Harding, L.; Alessandrini, S.; Monache, L.D. Short-term photovoltaic power forecasting using Artificial Neural Networks and an Analog Ensemble. Renew. Energy 2017, 108, 274–286. [Google Scholar] [CrossRef]

- Qiu, M.; Song, Y. Predicting the Direction of Stock Market Index Movement Using an Optimized Artificial Neural Network Model. PLoS ONE 2016, 11, e0155133. [Google Scholar] [CrossRef] [PubMed]

- Bugała, A.; Zaborowicz, M.; Boniecki, P.; Janczak, D.; Koszela, K.; Czekała, W.; Lewicki, A. Short-term forecast of generation of electric energy in photovoltaic systems. Renew. Sustain. Energy Rev. 2018, 81, 306–312. [Google Scholar] [CrossRef]

- Hinton, G.; Osindero, S.Y.-W. A Fast Learning Algorithm for Deep Belief Nets. Neural Comput. 2006, 18, 1527–1554. [Google Scholar] [CrossRef] [PubMed]

- Ioannou, Y. Restricted Connectivity in Deep Neural Networks; University of Cambridge: Cambridge, UK, 2017; Available online: https://yani.io/annou/presentations/kaistpresentation.pdf (accessed on 15 March 2020).

- Waliszewska, B.; Zborowska, M.; Pradzynski, W.; Kominer, A. Chemical composition and gross calorific value of selected Salix hybrids. In Wood Structure and Properties; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2006; pp. 171–173. [Google Scholar]

- Krzyżaniak, M.; Stolarski, M.J.; Waliszewska, B.; Szczukowski, S.; Tworkowski, J.; Załuski, D.; Śnieg, M. Willow biomass as feedstock for an integrated multi-product biorefinery. Ind. Crop. Prod. 2014, 58, 230–237. [Google Scholar] [CrossRef]

- Waliszewska, B.; Duda, M.; Waliszewska, H.; Spek-Dźwigała, A.; Sieradzka, A. The gross calorific value and the net calorific value of selected exotic wood species. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2016, 96, 226–229. [Google Scholar]

- Szambelan, K.; Nowak, J.; Frankowski, J.; Szwengiel, A.; Jeleń, H.; Burczyk, H. The comprehensive analysis of sorghum cultivated in Poland for energy purposes: Separate hydrolysis and fermentation and simultaneous saccharification and fermentation methods and their impact on bioethanol effectiveness and volatile by-products from the grain and the energy potential of sorghum straw. Bioresour. Technol. 2018, 250, 750–757. [Google Scholar]

- Cieślik, M.; Dach, J.; Lewicki, A.; Smurzyńska, A.; Janczak, D.; Pawlicka-Kaczorowska, J.; Boniecki, P.; Cyplik, P.; Czekała, W.; Jóźwiakowski, K. Methane fermentation of the maize straw silage under meso- and thermophilic conditions. Energy 2016, 115, 1495–1502. [Google Scholar] [CrossRef]

- Dach, J.; Koszela, K.; Boniecki, P.; Zaborowicz, M.; Lewicki, A.; Czekała, W.; Skwarcz, J.; Qiao, W.; Piekarska-Boniecka, H.; Białobrzewski, I. The use of neural modelling to estimate the methane production from slurry fermentation processes. Renew. Sustain. Energy Rev. 2016, 56, 603–610. [Google Scholar] [CrossRef]

- Dach, J. Energetic and economic efficiency of agricultural biogas plant working with different substrates. J. Res. Appl. Agric. Engng. 2016, 61, 72–76. [Google Scholar]

- Kasprzycka, A.; Lalak, J.; Tys, J. Impact of fragmentation on biogas production from plant biomass. Acta Agrophys. 2015, 22, 139–149. [Google Scholar]

- Dach, J.; Boniecki, P.; Przybył, J.; Janczak, D.; Lewicki, A.; Czekała, W.; Witaszek, K.; Rodríguez Carmona, P.C.; Cieślik, M. Energetic efficiency analysis of the agricultural biogas plant in 250kWe experimental installation. Energy 2014, 69, 34–38. [Google Scholar] [CrossRef]

- Ni, B.J.; Batstone, D.; Zhao, B.H.; Yu, H.Q. Microbial internal storage alters the carbon transformation in dynamic anaerobic fermentation. Environ. Sci. Technol. 2015, 49, 9159–9167. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Braeutigam, P.; Franke, M.; Ondruschka, B. Effect of ultrasound amplitude and reaction time on the anaerobic fermentation of chicken manure for biogas production. Biomass. Bioenerg. 2014, 63, 109–113. [Google Scholar] [CrossRef]

- Lewicki, A.; Kozłowski, K.; Pietrowski, M.; Zbytek, Z. Methane fermentation of chicken droppings. J. Res. Appl. Agric. Engng. 2016, 61, 28–30. [Google Scholar]

- Kafle, G.K.; Kim, S.H.; Sung, K.I. Ensiling of fish industry waste for biogas production: A lab scale evaluation of biochemical methane potential (BMP) and kinetics. Bioresour. Technol. 2013, 127, 326–336. [Google Scholar] [CrossRef]

- Chasnyk, O.; Sołowski, G.; Shkarupa, O. Historical, technical and economic aspects of biogas development: Case of Poland and Ukraine. Renew. Sustain. Energy Rev. 2015, 52, 227–239. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Cichosz, M. Biogas production in Poland—Current state, potential and perspectives. Renew. Sustain. Energy Rev. 2015, 50, 686–695. [Google Scholar] [CrossRef]

- Kwietniewska, E.; Tys, J. Process characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on microalgal biomass fermentation. Renew. Sustain. Energy Rev. 2014, 34, 491–500. [Google Scholar] [CrossRef]

- Niu, Q.; Hojo, T.; Qiao, W.; Qiang, H.; Li, Y.Y. Characterization of methanogenesis, acidogenesis and hydrolysis in thermophilic methane fermentation of chicken manure. Chem. Eng. J. 2014, 244, 587–596. [Google Scholar] [CrossRef]

- Wang, M.; Sun, X.; Li, P.; Yin, L.; Liu, D.; Zhang, Y.; Li, W.; Zheng, G. A novel alternate feeding mode for semi-continuous anaerobic co-digestion of food waste with chicken manure. Bioresour. Technol. 2014, 164, 309–314. [Google Scholar] [CrossRef] [PubMed]

- Orive, M.; Cebrián, M.; Zufía, J. Techno-economic anaerobic co-digestion feasibility study for two-phase olive oil mill pomace and pig slurry. Renew. Energy 2016, 97, 532–540. [Google Scholar] [CrossRef]

- Pérez-Zárate, D.; Santoyo, E.; Acevedo-Anicasio, A.; Díaz-González, L.; García-López, C. Evaluation of artificial neural networks for the prediction of deep reservoir temperatures using the gas-phase composition of geothermal fluids. Comput. Geosci. 2019, 129, 49–68. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Mazur, A.; Janczak, D.; Marczuk, A. Energy value estimation of silages for substrate in biogas plants usingan artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

| Feedstock | Calorific Value (kJ/kg) |

|---|---|

| Tulips with flowers | 15,210 |

| Stems and leaves of tulips | 16,890 |

| Roses | 17,720 |

| Stems of roses | 18,520 |

| Sunflowers | 17,640 |

| Stalks of sunflowers | 18,030 |

| Chrysanthemums | 15,560 |

| Stalks of chrysanthemums | 16,230 |

| Feedstock | Total Solids [%] | Volatile Total Solids [%] |

|---|---|---|

| Mesophilic inoculum | 2.49 | 70.80 |

| Thermophilic inoculum | 2.69 | 64.47 |

| Tulips | 7.90 | 95.42 |

| Roses | 21.95 | 93.24 |

| Sunflowers | 21.44 | 93.53 |

| Chrysanthemums | 25.46 | 89.42 |

| Feedstock | Days of Fermentation | CH4 Content (%) | Fresh Mass (m3/Mg of FM) | Total Solids (m3/Mg of TS) | Volatile Total Solids (m3/Mg of VTS) | |||

|---|---|---|---|---|---|---|---|---|

| Cumulated CH4 | Cumulated Biogas | Cumulated CH4 | Cumulated Biogas | Cumulated CH4 | Cumulated Biogas | |||

| Tulip chaff under mesophilic conditions | 23 | 54.37 | 28.30 | 52.04 | 358.18 | 658.83 | 375.37 | 690.39 |

| Tulip macerate under mesophilic conditions | 23 | 53.07 | 27.98 | 52.72 | 354.14 | 667.30 | 371.14 | 699.33 |

| Roses under mesophilic conditions | 25 | 49.92 | 61.28 | 122.76 | 294.17 | 589.28 | 316.15 | 633.35 |

| Roses under thermophilic conditions | 25 | 56.68 | 62.26 | 109.84 | 283.65 | 500.44 | 304.22 | 536.73 |

| Sunflowers under mesophilic conditions | 29 | 49.27 | 53.31 | 108.22 | 248.70 | 504.80 | 278.14 | 564.56 |

| Sunflowers under thermophilic conditions | 25 | 47.83 | 40.79 | 85.28 | 190.29 | 397.83 | 212.82 | 444.92 |

| Chrysanthemums under mesophilic conditions | 29 | 47.59 | 59.05 | 124.08 | 231.92 | 487.32 | 247.95 | 521.00 |

| Chrysanthemums under thermophilic conditions | 25 | 40.64 | 35.11 | 86.40 | 137.89 | 339.32 | 147.42 | 362.78 |

| Feedstock | Variants Per 1 Mg of | Produced Energy Amount (MWh) | Produced Heat Amount (MWh) | Produced Heat Amount (GJ) |

|---|---|---|---|---|

| Tulip chaff under mesophilic conditions | FM | 0.21 | 0.21 | 0.77 |

| TS | 2.66 | 2.72 | 9.92 | |

| VTS | 2.79 | 2.85 | 10.40 | |

| Tulip macerate under mesophilic conditions | FM | 0.21 | 0.22 | 0.79 |

| TS | 2.69 | 2.75 | 10.05 | |

| VTS | 2.82 | 2.89 | 10.53 | |

| Roses under thermophilic conditions | FM | 0.50 | 0.51 | 1.85 |

| TS | 2.37 | 2.43 | 8.87 | |

| VTS | 2.56 | 2.61 | 9.54 | |

| Roses under mesophilic conditions | FM | 0.44 | 0.45 | 1.65 |

| TS | 2.02 | 2.07 | 7.54 | |

| VTS | 2.17 | 2.21 | 8.08 | |

| Sunflowers under mesophilic conditions | FM | 0.44 | 0.45 | 1.63 |

| TS | 2.04 | 2.08 | 7.60 | |

| VTS | 2.28 | 2.33 | 8.50 | |

| Sunflowers under thermophilic conditions | FM | 0.34 | 0.35 | 1.28 |

| TS | 1.61 | 1.64 | 5.99 | |

| VTS | 1.80 | 1.84 | 6.70 | |

| Chrysanthemums under mesophilic conditions | FM | 0.50 | 0.51 | 1.87 |

| TS | 1.97 | 2.01 | 7.34 | |

| VTS | 2.10 | 2.15 | 7.85 | |

| Chrysanthemums under thermophilic conditions | FM | 0.35 | 0.36 | 1.30 |

| TS | 1.37 | 1.40 | 5.11 | |

| VTS | 1.46 | 1.50 | 5.46 |

| Network Characteristics | |

|---|---|

| MSE | 0.004186 |

| RMSE | 0.064700 |

| nobs | 14 |

| r2 | 0.991181 |

| mean_residual_deviance | 0.004186 |

| mae | 0.044468 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frankowski, J.; Zaborowicz, M.; Dach, J.; Czekała, W.; Przybył, J. Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods. Energies 2020, 13, 3014. https://doi.org/10.3390/en13113014

Frankowski J, Zaborowicz M, Dach J, Czekała W, Przybył J. Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods. Energies. 2020; 13(11):3014. https://doi.org/10.3390/en13113014

Chicago/Turabian StyleFrankowski, Jakub, Maciej Zaborowicz, Jacek Dach, Wojciech Czekała, and Jacek Przybył. 2020. "Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods" Energies 13, no. 11: 3014. https://doi.org/10.3390/en13113014

APA StyleFrankowski, J., Zaborowicz, M., Dach, J., Czekała, W., & Przybył, J. (2020). Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods. Energies, 13(11), 3014. https://doi.org/10.3390/en13113014